Page 1

KROHNE 08/2003 US size: 7.02264.71.00

©

DIN A4: 7.02264.31.00

Installation and

operating instructions

IFC 110 F V2.0

IFC 110 F-EEx V2.0

Signal converters for

electromagnetic flowmeters

Applicable to

Software Versions

How to use these Instructions

Flowmeters are delivered ready for operation.

The flow sensor must be installed in the pipeline as described in the instructions for

installation inside the packing of the flow sensor.

– Connection of power supply (Sect. 1.1-1.2) Pages 4- 5

– Electrical connection between IFC 110 F and primary head (Sect. 1.3) Pages 6-13

– Electrical connection of outputs and inputs (Sect. 2) Pages 14-22

– Start-up (Sect. 3) Pages 23

Power the flowmeter. THAT’S ALL. The system is operative.

Operator control of the IFC 110 F signal converter is described in Sect. 4.

● Display & control unit

No. 3.19937.02.00

● A/D converter

No. 8.13393.02.00

● Outputs/inputs (I/O)

No. 3.16230.01.00

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Page 2

A

The operating data are factory-set to your ordered specifications.

Signal converter versions

IFC 110 F / D Standard version, with local display and control elements

(Standard)

IFC 110 F / D / MP Same as display version, additional with magnetic sensors (MP)

(Option)

IFC 110 F / D / MP / EEx Same as display version (D + MP),

(Option) for operation with flow sensors installed in hazardous areas

IFC 110 F / RS 485 Same as standard version,

but additionally with different interfaces

• Signal converter in the version as ordered, see above.

Items included with supply

• Signal cable in the version and length as ordered (standard: signal cable A,

length 10 m / 30 ft)

• Condensed installation and operating manual in the ordered language for installation,

electrical connection, start-up and operator control of the signal converter.

• Service Manual in english language.

Please note!

In the Installation and Operating Manual there are hints with Sect. Numbers which you can find

in the Handbook / Service Manual only!

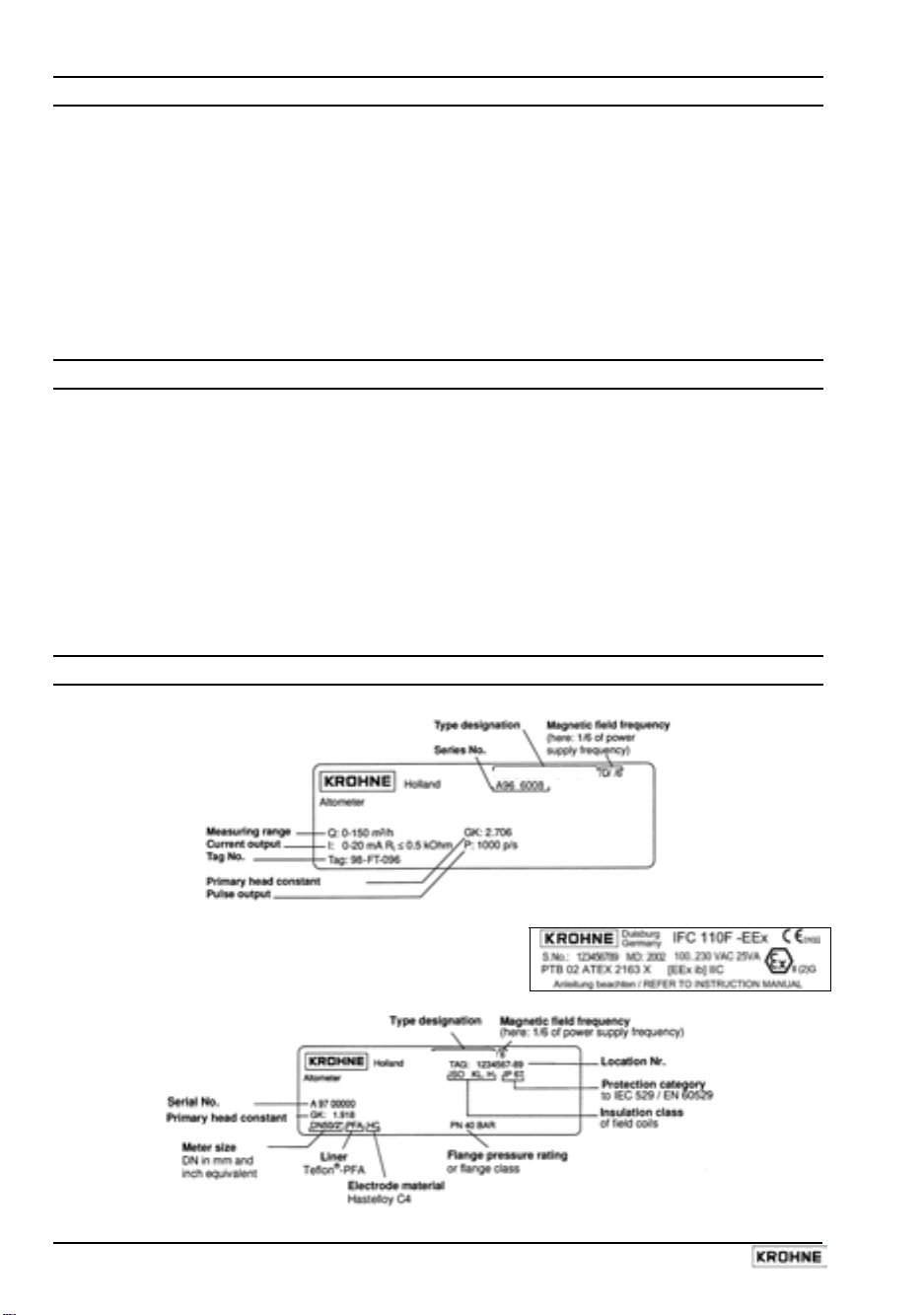

Instrument nameplates

Signal converter (example)

IFC 110 F

Signal converter IFC 110F-EEx (example)

Flow sensor (example)

LTOFLUX 4000 F

2 IFC 110 F

05/2003

Page 3

System description

Electromagnetic flowmeters are precision instruments designed for linear flow measurement of

liquid products

The process liquids must be electrically conductive:, ≥ 5 µS/cm

(for cold demineralized water ≥ 20 µS/cm).

The full-scale range Q

can be set as a function of the meter size: flow velocity of 0.3 - 12 m/s

100%

or 1 - 40 ft/s (s. Section 10.4.).

Product liability and warranty

The electromagnetic flowmeters are designed solely for measuring the volumetric flowrate of

electrically conductive, liquid process products.

These flowmeters are available for use in hazardous areas.

Special regulations apply in this case, which are given in the special EEx directions.

Responsibility as to suitability and intended use of these electromagnetic flowmeters rests

solelywith the operator.

Improper installation and operation of the flowmeters (systems) may lead to loss of warranty.

In addition, the “General conditions of sale” forming the basis of the purchase contract are

applicable.

If flowmeters need to be returned to KROHNE, please note the information given on the last-butone page of these Instructions. KROHNE regrets that it cannot repair or check your flowmeter(s)

unless accompanied by the completed form sheet.

CE / EMC / Standards / Approvals

The here described Electromagnetic flowmeters meet the NAMUR Directive NE21,

the protection requirements of Directive 89/336/EEC in conjunction with EN

61326-1 (1997) and A1 (1998), as well as Directives 73/23/EEC and 93/68/EEC

in conjunction with EN 61010-1, and bear the CE marking.

Software history

Display & control unit Amplifier (ADC) Inputs and outputs (I/O)

Software Status Software Status Software Status

3.19937.02.00

current

IMPORTANT!

In respect of EEx versions, pay regard to all directions marked with the

and also the information given in Sect. 6.1 and 13.

Only the EEx flow sensor may be installed in the hazardous area. The EEx

certified signal converter must be installed outside the hazardous area!

8.13393.02.00

current

3.16230.01.00

current

symbol,

IFC 110 F 3

05/2003

Page 4

1 Electrical connection: power supply

1.1 Location and important installation notes ……………………. PLEASE NOTE !

• Electrical connection in accordance with VDE 0100 ”Regulations for the erection of power

installations with nominal voltages up to 1000 V” or equivalent national regulations.

• Do not cross or loop cables inside the terminal compartment.

• Use separate wiring (PG screwed cable entries) for power supply, field current lines, signal

lines, outputs and inputs.

• Hazardous areas are subject to special regulations, see Section 6.1 and special installation

instructions for hazardous-duty versions.

• Do not expose signal converter and switchgear cabinets with built-in converters to direct

sunlight. Install a sunshade if necessary.

• Signal converters installed in switchgear cabinets require adequate cooling (e.g. by fans

or heat exchangers).

• Do not expose signal converters to intense vibration.

• Keep the distance between the flow sensor and signal converter as small as possible, for

empty pipe detection (EPD) ≤ 20 m / ≤ 66 ft. Observe maximum lengths of signal and field

current lines (see Section 1.3.4).

• Use KROHNE signal line A (type DS, standard) or signal line B (type BTS, bootstrap,

optional), standard length 10 m (33 ft).

• Generally use bootstrap signal lines B (type BTS) for PROFIFLUX 5000 F and VARIFLUX

6000 F flow sensors sized at DN 2.5-15 and 1/10’’-1/2’’ and for contaminated liquids which

tend to form electrically insulating deposits.

• Always calibrate flow sensor and signal converter together. During installation particular care

should therefore be given to identical settings of flow sensor constant GK (see instrument

nameplate of flow sensor). In case GK constants are not identical, the signal converter must

be adjusted to the flow sensor GK (see Sections 4 and 8.5).

• Dimensions of signal converter see Section 10.3.

IMPORTANT!

For EEx versions, also pay regard to all directions included in Sect. 6.1 and 13.

Only the EEx flow sensor may be installed in the hazardous area. The EEx

certified signal converter must be installed outside the hazardous area!

4 IFC 110 F

05/2003

Page 5

1.2 Power supply - connection

PLEASE NOTE !

• Type of enclosure

• Dimensioning:

moisture must always be kept closed. The selected clearances and creeping distances comply

with VDE 0110 and/or IEC 664 regulations for contamination grade 2. Supply circuits and

output circuits are designed to meet standards of overvoltage classes III and II, respectively.

• Fuse protection, disconnecting device: fuse protection for the feeding power circuit, and also a

disconnecting device (switch, circuit breaker) for isolating the signal converters must be

provided (see also Sect. 1.3.5 and 1.3.6).

100-230 V AC (tolerance range 85-255 V AC)

• Observe information on the instrument nameplate, power supply voltage and frequency.

• The protective conductor PE of the power supply must be connected to the separate

U-clamp terminal inside the terminal compartment of the signal converter.

• CAUTION: do not remove the internal connection (line) inside the terminal compartment of the

signal converter (yellow/green wire) between the U-clamp terminal and terminal 10 protective conductor (protection class I instrument).

• Connection diagrams I - IV for the power supply and for the electrical connection between

flow sensor and signal converter, see Sections 1.3.5 (Standard) and 1.3.6 (EEx).

24 V AC / DC (tolerance ranges: AC 20.4 - 26.4 V / DC 18 - 31.2 V)

• Observe information on the instrument nameplate, power supply voltage and frequency.

• For technical reasons concerning the measuring process, a functional grounding conductor

FE has to be connected to the separate U-clamp terminal inside the terminal compartment of

the signal converter.

• A facility providing a reliable electrical separation (PELV) has to be provided for connections

to functional extra-low voltages (24 V AC / DC) - (VDE 0100 / VDE 0106 and/or IEC 364 /

IEC 536 or equivalent national regulations).

• Connection diagrams I - IV for the power supply and for the electrical connection between

flow sensor and signal converter, see Sections 1.3.5 (Standard) and 1.3.6 (EEx).

Warning: Instrument must be properly grounded to avoid personnel shock hazard.

IP 65 to IEC 529 / EN 60529 equivalent to NEMA 4/4X.

the flowmeter housing protecting the electronic equipment against dust and

IMPORTANT!

For EEx versions, also pay regard to all directions included in Sect. 6.1 and 13.

Only the EEx flow sensor may be installed in the hazardous area. The EEx

certified signal converter must be installed outside the hazardous area!

IFC 110 F 5

05/2003

Page 6

1.3 Electrical connection of flow sensors

1.3.1 General remarks on signal lines A and B and field current line C

Proper operation of the equipment is ensured when KROHNE signal lines A and B are used with

foil screen and magnetic shield.

• Signal lines must be firmly installed.

• Shields are connected via stranded drain wires.

• Underwater or underground routing is possible.

• Insulating material flame-retardant to IEC 332.1 / VDE 0742.

• Low-halogen, unplasticized signal lines which remain flexible at low temperatures.

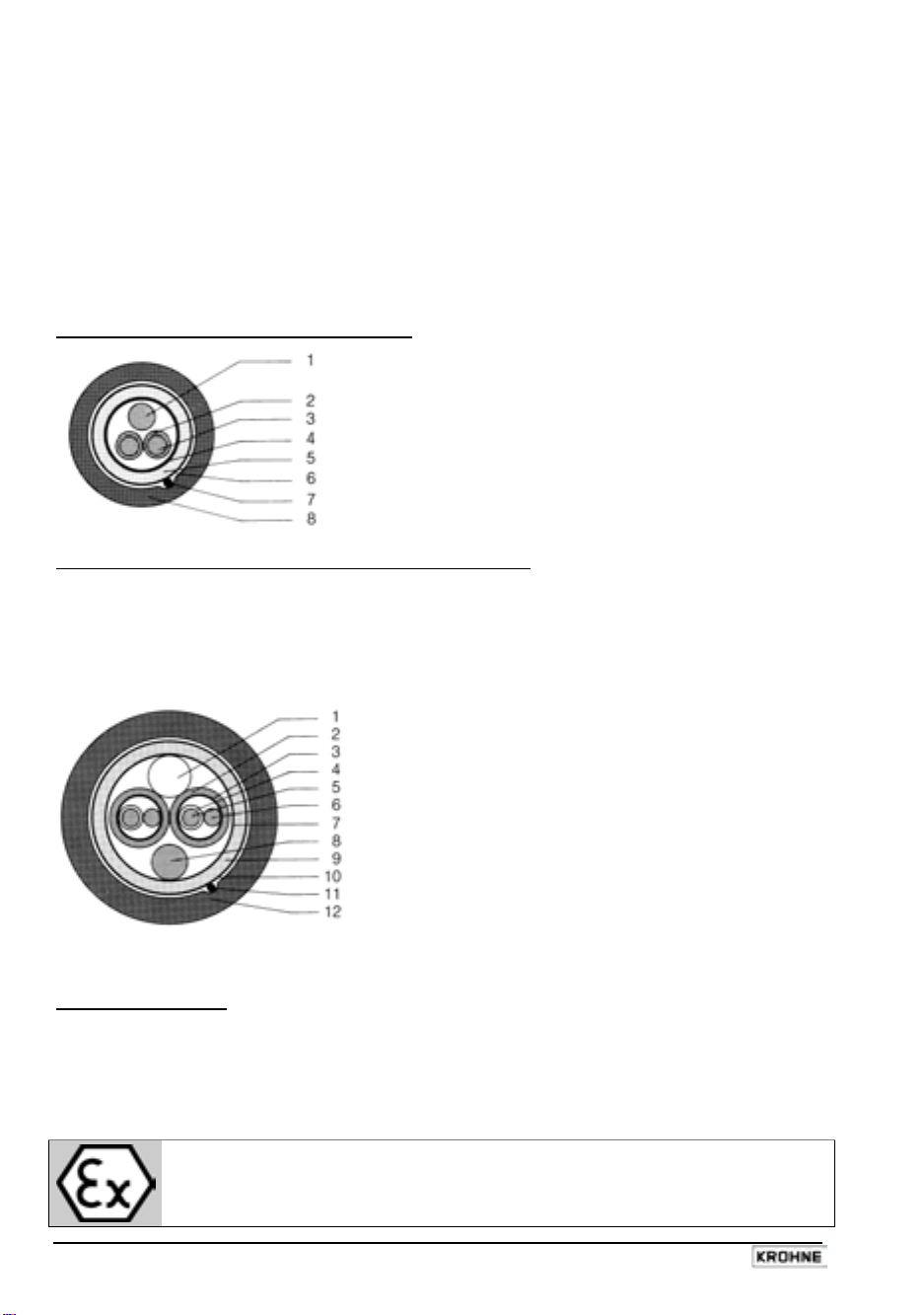

Signal line A (type DS) with double shielding

1 Stranded drain wire, 1st shield, 1.5 mm² or AWG 14

2 Insulation

3 Stranded wire 0.5 mm² or AWG 20 (3.1 red/3.2 white)

4 Special foil, 1st shield

5 Insulation

6 Mu-metal foil, 2nd shield

7 Stranded drain wire, 2nd shield, 0.5 mm² or AWG 20

Signal line B (type BTS) with triple shielding (bootstrap line)

8 Outer sheath

The bootstrap technology always controls the individual shields (3) of the signal converter exactly

to the voltage which is supplied to the signal conductors (5). As this prevents voltage differences

between the individual shields (3) and signal conductors (5), no current flows via the line

capacitances between 3 and 5. The line capacitance seems to become ”zero”.

This allows greater cable lengths in case the electric conductivity of the liquid to be measured is

low.

1

Dummy glider wire

2

Insulation (2.1 red/2.2 white)

3

Special foil, 1st shield (3.1/3.2)

4

Insulation (4.1/4.2)

5

Stranded wire 0.5 mm² or AWG 20

(5.1 red/5.2 white)

6

Stranded drain wire, 1st shield, 0.5 mm² or

AWG 20 (6.1/6.2)

7

Special foil, 2nd shield

8

Stranded drain wire, 2nd shield, 1.5 mm² or AWG 14

9

Insulation

10

Mu-metal foil, 3rd shield

11

Stranded drain wire, 3rd shield, 0.5 mm² or AWG 20

12

Outer sheath

Field current line C1

Line 2 x 0.75 mm² (18 AWG) Cu or 2 x (4 x) 1.5 mm² (14 AWG) Cu (Cu = copper cross section)

The cross section depends on the required cable length.

For max. permissible cable lengths please refer to Section 1.3.4

IMPORTANT!

For EEx versions, also pay regard to all directions included in Sect. 6.1 and 13.

Only the EEx flow sensor may be installed in the hazardous area. The EEx

certified signal converter must be installed outside the hazardous area!

6 IFC 110 F

05/2003

Page 7

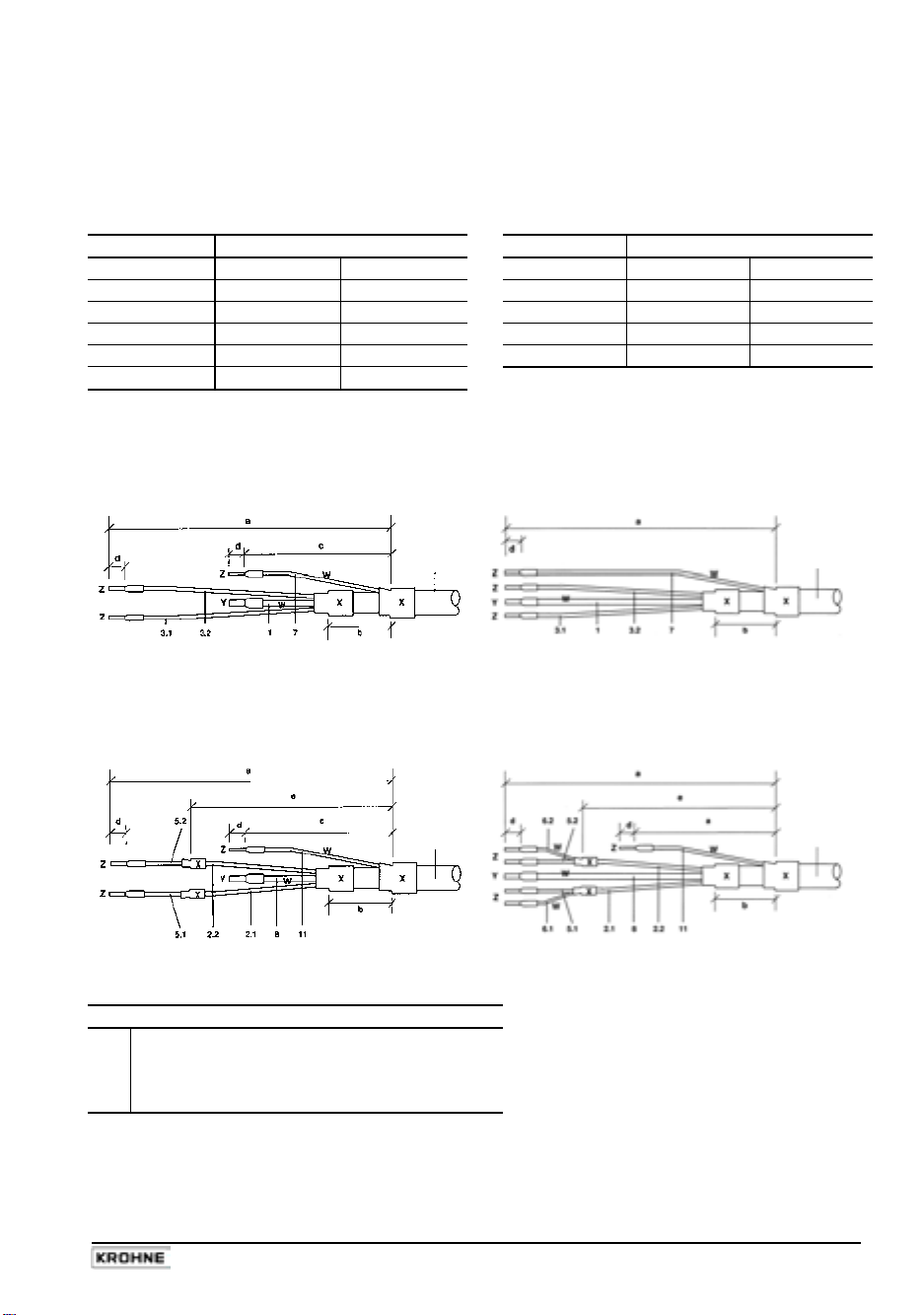

1.3.2 Stripping (preparation) of signal cables

Please note: The numbers in the drawings designate the stranded drain wires of signalling cables

A and B, see sectional drawings in Sect. 1.3.1.

Flow sensor Converter

Length flow sensor Length Converter

mm inch mm inch

a 90 3.60 a 50 2.00

b 8 0.30 b 8 0.40

c 25 1.00 d 8 0.40

d 8 0.30 e 20 0.80

e 70 2.80

Signal cable A (type DS),

double shielding

for flow sensor

Signal cable A (type DS),

double shielding

for IFC 110 F Converter

Signal cable A

bending radius

≥ 50 mm (≥ 2”)

Signal cable B (type BTS),

with triple shielding (bootstrap)

for flow sensor

Signal cable B

bending radius

≥ 50 mm (≥ 2”)

Customer-supplied materials

W

Insulation tubing (PVC), Ø 2.0-2.5 mm (Ø 1”)

X

Heat-shrinkable tubing or cable sleeve

Y

Wire end sleeve to DIN 41 228: E 1.5-8

Z

Wire end sleeve to DIN 41 228: E 0.5-8

Signal cable A

bending radius

≥ 50 mm (≥ 2”)

Signal cable B (type BTS),

with triple shielding (bootstrap)

for IFC 110 F Converter

Signal cable B

bending radius

≥ 50 mm (≥ 2”)

IFC 110 F 7

05/2003

Page 8

1.3.3 Grounding of flow sensor

• The flow sensor must be correctly connected to ground.

• The grounding cable may not transfer interference voltages.

• Do not use the grounding cable to connect more than one device to ground.

• In hazardous areas the grounding line is also used for potential equalizing purposes. Special

grounding instructions are contained in the installation instructions for hazardous-duty

instruments (only supplied together with such instruments).

• The flow sensor is connected to ground by means of a functional grounding conductor FE.

• Special grounding instructions for the connection of several flow sensors are contained in the

separate installation instructions of the flow sensors.

• These instructions also contain detailed descriptions on how to use grounding rings and how

to install flow sensors in metal or plastic pipes or in pipes which are coated on the inside.

Warning: Instrument must be properly grounded to avoid personnel shock hazard.

IMPORTANT!

For EEx versions, also pay regard to all directions included in Sect. 6.1 and 13.

Only the EEx flow sensor may be installed in the hazardous area. The EEx

certified signal converter must be installed outside the hazardous area!

8 IFC 110 F

05/2003

Page 9

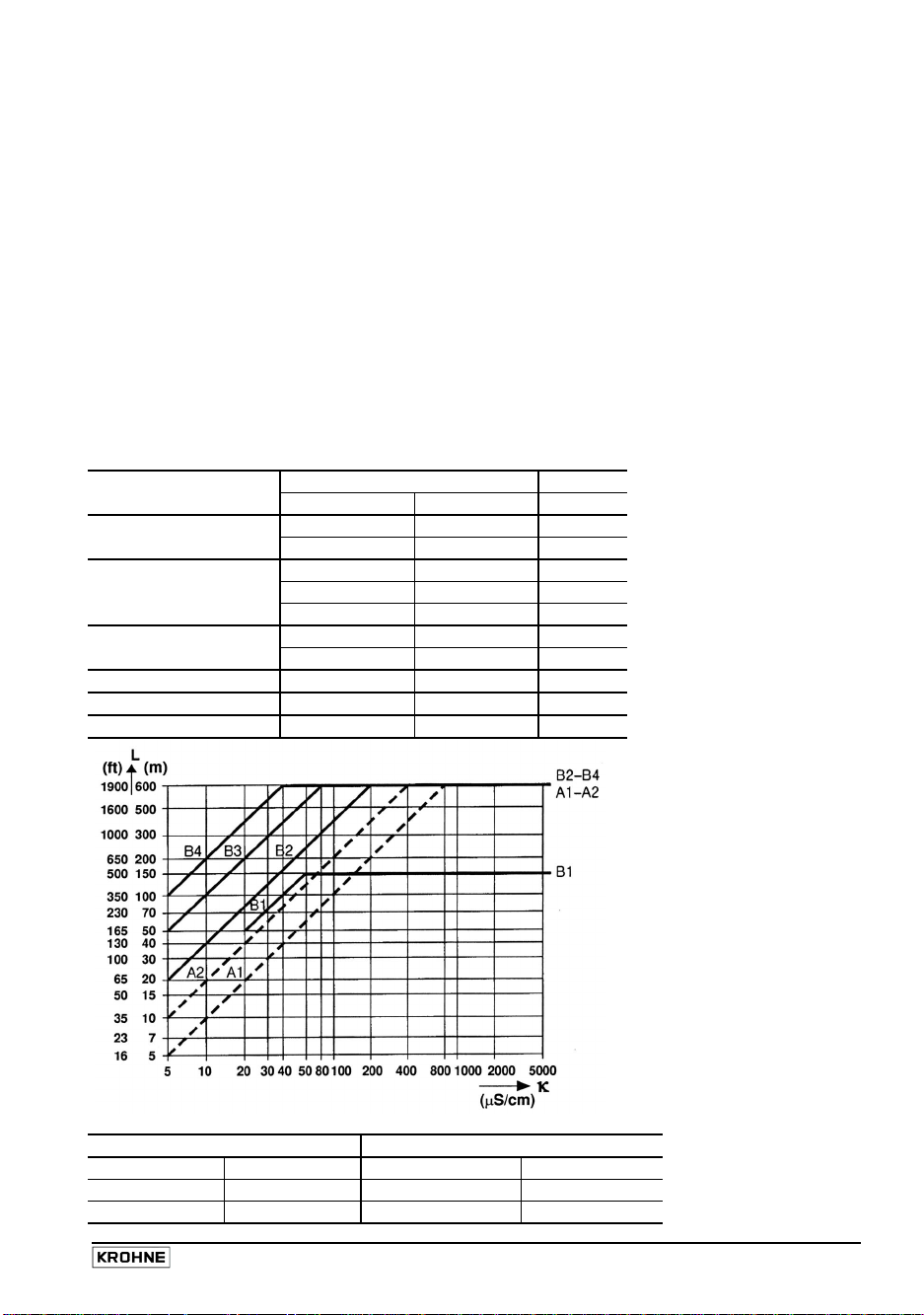

1.3.4 Cable lengths (max. distance between signal converter and flow sensor)

Abbreviations and explanations

The abbreviations used in the following tables, diagrams and connection diagrams stand for:

A Signal line A (type DS) with double shielding, max. length see diagram

B Signal line B (type BTS) with triple shielding, max. length see diagram

C Field current line, minimum cross section (A

) and max. length see table

F

D High-temperature silicone line, 3x1.5 mm² (14 AWG) Cu, with single shield,

max. length 5 m (16 ft)

E High-temperature silicone line, 2 x 1.5 mm² (14 AWG) Cu, max. length 5 m (16 ft)

Cross section of field current line C in Cu, see table

A

F

L Cable length in m or ft

Electrical conductivity of the process liquid

Κ

ZD Intermediate connection box required in connection with lines D and E for flow sensors

ALTOFLUX 4000 F, PROFIFLUX 5000 F and VARIFLUX 6000 F for process temperatures

exceeding 150°C (302°F).

Recommended length of signal line

for magnetic field frequencies ≤ 1/6 x power frequency

Flow Meter size Signal Please note!

sensor DN mm Inch line

VARIFLUX 6000 F 2.5 - 15 1/10 - 1/2 B1

25 - 80 1 - 3 A1 / B3

PROFIFLUX 5000 F 2.5 - 1/10 - B1

4 - 15 1/6 - 1/2 B2

For application with

empty pipe detection

(EPD) max. length

< 20 m / 66 ft.

25 - 100 1 - 4 A1 / B3

ALTOFLUX 4000 F 10 - 150 3/8 - 6 A1 / B3

200 - 1200 8 - 48 A2 / B4

ALTOFLUX 2000 F 150 - 250 6 - 10 A2 / B4

ECOFLUX 1000 F 10 - 150 3/8 - 6 A1 / B3

M900 10 - 300 3/8 - 12 A2 / B4

Max. length and minimum cross section of field current line

Length L Cross section AF (Cu), minimum

0 to 150 m 5 to 500 ft 2 x 0.75 mm² Cu 2 x 18 AWG

150 to 300 m 500 to 1000 ft 2 x 1.50 mm² Cu 2 x 14 AWG

300 to 600 m 1000 to 1900 ft 4 x 1.50 mm² Cu 4 x 14 AWG

05/2003

IFC 110 F 9

Page 10

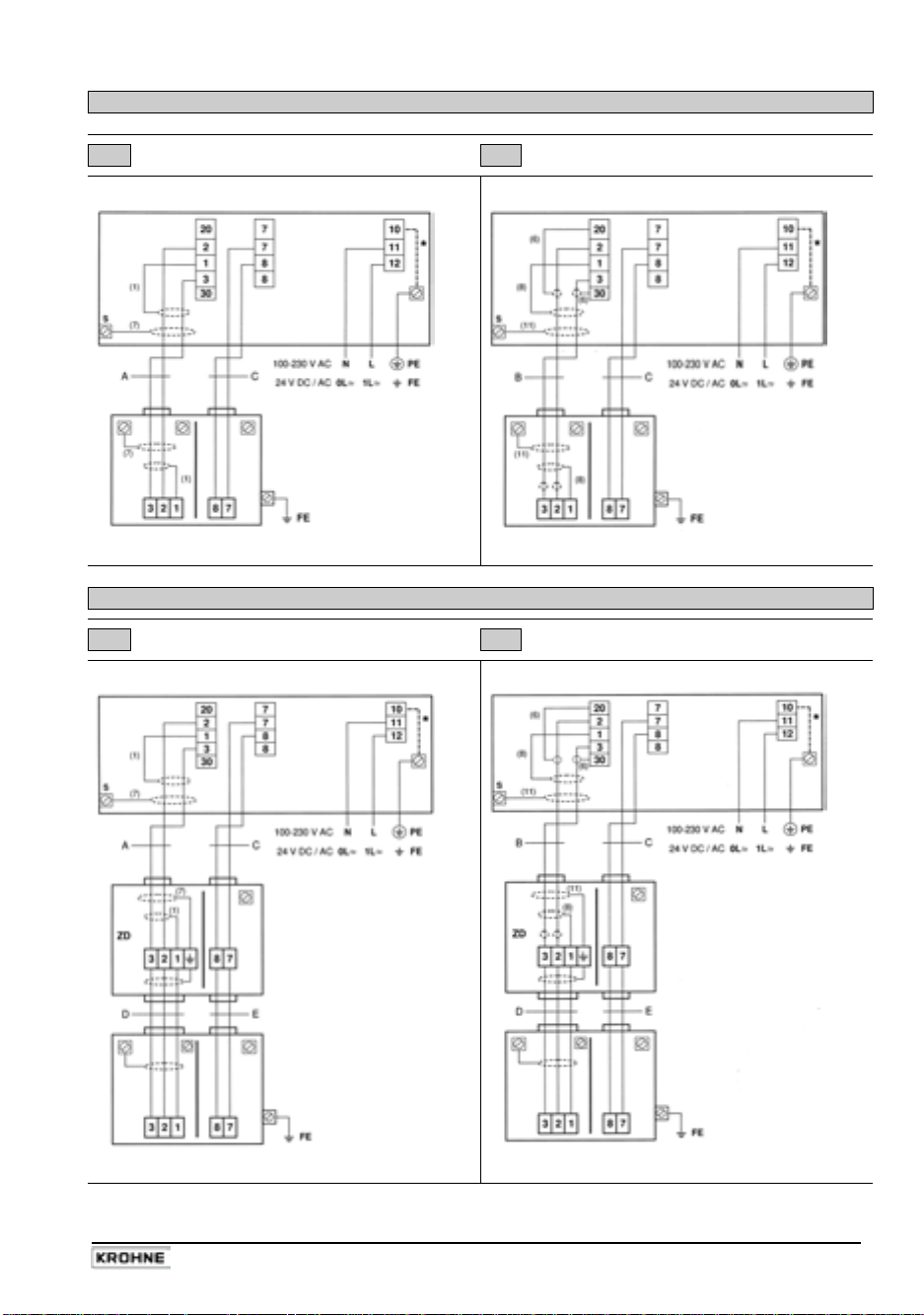

1.3.5 Connection diagrams for power supply and flow sensors

Important remarks for circuit diagrams PLEASE NOTE !

• The figures in brackets indicate the stranded drain wires of the shields (see cross-sectional

drawings of signal lines in Section 1.3.1).

• Electrical connection to VDE 0100 ”Regulations for the erection of power installations with

nominal voltages up to 1000 V”

• Power supply 24 V AC / DC:

• Systems to be used in hazardous areas are subject to special regulations applying to

electrical connections (see Section 1.3.6) for hazardous-duty instruments.

• PE = protective conductor

Do not remove the internal connection (cable) inside the terminal compartment of the signal

converter (yellow/green wire) between the U-clamp terminal and terminal 10 (protective

*

conductor for protection class I instruments).

IMPORTANT!

Electrical connection of EEx flow sensors and EEx signal converters to be carried

out as described in Sect. 1.3.6.

protective extra-low voltages (PELV) acc. to VDE 0100/

VDE 0106 and/or IEC 364/IEC 365, or corresponding

national regulations.

FE = functional ground conductor

10 IFC 110 F

05/2003

Page 11

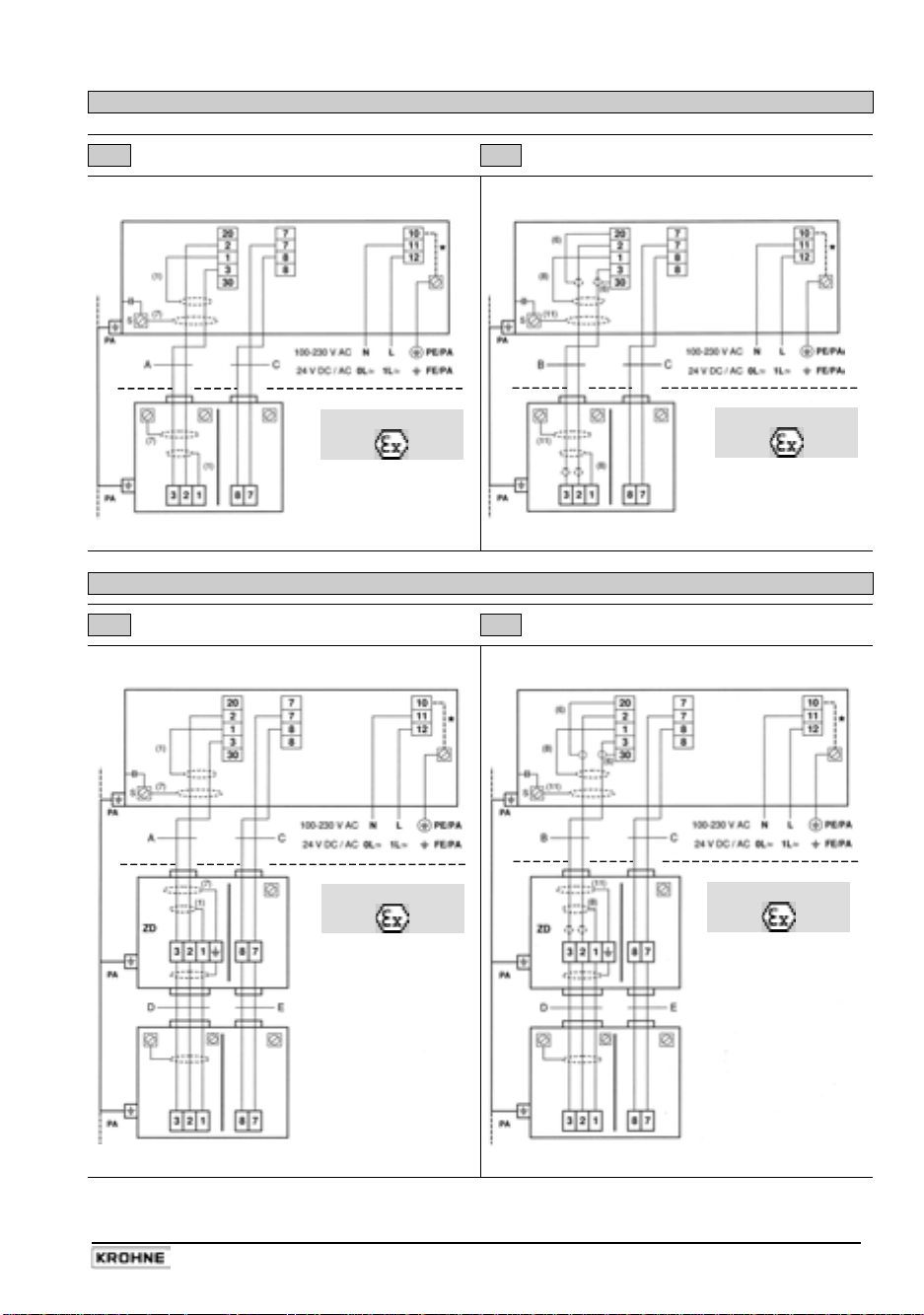

Process temperature below 150°C (302°F)

I Signal cable A (type DS) II Signal cable B (type BTS)

IFC 110 F V 2.0 IFC 110 F V 2.0

Flow sensor Flow sensor

III Signal cable A (type DS) IV Signal cable B (type BTS)

Process temperature above 150°C (302°F)

IFC 110 F V 2.0 IFC 110 F V 2.0

Flow sensor Flow sensor

IFC 110 F 11

05/2003

Page 12

1.3.6 EEx-Connection diagrams for power supply and flow sensors

PLEASE NOTE!

• The figures in brackets indicate the stranded drain wires for the shields (see cross-sectional

drawing of signal cable in Section 1.3.1).

• The connections for the intrinsically safe electrode circuit including the shield terminals

are safety-separated up to a peak value of 375 V from the terminals for thepower supply,

for the inputs/outputs and for the field circuit. They are galvanically isolated from the housing

(PE/PA).

• For connection of the intrinsically safe electrode circuit including shield terminals to the

primary head, please refer to Item 12 in EN 60079-14.

The non-intrinsically safe field circuit to be connected to the primary head in keeping with the

requirements of Item 9 in EN 60079-14 .

• The non-intrinsically safe input and output circuits may only be routed into the hazardous

area in compliance with appropriate measures as specified in EN 60079-14.

• Supply power (terminals 11,12)

In conformity with current regulations for electrical installations, an isolating facility is required

to be provided for the signal converter. The housing of the IFC 110 F – EEx signal converter

must be incorporated in the equipotential bonding system (via external PA connection).

Note!

A PE safety conductor is not connected if a functional extra-low voltage with safety

separation (PELV) is used. Grounding is then carried out by way of the equipotential

bonding conductor.

• Electrode circuit (terminals 1, 20, 2, 3, 30 and shield terminal S)

In conformity with the requirements for separation of intrinsically safe circuits, Category ib to

EN 50 020, the cable for the intrinsically safe electrode circuit must, up to the terminals, be

separated from all non-intrinsically safe circuits.

Terminals 20 and 30 are optionally provided for connecting cables with single shielding. The

terminal for the outer shield (S) is capacitance grounded in the signal converter. The outer

overall shield to be connected by the shortest possible wire to the shield terminal. Shields to

be carefully insulated from ground and from each other.

• Field circuit FSV (terminals 7, 8)

The field circuit is all-pole protected on the FSV circuit board with an internal fusible link

160mA / 250V.

• Input/output circuits

The connection is made to functional extra-low voltage circuits with safety separation (PELV).

The I/O functions and technical data are described in the Standard Installation and Operating

Instructions.

IMPORTANT!

For EEx versions, also pay regard to all directions included in Sect. 6.1 and 13.

Only the EEx flow sensor may be installed in the hazardous area. The EEx

certified signal converter must be installed outside the hazardous area!

Do not remove the internal connection (cable) inside the terminal compartment of the signal

converter (yellow/green wire) between the U-clamp terminal and terminal 10 (protective

*

conductor for protection class I instruments).

12 IFC 110 F

05/2003

Page 13

Process temperature below 150°C (302°F)

I Signal cable A (type DS) II Signal cable B (type BTS)

IFC 110 F V 2.0 IFC 110 F V 2.0

Hazardous area

Hazardous area

Flow sensor Flow sensor

III Signal cable A (type DS) IV Signal cable B (type BTS)

IFC 110 F V 2.0 IFC 110 F V 2.0

Process temperature above 150°C (302°F)

Hazardous area

Hazardous area

Flow sensor Flow sensor

IFC 110 F 13

05/2003

Page 14

2 Electrical connection: outputs and inputs

IMPORTANT!

For EEx versions, also pay regard to all directions included in Sect. 6.1 and 13.

Only the EEx flow sensor may be installed in the hazardous area. The EEx

certified signal converter must be installed outside the hazardous area!

2.1 Important information for outputs and inputs …….…………. PLEASE NOTE !

• The signal converter has the following outputs and inputs:

Output and Symbol Terminals Remarks

input group

Power output I IS / I active / passive selectable

Current output P P / P for electronic totalizers

Pulse output A1* (P2)

Status outputs A1* and A2

Status outputs D1 and D2

Control inputs C1 and C2

A1* / A⊥

A1* / A⊥ / A2 A⊥ common centre grounding contact

D1 / D⊥ / D2 D⊥ common centre grounding contact

C1 / C⊥ / C2 C⊥ common centre grounding contact

Internal power supply E E+ / E- for active mode of outputs and inputs

* Output A1 can be used as a 2nd pulse output P2 for electromechanical totalizers or as a

4th status output, see Section 4.4, Fct. 3.07 HARDWARE.

• The output and input groups are electrically isolated from each other and from all other input

and output circuits.

• Please note:

A⊥ common centre grounding contact for outputs A1 and A2

D⊥ common centre grounding contact for outputs D1 and D2

C⊥ common centre grounding contact for control inputs C1 and C2

• Active mode:

the signal converter supplies the power for the operation (selection) of

receiver instruments, observe max. operating data (terminals E+ and E-).

• Passive mode:

the operation (selection) of receiver instruments requires an external

power supply (U

), observe max. operating data.

ext

• Connection diagrams of outputs and inputs are shown in Section 2.6.

• For operating data of outputs and inputs please refer to Sections 2.6 and 10.1.

for electromechanical totalizers

14 IFC 110 F

05/2003

Page 15

2.2 Current output I

• The current output is electrically isolated from all other circuits.

• Setting data and functions can note down in the Table in Sect. 3.

Please also refer to Section 2.7 ”Standard factory settings”.

• All operating data and functions are adjustable (see Sections 4.4 and 5.6, Fct. 1.05).

• Max. load :

• Selfcheck :

- short-circuit of mA loop via test function, see Fct. 2.03

or when power supply is switched on in Fct. 3.07

Error message on display (see Fct. 1.04, Section 5.4) and/or

status output (see Fct. 1.07-1.10, Section 5.8).

• Current value for error identification is adjustable, see Fct. 1.05 and Section 5.6.

• Range change-over, automatically or externally by control input,

see Sections 4.4 and 5.19, Fct. 1.07-1.10 and 1.11-12.

Setting range from 5-80% of Q

(corresponding low to high range ratio from 1:20 to 1:1.25).

Change-over from high to low range at approx. 85% of low range and vice versa at approx.

98% of low range.

The active range is signalled via one of the four status outputs.

• Forward/reverse flow measurement (F/R mode) is possible (see Section 5.15).

• Connection diagrams see Section 2.6.

active operation 15-500 Ω

passive operation

≤ 800 Ω

- interrupting the mA loop, and

100%

IFC 110 F 15

05/2003

Page 16

2.3 Pulse outputs P and A1

2.3.1 Pulse output P for electronic totalizers (EC)

• Pulse output P is electrically isolated from all other circuits.

• Setting data and functions can note down in the Table in Sect. 3.

Please also refer to Section 2.7 ”Standard factory settings”.

• All operating data and functions are adjustable, see Sections 4.4 and 5.7, Fct. 1.05.

• Active mode:

Passive mode:

• Max. adjustable frequency 10 kHz

• Scaling

in pulses per unit volume

• Pulse width

automatic

pulse duty factor approx. 1:1 at Q

pulse width range from 0.01 to 1 s

correspondingly lower output frequency.

• Forward/reverse flow measurement (F/R mode) is possible, see Section 5.15.

• Connection diagrams see Section 2.6

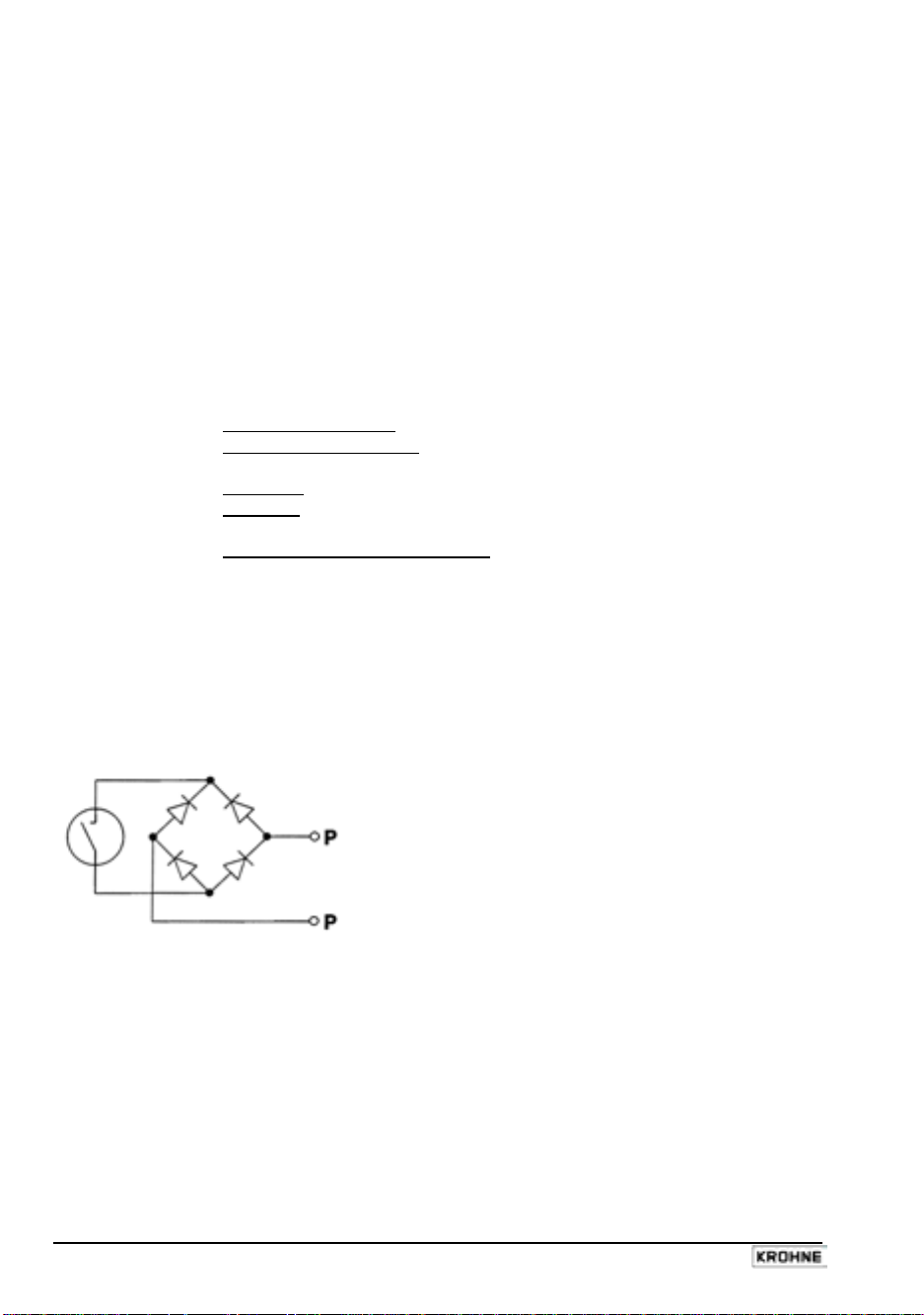

• Schematic wiring diagram for pulse output P for electronic totalizers EC

Similar to a relay contact, this pulse output switches direct and alternating voltages.

uses the internal power supply, terminals E+/Erequires external power supply, U

in pulses per unit time

(e.g. 1000 pulses/s at Q

≤ 32V DC/24V AC, I ≤ 30mA

ext

(e.g. 100 pulses/m³ or US Gal).

symmetric

, pulse duty factor 1:1, independent of output frequency,

, with optimum pulse width,

, or

100%

adjustable as required for

100%

flow) or

16 IFC 110 F

05/2003

Page 17

2.3.2 Pulse output A1 for electromechanical totalizers (EMC)

PLEASE NOTE:

The output terminal A1 can be used as status output A1 or as a 2nd pulse output A1 for

electromechanical totalizers.

Setting is as described in Fct. 3.07 HARDWARE, see Sections 4.4 and 5.18.

• Pulse output A1 is electrically connected to status output A2 (common centre grounding

contact A⊥) but electrically isolated from all other circuits.

• Setting data and functions can note down in the Table in Sect. 3.

Please also refer to Section 2.7 ”Standard factory settings”.

• All operating data and functions are adjustable, see Sections 4.4 and 5.7, Fct. 1.07.

• Active mode:

• Passive mode:

uses the internal power supply, terminals E+/Erequires external power supply, U

≤ 32V DC/24V AC, I ≤ 100mA

ext

(I ≤ 200mA for polarized DC operation, see Section 6.3)

• Max. adjustable frequency 50 kHz

• Scaling

in pulses per unit of time

(e.g. 10 pulses/s at Q

100%

flow) or

in pulses per unit of volume (e.g. 10 pulses/m³ or US Gal).

• Pulse width

symmetric

, pulse duty factor 1:1, independent of output frequency,

automatic, with optimum pulse width,

pulse duty factor approx. 1:1 at Q

pulse width range from 0.01 to 1 s

, or

100%

adjustable as required for

correspondingly lower output frequency.

• Forward/reverse flow measurement (F/R mode) is possible, see Section 5.15.

• Connection diagrams see Section 2.6

• Schematic wiring diagram for pulse output A1 for electromechanical totalizers EMC.

This pulse output has a MOSFET switch as output which switches direct and alternating

voltages similar to a relay contact.

IFC 110 F 17

05/2003

Page 18

2.4 Status outputs A1 / A2 / D1 / D2

PLEASE NOTE:

The output terminal A1 can be used as status output A1 or as a 2nd pulse output A1 for

electromechanical totalizers.

Setting is as described in Fct. 3.07 HARDWARE, see Sections 4.4 and 5.18.

• Status outputs A1/A2 and D1/D2 with the common centre grounding contacts A⊥ and B⊥ are

electrically isolated from each other and from all other circuits.

• Setting data and functions can note down in the Table in Sect. 3.

Please also refer to Section 2.7 ”Standard factory settings”.

• All operating data and functions are adjustable, see Sections 4.4 and 5.8, Fct. 1.07-1.10.

• Active mode:

Passive mode:

uses the internal power supply, terminals E+/Erequires external power supply, U

≤ 32V DC/24V AC, I ≤ 100mA

ext

(I ≤ 200mA for A1 in case of polarized DC operation, see Section 6.3)

• The following operating conditions can be signalled using the status outputs:

- flow direction (F/R mode)

- limits

- error messages

- active range in case of range change-over

- inverse operation of A1 and A2 or D1 and D2,

i.e. used as change-over switch with common centre grounding contact A⊥ or D⊥.

• Connection diagrams see Section 2.6

• Schematic wiring diagram for status outputs A1/A2 and D1/D2.

This status outputs have MOSFET switches as outputs which switch direct and alternating

voltages similar to relay contacts.

2.5 Control inputs C1 and C2

• Control inputs C1 and C2 are electrically connected (common centre grounding

contact C⊥) but electrically isolated from all other circuits.

• Setting data and functions can note down in the Table in Sect. 3.

Please also refer to Section 2.7 ”Standard factory settings”.

• All operating data and functions are adjustable, see Sections 4.4 and 5.9, Fct. 1.11-1.12.

• Active mode:

Passive mode:

uses the internal power supply, terminals E+/Erequires external power supply, U

≤ 32V DC/24V AC, I ≤ 10mA

ext

• The following operating conditions can be initiated using the control inputs:

- external range change

- holding of output values

- zeroing the outputs

- resetting the internal totalizer

- resetting (deleting) the error messages

• Connection diagrams see Section 2.6

18 IFC 110 F

05/2003

Page 19

2.6 Connection diagrams of outputs and inputs

IMPORTANT!

For EEx versions, also pay regard to all directions included in Sect. 6.1 and 13.

Only the EEx flow sensor may be installed in the hazardous area. The EEx

certified signal converter must be installed outside the hazardous area!

I

P, A1*

A1*, A2,

D1, D2

C1, C2

Current output (included HART

Pulse output

Status outputs

Control inputs

Totalizer

-electromechanical (EMC)

- electronic (EC)

milliampmeter

0-20 mA or 4-20 mA and other

Key, N/O contact

External voltage source (U

connection polarity arbitrary

DC voltage,

external power source (U

Active mode: the IFC 110 F supplies the power required for operating (driving) the receiver

instruments. Observe the max. operating data (terminals E+ and E-).

Passive mode: an external power supply source (Uext) is required for operating (driving) the

receiver instruments.

Groups A / C / D / E / I / P are electrically isolated from each other and from all other input and

output circuits.

Please note:

common reference potential

A⊥ for A1 and A2

C⊥ for C1 and C2

D⊥ for D1 and D2

®

)

), DC or AC voltage,

ext

), note connection polarity

ext

Please note ! Unwired

contacts or terminals may not

have any conductive

connection with other

electrically conducting parts.

Interface operation with

HART® or RS 485 (Option)

see Sect. 6.4.

*

selectable as

status output A1 or

pulse output A1

IFC 110 F 19

05/2003

Page 20

Current output I

{

active

Current output I

|

range change BA

with automatic

active

without external change-over relay

low range

high range

Ri 15 - 500 Ω

Ri 15 - 500 Ω

Current output I

}

(see Sect. 6.8 passive/active for pulse and current outputs (P and I

passive

Forward/reverse flow meausrement (F/R mode)

~

active

)

operation without external change-over relay

reverse

flow

forward

flow

reverse

flow

forward

flow

Ri 15 - 500 Ω

selectable with internal power supply

E or external power supply U

the connection diagrams for pulse output P on the

ext.

Electronic totalizers must be connected as shown in

following page.

U

15 - 22 V DC 22 - 32 V DC

ext.

R

0 - 500 Ω 0 - 800 Ω

i

Pulse output A1 active

Pulse output A1 passive

for electromechanical totalizers (EMC) for electromechanical totalizers (EMC)

≤ 32 V DC / ≤ 24 V AC I ≤ 10 mA

Ri ≥ 160 Ω

I ≤ 100 mA

20 IFC 110 F

U

ext.

oder umschaltbar auf

≤ 32 V DC I ≤ 200 mA

U

ext.2

05/2003

Page 21

Pulse output P

active

for electronic totalizers (EC)

for frequencies ≤ 1 kHz

Pulse output P

active

for electronic totalizers (EC)

for frequencies > 1 kHz

R1 = 1 kΩ/0.5 W I ≤ 20 mA R

> 100 kΩ R = 1 kΩ/0.35 W I ≤ 30 mA

i EC

R2 / 0.2 W

U

EC max

10 kΩ 1 kΩ 270 Ω

22 V 12 V 5 V

Pulse output P

passive

for electronic totalizers (EC)

for frequencies ≤ 1 kHz

U

≤ ≤ 32 V DC / ≤ 24 V AC

ext

I

≤ ≤ 30 mA

R

=

1 - 10 kΩ

P

≥

R

2

U

ext

R

for frequences > 1 kHz

U

=

ext

R

i EC

I ~ 30 mA ~ 18 mA

R

P

R

U

EC

≤ 24 V DC / AC

≥ 100 kΩ

560 Ω 1 kΩ

0.5 W 0.35 W

16 V 18 V

* Shielded cables

must be used to prevent radio interference at pulse output frequencies > 100 Hz

IFC 110 F 21

05/2003

Page 22

Status outputs D1 / D2 / A1 / A2 active

I ≤ 100 mA

e.g. message display

9

Control inputs C1 / C2 active

Status outputs D1 / D2 / A1 / A2 passive

≤ 32 V DC / ≤ 24 V AC

U

ext.

I ≤ 100 mA

9

e.g. message display

Control inputs C1 / C2 passive

Contacts 24 V, 10 mA

I ≤ 7 mA I ≤ 10 mA

22 IFC 110 F

≤ 32 V DC / ≤ 24 V AC

U

ext.

05/2003

Page 23

3 Start-up

• Before connecting to power, check that the instrument is correctly installed as described in

Sections 1 and 2.

• The flowmeter, flow sensor and signal converter are delivered ready for operation. All

operating data are set at the factory in accordance with your specifications.

Please also refer to Section 2.7 ”Standard factory settings”.

• Switch on the power supply. The flowmeter immediately begins to measure the flow.

• When the power supply is switched on, the display successively shows START UP and

READY. Then the current flow rate and/or the current totalizer count are displayed. Displays

are either steady or cyclic depending on the setting described for Fct. 1.04.

• 2 light-emitting diodes (LED) in the ”diagnostics” field on the front panel of the signal

converter indicate the status of measurement.

LED displays Status of measurement

Green ”normal” LED Everything O.K.

is flashing

Green ”normal” LED Momentary overload of outputs and/or A/D converter.

and red ”error” LED Detailed error messages by setting Fct. 1.04 DISPLAY,

are flashing alternately subfunction ”MESSAGES” to ”YES”, see Sections 4.4 and 5.5.

Red ”error” LED is Fatal Error, see Sections 7.3 and 7.4

flashing

IMPORTANT!

For EEx versions, also pay regard to all directions included in Sect. 6.1 and 13.

Only the EEx flow sensor may be installed in the hazardous area. The EEx

certified signal converter must be installed outside the hazardous area!

IFC 110 F 23

05/2003

Page 24

4 Operating of the signal converter

4.1 KROHNE operating concept

24 IFC 110 F

05/2003

Page 25

4.2 Operating and control elements

The instrument can be operated

by means of ....

…

the 15 keys ~

after removal of the glass cover,

…

the 3 magnetic sensors

bar magnet without opening the

housing (optional).

Display, 1st line Displaying numerical data

{

Display, 2nd line Displaying units and texts

|

Display, 3rd line 6 arrows to mark the current display

}

flow rate current flow rate

+

totalizer

-

control in

~

5 keys for operating the signal converter ← → ↵ ↑ ↓

10 keys for direct numerical setting of function values (not function numbers)

Compass field showing that a key is pressed

magnet active

green

red

3 magnetic sensors (optional), operated by bar magnet without opening the housing,

function of the sensors as described for the three keys → ↵ ↑, see

diagnostics

normal

error

IMoCom

supplementary equipment, see Section 6.4, slide window to the left

totalizer

totalizer

sum totalizer (+ and -)

Σ

1/2

control input 1 or 2 active

LED green/red, magnetic sensors active

= built-in magnetic sensors (optional), see

= operation of one of the 3 magnetic sensors

2 LEDs signalling the status of measurement

green LED

red LED

IMoCom bus, multipoint connector for connecting external

= correct measurement, everything O.K.

= error, parameter or hardware error

and accessible

.

~

and the

IFC 110 F 25

05/2003

Page 26

4.3 Key functions

In the following, the cursor or flashing part of the display is shown against a grey background.

To start operator control

Measuring mode

1 3 . 5 7 1

m 3 / h

PLEASE NOTE: if ”YES” is selected in Fct. 3.04 ENTRY CODE, ”CodE 1 - - - - - - - - -”

appears in the display after pressing the → key.

Enter the password for the entry code which is a sequence of 9 keys: → → → ↵ ↵ ↵ ↑ ↑ ↑

(each keystroke confirmed by ” * ”).

To terminate operator control

Press key ↵ any number of times until one of the following menus

Fct. 1.0 OPERATION, Fct. 2.0 TEST or Fct. 3.0 INSTALL is displayed.

F c t . 3. 0

I N S T A L L.

Store new parameters: acknowledge by

New parameters not to be stored:

Keyboard with 10 keys

The keyboard with the 10 keys (0-9) is used for setting all flashing numbers (cursor).

Exception: the digits of the function numbers, such as Fct. 1.03, can only be changed with

keys ↑ or ↓.

→

Press key ↵

↵

Operator control mode

F c t . 1. 0

O P E R A T I O N

S T O R E Y E S

pressing key ↵. Measuring mode is

continued with new parameters.

press key ↑ to display

”STORE NO”.

Measuring mode is continued with the ”old”

parameters after pressing key ↵.

26 IFC 110 F

05/2003

Page 27

To change numbers

3 9 7. 3 5

m 3 / h

increase number

decrease number

3 9 7. 4 5

↑

m 3 / h

↓

To shift cursor (flashing position)

3 9 7. 3 5

m 3 / h

shift to right

→

shift to left

3 9 7. 3 5

m 3 / h

←

To alter texts (units)

In case of units, the numerical

value is converted automatically.

3. 7 6 9 9

L i t e r / S e c

select next text

select preceding text

9 3. 3 6 5

↑

U S. G a l / m i n

↓

To change from text (unit) to numerical setting

1 3. 5 7 1

m 3 / h

change to numerical setting

1 3. 5 7 1

→

return to text setting

m 3 / h

←

To change to subfunction

Subfunctions have no “Fct. No.” and are identified by a “→”

2 D I R.

↵

→

R A N G E I

To revert to function display

10. 3

S e c

F c t. 1. 0 2

↵

T I M E C O N S T.

IFC 110 F 27

05/2003

Page 28

4.4 Table of settable functions

Abbreviations used:

A1, A2

Status outputs

(A1 can also be 2nd pulse output A1)

C1, C2

Control inputs

D1, D2

Status outputs

DN

Meter size, nominal size

F

= ½ x pulse width (s) for ≤ 50 Hz

max

≤ 10 kHz if ”AUTO” or ”SYM.” are selected in

subfunction ”PULSWIDTH”

F

= 10 pulses/h

min

FM

Conversion factor volume

see Fct. 3.05 ”FACT. VOL.”

F

Conversion factor time

T

see Fct. 3.05 ”FACT. TIME”

GK

Flow sensor constant

I

Current output

I

Current at 0% flow rate

0%

I

Current at 100% flow rate

100%

Fct. Text Description and setting

1.0 OPERATION Operating menu

FULL SCALE Full-scale range for flow rate Q

Selection of unit

Setting ranges

The range depends on the nominal width (DN) and the

flow velocity (v): Q

Nominal width/meter size vmin = 0.3 m/s (1 ft/s) vmax = 12 m/s (40 ft/s)

● DN 2.5–1200 / 1/10”–48”: 0.0053 – 48 860 m³/h

0.0237 – 218 560 US.Gal/min

● DN 1300–3000 / 52”–120” 1435 – 305 360 m³/h

(see Section 8.6) 6415 – 1 366 000 US.Gal/min

VALUE P

→

and/or

VALUE P2

→

been exceeded or would not have been reached.

1.02 TIMECONST. Time constant

Selection: ● ALL (applies to display and all outputs)

● ONLY I (only display, current and status outputs)

Range: ● 0.2 – 99.9 Sec

1.03 L.F. CUTOFF Low-flow cutoff (L.F. CUTOFF)

● OFF (fixed tripping points: ON = 0.1% / OFF = 0.2%)

● PERCENT (variable tripping points) ON OFF

1 – 19% 2 – 20%

Note: the cutoff ”OFF” value must be greater than the cutoff ”ON” value.

P (P2)

Pulse output (2nd pulse output A1)

P

= F

max

P

min

Q

Q

100%

Q

max

for any unit,

for any unit,

Q

min

SMU

v

v

max

v

min

F/R

m³/h

•

user unit, factory setting ”Liter/h” or ”US MGal/day” (see Fct. 3.05)

•

•

max/Q100%

= F

min/Q100%

Current flow rate

100% flow rate = full-scale range

π

= /4 DN² x v

4

Q

100%

π

= /4 DN² x v

4

Q

100%

Low-flow cutoff for I and P

Flow velocity

Maximum flow velocity (12 m/s or 40 ft/s) at Q

Minimum flow velocity (0.3 m/s or 1 ft/s) at Q

Forward/reverse flow in F/R measuring mode

100%

Liter/Sec

Press → key to change to numerical setting

π

= DN² x v

min

4

Press ↵ key to return to Fct. 1.01 FULL SCALE

Pulse value for pulse output P (Fct. 1.06 ”VALUE P”) and/or

for the 2nd pulse output A1 (Fct. 1.07 ”VALUE P2”) has been changed.

With the ”old” pulse values the output frequency (F) would have

/ Q

P

= F

min

min

100%

P

max

= F

max

/ Q

100%

Press ↵ key to change to numerical setting.

Press ↵ key to return to Fct. 1.02 TIMECONST.

Press → key to change to numerical setting.

Press ↵ key to return to Fct. 1.03 L.F. CUTOFF.

(= max. full-scale range

max

at v

= 12 m/s or 40 ft/s)

max

(= min. full-scale range

min

at v

= 0.3 m/s or 1 ft/s)

min

US.Gal/min

•

Q

min

= DN² x v

max

Check new values!

π

4

max

100%

100%

28 IFC 110 F

05/2003

Page 29

Fct. Text Description and setting

1.04 DISPLAY Display functions

→ DISP.FLOW

● NO DISP. ● User unit, factory setting ”Liter/h” or ”US MGal/day” (s. Sect. 3.05)

● m³/h ● PERCENT

● Liter/Sec ● BARGRAPH (value and bar graph display in %)

● US.Gal/min

● NO DISP. (totalizer is ON but no display)

● OFF (totalizer is OFF)

● + TOTAL. ● - TOTAL. ● +/- TOTAL.

● ALL (display single counts or all)

● m³ ● Liter ● US.Gal

● User unit, factory setting ”Liter” (s. Sect. 3.05)

Format setting

● Auto (exponent notation)

● # . ####### ● ##### . ###

● ## . ###### ● ###### . ##

● ### . ##### ● ####### . #

● #### . #### ● ########

● NO ● YES (cyclic change with display of measured values)

1.05 CURRENT I Current output I

● OFF (switched off)

● + DIR. ● - DIR. (measurement in one flow direction only)

● 2 DIR. (forward/reverse flow, F/R mode)

press this key to change to subfunction ”REV. RANGE”.

(only displayed when ”2 DIR.” is selected)

● 100 PCT. (same as forward flow Q

● PERCENT setting range: 005 - 150 % of Q

(different value for reverse flow)

● 0 - 20 mA ● 4 - 20 mA (fixed ranges)

● mA (user-defined range) I0% - I

(Value I0% < I

● 22 mA

1.06 PULS P Pulse output P

Description of function of pulse output P on the next page.

1.07 STATUS A1 Status output A1 A1 = terminal

PULS2 A1 2nd pulse output A1

Description of function of status output A1 or 2nd pulse output A1

DISP.TOTAL.

→

DISP.MSG.

→

FUNCT. I

→

REV.RANGE

→

RANGE I

→

I ERROR

→

or

Selection of flow display

Press ↵ key to change to subfunction ”DISP. TOTAL.”

Selection of totalizer display

● SUM (Σ)

Press ↵ key to change to setting of display unit.

Press → key to transfer to format setting.

Press ↵ key to change to subfunction ”DISP. MSG.”

Additional messages desired during measuring mode?

Press ↵ key to return to Fct. 1.04 DISPLAY.

Selecting the current output I function

Press ↵ key to change to subfunction ”RANGE I”; if ”2 DIR.” is selected

Setting the full-scale range for reverse flow of Q

, see Sect. 1.01)

100%

100%

Press → key to change to numerical setting.

Press ↵ key to change to subfunction ”RANGE I”

Selecting the measuring range

!) 0 - 16 mA 4 - 20 mA

Press → key to change to numerical setting!

Press ↵ key to change to subfunction ”I ERROR”.

Selecting the error value

Press → key to change to numerical setting.

Press ↵ key to return to Fct. 1.05 ”CURRENT OUTPUT I”.

connected as status or pulse output (P2)

on the next page.

100%

● 0.0 to I

}

mA (variable when I0% ≥ 1 mA, see above)

0%

s. Fct. 3.07 HARDWARE, ”Terminal A1”

100%

100%

IFC 110 F 29

05/2003

Page 30

Fct. Text Description and setting

1.08 STATUS A2 Status outputs A2, D1 and D2

1.09 STATUS D1 Description of function of status outputs A2, D1 and D2

1.10 STATUS D2

1.11 CONTROL C1 Countrol inputs C1 and C2

1.12 CONTROL C2

1.06 PULS P Pulse output P for electronic totalizers up to 10,000 pulses/s

1.07 PULS2 A1 2nd pulse output A1 for electromechanical totalizers up to max. 50 Hz.

Connection of terminal A1 as a 2nd pulse output A1 or as status output A1,

FUNCT. P

→

FUNCT. P2

→

● + DIR. ● - DIR. (measuring in one flow direction only)

● 2 DIR. (forward/reverse flow, F/R mode)

SELECT P

→

SELECT P2

→

● PULSE/TIME (pulses per unit time for 100% flow rate)

PULSWIDTH

→

PULSWIDTH

→

● AUTO (automatic = 50% of cycle duration of 100% output frequency)

● SYM (symmetric = pulse duty factor approx. 1:1 across the entire range)

VALUE P

→

VALUE P2

→

● xxxx PulS/m³ ● xxxx PulS/Liter ● xxxx PulS/US.Gal

● xxxx PulS/user unit, factory setting ”Liter” or ”US MGal” (s. Fct. 3.05)

Setting range ”xxxx” depends on pulse width and full-scale range:

P

accordance with the same setting mode.

VALUE P

→

VALUE P2

→

● xxxx PulSe/Sec (=Hz) ● xxxx PulSe/min ● xxxx PulSe/h

Fct. 1.06 and 1.07 have identical menus and are configured in

● xxxx PulSe/user unit, factory setting ”h” (s. Fct. 3.05)

Setting range ”xxxx” depends on pulse width (see above).

}

on the next page but one.

}

Description of function of control inputs on the next page but one.

see Fct. 3.07 HARDWARE, ”Terminal A1”.

Selecting the function for pulse outputs P and P2

● OFF

Press ↵ key to change to subfunction ”SELECT P or P2”.

Selecting the type of pulse

● PULSE/VOL. (pulses per unit volume, flow rate)

Press ↵ key to change to subfunction ”PULSWIDTH”.

Selecting the pulse width

● 0.01 - 1.00 s (only for F

Press ↵ key to change to subfunction ”VALUE P or P2”.

Setting the pulse value per unit volume (only displayed when

”PULSE/VOL.” is selected in ”SELECT P or P2”

= F

/ Q

100%

, P

min

min

Press ↵ key to return to Fct. 1.06 PULS P or Fct. 1.07 PULS2 A1.

Setting the pulse value per unit time (only displayed when

”PULSE/TIME” is selected in ”SELECT P or P2”

Press ↵ key to return to Fct. 1.06 PULS P or Fct. 1.07 PULS2 A1.

< 50 pulses/s)

max

= F

max

max

/ Q

100%

above).

above).

30 IFC 110 F

05/2003

Page 31

Fct. Text Description and setting

1.07 STATUS A1 Status output A1 (terminal A1 connected as status output A1 or

1.08 STATUS A2 Status output A2

1.09 STATUS D1 Status output D1

1.10 STATUS D2 Status output D2

● INVERS D1 (inverse mode of D1 and D2)

● INVERS A1 (inverse mode of A1 and A2 possible only if A1

is operated as status output, see Fct. 3.07 HARDWARE, ”terminal A1”)

● SIGN I, P or P2

(F/R mode)

● OVERFL. I, P or P2

(overloading the outputs)

● EMPTY PIPE (”tube empty” signal only with built-in option)

● TRIP. POINT

Selection: ● + DIR. ● - DIR. ● 2 DIR.

Setting range: 000 - 150 PERCENT

● AUTO. RNG. Setting range: 05-80 PERCENT (= lower to upper range ratio

1:20 to 1:1.25, value must be higher than that of Fct. 1.03 L.F. CUTOFF)

Fct. Text Description and setting

1.11 CONTROL C1 Control input C1 and C2

1.12 CONTROL C2 ● OFF ● EXT. RNG. (external range change)

● OUTP. HOLD (hold output values)

● OUTP. ZERO (set outputs to ”min. values”)

● TOTAL.RESET (reset the totalizer)

● ERROR.RESET (delete error messages)

Fct. Text Description and setting

2.0 TEST Test menu

TEST Q Test measuring range Q

Precautionary query

● SURE NO

● SURE YES

of set full-scale range Q

Displayed value is available at outputs I and P.

2.02 HARDW. INFO Hardware information and error status

Before consulting factory, please note down all 6 codes.

Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y Fct. 2.02 “HARDW. INFO“.

2.03 HARDW. TEST Hardware test (Precautionary query)

- SURE NO

- SURE YES

display next error. List of errors see Section 4.5.

→

Fct. 1.07 to 1.10 are configured in

accordance with the same setting

mode. Functions set for one of the

→

→ MODUL ADC

→ MODUL IO

→ MODUL DISP.

as a 2nd pulse output A1, see Fct. 3.07 HARDWARE, ”terminal A1”)

● OFF ● ON ● ALL ERROR ● FATAL.ERROR

dynamic behaviour

of outputs see Fct. 1.02

TIMECONST.:

}

I = ONLY I

P or P2 = ALL

Press → key to change to character.

Press ↵ key to change to numerical setting.

status outputs are no longer available

for the other status outputs.

Press ↵ key to change to numerical setting.

Press ↵ key to return to Fct. 1.06, 1.07, 1.08 or 1.09.

Setting range: 05-80 PERCENT (= lower to upper range ratio 1:20 to 1:1.25,

value must be higher than that of Fct. 1.03 L.F. CUTOFF)

Press ↵ key to change to numerical setting.

Press ↵ key to return to Fct. 1.11 or 1.12 CONTROL C1 or C2

Press ↵ key to return to Fct. 2.01 “TEST Q”.

Press ↵ key, then use ↑ key to

select value:

Press ↵ key to return to Fct. 2.01 “TEST Q”.

X . X X X X X . X X

X . X X X X X . X X

X . X X X X X . X X

If errors are found, the first one is displayed. Press ↓ key to

Press ↵ key to return to Fct. 2.03 ”HARDW. TEST”.

-110 / -100 / -50 / -10 / 0 / +10 / +50 / +100 / +110 PCT.

Press ↵ key to transfer to “MODUL IO“.

Press ↵ key to transfer to “MODUL DISP.“.

Press ↵ key to return to

Press ↵ key to return to Fct. 2.03 ”HARDW. TEST”.

Press ↵ key to start test, duration approx. 60 s

100%

.

IFC 110 F 31

05/2003

Page 32

Fct. Text Description and setting

3.0 INSTALL. Installation menu

3.01 LANGUAGE Select language for display texts

● GB / USA (English) ● S (Swedish)

● D (German) ● other languages on request

● F (French)

Press ↵ key to return to Fct. 3.01 “LANGUAGE”.

3.02 FLOWMETER Set data for flow sensor

DIAMETER

→

Select size from meter size table

● DN 2.5 - 1200 mm equivalent to 1/10 - 48 inch

● DN 1300 - 3000 mm equivalent to 52 - 120 inch (see Sect. 8.6)

FULL SCALE

→

Select with ↑ key.

Press ↵ key to change to subfunction “FULL SCALE”.

Full-scale range for flow Q

100%

To set, refer to Fct. 1.01 “FULL SCALE”.

VALUE P

→

and/or

VALUE P

→

Press ↵ key to change to subfunction “GK VALUE”.

Pulse value for pulse output P (Fct. 1.06 ”VALUE P”) and/or

for the 2nd pulse output A1 (Fct. 1.07 ”VALUE P2”) has been changed.

With the ”old” pulse values the output frequency (F) would have been exceeded

or would not have been reached.

GK VALUE

→

= F

/ Q

P

min

min

100%

P

max

Set primary constant GK

= F

max

/ Q

Check new value.

100%

See instrument nameplate of flow sensor.

Range: ● 1.0000 - 15.000

FIELD FREQ.

→

Press

key to change to subfunction “FIELD. FREQ.”.

↵

Magnetic field frequency

Values: 1/2, 1/6, 1/18 and 1/36 of power frequency, see instr. nameplate.

Press ↵ key to change to subfunction “FLOW DIR.”;

on DC instruments change to subfunction “LINE FREQ.”.

LINE FREQ.

→

Power frequency customary in the country where the instrument is used

Please note: this function is limited to instruments with DC supply unit (24 V DC)

to suppress line frequency interferences.

Values: 50 Hz and 60 Hz

FLOW DIR.

→

Press ↵ key change to subfunction “FLOW DIR.”.

Define flow direction (in F/R mode: forward flow).

Set according to direction of arrow on flow sensor:

● + DIR.

Press ↵ key to return to Fct. 3.02 “FLOWMETER”.

● – DIR. Select using ↑ key.

3.03 ZERO SET Zero calibration

Note: carry out only at ”0” flow and with completely filled measuring tube!

Precautionary query

● CALIB. NO

● CALIB. YES

Press ↵ key to return to Fct. 3.3 “ZERO SET”.

Press ↵ key to start calibration.

Duration approx. 15-90 s (depending on magnetic field

frequency), current flow rate displayed in the selected unit

(s. Fct. 1.04 ”DISP. FLOW”).

A ”WARNING” sign appears when flow rate ”>0”;

acknowledge by pressing ↵ key.

● STORE NO (do not store new zero value)

● STORE YES (store new zero value)

Press ↵ key to return to Fct. 3.03 “ZERO SET”.

3.04 ENTRY CODE Entry code required to enter setting mode?

● NO

● YES

Press ↵ to return to Fct. 3.04 “ENTRY CODE”.

(= entry with → only)

(= entry with → and Code 1:

→ → → ↵ ↵ ↵ ↑ ↑ ↑

)

32 IFC 110 F

05/2003

Page 33

Fct. Text Description and setting

3.05 USER UNIT Set any required unit for flowrate and counting

→ TEXT VOL.

Set text for required flowrate unit (max. 5 characters)

Factory setting = Liter or US MGal

Characters which can be assigned to each place:

● A-Z, a-z, 0-9, or “ – “ (= blank character).

FACT. VOL.

→

Press ↵ key to transfer to subfunction “FACT. VOL.”

Set conversion factor (F

) for volume

M

Factory setting ”1.00000 E+3” for ”Liter” or ”2.64172E-4” for ”US MGal”

(exponent notation, here 10³ or 2.64172 x 10-4)

Factor FM = volume per 1m³.

Setting range

● 1.00000 E-9 to 9.99999 E+9 (= 10-9 to 10+9)

TEXT TIME

→

Press ↵ key to transfer to subfunction “TEXT TIME”.

Set text for any time (max. 3 characters)

Factory setting = ”h” (hours)

Characters which can be assigned to each space:

● A-Z, a-z, 0-9, or “ – “ (= blank character).

FACT. TIME

→

Press ↵ key to transfer to subfunction “FACT. TIME”

Set conversion factor (F

) for time

T

Factory setting ”3.60000 E+3” for ”h” (exponent notation, here 3.3 x 103).

Set factor FT in seconds.

Setting range

● 1.00000 E-9 to 9.99999 E+9 (= 10-9 to 10+9)

Press ↵ key to return to Fct. 3.05 “USER UNIT”.

3.06 APPLICAT. Set modulation range of A/D converter

FLOW

→

● STEADY (150% of Q

) ● PULSATING (1000% of Q

100%

Press ↵ key to change to subfunction ”EMPTY PIPE”.

100%

)

EMPTY PIPE Empty pipe detection EPD (see Sect. 6.9)

● NO

● YES

● VAL. FULL

● CALIB. NO

● CALIB. YES

(Press ↵ key to change to subfunction “ADC Gain“)

(Press ↵ key to change to “VAL. FULL“)

(Press ↵ key, precautinory query)

(Press ↵ key to change to “VAL. EMPTY“)

(Press ↵ key, calibration will start with flashing display “WAIT“,

duration approx. 20 seconds)

Make sure that measuring tube is completely filled!

● STORE NO

● STORE YES

● VAL. EMPTY

● CALIB. NO

● CALIB. YES

(Press ↵ key to change to “VAL. EMPTY“)

(Press ↵ key to change to “VAL. EMPTY“)

(Press ↵ key, precautinory query)

(Press ↵ key to change to “VAL. EMPTY“)

(Press ↵ key, calibration will start with flashing display “WAIT“,

duration approx. 20 seconds)

Make sure that measuring tube is completely empty!

● STORE NO

(Press ↵ key to change to subfunction

” ADC GAIN“)

● STORE YES

(Press ↵ key to change to subfunction

“ADC GAIN“)

Please Note: The values of the measured impedances must be in range 0 - 150.

The difference of the value VAL. EMPTY must be

10 greater than the value of VAL. FULL!

ADC GAIN

→

● AUTO ● 10 ● 30 ● 100

SPEC. FILT.

→

Set gain of A/D converter

Select with key ↑ or ↓

Press ↵ key to change to subfunction ”SPEC. FILT.”.

Activate special filter for noise/interference suppression?

PLEASE NOTE information and examples given in Sect. 6.6.

● NO

● YES

(Press ↵ key to change to Fct. 3.06 ”APPLICAT.”)

(Press ↵ key to change to subfunction ”LIMIT VAL.”).

IFC 110 F 33

05/2003

Page 34

Fct. Text Description and setting

→ LIMIT VAL.

Set limit value for noise/interference suppression

(appears only when ”YES” is selected under ”SPEC. FILT.”, see above)

Setting range: 01-90 PERCENT of full-scale range Q

100%

see Fct. 3.02, subfunction ”FULL SCALE”

→ LIMIT CNT.

Press ↵ key to change to subfunction ”LIMIT CNT.”.

Totalizer active when exceeding limit value (see ”LIMIT VAL.” above)

(appears only when ”YES” is selected under ”SPEC. FILT.”)

Setting range: 001-250

Press ↵ key to return to Fct. 3.06 ”APPLICAT.”.

3.07 HARDWARE Determine HARDWARE functions

TERM.A1

→

Terminal A1

● PULSOUTP. ● STATUSOUTP.

SELFCHECK

→

Select with key ↑.

Press key ↵ to transfer to subfunction ”SELFCHECK”.

Carry out self check? See Section 5.18.

● YES ● NO (testing different parameters)

FIELDCUR.

→

Press key ↵ to transfer to subfunction “FIELD CURRENT”.

Determine field current

● INTERNAL

● EXTERNAL (only with power driver, see Sect. 8.6)

Press ↵ key to return to Fct. 3.07 ”HARDWARE”.

4.5 Error messages in measuring mode

The following list contains all errors which may occur during flow measurment. Errors are displayed when

”YES” is selected in Fct. 1.04 DISPLAY, subfunction ”DISP. MSG.”.

Error message Description of error Elimination of error

LINE INT. Power failure Note: Cancel error in RESET/QUIT. menu

no counting during power failure Reset totalizer if necessary.

OVERFLOW I Current output overranged. Check instrument parameters and

or

OVERFL. I2 the cause, the error message is

cancelled automatically.

See Sections 6.4 and 6.7.

OVERFLOW P Pulse output P Check instrument parameters and

or

OVERFL. P2 Pulse output range P2 exceeded the cause, the error message is

(flow rate > modulation range) cancelled automatically.

See Sections 6.4 and 6.7.

I SHORT or

I2 SHORT

I OPEN or

I2 OPEN

TOTALIZER Overflow of internal totalizer Delete error message in RESET/QUIT

menu, see Sect. 4.6

ADC Analog/digital converter range Set Fct. 3.06, subfunction ADC GAIN

exceeded to ”10”. See Sections 6.4 and 6.7.

If error message does not disappear,

consult factory.

ADC-PARAM. Check sum error Replace ADC printed circuit board

ADC-HARDW. Hardware error A/D converter Replace ADC printed circuit board

ADC GAIN Hardware error A/D converter Replace ADC printed circuit board

FC-HARDW. Hardware error on field current PCB Replace field current PCB

FATAL.ERROR Fatal error, measurement interrupted Replace electronic unit or consult factory.

EP PARAM. Parameters of “Empty Pipe” are wrong Error shut off automatically EPD function.

*

only for active operation

(flow rate > measuring range) correct if necessary. After elimination of

correct if necessary. After elimination of

or

*

Current output I or I2 externally Check mA loop and increase load using

shorted or load < 15 Ω

*

mA loop interrupted by current Check mA loop and reduce load to

output I or I2 or load > 500 Ω 500 Ω if necessary.

additional resistor if necessary.

Please check calibration values!

Value Empty Pipe – Value Full pipe ≥ 10

Values must be in range of 0 – 150.

34 IFC 110 F

05/2003

Page 35

4.6 Resetting the totalizer and deleting error messages, RESET/QUIT menu

Delete error messages in RESET/QUIT menu

Key Display Description

- - - - - - - - - - - - / - - - Measuring mode

↵

↑ →

→

↑

↵

↵

CodE 2 - - Key-in entry code 2 for RESET/QUIT menu:

ERROR QUIT. Menu for error acknowledgement

QUIT. NO Do not delete error messages,

QUIT. YES Delete error messages

ERROR QUIT. Error messages deleted.

- - - - - - - - - - - - / - - - Return to measuring mode

↑ →

press ↵ twice to return to measuring mode.

Reset totalizer in RESET/QUIT menu

Key Display Description

- - - - - - - - - - - - / - - - Measuring mode

CodE 2 - - Key-in entry code 2 for RESET/QUIT menu:

↑ →

↑

→

↑

↵

↵

ERROR QUIT. Menu for error acknowledgement

TOTAL.RESET Menu for resetting totalizer

RESET NO Do not reset totalizer,

RESET YES Reset totalizer

TOTAL.RESET Totalizer is reset

- - - - - - - - - - - - / - - - Return to measuring mode

↑ →

press ↵ twice to return to measuring mode

4.7 Examples of signal converter settings

In the following example the cursor or flashing part of the display is shown in bold characters.

• Change measuring range of current output and value for error messages (Fct. 1.05):

• Change measuring range from 04-20 mA to 00-20 mA

• Change value for error messages from 0 mA to 22 mA

Key Display Description

→

Fct. 1.00 OPERATION

→

4x ↑

→

→ ↵

→

2x ↑

↵

→

↑

↵

↵

↵

↵

If ”YES” is selected in Fct. 3.04 ENTRY

CODE, enter the 9-digit entry CODE 1:

Fct. 1.01 FULL SCALE

Fct. 1.05 CURRENT I

FUNCT. I

RANGE I

04-20 mA old current range

00-20 mA new current range

I ERROR

0 mA old value for error messages

22 mA new value for error messages

Fct. 1.05 CURRENT I

Fct. 1.00 OPERATION

STORE YES

- - - - - - - - - - - - / - - - Measuring mode with new current output data

→ → → ↑ ↑ ↑ ↵ ↵ ↵

IFC 110 F 35

05/2003

Page 36

6 Special Applications, Functional Checks, Service and Order Numbers

6.1 Use in hazardous areas

6.1.1 General

Signal converters of type IFC 110 F - EEx are type tested as associated electrical apparatus in

compliance with European Directive 94/9/EG (ATEX 100a) in conformity with European Standards

EN 50 014 / EN 50 020.

The EC type examination certificate has been issued by the Physikalisch-Technische

Bundesanstalt (PTB) under: PTB 02 ATEX 2163 X

Important, please note!

• Observe the directions, regulations and electrical data specified in the EC type

examination certificate, see Section 13.

• In addition to the regulations for power installations (VDE 0100), pay particular

attention to the regulations specified in EN 60079-14 “Electrical installations in

hazardous areas".

• Assembly, installation, commissioning and maintenance may only be carried out by

”personnel trained in explosion protection“!

6.1.2 Main safety features

Both generation of the intrinsically safe electrode circuit and also protection of the non-intrinsically

safe field circuit by fusible links form integral parts of the IFC 110 F - EEx signal converter.

• Category / Zone

IFC 110 F - EEx signal converters are associated electrical apparatus required to be installed

outside the hazardous area.

The intrinsically safe electrode circuit is designed in Category 2 for use in Zone 1.

• Types of protection

The electrode circuit is designed in Intrinsic Safety EEx ib IIC type of protection.

The non-intrinsically safe field circuit must be installed inside the hazardous area using a type

of protection conforming to European Standard (e.g. Increased Safety "e").

Power supply and signal inputs / outputs are non-intrinsically safe.

• Field current fuse protection

The field circuit is fuse-protected in the signal converter IFC 110F – EEx by two fusible links on

the FSV circuit board (TR5, 160 mA F).

• Safety-relevant type code

The following code is used for type designation:

110 F / … - E Ex

IFC

1 2 3 4 5 6

1 Electromagnetic signal converter

2 Type series

3 Field housing for “remote” measuring systems

4 Marking – no effect on explosion protection

S Special version for -40 °C

… others as required

5 Approval to European standard

6 Explosion-protected equipment

36 IFC 110 F

05/2003

Page 37

6.1.3 Installation and electrical connection

Type IFC 110 F - EEx signal converters are type tested as associated electrical apparatus.

They are installed outside the hazardous area.

The PE/PA connection (housing) must have protective bonding with the potential of the hazardous

area (PA).

Insulation ratings

The insulation of signal converters Type IFC 110 F - EEx is rated in conformity with

VDE 0110-1, equivalent to IEC 664-1, and the following rated values have been taken

into consideration:

• overvoltage category for the line circuit: III

• overvoltage category for the signal and measuring circuits: II

• insulation pollution degree: 2

Important, please note without fail!

• The buffer barrier for the intrinsically safe electrode circuit is an integral part of the

IFC 110 F - EEx signal converter and is safety galvanically isolated.

• The cable entry for the interconnecting cable of the intrinsically safe electrode circuit

is marked in light blue.

• The terminals of the intrinsically safe electrode circuit may only be connected to

intrinsically safe circuits, even if the device is operated in the non-hazardous area.

• Electrical connection between front panel and potential to ground to be made by

way of the fastening screws on the front panel. These must therefore always be

properly tightened down (torque approx. 1.3 Nm).

Start-up

Check the following points before starting up:

• that the line voltage (power supply) agrees with the details given on the nameplate.

• that the nominal value of the fuse for field current protection agrees with the maximum

permissible nominal value specified for the flow sensor.

Evidence shall be furnished of the intrinsic safety for the electrode circuit together with the safetyrelevant data of the interconnecting cable and of the flow sensor.

Operation

Operator control of the signal converter is permitted during operation. For this purpose, remove

the cover of the electronic compartment. Definitely avoid ingress of dirt and moisture when the

housing cover is open.

Preventive maintenance

The signal converter does not require any maintenance when used for the intended purpose.

Within the scope of checks required to be carried out in hazardous areas to maintain systems in

proper working order, visual inspection of the housing, cable entries and interconnecting cables

for signs of damage should be carried out at regular intervals.

Maintenance

Maintenance work of a safety-relevant nature within the meaning of explosion protection may only

be carried out by the manufacturer, his authorized representative or under the supervision of

authorized inspectors.

Please note !

Safety data see Sect. 10.1 !

IFC 110 F 37

05/2003

Page 38

10 Technical data

10.1 Signal converter

Mode of operation and system structure

Measurement principle Faraday’s law of induction

Modularity Measuring system consisting of

Measured variable Volumetric flowrate

Electrical conductivity of product

Versions

IFC 110 F / D (standard) Display version, with local display / control elements (15 keys)

IFC 110 F / D / MP (option) same as display version, additionally with magnetic sensors (MP) to control

IFC 110 F / D / MP / _ EEx (option) ATEX-EEx version for hazardous areas, PTB 02 ATEX 2163 X

Interfaces – HART

– RS 485 / PROFIBUS

Add-on equipment – CONFIG software and adapter for operator control via MS-DOS-PC,

Full-scale range

Flowrate for Q = 100% 6 Liter/h to 86 860 m³/h or 0.03 to 401 080 US Gal/min,

corresponding to flow velocity v = 0.3 – 12 m/s or v = 1 to 40 ft/s

Units m³/h, liter/s, US Gal/min or user-defined unit, e. g. liter/day or US Gal/day

Input / output circuits

Nominal voltages

Active / passive/ mode connection to protective extra-low voltage (PELV)

Current output

Function – all operating data configurable

– galvanically isolated from all input and output circuits

Current: fixed ranges 0 – 20 mA and 4 – 20 mA

variable ranges for Q = 0% I

for Q = 100% I

for Q > 100% I > 20 – 22 mA (maximum)

Load – active operation

– passive operation

Error identification 0 / 22 mA and variable

Forward/reverse flow measurement direction identified via status output

Pulse outputs (passive) P A1 (can also be operated as status output)

Function – for electronic totalizers – for electromechanical totalizers

– all operating data settable – all operating data configurable

Terminals P / P

Pulse rate 0 – 10 000 pulses per 0 – 50 pulses per

s [= Hz], min, h, m³, liter, etc., s [= Hz], min, h, m³, liter, etc.,

any scaling any scaling

Electrical data galvanically isolated galvanically isolated, but not from A2

note polarity

Pulse width automatic: pulse duty cycle 1:1, max. 10 000 pulses/s = 10 kHz

1

digital pulse division, interpulse period non-uniform, therefore if frequency

and cycle meters connected allow for minimum counting interval:

1000

Forward/reverse flow measurement direction identified via status output

signal converter and flow sensor

(electrode voltage from flow sensor)

≥ 5 µS/cm

≥ 20 µS/cm for demineralized cold water

the signal converter using bar magnet without opening the housing

®

add-on module

}

connection to internal IMoCom interface (equipment bus)

≤ 25 V AC / ≤ 50 V DC (safety value Um = 253 V)

= 0 – 16 mA

0%

= 4 – 20 mA

100%

adjustable in 1mA increments

}

min. 15 Ω

22 V DC ≤ U ≤ 32 V DC: R

15 V DC ≤ U ≤ 22 V DC: R

≤ 800 Ω

L

≤ 500 Ω

L

A1 / A ⊥

U ≤ 32 V DC / ≤ 24 V AC U ≤ 32 V DC / ≤ 24 V AC

I

≤ 30 mA, any polarity I

≤ 100 mA, any polarity

or U ≤ 32 V DC, I ≤ 200 mA

variable: 10 ms – 1 s, P

gate time, totalizer ≥

[pulses/s] = f

100%

[Hz]

P

100%

[Hz] =

max

2 x pulse width

38 IFC 110 F

05/2003

Page 39

Status outputs (passive) D1 / D2 / A2 A1 (can also be operated as pulse output)

Function, set for trip point trip point

flow direction flow direction

automatic range change automatic range change

error identification error identification

overdriving overdriving

empty pipeline empty pipeline

Terminals

Please note:

D1 / D2 / D ⊥ / A2 / A ⊥ A1 / A ⊥

D ⊥ common reference potential for D1 and D2

A ⊥ common reference potential for A1 and A2

Electrical data galvanically isolated galvanically isolated, but not from A2

U ≤ 32 V DC / ≤ 24 V AC U ≤ 32 V DC / ≤ 24 V AC

I

≤ 100 mA, any polarity I

≤ 100 mA, any polarity

or U ≤ 32 V DC, I ≤ 200 mA, note polarity

Control inputs C1 and C2 (passive)

Function, set for automatic range change, totalizer reset, error reset, start self-test,

set outputs to min. values or hold last measured values of outputs

Terminals

C1 / C ⊥ and C2 / C ⊥, galvanically isolated

Please note: C ⊥ common reference potential for C1 and C2

U = 8 – 32 V DC, I ≤ 10 mA, any polarity

Internal power supply for passive outputs and inputs and external receiver instruments

Terminals E + and E –, please note polarity, galvanically isolated

Electrical data

U = 24 V DC / R

Time constant 0.2 – 99.9 s, adjustable in increments of 0.1 second

Low-flow cutoff cutoff ”on“ value: 1 – 19 %

cutoff ”off“ value: 2 – 20 %

= approx. 15 Ohm / I ≤ 100 mA

i

of Q

}

, adjustable in 1% increments

100%

Local display and operation 3-line back-lit LCD

Display function actual flowrate, forward, reverse, sum totalizers (7 digits)

or 25-character bar graph with percent display and status messages