Page 1

11/97

Signal converters

for

Installation and

operating

instructions

electromagnetic flowmeters

IFC 090 K

IFC 090 F

How to use these Instructions

The flowmeters are supplied ready for operation.

The primary head must be installed in the pipeline as described in the installation

instructions inside the packing of the primary head.

- Installation location and connection to power (Section 1) Pages 1/1-1/6

- Electrical connection of outputs and inputs (Section 2) Pages 2/1-2/6

- Factory settings and start-up (Section 3) Pages 3/1-3/2

Power the flowmeter. THAT’S ALL. The system is operative.

Operator control of the IFC 090 signal converter is described in Sections 4 and 5.

Pull-out condensed instructions are located in the centrefold of this manual, pages A – D.

3.1M61EA3 119721 Order No. DIN A4: 7.02144.33.00

US size: 7.02144.73.00

Page 2

Contents

System description 0/4

Product liability and waranty 0/4

CE / EMC / Standards / Approvals 0/4

Items included with supply 0/4

Part A System installation and start-up 1/1-3/2

1 Electrical connection: power supply 1/1-1/6

1.1 Location and important installation notes – PLEASE NOTE ! 1/1

1.2 Connection to power 1/2

1.3 Electrical connection of separate primary head (F Version) 1/3-1/6

1.3.1 General information on signal cable A and field current cable C 1/3

1.3.2 Stripping (preparation) of signal converter 1/3

1.3.3 Grounding of primary head 1/4

1.3.4 Cable length (max. distance between signal converter and primary head) 1/5

1.3.5 Connection diagrams I and II (power supply, converter and primary head) 1/6

2

2.1 Combinations of outputs and inputs 2/1

2.2 Current output I 2/1

2.3 Pulse output B1 (terminals B1 / B⊥) 2/2

2.4 Status outputs B1 and B2 (terminals B1 / B⊥ and B2 / B⊥) 2/3

2.5 Control inputs B1 and B2 (terminals B1 / B⊥ and B2 / B⊥) 2/4

2.6 Connection diagrams for outputs and inputs 2/5-2/6

Electrical connection of outputs and inputs 2/1-2/6

3.

3.1 Switch-on and measurement 3/1

3.2 Factory settings 3/2

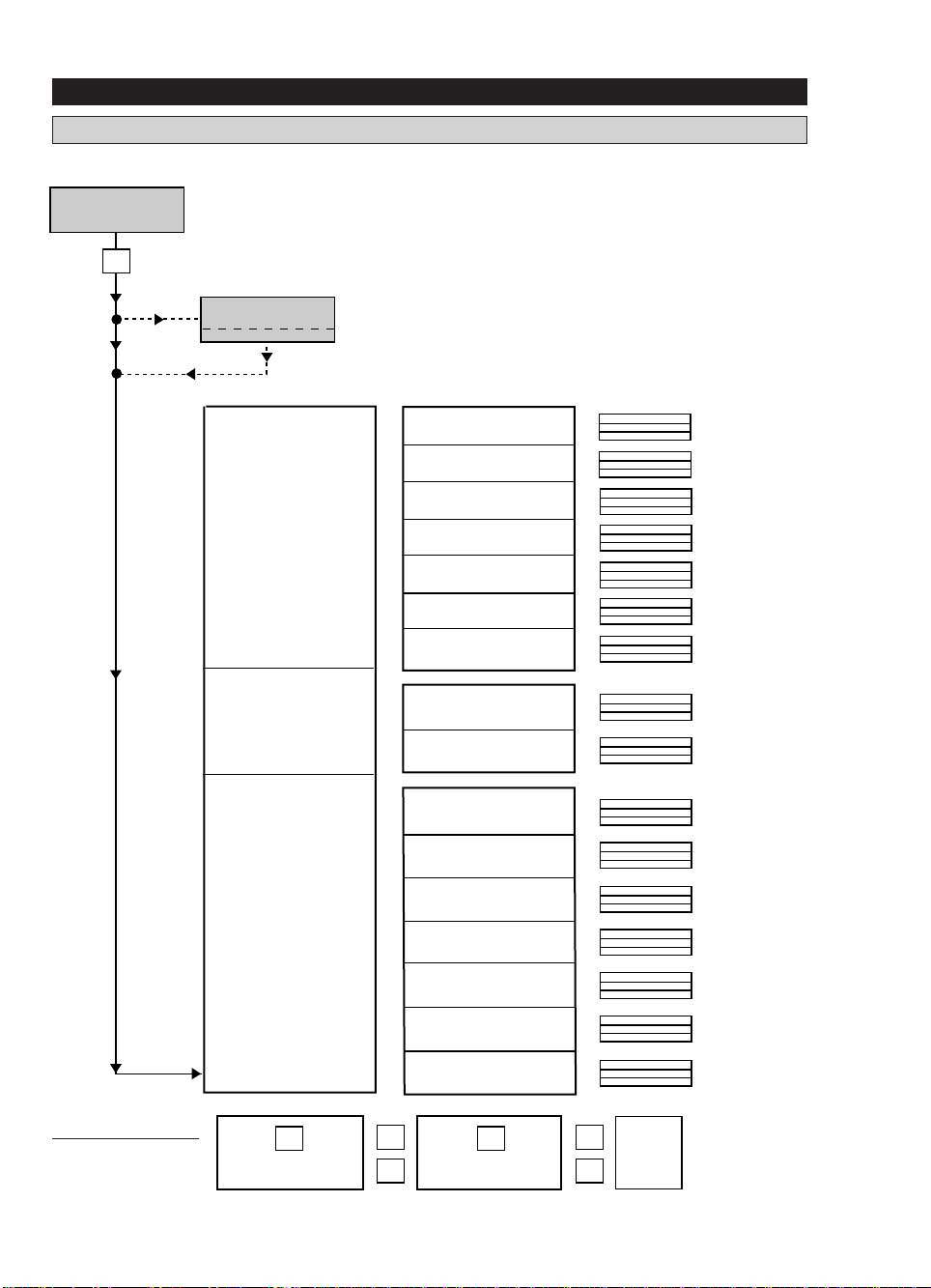

Part B IFC 090

4 Operation of the signal converter 4/1-4/12

4.1 Krohne operator control concept 4/1

4.2 Operating and check elements 4/2

4.3 Function of keys 4/3-4/4

4.4 Table of settable functions 4/5-4/9

4.5 Error messages in measuring mode 4/10

4.6 Reset totalizer and cancel error messages, RESET/QUIT menu 4/11

4.7 Examples of setting the signal converter 4/12

5

5.1 Full-scale range Q100% 5/1

5.2 Time constant 5/1

5.3 Low-flow cutoff 5/2

5.4 Display 5/2-5/3

5.5 Internal electronic totalizer 5/3

5.6 Current output I 5/4

5.7 Pulse output B1 5/5-5/6

5.8 Status outputs B1 and B2 5/7

5.9 Control inputs B1 and B2 5/8

5.10 Language 5/8

5.11 Entry code 5/8

5.12 Primary head 5/9

5.13 User-defined unit 5/10

5.14 F/R mode, forward/reverse flow measurement 5/11

5.15 Characteristic of outputs 5/11

5.16 Combinations of binary outputs and inputs 5/12

5.17 Limit switches 5/12

5.18 Automatic range change BA 5/13

5.19 Applications 5/14

Start-up 3/1-3/2

/D Signal converter 4/1-5/14

Description of functions 5/1-5/14

0/1

Page 3

Part C Special applications, functional checks, service, and order numbers 6/1-9/1

6 Special applications 6/1-6/4

6.1 Use in hazardous areas 6/1

6.2

RS 232 adapter incl. CONFIG software (option)

6/1

6.3 Stable signal outputs when measuring tube empty 6/2

6.4 Pulsating flow 6/3

6.5 Rapid changes in flowrate 6/3

6.6 Unsteady display and outputs 6/4

6.7 HART interface 6/5-6/6

7

Functional checks 7/1-7/12

7.1 Zero check with IFC 090 /D, signal converter, Fct. 3.03 7/1

7.2 Test of measuring range Q, Fct. 2.01 7/1

7.3 Hardware information and error status, Fct. 2.02 7/2

7.4 Faults and symptoms during start-up and process flow measurement 7/3-7/8

7.5 Test of primary head 7/9

7.6 Test of signal converter using GS 8A simulator (option) 7/10-7/12

8

Service 8/1-8/5

8.1 Replacement of power fuses 8/1

8.2 Changeover of operating voltage on AC Versions 1 and 2 8/1

8.3 Turning the display PCB 8/1

8.4 Retrofitting the display unit 8/2

8.5 Power fuses and illustrations to Sect. 8.1 to 8.4 8/2

8.6 Turning the converter housing of the compact flowmeters 8/3

8.7 IFC 090 Replacement of converter electronic unit 8/3

8.8 IFC 080 and SC 80 AS Replacement of electronic unit by IFC 090 8/4

8.9 Illustrations of the PCBs 8/5

9

Order numbers 9/1

Part D Technical data, measuring principle and block diagram 10/1-12/1

10 IFC 090 Technical data 10/1-10/5

10.1 Full-scale range Q

100%

10/1

10.2 IFC 090 F and ZD Dimensions and weights 10/1

10.3 Error limits at reference conditions 10/2

10.4 IFC 090 Signal converter 10/3-10/4

10.5 Instrument name plates 10/5

1

1 Measuring principle and function of the system 11/1

12 Block diagram - signal converter 12/1

Part E Index E1-E2

Printed form to accompany flowmeters returned to Krohne E3

0/2

Page 4

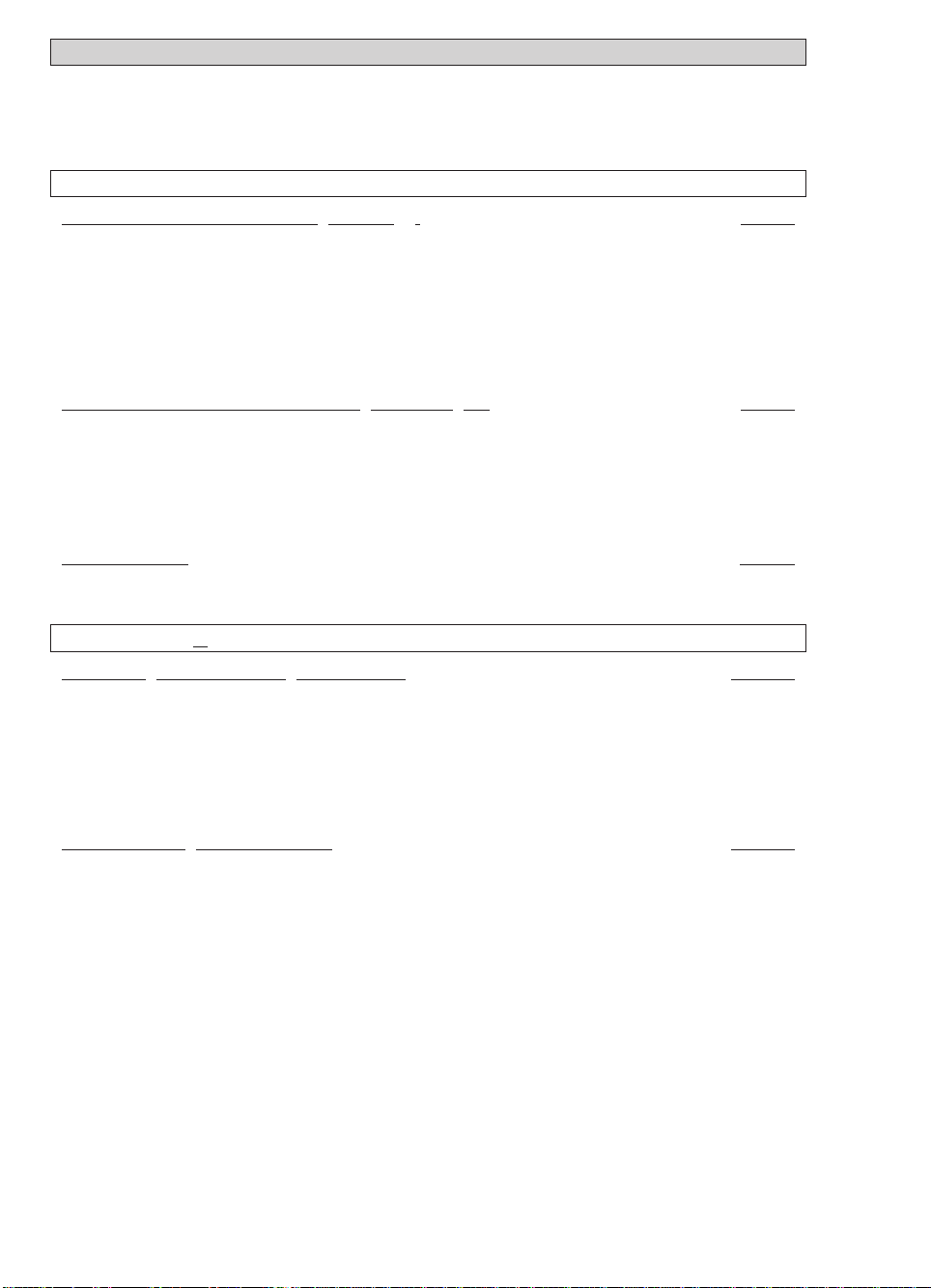

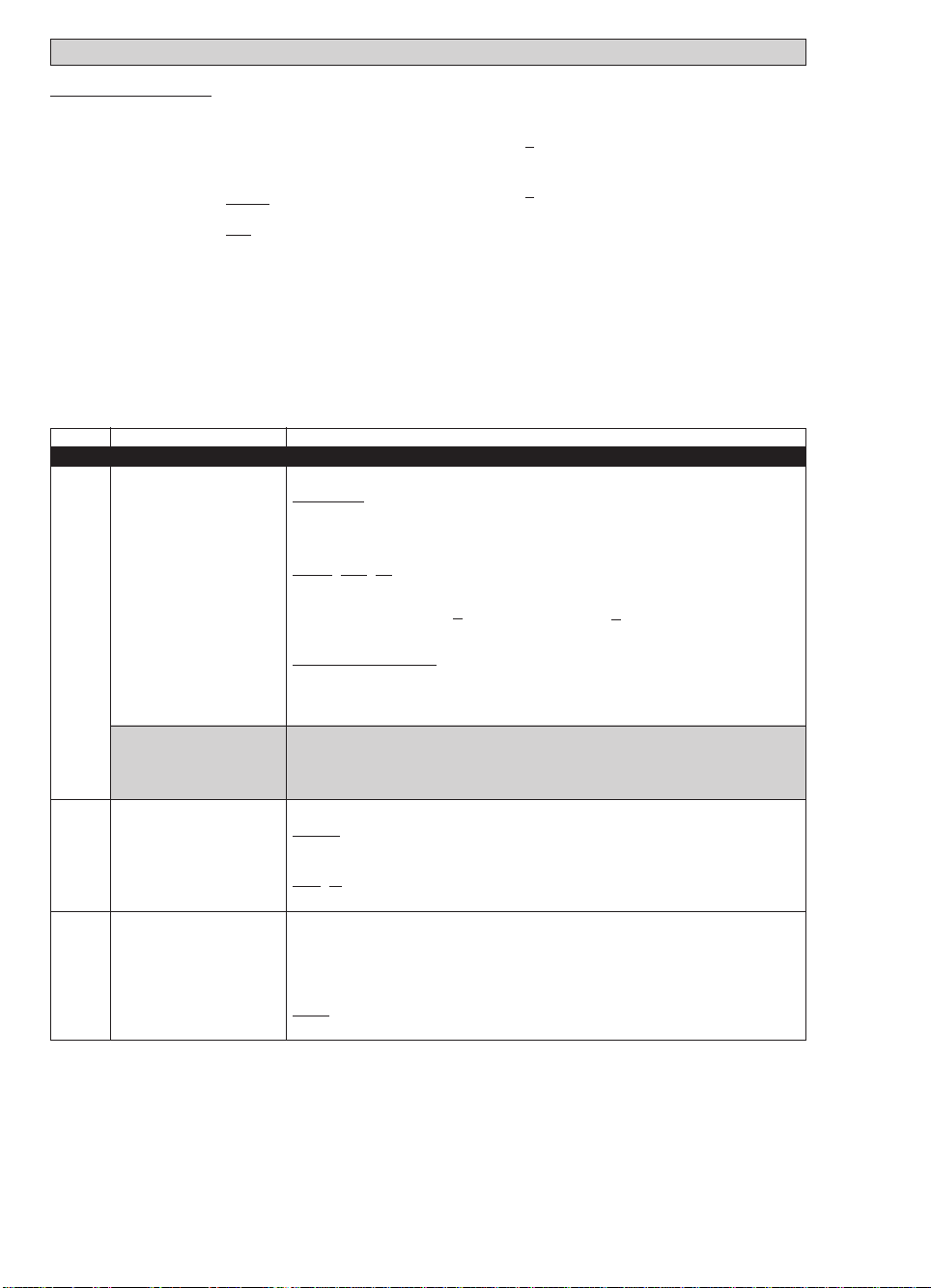

Here you can note down the settings of the signal converter !

Fct. No. Function Settings

1.01 Full-scale range

1.02 Time constant

1.03 Low-flow cut-off - ON: - OFF:

1.04 Display Flow

Totalizer

Messages

1.05 Current output I Function

Reverse range

Range I

Error

1.06 Output or input B1

(setting: see Fct. 3.07,

terminal B1)

1.07 Output or input B2

(setting: see Fct. 3.07,

terminal B2)

3.01 Language

3.02 Primary head Meter size

GK value

Field frequency

Power frequency

Flow direction

3.04 Entry code required ? - no - yes

→ → → ↵ ↵ ↵ ↑ ↑ ↑

3.05 User-defined unit

3.06 Application Flow is - steady

- pulsating

3.07 Hardware settings Terminal B1 is - pulse output

- status output

- control input

Terminal B2 is - status output

- control input

0/3

Page 5

System description

Electromagnetic flowmeters with the IFC 090 signal converter are precision instruments designed

for linear flow measurement of liquid products.

The process liquids must be electrically conductive: ≥ 5 µS/cm

(for cold demineralized water ≥ 20 µS/cm).

The full-scale range Q

DN 2.5.- 1000 / 01/10” - 40” Q

can be set as a function of the meter size:

100%

= 0.010 - 34 000 m3/hr = 0.03 - 151 000 US Gal/min

100%

This is equivalent to a flow velocity of 0.3 - 12 m/s or 1 - 40 ft/s.

Product liability and warranty

The electromagnetic flowmeters with the IFC 090 signal converter are designed solely for

measuring the volumetric flowrate of electrically conductive, liquid process products.

Special codes and regulations apply to their use in hazardous areas and these are referred to in

the special “Ex” Installation and Operating Instructions (supplied only with hazardous-duty

equipment).

Responsibility as to suitability and intended use of these compact electromagnetic flowmeters

rests solely with the operator.

Improper installation and operation of the flowmeters (systems) may lead to loss of warranty.

In addition, the “General conditions of sale” forming the basis of the purchase contract are

applicable.

If flowmeters need to be returned to Krohne, please note the information given on the last-but-one

page of these Instructions. Krohne regrets that it cannot repair or check your flowmeter(s) unless

accompanied by the completed form sheet.

CE / EMV / Standards / Approvals

• Electro magnetic flowmeters with the IFC 090 signal converter meet the requirements of the

EU-EMC Directives and bear the CE symbol.

• All factories and production sequences are ISO 9001 certified.

• Flowmeters are approved as hazardous-duty equipment to the harmonized European

Standards and to Factory Mutual (FM).

Further details are given in the “Ex” supplementary instructions provided only with

hazardous-duty equipment.

Items included with supply

• Signal converter as ordered

• Installation and operating instructions

• 2 plug connectors for power supply and outputs/inputs

• Special wrench for opening the housing covers

• Bar magnet to operate the display converter without opening the housing

• Additional instructions for hazardous-duty versions (applies only to hazardous-duty equipment)

0/4

Page 6

Part A System installation and start-up

1 Electrical connection: power supply

1.1 Location and important installation notes PLEASE NOTE !

• Electrical connection in accordance with VDE 0100 ”Regulations governing heavy-current

installations with line voltages up to 1000 V” or equivalent national regulations.

• Do not cross or loop cables inside the terminal compartment.

• Use separate cable entries (PG screwed conduit entries) for power supply,

field current cables, signal lines, outputs and inputs.

• Hazardous locations are subject to special regulations, see Section 6.1 and special

installation instructions for hazardous-duty (”Ex”) versions.

• Protect flowmeters or switchgear cabinets with built-in devices from direct sunlight.

Fit a sunshade if necessary.

• When installed in switchgear cabinets, signal converters must be adequately cooled,

e.g. use fans or heat exchangers.

• Do not expose signal converters to intense vibration.

Onl

y for separate systems/signal converters (F Versions)

• Keep distance between primary head and signal converter as short as possible.

Refer to Sect. 1.3.4 for maximum permissible length of signal and field current cables.

• Use the supplied Krohne signal cable A (Type DS), standard length 10 m (33 ft).

• Always calibrate primary head and signal converter together. Therefore, when installing,

ensure primary constant GK is identical; refer to instrument nameplate for the primary

head. If the GK is not identical, set the signal converter to the GK of the primary head.

Refer also to Sections 4 and 8.5.

• Dimensions of signal converter; refer to Section 10.2.

1/1

Page 7

PLEASE NOTE !

Connection to power 1.2

• Rated values:

The flowmeter housings protecting the electronic equipment from dust

and moisture must always be kept closed. The selected creepage distances and

clearances have been dimensioned in conformity with VDE 0110 and IEC 664 for

contamination category 2. Supply circuits and output circuits are designed to meet the

standards of overvoltage classes III and II, respectively.

• Safet

y isolation: the flowmeters (signal converters) must be provided with an

isolating facility.

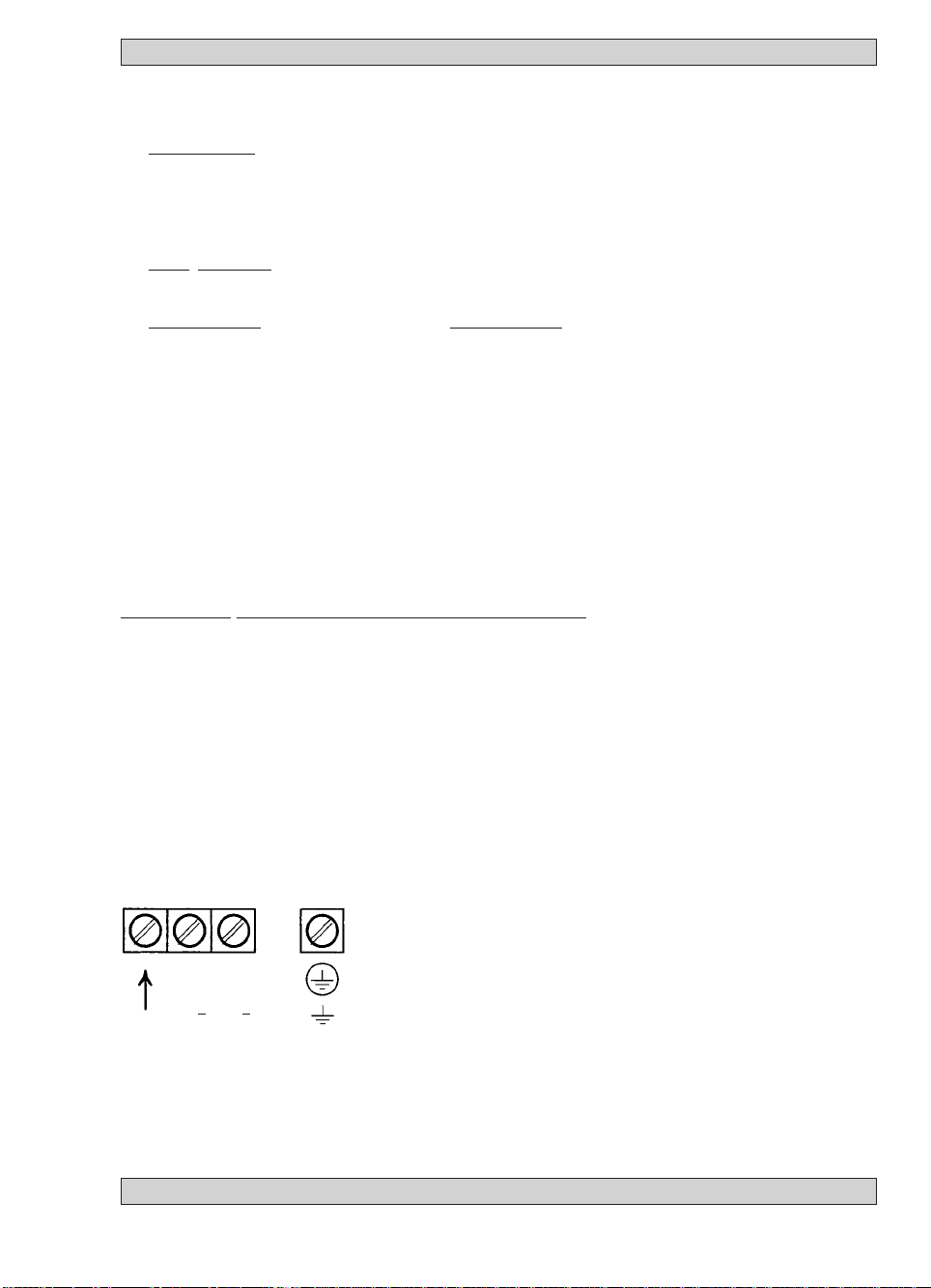

1. AC V

ersion 2. AC Version

230/240 V AC (200 - 260 V AC) 200 V AC (170 - 220 V AC)

switch-selectable to switch-selectable to

115/120 V AC (100 - 130 V AC) 100 V AC (85 - 110 V AC)

• Note information on instrument nameplate: supply voltage and frequency

• The PE protective ground conductor for the power supply must be connected to the

separate U-clamp terminal in the terminal compartment of the signal converter.

For exceptions (compact systems), refer to installation instructions for the primary head.

• Connection diagrams I and II for power supply and electrical connection between

primary head and signal converter: refer to Section 1.3.5.

24 V AC

/ DC (tolerance bands: AC 20 - 27 V / DC 18 - 32 V)

• Note information on instrument nameplate: supply voltage and frequency.

• For measurement reasons, connect an FE functional ground conductor to the separate

U-clamp terminal in the terminal compartment of the signal converter.

• If connected to a functional extra-low voltage source (24 V AC / DC), provide for protective

separation (PELV) in conformity with VDE 0100 / VDE 0106 or IEC 364 / IEC 536,

or equivalent national regulations.

• Connection diagrams I and II for power supply and electrical connection between primary

head and signal converter: refer to Section 1.3.5.

Connection to power

for

internal

use only

L N

∼∼ 0L∼∼

1L

PE 100 -240 V AC

FE 24 V AC/DC

(PE protective ground conductor)

(FE functional ground conductor)

Warning: Instrument must be properly grounded to avoid personnel shock hazard.

1/2

Page 8

1.3 Electrical connection of separate primary head (F Versions)

1.3.1 General information on signal cable A and field current cable C

Use of the Krohne signal cable A with foil screen and magnetic shield will ensure proper operation

of the equipment.

• Signal cable to be solidly laid.

• Connect shields via stranded drain wires.

• Underwater and underground installation possible.

• Insulating material is flame-retardant to IEC IEC 332.1 / VDE 0742.

• Signal cables are low in halogen, unplasticized, and stay flexible at low temperatures.

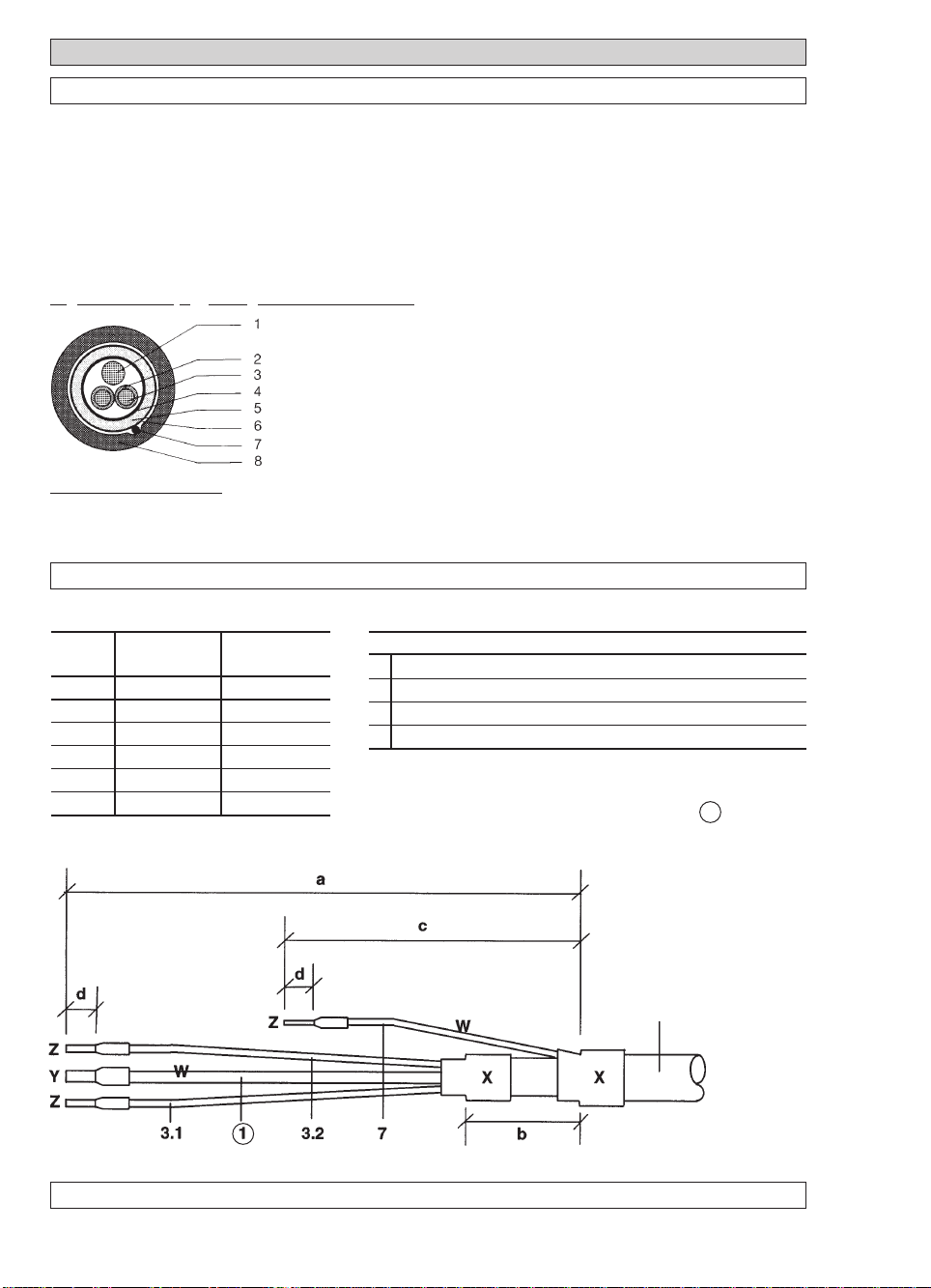

Si

gnal cable A (Type DS), with double shielding

2

1 Stranded drain wire, 1st shield, 1.5 mm

2 Insulation

3 Conductor 0.5 mm

2

or AWG 20 (3.1 red / 3.2 white)

or AWG14

4 Special foil, 1st shield

5 Inner sheath

6 Mu-metal foil, 2nd shield

7 Stranded drain wire, 2nd shield, 0.5 mm

2

or AWG20

8 Outher sheath

Field current cable C

with single shielding

Cross-section is dependent on required length of cable, see Table in Sect. 1.3.4.

1.3.2 Stripping (preparation) of signal cable A

Please note the different lengths given in the table for signal converter and primary head.

Length Converter Primary

head

mm (inch) mm (inch)

a 70 (2.80) 90 (3.60)

b 08 (0.30) 08 (0.30)

c 25 (1.00) 25 (1.00)

d 08 (0.30) 08 (0.30)

e 50 (2.00) 70 (2.80)

See Section 1.3.4 for max. permissible cable lengths

Customer-supplied materials

W

Insulation tubing (PVC), 2.0 - 2.5 mm dia. (1”)

X Heat-shrinkable tubing or cable sleeve

Y Wire end sleeve to DIN 41 228: E 1.5-8

Z Wire end sleeve to DIN 41 228: E 0.5-8

Please note:

For primary heads, stranded drain wire 1

must have the same length as stranded drain wire 7.

Signal cable A

bending radius

≥ 50 mm (≥ 2”)

1/3

Page 9

Grounding of primary head 1.3.3

• All flowmeters must be properly grounded.

• The grounding conductor should not transmit any interference voltages.

• Do not ground any other electrical device together with this conductor.

• In hazardous locations, the grounding conductor is used simultaneously for equipotential

bonding. Special grounding instructions are contained in the ”Ex” installation instructions

for hazardous-duty devices, supplied only with such devices).

• The primary head is connected to ground by means of an FE functional ground conductor.

• Special information on grounding various primary heads is contained in the separate

installation instructions for primary heads.

• These instructions also contain detailed descriptions on how to use grounding rings and

how to install primary heads in metal or plastic pipes or internally coated pipelines.

1/4

Page 10

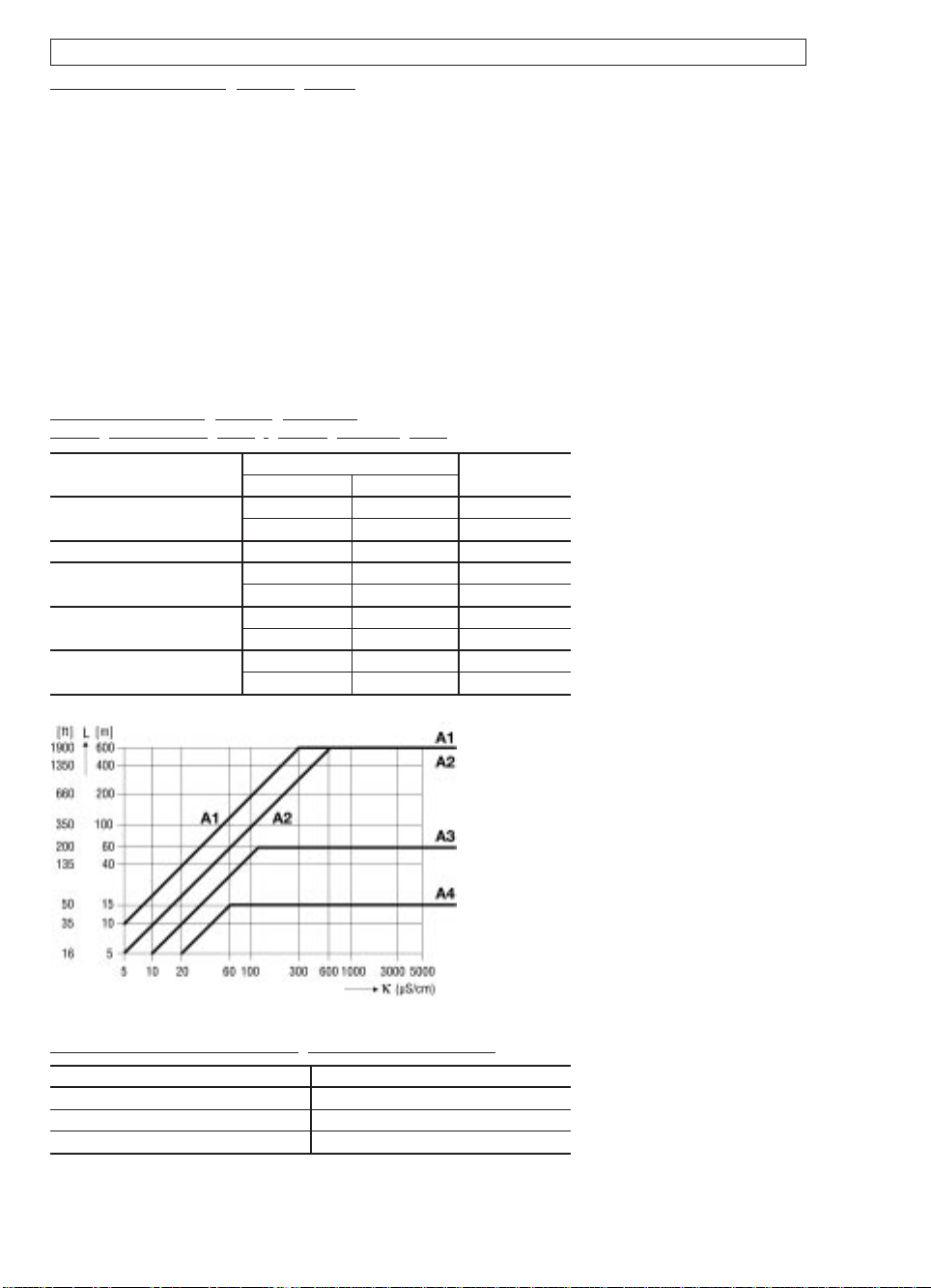

1.3.4 Cable lengths (max. distance between signal converter and primary head)

Abbreviations and ex

planatory notes

used in the following tables, diagrams and connection diagrams

A Signal cable A (type DS), with double shielding, see diagram for max. length

C Field current cable C, with single shielding,

type and length see Table

2

D High-temperature silicone cable, 3 × 1.5 mm

(14 AWG) Cu, with single shielding,

max. length 5 m (16 ft)

2

E High-temperature silicone cable, 2 × 1.5 mm

(14 AWG) Cu, max. length 5 m (16 ft)

L Cable length

κκ

Electrical conductivity of the process liquid

ZD Intermediate connection box required in connection with cables D and E for primary heads

ALTOFLUX IFS 4000 F, PROFIFLUX IFS 5000 F and VARIFLUX IFS 6000 F in cases where

process temperatures exceed 150 °C (302 °F)

Recommended len

gth of signal cable

for magnetic field frequency ≤ 1/6 × power frequency

Primary head

ECOFLUX IFS 1000 F

AQUAFLUX F

ALTOFLUX IFS 4000 F

PROFIFLUX IFS 5000 F

VARIFLUX IFS 6000 F

Meter size

DN mm

010.0 - 0015

025.5 - 0150

010.0 - 1000

010.0 - 0150

200.0 - 1000

002.5 - 0015

025.0 - 0100

002.5 - 0015

025.5 - 0080

Nennweite

inch

3

/8- 1/

2

1 - 06

3

/8- 40

3

/8- 06

8 - 40

1

/10-1/

2

1 - 04

1

/10- 1/

2

1- 03

Signal line

Kurve

A4

A3

A1

A2

A1

A4

A2

A4

A2

Field current cable C: max. length and min. crosssection

Length Type of cable,single shielding

000 - 150 m 0005-0500 ft 2 × 0,75 mm2Cu / 2 × 18 AWG

150 - 300 m 0500 - 1000 ft 2 × 1,50 mm2Cu / 2 × 14 AWG

2

300 - 600 m 1000 - 1900 ft 2 × 2,50 mm

Cu / 2 × 12 AWG

1/5

Page 11

Connection diagrams I and II (power supply, converter and primary head) 1.3.5

Im

portant information PLEASE NOTE !

• The figures in brackets indicate the stranded drain wires for the shields,

see cross-sectional drawing of signal cable in Section 1.3.1.

• Electrical connection to VDE 0100 ”Regulations governing heavy-current installations with

line voltages up to 1000 V“ or equivalent national regulations.

• Power supply 24 V AC / DC: functional extra-low voltage with protective separation in

conformity with VDE 0100, Part 410 or equivalent national

regulations.

• Systems used in hazardous locations are subject to special regulations applying to the

electrical connection; refer to special installation instructions for hazardous-duty devices that

are only supplied with such devices.

•PE= protective conductor FE = functional ground conductor

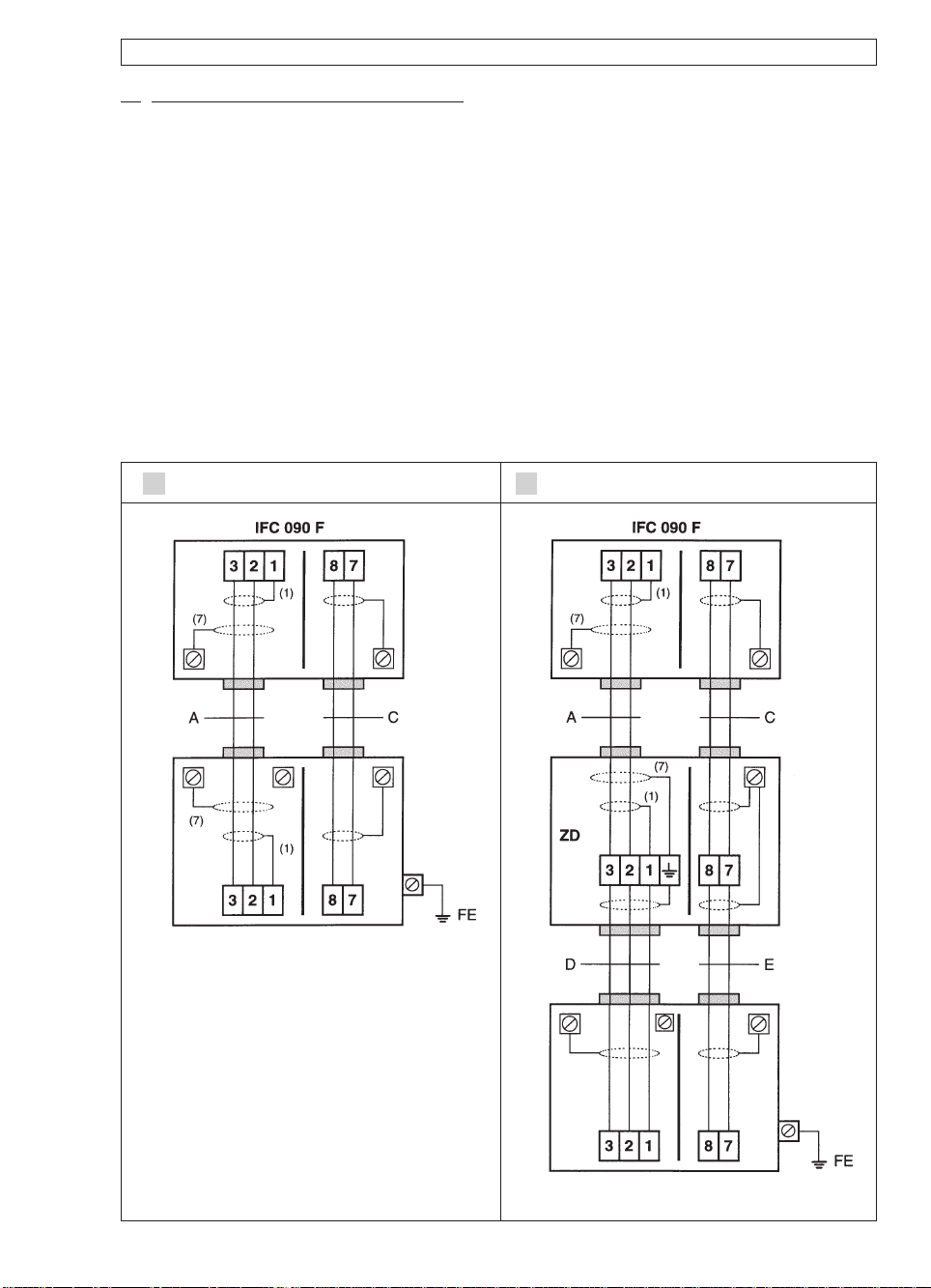

Process temperature < 150°C (302°F) Process temperature > 150°C (302°F)

I II

Primary heads

Primary heads

1/6

Page 12

2 Electrical connection of outputs and inputs

2.1 Combinations of outputs and inputs

Assignment of the binary outputs and inputs as required,

see 3.07 Fct. “HARDWARE” and Sect. 3.2 “Factory settings”.

Current output I – active or passive mode

– internal power source for the binary outputs and inputs

Binary outputs/inputs – terminal B1: Terminals

pulse output B1

status output B1 or

control input B1

– terminal B2:

B1 B⊥⊥B2 I+ I I

status output B2 or

control input B2

Binary outputs

and inputs

Output/input combinations 1) – 6)

T

erminals: I+ / I / I

⊥⊥

B1 / B

⊥⊥

B2 / B

⊥⊥

Combination: 1) IPS

2) IPC

3) ICS

4) ISC

5) IS1S2

6) IC1C2

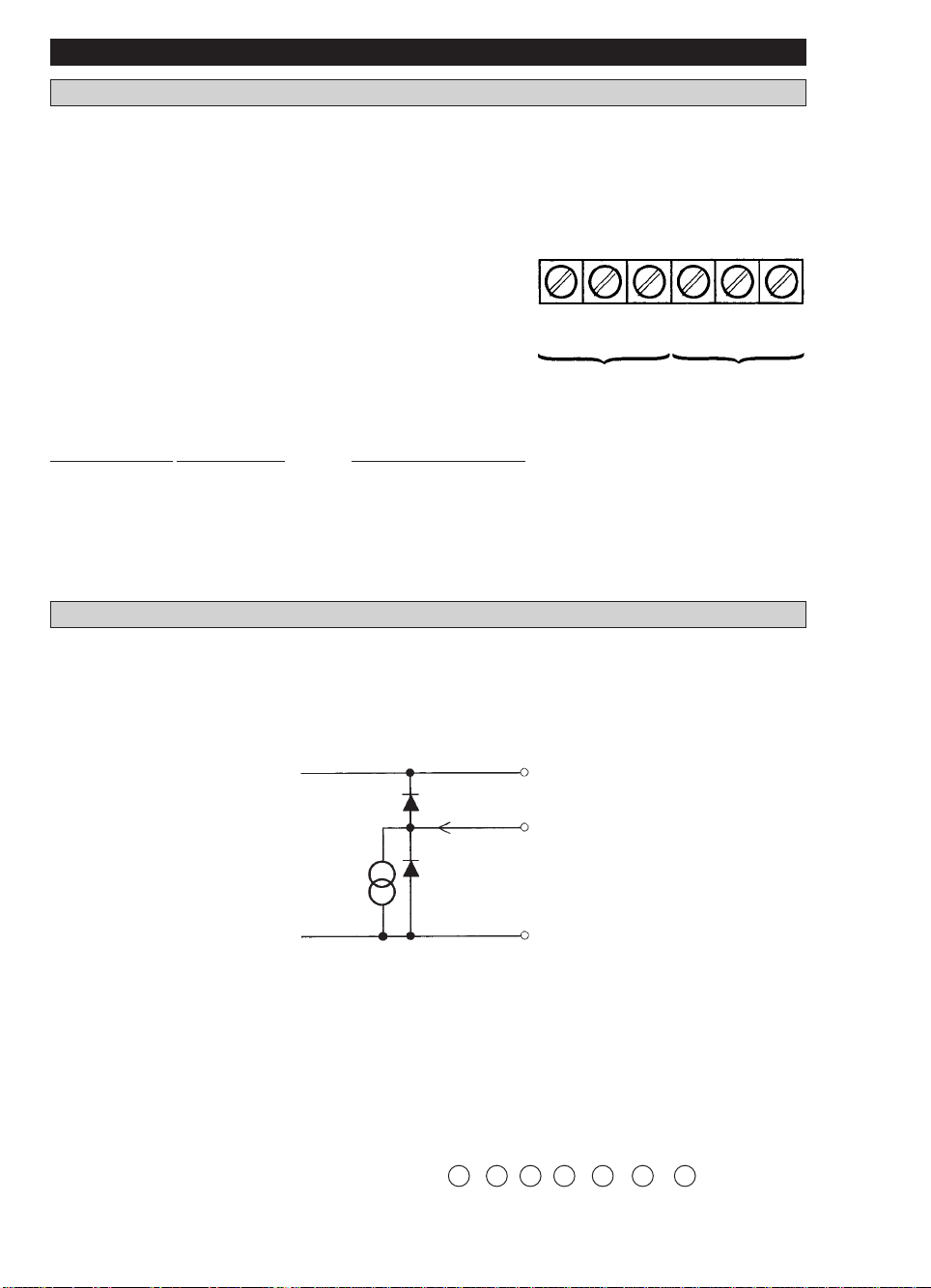

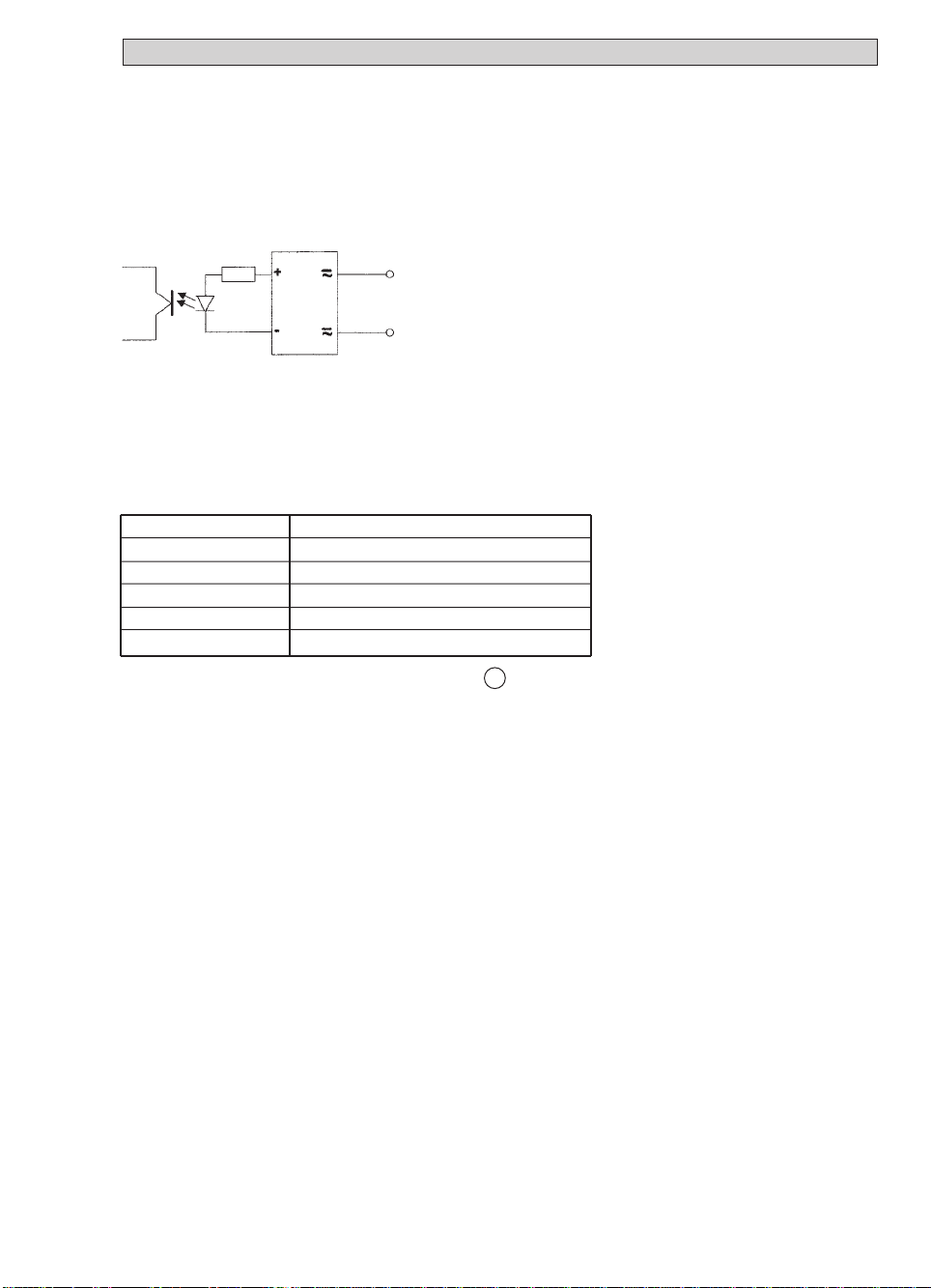

2.2 Current output I

• The current output is galvanically isolated from all input and output circuits.

• Setting data and functions can note down on page 0/3.

Please also refer to Sect. 3.2 “Factory settings”.

⊥⊥

Current output

I = current output

P = pulse output

S = status output

C = control input

• Typical current output

I+ approx. 15 V DC positive

voltage of current output

I current sink

I⊥ chassis ground,

current output

• All operating data and functions can be set.

• Display version: IFC 090 D, see Sect. 4 and 5.6, Fct. 1.05 for operator control

Basic version: IFC 090 B, see Sect. 6.2 for operator control

• The current output can also be used as an internal voltage source for the binary

outputs and inputs.

U

= 15 V DC I = 23 mA when operated without receiver instruments at the current output

int

I = 3 mA when operated with receiver instruments at the current output

Connection diagrams,

•

see Sect. 2.6: diagrams 1 2 3 6 9 10 11

2/1

Page 13

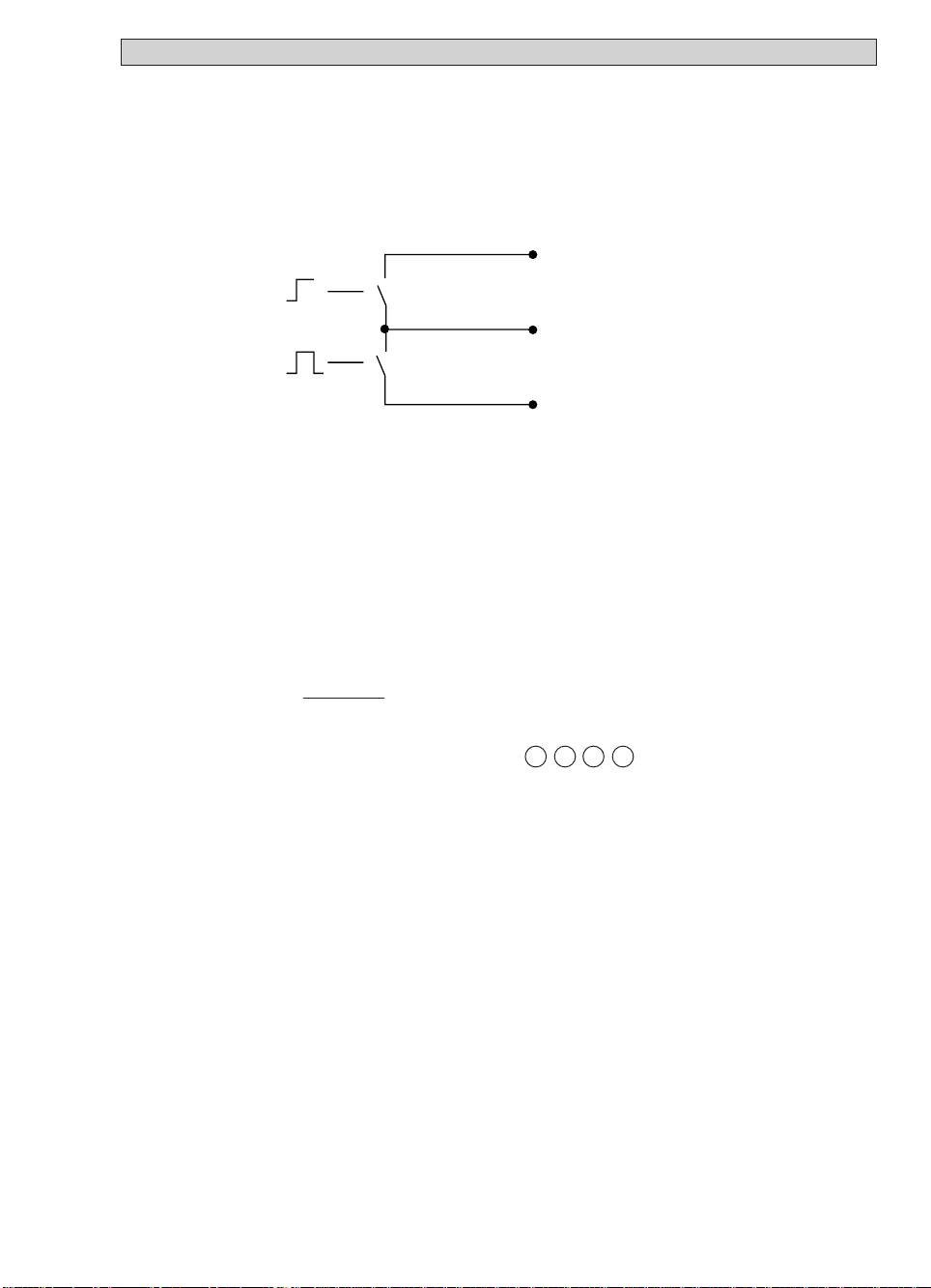

Pulse output B1 (terminals B1 / B⊥) 2.3

• The pulse output is galvanically isolated from the current output and all input circuits.

•

Setting data and functions can note down on page 0/3.

Please also refer to Sect. 3.2 “Factory settings” and Sect. 2.1 “Combinations of the

binary outputs and inputs”, Fct. 3.07 HARDWARE.

• Typical pulse output B1

B2 status output B2

or control input B2

B⊥⊥chassis ground, binary

outputs and inputs

B1 pulse output B1 (or status

output, control input)

• All operating data and functions can be set:

Display version: IFC 090 D, see Sect. 4 and 5.7, Fct. 1.06 for operator control

Basis version: IFC 090 B, see Sect. 6.2 for operator control

• The pulse output can be operated in the active or passive mode.

Active mode: The current output is the internal voltage source,

connection of electronic totalizers (EC)

Passive mode: External DC or AC voltage source required, connection of electronic (EC)

or electromechanical (EMC) totalizers

• Digital pulse division, interpulse period is non-uniform. Therefore, if frequency meters or

cycle counters are connected, allow for minimum counting interval:

gate time, counter ≤

1000

P

100% [ Hz]

• Connection diagrams, see Sect. 2.6: diagrams 3 4 5 9

2/2

Page 14

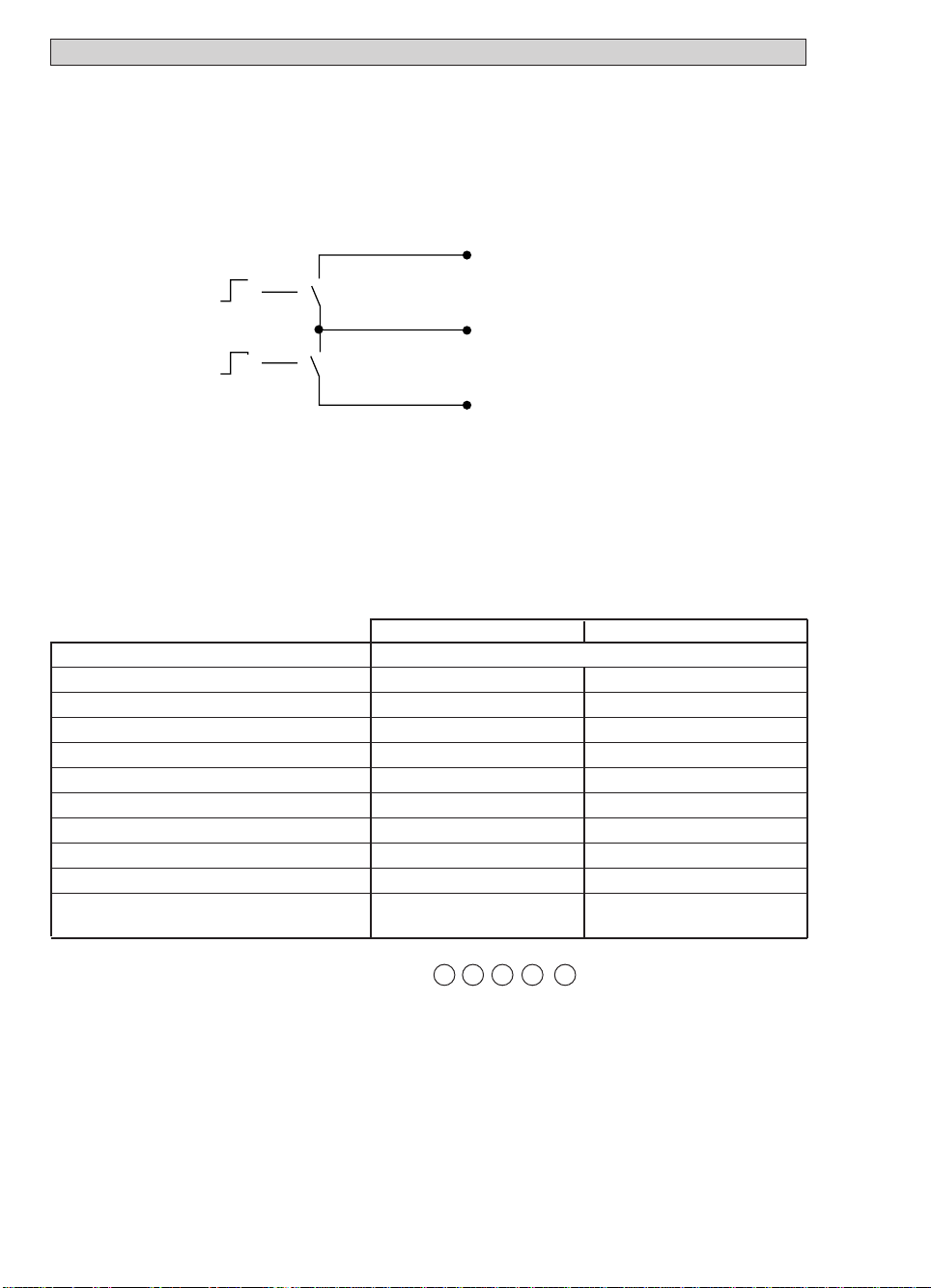

2.4 Status outputs B1 and B2 (terminals B1 / B⊥ and B2 / B⊥)

•

The status outputs are galvanically isolated from the current output and all input circuits.

•

Setting data and functions can note down on page 0/3.

Please also refer to Sect. 3.2 “Factory settings” and Sect. 2.1 “Combinations of

binary outputs and inputs”, Fct. 3.07 HARDWARE.

• Typical status outputs B1 and B2

B2 status output B2

(or control input B2)

B⊥⊥chassis ground, binary

outputs and inputs

B1 status output B1 (or pulse

output, control input)

• All operating data and functions can be set:

Display version: IFC 090 D, see Sect. 4 and 5.8, Fct 1.06 or 1.07 for operator control

Basic version: IFC 090 B, see Sect. 6.2 for operator control

• The status outputs can be operated in the active or passive mode.

Active mode: The current output is the internal voltage source.

Passive mode: External DC or AC voltage source required.

•

Characteristics of the status outputs

Switch open Switch closed

OFF (switched off) no function

ON (e.g. operation indicator) power OFF power ON

SIGN I (F/R mode) Forward flow Reverse flow

SIGN P (F/R mode) Forward flow Reverse flow

TRIP POINT (limit switch) inactive active

AUTO RANGE (automatic range change)

high range low range

OVERFLOW I (I overranged) current output OK current output overranged

OVERFLOW. P (P overranged) pulse output OK pulse output overranged

ALL. ERROR (all errors) errors no error

FATAL.ERROR (fatal errors only) errors no error

EMPTY PIPE (option) when measuring when measuring

tube is empty tube is full

Connection diagrams, see Sect. 2.6: diagrams 6 7 9 10 11

2/3

Page 15

Control inputs B1 and B2 (terminals B1 / B⊥ and B2 / B⊥) 2.5

• The control inputs are galvanically isolated from the current output and all input circuits.

Setting data and functions can note down on page 0/3.

•

Please also refer to Sect. 3.2 “Factory settings” and Sect. 2.1 “Combinations of

binary outputs and inputs”, Fct. 3.07 HARDWARE.

• Typical current inputs B1 and B2

B1 / B2

⊥⊥

B

• All operating data and functions can be set:

Display version: IFC 090 D, see Sect. 4 and 5.19, Fct. 1.06 and 1.07 for operator control

Basic version: IFC 090 B, see Sect. 6.2 for operator control

• The control inputs must be operated in the passive mode.

• Function of the control inputs

OFF switched off

EXT. RANGE external range change

OUTP. HOLD hold value of outputs

OUTP. ZERO set outputs to “MIN.VALUES”

TOTAL.RESET reset totalizer(s)

ERROR.RESET delete error messages

Connection diagram, see Sect. 2.6: diagram 8

2/4

Page 16

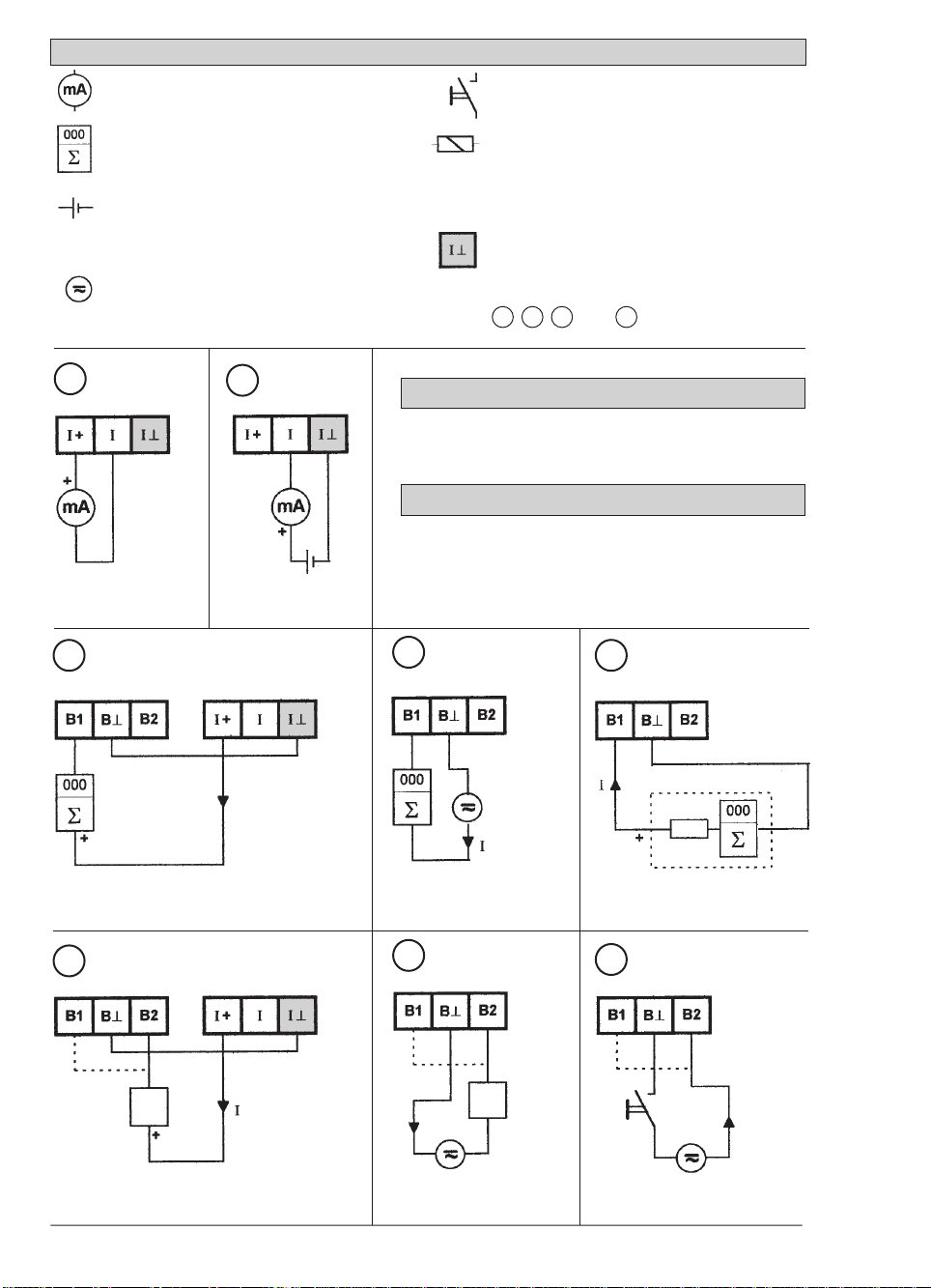

2.6 Connection diagrams for outputs and inputs

Current output

1

I

active

Ri≤ 500 Ω

Pulse output

3

P

active

for EC

Milliammeter

Totalizer

– electronic (EC)

– electromechanical (EMC)

DC voltage,

external power source (U

ext

note connection polarity

External voltage source (U

DC or AC voltage,

connection polarity arbitrary

Current output

2

I

passive

U

U

≤ 15 V DC

ext

Ri≤ 500 Ω

ext

ext

),

),

Key, N/O contact

Relay for forward/reverse

flow measurement (F/R)

and/or automatic range change (BA)

with 1 or 2 changeover contacts

Please note! This terminal is not

provided for hazardous-duty signal

converters. There is no passive current

output, see connection diagrams

2 , 3 , 6 and 11 .

Active mode

The current output supplies the power for operation

of the inputs and outputs.

Passive mode

External power source required for operation of the

inputs and outputs.

Pulse output

4

P

passive

for EC or EMC

Pulse output

5

P

active EC

passive

I

U ≤ 15 V DC from current output

I ≤ 23 mA

I ≤ 03 mA

6

operation without current output

operation with current output

Status output

S

active

(connection to B2 and/or B1)

Last

U ≤ 15 V DC from current output

I ≤ 23 mA

I ≤ 03 mA

operation without current output

operation with current output

2/5

U

≤ 32 V DC/≤ 24 VAC

ext

I ≤ 150 mA

Status output

7

S

passive

to B2 and/or B1)

I

U

U

≤ 32 V DC/≤ 24 V AC

ext

I ≤ 150 mA

U

ext

(

connection

Last

ext

U

≤ 32 V DC

ext

I ≤ 150 mA

Control input

8

C

passive

to B2 and/or B1)

U

≤ 32 V DC/≤ 24 VAC

ext

I ≤ 6 mA

(

connection

I

U

ext

Page 17

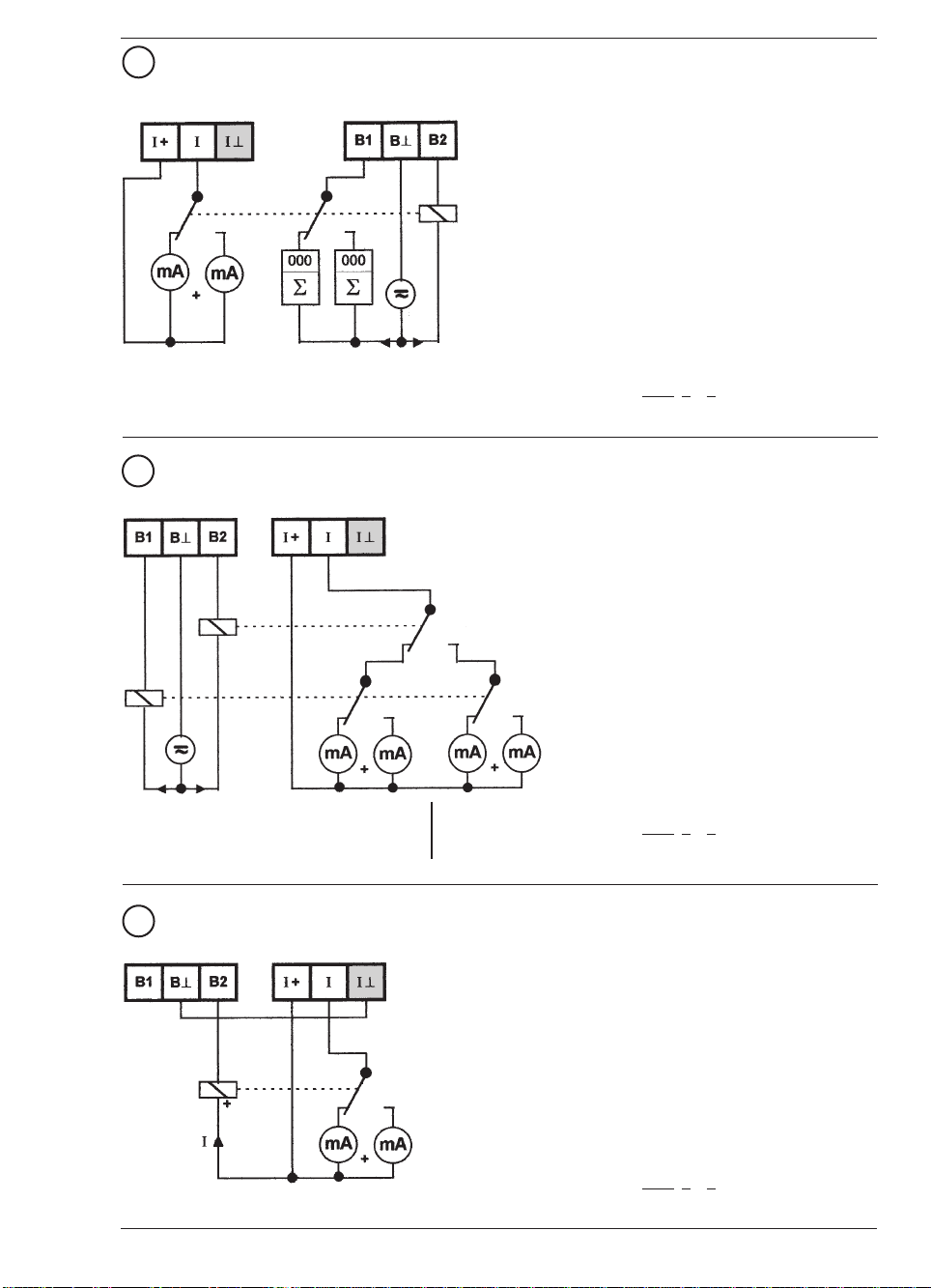

F/R flow measurement

9

I

and P

active

F/R changeover via S

R

U

≤ 32 V DC / ≤ 24 V AC

ext

I ≤ 150 mA

Automatic range change (BA) with F/R flow measurement

10

/ BA changeover via S2

I

active

passive

(B1)

VV

passive

(B2)

R

passive

U

ext

I

I

(B2) / F/R changeover via S1

y type

Rela

e.g. Siemens D1

(B1)

passive

BA

V/R

U

ext

I

I

U

≤ 32 V DC/≤ 24 V AC

ext

I ≤ 150 mA

Automatic range change (BA)

11

I

/ BA changeover via S

active

V

RR

high

range

(B2)

active

V

low

range

Relay type

e.g. Siemens D1

U ≤ 15 V DC

I ≤ 03 mA

high

range

low

range

Relay type

e.g. NAIS-Matsushita

type RH-C or DR-C

2/6

Page 18

3 Start-up

3.1 Switch-on and measurement

• Before powering the system, please check that it has been correctly installed according

to Sect. 1 and 2.

• The flowmeter is delivered ready for operational use. All operating data have

been factory set in accordance with your specifications.

Please refer to Sect. 3.2 “factory settings”.

• Power the unit, and the flowmeter will immediately start process flow

measurement.

Basic version

• A light emitting diode (LED) under the cover of the electronic section shows the

measurement status. Remove the cover using the special wrench.

LED flashing . . .

• Refer to Sect. 6.2 for operator control of the “basic version”.

Display version, signal converter IFC 090 / D

• When powered, the display shows in succession: START UP and READY.

This is followed by display of the current flow rate and/or the current totalizer count

on either a continuous or alternating basis, depending on the setting under Fct. 1.04.

• Refer to Sect. 4 and 5 for operator control of the “display version”.

, signal converter IFC 090 / B

green: measurement correct, everything all right.

green/ red: momentary overdriving of outputs

and/or A/D converter.

red: fatal error, parameter error or hardware fault,

please consult factory.

3/1

Page 19

Factory settings 3.2

All operating data are factory set according to your order specifications.

If you have not made any particular specifications at the time of ordering, the instruments will be

delivered with the standard parameters and functions listed in the Table below.

To facilitate easy and rapid initial start-up, current output and pulse output are set to process flow

measurement in “2 flow directions”, so that the current flowrate is displayed and the volumetric

flow counted independent of the flow direction. On instruments equipped with a display,

measured values may possibly be shown with a “ – ” sign.

This factory setting for the current and pulse outputs may possibly lead to measuring errors,

particularly in the case of volume flow counting:

for example, if pumps are switched off and a “backflow” occurs which is not within the range of

the low-flow cutoff (SMU), or if separate displays and counts are required for both flow directions.

To avoid faulty measurements, therefore, it may be necessary to change the factory setting of

some or all of the following functions:

– low-flow cutoff SMU, Fct. 1.03, Sect. 5.3

– current output I, Fct. 1.05, Sect. 5.6

– pulse output P, Fct. 1.06, Sect. 5.7

– display (option), Fct. 1.04, Sect. 5.4

For special applications, for example “pulsating flow”, see Sect. 6.

Instrument o

peration:

Display versions: IFC 090 _/ D, operation: refer to Sect. 4 and 5.

Basic versions: IFC 090 _/ B, operation: refer to Sect. 6.2.

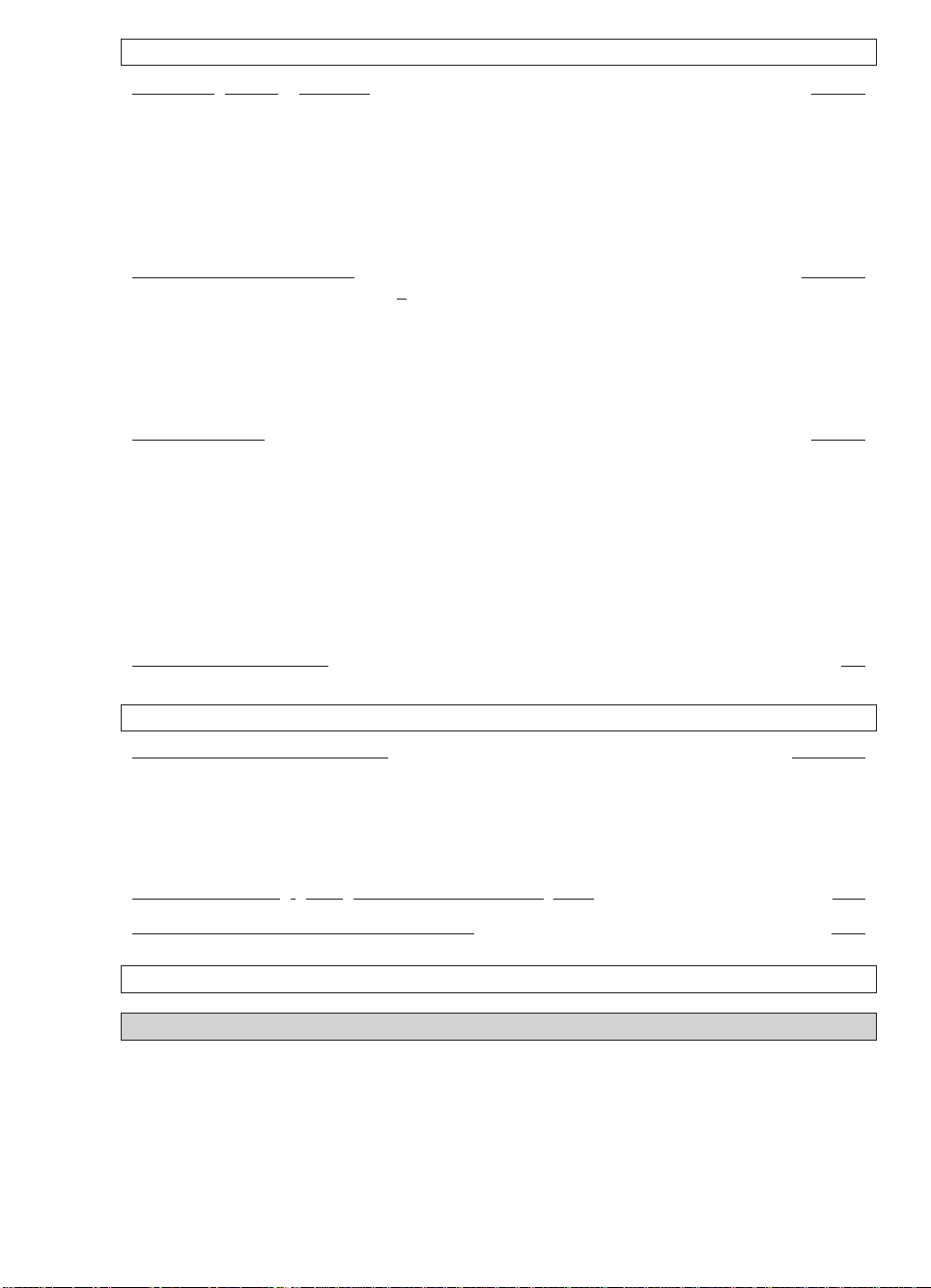

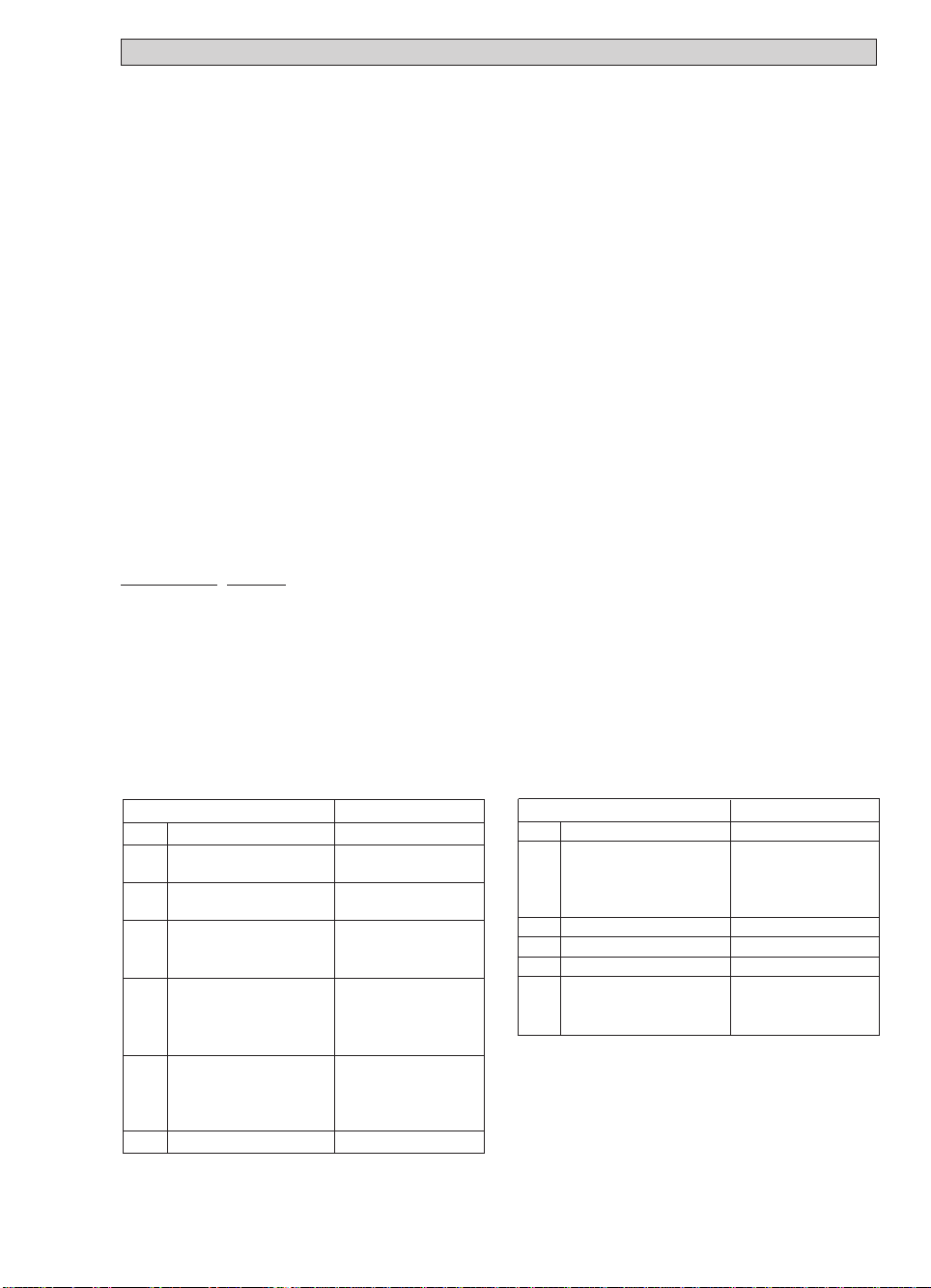

Table of standard factory settings

Function Setting

1.01 Full-scale range Q

1.02 Time constant 3 s, for I, S

1.03 Low-flow ON: 1 %

cutoff SMU OFF: 2 %

1.04 Display (option)

flow rate m

totalizer(s) m3 or US Gal

1.05 Current output I

function 2 directions

range 4 - 20 mA

error message 22 mA

1.06 Pulse output B1

function 2 directions

pulse value 1 pulse/s

pulse width 500 ms

1.07 Status output B2 flow direction

100%

see nameplate

and display

3

/hr or US Gal/min

Function Setting

3.01

Language for display only

3.02 Flowmeter

diameter see nameplate

flow direction (see arrow

on primary head)

3.04 Entry code no

3.05 User unit

3.06 Application steady

3.07 Hardware

Terminal B1 pulse output

Terminal B2 status output

English

+ direction

}

Liter/hrorUSMGal/day

3/2

Page 20

Part B IFC 090 _/ D Signal converter

4 Operation of the signal converter

4.1 Krohne operator control concept

1 3 6. 4 9

m3/hr

→

Measuring mode

CodE 1

Menu column Function column Data column

3.00 INSTALL.

2.00 TEST

When this display appears, press following keys:

→ → → ↵ ↵ ↵ ↑ ↑ ↑

3.07 HARDWARE

3.06 APPLICAT.

3.05 USER UNIT

3.04 ENTRY CODE

3.03 ZERO SET

3.02 FLOWMETER

3.01 LANGUAGE

2.02 HARDW. INFO

2.01 TEST Q

Direction of movement

4/1

1.00 OPERATION

↑

1.07

OUTPUT B2

INPUT B2

1.06

OUTPUT B1

INPUT B1

1.05 CURRENT I

1.04 DISPLAY

1.03 L.F. CUTOFF

1.02 TIMECONST.

1.01 FULL SCALE

→

↵

see

↑

→

Sect.

↵

4.4

Page 21

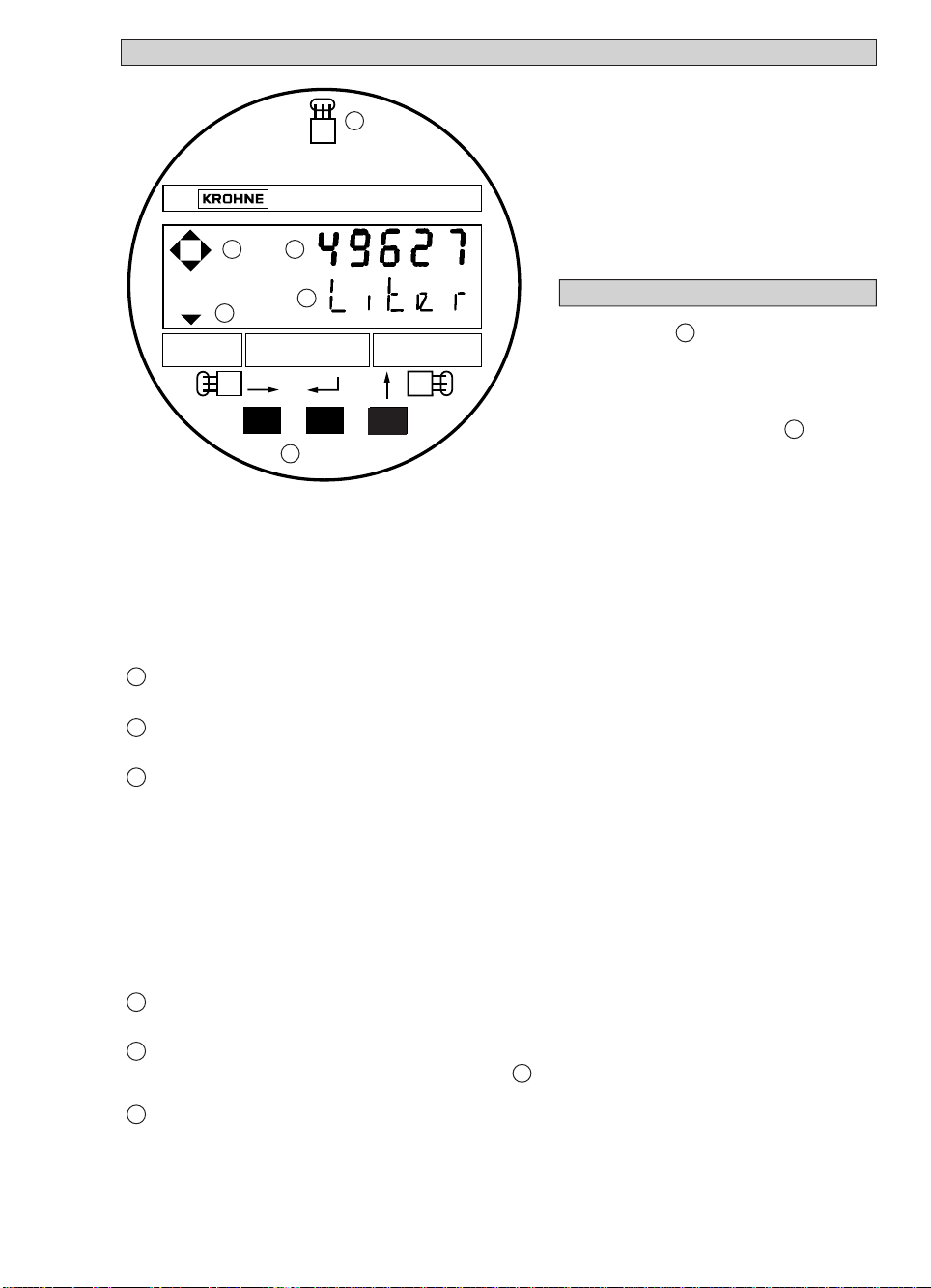

5

Operating and check elements 4.2

IFC 090 D

1

2

+ –

Totalizer

ΣΣ

I P

Overrange

Operator control by way of ...

... the 3 keys 4 . The keys are

accessible after unscrewing the cover

Flow

rate

6

3

of the electronic section using the

special wrench (supplied).

... the 3 magnetic sensors 5 and the

4

supplied bar magnet

without opening the housing.

PLEASE NOTE!

Do not damage the screw thread and the gasket, never allow dirt to accumulate, and make sure they

are well greased at all times.

Damaged gasket must be replaced immediately!

1

Display, 1st line

2

Display, 2nd line

Display, 3rd line: arrows to identify display

3

Flowrate

Totalizer

+ totalizer

current flowrate

– totalizer

Overrange

Σ

I overranging, current output I

sum totalizer (+ and –)

P overranging, pulse output P

4

Keys for operator control of signal converter

5

Magnetic sensors to set the converter by means of a handheld bar magnet without opening

housing. Function of sensors same as keys .

6

Compass field, signals actuation of a key.

4

4/2

Page 22

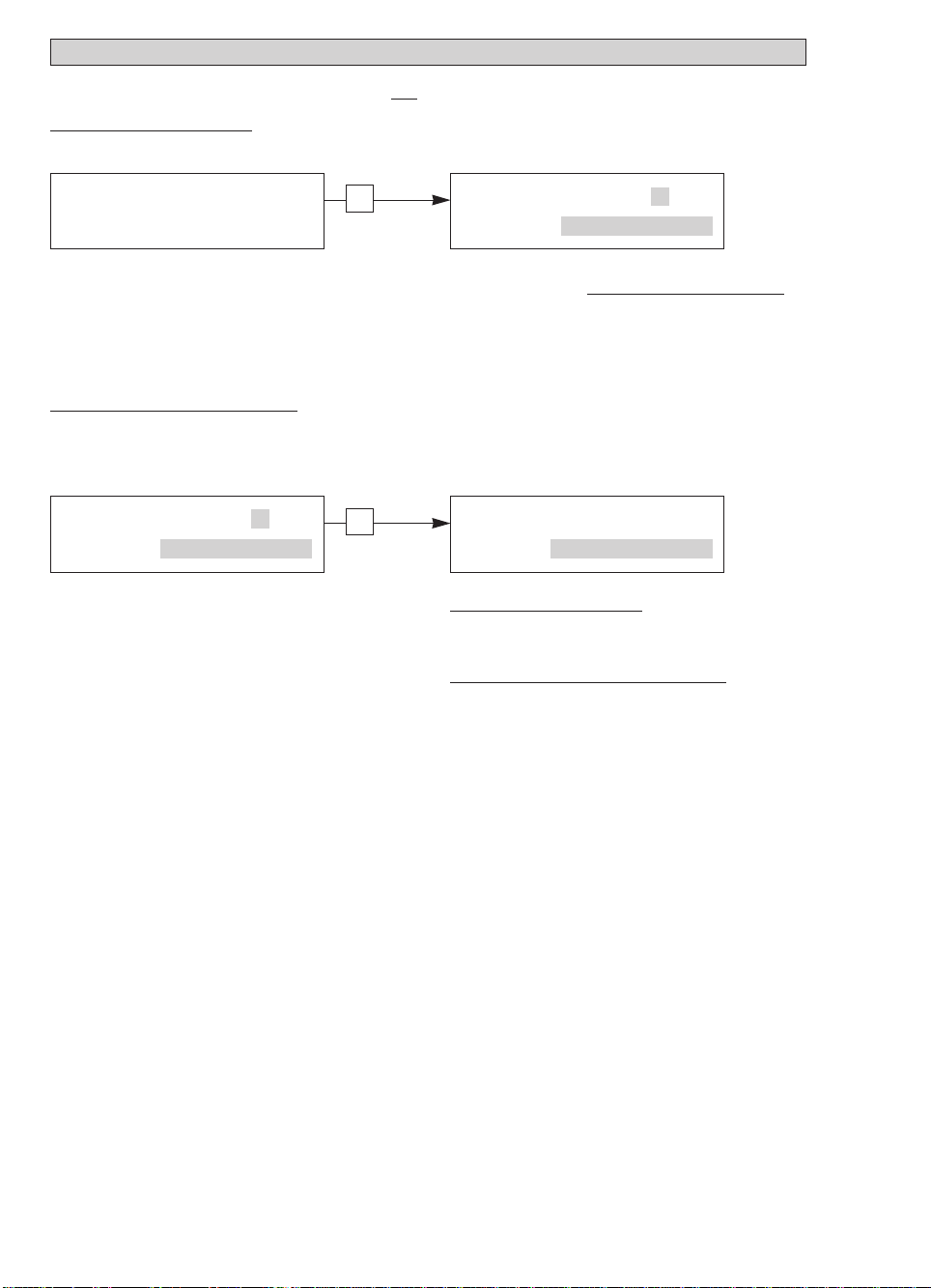

4.3 Function of keys

The cursor (flashing part of display) has a grey background in the following descriptions.

o start operator control

T

Measuring mode

Operator control mode

1 3 . 5 7 1

m 3 / h r

PLEASE NOTE: When “YES” is set under Fct. 3.04 ENTRY CODE, “CodE 1 - - - - - - - - -”

appears in the display after pressing the → key.

The 9-keystroke Entry Code 1 must now be entered: → → → ↵ ↵ ↵ ↑ ↑ ↑

(each keystroke acknowledged by “

o terminate operator control

T

Press key ↵ repeatedly until one of the following menus

Fct. 1.00 OPERATION, Fct. 2.00 TEST or Fct. 3.00 INSTALL. is displayed.

F c t . 3. 0 0

INSTALL.

→

”).

*

Press key

↵

↵

F c t . 1. 0 0

O P E R AT I O N

S T O R E Y E S

Store new parameters: acknowledge by

pressing key↵ . Measuring mode continued

with the new parameters.

New parameters not to be stored:

press key ↑ to display

„STORE.NO“.

Measuring mode continued with the „old“

↵

parameters after pressing key

.

4/3

Page 23

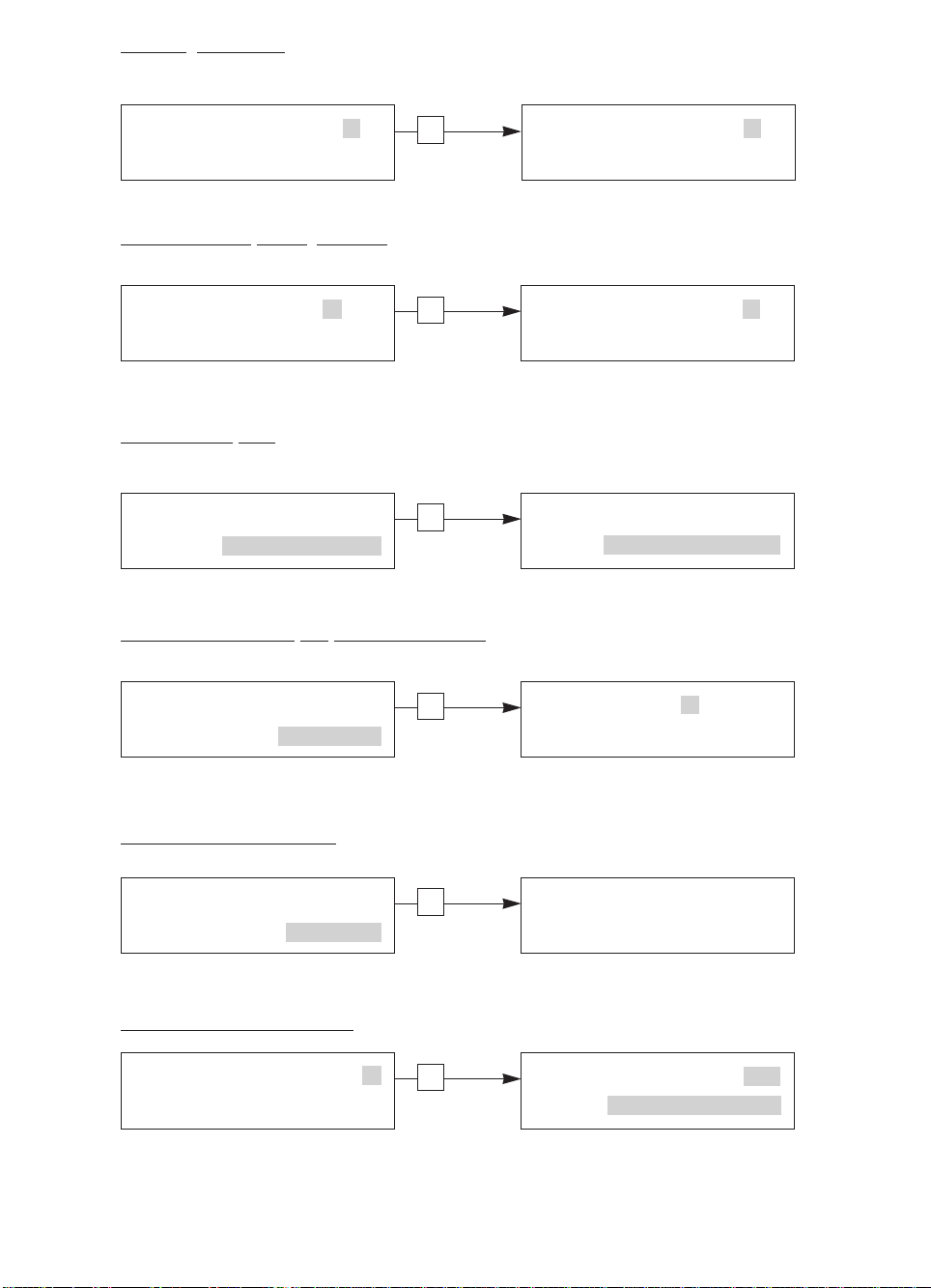

To change numbers

select next number

3 9 7. 3 5

↑

m 3 / h r

To shift cursor (flashing position)

shift to right

3 9 7. 3 5

→

m 3 / h r

To alter texts (units)

For units, the numerical value is

converted automatically.

3. 7 6 9 9

select next text

↑

L i t e r / S e c

To transfer from text (unit) to number setting

Change to number setting

3 9 7. 4 5

m 3 / h r

3 9 7. 3 5

m 3/hr

9 3. 3 6 5

U S. G a l / m i n

1 3. 5 7 1

→

m 3 / h r

To transfer to subfunction

Subfunctions do not have a “Fct.No.“ and are identified by a “ → ”.

↵

1 D I R.

To revert to function display

1 0. 3

↵

Sec

1 3. 5 7 1

m 3/hr

→

R A N G E I

F c t. 1. 0 2

T IME CONST.

4/4

Page 24

4.4 Table of settable functions

Abbreviations used

B1/B2 Status output, control input

DN Nominal size, meter size

F

= 1/2 x pulse width [s]

max

≤ 1 kHz, if “AUTO” or “SYM.” is selected

Q actual flowrate

Q

100%

Q

max

under subfunction “PULSWIDTH”

F

F

F

F/R Forward/reverse flow in F/R mode

GK Primary constant

I Current output

I

0%

I

100%

P Pulse output

P

P

= 10 pulse/h

min

Conversion factor volume for any unit,

M

see Fct. “FACT. VOL.”

Conversion factor time for any unit,

T

see Fct. 3.05 “FACT. Time”

Current at 0% flow

Current at 100% flow

= F

= F

max

min

/ Q

/ Q

100%

100%

max

min

Q

min

SMU Low-flow cutoff for I and P

v Flow velocity

v

max

v

min

Fct. Text Description and settings

1.00 OPERATION Operations menu

1.01 FULL SCALE Full-scale range for flowrate Q

Select unit

• m3/hr • Liter/Sec •US.Gal/min

• user unit, factory set is “Liter/hr” or “US MGal/day” (see Fct. 3.05)

Press →key to transfer to number setting.

Setting ranges

The ranges are dependent on the meter size (DN) and the flow

π

velocity (v): Q

= DN2x v

min

4

Nom. dia./meter size vmin = 0,3 m/s (1 ft/s) vmax = 12 m/s (40 ft/s)

•

DN 2.5–1000 /

1

/10”–40”: 0.0053 – 033 900 m3/hr

Press ↵key to return to Fct. FULL SCALE.

→ VALUE P Pulse value (Fct. 1.06

“VALUE P”

With the “old” pulse values the output frequency (F)

would have been exceeded or not reached.

P

= F

min

/ Q

100% Pmax

min

1.02 TIMECONST. Time constant

Select:

Press ↵key to transfer to number setting.

• ALL (applies to display and all outputs)

• ONLY I (only display, current and status outputs)

Range: • 0.2 – 99.9 Sec

Press ↵key to return to Fct. 1.02 TIMECONST.

1.03 L.F.CUTOFF Low-flow cutoff (SMU)

• OFF (fixed values: ON = 0.1% / OFF = 0.2%)

• PERCENT (variable values) ON OFF

Press →key to transfer to number setting.

Note: Cutoff “off” value must be greater than cutoff “on” value.

Press ↵key to return to Fct. 1.03 L.F. CUTOFF.

100% flow = full scale range

π

= DN2x v

4

at v

max

π

= DN2x v

4

at v

min

Max. flow velocity (12 m/s / 40 ft/s) at Q

Min. flow velocity (0.3 m/s / 1 ft/s) at Q

100%

minQmax

/ max. full-scale range (Q

max

= 12 m/s / 40 ft/s

/ min. full-scale range (Q

min

= 0.3 m/s / 1 ft/s

π

= DN2x v

4

100%

100%

100%

100%

max

0.0237 – 152 000 US.Gal/min

) has been changed.

= F

max

/ Q

Check new values!

100%

1 – 19% 2 – 20%

)

)

4/5

Page 25

Fct. Text Description and settings

1.04 DISPLAY Display functions

→

DISP.FLOW Select flow display

→

DISP.TOTAL. Select totalizer display

→

DISP.MSG. Additional messages required in measuring mode?

1.05 CURRENT I Current output I

→

FUNCT. I Select function for current output I

→

REV.RANGE Set full-scale range for reverse flow of Q

→

RANGE I Select measuring range

→

I ERROR Select error value

1.06 Output/input B1

PULS. B1 Pulse output B1

STATUS B1 Status output B1

CONTROL B1 Control input B1

1.07 Output/input B2

STATUS B2 Status output B2

CONTROL B2 Control input B2

• NO DISP. •

• m3/hr •PERCENT

• Liter/Sec • BARGRAPH (value and bargraph display in %)

• US.Gal/min

Press ↵key to transfer to subfunction “DISP. TOTAL.”.

• NO DISP. (totalizer switched on but not displayed)

• OFF (totalizer switched off)

• m3 • Liter • US.Gal

• user unit, factory set is “Liter” or “US MGal” (see Fct. 3.05).

Press →key to transfer to format setting.

Format setting

• Auto (exponent notation)

• # . ####### • ##### . ###

• ## . ###### • ###### . ##

• ### . ##### • ####### . #

• #### . #### • ########

Press ↵key to transfer to subfunction “DISP.MSG”.

• NO • YES (cyclic change with displays of measured values)

Press ↵key to return to Fct. 1.04 DISPLAY.

• OFF (switched off)

• 1 DIR. (1 flow direction)

• 2 DIR. (forward/reverse flow, F/R flow measurement)

Press key ↵, transfer to subfunction

if

“2 DIR.”

(appears only when “2 DIR.” selected)

• 100 PCT (same as forward flow Q

• PERCENT setting range: 005 - 150% of Q

(different value for reverse flow)

To transfer to number setting, press key→!

Press key ↵ to transfer to subfunction

• 0 - 20 mA • 4 - 20 mA (fixed ranges)

• mA (user-defined range) I

(Value I0%< I

To transfer to number setting, press key →!

Press key ↵ to transfer to subfunction

• 22 mA • 0.0 to I0%mA (variable, see above if I0%> 1 mA)

To transfer to number setting, press key →!

Press key ↵to revert to

user unit, factory set is “Liter/hr” or “US MGal/day (see Fct. 3.05)

selected, transfer to subfunction

!) 0 - 16 mA 4 - 20 mA

100%

}

Functional description of pulse output B1, status output B1

or control input B1, see next page.

}

Functional description of status output B2

or control input B2, see next page.

“RANGE I”;

“REV.RANGE”!

100%

, see Fct. 1.01)

100%

100%

“RANGE I”.

- I

0%

Fct. 1.05 CURRENT. I.

B1 = terminal, assigned as output or input,

see Fct. 3.07 “HARDWARE”

B2 = terminal, assigned as output or input,

see Fct. 3.07 “HARDWARE”

100%

“I ERROR“.

4/6

Page 26

Fct. Text Description and settings

1.06 PULS B1 Pulse output B1 (see Fct. 3.07 HARDWARE)

→

FUNCT. P Select function for pulse output P

→

SELECT P Select pulse type

→

PULSWIDTH Select pulse width

→

VALUE P Set pulse value per unit volume (appears only when

→

VALUE P Set pulse value per unit time (appears only when “PULSE/TIME”

• OFF (switched off)

• 1 DIR. (1 flow direction)

• 2 DIR. (forward/reverse flow, F/R flow measurement)

Press key ↵to transfer to subfunction

• PULSE/VOL. (pulses per unit volume, flowrate)

• PULSE/TIME (pulses per unit time for 100% flowrate)

Press key ↵to transfer to subfunction

• 0.01 - 1.00 Sec (only for F

• AUTO (automatic = 50% of the period duration

of the 100% output frequency)

• SYM. (symmetrical = pulse duty ratio 1:1 over total range)

Press key ↵to transfer to subfunction

“PULSE/VOL.” set under “SELECT P” above)

• xxxx PulS/m3 • xxxx PulS/Liter • xxxx PulS/US.Gal

• xxxx PulS/

Setting range “xxxx” is dependent on the pulse width and the

full-scale range: P

Press key ↵to return to

set under “SELECT P” above)

• xxxx PulSe/Sec (=Hz) • xxxx PulSe/min • xxxx PulSe/hr

• xxxx PulSe/user-defined unit, factory-set is “hr” or “day” (see Fct. 3.05)

Setting range “xxxx” is dependent on the pulse width, see above

Press key ↵to return to

user-defined unit, factory-set is “Liter” or “US M.Gal” (see Fct. 3.05)

= F

min

< 50 pulses/s)

max

/ Q

min

100%Pmax

Fct.1.06“PULS. B1”.

Fct.1.06“PULS. B1”.

“SELECT P”.

“PULSWIDTH”.

“VALUE P”.

= F

max

/ Q

100%

1.06 STATUS B1 Status output B1 and B2 (see Fct. 3.07 HARDWARE)

1.07 STATUS B2 • ALL ERROR • FATAL ERROR • OFF • ON

1.06 CONTROL B1 Control input B1 and B2 (see Fct. 3.07 HARDWARE)

1.07 CONTROL B2 • OFF • EXT.RANGE (external range change)

• SIGN. I

• SIGN. P

• OVERFLOW I

• OVERFLOW P

• AUTO RANGE (automatic range change)

Setting range 5 - 80 PERCENT (= ratio of lower to upper range from

1:20 to 1:1.25. Value must be higher than that of Fct. 1.03 L.F. CUTOFF)

• TRIP POINT: XXX - YYY XXX > YYY N/O contact

• EMPTY PIPE (signals that pipe is “empty”, only if option installed)

Press key

Press key ↵to return to

Setting range: 5 - 80 PERCENT (= ratio of lower to upper range from

1:20 to 1:1.25. Value must be greater than that of Fct. 1.03 L.F. CUTOFF).

Press

• OUTP.HOLD (hold value of outputs)

• OUTP.ZERO (set outputs to “min.values“)

• TOTAL. RESET (reset totalizers)

• ERROR. RESET (delete error messages)

Press key ↵to return to

F/R flow measurement

}

overranging

}

of outputs

0 - 150% 0 - 150% XXX < YYY N/C contact

Hysteresis ≥ 1%

(difference between XXX value and YYY value)

↵

to transfer to number setting.

Fct. 1.06 or 1.07 STATUS B1 orB2.

↵

key to transfer to number setting.

Fct. 1.06 or 1.07 CONTROL B1 or B2.

dynamic response

of outputs, see Fct. 1.02

TIMECONST.:

I = I only

}

P = ALL

4/7

Page 27

Fct. Text Description and settings

2.00 TEST Test menu

2.01 TEST Q Test measuring range Q

Precautionary query

• SURE NO

• SURE YES

select value:

Press ↵key to return to Fct. 2.01 “TEST Q”.

Press

↵

key, then use ↑ key to

-110 / -100 / -50 / -10 / 0 / +10 / +50 / +100 / +110 PCT.

of set full-scale range Q

Displayed value present at outputs I and P.

100%

Press ↵key to return to Fct. 2.01 “TEST Q”.

2.02 HARDW. INFO Hardware information and error status

Before consulting factory, please note down all 6 codes.

→ MODUL ADC X . X X X X X . X X

Y Y Y Y Y Y Y Y Y Y

Press ↵key to transfer to

→ MODUL IO X . X X X X X . X X

Y Y Y Y Y Y Y Y Y Y

Press ↵key to transfer to

→ MODUL DISP. X . X X X X X . X X

Y Y Y Y Y Y Y Y Y Y

Press ↵key to return to Fct. 2.02

“HARDW. INFO“.

3.00 INSTALL. Installation menu

3.01 LANGUAGE Select language for display texts

• GB / USA (English) • F (French)

• D (German) • others on request

Press ↵key to return to Fct. 3.01

“LANGUAGE”.

3.02 FLOWMETER Set data for primary head

→ DIAMETER Select size from meter size table

• DN 10 - 1000 mm equivalent to 3/8 - 40 inch

Select with

Press

→ FULL SCALE Full-scale range for flow Q

To set, refer to Fct. 1.01 “FULL SCALE” above.

Press

→ VALUE P Pulse value (Fct. 1.06

↑

key.

↵

key to transfer to subfunction “FULL SCALE”.

100%

↵ key to transfer to subfunction “GK VALUE”.

“VALUE P”

) has been changed.

With the “old” pulse values the output frequency (F)

would have been exceeded or not reached.

= F

min

/ Q

100% Pmax

P

min

= F

max

/ Q

100%

→ GK VALUE Set primary constant GK

see primary head nameplate.

ge: • 1.0000 - 9.9999

Ran

Press ↵key to transfer to subfunction

→ FIELD FREQ. Magnetic field frequency

Values: 1/2, 1/6, 1/18 and 1/36

of power frequency, see nameplate.

Press ↵key to transfer to subfunction “FLOW DIR.”;

DC units only: to transfer to subfunction

→ LINE FREQ. Normal line frequency in your country

Please note: This function is only provided for units

with DC power supply to suppress line-frequency interference.

Values:

50 Hz

and

60 Hz

Press ↵key to transfer to subfunction “FLOW DIR.”.

→ FLOW DIR. Define flow direction (in F/R mode: forward flow).

Set according to direction of arrow on primary head:

• + DIR. • – DIR.

Select using

Press ↵key to return to Fct. 3.02 “FLOWMETER”.

.

Check new values!

“FIELD. FREQ.”.

“LINE FREQ.”.

↑

key.

“MODUL IO“.

“MODUL DISP.“.

4/8

Page 28

Fct. Text Description and settings

3.03 ZERO SET Zero calibration

Note:

Carry out only at “0” flow and with completely filled

measuring tube!

Precautionar

• CALIB. NO

• CALIB. YES Press ↵

A “WARNING” sign appears when flowrate “> 0“;

acknowledge by pressing

• STORE NO (do not store new zero value)

• STORE YES (store new zero value)

y query

Press ↵key to return to Fct. 3.03 “ZERO SET”.

key to start calibration.

Duration approx. 25 seconds, current flowrate

displayed in the selected unit (see Fct. 1.04 “DISP. FLOW”).

↵

key.

Press ↵key to return to Fct. 3.03 “ZERO SET”.

3.04 ENTRY CODE Entry code required to enter setting mode?

• NO (= entry with → only)

• YES (= entry with → and Code 1: → → → ↵ ↵ ↵ ↑ ↑ ↑ )

Press ↵to return to Fct. 3.04 “ENTRY CODE”.

3.05 USER UNIT Set any required unit for flowrate and counting

→ TEXT VOL. Set text for required flowrate unit (max. 5 characters)

Factory-set: “Liter” or “MGal”.

Characters assi

• A-Z, a-z, 0-9, or “ – “ (= blank character).

gnable to each place:

Press ↵key to transfer to subfunction “FACT. VOL.”

→ FACT. VOL. Set conversion factor (FM) for volume

Factory set “1.00000” for “Liter” or “2.64172E-4” for “US MGal”

(exponent notation, here: 1x103or 2.64172x10-4).

Factor FM= volume per 1m3.

Setting range • 1.00000 E-9 to 9.99999 E+9 (= 10-9to 10+9)

Press ↵ key to transfer to subfunction “TEXT TIME”.

→ TEXT TIME Set text for required time unit (max. 3 characters)

→ FACT. TIME Set conversion factor (FT) for time

Factory-set: “hr” or “day”:

Characters assignable to each place:

• A-Z, a-z, 0-9, or “ – “ (= blank character).

Press

↵ key to transfer to subfunction “FACT. TIME”

Factory-set: “3.60000 E+3” for “hour” or “8.64000 E+4” for “day”

(exponent notation, here: 3.6 x103or 8.64 x10-4).

Set factor FTin seconds.

Setting range

• 1.00000 E-9 to 9.99999 E+9 (= 10-9to 10+9)

Press ↵ key to return to Fct. 3.05 “USER UNIT”.

3.06 APPLICAT. Set overload point for A/D converter

→ FLOW • STEADY (150% of Q

Press key ↵to return to

with installed option

change to subfunction

→ EMPTY PIPE Switch on “empty pipe” identifier option?

(appears only when this option is installed)

• YES • NO

Select with key ↑.

Press ↵key to return to

3.07 HARDWARE Assign outputs and inputs to terminals B1 and B2

→ TERM.B1 Terminal B1

• PULSOUTP. • STATUSOUTP. • CONTROLINP.

) • PULSATING (1000% of Q

100%

Fct. 3.06 “APPLICAT.“,

“empty pipe“

“EMPTY PIPE“.

,

Fct. 3.06 “APPLICAT.“.

Select with key ↑.

Press key ↵ to transfer to subfunction

→ TERM.B2 Terminal B2

• STATUSOUTP. • CONTROLINP.

“TERM. B2”.

Select with key ↑.

Press key ↵ to return to

Fct. 3.07 “HARDWARE”.

100%

)

4/9

Page 29

Error messages in measuring mode 4.5

The following list gives all errors that can occur during process flow measurement.

Errors shown in display when “YES” set in Fct. 1.04 DISPLAY, subfunction “DISP. MSG.”:

Error messages Description of error Error clearance

LINE INT. Power failure Note: Cancel error in RESET-QUIT menu

OVERFLOW I Current output overranged. Check and if necessary correct

OVERFLOW P Pulse output overranged. Check and if necessary correct

TOTALIZER Totalizer has been reset Cancel error message in

ADC Analog / digital Error message deleted automatically

FATAL. ERROR Fatal error, all outputs set Please consult factory.

EMPTY PIPE Pipe has run dry. Fill pipe.

no counting during power failure Reset totalizer if necessary.

instrument parameters. After

elimination of cause, error message

deleted automatically.

Note: instrument parameters. After

totalizer deviation possible. elimination of cause, error message

deleted automatically.

RESET/QUIT. menu.

converter overranged after elimination of cause.

to “min. values”

This message appears only when

the “empty pipe identifier”

option is installed and the function

is switched on under Fct. 3.06

APPLICAT., submenue

“EMPTY PIPE”.

4/10

Page 30

4.6 Reset totalizer and cancel error messages, RESET/QUIT menu

Cancel error messages in RESET / QUIT menu

Key Display Description

- - - - - - - - - - - - / - - - Measuring mode

↵ CodE 2 - - Key in entry code 2 for RESET/QUIT

↑ → ERROR QUIT. Menu for error acknowledgement

→ QUIT. NO Do not delete error messages,

↑ QUIT. YES Delete error messages

↵ ERROR QUIT. Error messages deleted

↵ - - - - - - - - - - - - / - - - Return to measuring mode

menu: ↑ →

press ↵ twice = return to measuring mode

Reset totalizer(s) in RESET / QUIT menu

Key Display Description

- - - - - - - - - - - - / - - - Measuring mode

↵ CodE 2 - - Key in entry code 2 for RESET/QUIT

↑ → ERROR QUIT. Menu for error acknowledgement

↑ TOTAL. RESET Menu for resetting totalizer

→ RESET NO Do not reset totalizer,

↑ RESET. YES Reset totalizer

↵ RESET QUIT. Totalizer reset

↵ - - - - - - - - - - - - / - - - Return to measuring mode

menu: ↑ →

press ↵ twice = return to measuring mode

4/11

Page 31

Examples of setting the signal converter 4.7

The cursor, flashing part of display, is shown below in bold type.

• Change measuring range of current output and value for error messages (Fct. 1.05):

• Change measuring range from 04-20 mA to 00-20 mA

• Change value for error messages from 0 mA to 22 mA

Key Display Description

→ If ”YES“ set under Fct. 3.04 ENTRY CODE, key in the

Fct. 1.00 OPERATION

→ Fct. 1.01 FULL SCALE

4x ↑ Fct. 1.05 CURRENT I

→ FUNCT. I

→↵ RANGE I If ”REV. RANGE“ appears here,

→ 04-20 mA Old current range

2x ↑ 00-20 mA New current range

↵ I ERROR

→ 0 mA Old value for error messages

↑ 22 mA New value for error messages

↵ Fct. 1.05 CURRENT I

↵ Fct. 1.00 OPERATION

↵ STORE YES

↵ - - - - - - - - - - - - / - - - Measuring range with new data for the current output

9-keystroke CODE 1 now: → → → ↑ ↑ ↑ ↵ ↵ ↵

press keys → and ↵ again.

4/12

Page 32

5 Description of functions

5.1 Full-scale range Q

100%

Fct. 1.01 FULL SCALE

Press→key.

Choice of unit for full-scale range Q

100%

• m3/hr (cubic metres per hour)

• Liter/Sec (litres per second)

• US.Gal/min (US gallons per minute)

• User-defined unit, factory-set is „Liter/hr“ (litres per hour) or “US MGal/day”, see Sect. 5.13.

Select with

↑ key.

Use →key to transfer to numerical setting, 1st number (cursor) flashes.

Set full-scale range Q

100%

The setting range is dependent on meter size (DN) and flow velocity (v).

Q

min

π

= DN2x v

4

minQmax

π

= DN2x v

4

0.0053 – 33 929 m3/hr

0.00147 – 9 424.5 Liter/Sec

0.00233 – 151 778 US.Gal/min

(refer to flow table in Sect. 10.1)

max

Change flashing number (cursor) with ↑key.

Use

→

Press

key to shift cursor 1 place to right.

↵

key to return to Fct. 1.01 FULL SCALE

.

Note if “VALUE P” is displayed after pressing ↵ key:

PULSE/VOL. is set under Fct. 1.06 PULS B1, subfunction “SELECT P”. Due to the changed

full-scale range Q

P

= F

min

/ Q

min

, the output frequency (F) of the pulse output will be over- or undershot:

100%

100%

P

= F

max

max

/ Q

100%

Change pulse value accordingly, see Sect. 5.7 pulse output B1, Fct. 1.06.

5.2 Time constant

Fct. 1.02 TIMECONST.

Press →key.

Choice

• ALL (applies to display and all outputs)

• ONLY I (applies only to display, current and status output)

Select with ↑.

Transfer to number setting with

↵

key. 1st number (cursor) flashes.

Set numerical value

• 0.2 - 99.9 Sec (seconds)

Change flashing number (cursor) with the↑key.

Use

→

Press

key to shift cursor 1 place to right.

↵

key to return to Fct. 1.02 TIMECONST.

5/1

Page 33

Low-flow cutoff 5.3

Fct. 1.03 L.F.CUTOFF

Press →key.

Choice

• OFF (fixed tripping point: ON = 0.1 % / OFF = 0.2 %)

• PERCENT (variable tripping points: ON = 1 - 19 % / OFF = 2 - 20 %)

Select with ↑key.

Transfer to number setting using

→

key (only if “PERCENT” selected).

1st number (cursor) flashes.

Setting the numerical value when “PERCENT” selected

• 01 to 19 (cutoff “on” value, left of hyphen)

• 02 to 20 (cutoff “off” value, right of hyphen)

Change flashing number (cursor) with the ↑key.

Shift cursor 1 place to right using

Press

↵

key to return to Fct. 1.03 L.F.CUTOFF.

Note: The cutoff “off” value must be greater than the cutoff “on” value.

Fct. 1.04 DISPLAY

→

key.

Press →key.

Display 5.4

→ DISP. FLOW = select unit for display of flowrate,

• NO DISP. (no display)

• m3/hr (cubic metres per hour)

• Liter/Sec (litres per second)

• US.Gal/min (US gallons per minute)

• user-defined unit, factory-set: “Liter/hr” (litres per hour) or “US MGal/day”, see Sect. 5.15

• PERCENT (percentage display)

• BARGRAPH (numerical value and bar graph display in %)

press → key

Select with ↑key.

Press

↵

key to transfer to subfunction “DISP. TOTAL”.

→ DISP. TOTAL = select unit for totalizer display,

• NO DISP. (no display)

• OFF (internal totalizer switched off)

• + TOTAL. • – TOTAL. • +/– TOTAL. • SUM (ΣΣ) • ALL (sequential)

press → key

Select with ↑key.

Transfer to totalizer unit setting using

•m3 (cubic metres)

• Liter (litres)

• US.Gal (US gallons)

• user-defined unit, factory-set: “Liter” or “US MGal”, see Sect. 5.12

↵

key.

Select with ↑key.

Transfer to totalizer format setting using

→

key.

Continuation see next page

5/2

Page 34

Setting of totalizer format

• Auto (exponent notation)

• # . ####### • ##### . ###

• ## . ###### • ###### . ##

• ### . ##### • ####### . #

• #### . #### • ########

Select with key↑.

Press

↵ key to transfer to subfunction “DISP. MSG”.

→

DISP. MSG. = additional messages required in measuring mode,

press → key

•NO (no other messages)

• YES (display other messages, e.g. errors, in sequence with the measured values)

Select using the ↑key.

Press

↵

key to return to Fct. 1.04 DISPLAY.

Note: “BUSY” is displayed in the measuring mode when all displays are set to “NO DISP.” or

“NO”. Sequencing of displays is automatic. However, in the measuring mode, manual sequencing

can be carried out with the ↑ key. Return to automatic sequencing after approx. 3 minutes.

Please refer to Sect. 3.2 “factory settings”

5.5 Internal electronic totalizer

The internal electronic totalizer counts in m3, regardless of the unit set under Fct. 1.04,

subfunction “DISP. FLOW”.

The counting range is dependent upon the meter size and has been selected such that the

totalizer will count for a minimum of 1 year without overflow:

Meter size Counting range

DN mm inch in m

3

10 - 50

65 - 200 2

/8- 2 0 - 999 999.99999999 0 - 264 172 052.35800

1

/2- 8 0 - 9 999 999.9999999 0 - 2 641 720 523.5800

3

US Gal equivalent

250 - 600 10 - 24 0 - 99 999 999.999999 0 - 26 417 205 235.800

700 -1000 28 - 40 0 - 999 999 999.99999 0 - 264 172 052 358.00

Only part of the totalizer count is shown in the display because it is not possible to output

a 14-digit number. Unit and format of the display are freely selectable, see Fct. 1.04, subfunction

“DISP. TOTAL” and Sect. 5.4. This determines which part of the count is to be displayed.

Display overflow and totalizer overflow are independent of one another.

Exam

ple

Internal count 0000123 . 7654321 m

3

Format, display unit XXXX . XXXX Liter

Internal count in unit 0123765 . 4321000 Liter

Displayed 3765 . 4321 Liter

5/3

Page 35

Fct. 1.05 CURRENT I

Press →key.

Current output I 5.6

→ FUNCT. I = Select function for current output,

• OFF (switched off, no function)

• 1 DIR. (1 flow direction)

• 2 DIR. (2 flow directions, F/R mode, forward/reverse)

press → key

Select using ↑key.

Transfer to subfunction “RANGE I”

with ↵key.

Exceptions: When “OFF” selected, return to Fct. 1.05 CURRENT I.

When “2 DIR.”selected, transfer to subfunction

→ REV.RANGE = define full-scale range for reverse flow

(appears only when “2 DIR.” set under “FUNCT. I” above)

“REV.RANGE”.

Press →key

• 100 PCT. (same full-scale value Q

• PERCENT (settable range) Settin

as forward flow, see Fct. 1.01)

100%

g range 005 – 150% of Q100% (see Fct. 1.01)

Select with ↑key.

Press

→

Press

→

RANGE I = select measuring range,

• 0 - 20 mA

• 4 - 20 mA

• mA (user-defined value) I

key to transfer to number setting.

↵ key to transfer to subfunction “RANGE I”.

fixed ranges

}

– I

0%

(value I0%< I

!) 0-16 mA 4-20 mA

100%

press → key

100%

Press →key to transfer to number setting.

Select with key

Press key

↑

.

↵

to transfer to subfunction “I ERROR”.

→ I ERROR = set error value,

• 22 mA (fixed value)

• 0.0 - I

mA (variable value; only variable when I0%≥ 1 mA, see ”RANGE I“ above)

0%

press → key

Select using key ↑. Press →key to transfer to number setting.

Press key

Refer to Sect. 2.6 for connection diagrams, and to Sect. 5.15 for characteristics.

↵

to return to Fct. 1.05 CURRENT I.

Please refer to Sect. 3.2 “Factory settings”.

5/4

Page 36

5.7 Pulse output B1

NOTE! Check whether under Fct. 3.07 “HARDWARE” the output terminal “B1” is defined as

pulse output, refer also to Sect. 2.2 and Sect. 5.16.

Fct. 1.06 PULS B1

Press key →.

→ FUNCT. P = select function for pulse output,

press → key

• OFF (switched off, no function)

• 1 DIR. (1 flow direction)

• 2 DIR. (2 flow directions, F/R mode, forward/reverse)

Select with key ↑.

Press

↵

key to transfer to subfunction “SELECT P”.

Exception: When “OFF” selected, return to Fct. 1.06 PULS B1.

→ SELECT P = select pulse type,

press → key

• PULSE/VOL. (pulses per unit volume, flowrate)

• PULSE/TIME (pulses per unit time for 100% flowrate)

Select with key ↑.

Press

↵

key to return to subfunction “PULSWIDTH”.

→ PULSWIDTH = select pulse width,

press key

→

• AUTO (automatic = 50% of the period length of the 100% output frequency)

• SYM. (symmetrical = 1:1 pulse duty ratio over entire range)

• SEC. (variable) setting range 0.01 - 1.00 SEC

Select with key ↑.

Press

→

1st number (cursor) flashes. Set numbers using keys

key to transfer to number setting.

↑ and →.

Press ↵key to transfer to subfunction “VALUE P” or return to Fct. 1.06 PULS B1,

depending on choice of pulse type in subfunction “SELECT P”.

Please note

= 10 pulses/h

F

min

F

=

max

2 x pulse width [s]

1

If “AUTO” or “SYM.” is selected under

subfunction “PULSWIDTH”

F

≤ 1 kHz !

max

5/5

Page 37

→ VALUE P = set pulse value per unit volume

(appears only when “PULSE/VOL.” set under “SELECT P”, press →

key.

• XXXX PulS/m3

• XXXX PulS/Liter

• XXXX PulS/US.Gal

• XXXX PulS/ user unit, factory-set: “Liter” or “US MGal”, see Sect. 5.13.

Select using ↑key.

Transfer to number setting with

→

key. 1st digit (cursor) flashes.

Set numerical value

• XXXX (setting range depends on pulse width and

full-scale range: P

min

= F

min

/ Q

100%

P

= F

max

/ Q

max

Change flashing digit (cursor) with ↑key,

shift cursor 1 place to right or left with

Press

↵

key to return to Fct. 1.06 PULS B1.

→

key.

or

→ VALUE P = set pulse value per unit time,

(a

ppears only when ”PULSE/TIME” has been set under “SELECT P”),

press→key.

• XXXX PulSe/Sec

• XXXX PulSe/min

• XXXX PulSe/hr

• XXXX PulSe/ user unit, factory-set: “hr”, or “day”, see Sect. 5.13.

Select using ↑key.

Transfer to number setting with

→

key, 1st digit (cursor) flashes.

100%

)

Set numerical value

• XXXX (setting range depends on pulse width)

Change flashing digit (cursor) with ↑key,

shift cursor 1 place to right or left with

Press

↵

key to return to Fct. 1.06 PULS B1.

→

key.

Please refer to Sect. 3.2 “factory settings”

Refer to Sect. 2.6 for connection diagrams, and to Sect. 5.15 for characteristics.

5/6

Page 38

5.8 Status outputs B1 and B2

NOTE: Check whether under Fct. 3.07 “HARDWARE” the output terminal “B1” and/or “B2” is

defined as status output B1 and/or B2, refer also to Sect. 2.1 and Sect. 5.16.

Fct. 1.06 and/or 1.07 ST

Press key →.

Select function of status outputs,

• ALL ERROR (indicates all errors)

• FATAL.ERROR (indicates fatal errors only)

• OFF (switched off, no function)

•ON (indicates that flowmeter is operative)

• SIGN. I

• SIGN. P

• OVERFLOW I overranging I = I ONLY

• OVERFLOW P of outputs P = ALL

• EMPTY PIPE (option ”empty tube identification)

• AUTO RANGE (automatic range change) Settin

(= ratio of upper to lower range, 1:20 to 1:1.25, value must be greater

than that of Fct. 1.03 “L.F.CUTOFF”, see also Sect. 5.18)

• TRIP POINT (define trip point) see also Sect. 5.17.

XXX – YYY

0 – 150% 0 – 150% N/O contact: XXX > YYY

Press ↵key to transfer to number setting, 1st digit (cursor) flashes.

Change flashing digit (cursor) with key

Press

↵

key to return to Fct. 1.06 and/or 1.07 STATUS B1 or B2.

• Characteristics of status outputs Switch open Switch closed

OFF (switched off) no function

ON (e.g. operation indicator) power OFF power ON

SIGN I (F/R mode) Forward flow Reverse flow

SIGN P (F/R mode) Forward flow Reverse flow

TRIP POINT (limit switch) inactive active

AUTO RANGE

OVERFLOW I (I overranged) current output OK current output overranged

OVERFLOW P (P overranged) pulse output OK pulse output overranged

ALL ERROR (all errors) errors no error

FATAL.ERROR (fatal errors only) errors no error

EMPTY PIPE (option) when measuring tube when measuring tube

(automatic range change)

ATUS B1 and/or B2

V/R mode

}

}

press → key

Dynamic response

of outputs, see Fct. 1.02, Sect. 5.2 “time constant”

}

g range 5-80 PERCENT

N/C contact: XXX < YYY

Hysteresis: difference between XXX and YYY.

↑

. Use key →to shift cursor 1 place to right.

high range low range

is empty is full

Please refer to Sect. 3.2 ”factory settings“.

Connection diagrams, see Sect. 2.6.

5/7

Page 39

Control inputs B1 and B2 5.9

NOTE! Check whether under Fct. 3.07 “HARDWARE” the output terminal “B1” and/or “B2” is

defined as control input B1 and/or B2, refer also to Sect. 2.1 and Sect. 5.16.

Fct. 1.06 and 1.07 CONTROL

Press key →twice.

Select function of control inputs,

• OFF (switched off, no function)

• OUTP. HOLD (hold value of outputs)

• OUTP. ZERO (set outputs to “min. values”)

• TOTAL. RESET (reset totalizers)

• ERROR. RESET (delete/acknowledge error messages)

• EXT. RANGE (external range change for automatic range change, see also Sect. 5.19,

Press

↵

key to return to Fct. 1.06 or 1.07 CONTROL B1 or B2.

Please refer to Sect. 3.2 ”factory settings“.

Connection diagram, see Sect. 2.6.

Fct. 3.01 LANGUAGE

Press →key.

Select language for texts in display

•D (German)

• GB/USA (English)

•F (French)

• others on request

settin

value must be greater than that of Fct. 1.03 L.F.CUTOFF)

Press ↵key to transfer to number setting, 1st digit (cursor) flashes.

Change flashing digit with key

press key → to shift cursor 1 place to the right.

B1/B2

press key↑ .

Functions also act on

}

display and totalizer

g range 5 – 80 PERCENT = ratio of low to high range 1:20 to 1:1.25,

↑

,

Language 5.10

Select using ↑key.

Press

↵

key to return to Fct. 3.01 LANGUAGE.

Entry code 5.11

Fct. 3.04 ENTRY CODE

Press →key.

Choice

•NO (no code, enter setting mode with → key)

• YES (enter setting mode with → key and Code 1: → → → ↵ ↵ ↵ ↑ ↑ ↑)

Select using ↑key.

Press

↵

key to return to Fct. 3.04 ENTRY CODE.

5/8

Page 40

5.12 Primary head

Fct. 3.02 FLOW METER

Press →key.

→ DIAMETER = set meter size (see instrument nameplate)

press → key

Select size from table of meter sizes:

• DN 2.5 - 1000 mm equivalent to

1

/10 - 40 inch

Select using ↑key.

Transfer to subfunction “FULL SCALE”

→ FULL SCALE = set full-scale range,

with ↵key.

press → key.

Set as described in Sect. 5.1.

Transfer to subfunction “GK VALUE” with ↵key.

Note: if “VALUE P” is displayed after pressing ↵ key.

PULSE/VOL. is set under Fct. 1.06 PULS B1, subfunction “SELECT P”. Because the full-scale

range Q

undershot: P

has been changed, the output frequency (F) of the pulse output is over- or

100%

min

= F

min

/ Q

100%

P

= F

max

max

/ Q

100%

Change pulse value accordingly, see Sect. 5.7 pulse output B1, Fct. 1.06.

→

GK VALUE = set primary constant GK,

press → key.

• 1.0000 - 9.9999 (note information on instrument nameplate, do not change setting !)

Change flashing digit (cursor) with ↑key.

Shift cursor 1 place to right or left with

Transfer to subfunction “FIELD

FREQ.” with ↵key.

→ FIELD FREQ. = set magnetic field frequency,

→

key.

press → key

• 1/2 • 1/6 (1/2, 1/6, 1/18 and 1/36 of power frequency, see instrument nameplate,

• 1/18 • 1/36 do not change setting, exce

ptions see Sect. 6.4-6.6 !)

Select using ↑key.

Transfer to subfunction “FLOW DIR.”

with ↵key.

(only for units with DC power supply, transfer to subfunction “LINEFREQ”).

→ LINE FREQ. = normal line frequency in your country,

• 50 Hz

• 60 Hz

→ FLOW DIR. = set flow direction,

Select using the ↑key.

Transfer to subfunction “FLOW DIR.” with ↵ key.

press → key.

press → key.

• + DIR. (for identification of flow direction, see “+” arrow on primary head;

• - DIR. for F/R mode, identifies the “positive” flow direction)

Select using the ↑key.

Press

↵

key to return to Fct. 3.02 FLOW METER.

Zero check, see Fct. 3.03 and Sect. 7.1.

Please refer to Sect. 3.2 “factory settings”

5/9

Page 41

User-defined unit 5.13

Fct. 3.05 USER UNIT

Press → key.

→ TEXT VOL = set text for user-defined unit,

press → key

• Liter (max. 5 characters, factory-set: “Liter” or “US MGal”)

Characters assi

gnable to each place: A-Z, a-z, 0-9, or “–” (= blank character)

Change flashing place (cursor) using ↑key.

Use

→

Transfer to subfunction “F

→ FACT. VOL. = set factor FM for volume,

key to shift cursor 1 place to right.

ACT. VOL.” with ↵key.

press → key

• 1.00000 E+3 (factory-set: “103or 2.64172 x 10-4” / factor FM= volume per 1 m3)

Settin

g range: 1.00000 E-9 to 9.99999 E+9 ( = 10-9to 10+9)

Change flashing place (cursor) using ↑key.

Use

→

Transfer to subfunction “TEXT TIME”

→ TEXT TIME = set text for required time,

key to shift cursor 1 place to right.

with ↵key.

press → key

•hr (max. 3 places, factory-set: “hr = hour” or “day”)

Characters assi

gnable to each place: A-Z, a-z, 0-9, or “–” (= blank character)

Change flashing place (cursor) using ↑key.

Use

→

Transfer to subfunction “F

→ FACT. TIME = set factor FT for time,

key to shift cursor 1 place to right.

ACT. TIME” with ↵key.

press → key

• 3.60000 E+3 (factory-set: “3.6 x 103” for hour or “8.64 x 104” for day / set factor FT

in seconds)

Settin

g range: 1.00000 E-9 to 9.99999 E+9 ( = 10-9to 10+9)

Change flashing place (cursor) using ↑key.

Use

→

Press

key to shift cursor 1 place to right.

↵

key to return to Fct. 3.05 USER UNIT.

Factors for volume FM(factor FM= volume per 1 m3)

Volumetric unit Text examples Factor F

Cubic metres m3 1.0 1.00000 E+0

Litres Liter 1 000 1.00000 E+3

Hectolitres h Lit 10 1.00000 E+1

Decilitres d Lit 10 000 1.00000 E+4

Centilitres c Lit 100 000 1.00000 E+5

Millilitres m Lit 1 000 000 1.00000 E+6

US gallons USGal 264.172 2.64172 E+2

Millions US gallons USMG 0.000264172 2.64172 E -4

Imperial gallons GBGal 219.969 2.19969 E+2

Mega imperial gallons GBMG 0.000219969 2.19969 E-4

Cubic feet Feet3 35.3146 3.53146 E+1

Cubic inches inch3 61 024.0 6.10240 E+4

US barrels liquid US BaL 8.36364 8.38364 E+0

US barrels ounces US BaO 33 813.5 3.38135 E+4

M

Setting

Factors for time FT(factor FTin seconds)

Time unit Text examples Factor FT (seconds) Setting

Seconds Sec 1 1.00000 E+0

Minutes min 60 6.00000 E+1

Hours hr 3 600 3.60000 E+3

Day DAY 86 400 8.64000 E+4

Year (= 365 days) YR 31 536 000 3.15360 E+7

5/10

Page 42

5.14 F/R mode, forward/reverse flow measurement

• Refer to Sect. 2.6 for electrical connection of outputs.

• Define direction of forward (normal) flow, see Fct. 3.02, subfunction “FLOW DIR.”:

in conjunction with F/R operation, set the direction for the forward flow here.

“+” signifies the same direction as shown by the arrow on the primary head,

“–” signifies the opposite direction.

• Set the status output to “SIGN I” or “SIGN P”, see Fct. 1.06 or 1.07, “STATUS B1 or B2”.

For dynamic response of the outputs with “SIGN I” or “SIGN P” see Sect. 5.8.

• Current and/or pulse output must be set to “2 DIR.”, see Fct. 1.05 and 1.06, subfunctions

“FUNCT. I” and “FUNCT. B1”.

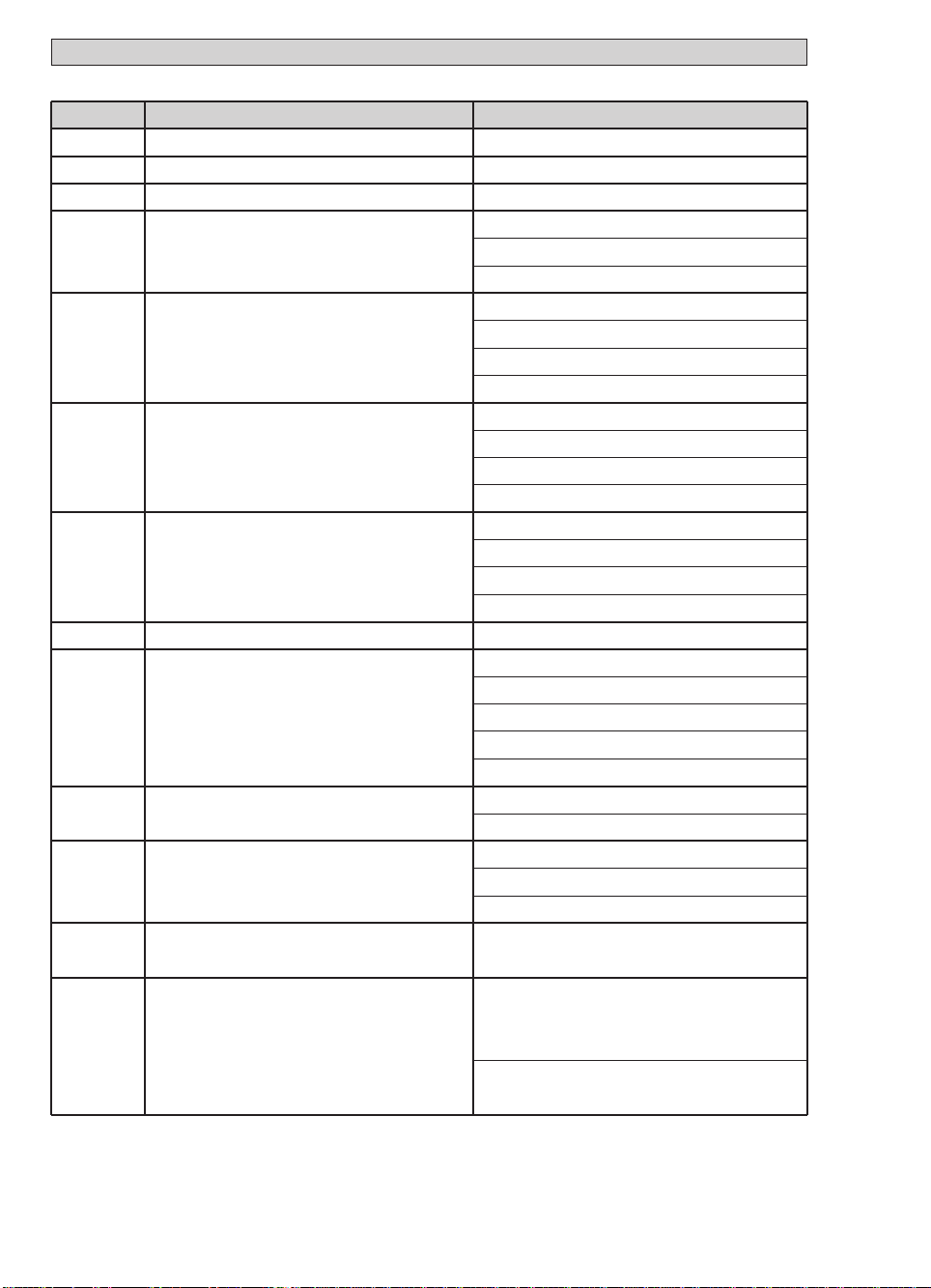

5.15 Characteristic of outputs

I Current output

I

0%

I

100%

0 or 4 mA

20 mA

P Pulse output

P

100%

Pulses at Q

, full-scale range

100%

Q

Q

Q

F

R

100%

1 flow direction, forward flow in F/R operation

Reverse flow in F/R operation

Full-scale range

S Status output B1 or B2

switch open

switch closed

1 flow direction 2 flow directions, F/R operation

I

I

max

I

100%

Q

R

%

Q

R

%

I

0%

0

P

P

115%

max

P

100%

P= 0 Hz

0

Q

F

%100 Max

Q

F

%100 Max

Q

%

Q

%

R

Max 100

R

Max 100

I

I

max

I

100%

I

0%

0

P

P

115%

max

P

100%

P= 0 Hz