Page 1

© KROHNE 11/2000

Remote Operation

Instructions

HART Communicator 275

Asset Management Solutions (AMS)

IFC090

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 ! D-47058 Duisburg

Tel.: 0203-301 0 ! Fax: 0203-301 389 · e-mail: krohne@krohne.de

1/8

Page 2

Remote Operation Instructions IFC090 HART

1 General Information 3

2 IDs and Revision numbers 4

3 Implementation Peculiarities 4

4 HART Communicator 275 (HC275) 4

4.1 Installation 4

4.2 Operating 5

5 Asset Management Solutions (AMS) 5

5.1 Installation 5

5.2 Operating 5

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 ! D-47058 Duisburg

Tel.: 0203-301 0 ! Fax: 0203-301 389 · e-mail: krohne@krohne.de

2/8

Page 3

Remote Operation Instructions IFC090 HART

1 General Information

The IFC090 is a two-wire transmitter with 4...20mA current output and HART capability. Dependent on device

implementation it is available with active current output (‘Standard + HART’, ‘Modis-3’) or passive current output

(‘Standard + HART’, ‘Modis -1 ’, ‘Mo d is- 2’) .

General Characteristics of the IFC090 HART interface:

•

Multidrop Mode is supported

•

Burst Mode is not supported

Electrical connection: Refer to sections 2.1, 2.2, 2.6 of the “Installation and Operating Instructions Electromagnetic

flowmeters IFC 090 K/F” (KROHNE) – for ‘Standard + HART’ device implementation, and to sections 4-6 of the

“Information about IFC 090i (Modis-devices)” (KROHNE) – for ‘Modis’ instrument implementations.

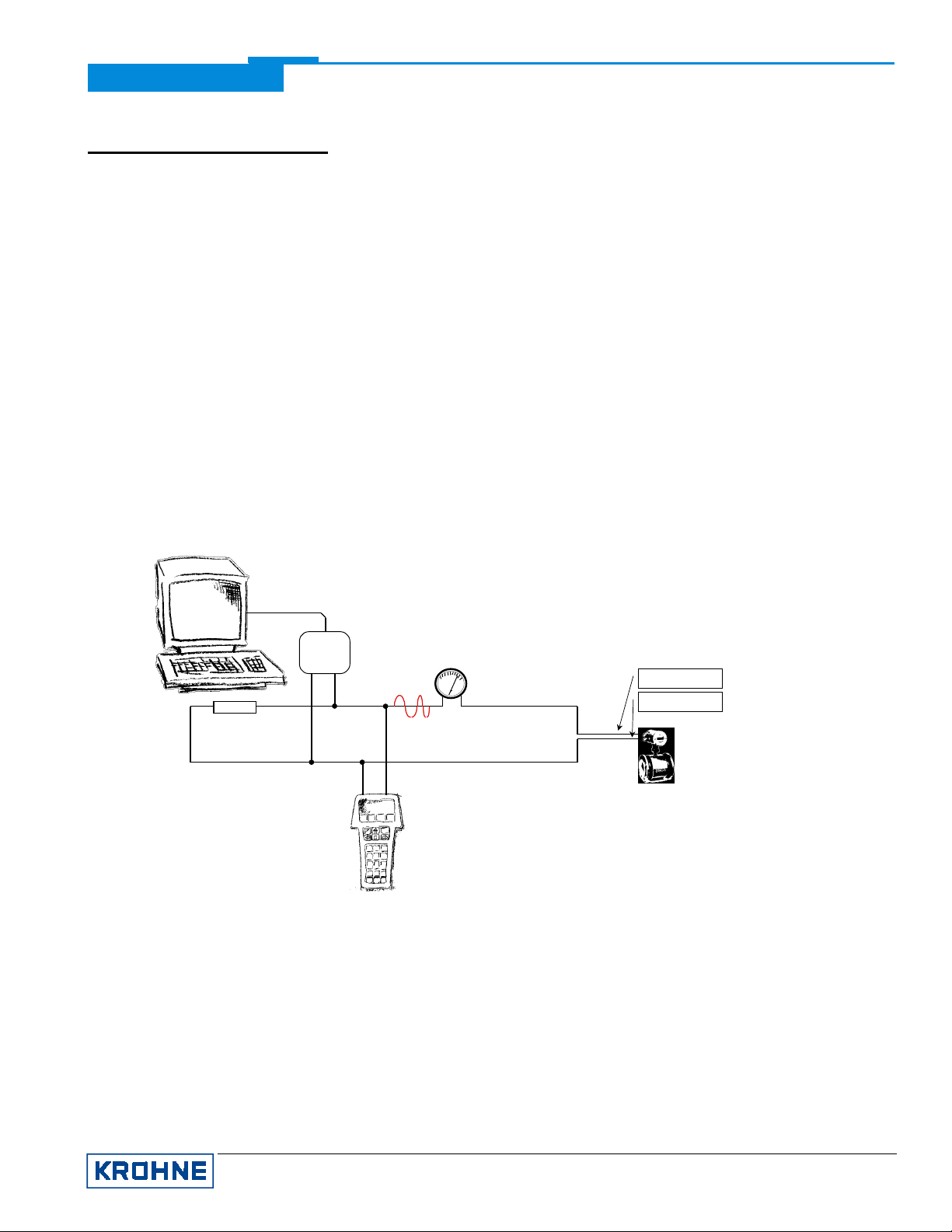

There are two ways of using the HART communication:

a) As a point-to-point connection between the IFC090 and the HART master equipment. The instrument may be

equipped with either active or pass ive curr ent out put ( ‘Modis ’) or be conf igure d with des ir ed current output (‘Standard

+ HART’).

Point-to-Point Analog/Digital Mode

Primary Master

250 Ω

≥≥≥≥

Secondary Master

HART

Modem

HART

Analog

mA

4

20

4...20 mA

Terminal I

Terminal I

IFC090

Addr. 0

(active Current Output)

+

⊥

b) As a multipoint connection (multidrop) with up to 15 devices (IFC090 or other HART equipment) in parallel. The

instruments must be equipped (or configured) with passive current output.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 ! D-47058 Duisburg

Tel.: 0203-301 0 ! Fax: 0203-301 389 · e-mail: krohne@krohne.de

3/8

Page 4

Power

Supply

250 Ω

≥≥≥≥

Primary Master

HART

Modem

Remote Operation Instructions IFC090 HART

Multidrop Mode

HART

Terminal I

4 mA 4 mA

Terminal I

. . .

⊥

Secondary Master Up to 15

IFC090

Addr. > 0

(passive Current Output)

Slaves

. . .

IFC090

Addr. > 0

(passive Current Output)

2 IDs and Revision numbers

The HART Device Descriptions described in this document have the following IDs and revision numbers:

Manufacturer ID: 69 (0x45)

Device Type: 244 (0xF4)

Device Revision: 2

DD Revision: 1

HART Universal Revision: 5

HC 275 OS Revision:

AMS Version:

For information about Transmitter Revisions and related Device Descriptions refer to the KROHNE HART Device

List.

≥

≥

4.9

5.0

3 Implementation Peculiarities

Variables and functions/processes of the

layer. Still a subset of service parameters is transferred via bus (only reading is possible): it applies to variables that

control the limits, availability, etc. of maintenance data.

Service Menu

are not maintained by the instrument HART® application

4 HART Communicator 275 (HC275)

4.1 Installation

The HC275 has to be programmed with the IFC090 HART Device Description. Otherwise the HC275 user will work

with the instrument as a generic one thus loosing opportunity for entire instrument control.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 ! D-47058 Duisburg

Tel.: 0203-301 0 ! Fax: 0203-301 389 · e-mail: krohne@krohne.de

4/8

Page 5

Remote Operation Instructions IFC090 HART

4.2 Operating

Refer to the IFC090 Menu Tree HC275 (Attachment A).

The IFC090 operation via HC275 is made quite close to the manual instrument control via keypad.

The online help of each parameter contains its function number as a reference to the device’s local display and the

“Installation and Operating Instructions”.

Parameter protection via password (Entry Code) is the same as on local display. Please refer to the online help for

valid symbols according to device’s keypad.

While saving configuration to HC275 from connected instrument, some crucial service variables (refer to section 2)

are also stored. Hence in the offline mode their values cannot be changed (and will not be sent to device), but are

shown to HC275 user and control assignments for maintenance data.

As soon as service functionality is not available via HART transmitter, the difference between “standard

configuration” of HC275 and its “full configuration” consists in some read-only parameters (sensor limits, device

modules’ IDs, etc.) that are either transferred to AMS (“full configuration”) or are shown on AMS tabs as empty fields

(“standard configuration”).

5 Asset Management Solutions (AMS)

5.1 Installation

If the IFC090 Device Description is not already installed on the AMS System a so called

AMS

is needed (available on floppy disk from KROHNE or as download from KROHNE Internet page).

For installing the DD with the Installation Kit refer to the

“Adding new Device Types to AMS”

“Install Device Types Manually”

/

“AMS User's Guide”

.

section 3:

Installation Kit IFC090 HART

”Managing HART Devices”

/

5.2 Operating

Refer to the IFC090 Menu Tree AMS (Attachment B).

Due to AMS requirements and conventions the IFC090 operation differs a little from operation with HC275 and via

local keypad.

The online help of each parameter contains its function number as a reference to the device’s local display and the

“Installation and Operating Instructions”.

Parameter protection via password (Entry Code) is the same as on local display. Please refer to the online help for

valid symbols according to device’s keypad.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 ! D-47058 Duisburg

Tel.: 0203-301 0 ! Fax: 0203-301 389 · e-mail: krohne@krohne.de

5/8

Page 6

Remote Operation Instructions IFC090 HART

Attachment A

1 Process

Variables

2 Outputs/

Inputs

3 Operation

4 Test

5 Installation

IFC090 Menu Tree HC275

1 Raw Flow

2 Smoothed Flow

3 Positive Totalizer

4 Negative Totalizer

5 Totalizers’ Sum

1 Full Scale

2 Damping Control

3 Time Constant

4 Cutoff Control

*

Cutoff ‘On’ value

5

*

Cutoff ‘Off’ value

6

7 Display

8 Current Output I

opt

9

Pulse B1

opt

Control/Status B1

9

opt

10

Control/Status B2

*

Auto/Extern. Range

11

*

Trip.Point 1, Low

12

*

Trip.Point 1, High

13

14* Trip.Point 2, Low

15* Trip.Point 2, High

1 Test Range (M)

2 Hardware Info M)

3 Sensor Limits

1 Language

2 Flowmeter

3 Zero trim (M)

4 User Unit

5 Application

6 Hardware

1 Current Ou tput Value

2 PV %Range

opt

Pulse Output Value

3

opt

4

Control/Stat us B1

opt

Control/Stat us B2

5

1 Display Flow

2 Display Counters

3 Display Value P

1 Function I

2 Rev.Range Control

*

Rev.Range Scale

3

4 I 0%

5 I 100%

6 I Max

7 I Error

1 Upper Sensor Limit

2 Sensor Min Span

1 Flow

opt

2

Empty Pipe

1 Flow Units

loc

2

Flow Format

1 Totalizer Units

loc

Totalizer Format

2

1 Pulse Value Units

loc

Pulse Value Fmt

2

1 Function P

2 Pulse Type

3 Pulse Control

*

Pulse Width

4

5 Pulse Value

1 Diameter

2 Full Scale

3 GK Value

4 Field Frequency

5 Line Frequency

6 Flow Direction

1 Text Volume

2 Factor Volume

3 Text Time

4 Factor Time

6 Quit/Reset

1 Hardware

1 Terminal B1

2 Terminal B2

2 Tag

7 Set/Reset

Password (M)

8 HART

Variables

3 Device Id

4 Field Device Rev

5 Software Rev

6 Hardware Rev

7 Message

8 Descriptor

1 Counters

2 Error List (M)

1 Stop/Resume (M)

2 Reset Counters (M)

9 Date

10 Final asmbly num

11 PV Sensor serial num

12 Num response preams

13 Polling address

Designations:

opt

– Optional item, depends on device implementation: availability of Binary Terminals B1/B2 and their assignment, etc.;

N* – Availability of the item depends on the assignment made for some previous item(s): say, cutoff values become

visible/editable only if ‘Cutoff Control’ parameter is set to “Yes”;

loc

– Local HC275 variable, that is not read/written to instrument;

(M) – Method is invoked to retrieve/change data.

KROHNE IFC090 45f40201

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 ! D-47058 Duisburg

Tel.: 0203-301 0 ! Fax: 0203-301 389 · e-mail: krohne@krohne.de

6/8

Page 7

Attachment B

Process Variables

Status

Scan Device

-----------------------------------

Diagnostics and Test

Calibrate

----------------------------------Reset totalizers

Stop/resume totalizers

Set/reset password

----------------------------------Audit Trail

Drawing Notes ...

Help ...

----------------------------------Clear Offline Configuration

Compare Configurations

Configuration Properties

Remote Operation Instructions IFC090 HART

IFC090 Menu Tree AMS

•

Flow

•

Flow, Percent Range

•

Positive Totalizer

•

Negative Totalizer

•

Totalizers’ Sum

•

Current Output

•

Pulse Output

•

Control/Status B1 State

•

Control/Status B2 State

Overview

•

Primary variable out of limits

•

Non-primary variable out of limits

•

Primary variable analog output saturated

•

Primary variable analog output fixed

•

Cold start

•

Configuration changed

•

Field device malfunction

Fatal errors

•

Analog Digital Converter fatal error

•

Device Block fatal error

•

Display module fatal error

Opt

Opt

Opt

I/O module fatal error

•

Fatal error of Current Output

•

Fatal error of Pulse Output

•

Fatal error of Control Input 1

•

Fatal error of Control Input 2

•

Fatal error of Status Output 1

•

Fatal error of Status Output 2

Opt

Opt

Opt

Opt

Opt

Data Errors

Checksum error in Parameter EEPROM

•

Checksum error in General Block

•

Checksum error in Current Block

•

Checksum error in Pulse/Frequen cy Block

•

Checksum error in Control/Indication Block

•

Checksum error in Display Block

•

Checksum error in Communication Block

Warnings

•

Current output overranged

•

Pulse output overranged

•

Counter overflow

•

Power fail detected

•

Error in IMoCom configuration

•

Analog/digital converter overranged

•

Empty pipe

Opt

Designations:

Opt

– Optional variable, depends on device implementation: availability of Binary Terminals B1/B2 and

their assignment, etc.;

– refer to the next page.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 ! D-47058 Duisburg

Tel.: 0203-301 0 ! Fax: 0203-301 389 · e-mail: krohne@krohne.de

Opt

KROHNE IFC090 45f40201

7/8

Page 8

Attachment B

(continued from the previous page)

Remote Operation Instructions IFC090 HART

IFC090 Menu Tree AMS

Process Variables

Status

Scan Device

----------------------------------Diagnostics and Test

Calibrate

----------------------------------Reset totalizers

Stop/resume totalizers

Set/reset password

----------------------------------Audit Trail

Drawing Notes ...

Help ...

----------------------------------Clear Offline Configuration

Compare Configurations

Configuration Properties

Loop test

Test measuring range

----------------------------Hardware information

Quit/view errors

Zero trim

Apply values

------------------------------Calibration Management

Basic Setup

•

Hardware

•

Tag

--------------------------------

•

Upper Sensor Limit

•

Sensor Minimum Span

Rd

Rd

--------------------------------

•

Time Constant

•

Flow Units

--------------------------------

•

Full Scale Value

•

Flow Min

•

Damping Control

--------------------------------

•

Termina l B1

•

Termina l B2

Rd

Opt

Opt

Designations:

Opt

– Optional variable, depends on device implementation:

availability of Binary Terminals B1/B2 and their assignment,

etc.;

Rd

– Read-only variable;

Loc

– Local AMS variable, affects only AMS faceplates and

configuration tabs and is not read/written from/to instrument.

Sensor

•

PV Sensor serial num

•

Diameter

•

GK Value

•

Flow Direction

Rd

--------------------------------

•

Upper Sensor Limit

•

Sensor Minimum Span

--------------------------------

•

Application

•

Field Frequency

•

Line Frequency

--------------------------------

•

ADC firmware Id

•

I/O firmware Id

•

Display firmware Id

Process Input

•

Flow Units

•

Totalizer Units

•

Pulse Value Units

•

Time Constant

Rd

Rd

Rd

--------------------------------

•

Flow format

Rd

•

Totalizers’ format

•

Pulse Value format

Rd

Loc

Loc

Loc

Analog Output

•

Function I

•

Rev.Range Control

•

Rev.Range Scale

•

I 0%

•

I 100%

•

I Max

•

I Error

--------------------------------

•

AO Alarm type

--------------------------------

•

Function P

•

Pulse Type

•

Pulse Control

•

Pulse Width

•

Pulse Value

Rd

Opt

Opt

Opt

Opt

Opt

--------------------------------

•

Cutoff Control

•

Cufoff ‘On’ value

•

Cutoff ‘Off‘ value

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 ! D-47058 Duisburg

Tel.: 0203-301 0 ! Fax: 0203-301 389 · e-mail: krohne@krohne.de

Binary I/O

•

Terminal B1 Function

•

Terminal B2 Function

Opt

Opt

--------------------------------

•

Trip.Point 1, Low

•

Trip.Point 1, High

•

Trip.Point 2, Low

•

Trip.Point 2, High

•

Auto/External Range

HART

•

Tag

•

Device Id

•

Final assembly num

•

Date

•

Descriptor

•

Message

--------------------------------

•

Universal revision

•

Num request preams

•

Num response preams

•

Polling address

Rd

Rd

Rd

Device

•

Model

•

Manufacturer

•

Field device revision

•

Hardware revision

•

Software revision

•

Write protect

--------------------------------

•

Empty Pipe

--------------------------------

•

Termina l B1

•

Termina l B2

--------------------------------

•

Text Volume

•

Text Time

•

Factor Volume

•

Factor Time

Rd

Rd

Rd

Rd

Rd

Opt

Opt

Opt

KROHNE IFC090 45f40201

8/8

Loading...

Loading...