Page 1

GR

Condensed Instructions

IFC 010 C

IFC 010 W

Signal converters for

OPTIFLUX flowmeters

Variable area flowmeters

Vor tex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

©

KROHNE 08/2004 7.02140.35.00

Subject to change without notice.

Applicable to

Software-Versions

● IFC 010 _/ D

Display version

No. 806325.07

and

No. 317551.02

and higher

● IFC 010 _/ B

Basic version

operator-controllable

HHT 010

No. 806323.06

and higher

PLEASE NOTE

These concise instructions do not include the following: device description,

technical data, standards, approvals, etc., nor conditions pertaining to

product liability and warranty.

The operator is, however, obligated to take note of these sections in the

detailed Installation and Operating Instructions.

Page 2

Contents

1

Electrical connection: power supply.............................................................................................................................................3

1.1 Important installation notes ...............................................................................................................................................................3

1.1.1 Location.............................................................................................................................................................................................3

1.1.2 Only for separate systems/signal converters (W versions) ..............................................................................................................3

1.1.3 Cable entries .....................................................................................................................................................................................3

1.2 Connection to power .........................................................................................................................................................................4

1.3 Electrical connection of separate flow sensor (W Versions) ............................................................................................................5

1.3.1 General information on signal cable A and field current cable C ......................................................................................................5

1.3.2 Grounding of flow sensor ..................................................................................................................................................................5

1.3.3 Cable preparation..............................................................................................................................................................................5

1.3.4 Cable lengths (max. distance between signal converter and flow sensor)........................................................................................6

1.3.5 Connection diagrams I and II (power supply, converter and flow sensor)........................................................................................7

2

Electrical connection of outputs...................................................................................................................................................8

2.1 Current output I .................................................................................................................................................................................8

2.2 Pulse output P and status output S ...................................................................................................................................................8

2.3 Connection diagrams for outputs ......................................................................................................................................................9

3

Start-up...........................................................................................................................................................................................10

3.1 Powering up and measurement ......................................................................................................................................................10

3.2 Factory settings............................................................................................................................................................................... 10

4

Operation of the signal converter................................................................................................................................................12

4.1 Operating concept........................................................................................................................................................................... 12

4.2 Table of settable functions ..............................................................................................................................................................13

4.3 Error messages in measuring mode ...............................................................................................................................................16

Return a device for testing or repair to KROHNE................................................................................................................................... 19

2 IFC 010

Page 3

1 Electrical connection: power supply

1.1 Important installation notes

1.1.1 Location Electrical connection in accordance with VDE 0100 ”Regulations governing heavy-current installations with

Do not cross or loop cables inside the terminal compartment.

Use separate cable entries (see below) for power supply, field current cables, signal lines, outputs and inputs.

Protect flowmeters or switchgear cabinets with built-in devices from direct sunlight. Fit a sunshade if necessary.

When installed in cabinets, signal converters must be adequately cooled, e.g. use fans or heat exchangers.

1.1.2 Only for separate

systems/signal converters

(W versions)

Use the supplied KROHNE signal cable A (Type DS), standard length 5 m (16 ft).

1.1.3 Cable entries

line voltages up to 1000 V” or equivalent national regulations.

Do not expose signal converters to intense vibration.

Keep distance between flow sensor and signal converter as short as possible. See Sect. 1.3.4 for maximum

permissible length of signal and field current cables.

Always calibrate flow sensor and signal converter together. Therefore, when installing, ensure primary

constant GKL is identical; see instrument nameplate for the flow sensor. If the GKL is not identical, set the

signal converter to the GKL of the flow sensor. Refer also to Sections 4.

NOTE:

Ensure gaskets are fitted correctly and maintain the following max. torques!

1 Max. torques for M 20,

2

3 Gasket

A) M 20 cable entries

These cable entries may only be used for flexible electrical cables if the relevant electrical regulations so allow,

B) ½" NPT adapters C) ½" PF adapters

For most North American systems the regulations require that electrical conductors be laid in conduits,

1/2" NPT or 1/2" PF adapters: 4 Nm / 2.8 ft × lbf

Max. torques for M 20 only: 3 Nm / 2.1 ft × lbf

1

2

e.g. National Electric Code (NEC).

Do not fix rigid metal conduits (IMC) or flexible plastic conduits to the M 20 cable entries, refer to “Point B, C”

below (1/2” NPT or PF adapters).

particularly for power voltages > 100 V AC.

In such cases, use the 1/2" NPT or 1/2" PF adapters to which flexible plastic conduits can be screwed. Do not

use rigid metal conduits (IMC)!

Lay conduits such that no moisture can penetrate into the converter housing.

Should there be risk of any condensation water forming, inside cross-section of the conduit around the cables at

these adapters with a suitable sealing compound.

3

IFC 010 3

Page 4

1.2 Connection to power

Rated values: The flowmeter housings protecting the electronic equipment from dust and moisture must always

be kept closed. The selected creepage distances and clearances have been sized in conformity with VDE 0110

and IEC 664 for contamination category 2. Supply circuits and output circuits are designed to meet the standards

Safety isolation: the flowmeters (signal converters) must be provided with an isolating facility.

1. AC Version 2. AC Version

230/240 V AC (200 - 260 V AC)

Note information on instrument nameplate: supply voltage and frequency

The PE protective ground conductor for the power supply must be connected to the separate U-clamp

Connection diagrams I and II for electrical connection between flow sensor and signal converter: refer to

3. AC Version DC Version

48 V AC (41 - 53 V AC)

Note information on instrument nameplate: supply voltage and frequency.

For measurement reasons, connect an FE functional ground conductor to the separate U-clamp terminal in the

If connected to a functional extra-low voltage source (24 V AC / DC, 48 V AC), provide for protective separation

Connection diagrams I and II for power supply and electrical connection between flow sensor and signal

Connection to power

Power fuse F1 Power U-clamp terminal

AC: 100 – 240 V L N PE protective conductor

AC: 24 / 48 V 1L~ 0L~ FE

DC: 24 V L+ L– FE

of overvoltage classes III and II, respectively.

200 V AC (170 - 220 V AC)

switchable to

115/120 V AC (100 - 130 V AC)

terminal in the terminal compartment of the signal converter. For exceptions (compact systems), refer to

installation instructions for the flow sensor.

Section 1.3.5.

switchable to

24 V AC (20 - 26 V AC)

terminal compartment of the signal converter.

(PELV) in conformity with VDE 0100 / VDE 0106 or IEC 364 / IEC 536, or equivalent national regulations.

converter: refer to Section 1.3.5.

for

internal

use only

switchable to

100 V AC (85 - 110 V AC)

24 V DC (11-32 V DC)

functional ground

}

Warning:

Instrument must be properly grounded to avoid electrical shock.

4 IFC 010

Page 5

1.3 Electrical connection of

separate flow sensor

(W Versions)

1.3.1 General information on

signal cable A and field current

cable C

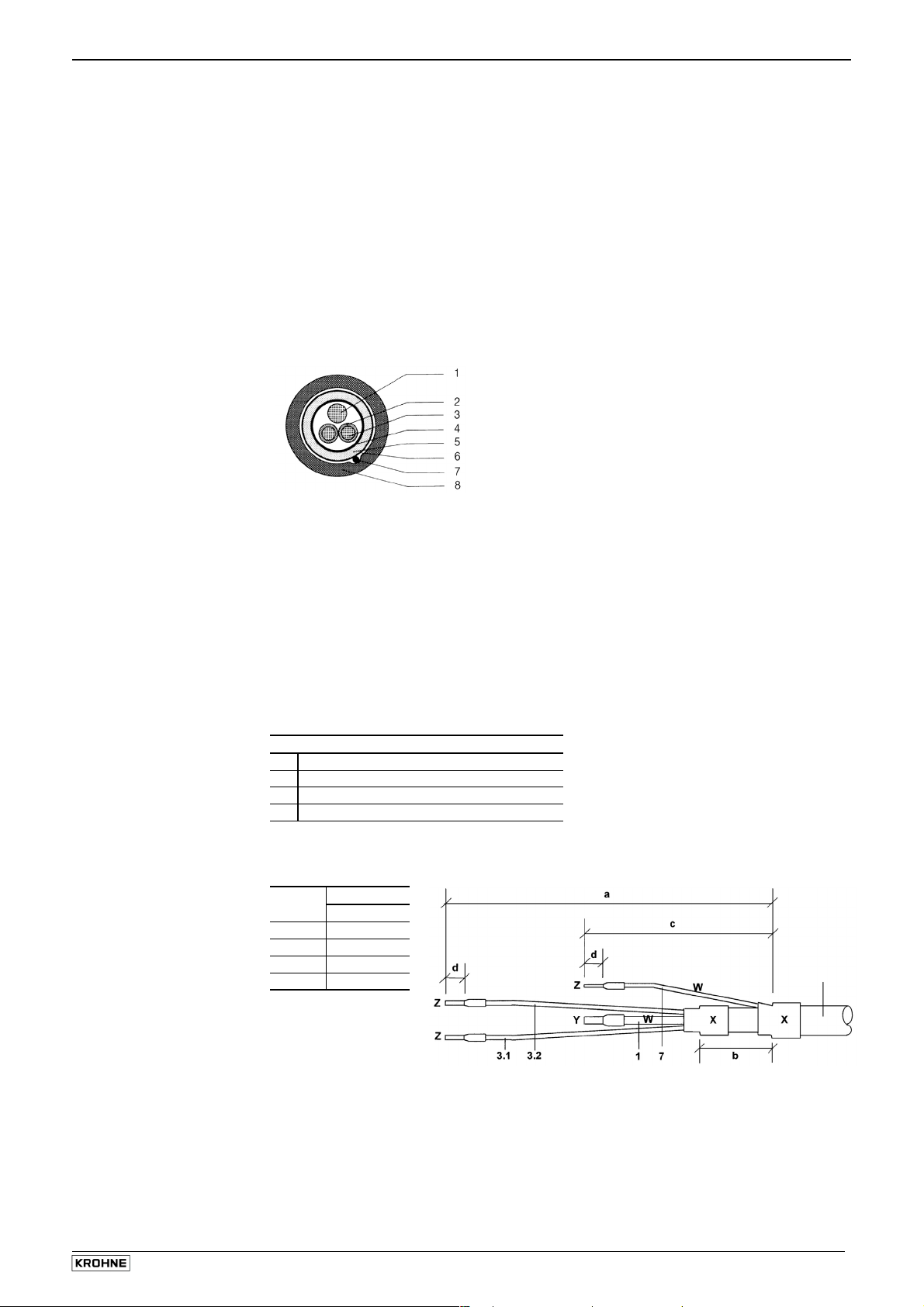

Signal cable to be permanently laid.

Signal cable Type DS, with double shielding

1 Stranded drain wire, 1st shield, 1.5 mm

2 Insulation

3 Conductor 0.5 mm

4 Special foil, 1st shield

5 Inner sheath

6 Mu-metal foil, 2nd shield

7 Stranded drain wire, 2nd shield, 0.5 mm

Field current cable C with single shielding

Cross-section is dependent on required length of cable, see Table in Sect. 1.3.4.

1.3.2 Grounding of flow sensor All flowmeters must be properly grounded.

1.3.3 Cable preparation Customer-supplied materials

W Insulation tubing (PVC), Ø 2.0-2.5 mm (dia. 1")

X Heat-shrinkable tubing or cable sleeve

Y Wire end sleeve to DIN 41 228: E 1.5-8

Z Wire end sleeve to DIN 41 228: E 0.5-8

Preparation for connection to flow sensor

Length Ferrule

mm inch

a 55 2.17

b 10 0.39

c 15 0.59

d 8 0.30

Use of the KROHNE shielded signal cable type DS with foil screen and magnetic shield will ensure proper

operation of the equipment.

Connect shields via stranded drain wires.

Underwater and underground installation possible.

Insulating material is flame-retardant to IEC IEC 332.1 / VDE 0742.

Signal cables are low in halogen, unplasticized, and stay flexible at low temperatures.

2

or AWG14

2

or AWG 20 (3.1 red / 3.2 white)

2

or AWG 20

8 Outer sheath

The grounding conductor should not transmit any interference voltages.

Do not ground any other electrical device together with this conductor.

The flow sensor is connected to ground by means of an FE functional ground conductor.

Special information on grounding various flow sensors is contained in the separate installation instructions for

flow sensors.

These instructions also contain detailed descriptions on how to use grounding rings and how to install flow

sensors in metal or plastic pipes or internally coated pipelines.

DS signal cable

bending radius

≥ 50 mm (≥ 2")

IFC 010 5

Page 6

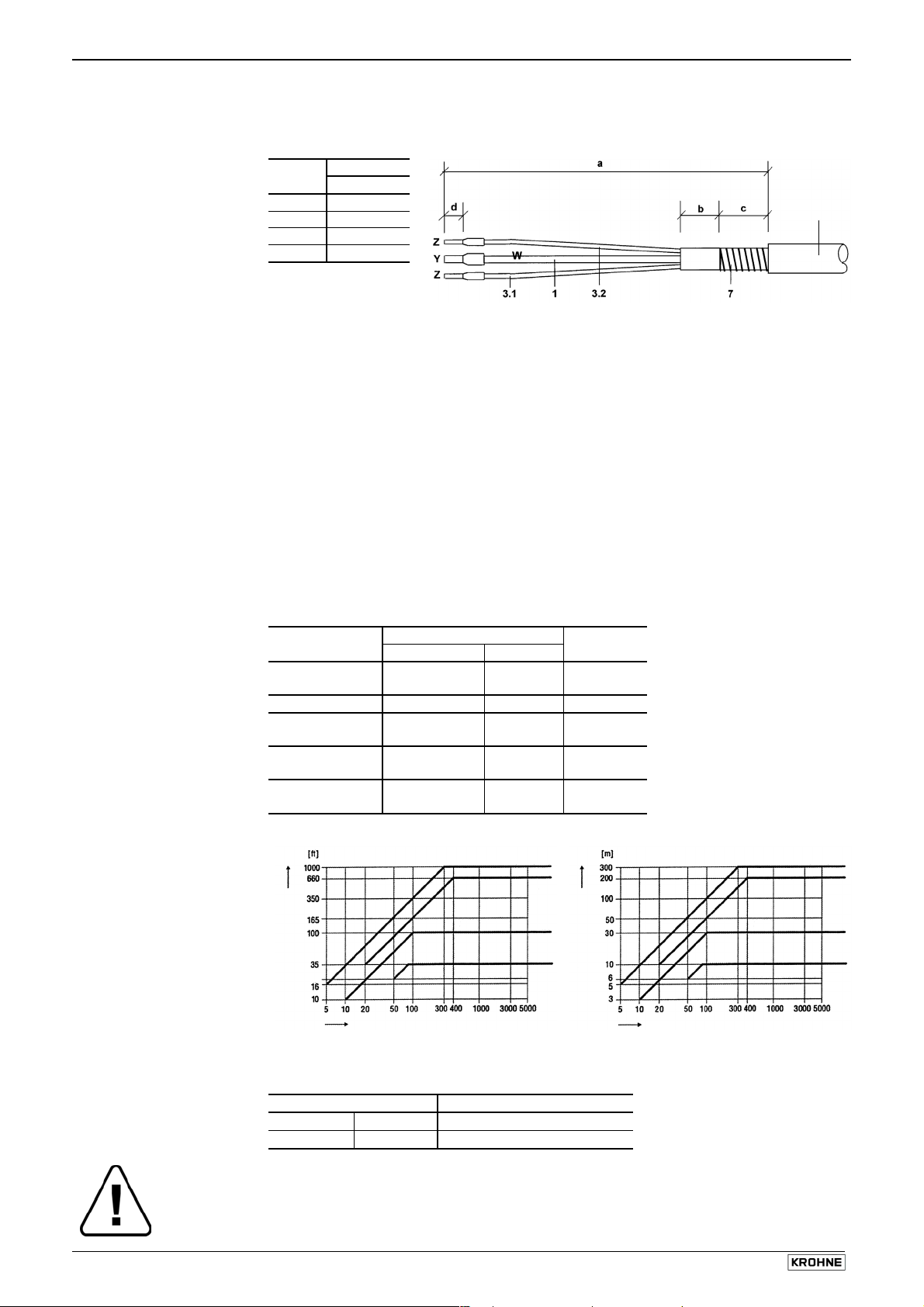

Preparation for connection to IFC 010 W signal converter

Length Ferrule

mm inch

a 90 3.60

b 8 0.30

c 25 1.00

d 8 0.30

External shielding of DS signal cable

Wrap stranded drain wire (7) around the metal foil and clamp under the shield terminal in the signal converter

1.3.4 Cable lengths (max.

distance between signal

terminal box.

Abbreviations and explanatory notes

used in the following tables, diagrams and connection diagrams

converter and flow sensor)

C Field current cable C, with single shielding, type and length see Table

2

D High-temperature silicone cable, 3 × 1.5 mm

(14 AWG) Cu, with single shielding, max. length 5 m (16 ft)

E High-temperature silicone cable, 2 × 1.5 mm2 (14 AWG) Cu, max. length 5 m (16 ft)

L Cable length

CB Intermediate connection box required in connection with cables D and E for flow sensors

OPTIFLUX 4000 F, 5000 F and 6000 F in cases where process temperatures exceed 150 °C (302 °F)

Recommended length of signal cable

for magnetic field frequency ≤ 1/6 × power frequency

Flow sensor Meter size Signal cable

DN mm inch

OPTIFLUX 1000 F 10 – 15 3/8 – 1/2 DS A4

25 – 150 1 – 6 DS A3

AQUAFLUX F 10 – 1000 3/8 – 40 DS A1

OPTIFLUX 4000 F 10 – 150 3/8 – 6 DS A2

200 – 1000 8 – 40 DS A1

OPTIFLUX 5000 F 4.5 – 15 1/8 – 1/2 DS A4

25 – 100 1 – 4 DS A2

OPTIFLUX 6000 F 10 – 15 1/8 – 1/2 DS A4

25 – 80 1 – 3 DS A4

Cable

length

DS1

Cable

length

DS signal cable

bending radius

≥ 50 mm (≥ 2")

DS1

DS2

DS3

DS4

Electrical conductivity of process liquid

DS2

DS3

DS4

Electrical conductivity of process liquid

Field current cable C: max. length and min. cross-section

Length Type of cable, single shielding

0 - 150 m 5 - 500 ft

150 - 300 m 500 - 1000 ft

2 × 0.75 mm

2 × 1.50 mm

2

Cu / 2 × 18 AWG

2

Cu / 2 × 14 AWG

Warning:

Instrument must be properly grounded to avoid electrical shock.

6 IFC 010

Page 7

1.3.5 Connection diagrams I

and II (power supply, converter

and flow sensor)

Electrical connection to VDE 0100 “Regulations governing heavy-current installations with line voltages up to

Power supply 24 V AC / DC: functional extra-low voltage with protective separation in conformity with

IFC 010 W IFC 010 W

The figures in brackets indicate the stranded drain wires for the shields, as shown in cross-sectional drawing of

signal cable.

1000 V” or equivalent national regulations.

VDE 0100, Part 410 or equivalent national regulations.

FE = functional ground conductor

I Process temperature < 150°C / 302°F

II Process temperature > 150°C / 302°F

DS

DS

CB

Flow sensors

Flow sensors

IFC 010 7

Page 8

Connection of shields to the IFC 010

1 DS Signal cable

2 Shield terminal for shielded signal cable

3 Field power cable

4 Shield terminal for shielded field power cable

5 Housing wall, signal converter

6 Cable entries

2 Electrical connection

of outputs

2.1 Current output I

U

I = 3 mA when operated with receiver instruments at the current output

2.2 Pulse output P and status

output S

S status output

P pulse output

Active mode: The current output is the internal voltage source, connection of electronic totalizers

Passive mode: External DC or AC voltage source required, connection of electronic or

Digital pulse division, interpulse period is non-uniform. Therefore, if frequency meters or cycle counters are

10.000

• The current output is galvanically isolated from all input and output circuits.

• Typical current output

approx. 15 V DC positive

voltage of current output

current sink

chassis ground, current output

• The current output can also be used as an internal voltage source for the outputs.

= 15 V DC I = 23 mA when operated without receiver instruments at the current output

int

• Connection diagrams, see Sect. 2.3.

• The pulse and status outputs are galvanically isolated from the current output and all input circuits.

• Typical pulse and status outputs B1

P ⊥ chassis ground

• The pulse and status outputs can be operated in the active or passive mode.

electromechanical totalizers

connected, allow for minimum counting interval:

gate time, counter ≤

P

100%

[ Hz ]

8 IFC 010

Page 9

2.3 Connection diagrams for

outputs

DC voltage, external power source (U

External voltage source (U

), DC or AC voltage, connection polarity arbitrary

ext

Current output Current output

I

active

I

Passive mode

U

ext

I = 0/4 - 20 mA

I = 0/4 - 20 mA U

15...20 V DC 20...32 V DC

ext

Ri ≤ 500 Ω Ri 0...500 Ω 250...750 Ω

Pulse output P

for electronic or

Pulse output P

passive

(and current output Iactive) for electronic (EC) totalizers with and

electromechanical without current output I

totalizers

U

ext

U

I

(incl. status output) I

≤ 32 V DC/ ≤ 24 V AC U

ext

≤ 150 mA Operation with current output:

max

≤ 15 V DC from current output

int

≤ 3 mA

max

Operation without current output:

I

≤ 23 mA

max

15 V

R ≤

Status output S

Status output S

passive

with and without current output I

U

from current output

I

Operation with current output

Load

I

U

I

≤ 32 V DC/ ≤ 24 V AC

ext

≤ 150 mA

max

(incl. status output)

), note connection polarity

ext

Active mode

passive

The current output supplies the

power for operation of the

outputs.

External power source

required for operation of the

active

outputs.

I

max

active

≤ 15 V DC

int

≤ 3 mA

max

Load

≤ 23 mA

max

Operation with current output

IFC 010 9

Page 10

3 Start-up

3.1 Powering up and

measurement

Power the unit, and the flowmeter will immediately start process flow measurement.

Basic version, signal converter IFC 010 _ / B

A light emitting diode (LED) under the cover of the electronic section shows the measurement status.

LED flashing . . .

green: measurement correct, everything all right.

green / red: momentary overdriving of outputs

red: fatal error, parameter error or hardware fault,

Display version, signal converter IFC 010 _ / D

When powered, the display shows in succession: START UP and READY.

3.2 Factory settings All operating data are factory set according to your order specifications.

If you have not made any particular specifications at the time of ordering, the instruments will be delivered with

To facilitate easy and rapid initial start-up, current output and pulse output are set to process flow measurement

This factory setting for the current and pulse outputs may possibly lead to measuring errors, particularly in the

For example, if pumps are switched off and a “backflow” occurs which is not within the range of the low-flow

To avoid faulty measurements, it may therefore, be necessary to change the factory settings of some or all of the

– low-flow cutoff, Fct. 1.03

– current output I, Fct. 1.05

– pulse output P, Fct. 1.06

– display (option), Fct. 1.04

The flowmeter is delivered ready for use. All operating data have been factory set in accordance with your

specifications.

This is followed by display of the current flow rate and/or the current totalizer count on either a continuous or

alternating basis, depending on the setting under Fct. 1.04.

the standard parameters and functions listed in the Table below.

in “2 flow directions”, so that the current flowrate is displayed and the volumetric flow counted independent of the

flow direction. On instruments equipped with a display, measured values may possibly be shown with a “ – ” sign.

case of volume flow counting:

cutoff, or if separate displays and counts are required for both flow directions.

following functions:

and/or A/D converter.

please consult factory.

10 IFC 010

Page 11

Standard factory settings

Function Setting

1.01 Full-scale range Q

1.02 Time constant 3 s, for I, S and display

1.03 Low-flow ON: 1 %

cutoff OFF: 2 %

1.04 Display (option)

flow rate m3/hr or US Gal/min

Totalizer(s) m3 or US Gal

1.05 Current output I

function 2 directions

range 4 – 20 mA

error message 22 mA

1.06 Pulse output P

function 2 directions

pulse value 1 pulse/s

pulse width 50 ms

1.07 Status output P Flow direction

3.01 Language for display only English

3.02 Flowmeter

diameter see nameplate

flow direction (see arrow on flow sensor) + direction

3.04 Entry code no

3.05 User unit Liter/hr or US Mgal/day

see nameplate

100%

IFC 010 11

Page 12

Part B IFC 010 _ / D Signal converter

4 Operation of the signal

converter

4.1 Operating concept

1 3 6. 4 9

m 3 / h r

Measuring mode

CodE 1

- - - - - - - - - - - - -

When this display appears, press following keys:

→ → → ↵ ↵ ↵ ↑ ↑ ↑

Menu column

3.00 INSTALL.

2.00 TEST

Function column

3.05 USER UNIT

3.04 ENTRY CODE

3.03 ZERO SET

3.02 FLOWMETER

3.01 LANGUAGE

2.02 HARDW. INFO

2.01 TEST Q

1.07 IND. OUTP. S

1.06

PULS. OUTP. P

1.05 CUR. OUTP. I

1.04 DISPLAY

Data column

1.03 L.F. CUTOFF

1.02 TIMECONST.

1.00 OPERATION

Direction of

movement

12 IFC 010

1.01 FULL SCALE

See

Handbook

Sect. 4.4

Page 13

4.2 Table of settable functions Function Text Description and settings

1.00 OPERATION Operations menu

1.01 FULL SCALE Full-scale range for flowrate Q

Select unit

• m3/hr • Liter/Sec • US.Gal/min

• user unit, factory set is “Liter/hr” or “US MGal/day” (see Fct. 3.05)

Press → key to transfer to number setting.

Setting ranges

The ranges are dependent on the meter size (DN) and the flow

velocity (v): Q

Nom. dia./meter size v

π

= DN2 x v

min

4

min

(1 ft/s) (40 ft/s)

• DN 2.5–1000 / 1/10”–40”: 0.0053 – 33 900 m3/hr

0.0237 – 152 000 US.Gal/min

→ VALUE P

Pulse value (Fct. 1.06 “VALUE P”) has been changed.

1.02 TIMECONST. Time constant

Select: • ALL

(applies to display and all outputs)

• ONLY I+S

(only display, current and status outputs)

Range: • 0.2 – 99.9 Sec

1.03 L.F.CUTOFF Low-flow cutoff (SMU)

• OFF (fixed trip points: ON = 0.1% / OFF = 0.2%

for 100 and 1000 Hz, see Fct. 1.06, 1% or 2%)

• PERCENT (variable values) ON OFF

1 – 19% 2 – 20%

Note:

Cutoff “off” value must be greater than cutoff “on” value.

Press ↵ key to return to Fct. 1.03 L.F. CUTOFF.

1.04 DISPLAY Display functions

→ DISP.FLOW

Select flow display

• NO DISP.

• user unit, factory set is “Liter/hr” or “US MGal/day (see Fct. 3.05)

• m3/hr

• PERCENT

• Liter/Sec

• BARGRAPH (value and bargraph display in %)

• US.Gal/min

→ DISP.TOTAL.

Select totalizer display

• NO DISP. (totalizer switched on but not displayed)

• OFF (totalizer switched off)

• +TOTAL. • –TOTAL. • +/–TOTAL. • SUM (Σ)

• ALL (displaysingle counts or all)

• m3 • Liter • US.Gal

• user unit, factory set is “Liter” or “US MGal” (see Fct. 3.05).

Press → key to transfer to format setting.

Format setting

• Auto (exponent notation)

• # . ####### • ##### . ###

• ## . ###### • ###### . ##

• ### . ##### • ####### . #

• #### . #### • ########

→ DISP.MSG.

Additional messages required in measuring mode?

• NO

• YES (cyclic change with displays of measured values)

Press ↵ key to return to Fct. 1.04 DISPLAY.

100%

Q

min

= 0,3 m/s v

π

= DN2 x v

max

4

= 12 m/s

max

max

IFC 010 13

Page 14

Function Text Description and settings

1.05 CURRENT I Current output I

• OFF (switched off)

• 1 DIR. (1 flow direction)

• 2 DIR. (forward/reverse flow, F/R flow measurement)

• 0 - 20 mA

• 4 - 20 mA (fixed ranges)

• 0 mA

• 3.6 mA (only with range 4-20 mA)

• 22 mA

1.06 PULS.OUTP. P Pulse output P

• OFF (switched off)

• 1 DIR. (1 flow direction)

• 2 DIR. (forward/reverse flow, F/R measurement)

• 100 Hz

• PULSE/VOL. (pulses per unit volume, flow rate)

• 1000 Hz

• PULSE/TIME (pulses per unit time for 100% flowrate)

• 50 mSec • 100 mSec • 200 mSec

• 500 mSec • 1 Sec

(appears only when “PULSE/VOL.“ has been set under “SELECT P“)

• xxxx PulS/m3 • xxxx PulS/Liter • xxxx PulS/US.Gal

• xxxx PulS/ user unit, factory set is “Liter“ or “US MGal“ (see Fct. 3.05).

(appears only when „PULSE/TIME“ has been set under „SELECT P“).

• xxxx PulS/Sec (=Hz) • xxxx PulS/min • xxxx PulS/hr

• xxxx PulS/user unit, factory set is “hr” or “day” (see Fct. 3.05)

1.07 IND. OUTP. S Status output S

• ALL ERROR • FATAL ERROR • OFF • ON

• F/R INDIC.

(F/R indication for forward/reverse measurement)

• TRIP. POINT Setting range: 002 - 115 PERCENT

• EMPTY PIPE (appears only when this option is installed)

2.00 TEST Test menu

2.01 TEST Q Test measuring range Q

Precautionary query

• SURE NO

• SURE YES

-110 / -100 / -50 / -10 / 0 / +10 / +50 / +100 / +110 PCT.

2.02 HARDW. INFO Hardware information and error status

Before consulting factory, please note down all 6 codes.

Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y

Y Y Y Y Y Y Y Y Y Y

→ FUNCT. I

→ RANGE I

→ I ERROR

→ FUNCTION P

→ SELECT P

→ PULSWIDTH

→ VALUE P

→ VALUE P

→ MODUL ADC

→ MODUL IO

→ MODUL DISP.

Select function for current output I

Select measuring range

Select error value

Select function for pulse output P

Select pulse type

Select pulse width

Set pulse value per unit volume

Set pulse value per unit time

Press ↵ key to return to Fct. 2.01 “TEST Q”.

Press ↵ key, then use ↑ or ↓ key to select value:

X . X X X X X . X X

X . X X X X X . X X

X . X X X X X . X X

14 IFC 010

Page 15

Function Text Description and settings

3.00 INSTALL. Installation menu

3.01 LANGUAGE Select language for display texts

• GB / USA (English) • F (French)

• D (German) • others on request

3.02 FLOWMETER Set data for flow sensor

→ DIAMETER

• DN 10 - 1000 mm or 3/8 - 40 inch

→ FULL SCALE

To set, refer to Fct. 1.01 “FULL SCALE” above.

→ VALUE P

→ GKL VALUE

see flow sensor typeplate.

Range: • 1.0000 - 9.9999

→ FIELD FREQ.

Values: 1/6 or 1/18 of power frequency, see typeplate.

→ LINE FREQ.

Please note:

Values: 50 Hz and 60 Hz

→ FLOW DIR.

Set according to direction of arrow on flow meter:

• + DIR. • – DIR.

3.03 ZERO SET Zero calibration

Note:

Precautionary query

• CALIB. NO

• CALIB. YES

• STORE NO

• STORE YES

3.04 ENTRY CODE Entry code required to enter setting mode?

3.05 USER UNIT Set any required unit for flowrate and counting

→ TEXT VOL.

Factory-set: “Liter” or “MGal”.

Characters assignable to each place:

• A-Z, a-z, 0-9, or “ – ” (= blank character).

→ FACT. VOL.

Factory set “1.00000” for “Liter” or

“2.64172E-4” for “US MGal”

(exponent notation, here: 1 x 103 or 2.64172 x 10-4).

Factor FM = volume per 1m3.

Setting range • 1.00000 E-9 to 9.99999 E+9 (= 10-9 to 10+9)

→ TEXT TIME

Factory-set: “hr” or “day”:

Characters assignable to each place:

• A-Z, a-z, 0-9, or “ – ” (= blank character).

→ FACT. TIME

Factory-set: “3.60000 E+3” for “hour” or

“8.64000 E+4” for “day”

(exponent notation, here: 3.6 x 103 or 8.64 x 10-4).

Set factor FT in seconds.

Setting range

• 1.00000 E-9 to 9.99999 E+9 (= 10-9 to 10+9)

3.06 APPLICAT. Set overload point for A/D converter

→ EMPTY PIPE

(appears only when this option is installed)

• YES • NO

Select size from meter size table

Full-scale range for flow Q

100%

Pulse value (Fct. 1.06 “VALUE P”) has been changed.

Set primary constant GKL

Magnetic field frequency

Normal line frequency in your country

This function is only provided for units with DC power supply to

suppress line-frequency interference.

Define flow direction (in F/R mode: forward flow).

Carry out only at “0” flow and with completely filled measuring tube!

• NO (= entry with → only)

• YES (= entry with → and Code 1: → → → ↵ ↵ ↵ ↑ ↑ ↑)

Set text for required flowrate unit (max. 5 characters)

Set conversion factor (FM) for volume

Set text for required time unit (max. 3 characters)

Set conversion factor (FT) for time

Switch on “empty tube” identifier option?

IFC 010 15

Page 16

4.3 Error messages in

measuring mode

Error messages Description of error Error clearance

LINE INT. Power failure

CUR. OUTP. I Current output overranged. Check and if necessary correct

PULSOUTP. P Pulse output overranged.

ADC Analog / digital

FATAL. ERROR Fatal error, all outputs set to “min. values” Please consult factory.

TOTALIZER Totalizer has been reset Cancel error message in

EMPTY PIPE Pipe has run dry. Message appears only

The following list gives all errors that can occur during process flow measurement.

Errors shown in display when “YES” set in Fct. 1.04 DISPLAY, subfunction “DISP. MSG.”

Cancel error in RESET/QUIT. Menu

Note: no counting during power failure

Note: totalizer deviation possible.

converter overranged

when the “empty pipe identifier” option

is installed and the function is activated

under Fct. 3.06 APPLICAT., submenu

“EMPTY PIPE”.

Reset totalizer if necessary.

instrument parameters. After elimination

of cause, error message deleted

automatically.

Check and if necessary correct

instrument parameters. After elimination

of cause, error message deletes

automatically.

Error message deletes automatically after

elimination of cause.

RESET/QUIT menu.

Fill pipe.

16 IFC 010

Page 17

Notes

IFC 010 17

Page 18

Notes

18 IFC 010

Page 19

Return a device for testing or repair to KROHNE

This device has been carefully manufactured and tested. If installed and

operated in accordance with these operating instructions, it will rarely

present any problems. Should you nevertheless need to return a device for

inspection or repair, please pay strict attention to the following points:

Due to statutory regulations on environmental protection and safeguarding

the health and safety of our personnel, KROHNE may only handle, test and

repair returned devices that have been in contact with products without risk

to personnel and environment.

This means that KROHNE can only service this device if it is accompanied

by the following certificate confirming that the device is safe to handle.

S P E C I M E N certificate

Company: ………………………………………………………………………... Address: ………………………………………………………………………………

Department: ……………………………………………………………………... Name: …………………………………………………………………………………

Tel. No.: ………………………………………………………………………….. Fax No.: ………………………………………………………………………………

The enclosed device

Type: …………………………………………………………………………………………………………………………………………………………………………….

KROHNE Order No. or Series No.: ………………………………………………………………………………………………………………………………………….

has been operated with the following liquid: ………………………………………………………………………………………………………………………………..

Because this liquid is water-hazardous toxic caustic flammable

we have checked that all cavities in the instrument are free from such substances /

flushed out and neutralized all cavities in the device

We confirm that there is no risk to humans or environment through any residual liquid contained in this device.

Date: …………………………………… Signature: ………………………………………………………………………………

Company stamp:

If the device has been operated with toxic, caustic, flammable or waterendangering products, you are kindly requested:

• to check and ensure, if necessary by rinsing or neutralizing, that all

cavities are free from such dangerous substances,

• to enclose a certificate with the device confirming that is safe to handle

and stating the product used.

We cannot service this device unless accompanied by such a certificate.

IFC 010 19

Loading...

Loading...