KROHNE FMCW80G74LA, FMCW80G74TA User Manual

Handbook

Handbook

OPTIWAVE 7500 C

OPTIWAVE 7500 C

OPTIWAVE 7500 COPTIWAVE 7500 C

Radar (FMCW) Level Transmitter for high-precision

storage of liquids

HandbookHandbook

© KROHNE 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

:

IMPRINT

:::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2016 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

CONTENTS

1 Safety instructions 7

1.1 Software history ............................................................................................................... 7

1.2 Intended use ..................................................................................................................... 7

1.3 Certification ...................................................................................................................... 8

1.4 Electromagnetic compatibility ......................................................................................... 8

1.5 Radio approvals ................................................................................................................ 9

1.5.1 European Union (EU)............................................................................................................... 9

1.5.2 U.S.A...................................................................................................................................... 11

1.5.3 Canada................................................................................................................................... 13

1.6 Safety instructions from the manufacturer................................................................... 15

1.6.1 Copyright and data protection .............................................................................................. 15

1.6.2 Disclaimer ............................................................................................................................. 15

1.6.3 Product liability and warranty .............................................................................................. 16

1.6.4 Information concerning the documentation......................................................................... 16

1.6.5 Warnings and symbols used................................................................................................. 17

1.7 Safety instructions for the operator............................................................................... 17

2 Device description 18

2.1 Scope of delivery............................................................................................................. 18

2.2 Device description .......................................................................................................... 19

2.3 Visual Check ................................................................................................................... 20

2.4 Nameplates .................................................................................................................... 21

2.4.1 Nameplate (examples).......................................................................................................... 21

3 Installation 22

3.1 General notes on installation ......................................................................................... 22

3.2 Storage ........................................................................................................................... 22

3.3 Transport ........................................................................................................................ 22

3.4 Pre-installation requirements ....................................................................................... 22

3.5 Pressure and temperature ranges ................................................................................ 23

3.6 Recommended mounting position ................................................................................. 24

3.6.1 General notes........................................................................................................................ 24

3.6.2 Tanks with conical bottoms .................................................................................................. 24

3.7 Mounting restrictions ..................................................................................................... 24

3.7.1 General data for TLPR devices ............................................................................................. 25

3.7.2 Obstacles in the tank ............................................................................................................ 25

3.7.3 Process connections............................................................................................................. 26

3.8 How to turn or remove the display module (option) ...................................................... 27

3.9 How to turn or remove the signal converter.................................................................. 28

3.10 Weather protection....................................................................................................... 29

3.10.1 How to attach the weather protection to the device........................................................... 29

3.10.2 How to open the weather protection .................................................................................. 31

4 Electrical connections 32

4.1 Safety instructions.......................................................................................................... 32

4.2 Electrical installation: 2-wire, loop-powered ................................................................ 32

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

3

CONTENTS

OPTIWAVE 7500 C

4.3 Electrical connection for current output ....................................................................... 36

4.3.1 Non-Ex devices ..................................................................................................................... 36

4.3.2 Devices for hazardous locations........................................................................................... 36

4.4 Protection category ........................................................................................................36

4.5 Networks ........................................................................................................................ 37

4.5.1 General information.............................................................................................................. 37

4.5.2 Point-to-point connection..................................................................................................... 37

4.5.3 Multi-drop networks ............................................................................................................. 38

5 Start-up 39

5.1 Start-up checklist........................................................................................................... 39

5.2 How to start the device................................................................................................... 39

5.3 Operating concept ..........................................................................................................39

5.4 Digital display screen .....................................................................................................40

5.4.1 Display screen layout............................................................................................................ 40

5.4.2 Keypad buttons ..................................................................................................................... 41

5.5 Remote communication with PACTware™ .................................................................... 43

5.6 Remote communication with the AMS™ Device Manager............................................. 44

6 Operation 45

6.1 User modes .................................................................................................................... 45

6.2 Normal mode.................................................................................................................. 45

6.3 Program mode................................................................................................................ 47

6.3.1 General notes........................................................................................................................ 47

6.3.2 Protection of the device settings (security levels) ............................................................... 47

6.3.3 How to get access to the Quick Setup menu ........................................................................ 49

6.3.4 Keypad functions................................................................................................................... 50

6.3.5 How to save settings changed in program mode ................................................................. 53

6.3.6 Menu overview ...................................................................................................................... 54

6.3.7 Function description ............................................................................................................. 60

6.4 Further information on device configuration in program mode ................................... 79

6.4.1 Standard Setup ..................................................................................................................... 79

6.4.2 Empty spectrum recording................................................................................................... 82

6.4.3 HART® network configuration ............................................................................................. 84

6.4.4 Distance measurement ........................................................................................................ 85

6.4.5 Level measurement .............................................................................................................. 85

6.4.6 How to configure the device to measure volume or mass................................................... 86

6.4.7 How to make a filter to remove radar signal interference .................................................. 87

6.4.8 ............................................................................................................................................... 87

6.5 Status messages and diagnostic data............................................................................ 88

7 Service 94

7.1 Periodic maintenance..................................................................................................... 94

7.1.1 General notes........................................................................................................................ 94

7.1.2 Maintainance of the O-rings for the housing covers ............................................................ 94

7.1.3 How to clean the top surface of the device........................................................................... 95

7.1.4 How to clean horn antennas under process conditions....................................................... 95

7.2 Service warranty............................................................................................................. 95

4

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

CONTENTS

7.3 Spare parts availability...................................................................................................95

7.4 Availability of services .................................................................................................... 95

7.5 Returning the device to the manufacturer..................................................................... 96

7.5.1 General information.............................................................................................................. 96

7.5.2 Form (for copying) to accompany a returned device............................................................ 97

7.6 Disposal .......................................................................................................................... 97

8 Technical data 98

8.1 Measuring principle........................................................................................................98

8.2 Technical data................................................................................................................. 99

8.3 Minimum power supply voltage ................................................................................... 103

8.4 Guidelines for maximum operating pressure.............................................................. 104

8.5 Dimensions and weights .............................................................................................. 105

9 Description of HART interface 107

9.1 General description ...................................................................................................... 107

9.2 Software history ...........................................................................................................107

9.3 Connection variants...................................................................................................... 108

9.3.1 Point-to-Point connection – analogue / digital mode ........................................................ 108

9.3.2 Multi-Drop connection (2-wire connection) ....................................................................... 108

9.4 HART® device variables............................................................................................... 108

9.5 Field Communicator 475 (FC 475)................................................................................ 109

9.5.1 Installation .......................................................................................................................... 109

9.5.2 Operation............................................................................................................................. 109

9.6 Asset Management Solutions (AMS®) ......................................................................... 109

9.6.1 Installation .......................................................................................................................... 109

9.6.2 Operation............................................................................................................................. 110

9.6.3 Parameter for the basic configuration ............................................................................... 110

9.7 Field Device Tool / Device Type Manager (FDT / DTM)................................................ 110

9.7.1 Installation .......................................................................................................................... 110

9.7.2 Operation............................................................................................................................. 110

9.8 Process Device Manager (PDM)................................................................................... 110

9.8.1 Installation .......................................................................................................................... 110

9.8.2 Operation............................................................................................................................. 111

9.9 HART® menu tree for AMS .......................................................................................... 111

9.9.1 Overview AMS menu tree (positions in menu tree)............................................................ 111

9.9.2 AMS menu tree (details for settings).................................................................................. 111

9.10 HART® menu tree for PDM........................................................................................ 111

9.10.1 Overview PDM menu tree (positions in menu tree).......................................................... 111

9.10.2 PDM menu tree (details for settings) ............................................................................... 112

10 Appendix 116

10.1 Order code .................................................................................................................. 116

10.2 Spare parts ................................................................................................................. 116

10.3 Accessories................................................................................................................. 120

10.4 Glossary ...................................................................................................................... 121

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

5

CONTENTS

OPTIWAVE 7500 C

11 Notes 123

6

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

1.1 Software history

"Firmware revision" agrees with NAMUR NE 53. It is a series of numbers used to record the

revision status of embedded software (firmware) in electronic equipment assemblies. It gives

data on the type of changes made and the effect that changes have on compatibility.

SAFETY INSTRUCTIONS

1

Data about software revisions is shown in menu 1.1.0 IDENT. For more data, refer to

description

of the device (given on the device nameplate) and speak to the supplier.

Release

date

YYYY-MM-DDConverter 1.00.0x 400xxxxx01 — HB OPTIWAVE

Printed circuit

assembly

Sensor 1.00.0x 400xxxxx01

HMI (LCD display

option)

on page 60. If it is not possible to refer to the device menu, record the serial number

Firmware

revision

1.00.0x 400xxxxx01

Hardware

revision

Changes and

compatibility

Documentation

7500 R01

Function

1.2 Intended use

CAUTION!

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

CAUTION!

SIL-qualified devices:

SIL-qualified devices:

SIL-qualified devices:SIL-qualified devices:

For more data, refer to the Safety Manual.

This radar level transmitter measures distance, level, mass, volume and reflectivity of liquids,

pastes and slurries.

It can be installed on tanks, reactors and open channels.

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

7

1

SAFETY INSTRUCTIONS

1.3 Certification

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

INFORMATION!

For SIL-approved devices; please refer to the safety manual.

CE marking

The device meets the essential requirements of the EU Directives:

• Electromagnetic Compatibility (EMC) directive

• The safety part of the Low-Voltage directive

• For devices used in hazardous locations: ATEX directive

OPTIWAVE 7500 C

The manufacturer certifies successful testing of the product by applying the CE marking. For

more data about the EU Directives and European Standards related to this device, refer to the EU

Declaration of Conformity. You can find this documentation on the DVD-ROM supplied with the

device or it can be downloaded free of charge from the website (Download Center).

All devices are based on the CE marking and meet the requirements of NAMUR

Recommendations NE 21, NE 43, NE 53 and NE 107.

1.4 Electromagnetic compatibility

The device agrees with Electromagnetic Compatibility Directive.

You can install the device on tanks, open vessels or channels, but the type of antenna must agree

with the location of the device. For more data, refer to

INFORMATION!

This agrees with Immunity and Emissions requirements for industrial environments.

Radio approvals

on page 9.

8

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

1.5 Radio approvals

1.5.1 European Union (EU)

INFORMATION!

LPR (Level Probing Radar)

LPR (Level Probing Radar) equipment are devices for the measurement of level in the open air

LPR (Level Probing Radar)LPR (Level Probing Radar)

or in a closed space (a metallic tank etc.). TLPR (Tank Level Probing Radar)

devices for the measurement of level in a closed space only. You can use LPR devices for TLPR

applications. The LPR and TLPR devices meet the requirements of the RED (Radio Equipment

Directive) for use in the member countries of the EU.

SAFETY INSTRUCTIONS

TLPR (Tank Level Probing Radar) equipment are

TLPR (Tank Level Probing Radar)TLPR (Tank Level Probing Radar)

1

For more data about the order code, refer to Order code on page 116

.

This level transmitter is approved to be used outside metallic tanks. If you use the device

outdoors, read the device nameplate to make sure that the device can be used for your

application. Refer also to the table that follows:

Antenna type Order code Permitted for:

PEEK / Lens Ø20 mm / ¾¨ VFDFxxxxxxxxxxxxx1xx... TLPR

PEEK / Lens Ø25 mm / 1¨ VFDFxxxxxxxxxxxxx2xx... TLPR

PEEK / Lens Ø40 mm / 1.57¨ VFDFxxxxxxxxxxxxx3xx... LPR

PEEK / Lens Ø70 mm / 2.75¨ VFDFxxxxxxxxxxxxx4xx... LPR

S/N: xxxxxxxxxxxxxxxxxxx

Manufacturing date: YYYY-MM-DD

Tag No:

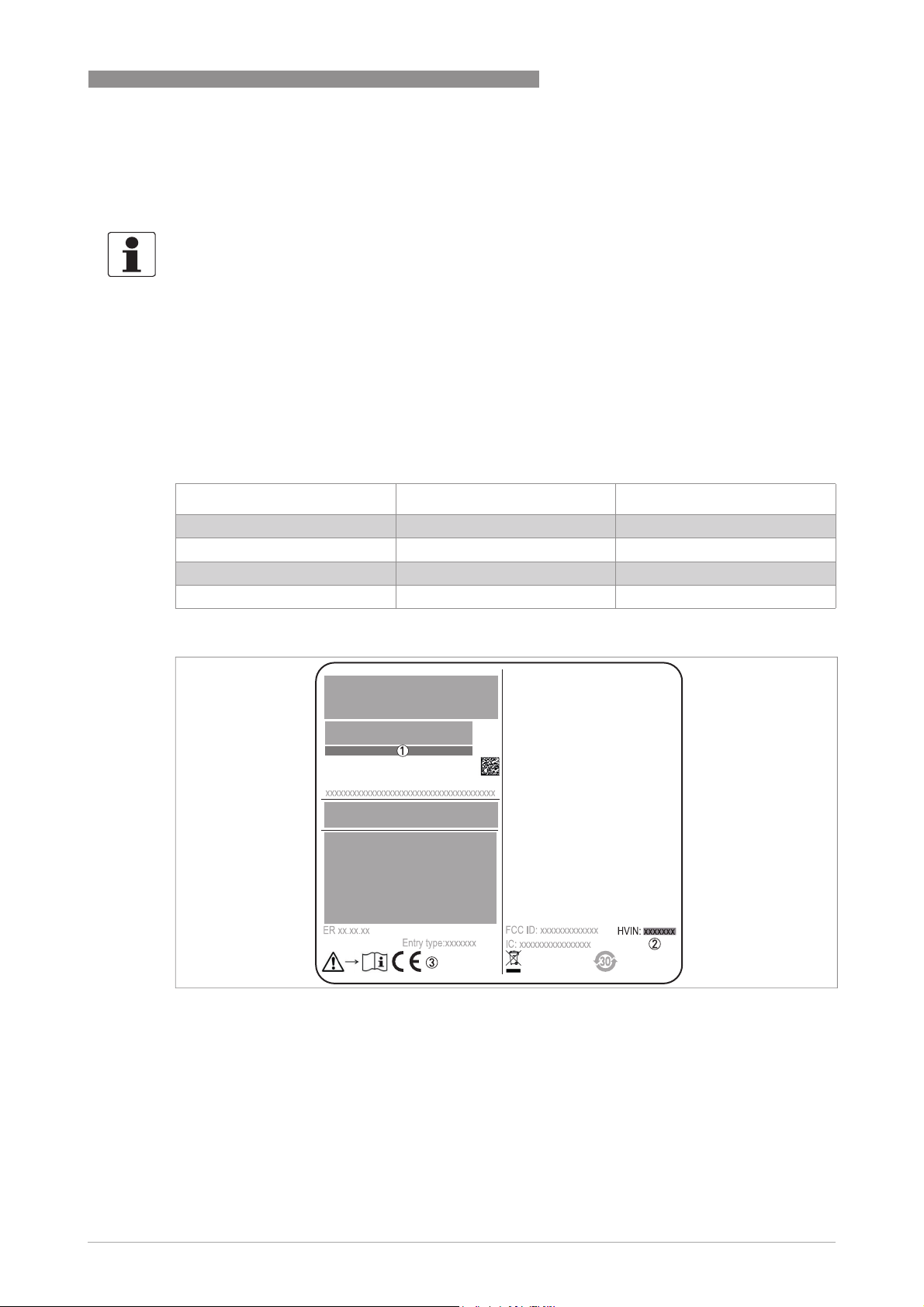

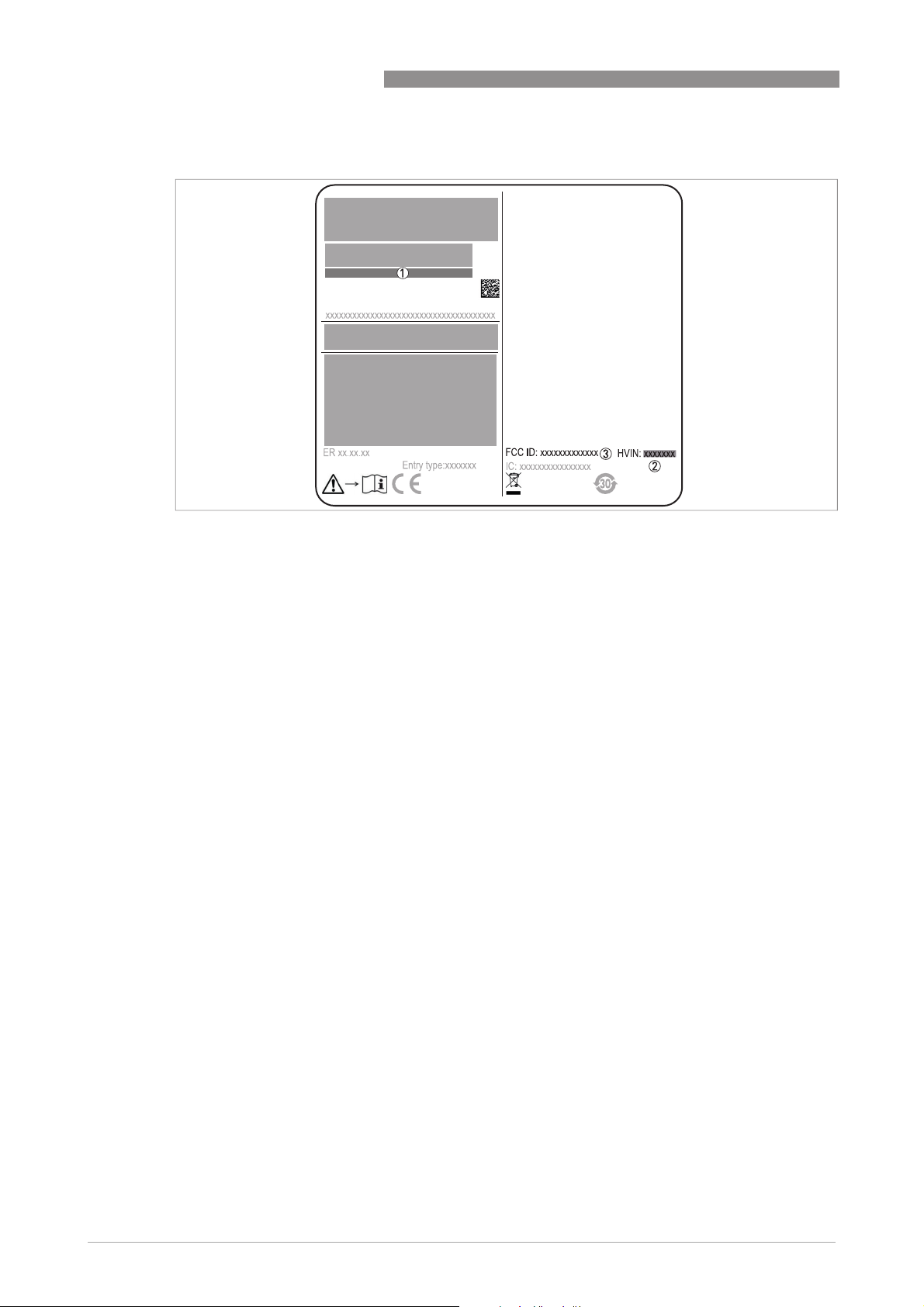

Figure 1-1: Radio approval information on the nameplate

1 Type code (defined in order)

2 HVIN (Hardware Version Identification Number). This number gives the radar signal frequency (80G = 80 GHz), the lo-

cation of the device (T=TLPR or L=LPR) and the type of signal converter (compact (C))

TLPR device: HVIN: 80G-T-C

LPR device: HVIN: 80G-L-C

3 CE sign

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

9

1

SAFETY INSTRUCTIONS

TLPR (Tank Level Probing Radar) devices only

Use approved personnel to install the device. The device and the tank agree with the RED (Radio

Equipment Directive) if you obey the instructions that follow:

• TLPR (Tank Level Probing Radar) are required to be installed at a permanent fixed position at

a closed (not open) metallic tank or reinforced concrete tank, or similar enclosure structure

made of comparable attenuating material;

• flanges and attachments of the TLPR equipment shall provide the necessary microwave

sealing by design;

• sight glasses shall be coated with a microwave-proof coating when necessary (i.e. electrically

conductive coating);

• manholes or connection flanges at the tank shall be closed to ensure a low-level leakage of

the signal into the air outside the tank;

• whenever possible, mounting of the TLPR equipment shall be on top of the tank structure

with the orientation of the antenna to point in a downward direction;

• installation and maintenance of the TLPR equipment shall be performed by professionally

trained individuals only.

OPTIWAVE 7500 C

For data about how to install EMI/RFI shielding gaskets, refer to the instructions supplied with

this accessory.

LPR (Level Probing Radar) devices only

Use approved personnel to install the device. If the device is operated in the open air (outdoors),

it agrees with the RED (Radio Equipment Directive) if you obey these instructions:

• The antenna must always point downwards. The boresight direction of the antenna must be

vertical. No other angles are permitted.

• Install the device more than 4 km / 2.485 mi away from radio astronomy sites.

• If the device is 4...40 km / 2.485...24.855 mi away from radio astronomy sites, do not install the

device more than 15 m / 49.21 ft above the ground.

CAUTION!

If it is necessary to install the device less than 4 km / 2.485 mi from radio astronomy sites, you

must get the approval of the national regulatory authority before installation (e.g. ANFR

(France), Bundesnetzagentur (Germany), Ofcom (United Kingdom) etc.).

Radio quiet zones: locations of radio astronomy sites (stations) in Europe and northern Eurasia

Country Name of the station Location

Latitude, ϕ Longitude, λ

Finland Metsähovi 60°13'04" N 24°23'37" E

France Plateau de Bure 44°38'01" N 05°54'26" E

Germany Effelsberg 50°31'32" N 06°53'00" E

Italy Sardinia 39°29'50" N 09°14'40" E

Spain Yebes 40°31'27" N 03°05'22" W

Pico Veleta 37°03'58" N 03°23'34" W

Sweden Onsala 57°23’45" N 11°55’35" E

10

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

1.5.2 U.S.A.

INFORMATION!

LPR (Level Probing Radar)

LPR (Level Probing Radar) equipment are devices for the measurement of level in the open air

LPR (Level Probing Radar)LPR (Level Probing Radar)

or in a closed space (a metallic tank etc.). TLPR (Tank Level Probing Radar)

devices for the measurement of level in a closed space only.

This level transmitter is approved to be used outside metallic tanks. If you use the device in the

open air, read the device nameplate to make sure that the device can be used for your

application:

PEEK / Lens Ø40 mm / 1.5¨ VFDFxxxxxxxxxxxxx3xx... LPR + TLPR

PEEK / Lens Ø70 mm / 2.75¨ VFDFxxxxxxxxxxxxx4xx... LPR + TLPR

LEGAL NOTICE!

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference which may cause un-

desired operation.

Changes or modifications made to this equipment not expressly approved by the manufacturer

may void the FCC authorizations to operate this equipment.

SAFETY INSTRUCTIONS

TLPR (Tank Level Probing Radar) equipment are

TLPR (Tank Level Probing Radar)TLPR (Tank Level Probing Radar)

Antenna type Order code Permitted for:

1

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and

can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

•

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

•

Consult the dealer or an experienced radio/TV technician for help.

The Product Marketing Name (PMN) of this device is "Optiwave x500 series".

This level transmitter is approved to be used outside metallic tanks. If you use the device in the

open air, read the device nameplate to make sure that the device can be used for your

application. Only the antenna that follows is permitted for open-air applications:

• VFDFxxxxxxxxxxxxx3xx...

• VFDFxxxxxxxxxxxxx4xx...

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

11

1

SAFETY INSTRUCTIONS

S/N: xxxxxxxxxxxxxxxxxxx

Manufacturing date: YYYY-MM-DD

Tag No:

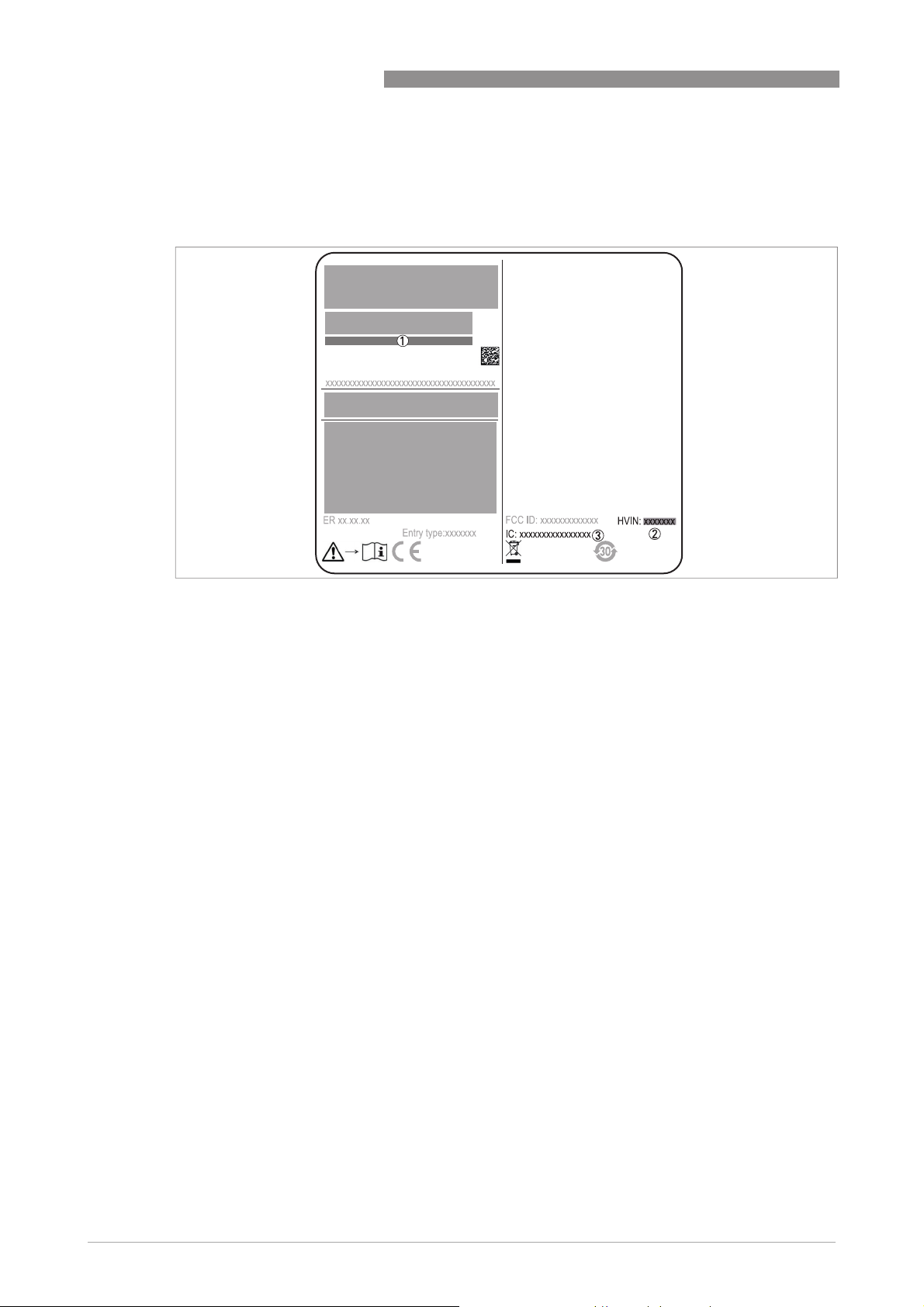

Figure 1-2: FCC ID

1 Type code (defined in order)

2 HVIN (Hardware Version Identification Number). This number gives the radar signal frequency (80G = 80 GHz), the lo-

cation of the device (T=TLPR or L=LPR) and the type of signal converter (compact (C))

TLPR device: HVIN: 80G-T-C

LPR device: HVIN: 80G-L-C

3 FCC ID

TLPR device: FCC-ID: Q6BFMCW80G74T-A

LPR device: FCC-ID: Q6BFMCW80G74L-A

OPTIWAVE 7500 C

12

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

1.5.3 Canada

INFORMATION!

LPR (Level Probing Radar)

LPR (Level Probing Radar) equipment are devices for the measurement of level in the open air

LPR (Level Probing Radar)LPR (Level Probing Radar)

or in a closed space (a metallic tank etc.). TLPR (Tank Level Probing Radar)

devices for the measurement of level in a closed space only.

This level transmitter is approved to be used outside metallic tanks. If you use the device in the

open air, read the device nameplate to make sure that the device can be used for your

application:

PEEK / Lens Ø20 mm / ¾¨ VFDFxxxxxxxxxxxxx1xx... TLPR

PEEK / Lens Ø25 mm / 1¨ VFDFxxxxxxxxxxxxx2xx... TLPR

PEEK / Lens Ø40 mm / 1.57¨ VFDFxxxxxxxxxxxxx3xx... LPR

PEEK / Lens Ø70 mm / 2.75¨ VFDFxxxxxxxxxxxxx4xx... LPR

LEGAL NOTICE!

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following conditions:

1. this device may not cause harmful interference, and

2. this device must accept any interference received, including interference that may cause un-

desired operation.

SAFETY INSTRUCTIONS

TLPR (Tank Level Probing Radar) equipment are

TLPR (Tank Level Probing Radar)TLPR (Tank Level Probing Radar)

Antenna type Order code Permitted for:

1

This device and the handbook complies with the requirements of RSS-Gen. Operation is subject

to the conditions that follow:

1. The installation of the LPR/TLPR device shall be done by trained installers, in strict compliance

with the manufacturer

’

s instructions.

2. The use of this device is on a "no-interference, no-protection" basis. That is, the user shall ac-

cept operations of high-powered radar in the same frequency band which may interfere with or

damage this device. However, devices found to interfere with primary licensing operations will

be required to be removed at the user

’

s expense.

3. The TLPR device shall be installed and operated in a completely enclosed container to prevent

RF emissions, which can otherwise interfere with aeronautical navigation.

4. LPR devices: Ensure a vertically downward orientation of the transmit antenna and a installa-

tion only at fixed locations.

5. The installer / user of this device shall ensure that it is at least 10 km from the Dominion Radio

Astrophysical Observatory (DRAO) near Penticton, British Columbia. The coordinates of the

DRAO are latitude 49

°

19'15" N and longitude 119°37'12" W. For devices not meeting this 10 km

separation (e.g. those in the Okanagan Valley, British Columbia) the installer / user must coordinate with, and obtain the written concurrence of, the Director of the DRAO before the equipment can be installed or operated. The Director of the DRAO may be contacted at 250-497-2300

(tel.) or 250-497-2355 (fax). Alternatively, the Manager, Regulatory Standards, Industry Canada,

may be contacted.

The Product Marketing Name (PMN) of this device is "Optiwave x500 series".

This level transmitter is approved to be used outside metallic tanks. If you use the device in the

open air, read the device nameplate to make sure that the device can be used for your

application. Only the antenna that follows is permitted for open-air applications:

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

13

1

SAFETY INSTRUCTIONS

• VFDFxxxxxxxxxxxxx3xx...

• VFDFxxxxxxxxxxxxx4xx...

S/N: xxxxxxxxxxxxxxxxxxx

Manufacturing date: YYYY-MM-DD

Tag No:

OPTIWAVE 7500 C

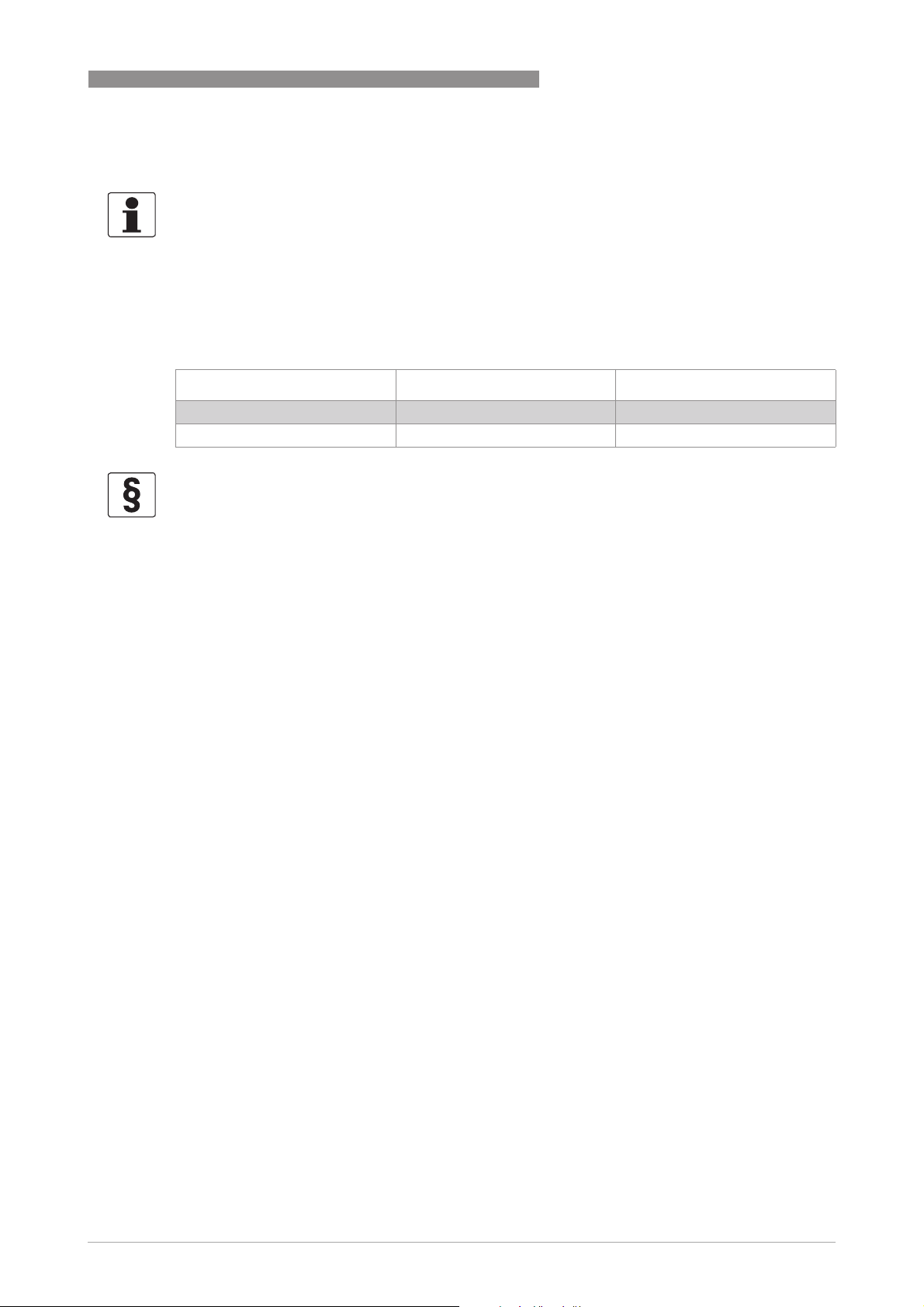

Figure 1-3: IC number

1 Type code (defined in order)

2 HVIN (Hardware Version Identification Number). This number gives the radar signal frequency (80G = 80 GHz), the lo-

cation of the device (T=TLPR or L=LPR) and the type of signal converter (compact (C))

TLPR device: HVIN: 80G-T-C

LPR device: HVIN: 80G-L-C

3 IC number

TLPR device: 1991D-FMCW80G74T-A

LPR device: 1991D-FMCW80G74L-A

14

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

1.6 Safety instructions from the manufacturer

1.6.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

SAFETY INSTRUCTIONS

1

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.6.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

15

1

SAFETY INSTRUCTIONS

1.6.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation or operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.6.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of icons as shown below.

OPTIWAVE 7500 C

16

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

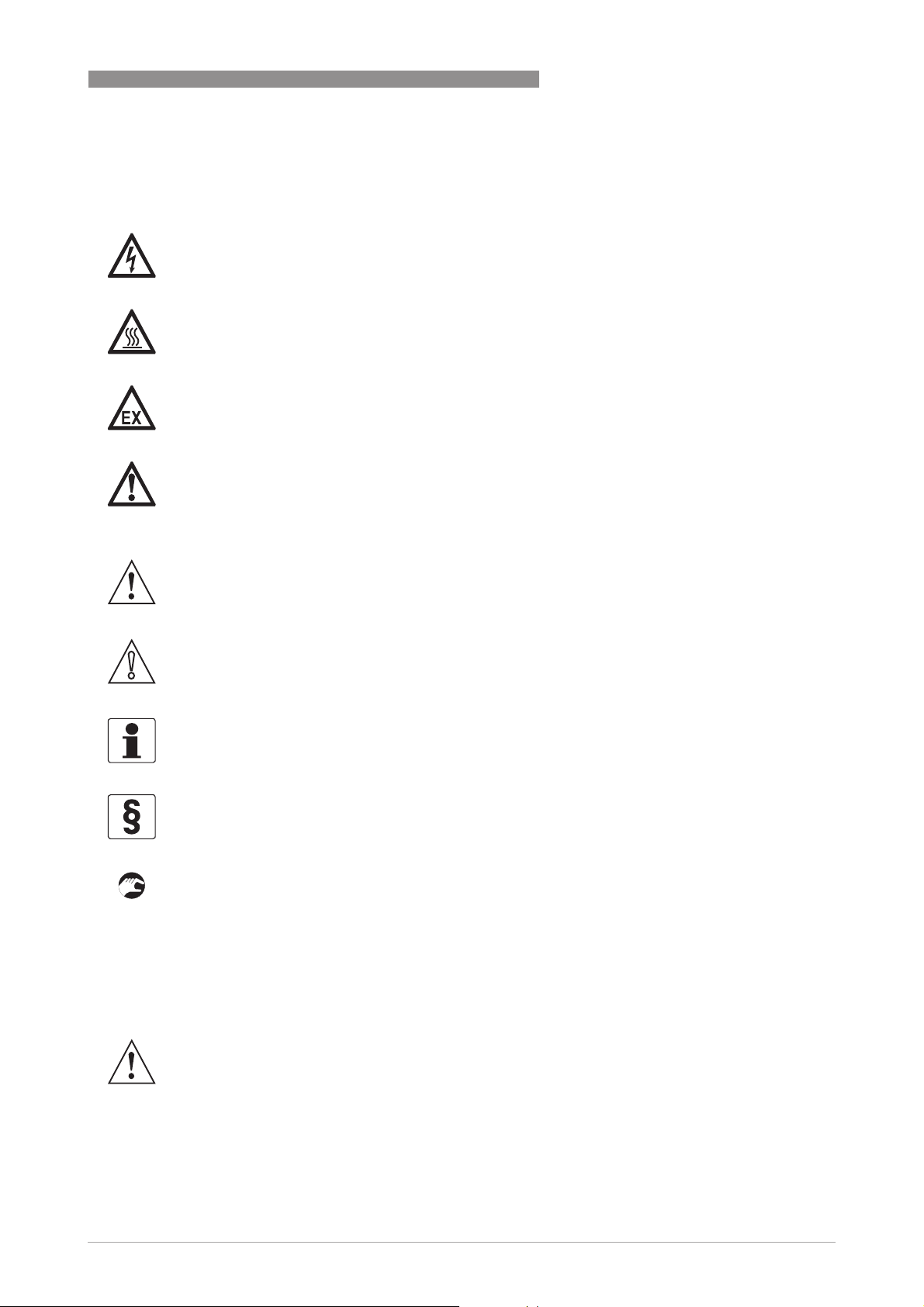

1.6.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

SAFETY INSTRUCTIONS

1

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.7 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

17

2

DEVICE DESCRIPTION

2.1 Scope of delivery

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

Scope of delivery

OPTIWAVE 7500 C

Figure 2-1: Scope of delivery

1 Signal converter and antenna in the ordered version

2 Antenna extensions (option)

3 Quick start

4 Certificates and calibration report (if the device has the appropriate options)

5 DVD-ROM (including handbook, quick start, technical data sheet and related software)

6 Bar magnet

7 Handle (for removal of the optional display module)

8 Wrench (for removal of the device covers)

18

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

2.2 Device description

This device is a 80 GHz FMCW-radar level transmitter. It is a non-contact technology and is 2wire loop-powered. It is designed to measure the distance, level, mass, volume and reflectivity of

liquids, pastes and slurries. For more data about the measuring principle,.

Radar level transmitters use an antenna to emit a signal to the surface of the measured product.

The device has many antennas available. Thus, it can measure most products even in difficult

conditions. Also refer to

If the device is ordered with the applicable options, it can be certified for use in hazardous areas.

The signal converter is attached directly to the process connection and the antenna. The

illustration that follows shows the types of antenna.

Technical data

on page 98.

DEVICE DESCRIPTION

2

Figure 2-2: Types of antenna

1 Lens antennas (available antenna sizes: Ø20 mm (0.75¨), Ø25 mm (1¨), Ø40 mm (1.5¨) and Ø70 mm (2.75¨) made of

PEEK)

These accessories are available:

• Stainless steel weather protection.

• RS232 / HART® converter (VIATOR).

• USB / HART® converter.

INFORMATION!

For more data on accessories.

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

19

2

DEVICE DESCRIPTION

2.3 Visual Check

WARNING!

If the display screen glass is broken, do not touch.

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

OPTIWAVE 7500 C

Figure 2-3: Visual check

1 Device nameplate (for more data refer to

2 Process connection data (size and pressure rating, material reference and heat number)

3 Gasket material data – refer to the illustration that follows

Figure 2-4: Symbols for the supplied gasket material (on the side of the process connection)

1 EPDM

2 Kalrez® 6375

Nameplate (examples)

on page 21)

If the device is supplied with an FKM/FPM gasket, there is no symbol on the side of the process

connection.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

INFORMATION!

Compare the material references on the side of the process connection with the order.

20

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

2.4 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

2.4.1 Nameplate (examples)

DEVICE DESCRIPTION

2

Figure 2-5: Non-Ex nameplate attached to the housing

1 Cable entry size

2 Hardware revision / Software revision (according to NAMUR NE 53)

3 Signal output (analog, HART®, fieldbus, etc.), input voltage and maximum current (fieldbus options: basic current)

4 Degree of ingress protection (according to EN 60529 / IEC 60529)

5 Customer tag number

6 Date of manufacture

7 Order number

8 Type code (defined in order)

9 Model name and number. C = compact version.

10 Company logo, name and postal address

Country of manufacture / Company web address

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

21

3

INSTALLATION

3.1 General notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

WARNING!

Do not keep the device in a vertical position. This will damage the antenna and the device will not

measure correctly.

OPTIWAVE 7500 C

• Store the device in a dry and dust-free location.

• Store the device in its original packing.

3.3 Transport

Figure 3-1: How to lift the device

1 Remove the converter before you lift the device with a hoist.

WARNING!

Lift the device carefully to prevent damage to the antenna.

3.4 Pre-installation requirements

INFORMATION!

Obey the precautions that follow to make sure that the device is correctly installed.

• Make sure that there is sufficient space on all sides.

22

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

• Protect the signal converter from direct sunlight. If necessary, install the weather protection

accessory.

• Do not subject the signal converter to heavy vibrations. The devices are tested for vibration

and agree with EN 50178 and IEC 60068-2-6.

3.5 Pressure and temperature ranges

INSTALLATION

3

Figure 3-2: Pressure and temperature ranges

1 Temperature at the process connection

Non-Ex devices: The temperature range depends on the type of antenna, process connection and the seal material.

Refer to the table that follows.

Devices with Hazardous Location approvals: see supplementary instructions

2 Ambient temperature for operation of the display

-20...+70°C / -4...+158°F

If the ambient temperature is not between these limits, then this condition can stop the display. The device continues

to operate.

3 Ambient temperature

Non-Ex devices: -40...+80°C / -40...+185°F

Devices with Hazardous Location approvals: see supplementary instructions

WARNING!

The process connection temperature range must agree with the temperature limits of the

gasket material. The operating pressure range is subject to the process connection used and the

flange temperature.

For more data on pressure ratings,.

Figure 3-3: Ambient temperature / flange temperature, flange and threaded connection, in °C

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

23

3

INSTALLATION

3.6 Recommended mounting position

CAUTION!

Follow these recommendations to make sure that the device measures correctly. They have an

effect on the performance of the device.

We recommend that you prepare the installation when the tank is empty.

3.6.1 General notes

CAUTION!

Follow these recommendations to make sure that the device measures correctly.

Point the cable entries on the housing in the direction of the nearest tank wall.

OPTIWAVE 7500 C

3.6.2 Tanks with conical bottoms

Figure 3-4: Tanks with dish-shaped or conical bottoms

Dish-shaped or conical bottoms have an effect on the measuring range. The device cannot measure to the bottom of the

tank.

1 Axis of radar beam

2 Minimum level reading

3.7 Mounting restrictions

CAUTION!

Follow these recommendations to make sure that the device measures correctly. They have an

effect on the performance of the device.

We recommend that you prepare the installation when the tank is empty.

24

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

3.7.1 General data for TLPR devices

CAUTION!

Do not install the device above objects in the tank (ladder, supports etc). Objects in the tank can

cause parasitic signals. If there are parasitic signals, the device will not measure correctly.

If it is not possible to install the device on another part of the tank, do an empty spectrum scan.

INFORMATION!

If possible, do not install a nozzle on the tank centerline.

3.7.2 Obstacles in the tank

Obstacles in the tank can cause parasitic signals. They have an effect on the performance of the

device.

CAUTION!

If there are parasitic signals, the device will not measure correctly. Parasitic signals are caused

by:

•

Objects in the tank.

•

Sharp corners that are perpendicular to the path of the radar beam.

INSTALLATION

3

Do an Empty Spectrum recording (refer to Operation

Operation) to remove parasitic signals with a filter.

OperationOperation

CAUTION!

Do not put the device near to the product inlet. If the product that enters the tank touches the

antenna, the device will measure incorrectly. If the product fills the tank directly below the

antenna, the device will also measure incorrectly.

Figure 3-5: Product inlets

1 The device is in the correct position.

2 The device is too near to the product inlet.

CAUTION!

Do not put the device near to the product inlet. If the product that enters the tank touches the

antenna, the device will measure incorrectly. If the product fills the tank directly below the

antenna, the device will also measure incorrectly.

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

25

3

INSTALLATION

3.7.3 Process connections

Requirements for flange connections

Figure 3-6: Flange connection

Equipment needed:

• Device

• Flange gasket (not supplied)

• Wrench (not supplied)

OPTIWAVE 7500 C

• Make sure the flange on the nozzle is level.

• Make sure that you use the applicable gasket for the flange dimensions and the process.

• Align the gasket correctly on the flange facing of the nozzle.

• Lower the antenna carefully into the tank.

• Make sure that you point the device in the correct direction. Refer to "Point the device in the

correct direction" in this section.

• Tighten the flange bolts.

i Refer to local rules and regulations for the correct torque to apply to the bolts.

Equipment needed:

• Device

• Gasket for G 1½ connection (not supplied)

• Thread seal tape (PTFE) for 1½ NPT connection (not supplied)

• 50 mm / 2¨ wrench (not supplied)

WARNING!

Do not tighten the connection to a torque more than 40 N

·

m / 29.5 lb·ft. If the connection is too

tight, this will damage the thread.

To prevent damage to the antenna, make sure that the minimum diameter of the hole for a

1

½

NPT or 2 NPT thread connection is not less than 43.4 mm / 1.71¨.

26

• Make sure the tank connection is level.

• ISO 228-1 (G) connection:

ISO 228-1 (G) connection: Make sure that you use the applicable gasket for the connection

ISO 228-1 (G) connection:ISO 228-1 (G) connection:

dimensions and the process.

• ISO 228-1 (G) connection:

ISO 228-1 (G) connection: Align the gasket correctly.

ISO 228-1 (G) connection:ISO 228-1 (G) connection:

• NPT connection:

NPT connection: Wind the thread seal tape around the process connection in agreement with

NPT connection:NPT connection:

good engineering practice.

• Lower the antenna carefully into the tank.

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

• Turn the threaded connection on the antenna to attach the device to the process connection.

• Make sure that you point the device in the correct direction. Refer to "Point the device in the

correct direction" in this section.

• Tighten the connection to the correct torque (not more than 40 N·m/ 29.5lb·ft).

3.8 How to turn or remove the display module (option)

If there is an object adjacent to the device that makes it difficult to read the display, you can

rotate the display in increments of 90°.

INSTALLATION

3

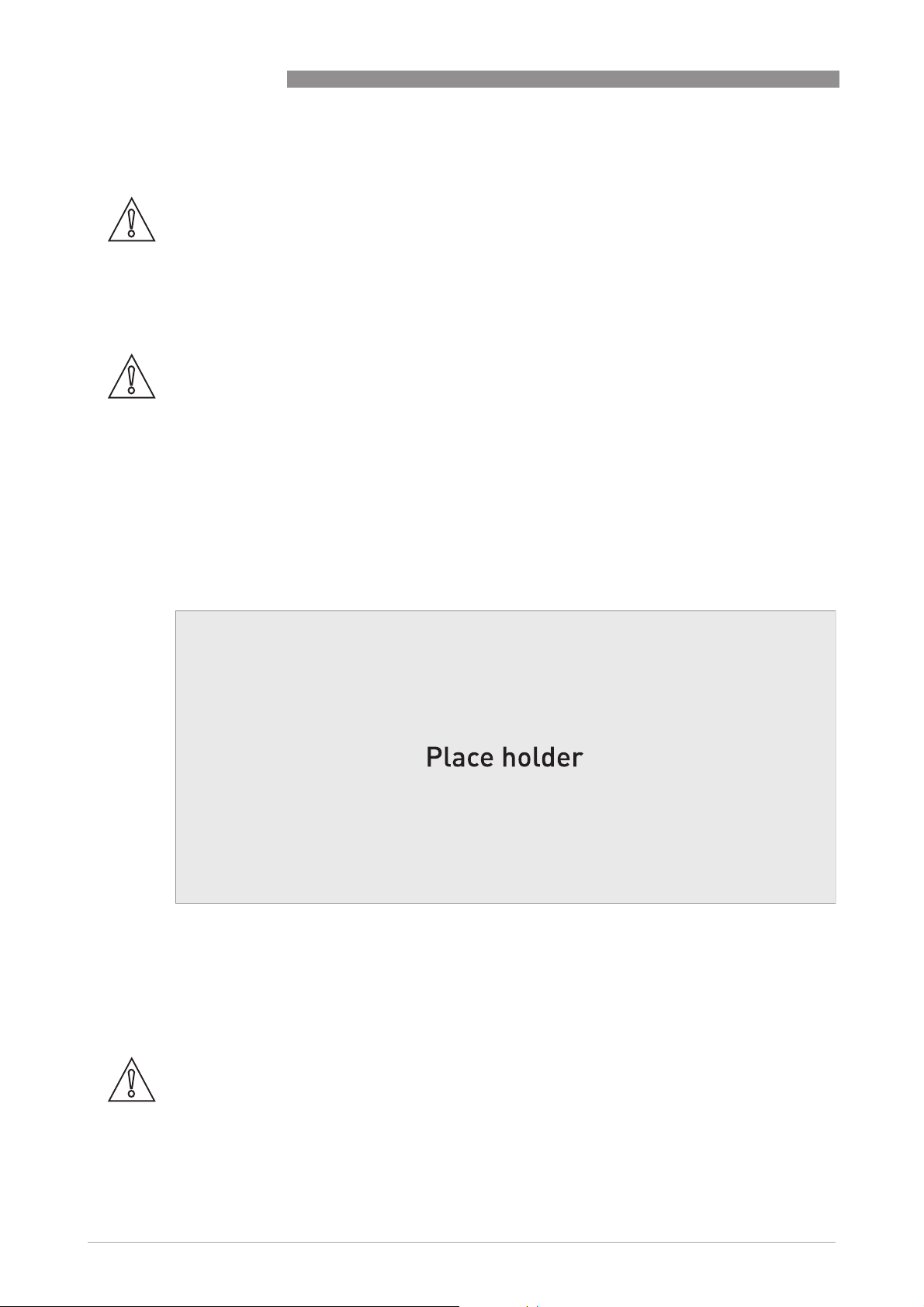

Figure 3-7: How to turn or remove the display module (option)

1 Tool: Wrench (for removal of the device covers)

2 Tool: Handle (for removal of the display module)

Follow this procedure:

• Disconnect the power supply from the device.

• Remove the housing cover with the wrench 1.

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

27

3

INSTALLATION

• Use the handle to remove the display module.

• First put the handle on side "a" and then on side "b" of the display, and then carefully remove

the display 2 from housing. Remove the handle from the display module first on side "a" and

then on side "b".Turn it into the favoured position 3.

• Turn the display module until it points to the user.

• Push the display onto the clips in the housing 4, until they make a click.

• Make sure that the housing cover has a gasket. Attach the cover on the housing and tighten it

by hand.

INFORMATION!

Before you close the housing cover, refer to How to turn or remove the display module (option)

on page 27

.

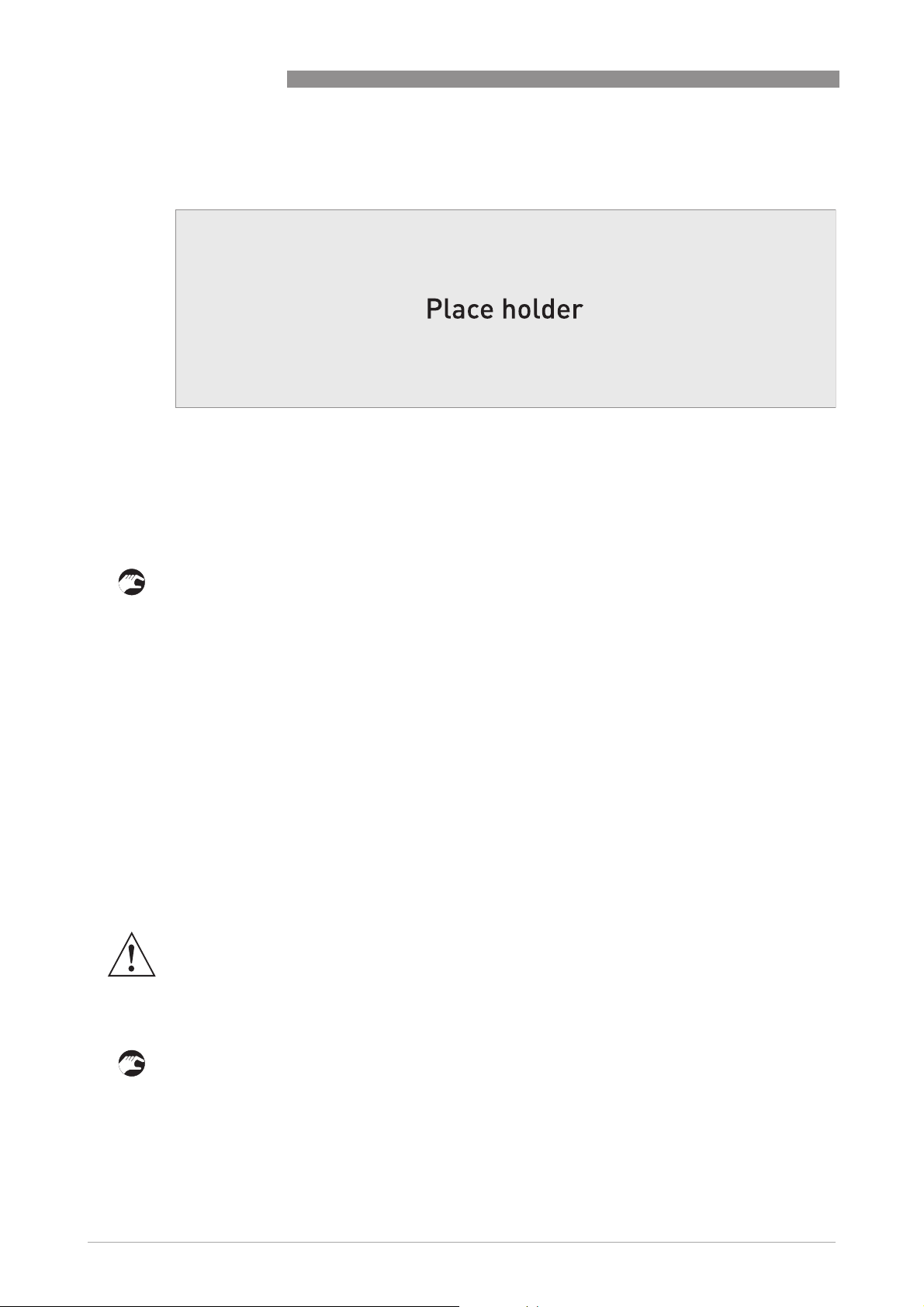

3.9 How to turn or remove the signal converter

INFORMATION!

The converter turns 360

under process conditions.

°

. The converter can be removed from the process connection assembly

OPTIWAVE 7500 C

28

Figure 3-8: How to turn or remove the signal converter

1 Tool: 5 mm Allen wrench (not supplied)

2 Cover for the wave guide hole on top of the process connection assembly (not supplied)

CAUTION!

If you remove the converter, put a cover on the wave guide hole on top of the process connection

assembly.

When the converter is attached to the process connection assembly, tighten the lock screw.

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

OPTIWAVE 7500 C

3.10 Weather protection

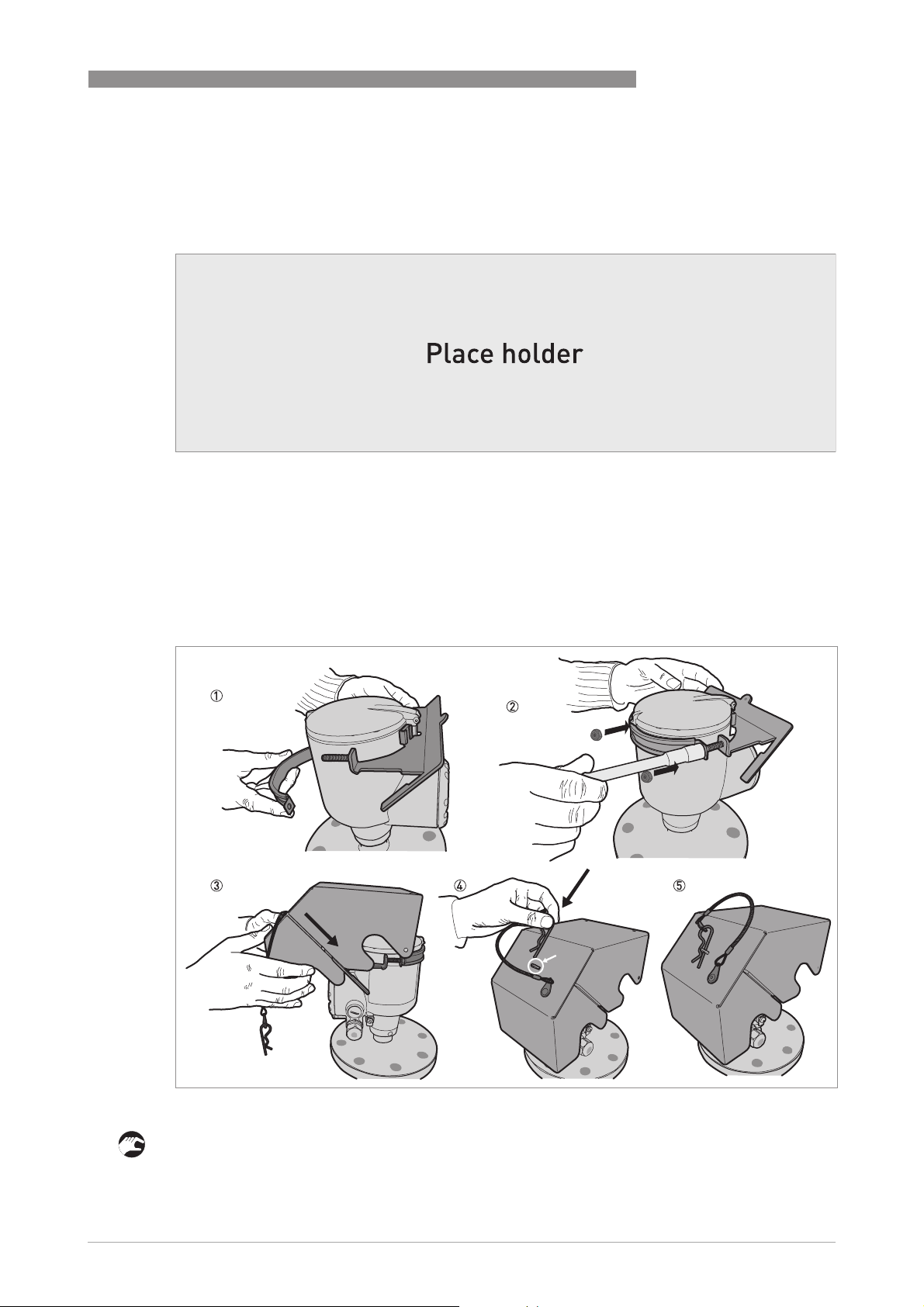

3.10.1 How to attach the weather protection to the device

Figure 3-9: Equipment needed to assemble the weather protection

1 Weather protection cover (with a split pin to hold the cover on the clamp)

2 Device

3 Weather protection clamp (2 parts)

4 2 locking nuts

5 10 mm socket wrench (not supplied).

INSTALLATION

3

The overall dimensions of the weather protection are on page 105.

Figure 3-10: Installation of the weather protection

• Put the weather protection clamp around the top of the device.

• Attach the two locking nuts to the threads on the weather protection clamp. Tighten the

locking nuts with a 10 mm socket wrench.

www.krohne.com10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

29

3

INSTALLATION

• Lower the weather protection cover onto weather protection clamp until the hole for the lock

is in the slot at the front of the cover.

• Put the R-clip into the hole at the front of the weather protection cover.

• End of the procedure.

OPTIWAVE 7500 C

30

www.krohne.com 10/2016 - 4004375401 - MA OPTIWAVE 7500 R01 en

Loading...

Loading...