Page 1

96M11843

Environment Resisting Type

Built-in-amplifier Pressure Sensors

GP-M Series

Instruction Manual

Read this instruction manual before using the product in order to

achieve maximum performance.

Keep this instruction manual in a safe place after reading it so that it

can be used at any time.

Page 2

Symbols

DANGER

WARNING

CAUTION

NOTICE

Reference

WARNING

In this instruction manual, the following symbols will be used to so

that important points can be understood at one glance.

Be sure to read these messages carefully.

It indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

It indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

It indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

It indicates a situation which, if not avoided, could

result in product damage as well as property damage.

It indicates tips for better understanding or useful infor mation.

Safety Information for GP-M Series

1. Do not use this product for the purpose to

protect a human body or a part of human body.

2. This product is not intended for use as an

explosion-proof product. Do not use this

product in hazardous locations and/or

potentially explosive atmospheres.

3. The GP-M Series is not designed to sanitary

specifications. Do not use the product for

applications such as drinks, foods, or medical

liquids.

4. Do not use the GP-M Series for applications

requiring safety measures, such as any

nuclear, railroad, aircraft, vehicle, or

playground equipment.

2

Page 3

1. You must verify that the GP-M Series is

CAUTION

NOTICE

operating correctly in terms of functionality

and performance before the start and

operation of the GP-M Series.

2. We recommend that you take all the necessary

safety measures to avoid any damage in the

unlikely event of a problem occurring.

3. Do not use the GP-M Series with corrosive liquids.

1. We cannot guarantee the functions and/or

performance in the event that the product is

used outside the standards of the

specification, or if the product is modified.

2. When using our product in combination with

another product, based on such factors as

conditions of use and surrounding

environment, sometimes functions and

performance may not be fully realized. In such

a case, use after adequate examination.

Precautions on Regulations and Standards

CE Marking

KEYENCE Corporation has confirmed that this product complies with the

essential requirements of the applicable EC Di rectives, based on the

following specifications. Be sure to consider the following specifications

when using this product in the Member States of European Union.

z EMC Directive (2004/108/EC)

• Applicable standards EMI: EN61326-1, Class A

Remarks

These specifications do not give any guarantee that the

end-product with this product incorporated complies with the

essential requirements of EMC Directive.

The manufacturer of the end-product is solely responsible for the

compliance on the end-product itself according to EMC Directive.

EMS: EN61326-1

3

Page 4

CSA Certificate

CAUTION

NOTICE

GP-M Series complies with the following CSA and UL standards and

has been certified by CSA.

• Applicable standard CAN/CSA C22.2 No.61010-1

Be sure to consider the following specifications when using this

product as a product certified by CSA.

• Overvoltage category: 1

• Use this product under pollution degree 2.

• Use this product at the altitude of 2000 m or less.

• Indoor use only.

• Use CSA/UL certified power supply that provides Class 2 output

as defined in the CEC (Canadian Electrical Code) and NEC

(National Electrical Code), or CSA/ULcertified power supply that

has been evaluated as a Limited Power Source as defined in

CAN/CSA-C22.2 No. 60950-1/UL60950-1.

• Do not use the GP-M Series for poizonous fluid.

Caution when handling

1. When detecting the temperature of the fluid, the

2. The screw part of the main unit is sharp, take

1. Do not drop or hit the device, and avoid any

2. Do not use a sharply pointed object to press

3. If the detection portion is pushed with sharp

UL61010-1

housing of the product will be hot, and there is

the danger of a burn injury. Do not touch the

metal housing while the product is in operation.

care to avoid injury.

other large shock to the device.

the setting keys.

thing, damage may occur to the detection

surface. Also, for devices where the measuring

range is low, the detection portion is thin and

easy to break. Touch as little as possible.

4

Page 5

Precautions for wiring

CAUTION

NOTICE

NOTICE

1. Do not modify or disassemble unnecessarily. It

may cause electric shock or improper operation.

2. Do not work on the wiring with bare hands.

Even if the power is OFF, electric charge may

remain and cause electric shock.

3. Do not work on the pipe work or wiring with

wet hands. It may cause electric shock.

4. When wiring, confirm the pin position.

5. Use the GP-M Series within the rated range.

The GP-M Series is a sensor that uses a DC

(direct current) power source. Do not apply

alternating current or other power supplies. Do

not use a load that exceeds the allowable limit.

1. Use an insulated stabilizing supply for the

power supply.

2. Do not pull strongly on the cable.

3. Ensure that the cable tip is not submersed in

water during wiring work.

4. Isolate the cable from power supply lines or

power lines.

5. Isolate the cable as far as possible from any

source of noise.

Other precautions

1. The power ON reset time for the GP-M Series is

2 seconds after power is turned on. Do not use

outputs from the sensor during this period.

2. Initial drift may occur after supplying power to

the GP-M Series. To detect a minute difference

in the pressure, let the GP-M Series warm up

for approximately 15 to 30 minutes.

3. Do not bring a strong magnet or magnetic field

close to the main body of the GP-M Series.

5

Page 6

4. Do not remove the seal of the air hole of the

NOTICE

GP-M001/M010/M025. It will no longer be

waterproof.

5. When condensation occurs, it may become

impossible to make measurements, or,

damage may occur. Take measures such as

the following to prevent condensation.

• Ensure that the ambient temperature is the same

or lower than the fluid temperature.

• Remove moisture via air conditioning

• Separate the sensor 30 cm or more from the

cooling pipes using the connector pipe.

6. When conducting maintenance, use a soft

brush so as not to damage items such as the

detection surface or the O-Ring.

7. When replacing the O-Ring, clean all of the

debris from the surface that will be in contact

with the O-Ring.

Checking the Packed Items

GP-M001/M010/M025

Sensor x 1

Instruction manual x 1

GP-M100/M250/M400

Sensor x 1

Instruction manual x 1

O-Ring x 1

(OP-87287)

O-Ring set x 1

(OP-87288)

6

Page 7

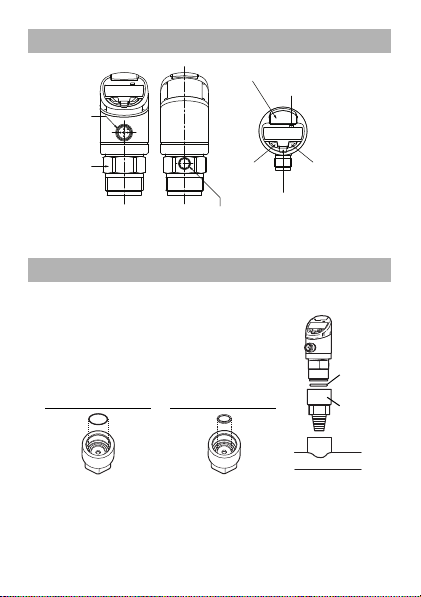

Name and Function of Each Part

1

Connector

for input

cable use

2

Clasp

3 Air hole

*

4 Operating light (output 1)

5 Operating light

(output 2)

8 MODE button

6

UP button

(U)

7 DOWN

button (V)

O-Ring

Adapter

* Only for the GP-M001/M010/M025

Piping/Installation

Piping

• Use the adapter for matching with the

diameter of the piping.

• When using a replacement adapter, attach

the O-Ring included with the Main Unit to the

groove of the G3/4 female screw part.

(Refer to the diagram below)

GP-M001/M010/M025

GP-M100/M250/M400

Adapter

• Inquire to us when connecting the pipes directly using the GP-M

Series with a G3/4 female screw.

• The body may be rotated horizontally to 330°. When rotating,

hold the clasp in place with something such as a wrench.

Adapter

7

Page 8

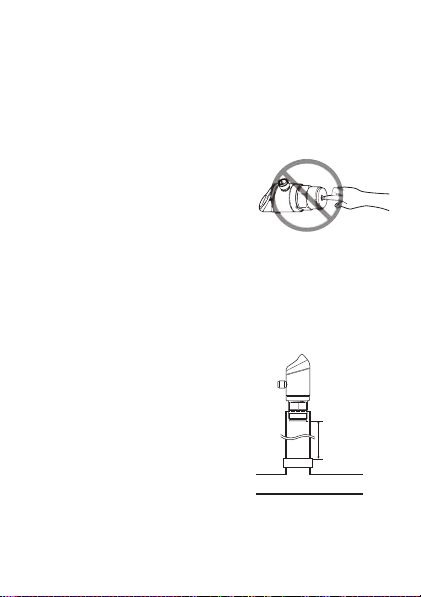

Precautions when installing

Cooling pipe

30 cm or more

z Attaching the coupling

The recommended tightening torque when installing the adapter

to the main body of the sensor is 20 N•m. It is recommended to

apply grease to the G3/4 screw part in order to avoid scorching.

z Grounding of metal parts

The metal parts of the main body, the internal circuits 0 V are insulated.

z Other precautions

• Regardless of whether the power

of the device is ON or OFF, do not

touch the main part of the

pressure detector, if the if the

pressure detector is touched,

damage may occur due to static

electricity.

• If using a non-conductive liquid such as oil, and plastic piping

are used, the risk of an offset change will become greater. In

such a case, it is recommended to ground the metal housing.

• In the case that noise causes malfunction, grounding the

metal housing may improve performance.

• After installation, conduct an atmospheric correction by

making the applied pressure the same as regular room

pressure. (Refer to page 10)

• When there is condensation,

separate the sensor from cooling

pipe by at least 30 cm using the

connecting pipe.

8

Page 9

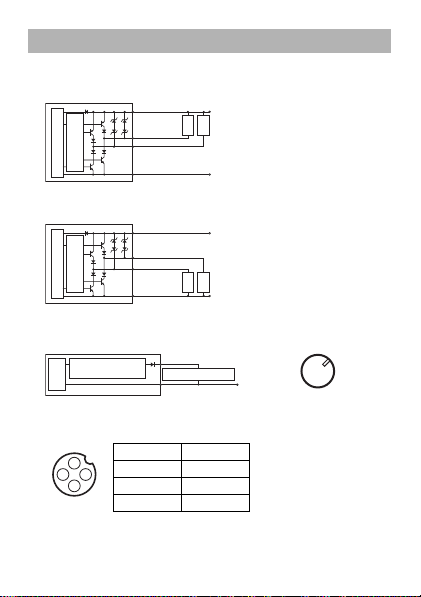

Wiring, Output Diagram

3

2 (Output 2)*

1

10 to 30 VDC

4 (Output 1)

0 V

Overcurrent

protection circuit

Main circuit

Load

Load

3

2

(Output 2)*

1

10 to 30 VDC

4 (Output 1)

0 V

Overcurrent

protection circuit

Main circuit

Load

Load

3

2 4 to 20 mA*

Analog current

output circuit

0 V

Main

circuit

Analog input device

2

3

1

4

Output diagram

z When choosing an NPN output

*

When choosing the function of output 2

QWV

(control output) only.

z When choosing a PNP output

*

When choosing the function of output 2

QWV

(control output) only.

Analog output diagram Pin

2

13

4

* When Choosing

#P.)

of the Function of Output 2 only.

M12 Connector Cable (Optional) Pin Position

1 Brown

2 White

3 Blue

4 Black

9

Page 10

Initial Settings at the Time of Delivery

Push briefly

MODE

Settings finish

2P

Polarity of control output

Select by button.

P2P NPN type

2P2 PNP type

Choose function of output 2

Select by button.

QWV Control output

#P.) Analog output

Alternate

QWV

KQ

P2P

Alternate

Push briefly

MODE

*

MODE

Reference

MODE

Correct the atmospheric pressure

When turning the power ON for the first time after delivery, set the

initial settings according to the outline below.

* On this screen, press the V button 5 times while pressing and

holding the button to move to the unit switch screen “

using UV the unit can be selected from , , ,

(except GP-M100/M250/M400), and (except GP-M001).

Pushing while pushing U

the previous screen.

briefly will return you to

7PKV

”. By

Atmospheric Pressure Correction

Function for correcting the measurement value to 0 due to problems

such as long term use.

Main

Push and

screen

• Always correct the atmospheric pressure by making the applied

• The air pressure correction is effective within a range of ±10 of

hold +

pressure the same as regular room pressure.

F.S. If it is executed outside of that range, “

no correction will occur.

The screen will blink

and the present pressure

will be corrected to 0.

10

” is displayed and

Page 11

• The atmospheric pressure correction will be reflected on the

Activate/Deactivate Key Lock

From the main screen, press and hold the MODE button and

the U button (or the V button) simultaneously.

If “

.QE

” is displayed while blinking, the Key Lock is enabled. With

the same operation it can be disabled (“

WP.

” will be displayed

while blinking).

Reference

Disabling the Key Lock with Password

1. From the main screen press and hold the MODE button

simultaneously with the U button (or the V button).

“

2#55

” and a number value alternately is displayed.

2. Select a password with the UV and press the MODE

button to select.

If the correct password is entered:

“

WP.

” will appear as a blinking display, and Key Lock will be

disabled.

If an incorrect password is entered:

“

'T2

” will appear as a blinking display, Key Lock will not be

disabled, and the screen will return to the main screen.

analog output.

Key Lock

Function for preventing operation error.

• If the Key Lock is enabled, the setting value change (the

detail settings from pressing and holding the MODE

button) is not available. (“

•If “

2#55

” is set to a value other than “

value)” via the extended function (page 16), when

the Key Lock is disabled a password will be

requested. (Refer to below)

.QE

” will display as blinking”)

11

(initial

Page 12

Changing the Setting Value of Output 1

Push briefly

MODE

*4

*2

*3

52

Push briefly

MODE

Switch-on point 1

Select using the buttons.

Setting range: 1% of F.S. to 100% of F.S.

(Details on page 17)

Switch-off point 1

Select using the buttons.

Setting range: 0% of F.S. to

(Switch-on point) -1% of F.S.

(Details on page 17)

Finish settings

Return to main

screen

Alternate

T2

Alternate

Press or briefly

*1

*3. The detection mode of the Output 1 is

displayed as “(.” when in window mode.

*4. If it is not used for 4 seconds it will return

to the main screen.

*1. The detection mode of the Output 1 is

displayed as “(*” when in window mode.

*2. If it is not used for 4 seconds it will return

to the main screen.

Display Pressure Unit

If the MODE button is pressed briefly on the main screen, the

pressure unit will display.

If it is not used for 2 seconds it will return to the main screen.

Display Peak and Bottom H old

If the MODE button + the U (V) button are pressed briefly on

the main screen, the peak (bottom) hold value will display.

(“

2A*

” (“

DA*

”) and hold value will blink alternately.)

Change the setting value of output 1. The changing of setting values

of output 2 is done by pressing and holding the MODE button.

(Refer to page 15)

Display Pressure Unit/Hold Display

12

Page 13

• Peak (bottom) hold value will be stored into

Reference

*

MODE

MODE

EEPROM every 45 seconds.

• If the U and V buttons are pressed and held

simultaneously on the peak (bottom) hold screen, the

peak (bottom) hold value of the initial reset will be cleared.

• To return to the previous screen, press the MODE

button briefly.

Initial Reset (Initialization)

Briefly press the button 5 times while continuously pressing

Alternate

T5'V

MODE

Push briefly

Alternate

2P

MODE

Push briefly

Alternate

KQ

MODE

Push briefly

Finish settings

* On this screen, press the V button 5 times while pressing and

holding the button to move to the unit switch screen “

using UV the unit can be selected from , , ,

(except GP-M100/M250/M400), and (except GP-M001).

If anything other than the default value is selected, and when

is pressed briefly on the

appear.

Initialization Yes/No

PQ

Select using the buttons.

PQ Initialization is interrupted,

returns to main screen.

;'5 All items will be initialized.

P2P

Polarity of Control Output

Select using the buttons.

P2P NPN type

2P2 PNP type

QWV

Select function of Output 2

Select using the buttons.

QWV Control output

#P.) Analogue output

2P

screen, the unit switch screen will

13

7PKV

MODE

”. By

Page 14

Reference

MODE

Pressing and U at the same time will return to the

previous screen.

Initialization Value List

Item Default value (by model)

Model

Unit kPa MPa

SP1/FH1

(Switch-on point 1)

rP1/FL1

(Switch-off point 1)

SP2/FH2

(Switch-on point 2)

rP2/FL2

(Switch-off point 2)

ASP (Analog

point (4 mA))

AEP (Analog

point (20 mA))

ou1 (detection mode of output 1) Hno

ou2 (detection mode of output 2) Hno

CoF (offset correction) No correction

dS1/dr1/dS2/dr2 (direct timer) 0.00 (s)

SPEd (responsiveness) 3 (ms)

Eco (power-save mode) oFF

HYS

(presence of hysterisis when in window mode)

diS.U (display renew cycle) 200 (ms)

diS.r (display inversion) no

PASS (password) 0000

GP-M

GP-M

010

GP-M

025

001

40.0 0.400 1.000 4.00 10.00 16.00

20.0 0.200 0.500 2.00 5.00 8.00

100.0 1.000 2.500 10.00 25.00 40.00

80.0 0.800 2.000 8.00 20.00 32.00

start

-100.0 0.000 0.000 0.00 0.00 0.00

end

100.0 1.000 2.500 10.00 25.00 40.00

Item

Default value (for all models)

14

GP-M

100

GP-M

250

on

GP-M

400

Page 15

Settings of Each Setting Function

Push briefly

MODE

Push briefly

MODE

Push

briefly

MODE

Push

briefly

MODE

Push

briefly

MODE

Push

briefly

MODE

Enhanced Functions

Continue to next page

*2 Detection mode of output 2 is displayed as (.

when in window mode.

4. Switch-off point 2

Select using the buttons.

Setting range: 0% of F.S. to

(Switch-on point) -1% of F.S.

(Details on page 17)

3. Switch-on point 2

Select using the buttons.

Setting range:

1% of F.S. to 100% of F.S.

(Details on page 17)

#'2

6. Analog end point (20mA)

Select using the buttons.

Setting range:

0% of F.S. to 100% of F.S.

(Details on page 18)

Alternate

52

Alternate

Output 2 is analogue

output time

2. Configuration of output 2

Select using the buttons.

*PQ Hysteresis Mode N.O.

*P% Hysteresis Mode N.C.

(PQ Window Mode N.O.

(P% Window Mode N.C.

(Details on page 17)

#52

5. Analog start point (4mA)

Select using the buttons.

Setting range:

0% of F.S. to 100% of F.S.

(Details on page 18)

Alternate

QW *PQ

Alternate

'PF Finish settings

Return to regular screen

Press and hold

button

MODE

Select using the button

'('PF

QW

1. Configuration of output 1

Select using the buttons.

*PQ Hysteresis Mode N.O.

*P% Hysteresis Mode N.C.

(PQ Window Mode N.O.

(P% Window Mode N.C.

(Details on page 17)

Alternate

T2

*PQ

Alternate

Output 2 at time

of control output

*2

*1

*1 Detection mode of output 2 is displayed as (*

when in window mode.

Push

briefly

MODE

Push

briefly

MODE

• Whi le setting any

items you can return

to the main screen

by pressing and

holding the

button.

• Pressing and

U at the same time

will return the

previous screen.

Reference

15

MODE

MODE

Page 16

7. Offset correction

Reference

MODE

MODE

Alternate

Select using the buttons.

Setting range: Present

MODE

value ±10% of F.S.

Push

(Details on page 19)

briefly

8.

Alternate

Push

briefly

Alternate

Push

briefly

Alternate

Push

briefly

Alternate

Push

briefly

Alternate

Push

briefly

ON delay timer of output 1

Select using the buttons.

Setting range:

MODE

0.00 to 50.00 (s)

(Details on page 19)

9.

OFF delay timer of output 1

Select using the buttons.

MODE

Setting range:

0.00 to 50.00 (s)

(Details on page 19)

10.

ON delay timer of output 2

Select using the buttons.

Setting range:

MODE

0.00 to 50.00 (s)

(Details on page 19)

11.

OFF delay timer of output 2

Select using the buttons.

Setting range:

MODE

0.00 to 50.00 (s)

(Details on page 19)

12. Responsiveness

Select using the buttons.

MODE

Setting range: 3 to 5000 (ms)

(Details on page 20)

• While setting any items you can return to the main

screen by pressing and holding the button.

• Pressing and U at the same time will return the

previous screen.

%Q(

F5

FT

*2

*1

F5

FT

52'F

Alternate

'EQ

Q((

MODE

Push

*3

briefly

Alternate

*;5

QP

MODE

Push

briefly

Alternate

FK57

MODE

Push

briefly

Alternate

diS.r

PQ

MODE

Push

briefly

Alternate

2#55

MODE

Push

briefly

'PF Finish settings

Return to main screen

*1 Output 2 when control output

*2 Output 2 when analog output

*3 Only when the detection mode of both output 1

and output 2 are in hysterisis mode.

13. Power save mode

Select using the buttons.

Q(( Power save mode OFF

QP Power save mode ON

(Details on page

20

14. Hysteresis of Window mode,

Yes/No

Select using the buttons.

QP Hysteresis yes

Q(( Hysteresis no

(Details on page

15. Update of measuring value

on display

Select using the buttons.

Update of measuring value 50 ms

Update of measuring value 100 ms

Update of measuring value 200 ms

Update of measuring value 500 ms

Update of measuring value 1000 ms

(Details on page 20)

16. Display rotation

Select using the buttons.

PQ Regular display

;'5 Rotate by 180°

(Details on page

17. Password

Select using the buttons.

Setting range: to

(Details on page 11)

)

17

)

20

)

16

Page 17

Explanation of All Functions

*P%

*PQ

Hysteresis

T2

52

(1) (2) (3)

Detection mode and setting value

The GP-M Series has two types of detection modes which are

described below.

When the selected function of output 2 is

output 1 and output 2 can be set separately.

Hysteresis mode (

Considering

setting value when ON and when OFF.

• When the output is OFF (right

diagram 1), and the measured

value becomes more 52 than it

will turn on (right diagram 2).

• When the output is ON, and the

measuring value becomes less

than T2, it will turn OFF (right

diagram 3).

Window mode (

This mode determines whether the measured value is within or

outside the area of (* to (..

• If the detection value of the

output OFF condition in the right

diagram 1 is more than ((. +

*;5

) or less than (*, it will turn

ON (right diagram2).

• From that condition the measured

value is larger than (* (right

diagram 3), or, less than (., the

right diagram will be OFF.

• If the measured value of the

condition in the diagram on the

right is less than ((* more than (., it will be ON.

*PQ/*P%

5RT2

)

= hysteresis, it is the mode for changing the

(PQ/(P%

)

*;5

) or

QWV

(control output), the

(*

(1) (2) (3)

(.

17

(4) (5)

*;5

*;5

(PQ

(P%

Page 18

If

Reference

* Selection is possible when the selection function of output 2

(control output) is

QWV

.

Output Detection Mode

Switch on

point

Switch off

point

Output 1

when choosing

hysteresis mode

52 T2

Output 2 52

*

T2

*

Output 1

when choosing

window mode

(* (.

Output 2 (*

*

(.

*

Reference

*;5

is fixed at 0.5% of F.S., the presence or absence of hysterisis

can be selected by the extended function (page 16).

The name of the setting values depending on the mode

and output are as follows.

Free range analog output

Set the pressure value for the respective free range analog start

point and end point. The function of the output 2 can be selected at

the time of

#P.)

within the measured range. Operation is as follows.

1. When

• When

becomes 20 mA

• If the measurement value falls below

#52

• If the measurement value rises above

#'2

2. When

• When

becomes 20 mA

• If the measurement value falls below

#'2

• If the measurement value rises above

#52

(analogue output).

#52

<

#'2

#52

becomes

#'2

, output will be up to 3.8 mA

, output will be up to 20.5 mA

#52

>

#'2

#52

becomes

#'2

, output will be up to 20.5 mA

, output will be up to 3.8 mA

When system error (

#52

and

#'2

: 4 mA

: 4 mA

Current

20 mA

4 mA

3.8 mA

Current

20.5 mA

20 mA

'T5

) occurs, 2 mA will be output.

4 mA

18

can be set freely

#52 #'2

20.5 mA

3.8 mA

#52#'2

Measured

value

Measured

value

Page 19

Offset correction

Pressure value

±10%F.S.

Display value

Solid line:

condition at shipping

Reference

Concerning the value at the time of

shipping, there may be as much

as ±10%F.S. offset correction.

This activates in the case of a

margin of error in the displayed

pressure value and the actual

pressure value.

The pressure value after the offset

correction is displayed on the

setting screen and can be adjusted with the UV buttons.

• Offset correction works in conjunction with “Atmospheric

pressure correction”.

•If the UV buttons are pressed and held simultaneously

on the offset correction screen, the offset correction

value and the air pressure correction value will revert to

the condition at shipping (no correction).

Delay timer

The delay timer can be set within the range of 0.00 to 50.00(s)

When the function selection of output 2 is out (control output) the

delay timer for output 1 and output 2 can be set separately.

Setting

item

Concerning the ON delay timer of output 1/output 2. When the

F5/F5

judgment switches from OFF to ON, t he set delay time will elapse.

Concerning the OFF delay time of output 1/ output 2. When the

FT/FT

* The setting of the dS2, dr2 is possible when the function of output 2 is

judgment switches from ON to OFF, the set delay time will elapse.

selected as out (control output).

Meaning

19

Page 20

Time chart

Reference

j

Output

udgment

ON

OFF

Control output

after delay

OFF

ON

F5/F5

(ON delay)

FT/FT

(OFF delay)

Responsiveness

The time until 100% response of the internal judgment value can be

set from within the range of 3 to 5000 (ms).

The response time of the analog output (90% response) will be an

additional 2 ms from this point.

Power Save Mode

When QP is selected, if the key operation does not occur for 15

seconds (Power Save) will be displayed.

The “”at the time of power save display will move from the left to

the right, and the operation indicator will operate normally. To return

the display status to normal, press any key. When there is an error,

regardless of whether power save mode is QP/

displayed.

Q((

, the error will be

Display Renewal Cycle

Set the interval to renew the display contents. When a value is increased,

only for that time the value will continue to be displayed the same. From

after the renewal until the next renewal, the measurement value will be

averaged so as to control fluctuations in the display value. However,

there will be no influence on the control output and the analog output.

Display inversion

When PQ is selected: regular display

When

;'5

is selected: The display will be inverted vertically 180°.

20

Page 21

Error Display and Countermeasures

Error

display

'T%

Q.

W.

'T2

'T'

'T5

Cause Measures

At the time of atmospheric

pressure correction there is

±10% F.S. applied pressure.

There is too much current flowin g

through the control output.

Outside possible display

range (above)

Outside possible display

range (below)

An incorrect password was

entered at the time of the

Key Lock release.

Write/load to EEPROM

error

System error

Return the air to the room

pressure, once again set

the sensitivity setting.

Check the load, and return

to the rated range.

Return to the rated

pressure range.

Return to the rated

pressure range.

Enter the correct

password. If the password

has been forgotten contact

your nearest sales office.

Do an initial reset. If in that

case the problem has not

been fixed please contact us.

Contact the nearest sales office

Output Condition at the Time of Error.

Error

display

'T%

Q.

W.

'T2

'T'

'T5

Output judgment Analog output

Regular operation Regular operation

OFF Regular operation

Operation at the maximum possible display range

Operation at the minimum possible display range

Regular operation Regular operation

Regular operation Regular operation

OFF 2 mA

21

.

Page 22

Specifications (Differs by model type)

GP-M

GP-M

GP-M

GP-M

GP-M

Model

Rated

pressure

Possible

display

range

Allowable

pressure

Burst

pressure

Display

resolution

Fluid type

001

010

025

-100 to

-0.1 to

+100

+1

kPa

MPa

-120.0 to

-0.210 to

+120.0

+1.110

kPa

MPa

400 kPa 4 MPa 10 MPa 30 MPa 50 MPa 50 MPa

1.5 MPa

15 MPa 35 MPa

0.1 kPa

Gas or liquid that will not

corrode the liquid contact

0.001 MPa 0.01 MPa

part

100

-0.1 to

0 to +10

+2.5

MPa

MPa

-0.360 to

-1.00 to

+2.760

+11.00

MPa

MPa

100

MPa

Liquid that will not corrode

the liquid contact part

250

0 to +25

MPa

-2.50 to

+27.50

MPa

100

MPa

GP-M

400

0 to +40

MPa

-4.00 to

+44.00

MPa

100

MPa

Specifications (All model types are the same)

Type of pressure Gage pressure

Repeatability

characteristics

Zero-cut pressure

Box rotation angle Maximum 330°

*1

Precision

Temperature

value

Connection

diameter

*2

G3/4 (Changes to the R1/8 male,

±1.0% of F.S. or less

±0.3% of F.S. or less

±0.6% of F.S./10°C

±0.5% of F.S.

R3/8 male, G1/4 female, NPT1/8 male, and

NPT1/4 male option adapters are available.)

22

R1/4 male,

Page 23

Medium temperature

Rating

Output

Power supply

volta ge

Current

consumption

Display method

Operation display

light

Hysteresis

Control

Response

Environmental

resistance

output

Analog

output

Output 1

control output

Control

Output 2

output

(

replace

-ment

Analog

type

)

output

Ambient

temperature

Relative

humidity

Vibration

Shock

Enclosure

protection

-20 to +100°C (no freezing/condensation)

10-30 VDC, Ripple (P-P): 10% max,

Class 2 or LPS

50 mA or less (when 24 V: 32 mA or less, when

12 V: 48 mA or less. Excluding output)

4 column digital LED red/

Vertical inversion display possible

Operation indicator (output 1) (orange)

Operation indicator (output 2) (orange)

During hysteresis mode: variable

(Difference between switch-on point and

switch-off point is hysteresis)

During window mode: fixed (0.5% of F.S.)

*3 *6

*4

Selectable from 3 to 5000 ms

As above + 2 ms (90% response)

NPN/PNP open collector (Selectable)

30 V or less, Max. 250 mA

Residual voltage for the Main Unit is

1 V or less, N.O./N.C. selectable

4-20 mA, maximum load resistance 500 Ω

(When the electric voltage is more than 20 V)

-20 to +80°C (no freezing/condensation)

35 to 85% RH (no condensation)

IEC60068-2-6 20 G (10 to 2000 Hz

In each direction of X, Y, Z for 2 hours)

IEC60068-2-27 50 G (11 ms

In each direction X, Y, Z 3 times)

*6

IP67

*5

*6

23

Page 24

Pressure port: SUSXM7/

10

20

30

40

50

60

70

80

90

Ambient temperature (°C)

020406080

Relative humidity (%RH)

0

Diaphragm pressure port: Al2O3/O-Ring: FKM

Housing metal portion: SUS304, SUS303

Housing plastic portion: PPSU

Air hole*7: PTFE, nickel-plated brass.

Material

properties

Wette d

part

Other

parts

Applicable cable M12 connector 4 pin

Weight App. 150 g

*1 This is the value when considering linearity + hysterisis + repeatability

in a stable environment of 23°C.

*2 The repeatability, based on consistent conditions, is the difference in

the detection points at the time of fluctuations in the repetition.

When the temperature of the piping exceeds 80°C, do not connect the cable.

*3

*4 Consumption current including output is 0.6 A and under.

*5 The maximum load resistance R will be the values below in response to

the electric voltage E.

When 10-23V: R = (38 x (E-10) + 128) Ω

When 23-30V: R = 622 Ω

*6 Take measures such as the following to prevent condensation.

Ensure that the ambient temperature is equal or lower than the fluid temperature.

•

• Dehumidify using an air-conditioner

• Separate the sensor from the cooling pipe by at least 30 cm using

the connecting pipe.

Also, it is recommended that ambient temperature and relative humidity should

be within the range of the diagonal line depicted in the graph below.

*7 Only for the GP-M001/M010/M025

24

Page 25

Dimensions

(27.5)

44.3

86.7

ø34.2

44.6

ø30

(Two surface width)

27

29.2

2.6

15.4

G3/4 A

Useable length 10

M12 × 1

Detecting element

ø11 depth 1.2 (GP-M001/M010/M025)

ø7 depth 2.9 (GP-M100/M250/M400)

*

* There is no air hole

on the GP-M100/

M250/M400.

(Unit : mm)

ø19.5

ø22.5

1.5

A-A

A

A

ø15

ø8

ø12.8

2.4

A-A

1.9

A

A

O-ring

for GP-M001/M010/M025 use

O-ring set

for GP-M100/M250/M400 use

25

Page 26

Warranties and Disclaimers

(1) KEYENCE warrants the Products to be free of defects in materials and

workmanship for a period of one (1) year from the date of shipment. If

any models or samples were shown to Buyer, such models or samples

were used merely to illustrate the general type and quality of the

Products and not to represent that the Products would necessarily

conform to said models or samples. Any Products found to be

defective must be shipped to KEYENCE with all shipping costs paid by

Buyer or offered to KEYENCE for inspection and examination. Upon

examination by KEYENCE, KEYENCE, at its sole option, will refund the

purchase price of, or repair or replace at no charge any Products

found to be defective. This warranty does not apply to any defects

resulting from any action of Buyer, including but not limited to improper

installation, improper interfacing, improper repair, unauthorized

modification, misapplication and mishandling, such as exposure to

excessive current, heat, coldness, moisture, vibration or outdoors air.

Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various

Products. They are only suggestions, and it is Buyer's responsibility to

ascertain the fitness of the Products for Buyer’s intended use.

KEYENCE will not be responsible for any damages that may result from

the use of the Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer

are not to be used internally in humans, for human transportation, as

safety devices or fail-safe systems, unless their written specifications

state otherwise. Should any Products/Samples be used in such a

manner or misused in any way, KEYENCE assumes no responsibility,

and additionally Buyer will indemnify KEYENCE and hold KEYENCE

harmless from any liability or damage whatsoever arising out of any

misuse of the Products/Samples.

(4)

OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES

ARE PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER.

ALL EXPRESS, IMPLIED, AND STATUTORY WARRANTIES,

INCLUDING, WITHOUT LIMITATION, THE WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE,

AND NON-INFRINGEMENT OF PROPRIETARY RIGHTS, ARE

EXPRESSLY DISCLAIMED.

IN NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES

BE LIABLE TO ANY PERSON OR ENTITY FOR ANY DIRECT,

26

Page 27

INDIRECT, INCIDENTAL, PUNITIVE, SPECIAL OR

CONSEQUENTIAL DAMAGES (INCLUDING, WITHOUT LIMITATION,

ANY DAMAGES RESULTING FROM LOSS OF USE, BUSINESS

INTERRUPTION, LOSS OF INFORMATION, LOSS OR INACCURACY

OF DATA, LOSS OF PROFITS, LOSS OF SAVINGS, THE COST OF

PROCUREMENT OF SUBSTITUTED GOODS, SERVICES OR

TECHNOLOGIES, OR FOR ANY MATTER ARISING OUT OF OR IN

CONNECTION WITH THE USE OR INABILITY TO USE THE

PRODUCTS, EVEN IF KEYENCE OR ONE OF ITS AFFILIATED

ENTITIES WAS ADVISED OF A POSSIBLE THIRD PARTY’S CLAIM

FOR DAMAGES OR ANY OTHER CLAIM AGAINST BUYER.

jurisdictions, some of the foregoing warranty disclaimers or damage

limitations may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or

delivered to a third party, Buyer must provide such third party with a

copy of this document, all specifications, manuals, catalogs, leaflets

and written information provided to Buyer pertaining to the Products/

Samples.

27

In some

E 1101-3

Page 28

Copyright (c) 2011 KEYENCE CORPORATION. All rights reserved.

11843E 1012-1a 96M11843 Printed in Japan

Loading...

Loading...