Page 1

Warning

SEL

M

SEL

M

DSC

DSC

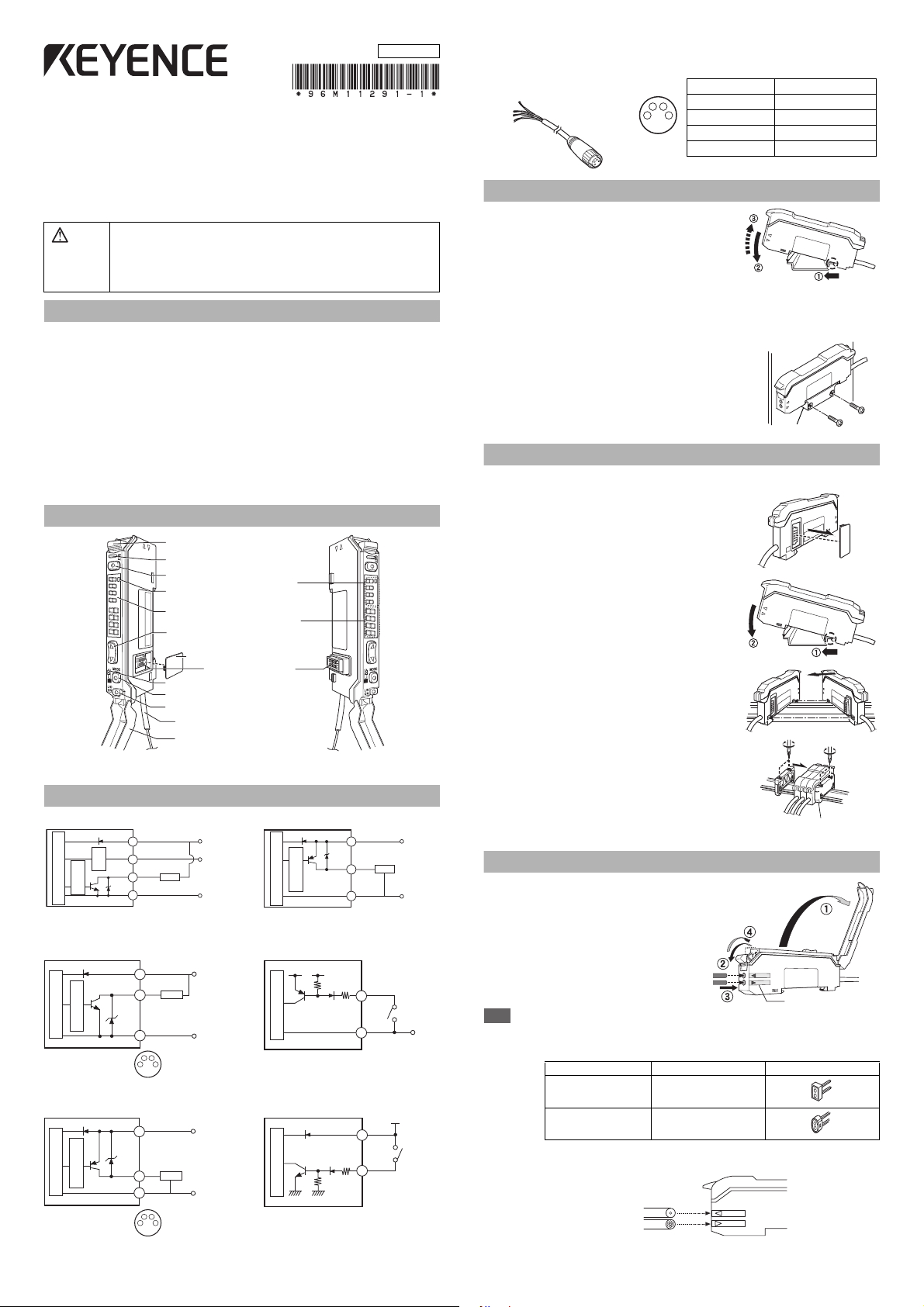

Operation status indicators

Digital monitor

Setting value

(Displayed in green)

Current value

(Displayed in red)

Dust cover

Fiber lock lever

Set button (SET)

DSC indicator

Manual button

Mode button

Power selection switch*1

Expansion protective cover

Expansion connector

Output selector

Cable*2

*1 When set to “M”, the power mode is fixed to Mega Turbo.

*2 FS-V30 does not have the cable. M8 connector for FS-V31C(P)/32C(P)

Photoelectric sensor main circuit

Max. 100mA

0 VDC

12 to 24 VDC

(Control output)

Brown *3

Blue *3

Black

Load

Overcurrent

protection circuit

0 VDC

12-24 VDC

(1)

*

(4)

Sensor main circuit

Overcurrent protection circuit

Load

(3)

*

123

4

Pin assignment

* FS-V31C only

(1)

*

(3)

*

(4)

0 VDC

12-24 VDC

Sensor main circuit

Overcurrent protection circuit

Load

* FS-V31CP only

123

4

Pin assignment

Connected pin No. Core wire cover color

(1) Brown

(2) White

(3) Blue

(4) Black

OP-73864 (cable length:2 m)

OP-73865 (cable length:10 m)

OP-73880

OP-26751 (a set of two)

96M11291

Socket Cable (Sold Separately)

For FS-V31C(P)/32C(P) Pin and wire color table

DIGITAL FIBER SENSOR

FS-V30/31(P)/31C(P)/31M/32(P)/32C(P)

Instruction Manual

Read this manual before using the product in order to achieve maximum performance.

Keep this manual in a safe place after reading it so that it can be used at any time.

• This product is just intended to detect the object(s). Do not use this product

for the purpose to protect a human body or a part of human body.

• This product is not intended for use as explosion-proof product. Do not use

this product in a hazardous location and/or potentially explosive atmosphere.

• This product is a sensor of DC power supply type. Do not apply AC power.

The product may explode or burn if an AC voltage is applied.

Precautions on Regulations and Standards

UL Certificate

This product is an UL/C-UL Listed product.

• UL File No. E301717

• Category NRKH,NRKH7

• Enclosure Type 1 (Based on UL50)

Be sure to consider the following specifications when using this product as an UL/

C-UL Listed Product.

• Use the power supply with Class 2 output defined in NFPA70 (NEC: National

Electrical Code).

• Power supply/ Control input/ Control output circuits shall be connected to a

single Class 2 source only.

• Use with the over current protection device which is rated 24V or more and not

more than 2A.

Part Names

412

3

Mounting Unit

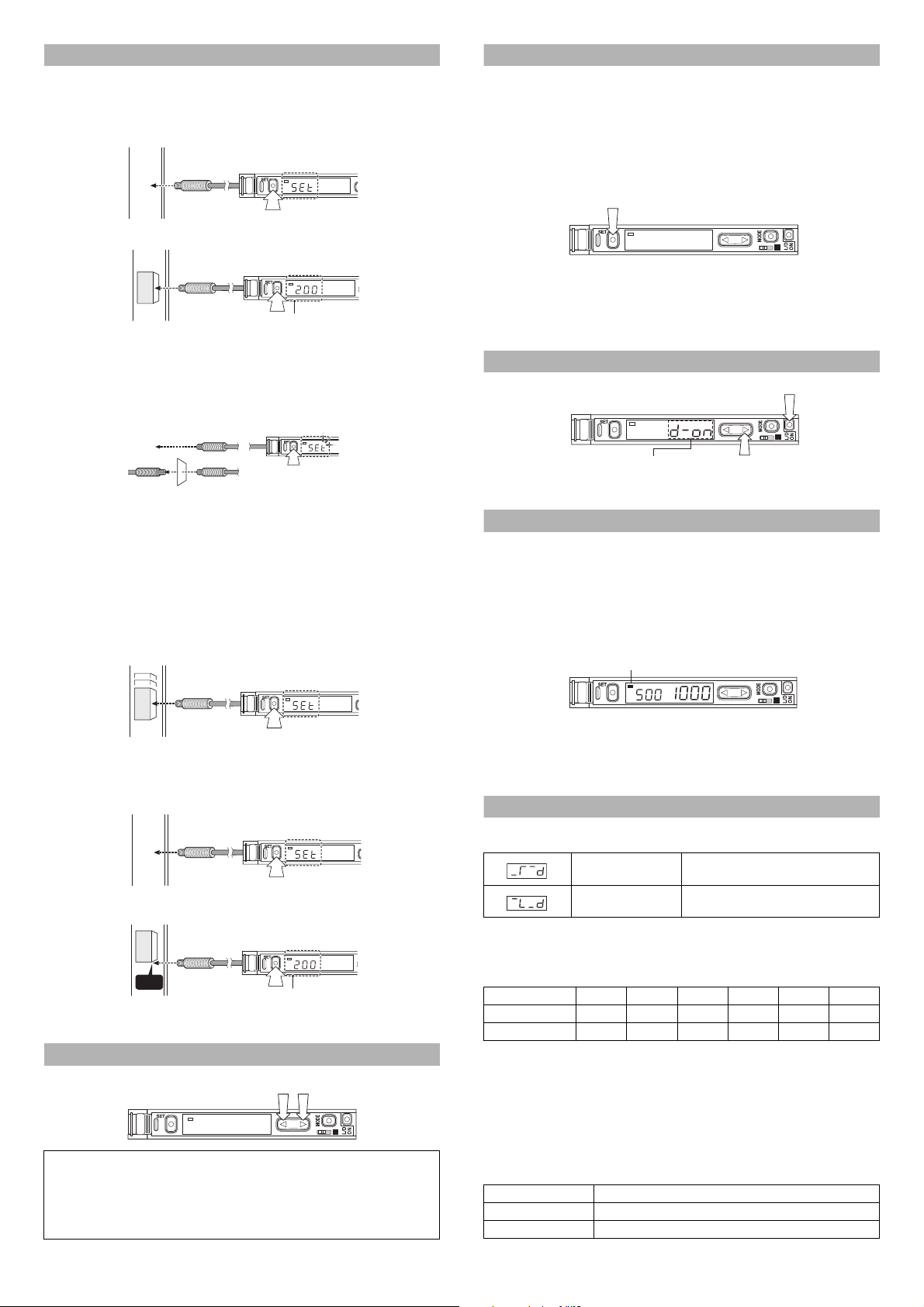

Mounting on a DIN Rail

1

Align the claw at the bottom of the main body with

the DIN rail. While pushing the main body in the

direction of the arrow 1, slant it in the direction of

the arrow 2.

2

To dismount the sensor, raise the main body in

the direction of the arrow 3 while pushing the

main body in the direction of the arrow 1.

Installation on a Wall (Main Unit Only)

Attach the unit to the optional mounting bracket

(OP-73880), mount them together, and secure

them with two M3 screws as shown in the

illustration.

Connecting Multiple Amplifiers

Up to 16 sub units can be connected to one main unit.

1 Remove the protection cover on the side of

the main unit.

I/O Circuit

FS-V31/32/31M FS-V31P/32P

Brown *1

Monitor output

(1 to 5 V)*2

Orange

circuit

Protection

Overcurrent

protection circuit

Photoelectric sensor main circuit

Max. 100mA

Black

(Control output)

Blue *1

*1 FS-V31/31M only *2 FS-V31M only *3 FS-V31P only

FS-V31C/32C

Output Circuit Diagram Input Circuit Diagram

FS-V31CP/32CP

Output Circuit Diagram Input Circuit Diagram

12 to 24 VDC

Devices with

10 kΩ input

impedance min.

Load

0 VDC

Sensor main circuit

Sensor main circuit

DC3.3 V

(Short-circuit current

1 mA or less)

(Short-circuit

current 2 mA

or less)

2 Install the amplifier one by one on the DIN

rail.

3 Engage the two claws of the child unit with

the recesses on the main unit side until you

hear a click sound.

4 Attach the end units (option: OP-26751) to the

both ends of the connected amplifiers in the

same way as in step (2).

5 Sandwich the amplifiers between the end

units. Tighten the screws at the top (two

screws x two units) with a Phillips screwdriver

to fix the end units.

Connecting Fiber Unit

1 Open the dust cover in the direction

shown by arrow 1.

2 Move down the fiber lock lever in the

direction shown by arrow 2.

3 Insert a fiber unit into the fiber insertion

holes to a length of the fiber insertion

sign (i.e., approximately 14 mm).

(2)

PLC, etc.

*

(3)

(1)

(2)

0 VDC

12-24 VDC

*

PLC, etc.

4 Move down the fiber lock lever in the

direction shown by arrow 4.

Note

If a thin fiber unit is used, an adapter provided with the thin fiber unit will be required.

Unless the right adapter is connected, the thin fiber unit will not detect targets correctly.

(The adapter is supplied with the fiber unit.)

Cable outer dia. Adapter Appearance

φ1.3

φ1.0

•

To connect the coaxial reflective type fiber unit to the amplifier, connect the single-core

Adapter A

(OP-26500)

Adapter B

(OP-26501)

fiber to the transmitter side, and connect the multiple-core fiber to the receiver side.

Single-core fiber

Multi-core fiber

Transmitter

Receiver

1

Fiber insertion sign

Page 2

Making Sensitivity Settings

DSC

DSC

When the setting is completed,

the setting value is displayed.

Workpiece

DSC

3 sec or longer

"Reflective model"

"Through-beam model"

DSC

Workpiece

DSC

When the setting is completed,

the setting value is displayed.

Head

Workpiece

SEL

M

DSC

Two-point Calibration

In this mode, the PV used will be the mean value of two sensing values obtained

with and without a workpiece.

1

Press the SET button without any workpiece placed in front of the fiber unit.

2

Place a workpiece placed in front of the fiber unit, and press the SET button.

If the sensitivity difference does not have enough room, “

” flashes for about two seconds

after the calibration is complete. The set value is stored in memory even in that case.

Maximum Sensitivity Setting

Set the sensitivity without a workpiece in the case of the reflective type, and with a

workpiece in the case of the through-beam or retro-reflective type.

Press the SET button for three seconds in the state as shown in the above figure.

(Release the button when SET flashes.)

When setting the sensitivity, set the value slightly higher than the received light intensity.

Full Auto Calibration

In this mode, the PV will be set to the mean value of the maximum and minimum incident

values obtained within a certain period. Use this mode to detect moving workpieces.

1 Press the set button for a minimum of three seconds while the target

workpiece is passing the sensing area of the fiber unit.

• While the SET button is pressed, the sensitivity of the sensor will be set

according to the incident values.

DSC

Workpiece

• After the setting is completed, the setting value is displayed on the digital monitor.

Positioning Calibration

1 Press the SET button without any workpiece placed in front of the fiber unit.

2 Place a workpiece on the position where you want to perform positioning.

Press the SET button for 3 seconds or longer until the display flashes.

Fine-adjusting Sensitivity

The setting value can be directly changed by pressing the manual button.

DSC

When extension display (page 5, No.8) is set for the number of digits to be

displayed for the received light intensity

1

Press the manual button quickly once, and check that the setting value flashes.

2

While the setting value is flashing, change the setting value with the Manual button.

M

SEL

Percentage (%) Calibration

This is a calibration method that can set the setting value by percentage with reference to the received light intensity at the time of sensitivity setting.

For example, if the target value is set to –10P, the setting value is determined 10%

lower than the received light intensity when the SET button is pressed.

1 When selecting the sensitivity setting method (page 4, No. 2), select the %

calibration, and set the target value of calibration.

2 Taking the desired light intensity as a reference (normally without a

workpiece), press the SET button.

* While the % calibration is in use, other calibrations (sensitivity setting) cannot

be used.

* With FS-V31C(P)/32C(P), by periodically performing external calibration from

PLC or other devices, stable detection can be performed even with a small

sensitivity difference.

Output Selection

Either light-ON mode or dark-ON mode is selectable.

(1)

Press

DSC

When the area detection mode is

selected, the selection options are

NO and NC.

Dynamic Sensitivity Correction (DSC) Function

DSC automatically corrects the setting value according to the changes in the

received light intensity when there is no workpiece (output OFF).

This function is effective when the light intensity difference is small when judging

whether or not there is a workpiece.

At Detection mode selection (page 4, No.4), select “Dynamic sensitivity correction

mode” beforehand.*

How to set the sensitivity is the same as in the normal mode.

The DSC indicator illuminates when the DSC function is set.

DSC indicator

DSC

* When Light ON is selected, the upper limit of the correctable range is twice as

much as the initial setting value.

* The value is stored in memory even after the power is turned off.

*

The DSC indicator flashes when the light intensity during output OFF greatly fluctuates

or the L/D ON selection is inappropriate. In such a case, check the setting again.

Edge Detection Mode

This mode detects the change in the received light intensity during a given period

of time.

Rising edge detection Detects the increase (rising edge) of the

Falling edge detection Detects the decrease (falling edge) of the

received light intensity

received light intensity

Filter Setting

Basically, leave this setting as its initial value. If the passage interval of workpieces

is too short for the unit to respond, strengthen the level and try again.

The selectable filter level differs depending on the power modes.

Filter level HSP* FINE

Default state589999

Setting range 1 to 5 4 to 8 5 to 9 6 to 9 8 to 9 9 only

*HSP: HIGH SPEED

As the number becomes smaller, the filter becomes stronger, which makes the unit difficult to

respond to gradual changes in light intensity.

TURBO

Making Sensitivity Settings

The sensitivity is set to maximum when the SET button is pressed quickly once.

When the setting value is too low and the unit detects objects other than the workpiece, fine-adjust the setting value to a higher number.

Operation When Switching Outputs

Setting Operation

L-ON Normally OFF. Turns ON only when the light intensity changes.

D-ON Normally ON. Turns OFF only when the light intensity changes.

2

M

SEL

(2)

Press (2) within five seconds

after pressing (1).

M

SEL

SUPER ULTRA MEGA

Page 3

Area Detection Mode

HI: Upper limit

setting value

LO: Lower limit

setting value

ON

OFF

OFF

Received light

intensity

(1)pin *

(3)pin *

(2)pin

+V

0V

FS-V31C/V32C FS-V31CP/V32CP

Input OFF

Input ON

% calibration Display scaling

3 seconds

or less

Input OFF

Input ON

% calibration% calibration

3 seconds or more

Press

MODE

DSC

DSC

Press for 2 seconds

or longer.

.

.

.

.

.

Hold display selection

Select the setting by pressing the button.

Updates every time the current light

intensity is less (or more) than the

specified peak and bottom values.

Displays the maximum and minimum peak

values since the power is turned on (total

number).

Displays the maximum and minimum

bottom values since the power is turned on

(total number).

Displays the minimum peak value and the

maximum bottom value since the power is

turned on (total number).

Displays the maximum peak value and the

minimum bottom value since the power is

turned on (total number).

This mode is suited to detecting the received light intensity only of a certain range.

To set this mode, select the area detection mode at Detection mode selection (page 4, No.4).

Set the value so that the upper limit setting value is

larger than the lower limit setting value.

The unit does not respond when the upper limit setting value is less than or equal to the lower limit setting value.

Even when the above condition is satisfied, the unit

may not respond when the HI and LO values are close

to each other because of hysteresis. Be sure to operate the unit to check whether the values are valid.

How to switch the upper limit setting value (HI) and the lower

limit setting value (LO)

When the button is pressed, “HI” or “LO” and the setting value alternately flash.

When the MODE button is pressed while the display alternately flashes, the “HI” or

“LO” display changes. How to configure the sensitivity setting is the same as

when in the normal detection mode.

Setting the Display Scaling

This is the function to adjust the current received light intensity to the ìscaling target value.

1 When selecting a display value correction function (page 5, No. 6), select the

display scaling function, and set the target value.

2

During the normal display, press the SET button while pressing the MODE button.

(Scaling is performed for the current light intensity at this time.)

The reference light intensity can be set in the following range in reference with the

currently received light intensity:

Power mode Minimum value Maximum value

HIGH SPEED/FINE/TURBO

SUPER Approx. 1/40 times Approx. 8 times

ULTRA

MEGA

Approx. 1/20 times Approx. 16 times

Approx. 1/160 times

Approx. 1/320 times

Approx. 2 times

Approx. 1 time

• No value can be set when the Edge detection mode is selected.

• The value is stored in memory even after the power is turned off.

• The value is not reflected to the analog output of the FS-V31M.

• When using FS-V31C(P)/32C(P), external inputs can be used.

If the value exceeds the

range, 'TT is displayed

and scaling is performed

up to the possilbe range.

Display Selection

The factory default value is “1” only. Other items can be displayed only after being

selected at Display customization selection (page 5, No.8).

(1) (7)

DSC

Parameter Current received

(2)

Extension display

(received light intensity) *1

(3)

Bar display *2

(4)

Bar display *2 Excess gain (%) *3

DSC

DSC

DSC

light intensity

MODE

Press

MODE

Press

Current received

light intensity

MODE

Press

*1 When ULTRA/MEGA mode is selected, the current received light intensity can

be displayed up to 5 digits.

The setting value flashes when the

The setting can be changed by pressing the button while flashing.

*2 The excess gain is displayed in a 5% increment from 85 to 115%.

*3 The current light intensity for the setting value is displayed in percentage.

*4 Holds and displays the peak value and the bottom value.

How to reset the peak and bottom values (with the 5/6 display)

While pressing the MODE button, press the SET button for 3 seconds or longer to reset

the peak and bottom values. Turning the power off also resets the values.

With FS-V31C(P)/32C(P), the value can be reset externally by selecting Reset at

External input function selection (page 4, No.4-C).

User-friendly Functions (Direct Access Menu)

The hold display (5/6) can be set in detail by pressing the button for 2 seconds or longer.

Press

Press

MODE

DSC

Power mode

(6)

DSC

DSC

Excess gain (%)

Peak value

*4

(5)

MODE

DSC

DSC

Received light

intensity

Peak value *4

button is pressed once.

Current received

light intensity

MODE

Press

Excess gain (%)

Bottom value

*4

MODE

Press

Received light

intensity

Bottom value *4

Zero-shift Function

The Zero-shift function is used to forcibly set the current light intensity to zero.

1

At Display value correction function selection (page 5, No.6), select “Zero-shift function”.

2 When the SET button is pressed while the MODE button is pressed, the current

light intensity is forcibly set to zero.

• This function cannot be used when the Dynamic sensitivity correction (DSC) or

Edge detection mode is selected.

• The value is stored in memory even after the power is turned off.

• The value is not reflected to the analog output of the FS-V31M.

• When using FS-V31C(P)/32C(P), external inputs can be used.

External Input [Function only for FS-V31C(P)/V32C(P)]

1

Signals can be input externally by selecting an external input function (page 4, No. 4-C).

2

The signal can be accepted by short-circuiting the pin (2) for 2 ms or more as

shown below for each model (20 ms for OFF).

(1)pin *

(2)pin

(3)pin *

* For FS-V31C/31CP only.

• Setting using an external input is up to 1 million times.

• No inputs are accepted while setting each mode.

When external calibration is selected, the operation is the same as with the SET button.

Special Function

By performing the following operation, both sensitivity setting and scaling can be

performed using external input. Select external calibration (page 4, No. 4-C) and

display scaling. The following is the example when using the % calibration.

The power mode and attenuation function for the power mode display (3) can be

set by pressing the button for 2 seconds or longer.

DSC

Press for 2 seconds or longer.

DSC

+V

DSC

0V

Press to select (see page 4, No. 1).

MODE

Press

Press to select (see page 5, No. 5).

MODE

Press

Key Lock Function

The key lock function disables the operation of all keys.

1

While pressing the MODE button, press the ( ) button for at least three seconds.

DSC

M

SEL

The same steps can be taken to deactivate key lock.

For more information on the key lock levels and the PIN number key lock function,

refer to page 6.

3

Page 4

Operation Configuration

Basic

setting menu

1. Power mode selection

2. Sensitivity setting method selection

3. Timer mode selection

4. Detection mode selection

4-C. External input function selection

5. Light emission power selection

6. Display value correction function selection

7. Display reverse selection

8. Display customization selection

9. APC function setting

10. Power save mode setting

11. Key lock level setting

12. Interference prevention function setting

Detection

setting menu

Display

setting menu

System

setting menu

Normally, this unit can be used in the basic settings.

Set other functions as necessary.

Pressing for 3 seconds or longer displays the basic menu.

Select a function with the button, and press to confirm.

The setting for each item is confirmed when selecting END and pressing .

MODE

MODE

MODE

Detection Setting Menu

From the basic menu

DSC

MODE

Press

DSC

MODE

Press

When Timer OFF

is selected

When other

than Timer OFF

is selected

3

Timer mode selection

Select the setting by pressing the button.

Timer OFF

Off-delay

On-delay

One-shot

On-delay Off-delay *1

On-delay One-shot *1

Basic Setting Menu

Press for 3 seconds or longer

MODE

DSC

MODE

Press

DSC

MODE

Press

When Std is

selected

DSC

When SEtP

is selected

A

DSC

MODE

Press

When StG-Func

is selected

Detection

setting menu

When StG-diSP

is selected

Display

setting menu

When End is

selected

When StG-SYS

is selected

System

setting menu

End of basic menu

display

1

Power mode (response time) selection

Select the setting by pressing the button.

.

HIGH SPEED: 33 μs

.

FINE: 250 μs

.

TURBO: 500 μs

.

SUPER: 1 ms

.

ULTRA: 4 ms

.

MEGA: 16 ms

(Can be switched when the power

selection switch is set to SEL.)

2

Sensitivity setting method selection

Select the setting by pressing the button.

.

Normal sensitivity setting (see page 2)

.

Percentage(%) calibration (see page 2)

Percentage calibration target value setting

Select the setting by pressing the button.

MODE

Press

Can be set between –99 and +99%.

Menu end/continue selection

Select the setting by pressing the button.

.

.

.

.

Ends the menu.

Configures detection

settings.

(Timer, DSC, etc.)

Configures display

settings.

(Scaling, inversion, etc.)

Configures system

settings.

(APC, Power Save, etc.)

DSC

When Std or

ArEA is selected

When using

FS-V31(P)

FS-V32(P)

FS-V31M

FS-V30

DSC

When other

than SCAL

is selected

DSC

a

DSC

DSC

MODE

Press

DSC

DSC

DSC

When using

FS-V31C(P)

FS-V32C(P)

MODE

Press

DSC

Press

At Timer mode selection,

* other than 1 is selected → a

* 1 is selected → b

b

or

Press

When dSc is

selected

Press

Press

When Edge detection

is selected

Press

When SCAL

is selected

Press

Timer setting

Configure setting by pressing the button.

MODE

Can be set between 0.1 and 9999 ms.

When 1 is selected, On-delay timer is set.

Timer setting 2

Sets the time of Off-delay (One-shot).

Configure setting by pressing the button.

Can be set between 0.1 and 9999 ms.

MODE

4

Detection mode selection

Select the setting by pressing the button.

.

Normal (light intensity) detection mode

.

Dynamic sensitivity correction mode

(see page 2)

.

Area detection mode (see page 3)

.

Detects the rising edge of the received

light intensity (Edge detection mode)

(see page 2)

.

Detects the falling edge of the received

light intensity (Edge detection mode)

(see page 2)

Detection operation selection

Select the setting by pressing the button.

MODE

.

Mainly reflective type

[Light intensity with workpiece >

Light intensity without workpiece]

(The output is ON when the light

enters.)

.

Mainly transmission type

[Light intensity with workpiece <

Light intensity without workpiece]

(The output is ON when the light

is blocked.)

Correction speed selection

Select the setting by pressing the button.

MODE

1 to 3

The correction is made faster as the number

becomes larger. (Select 1 in normal cases.)

Power mode

hSP

FinE

Turb/SuPr/Ultr/MEGA

Filter time selection

Select the setting by pressing the button.

MODE

Select larger number (initial state) in normal

cases. The selectable level depends on the

power modes. (see page 2)

4-C

External input function selection

(for the connector type only)

Select the setting by pressing the button.

.

.

.

.

.

.

Display scaling target value setting

Select the setting by pressing the button.

MODE

The value can be set between 100 and 10000

in unit of 100.

10000 is displayed as .

Level 1

Level 2

114.7ms

7.34s

819.2ms

52.43s

104.86s

Does not use external input.

External calibration

Display scaling

Zero shift

Hold display reset

Light emission stop

1.64s

Level 3

1.8ms

12.8ms

25.6ms

4

Page 5

System Setting Menu

Back to A of

the basic setting.

DSC DSC

5

Light emission power selection

Select the setting by pressing the button.

Display

Power mode

FinE

Normal

Approx. 15% of the normal time

Approx. 3% of

the normal time

Turb/SuPr/

uLtr/MEGA

Approx. 1.5% of

the normal time

hSP

Approx. 11% of

the normal time

Press

MODE

Select the setting by pressing the button.

Not to be used.

Uses the display scaling function.

Uses the zero-shift function.

Display scaling target value setting

Configure setting by pressing the button.

The value can be set between 100 and

10000 in unit of 100.

10000 is displayed as FuLL.

When oFF or

ShFt is selected

When no is

selected

When SCAL

is selected

DSC

DSC

DSC

DSC

DSC

DSC

DSC

DSC

Select the setting by pressing the button.

Normal display

Reverses the display.

Even when the display is reversed,

the green light indicates setting values,

and the red light indicates received

light intensity.

Select the setting by pressing the button.

Does not customize the display.

Customizes the display.

Selectable display setting

The items shown left are displayed in

order every time the MODE button is

pressed. (see page 3)

Select the setting by pressing the

button.

Adds the item to the

selectable display.

Deletes the item from the

selectable display.

When no is

selected

Normal

Extension

Bar

Excess gain

(%)

6

Display value correction function selection

7 Display reverse selection

8 Display customization selection

(1)

(2)

(3)

(4)

Press

MODE

Press

MODE

Press

MODE

Press

MODE

.

.

.

.

.

.

.

.

.

From the basic menu

Back to A of

the basic setting.

DSC

DSC

DSC

HOLD

Power mode

HOLD

Excess gain

(%)

(5)

(7)

(6)

Press

MODE

Press

MODE

Press

MODE

When SCAL or

ShFt is selected

on page 4, No.4-C

Press

MODE

Press

MODE

Press

MODE

Press

MODE

Press

MODE

When setting each mode, the display returns normal by pressing the

button for 3 seconds or longer.

Reference

From the basic menu

DSC

MODE

Press

Display Setting Menu

MODE

DSC

Press

DSC

Press

DSC

Press

DSC

Press

Back to A of

the basic setting.

MODE

MODE

MODE

MODE

9

S-APC setting

Configure setting by pressing the button.

.

APC is enabled.

.

APC is disabled.

About APC (Auto Power Control)

In normal cases, use the sensor with APC

disabled.

When APC is enabled, the light intensity is

monitored and corrected in order to maintain

regular light transmission. If the environment is

sufficiently clean, a highly accurate detection can

constantly be performed.

Note: Long-ter m use of APC imposes heavier

load on the LED than when disabled.

10

Power save mode setting

Configure setting by pressing the button.

.

Saves power (Turns off the display).

While the power save mode is

activated, only one segment on the

digital monitor remains displayed.

.

Normal display

To turn all the displays OFF (both digital

monitor and operation status indicators)

ALL can be selected when is pressed for 3

seconds or longer while “on” is selected.

To restore the display from Display OFF, press

MODE and L/D ON buttons simultaneously for 3

seconds or longer.

11

Key lock level setting (see page 6)

Select the setting by pressing the button.

.

Level 1

.

Level 2

.

Level 3

12

Selecting the number of units of interference prevention

Select the setting by pressing the button.

.

Normal

.

The number of units of interference

prevention is twice as many as in the

normal time. (The response time is also

twice as long as in the normal time.

The detection distance is the same

as in the normal time.

Initializing, Saving and Loading the Settings

Initializing the settings

1 While pressing , press for 5 seconds or longer.

2 Select “T5V “with the button, and press .

3 Select “KPKV” with the button, and press to initialize.

Default setting

Power mode: FINE

Detection mode: Normal

Setting value: 50

Output selection: L ON

Saving the settings

1 While pressing , press for 5 seconds or longer.

2 Select “5#X'” with the button, and press .

3 Select “;'5” with the button, and press to save.

Loading the setting

1 While pressing , press for 5 seconds or longer.

2 Select “T5V” with the button, and press .

3 Select “=X5V” with the button, and press to load.

L/D

ON

L/D

ON

L/D

ON

SET

MODE

MODE

SET

MODE

MODE

SET

MODE

MODE

5

)

Page 6

Copyright (c) 2010 KEYENCE CORPORATION. All rights reserved.

11291E 1070-1 96M11291 Printed in Japan

Key Lock Level Details

Note

Power mode HIGH SPEED FINE

TURBO/SUPER/ULTRA/MEGA

Number of units

required to pre-

vent interference

0 units 4 units 8 units

Power mode HIGH SPEED FINE

TURBO/SUPER/ULTRA/MEGA

Number of units

required to pre-

vent interference

0 units 8 units 16 units

By selecting the key lock (page 5, No.11) level (1-3), key operations to be disabled can be changed.

(The default value is level 1.)

Basic Operations Button

Sensitivity

settings (p.2)

Sensitivity fineadjustment (p.2)

Power selection

(p.1)

Output

selection (p.2)

Menu selection

(p.4)

c: Normal operation is possible. °: Operation is not possible.

: The settings can be checked but cannot be changed .

SET

Power selection

switch

L/D ON

Press and hold

MODE

Level

123 123

°cc

°°°

°°°

°°

cc

Advanced Operations

Initialization

(p.3)

Display scaling

(p.3)

Zero shift (p.3)

Direct access

menu (p.3)

Display OFF/

ON (p.5, No.10)

Button

L/D ON + press

and hold SET

MODE + quickly

press SET

MODE + quickly

press SET

Press and hold

L/D.ON + press

and hold MODE

Level

°°°

°cc

°cc

°°

ccc

PIN Number Key Lock Function

The unit can be locked using a PIN number to ensure securer locking effect.

1 While pressing the MODE button, press the

DSC

()

button 10 times.

SEL

M

2 Select a PIN number between 0 and 9999 using the button.

3 Press the MODE button to activate key lock.

Follow the same step to disable the key lock. Use the same PIN number used for

locking.

Specifications

Type Main unit

NPN

output

Cable

Model

Connector

Light source Red 4-element LED (peak wave length: 640 nm typ.)

Control

output*1

Control input

(connector type only)

Response

time

Number

of interference

preven-

tion units

Power voltage 12-24 VDC, Ripple (P-P): 10% max, Class2

Power

con-

sump-

tion*3

Operat-

Incandescent lamp 20,000 lx max.

ing ambi-

ent

lumi-

nance

Operating ambient tempera-

Operating ambient humidity 35 to 85% RH (No condensation)

*1

*2

*3

ture*1

Vibration resistance

Shock resistance

Material Main unit, housing material: Polycarbonate

Weight (including cable) Approx. 80g Approx. 45g Approx. 80g Approx. 25g

When several units are connected, the operating ambient temperature varies depending on the

number of units to be connected.When connecting several units, be sure to mount the units on

the DIN rail (mounted on a metal plate), and keep the output current within 20mA.

When 1 to 2 units are connected : -10 to +55 °C,

When 3 to 10 units are connected : -10 to +50 °C,

When 11 to 16 units are connected : -10 to 45 °C

When double is set, the response time is twice as long as the normal response time.

When using the HIGH SPEED mode, the power consumption increases by 160 mW (7 mA).

PNP

output

NPN

output

PNP

output

NPN output NPN open collector 24 V 100 mA max. –

PNP output PNP open collector 24 V 100 mA max. –

Analog output

(FS-V31M only)

ON/OFF

Output

Normal time

When

double is set *2

NPN output

PNP output

Sun light 30,000 lx max.

FS-V31 FS-V32 FS-V31M FS-V30

FS-V31P FS-V32P – –

FS-V31C FS-V32C – –

FS-V31CP FS-V32CP – –

1-5 V voltage output: 1-5 V for the display 0-4095 of HSP/FINE/

TURBO, load resistance 10 k¾ or more, response time 1 ms

Calibration/scaling/zero shift/

reset/light emission stop

(input time: ON: 2 ms, OFF: 20 ms)

33 μs (HIGH SPEED)/250 μs (FINE)/

500 μs (TURBO)/1 ms (SUPER)/

Normal: 710 mW max. (Using 24 V, 29 mA max., using 12 V, 40 mA max.)

Power saving: 540 mW max. (Using 24 V, 22 mA max., using 12 V, 28 mA max.)

750 mW max. (Using 24 V, 31 mA max.,

using 12 V, 40 mA max.)/

Power saving 580 mW max. (Using 24 V,

24 mA max., using 12 V, 28 mA max.)

10 to 55 Hz Compound amplitude 1.5 mm, 2 hours for each of

Sub unit

(one line)

4 ms (ULTRA)/16 ms (MEGA)

-10 to +55 °C (No freezing)

500 m/s2 3 times for each of XYZ axes

The accessory of this unit is this instruction manual only.

Analog output

XYZ axes

(main unit)

Sub unit

(zero line)

–

193 μs to 16.7

–

ms

Write down the PIN number in case it is forgotten.

The key lock cannot be disabled unless the correct PIN number is used.

Hints On Correct Use

•

Do not wire the amplifier line along with power lines or high-tension lines, otherwise the

sensor may malfunction or receive damage due to noise.

• When using a commercially available switching regulator, ground the frame

ground terminal and ground terminal.

• Do not use the FS series outdoors, or in a place where extraneous light can

enter the light receiving surface directly.

• Due to the individual dispersion of characteristics and the difference in fiber

unit model, the maximum sensing distance or displayed value of all the units

are not the same.

• If the sensor is used in S-APC mode for a long time, the LED indicators will be

imposed with a heavy load. In that case, the sensor will be automatically set to

ACC mode where the current consumption of the sensor for light emission will

be constant, and “END APC” will be displayed. The sensor can be continuously

used in this case. Replace the sensor, however, if highly precise detection is

required.

Warranties and Disclaimers

KEYENCE, at its sole option, will refund, repair or replace at no charge any defective Products within 1 year from the date of shipment. Unless stated otherwise

herein, the Products should not be used internally in humans, for human transportation, as safety devices or fail-safe systems. EXCEPT FOR THE FOREGOING,

ALL EXPRESS, IMPLIED AND STATUTORY WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND

NONINFRINGEMENT OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED.

KEYENCE SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL,

CONSEQUENTIAL OR OTHER DAMAGES, EVEN IF DAMAGES RESULT FROM

THE USE OF THE PRODUCTS IN ACCORDANCE WITH ANY SUGGESTIONS OR

INFORMATION PROVIDED BY KEYENCE. In some jurisdictions, some of the foregoing warranty disclaimers or damage limitations may not apply.

Error Displays and Corrective Actions

Error display Cause Corrective action

'T=

'TG

'PF#2=

Overcurrent is flowing in the control

Failed to write/read the internal data. Perform initialization (p.5).

The load on the light source is large.

output.

Check the load and return the current

within the rated value.

Replace the sensor if high-accuracy

detection is required.

6

Loading...

Loading...