Page 1

Instruction

Manual

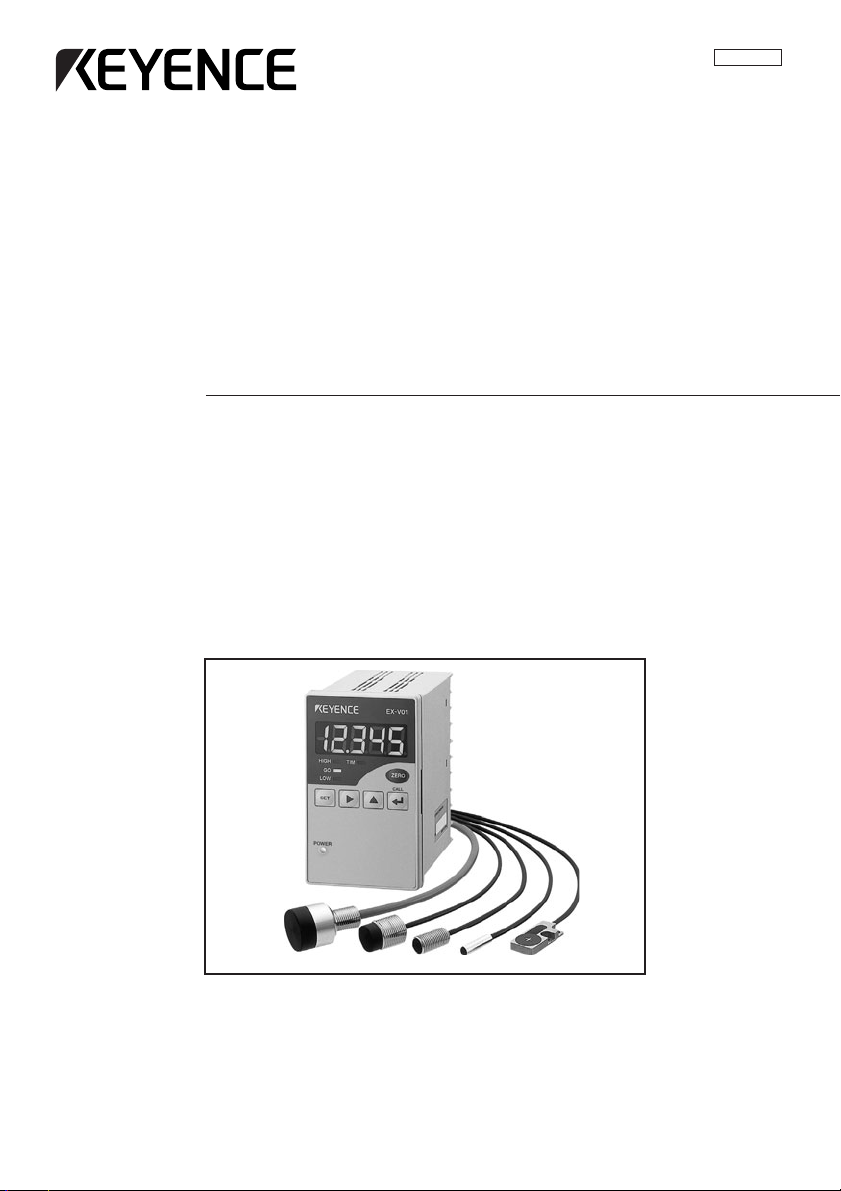

High-speed, High-Accuracy

Digital Displacement Sensor

EX-V Series

96M0558

Page 2

Safety Precautions

Symbols

This instruction manual describes the operation and function of the EX-V. Read this

manual carefully to ensure safe use and maximum performance from your EX-V.

The following symbols alert you to important messages. Be sure to read these

messages carefully.

WARNING

Failure to follow instructions may lead to injury. (electric

shock, burn, etc.)

General precautions

CAUTION

Note:

• At startup and during operation, be sure to monitor the functions and performance of the EX-V.

• We recommend that you take substantial safety measures to avoid any damage

in the event a problem occurs.

• Do not open or modify the EX-V or use it in any way other than described in the

specifications.

• When the EX-V is used in combination with other instruments, functions and

performance may be degraded, depending on operating conditions and the

surrounding environment.

• Do not use the EX-V for the purpose of protecting the human body.

Failure to follow instructions may lead to product damage.

Provides additional information on proper operation.

i

Page 3

Warning and cautions specific to the EX-V Series

Operating environment

For optimum performance of the EX-V, always maintain a proper operating environment.

CAUTION

Connecting the EX-V to analog input equipment

To prevent malfunction, do not install the EX-V in the following places:

• Places directly exposed to sunlight.

• Places where the ambient temperature drops below 0

• Places where the relative humidity drops below 35% or exceeds 85%.

• Places where temperature fluctuations may cause condensation.

• Places where the EX-V may be exposed to corrosive or flammable gas.

• Places exposed to airborne dust or corrosive substances such as salt or

metal particles.

• Places where the EX-V may be subjected to vibration or impact.

• Places where water, oil or chemicals may splash the EX-V .

• Places where the EX-V may be affected by noise interference.

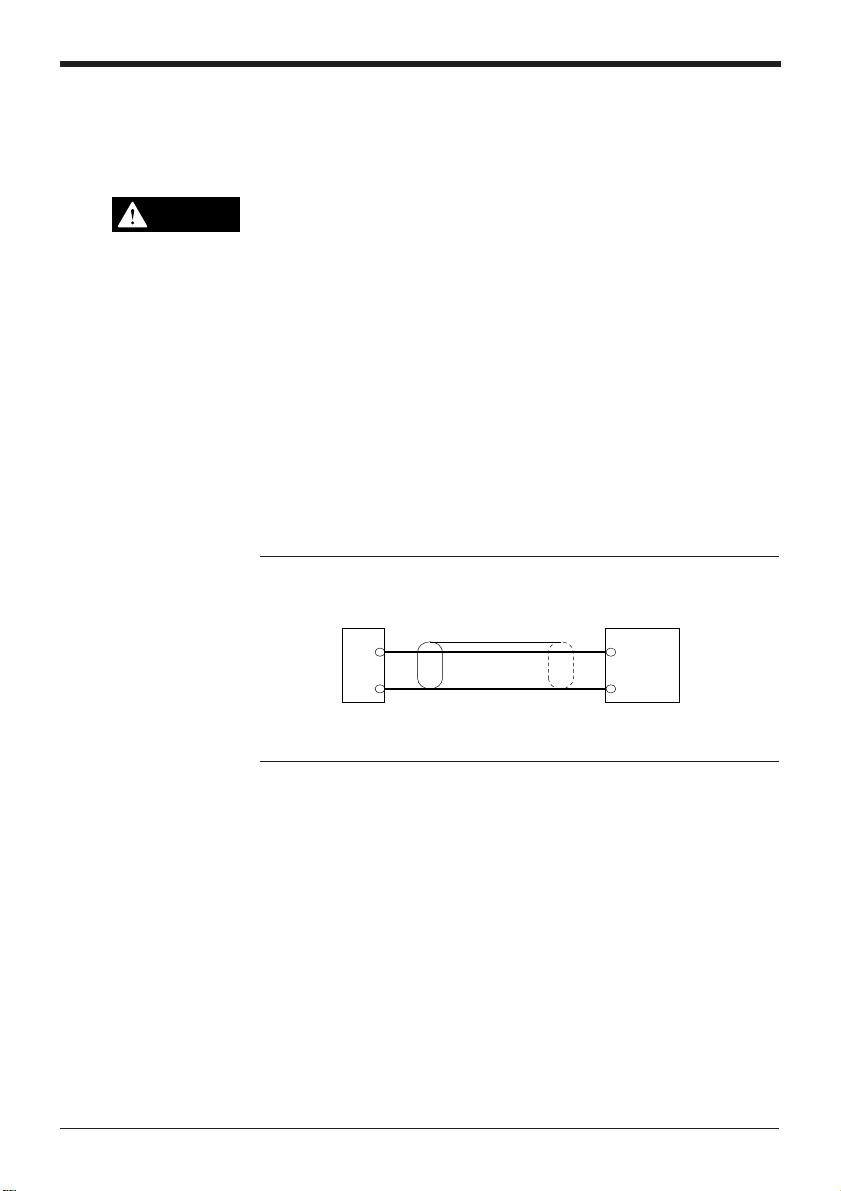

Take the following countermeasures to prevent the EX-V from malfunctioning due

to noise interference.

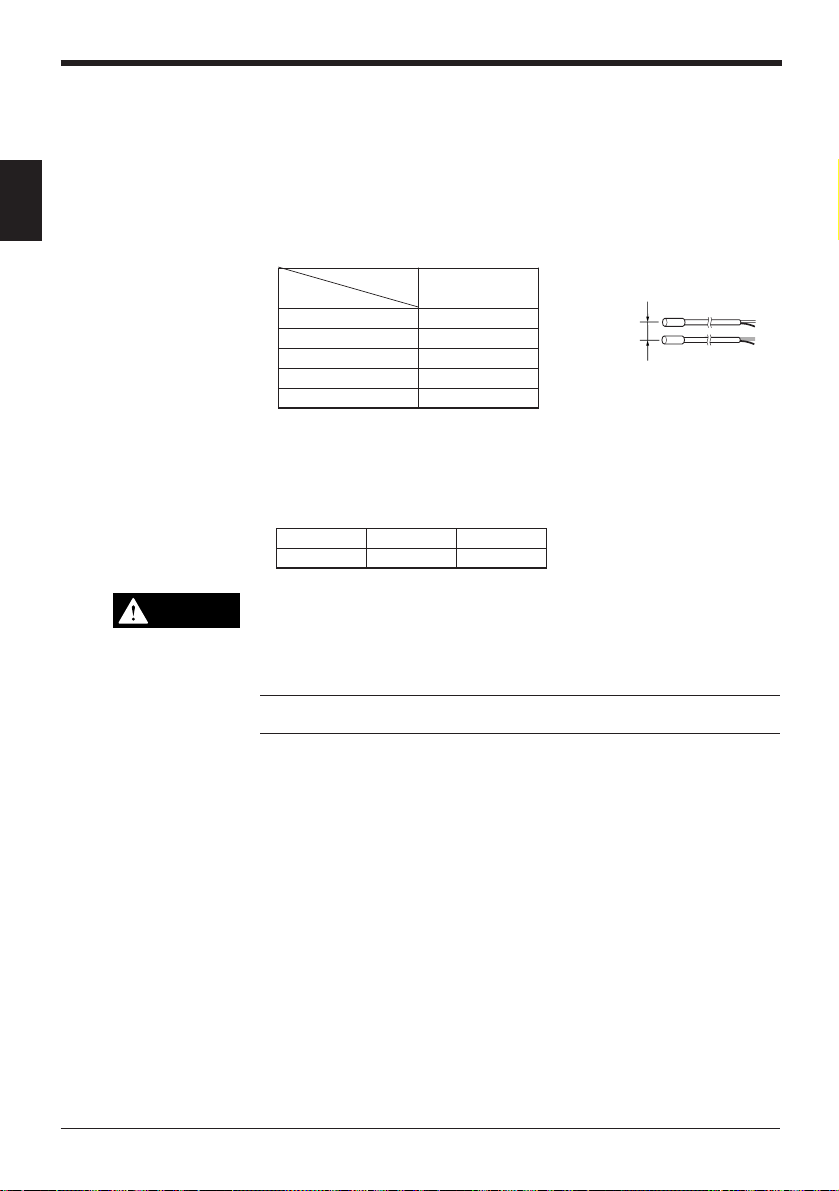

Note 1: Use a 1-core shielded cable for the output line. When using an analog

voltage signal, do not use a cable longer than 10 m. If the cable needs to be

longer than 10 m, convert the voltage signal into a current signal.

1-core shielded cable

EX-V

Analog

voltage

output

0 V

Note 2: Keep the wiring and connection cables separate.

Note 3: Isolate the wiring and connection cables from high-voltage or power lines;

otherwise noise may cause the EX-V to malfunction.

°

C or exceeds 50°C.

Various types of

Input

0V

display equipment

96M0558

ii

Page 4

MEMO

iii

Page 5

How this manual is organized

Chapter 1 Preparation

Describes the package contents, and explains the mounting and adjusting procedures of the controller and sensor head.

Chapter 2 Quick Guide to Basic Mode Operation

Explains the kinds of the measurement modes and the selection procedure.

Selecting the mode best suited to your detection purpose allows you to quickly

operate the sensor by easy setting.

Chapter 3 Use of Common Functions

Explains the functions common to the respective modes and the setting

procedure.

Chapter 4 Use of Data Processing Functions

Explains the setting and operation procedures of the respective functions.

Chapter 5 Troubleshooting

Explains the error messages displayed when an error has occurred, and

countermeasures to be taken.

Chapter 6 Specifications and Dimensions

Read as necessary.

Index

Read as necessary.

Warranties

iv

Page 6

Contents

Chapter 1 Preparation

1.1 Checking the Package Contents .......................................................... 2

1.2 Part Names and Functions .................................................................... 3

1.3 Terminal Names and Connections .......................................................4

1.4 Input/output Circuits .............................................................................. 5

1.5 Mounting ................................................................................................. 6

1.5.1 Mounting and dismounting the controller .................................................. 6

1.5.2 Mounting the sensor head ........................................................................ 7

1.6 Adjustment ............................................................................................. 9

1.6.1 Connection ................................................................................................9

1.6.2 Adjusting the output characteristics .......................................................... 9

Chapter 2 Quick Guide to Basic Mode Operation

2.1 Measurement Modes ........................................................................... 12

2.1.1 Bottom-dead-center mode ...................................................................... 12

2.1.2 Eccentricity/vibration mode ..................................................................... 12

2.1.3 Thickness/gap mode ...............................................................................13

2.1.4 Manual mode .......................................................................................... 13

2.2 Quick Guide to Basic Mode Operation .............................................. 14

2.2.1 Setting the bottom-dead-center mode .................................................... 14

2.2.2 Setting the eccentricity/vibration mode ................................................... 18

2.2.3 Setting the thickness/gap mode ..............................................................21

2.3 Auto-Zero Function .............................................................................. 24

2.4 Tolerance Limit Value Setting ............................................................. 25

2.5 Checking the Tolerance Limit Values

(Calling the tolerance limit values) ..................................................... 27

Chapter 3 Use of Common Functions

3.1 Table of Functions and Function Numbers ....................................... 30

3.2 Function Setting Flow ......................................................................... 31

3.2.1 Selecting the function using the

3.2.2 Display scaling function [E] ..................................................................... 33

3.2.3 Monitor (analog voltage) output setting function [F] ................................ 36

3.2.4 Digits function/decimal point function [g] ................................................. 39

3.2.5 Offset function [x] ....................................................................................40

3.2.6 Output form selection function [I] ........................................................... 42

3.2.7 Panel-lock function [j] ............................................................................. 43

v

key .................................................. 31

Page 7

Chapter 4 Use of Data Processing Functions

4.1 Table of Data Processing Functions .................................................. 46

4.2 Details of Bottom-dead-center Mode ................................................. 47

4.2.1 No. of averaging measurements/Digital filter [A] ..................................... 47

4.2.2 Measurement type [b] ............................................................................. 49

4.2.3 Measurement period [[] .......................................................................... 53

4.2.4 Previous value comparison function [d] .................................................. 56

4.3 Details of Eccentricity/vibration Mode .............................................. 57

4.3.1 No. of averaging measurements/Digital filter [A] ..................................... 57

4.3.2 Measurement type [b] ............................................................................. 57

4.3.3 Measurement period [[] .......................................................................... 61

4.4 Details of Thickness/gap Mode ......................................................... 64

4.4.1 No. of averaging measurements/Digital filter [A] ..................................... 64

4.4.2 Measurement type [b] ............................................................................. 64

4.4.3 Measurement period [[] .......................................................................... 69

4.4.4 Inverse/normal display function [d] ......................................................... 73

4.5 Details of Manual Mode .......................................................................74

4.5.1 No. of averaging measurements/Digital filter [A] ..................................... 74

4.5.2 Measurement type [b] ............................................................................. 74

4.5.3 Measurement period [[] .......................................................................... 84

4.5.4 Previous value comparison function [d] .................................................. 84

4.6 Hysteresis Setting ................................................................................ 85

4.7 Initialization .......................................................................................... 86

Chapter 5 Troubleshooting

5.1 Error Messages ....................................................................................88

5.2 Troubleshooting List ........................................................................... 89

Chapter 6 Specifications and Dimensions

6.1 Specifications ....................................................................................... 92

6.2 Characteristics Charts ......................................................................... 93

6.3 Minimum Input Time and Output Response Time ............................ 96

6.4 Dimensions ........................................................................................... 98

Index

Index .............................................................................................................. 101

Warranties

WARRANTIES AND DISCLAIMERS ............................................................ 109

vi

Page 8

Quick Index by Function/Operation

This index helps you quickly find proper EX-V function/operation according to your

purpose.

Select action or operation you need to find the proper page and description.

Display/Setup

noitarepO/noitcnuFnoitpircseDegaP

tfirderutarepmet

ecived

noitcnufhcae

sliateddna

stluafed

tnemtsujda

reggirt

dohtem

eulav

langistuptuo

ecivedlanretxemorf

stigid

"0"oteulav

tnemtsujda

yrotcafotsgnittesllagnizilaitinI

noitarepolenaptnorfgnikcoLnoitcnufkcol-lenaP34

eulavyalpsidmorf/ot

tuptuoegatlovrotinomgnitteS

eulavyalpsidmorftnednepedni

GN/KOrofseulavecnarelotgniweiVseulavtimilecnarelotehtgnillaC72

GN/KOrofseulavecnarelotgnitteSgnitteSeulaVtimiLecnareloT

ropu-tratstanoitautculfgnirongI

lanretxemorflangisgnimitgnittupnI

fossecorpputesfoeniltuogniweiV

srebmunnoitcnufllafotsilgniweiV

gniruddoireptnemerusaemgnikcehC

srosnesgnimittuohtiwgnireggirTreggirtlanretnI35

tinuegnahcottnioplamicedgnivoMnoitcnuftnioplamiceD93

lanretnirofemitgnirusaemgnignahC

gnigarevatnemerusaemgnidiceD

lortnoc/tupniehtotgnidroccaemit

gniveihcarofeulavtesffo/niaggnitteS

tupnitsniagaeulavyalpsidderised

rotarapmocrofremityaled-ffognitteS

langistuptuorotarapmocgnidloHtuptuodloH24

eulavecnarelotrotarapmocgnitceleS

4ottigideulavyalpsidgnignahC

eulavderisedgnitcartbus/gniddA

yalpsid)gnitteser(gnignahcylkciuQ

gnirudtuptuorotarapmocgnilbasiD

retnec-daed-mottobenihcamsserp

tupnignimiT4

yek]TES[gnisunoitcnuf

srebmuN

noitazilaitinI68

tuptuoebortS4

yaledgnilpmaS35

noitcnuf

tuptuoyaled-ffO24

tupnignitteslanretxE21

noitcnufstigiD93

noitcnuftesffO04

noitcnuForeZ-otuA42

tupnielbasidtuptuO41

noitcnuf

noitcnufnosirapmoceulavsuoiverP65

hcaerofssecorpputesfoeniltuO

noitcnuFdnasnoitcnuFfoelbaT

stnemerusaemgnigarevafo.oN84

gnittestuptuo)egatlovgolana(rotinoM

gnittestuptuo)egatlovgolana(rotinoM

52

64

64,03

63

63

vii

Page 9

Measurement

Installation

noitarepO/noitcnuF

ssenkcihtgnirusaeM

rettamngierof

noitrop

noitisop

oteuderuliaferusolceidgnikcehC

eliforpwolfothgiehgnirusaeM

nigirofotnemecalpsidgnirusaeM

htiwgnimrofnieruliafgnitceteD

enihcamgnidlomnoitcejni

rorregnikcuhcgnitceteD

etalpesabfonoitarbivgnirusaeM

lootgnittucfotuonurgnirusaeM

ecnarelotrotarapmocgnittupnI 52

rellorfoyticirtneccegnirusaeM

.erusolc

noitpircseD

edompag/ssenkcihtehtgnitteS.1

timilecnarelotehtgnitteS.2

niedomtnemerusaemehtgnitteS.1

.)edomlamroN(gnitteslaitini

timilecnarelotehtgnitteS.2

otepyttnemerusaemehtgnitteS.1

timilecnarelotehtgnitteS.2

niedomtnemerusaemehtgnitteS.1

.)edomlamroN(gnitteslaitini

timilecnarelotehtgnitteS.2

\otepyttnemerusaemehtgnitteS.1

otretnec-daed-mottobdetimiL

gnirudecnaraelcdlomehterusaem

timilecnarelotehtgnitteS.2

timilecnarelotehtgnitteS.2

timilecnarelotehtgnitteS.2

timilecnarelotehtgnitteS.2

timilecnarelotehtgnitteS.2

egaP

.putesforedroehtetacidni.2dna.1srebmuN

12

67

.edompaG/ssenkcihTnitnettimretnI

12

67

41

edomnoitarbiv/yticirtnecceehtgnitteS.1

81

edomnoitarbiv/yticirtnecceehtgnitteS.1

81

edomnoitarbiv/yticirtnecceehtgnitteS.1

81

edomnoitarbiv/yticirtnecceehtgnitteS.1

81

noitarepO/noitcnuFnoitpircseDegaP

lairetamlatemotnirosnesgniddebmEtnuom-hsulF

noitisop

elbacrosnesgnidnetxE.dnetxetonoD8

elbacrosnesgnittuC.tuctonoD8

esolcnisrosneselpitlumgnillatsnI

ecnerefretnilautuM8

7

viii

Page 10

ix

Page 11

Chapter 1

Preparation

Describes the package contents, and explains the mounting and adjusting

procedures of the controller and sensor head.

1.1 Checking the Package Contents ......................................... 2

1.2 Part Names and Functions .................................................. 3

1.3 Terminal Names and Connections ......................................4

1.4 Input/output Circuits ............................................................ 5

1.5 Mounting ................................................................................ 6

1.5.1 Mounting and dismounting the controller ................................. 6

1.5.2 Mounting the sensor head ....................................................... 7

1.6 Adjustment ............................................................................ 9

1.6.1 Connection............................................................................... 9

1.6.2 Adjusting the output characteristics .........................................9

Page 12

Chapter 1 Preparation

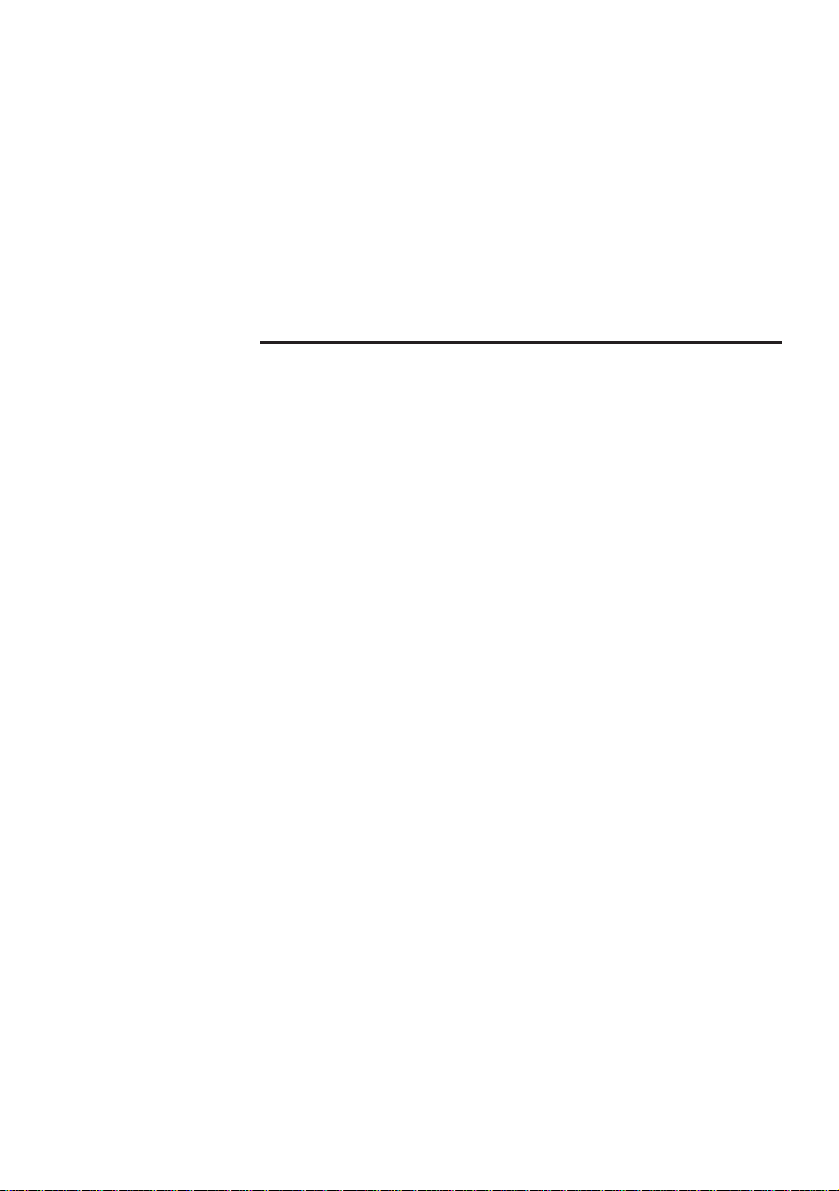

1.1 Checking the Package Contents

The EX-V series package includes the following parts and equipment. Check that

all the parts and equipment are included in the package.

1

• Instruction manual: 1 • Controller: 1

Instruction

Manual

High-speed, High-Accuracy

Digital Displacement Sensor

EX-V Series

• Sensor head: • Panel mounting frame: 1

Ordered one of the following

EX-305V

EX-110V

EX-416V

EX-422V

EX-614V

2

Page 13

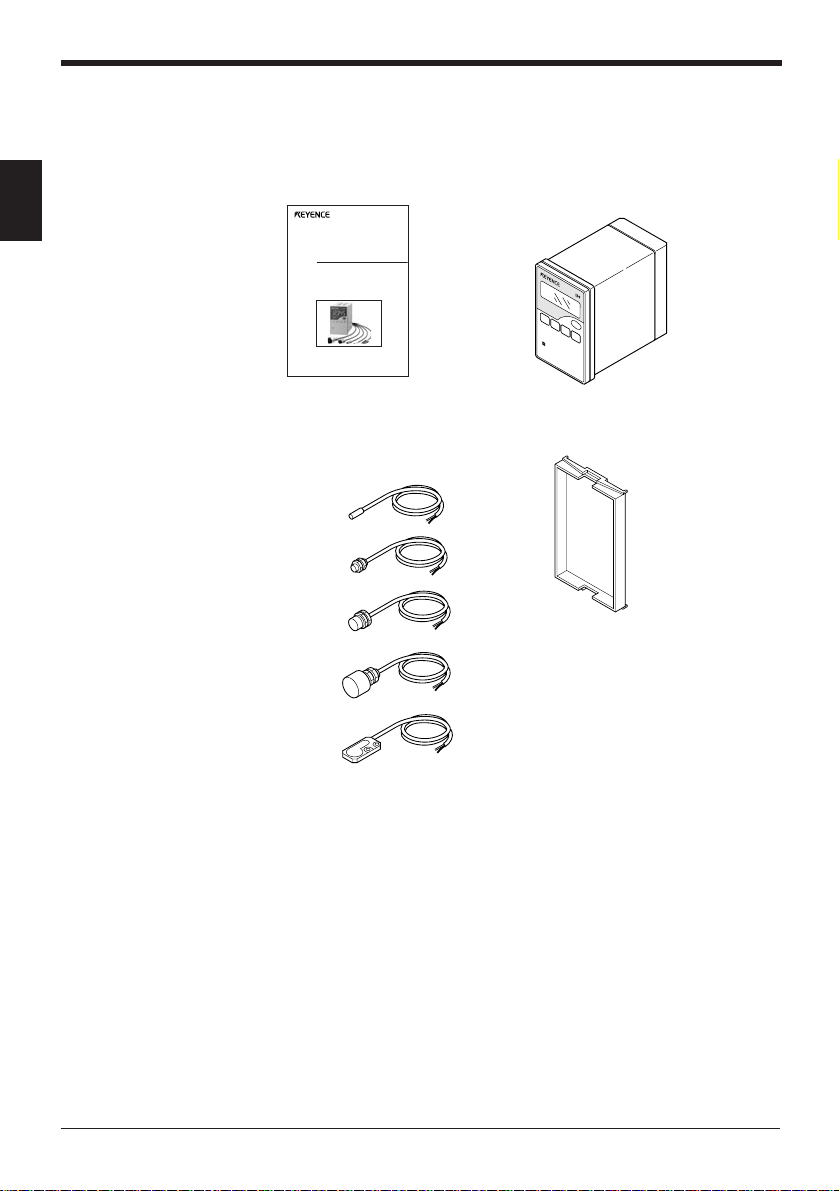

1.2 Part Names and Functions

This section explains the part names and functions.

■ Controller

Display

Displays the measured value. The value is

displayed in green when the measured value is

within the tolerance range. The value is displayed

in red when the measured value is out of the

tolerance range.

Comparator output indicators

Illuminates when the comparator output

(HIGH, GO, LOW) is turned on.

Indicates the type of displayed tolerance limit

value when setting or calling the tolerance

limit value.

POWER indicator

Illuminates green:

When operation is normally performed

Illuminates red:

When the control output is reset to OFF

■ Displays and functions

yalpsiDnoitcnuF

)999.91±(eulavciremuN

)V8.5+:tuptuo

)V8.5-:tuptuo

Chapter 1 Preparation

1

TIMING input

.egnaryalpsidehtwolebsi

indicator

Illuminates

when a timing

signal is input.

Operation

keys

.deyalpsidebottlusernoitarepoonsierehT

ciremunasadeyalpsidsitlusernoitarepoehT

sitlusernoitarepoehtnehwdeyalpsidsi"FFFF"

tlusernoitarepoehtnehwdeyalpsidsi"FFFF-"

HIGH TIM

GO

LOW

POWER

SET

FUNC

UTILITY

MODE

CALL

CALIB

.eulav

egatlovgolanA,NO:tuptuoHGIH(FFFF

.egnaryalpsidehtevoba

egatlovgolanA,NO:tuptuoWOL(FFFF-

)V0:tuptuoegatlovgolanA

,FFO:stuptuoWOLdnaOG,IH(----

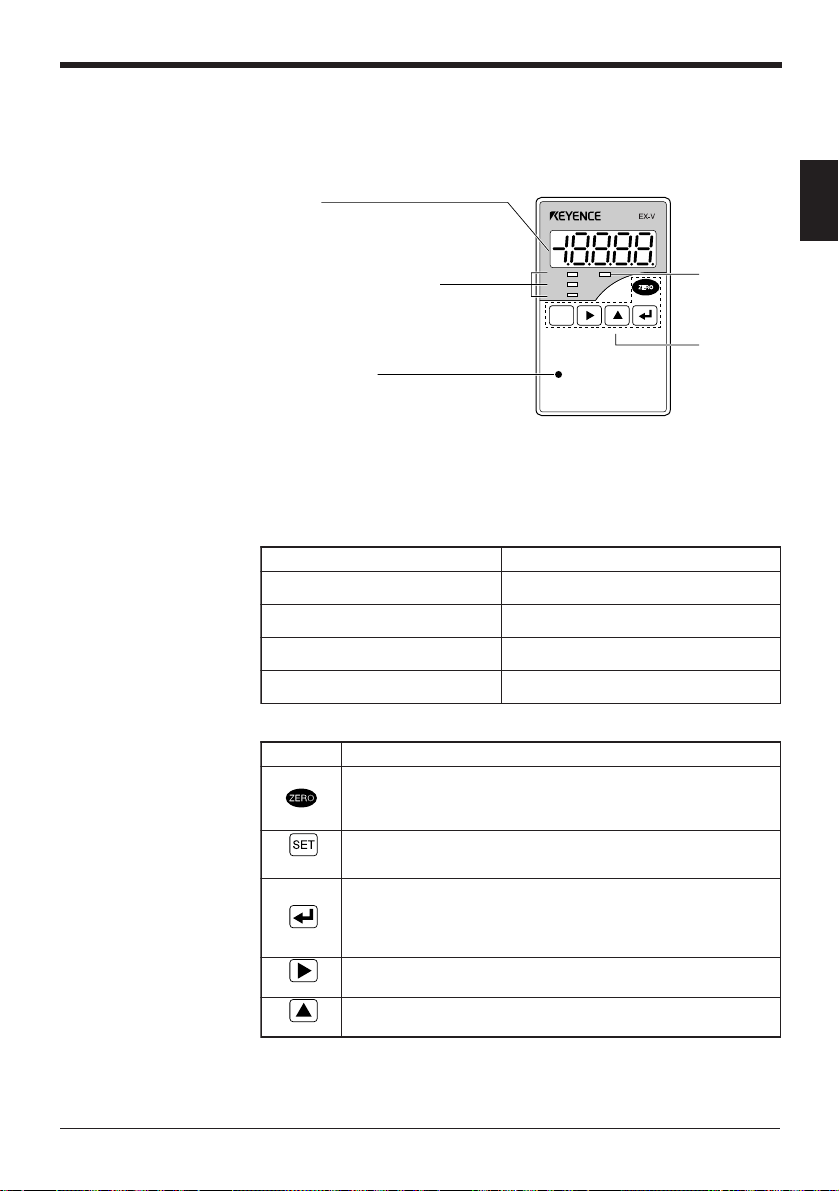

■ Operation keys

yeKnoitcnuF

➮

(.eulav

FUNC

CALL

CALIB

UTILITY

MODE

(

➮

(.noitcnuf

➮

.)orez("0000"otyalpsidehtnoeulavehtsteseR•

.04egapees,sliatedroF

)

➮

(.edomgnittestimilecnarelotehtsllaC•

.edomtnemtsujdaehtsllaC•

.gnitteshcaesevaS•

.egassemrorrehcaeslecnaC•

.72egapees,sliatedroF

)

.gnitteshcaestceleS•

.rebmunnoitcnufhcaesteS•

.edomtnemerusaemehtsllaC•

.gnittesnoitcnufgnirudsgnittesnoitcnufllasezilaitinI•

.47dna,46,75,84segapees,sliatedroF

)

.tnemerusaemgnirudeulavtimilecnarelotehtsllaC•

.)"J"ot"E"(sedomnoitcelesnoitcnufnommocehtsllaC•

tesffoehtottesersiyalpsidnoeulaveht,detcelessinoitcnuftesffoehtfI

.52egapees,sliatedroF

)

hcaefognittesmrofrepot)"D"ot"A"(sedomgnittesnoitcnufehtsllaC•

3

Page 14

Chapter 1 Preparation

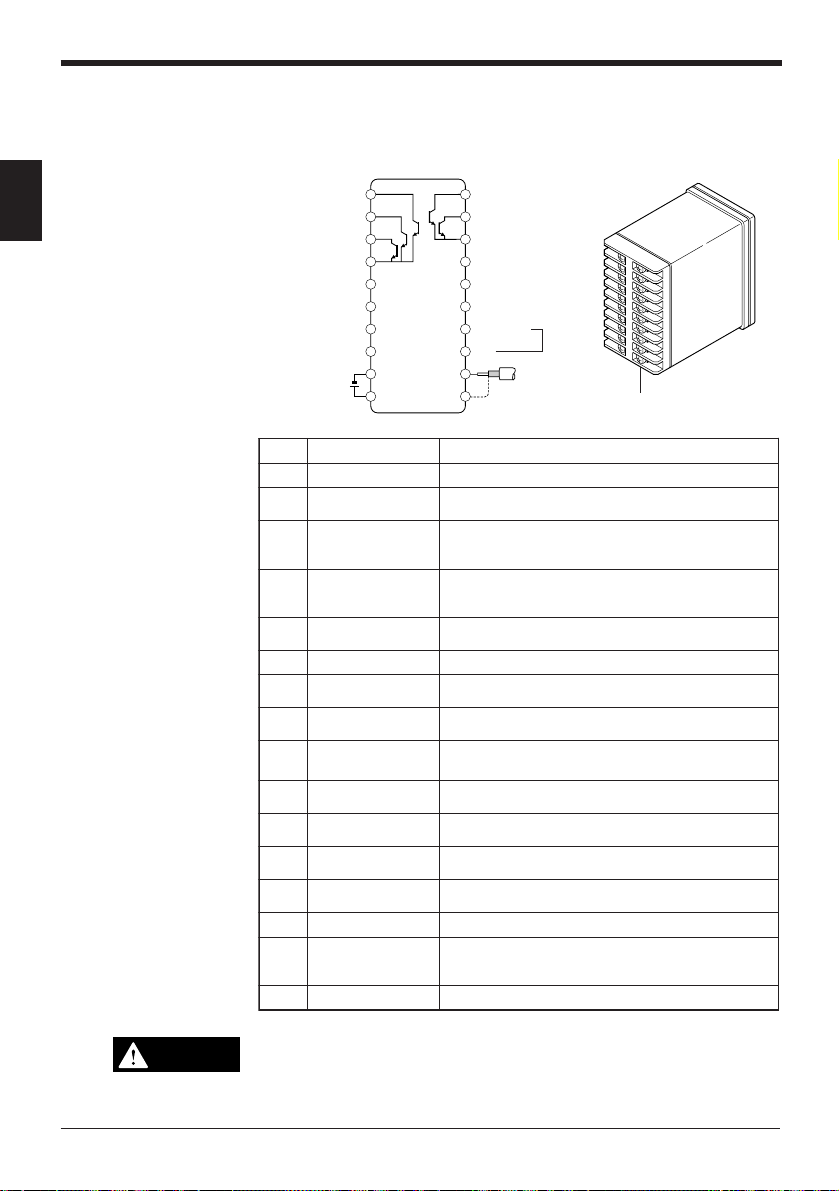

1.3 Terminal Names and Connections

This section explains the terminal names and functions.

10

1

OUTPUT DISABLE

HIGH

GO

LOW

GND1

TIMING

HOLD RESET

ZERO

24V DC

9

8

7

6

5

4

3

–

2

+

1

20

ALARM

19

STROBE

18

GND2

17

EXT1

16

EXT2

15

SYNC

14

MONITOR

13

0V

12

11

Sensor head

Terminal block

.oNemanlanimreTnoitcnuF

2,1ylppusrewoP %01±CDV42

3

4tupniorez-otuA

5tupniteser-dloH

6tupnignimiT

tuptuorotarapmoC

tupnielbasid

.lanimretgnidnuorgehtotdetiucric-trohs

.lanimretgnidnuorgehtotdetiucric-trohs

.atadedomdlohhcaesteseR.2.tuptuo

.lanimretgnidnuorgehtot

silanimretsihtnehwFFOottuptuorotarapmocehtsteseR

eulavtesffo("0000"otyalpsidehtnoeulavehtsteseR

silanimretsihtnehw)detcelessinoitcnuftesffoehtnehw

gnidnuorgehtotdetiucric-trohssilanimretsihtnehW

rotcellocnepoehtfoetatsdlohehtslecnaC.1:lanimret

detiucric-trohssilanimretsihtnehwlangisgnimitastupnI

7gnidnuorG

8tuptuoWOL

9tuptuoOG

01tuptuoHGIH

21,11

41,31

51tupnisuonorhcnyS

71,61

.eulavtimil

.egnar

.eulavtimil

daehrosneS

noitcennoc

golana(rotinoM

tuptuo)egatlov

gnitteslanretxE

tupni

.eulavdeyalpsid

.daehrosnesehtstcennoC

WOLehtnahtrewolsieulavdeyalpsidehtnehwstuptuO

ecnarelotehtnihtiwsieulavdeyalpsidehtnehwstuptuO

HGIHehtnahtrehgihsieulavdeyalpsidehtnehwstuptuO

ehtotnoitroporpni)V5+ot5-(egatlovgolanastuptuO

nehwtuptuoehtsdlohdnanoitallicsodaehrosnesspotS

.lanimretgnidnuorgehtotdetiucric-trohssilanimretsiht

sihT.seulavtimilecnarelotfosdnikruofteserpehtsllaC

.NOottessinoitcnufkcol-lenapehtnehwdelbanesitupni

81gnidnuorG

91tuptuoebortS

).O.N(

silanimretsihT.doirepgnilpmasehtgnirudNOsnruT

.desusinoitcnufreggirtlanretniehtnehwylnodelbane

02tuptuomralA ).C.N(.sruccoetatslamronbananehwstuptuO

CAUTION

Since the power GND, GND1 and GND2 are connected through choke coils,

make sure so that no potential difference develops.

4

Page 15

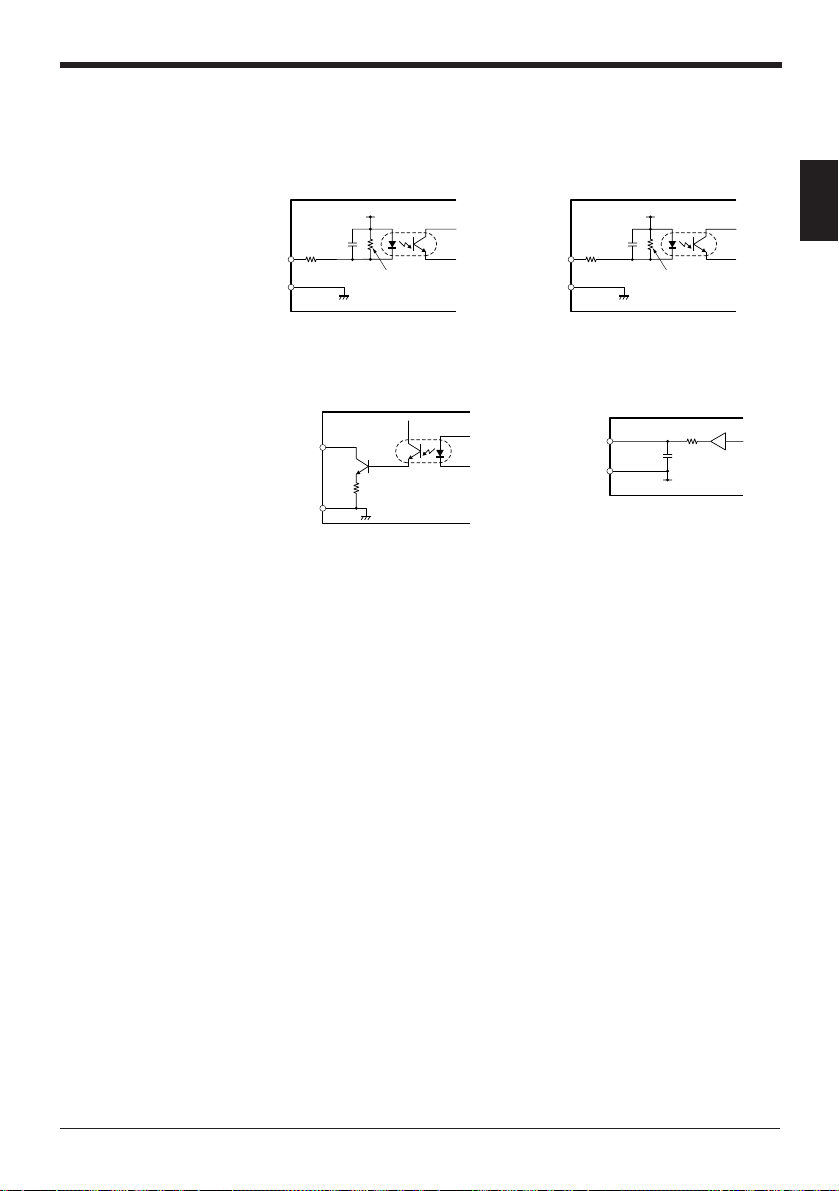

1.4 Input/output Circuits

Input circuit

TIMING, HOLD RESET ZERO, EXT1•2, OUTPUT DISABLE

+24 V

SYNC

Chapter 1 Preparation

+24 V

1

Output circuit

GND

3 kΩ

IN

470 Ω

GND

10 kΩ

IN

3 kΩ

HIGH, GO, LOW, STROBE MONITOR (analog voltage) output

NPN Output

GND

Output

0 V

100 Ω

0 V

NPN open-collector, 40 V, 100 mA max.

5

Page 16

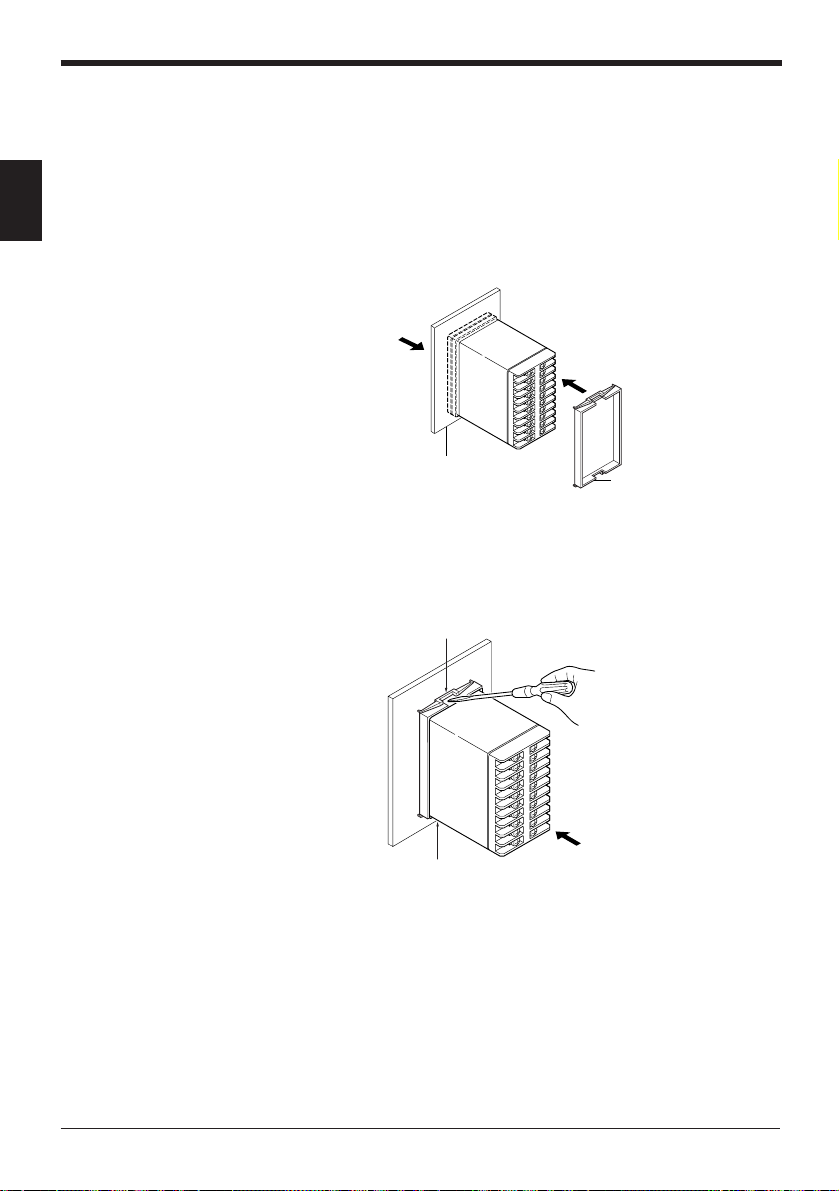

Chapter 1 Preparation

1.5 Mounting

This section explains the mounting procedure for the controller and sensor head

and the wiring connections.

1.5.1 Mounting and dismounting the controller

1

Mounting

Insert the controller from the front of the panel and fix it using the panel mounting

frame.

Dismounting

1. Insert the controller.

Panel

While raising the catches at sections 1 and 2 with a flat blade screwdriver, push the

controller forward from the back.

1

2

2. Fix the controller using the

panel mounting frame.

Panel mounting frame

Push the controller forward.

6

Page 17

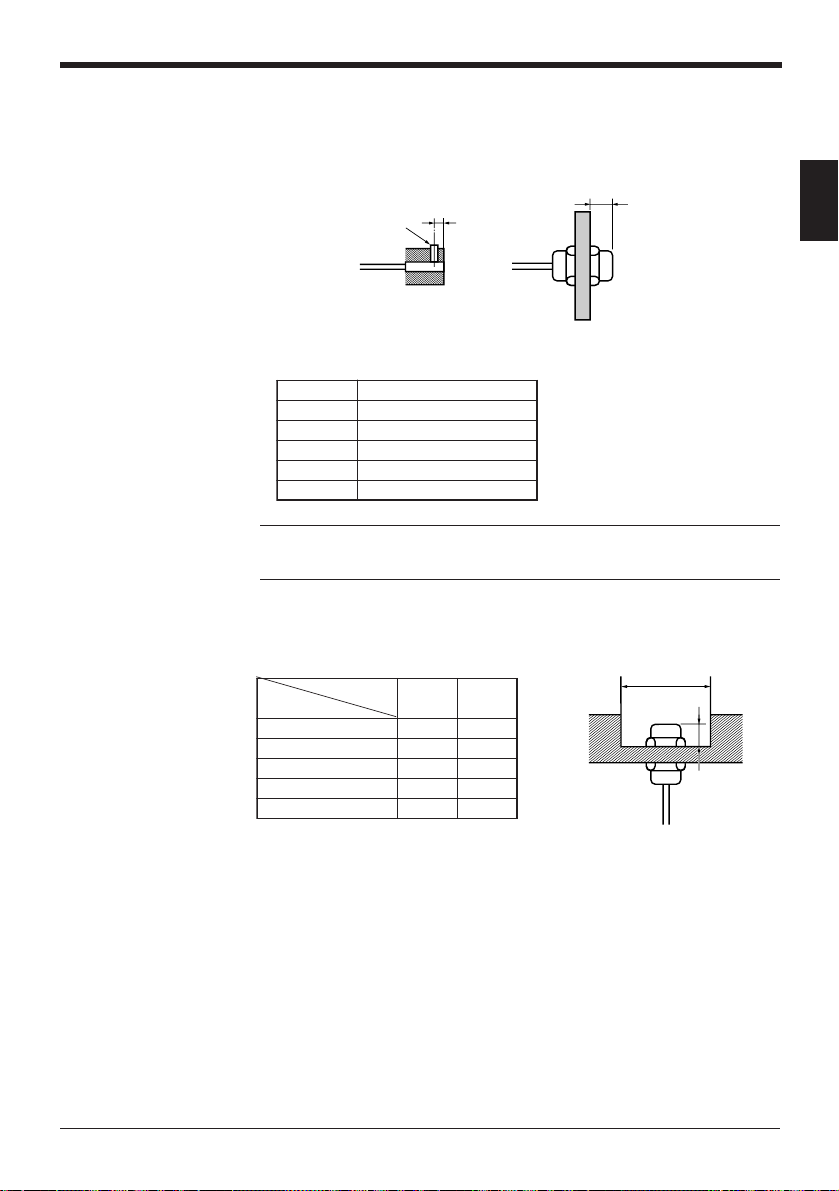

1.5.2 Mounting the sensor head

Mounting

• Tighten the EX-305V set screw and EX-110V nut away from the tip of the

sensor head as shown in the figure.

M3 set screw

EX-305V

• Referring to the measuring distance in the table below, determine the distance

between the tip of the sensor head and target.

ledoM)mm(ecnatsidgnirusaeM

V503-XE1

V011-XE2

V614-XE5

V224-XE01

V416-XE4

Note: After making the adjustment, do not change the position of the nut or screw.

If the position is changed, the output characteristics may change even when the

nut or screw is positioned in the range shown in the figure.

Flush-mounting

To flush-mount the sensor head in a metal base, follow the guidelines given in the

table below.

ledoM

V503-XE019

V011-XE219

V614-XE5301

V224-XE5502

V416-XE23x615

5 mm min.

)mm(ecnatsiD

AB

Chapter 1 Preparation

8 mm min.

1

EX-110V

øA

B

* The table above shows the dimensions to use when the metal base is iron.

* The table above shows the dimensions to satisfy the specifications when the

sensor head is flush-mounted after the output characteristics have been

adjusted with no metal present around the head.

7

Page 18

Chapter 1 Preparation

When mounting two or more sensor heads of the same model in parallel

• The sensor may not output the correct voltage due to mutual interference. Make

sure that the distance between sensor heads adjacent to each other is larger

than the values shown in the table below. (This allows the display resolution

specification to be satisfied when the number of measurements to average is

1

"64".)

• When two sensor heads are mounted in parallel, mutual interference can be

prevented by alternately oscillating the sensor heads using the synchronous

input terminal (

ledoM

➮

page 4

).

)mm(ecnatsiD

V503-XE08

V011-XE003

V614-XE056

V224-XE013

V416-XE542

Tightening torque

To tighten the EX-305V set screw, apply a torque of 0.2 N•m or less.

To tighten the nut of the other sensor heads, apply a torque shown in the table

below or less.

V011-XEV614-XEV224-XE

.xamm•N01.xamm•N02.xamm•N01

gnitnuomlellaraP

Parallel mounting

CAUTION

• If the applied tightening torque exceeds the specified one, the sensor

head may be deformed or malfunction.

• If the sensor cable is installed in the same conduit as high voltage lines or

power lines, the sensor may malfunction. Be sure to keep the wiring

separate.

Note: Do not change the sensor cable length (3 m). If the cable is extended or cut,

the characteristics will change.

8

Page 19

1.6 Adjustment

1.6.1 Connection

Chapter 1 Preparation

Though the EX-V series has been factory-adjusted, follow the procedure described

below to adjust the sensor using your actual target in order to satisfy the

specifications. When the sensor head has been replaced, be sure to make this

adjustment.

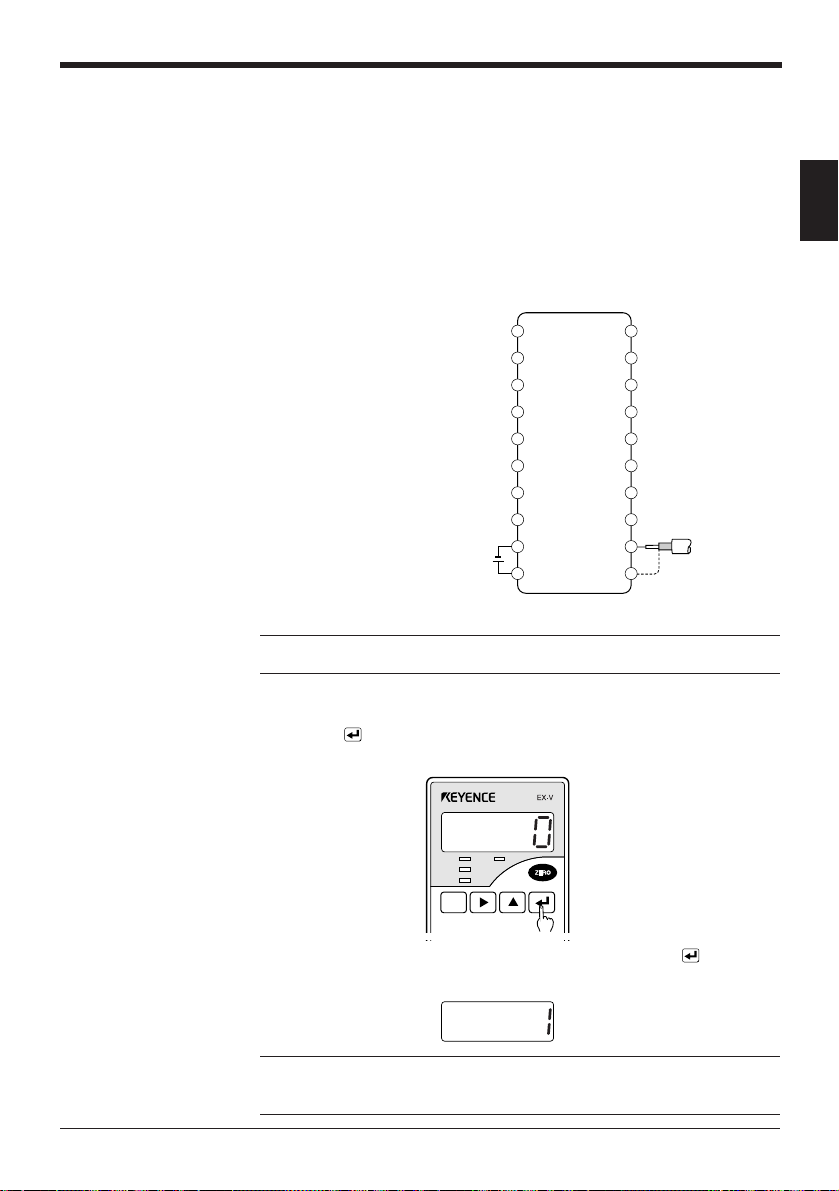

1. Connect the core and shielding wires of the sensor head to sensor head

connection terminals 11 and 12 of the controller.

1

2. After making the connection,

connect the power supply cable to

power supply terminals 1 and 2.

The POWER indicator on the

controller illuminates, and the

sensor enters the operation state.

24V DC

Note: Let the sensor warm up for 30 minutes or more after supplying power to it,

and then start the adjustment.

1.6.2 Adjusting the output characteristics

1. Press the key for at least 2 seconds.

The sensor displays "0" and enters the adjustment mode.

HIGH TIM

GO

LOW

SET

FUNC

UTILITY

–

+

MODE

10

9

8

7

6

5

4

3

2

1

Terminal block

CALL

CALIB

20

19

18

17

16

15

14

13

12

11

Sensor head

2. With no metal object present around the sensor head, press the

key.

The sensor displays "1" and moves to the next setting step.

Note 1: Do not touch the metal area of the sensor head with your hand.

Note 2: Make sure that no metal object is present within a radius of 15 centimeters

around the sensor head.

9

Page 20

Chapter 1 Preparation

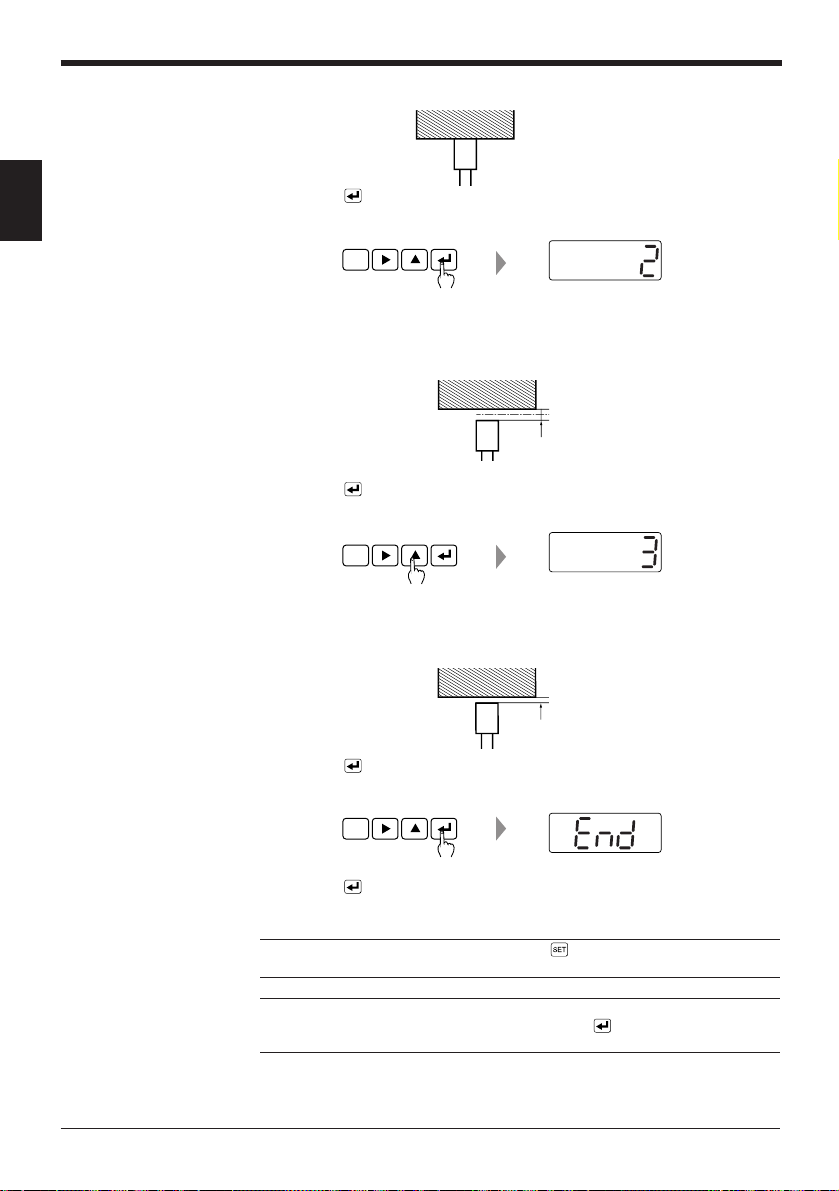

3. Bring the sensor head in contact with the target.

SET

key.

CALL

1

4. Press the

The sensor displays "2" and moves to the next setting step.

5. Move the sensor head.

Move the sensor head so that the distance between the sensor head and target

is the full scale of the measuring distance (maximum distance) of the sensor

head.

Full scale

6. Press the

key.

The sensor displays "3" and moves to the next setting step.

SET

CALL

7. Move the sensor head.

Move the sensor head so that the distance between the sensor head and target

is half the measuring distance (half scale).

Half scale

8. Press the

key.

The sensor displays "End".

SET

CALL

10

9. Press the

key to complete the adjustment.

The sensor starts measurement.

Reference: To stop the adjustment, press the key. Then, the sensor starts

measurement without making the adjustment.

Note: If the distance between the sensor head and target is improperly adjusted

during the adjustment, "Err 6" is displayed. Press the key to cancel the error,

and then readjust the distance.

Page 21

Chapter 2

Quick Guide to Basic Mode Operation

Explains the kinds of the measurement modes and the selection procedure.

Selecting the mode best suited to your detection purpose allows you to quickly

operate the sensor by easy setting.

2.1 Measurement Modes ........................................................... 12

2.1.1 Bottom-dead-center mode .....................................................12

2.1.2 Eccentricity/vibration mode .................................................... 12

2.1.3 Thickness/gap mode.............................................................. 13

2.1.4 Manual mode .........................................................................13

2.2 Quick Guide to Basic Mode Operation .............................. 14

2.2.1 Setting the bottom-dead-center mode ................................... 14

2.2.2 Setting the eccentricity/vibration mode ..................................18

2.2.3 Setting the thickness/gap mode............................................. 21

2.3 Auto-Zero Function ............................................................. 24

2.4 Tolerance Limit Value Setting ............................................ 25

2.5 Checking the Tolerance Limit Values

(Calling the tolerance limit values) .................................... 27

Page 22

Chapter 2 Quick Guide to Basic Mode Operation

2.1 Measurement Modes

The EX-V series provides the following four measurement modes: "Bottom-deadcenter mode", "Eccentricity/vibration mode", "Thickness/gap mode" (which are

basic modes for quick operation), and "Manual mode" (which allows users to

perform setting as desired). This section explains the major functions of each

mode.

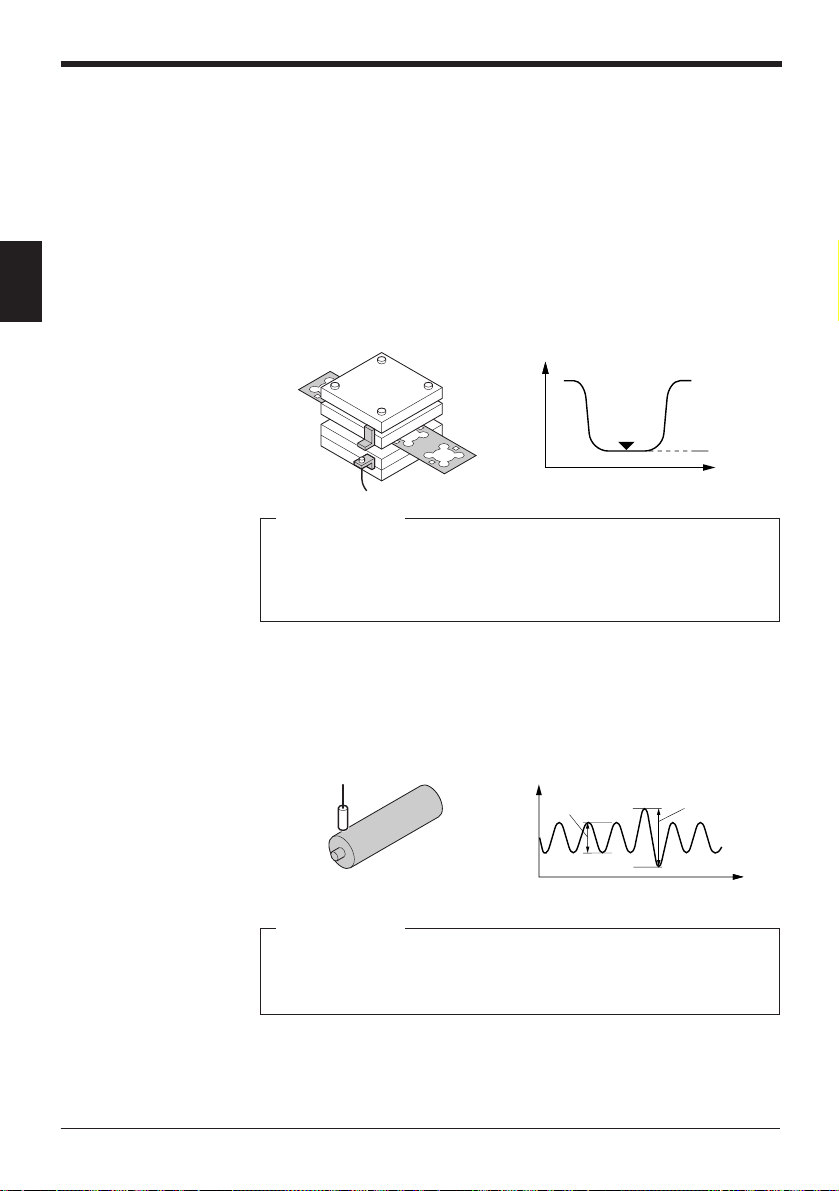

2.1.1 Bottom-dead-center mode

2

This mode is used to measure the displacement of the origin position of a machine

with stroke movements such as a press. When the displacement of the bottom

dead center or origin position is out of the preset tolerance range, the sensor

outputs an Alarm signal.

Major applications

• Detecting the bottom dead center position of a press

• Detecting the bottom dead center position of a press-fit machine

• Detecting the bottom dead center position of a welding machine

• Pressure control for a injection molding machine

• Measuring the depth of the recess on a piston head

Displacement

Bottom dead

center

Displayed value

Time

2.1.2 Eccentricity/vibration mode

This mode is used to measure the roller eccentricity or abnormal machine vibration.

When the amplitude of the runout or vibration is larger than the preset tolerance

limit value, the sensor outputs an Alarm signal.

Major applications

• Measuring roller eccentricity

• Measuring surface plate runout

• Detecting runout due to improper chucking

• Measuring drill bit eccentricity

12

OK

Displacement

NG

Time

Page 23

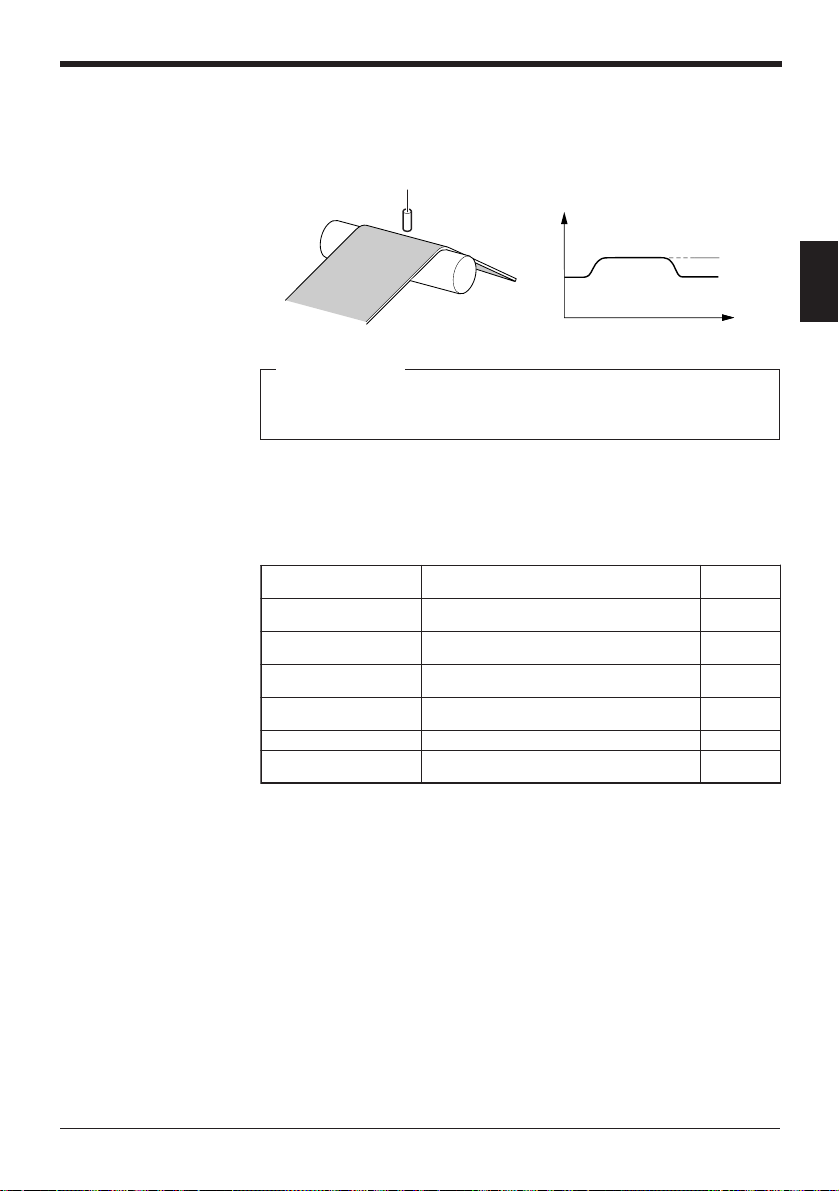

2.1.3 Thickness/gap mode

This mode is used to measure target thickness or gap with a direct reading value.

When the thickness or gap is larger or smaller than the preset upper or lower value

for the tolerance limit, the sensor outputs an Alarm signal.

Chapter 2 Quick Guide to Basic Mode Operation

Displayed value

2.1.4 Manual mode

Displacement

Time

Major applications

• Measuring hoop material thickness

• Checking grindstone abrasion

• Thickness control during polishing ceramic components

In addition to the modes above, the manual mode is available. The manual mode

provides the following six data processing modes to allow adaptable measurement.

For details, see pages that describe each data processing mode.

edomgnissecorpataDnoitcnuF

tnemerusaemlamroN

dlohkaeP

dlohmottoB

dlohkaep-ot-kaeP

dlohelpmaS.emitdeificepsataeulavehtserusaeM18

dlohegarevA

.ylsuounitnoc

.doirepdeificeps

.doirep

eulavderusaemehtstuptuo/syalpsiD

agnirudeulavmumixamehtserusaeM

deificepsagnirudeulavmuminimehtserusaeM

mumixamehtneewtebecnereffidehtserusaeM

.doirepdeificepsagnirudseulavmuminimdna

derusaemfoegarevaelpmisehtserusaeM

.doirepdeificepsagnirudseulav

egap

67

67

87

97

28

2

ecnerefeR

13

Page 24

Chapter 2 Quick Guide to Basic Mode Operation

2.2 Quick Guide to Basic Mode Operation

This section describes the major measurement modes and an easy setting

method.

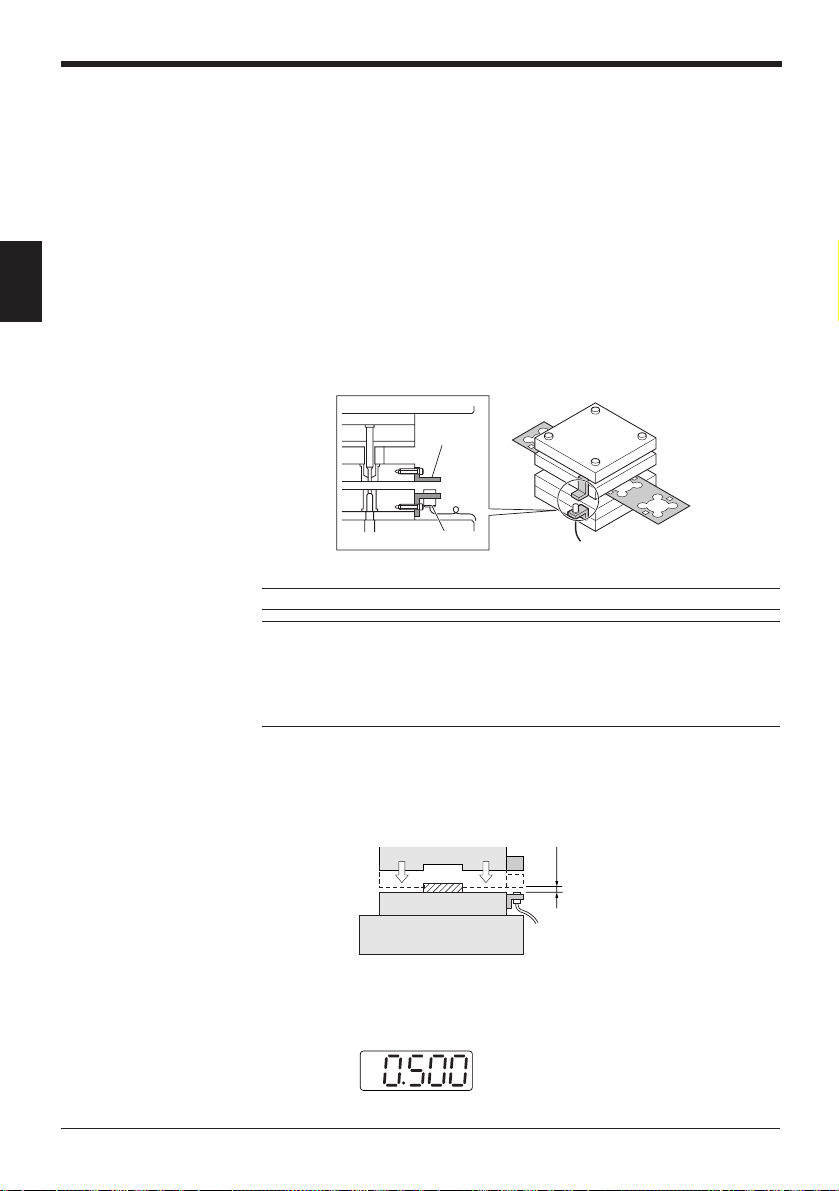

2.2.1 Setting the bottom-dead-center mode

The following example explains how to mount the EX-V series to a press.

The basic operation is the same when mounting the EX-V series to other devices.

Be sure to adjust the output characteristics before performing the following procedure. (➮

2

Refer to page 9

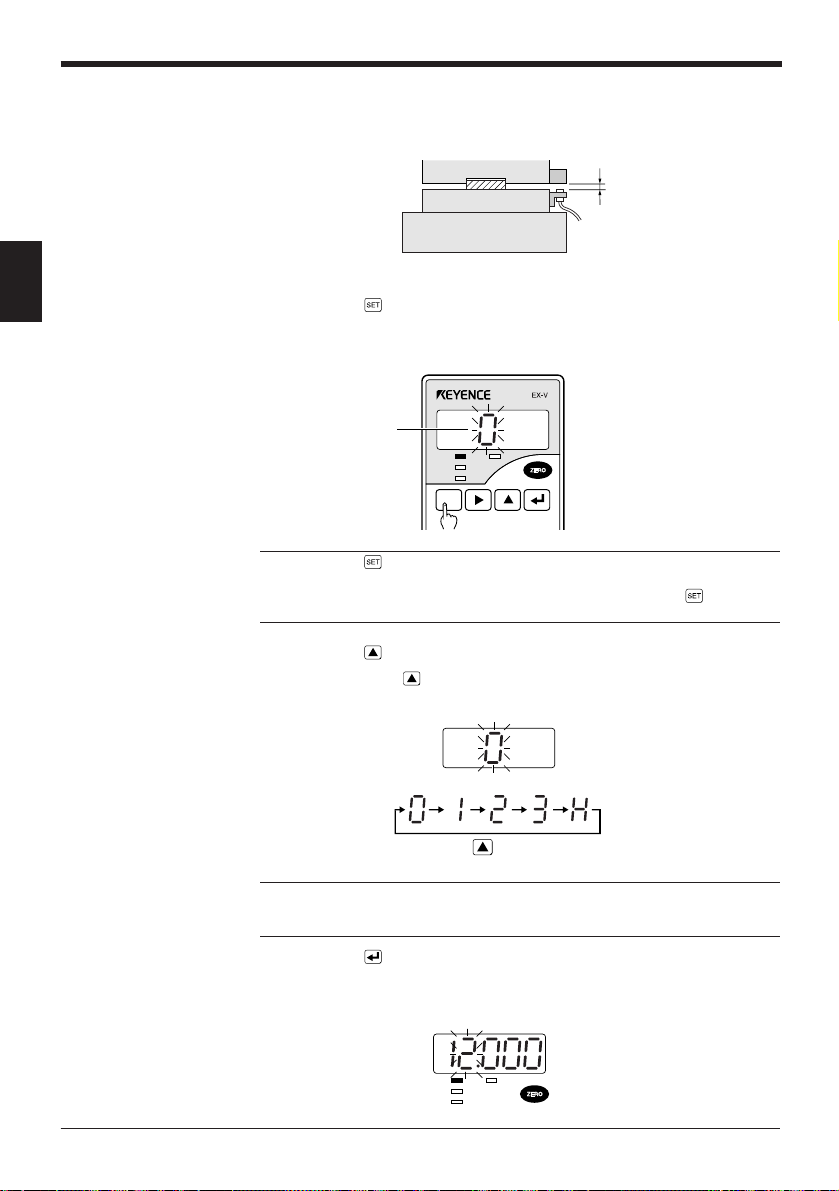

1. Secure the sensor head to the lower die of the press.

• Referring to the figure below, prepare the sensor head mounting jig and a

target.

• Refer to pages 7 and 8 for the position of the sensor head nut and the tightening torque.

.)

Target

Sensor head

14

Note: Be sure to use an IRON target with sufficient area for detection. (➮

Reference: When the comparator output is already connected to the emergency

stop or another input for the facility, short-circuit the OUTPUT DISABLE input

(terminal 3) and grounding terminal (terminal 7) to disable the comparator output

before making the adjustment.

* After making the adjustment, be sure to disconnect these terminals to enable the

comparator output.

2. Adjust the distance between the sensor head and target.

Move the press an inch at a time and lower the stripper (or upper die) to the

bottom dead center position. (Refer to the figure below.)

Half the measuring range

Stripper or upper die

Lower die

Die set

Adjust the distance between the sensor head and target so that the distance

between them is about half the measuring distance when the stripper is in the

bottom dead center position. The controller’s display shows a value close to the

half scale.

of the sensor to be used.

In the case of the EX-305V,

the value is close to “0.5”.

p.95

)

Page 25

Chapter 2 Quick Guide to Basic Mode Operation

* The distance between the sensor head and target should be more than the full scale when the

stripper is in the top dead center position.

Sensor model

EX-305V 1 0.5

EX-110V 2 1

EX-416V 5 2.5

EX-422V 10 5

EX-614V 4 2

Measuring distance Half scale

(mm) (Full scale) (mm)

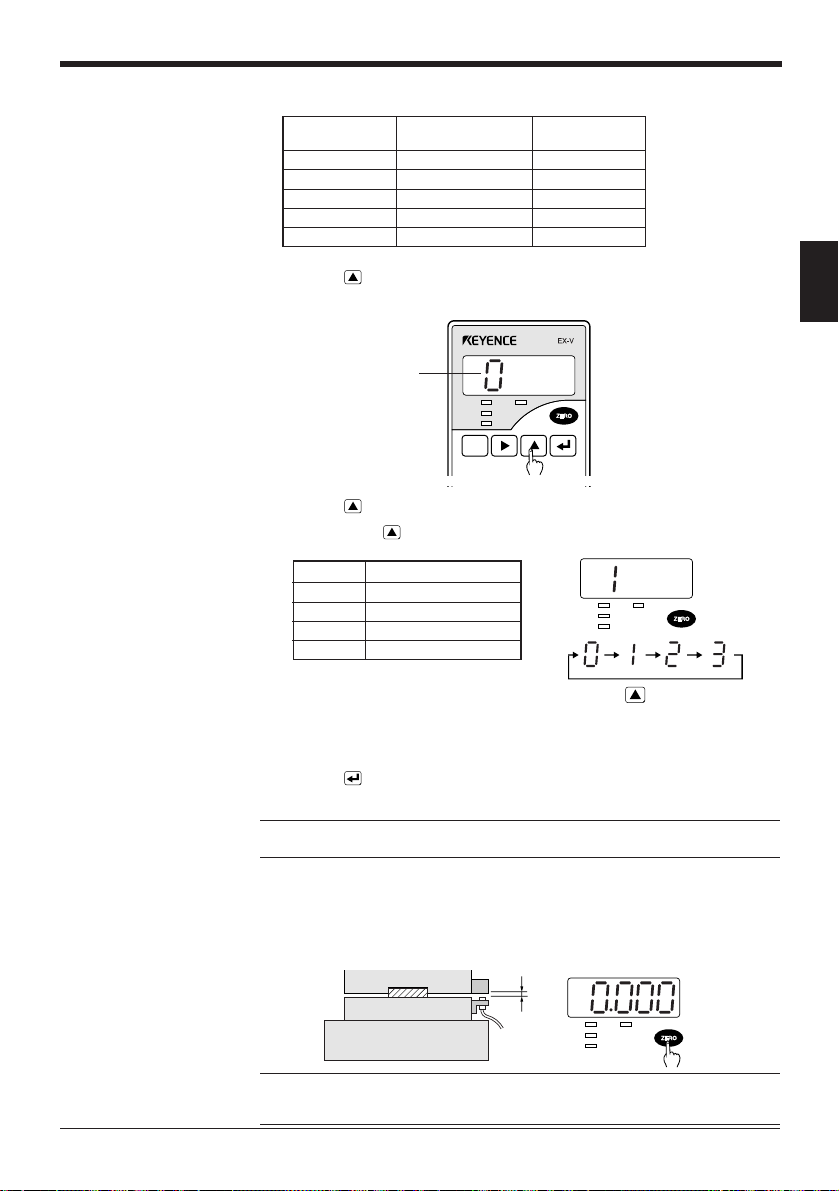

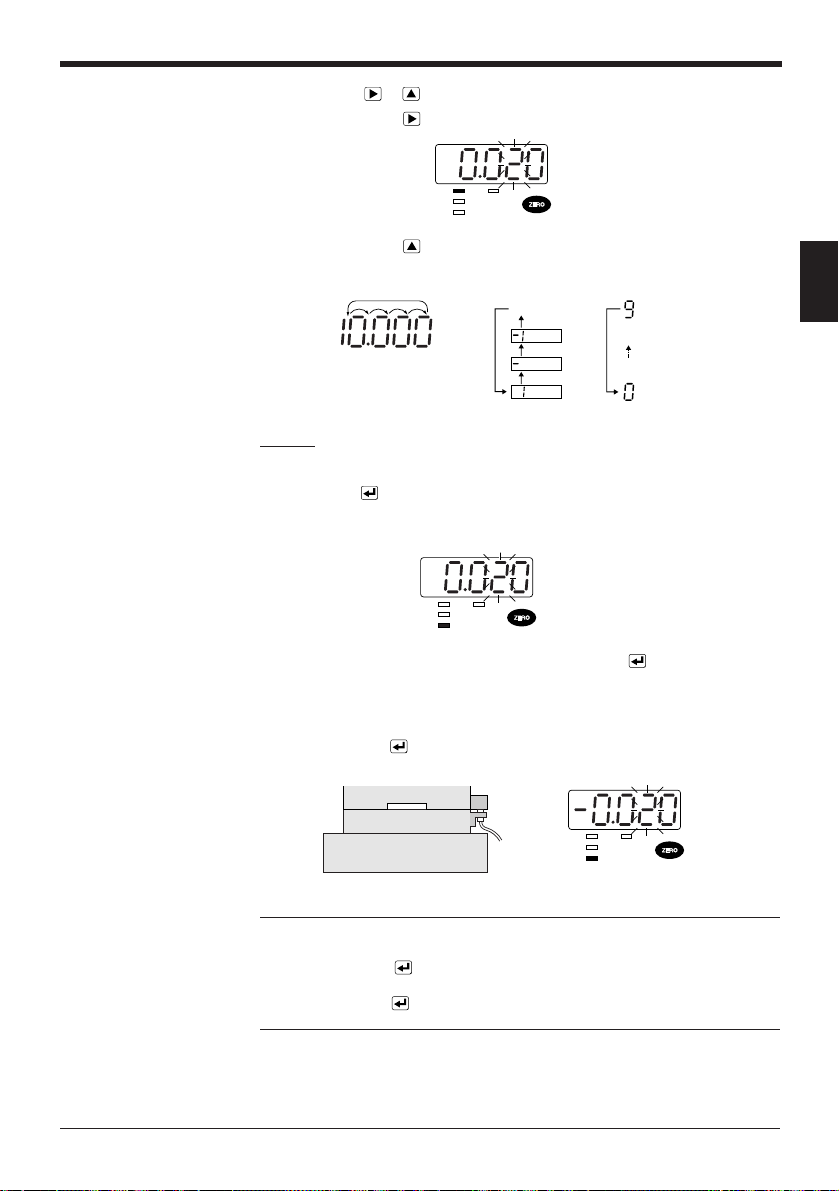

3. Press the key for at least 2 seconds.

The sensor enters the mode setting state and displays the mode number.

Mode No

HIGH TIM

GO

4. Press the

• Pressing the

LOW

SET

FUNC

UTILITY

key to display “1” which indicates the “bottom-dead-center” mode.

key changes the mode number sequentially.

MODE

CALL

CALIB

Mode No. Measurement mode

0 Manual

1 Bottom-dead-cente

2 Eccentricity/vibration

HIGH TIM

GO

LOW

3 Thickness/gap

key

• The measurement mode is factory-set to manual.

➮

For the initial setting of each measurement mode, refer to “4.1 Table of Data Processing

Functions” on page 46.

5. Press the key to save the measurement mode setting.

The sensor returns to the measurement state.

Note: Changing the measurement mode initializes all preset values except for the

tolerance limit values.

2

6. Activate the machine and check the bottom dead center position during normal

operation. Press the [ZERO] key to set this position as the reference point.

When the [ZERO] key is pressed, “0000” appears on the measured value

display.

Stripper or upper die

Lower die

Die set

Reference: To compensate for the slight variation in the bottom dead center

position at press startup or the influence of temperature fluctuation, refer to “Previous value comparison function [d]” on page 56.

Normal bottom

dead center

HIGH TIM

GO

LOW

15

Page 26

Chapter 2 Quick Guide to Basic Mode Operation

7. Set the upper value for the tolerance limit.

For a press, set the threshold value to the amount of the rise of the bottom dead

center due to swarf.

Stripper or upper die

Lower die

Die set

Upper limit value

2

1) Press the

• The sensor enters the tolerance limit setting mode.

• The setting number is displayed.

Note: Press the key for a short time. When the key is pressed for 2 seconds or

longer, the sensor enters the function setting mode and displays “Ab[d”. If you

accidentally put the sensor into the function setting mode, press the key again

to return to the measurement state.

2) Press the

• Pressing the

•“x” indicates the hysteresis setting. (➮

key.

Mode No

HIGH TIM

GO

LOW

SET

FUNC

UTILITY

MODE

CALL

CALIB

key to display the desired setting number.

key changes the setting number sequentially.

key

Refer to page 85.

)

16

Reference: Four kinds of tolerance limit values (“0” to “3”) can be saved in the

memory. The registered setting numbers can be switched using external signals.

(➮

Refer to page 4.

3) Press the

)

key.

• The sensor automatically enters the HIGH limit value setting mode.

• The setting value is displayed in red and the HIGH indicator illuminates.

HIGH TIM

GO

LOW

Page 27

Chapter 2 Quick Guide to Basic Mode Operation

4) Press the or key to display the desired value.

• Pressing the

key changes the flashing digit to the right.

HIGH TIM

GO

LOW

• Pressing the

key changes the value.

• All digits flash when the fifth digit and sign can be changed.

No setting

(5th digit)

(1st to 4th digits)

Example

When setting the tolerance to +20 µm, specify “0020”.

5) Press the

key.

The HIGH limit setting value is saved. The sensor automatically enters the

LOW limit value setting mode.

HIGH TIM

GO

LOW

8. Set the lower value for the tolerance limit and press the

key.

• For a press, set the threshold value to the amount of the lowering of the

bottom dead center due to the absence of a target.

• Set the LOW limit value using the same procedure as in steps 7 3) and 4),

and press the

key to save the value.

Stripper or upper die

Lower die

Die set

HIGH TIM

GO

LOW

2

Note 1: The output is disabled during the tolerance limit value setting. When the

output is already on, however, the output is retained.

Note 2: Pressing the

key does not save the changes if [HIGH setting value –

Hysteresis] is smaller than [LOW setting value + Hysteresis]. In this case, “Err1” is

displayed. Press the

key again to cancel the error, and then specify the correct

values.

17

Page 28

Chapter 2 Quick Guide to Basic Mode Operation

2.2.2 Setting the eccentricity/vibration mode

The following example explains the procedure for roller eccentricity measurement.

The basic operation is the same when mounting the EX-V series to other devices.

Be sure to adjust the output characteristics before performing the following

procedure (

➮

page 9

1. Mount the sensor head to the machine.

➮

For the sensor head mounting procedure, read "Mounting the sensor head" (pages 7 and 8).

2

).

Note: Be sure to use an IRON target with sufficient area for detection. (

➮

page 95

Reference: When the comparator output is already connected to the emergency

stop or another input for the facility, short-circuit the OUTPUT DISABLE input

(terminal 3) and grounding terminal (terminal 7) to disable the comparator output

before making the adjustment.

* After making the adjustment, be sure to disconnect these terminals to enable

the comparator output.

2. Press the

key for at least 2 seconds.

The sensor enters the mode setting state and displays the mode number.

Mode No.

HIGH TIM

GO

3. Press the

LOW

SET

FUNC

UTILITY

key to display "2" which indicates the "eccentricity/vibration"

MODE

CALL

CALIB

mode.

• Pressing the

0launaM

1retnec-daed-mottoB

2noitarbiv/yticirtneccE

3pag/ssenkcihT

key changes the setting number sequentially.

.oNedoMedomtnemerusaeM

HIGH TIM

GO

LOW

)

18

key

Page 29

Chapter 2 Quick Guide to Basic Mode Operation

• The measurement mode has been factory-set to manual.

➮

For the initial setting of the functions for each measurement mode, refer to "4.1 Table of Data

Processing Functions" (page 46).

4. Press the key to save the measurement mode setting.

The sensor returns to the measurement state.

Note: Changing the measurement mode initializes all preset values except for the

tolerance limit values.

5. Activate the machine and check the runout value during normal operation.

The value displayed in this step is the runout per cycle.

6. Set the upper value for the tolerance limit.

Calculate the upper limit value by adding the upper limit value of the required

tolerance to the value displayed during normal operation, and set the value as

the HIGH limit value.

Example

When the runout value during normal operation is "10 µm" and the tolerance is

"+30 µm", set the HIGH limit value to "0.040". When the runout value exceeds "40

µm", the comparator output is turned on.

1) Press the

key.

• The sensor enters the tolerance limit setting mode.

• The setting number is displayed.

Setting No.

HIGH TIM

GO

LOW

SET

FUNC

UTILITY

MODE

CALL

CALIB

Note: Press the key for a short time. When the key is pressed for 2 seconds or

longer, the sensor enters the function setting mode and displays "Ab(d". If you

accidentally put the sensor into the function setting mode, press the key again

to return to the measurement state.

2

2) Press the

• Pressing the

key to display the desired setting number.

key changes the setting number sequentially.

• "x" indicates the hysteresis setting (

➮

page 85

key

).

19

Page 30

Chapter 2 Quick Guide to Basic Mode Operation

Reference: Four kinds of tolerance limit values ("0" to "3") can be saved in the

memory. The registered setting numbers can be switched using external signals

(

➮

page 4

).

3) Press the

key.

• The sensor automatically enters the HIGH limit value setting mode.

• The setting value is displayed in red and the HIGH indicator illuminates.

2

4) Press the

• Pressing the

• Pressing the

or key to display the desired value.

HIGH TIM

GO

LOW

key changes the flashing digit to the right.

HIGH TIM

GO

LOW

key changes the value.

• All digits flash when the fifth digit and sign can be changed.

No setting

(5th digit)

(1st to 4th digits)

5) Press the key.

The HIGH limit setting value is saved. The sensor automatically enters the

LOW limit value setting mode.

20

HIGH TIM

GO

LOW

6) Press the

key again.

7. Activate the machine to check whether the comparator output correctly works

according to the tolerance limit setting values.

• The GO comparator output indicator on the controller illuminates when the

measured value is within the tolerance range. The HIGH indicator illuminates

when the measured value is higher than the upper limit value. The LOW

indicator illuminates when the measured value is lower than the lower limit

value.

• To perform fine adjustment of the tolerance limit values, repeat steps 5) and

6) described above.

Page 31

2.2.3 Setting the thickness/gap mode

The following example explains the procedure for sheet material thickness

measurement.

The basic operation is the same when mounting the EX-V series to other devices.

Be sure to adjust the output characteristics before performing the following

procedure (

1. Mount the sensor head to the machine.

➮

page 9

).

➮

For the sensor head mounting procedure, read "Mounting the sensor head" (pages 7 and 8).

Chapter 2 Quick Guide to Basic Mode Operation

2

Note: Be sure to use an IRON target with sufficient area for detection. (

➮

page 95

Reference: When the comparator output is already connected to the emergency

stop or another input for the facility, short-circuit the OUTPUT DISABLE input

(terminal 3) and grounding terminal (terminal 7) to disable the comparator output

before making the adjustment.

* After making the adjustment, be sure to disconnect these terminals to enable

the comparator output.

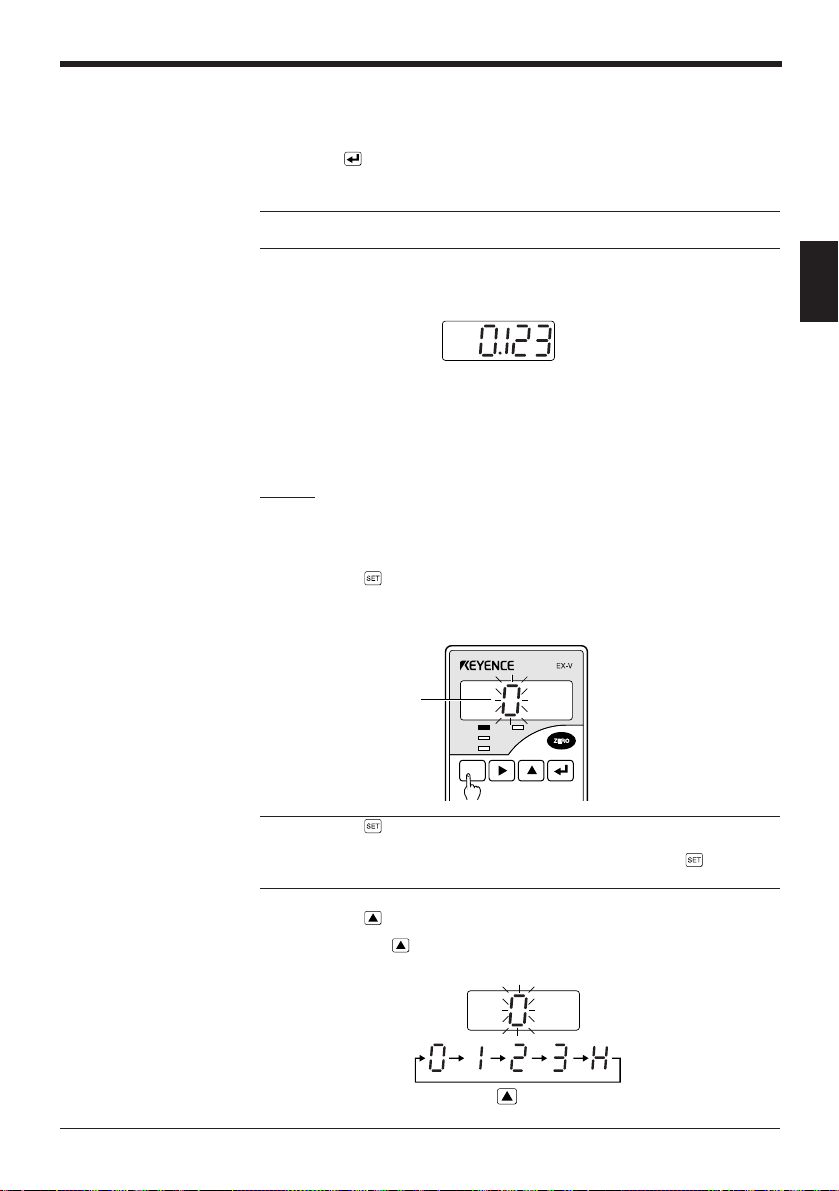

2. Press the

The sensor enters the mode setting state and displays the mode number.

3. Press the

• Pressing the

key for at least 2 seconds.

GO

LOW

SET

FUNC

UTILITY

MODE

CALIB

CALL

Mode No.

key to display "3" which indicates the "thickness/gap" mode.

key changes the setting number sequentially.

key

.oNedoMedomtnemerusaeM

0launaM

1retnec-daed-mottoB

2noitarbiv/yticirtneccE

3pag/ssenkcihT

)

• The measurement mode has been factory-set to manual.

➮

For the initial setting of the functions for each measurement mode, refer to "4.1 Table of Data

Processing Functions" (page 40).

21

Page 32

Chapter 2 Quick Guide to Basic Mode Operation

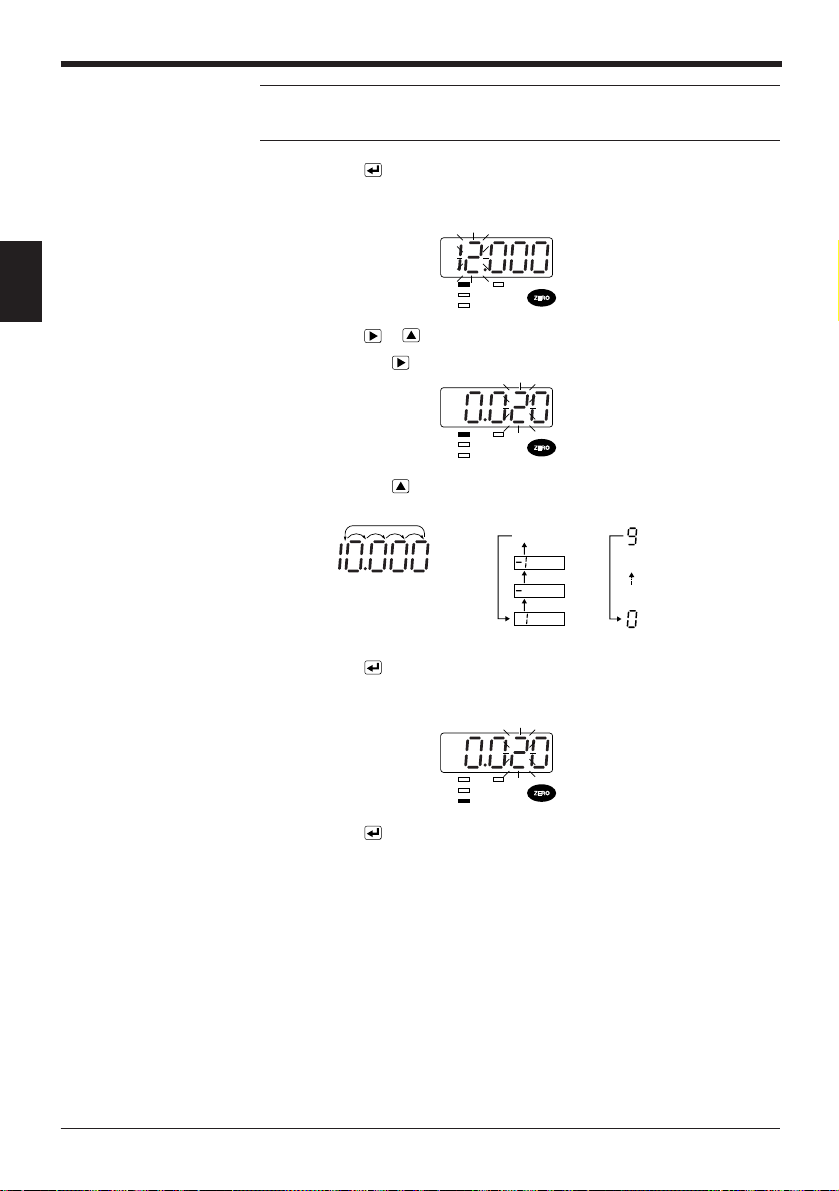

4. Press the key to save the measurement mode setting.

The sensor returns to the measurement state.

Note: Changing the measurement mode initializes all preset values except for the

tolerance limit values. If you accidentally put the sensor into the function setting

mode, press the key again to return to the measurement mode.

5. Set the upper value for the tolerance limit.

• Place the reference target in the correct measuring position and check the

2

• Calculate the upper limit value by adding the upper limit value of the required

Example

When the normal thickness measurement is "1 mm" and the tolerance is "±0.1

mm", set the HIGH limit value to "1.100" and the LOW limit value to "0.900".

normal thickness measurement.

tolerance to the normal thickness measurement, and set the value as the

HIGH limit value.

1) Press the

key.

• The sensor enters the tolerance limit setting mode.

• The setting number is displayed.

Setting No.

HIGH TIM

GO

LOW

SET

FUNC

UTILITY

MODE

CALL

CALIB

Note: Press the key for a short time. When the key is pressed for 2 seconds or

longer, the sensor enters the function setting mode and displays "Ab(d". If you

accidentally put the sensor into the function setting mode, press the key again

to return to the measurement state.

2) Press the

• Pressing the

• "x" indicates the hysteresis setting (

key to display the desired setting number.

key changes the setting number sequentially.

➮

page 85

).

key

Reference: Four kinds of tolerance limit values ("0" to "3") can be saved in the

memory. The registered setting numbers can be switched using external signals (

page 4

).

3) Press the

key.

• The sensor automatically enters the HIGH limit value setting mode.

• The setting value is displayed in red and the HIGH indicator illuminates.

➮

22

HIGH TIM

GO

LOW

Page 33

Chapter 2 Quick Guide to Basic Mode Operation

4) Press the or key to display the desired value.

• Pressing the

• Pressing the

key changes the flashing digit to the right.

HIGH TIM

GO

LOW

key changes the value.

• All digits flash when the fifth digit and sign can be changed.

No setting

2

(1st to 4th digits)

5) Press the

(5th digit)

key.

The HIGH limit setting value is saved. The sensor automatically enters the

LOW limit value setting mode.

6. Set the lower value for the tolerance limit.

• Set the lower limit value.

• Use procedures 3) and 4) in step 5 to set the LOW limit value. Then, press

key to save the value.

the

HIGH TIM

GO

LOW

Note 1: The output is disabled during the tolerance limit value setting. When the

output is already on, however, the output is retained.

Note 2: Pressing the

key does not save the changes if [HIGH setting value -

Hysteresis] is smaller than [LOW setting value + Hysteresis]. In this case, "Err1" is

displayed. Press the

key again to cancel the error, and then specify the correct

value.

Reference: When the thickness/gap mode is selected, in the initial setting state the

measured value becomes larger as the distance between the sensor head and

target is shorter. When you want to make the measured value smaller as the

distance is shorter, set function "d" (inverse/normal display function) to normal.

For details, see page 73.

Direction in which the

measured value increase

23

Page 34

Chapter 2 Quick Guide to Basic Mode Operation

2.3 Auto-Zero Function

The displayed value can be instantaneously reset to "0000" by pressing the

[ZERO] key or input through the AUTO-ZERO input terminal. The increase or

decrease in the value measured after activating the auto-zero function can be

displayed using "±" (plus or minus). This function simplifies zero-point adjustment

at product type changeovers.

Using the front panel key

• Press the [ZERO] key to reset the displayed value to "0000".

2

Using the AUTO-ZERO input terminal

• The value displayed just as the key is released is reset to "0000".

Short-circuit the ZERO 4 and GND 7 terminals to activate the auto-zero function.

HIGH TIM

GO

LOW

SET

CALL

GND

TIMING

67

RESET

5

ZERO

4

or

GND

TIMING

67

RESET

5

ZERO

4

Canceling the auto-zero function (Restoring the value reset using the auto-zero function)

Press the [ZERO] key for 3 seconds to cancel the auto-zero function.

Note 1: When an offset value is set, the offset value is displayed when the autozero function is activated. For details, see "Offset function [x]" (

➮

Note 2: When using the internal trigger function (

page 46

➮

pages 40 and 41

), adjust the trigger

level after activating the auto-zero function. (The internal trigger function works with

regard to the value displayed after the auto-zero function is activated.)

CAUTION

If frequently activating the auto-zero function using the external input

terminal, set the panel-lock function to ON to protect the memory. Then, the

displayed value will not be stored in the internal memory.

For details of the panel-lock function, see "Panel-lock function [J]"

(➮ page 43).

).

24

Page 35

2.4 Tolerance Limit Value Setting

You can set the allowable range for the tolerance limit value. After the comparator

of measured values, signals are output at three levels: when the measured value

exceeds the upper limit (HIGH), when it is below the lower limit (LOW), and when it

is within the allowable range (GO). The measured value is displayed in green for

the GO output and in red for the HIGH and LOW outputs.

Chapter 2 Quick Guide to Basic Mode Operation

Operation diagram

HIGH limit value

LOW limit value

Displayed value

HIGH OUT

GO OUT

LOW OUT

Setting the tolerance limit values

1. Press the key.

• The sensor enters the tolerance limit setting mode.

• The setting number is displayed.

(v)

ON

OFF

ON

OFF

ON

OFF

Setting No.

*

*

When a signal is output, the comparator output indicator on the

controller’s front panel illuminates.

* With the factory setting, a hysteresis of 5 digits is applied

when the output changes from LOW to GO or HIGH to GO.

HIGH TIM

GO

LOW

SET

FUNC

UTILITY

MODE

CALL

CALIB

2

(t)

2. Press the

Pressing the

key to display the desired setting number.

key changes the setting number sequentially.

key

25

Page 36

Chapter 2 Quick Guide to Basic Mode Operation

3. Press the key.

• The sensor automatically enters the HIGH limit value setting mode.

• The setting value is displayed in red and the HIGH indicator illuminates.

HIGH TIM

GO

LOW

2

Note: Setting the panel-lock function to ON allows the terminals to switch the

setting number for the tolerance limits. For details of the panel-lock function, see

"Panel-lock function [ ]" (➮

4. Press the

or key to display the desired value.

• Pressing the

• Pressing the

page 43

W

).

key changes the flashing digit to the right.

key changes the value.

• All digits flash when the fifth digit and sign can be changed.

No setting

HIGH TIM

GO

LOW

5. Press the

(5th digit)

key.

(1st to 4th digits)

• The HIGH limit setting value is saved. The sensor automatically enters the

LOW limit value setting mode.

• Set the LOW limit value using the same procedure as in steps 3 and 4.

HIGH TIM

GO

LOW

Note 1: The output is disabled during the tolerance limit value setting. When the

output is already on, however, the output is retained.

Note 2: Pressing the

key does not save the changes if [HIGH setting value -

Hysteresis] is smaller than [LOW setting value + Hysteresis]. In this case, “Err1” is

displayed. Press the

key again to cancel the error, and then specify the correct

values.

26

Page 37

Chapter 2 Quick Guide to Basic Mode Operation

2.5 Checking the Tolerance Limit Values (Calling the tolerance limit values)

The preset tolerance limit values can be checked during measurement.

1. Press the

key.

The preset setting number ("0" through "3") is displayed.

Setting No.

HIGH TIM

GO

LOW

SET

FUNC

UTILITY

MODE

CALL

CALIB

Note: Press the key for a short time. When the key is pressed for 2 seconds or

longer, the sensor enters the adjustment mode. If you accidentally put the sensor

into the adjustment mode, "0" appears at the right end on the display. At this time,

press the key to return to the measurement state.

2. Press the

key.

The HIGH indicator flashes and the preset HIGH limit value appears on the

display.

HIGH TIM

GO

LOW

3. Press the

key again.

The LOW indicator flashes and the preset LOW limit value appears on the

display.

2

HIGH TIM

GO

LOW

4. Press the

key to return to measured value display.

Note 1: The EX-V series internally performs measurement and comparison even

while displaying the tolerance limit value. When the measured value exceeds the

tolerance limit value while the tolerance limit value is called out on the display, the

displayed value changes from green to red to indicate that the measured value is

out of the tolerance range.

Note 2: When you want to change the preset value while calling out the tolerance

limit value on the display, press the

limit setting mode. Refer to "2.4 Tolerance Limit Value Setting" (

26

).

key. This allows you to enter the tolerance

➮

pages 25 and

27

Page 38

Chapter 2 Quick Guide to Basic Mode Operations

MEMO

Page 39

Chapter 3

Use of Common Functions

Explains the functions common to the respective modes and the setting procedure.

3.1 Table of Functions and Function Numbers....................... 30

3.2 Function Setting Flow ......................................................... 31

3.2.1 Selecting the function using the

3.2.2 Display scaling function [E] .................................................... 33

3.2.3 Monitor (analog voltage) output setting function [F] ............... 36

3.2.4 Digits function/decimal point function [g] ............................... 39

3.2.5 Offset function [x]................................................................... 40

3.2.6 Output form selection function [I] ..........................................42

3.2.7 Panel-lock function [j] ........................................................... 43

key .................................31

Page 40

Chapter 3 Use of Common Functions

3.1 Table of Functions and Function Numbers

Use the operation keys to set the functions of each mode. This section describes

the table of functions "E" through "J".

Table of functions and function numbers

noitcnuF

edoc

e

f

3

g

x

i

j

* The setting in each shaded column of the table above shows the factory-set value.

noitcnuF

gnilacsyalpsiDulavdeyalpsidehtrofnoitcnufgnilacsehtgnitteS

rotinoM

gnittestuptuo

stigiD

tnioplamiceD

tesffO 000.0:eulavlaitini(eulavciremunehtgnitteS

mroftuptuO

kcol-lenaP

)noitceles(

0123456789

)egatlovgolana(

dohtem

stigid5stigid5stigid5stigid5stigid4stigid4stigid4

tigidht4tigiddr3tigiddn2

.O.N

lamroN

FFO

.C.N

lamroN

NO

-ret(

)lanim

oN

lamiced

tniop

.O.N

.O.N

dloH

yaled-ffO

e

tigidht4tigiddr3tigiddn2tigiddn2

)

.oNnoitcnuF

tuptuoehtgnitcelesdnatuptuo)egatlovgolana(rotinomehtrofnoitcnufgnilacsehtgnitteS

-hgiH

ycarucca

edom

30

Page 41

3.2 Function Setting Flow

This section explains how to set functions "E" through "j" using the key.

3.2.1 Selecting the function using the key

Select the function to be set from functions "E" through "j" and then enter the

desired function number or numeric value.

Chapter 3 Use of Common Functions

1. Press the

key for at least 2 seconds.

• The sensor enters the common function selection mode.

• The function parameter of the flashing function code can be set.

HIGH TIM

GO

2. Press the

Pressing the

SET

3. Press the

LOW

SET

FUNC

UTILITY

key to select the function to be set.

key changes the flashing digit to the right.

CALL

or key to enter the function number setting state.

MODE

CALL

CALIB

4. Set the function parameter.

➮

For details of each function, see pages 33 to 43.

3

5. Press the key.

The sensor saves the setting and returns to the measurement state.

6. To set two or more functions, repeat steps 1 through 5 described above.

31

Page 42

Chapter 3 Use of Common Functions

3

Reference 1: When the initial setting for a function is changed, the setting is

displayed in red.

Reference 2: To return to the common function selection mode without changing

the setting, press the key.

Note 1: When you return to the measurement state by pressing the key even

after entering a function number or numeric value, the number or value is not

saved.

Note 2: The output is disabled for the time between entering the common function

selection mode with the

setting. However, if the output is already on before the sensor enters the common

function selection mode, the output is retained.

key and returning to the measurement state after

32

Page 43

3.2.2 Display scaling function [E]

This function is used to change the ratio of the displayed value relative to the

measured value (input value from the sensor head). To perform scaling, enter the

desired display value respectively for two desired correction points.

Example

To display the original display value changing from "1" to "5" as a value changing

from "0" to "10"

Before scaling After scaling

Display Display

5

1

15

Original display

10

0

1

Original display

Chapter 3 Use of Common Functions

Setting

Point 1

Original display (input value) : 1.000

Changed display (display value) : 0.000

Point 2

Original display (input value) : 5.000

Changed display (display value) : 10.000

5

3

1. Press the

key for at least 2 seconds.

The sensor enters the common function selection mode.

2. Press the

key to select function "E".

Check that "E" is flashing.

HIGH TIM

GO

3. Press the

4. Press the

LOW

SET

FUNC

UTILITY

key to enter the display scaling function setting state.

key to select the input method. After the selection, press the

MODE

CALL

CALIB

key to save the input method setting.

• Pressing the

.oN

0-nI

1-nI

key changes the input method number.

noitcnuF

noitcnuF

gnittesrof

tupniyeknoitarepognisU

morfeulavtupnignisU

gnittesrofdaehrosnes

Using input value from

sensor head for setting

Using operation key

input for setting

• Select "0" or "1" and follow the procedure described below according to the

selected input method.

33

Page 44

Chapter 3 Use of Common Functions

When selecting "In-0"

5. Set the input value for correction point 1.

Use the

• The value on the flashing digit can be changed.

• Pressing the

3

• Pressing the

• All digits flash when the fifth digit and sign can be changed.

6. Press the

enters the display value setting state.

The display value is displayed in green.

7. Set the display value for correction point 1 in the same procedure as step 5, and

use the

or key to set the desired numeric value.

key changes the flashing digit to the right.

key changes the value.

key to save the input value for correction point 1. Then, the sensor

key to save the setting value.

No setting

(5th digit)

(1st to 4th digits)

34

8. Set and save the input and display values for correction point 2.

• Repeat steps 5 and 6 to set and save the input and display values for

correction point 2.

• After saving the display value for point 2, the sensor returns to the

measurement state.

Page 45

When "In-1" is selected

Chapter 3 Use of Common Functions

5. Set and save the input value for correction point 1 using the value measured by

the sensor (input from the sensor head).

• Move the sensor head or target to the distance to be set as correction point

1.

• Press the

key to save the measured value.

6. Use the

• Pressing the

• Pressing the

• All digits flash when the fifth digit and sign can be changed.

7. Press the

8. Set and save the values for correction point 2.

• Repeat steps 5 through 7 to set and save the input and display values for

• After saving the display value for point 2, the sensor returns to the

Note 1: The input and display values for display scaling can be set between 19999 and +19999.

Note 2: To set the scaling function, be sure to satisfy the following conditions. If

these conditions are not satisfied, "Err2" is displayed and the setting procedure is

disabled. When the error message is displayed, press the

error message and retry the setting.

(1) Input value 1 - input value 2 ≠ 0

(2) Display value 1 - display value 2 ≠ 0

(3) After scaling, the display value is within the range of ±19.999 when the input

value is "0".

(4)

0.0001 ≤

Note 3: When using the internal trigger function (

level after performing scaling. (The internal trigger function works with regard to the

value displayed after scaling is performed.)

or key to set the display value for correction point 1.

key changes the flashing digit to the right.

key changes the value.

No setting

(5th digit)

key to save the setting value.

correction point 2.

measurement state.

(display value 1 - display value 2 )

(input value 1 - input value 2)

≤ 15

➮

page 46

(1st to 4th digits)

key to cancel the

), adjust the trigger

3

35

Page 46

Chapter 3 Use of Common Functions

3.2.3 Monitor (analog voltage) output setting function [F]

This function is used to change the ratio of the analog voltage output value relative

to the displayed value, provided that the output voltage is between -5 and +5 V. By

performing scaling, you can change the output voltage value to the desired level. In

addition, you can select either of the following two output methods: one outputs

analog voltage according to the displayed value and the other outputs the input

value from the sensor head.

Reference: The initial state outputs the voltage equal to the displayed value.

Output scaling

The ratio of the analog voltage output relative to the displayed value can be

changed, provided that the output voltage is between -5 and +5 V. To perform

scaling, enter the desired monitor (analog voltage) output value respectively for two

3

desired correction points.

Before scaling

Monitor (analog voltage)

output (V)

55

5.000

1. Press the

After scaling

Monitor (analog voltage)

output (V)

Display

00

10.000

Display

key for at least 2 seconds.

The sensor enters the common function selection mode.

Setting

Point 1

Display value: 0.00

Monitor (analog voltage) output value: 0

Point 2

Display value: 10.000

Monitor (analog voltage) output value: 5

36

2. Press the

3. Press the

4. Press the

key to make "F" flash.

or key to enter the monitor output setting mode.

key with "F-0" displayed.

The sensor enters the monitor output scaling setting state.

Page 47

5. Set the display value for correction point 1.

The display value is displayed in red.

Chapter 3 Use of Common Functions

• The value on the flashing digit can be changed.

• Pressing the

• Pressing the

• All digits flash when the fifth digit and sign can be changed.

6. Press the

• Then, the sensor enters the monitor output value setting state.

7. Set the monitor output value for correction point 1 in the same procedure as

step 5, and use the

• The monitor output value is displayed in green.

8. Repeat steps 5 through 7 to set and save the display and monitor output values

for correction point 2.

• After saving the monitor output value for point 2, the sensor returns to the

measurement state.

key changes the flashing digit to the right.

key changes the value.

No setting

(1st to 4th digits)(5th digit)

key to save the display value for correction point 1.

key to save the setting value.

3

Note 1: The display and monitor output values for monitor output scaling can be

set between -19999 and +19999.

Note 2: To set the scaling function, be sure to satisfy the following conditions. If

these conditions are not satisfied, "Err3" is displayed and the setting procedure is

disabled. When the error message is displayed, press the

error message and retry the setting.

(1) Display value 1 - display value 2 ≠ 0

(2) Monitor output value 1 - monitor output value 2 ≠ 0

(3)

(monitor output value 2 - monitor output value 1 )

0.001 ≤

(display value 2 - display value 1)

key to cancel the

≤ 6

37

Page 48

Chapter 3 Use of Common Functions

Selecting the output method

1. Press the key for at least 2 seconds.

The sensor enters the common function selection mode.

2. Press the

3. Press the

key to make "F" flash.

or key to enter the monitor output setting mode.

3

4. Press the

Press the

5. Select the desired output method.

Pressing the

key to display "F-1".

key to enter the monitor output method selection state.

key changes the function number.

noitcnuF

.oN

01-f

11-f

noitcnuF

golanastuptuorosnesehT

ehtotgnidroccaegatlov

.eulavdeyalpsid

ehtgniretlifrognilacsretfA

ehtmorftupnilangis

rosneseht,daehrosnes

.langisehtstuptuo

Outputs the input value.

Outputs the displayed value.

38

Reference: When using the hold mode in the bottom-dead-center or eccentricity/

vibration mode (in which only the operation result is retained and displayed), set

the output method to "F-11". This allows you to check the current change of the

measured value.

6. Press the

After saving the setting, the sensor returns to the measurement state.

key to save the output method setting.

Page 49

3.2.4 Digits function/decimal point function [g]

The digits function is used to delete the last digit on the display. The decimal point

function is used to place the decimal point on the desired position.

Chapter 3 Use of Common Functions

Table of function number

Setting function "g"

.oNnoitcnuF

0

1

2

3

4

5

6

7*

* Only with the 1-mm type and 2-mm type, the high-accuracy mode can be used. The least significant

digit shows sub-micron.

forebmuN

stigiddeyalpsid

stigid5tigidht4

stigid5tigiddr3

stigid5tigiddn2

stigid5ttnioplamicedoN

stigid4tigidht4

stigid4tigiddr3

stigid4tigiddn2

ycarucca-hgiHtigiddn2

tnioplamiceD

noitisop

yalpsiD

888.81

88.881

8.8881

88881

88.81

8.881

0.081

8.8881

1. Press the key for at least 2 seconds.

The sensor enters the common function selection mode.

2. Press the

3. Press the

4. Press the

Pressing the

key to make "g" flash.

or key to enter the digits/decimal point setting state.

key to select the desired function number.

key changes the function number sequentially.

3

5. Press the

key.

The sensor saves the setting and returns to the measurement state.

Note 1: Even when the number of displayed digits is set to 4 digits, the tolerance

limit values are displayed with 5 digits. The actual measured value (including the

last digit), instead of the displayed value, is used for comparison with the tolerance

limit values.

Note 2: When the decimal point position on the display is shifted, that of the

tolerance limit values is shifted to the same position.

Note 3: When changing the sensor to the high accuracy mode while the internal

trigger function (

➮

page 46

) is activated, adjust the trigger level after the changing.

(The internal trigger function works with regard to the value displayed after the

changing.)

39

Page 50

Chapter 3 Use of Common Functions

3.2.5 Offset function [x]

The offset function allows any value to be added to or subtracted from the

displayed value. When an offset value is preset, activating the auto-zero function

displays the offset value.

Applications of the offset function

• The displayed value can be changed to a desired value by performing addition

or subtraction.

3

Setting function "x"

HIGH TIM

GO

LOW

SET

FUNC

UTILITY

MODE

Add "0.003" to the

displayed value using the

offset function.

CALL

CALIB

HIGH TIM

GO

LOW

SET

FUNC

UTILITY

MODE

CALL

CALIB

• The displayed value can be reset to the dimension of the master target that was

previously measured.

The master target

measures 10 mm.

Set the offset value to

"10.000" and then

activate the auto-zero

function.

HIGH TIM

GO

LOW

SET

FUNC

UTILITY

MODE

CALL

CALIB

1. Press the for at least 2 seconds.

The sensor enters the common function selection mode.

2. Press the

3. Press the

key to make "x" flash.

or key to enter the offset setting state.

40

Page 51

Chapter 3 Use of Common Functions

4. Use the or key to set the desired numeric value.

• The value on the flashing digit can be changed.

Pressing the

• Pressing the

No setting

key changes the flashing digit to the right.

key changes the value.

(5th digit)

(1st to 4th digits)

HIGH TIM

GO

LOW

• All digits flash when the fifth digit and sign can be changed.

Reference: Pressing the [ZERO] key in this step resets the display to "0000".

5. Press the

key.

The sensor saves the setting value and returns to the measurement state.

Reference: The offset value can be set within the range of ±19.999.

Note: When using the internal trigger function (

➮

page 46

), adjust the trigger level

after entering the offset value. (The internal trigger function works with regard to

the displayed value.)

3

41

Page 52

Chapter 3 Use of Common Functions

3.2.6 Output form selection function [I]

This function is used to select the output form from the open-collector (HIGH, GO,

LOW) to output the signal for indicating that the measured value is out of the

tolerance range.

noitcnuF

.oN

0

1

2

3*

3

Setting function "I"

*"3" is displayed only when normal measurement in the manual mode or continuous measurement in

the thickness/gap mode is selected.

1. Press the key for at least 2 seconds.

The sensor enters the common function selection mode.

emaNnoitarepO

lamron.O.N

tuptuo

tuptuo

dloh.O.N

tuptuo

tuptuo

.langis

lamron.C.N

.langis

yaled-ffo.O.N

)tcatnoc-a(nepoyllamronasasevrestuptuorotarapmocehT

)tcatnoc-b(desolcyllamronasasevrestuptuorotarapmocehT

litnuseunitnoctuptuoehtdna,deniatersituptuolamron.O.N

.deniatertonsituptuoOG,revewoH.tupnisilangistesereht

.sm06ybdeyaledsituptuolamron.O.N

2. Press the

3. Press the

4. Press the

Pressing the

5. Press the

key to make "I" flash.

HIGH TIM

GO

LOW

SET

FUNC

UTILITY

MODE

CALL

CALIB

or key to enter the output form selection state.

key to select the desired function number.

key changes the function number sequentially.

N.O. off-delay output

N.O. hold output

N.C. normal output

N.O. normal output

key.

The sensor saves the setting and returns to the measurement state.

42

Page 53

3.2.7 Panel-lock function [j]

The panel-lock function is used to inhibit front panel key operation. Use this function to prevent the accidental pressing of the keys, which may cause malfunctions.

When the panel-lock function is set to ON, all key operations are ignored, except