Page 1

Instruction

Manual

Inductive Gauging Sensor

96M0368

EX-500(W) Series

Page 2

CONTENTS

SAFETY PRECAUTIONS

Part Names and Functions.......................................................... 3

Connections ................................................................................ 4

Example of connections .............................................................. 5

Hints on correct use .................................................................... 5

Installation ................................................................................... 6

Adjustment .................................................................................. 7

Measuring range vs. analog output ............................................. 9

Auto-zero/Auto-span functions .................................................... 9

Interference suppression function ............................................. 12

Specifications ............................................................................ 13

Troubleshooting guide .............................................................. 14

Characteristics .......................................................................... 14

Dimensions ............................................................................... 15

WARRANTIES AND DISCLAIMERS ........................................ 16

Note

This is a class A (EN55011: EMI standard) product. In a domestic

environment this product may cause radio interference in which

case the user may be required to take adequate measures.

This manual describes how to install the EX-500(W) Series as well as its

operating procedures and precautions. Please read this manual carefully

to get the best from your EX-500(W) Series.

Safety precautions

Symbols

The following symbols alert you to important messages. Be sure to read

these messages carefully.

WARNING

CAUTION

Note

Failure to follow instructions may lead to injury.

(electric shock, burn, etc.)

Failure to follow instructions may lead to product

damage.

Provides additional information on proper operation.

General precautions

• At startup and during operation, be sure to monitor the functions and performance of the EX-500(W) series.

• We recommend that you take substantial safety measures to

avoid any damage in the event a problem occurs.

• Do not open or modify the EX-500(W) series or use it in any

way other than described in the specifications.

• When the EX-500(W) series is used in combination with other

instruments, functions and performance may be degraded,

depending on operating conditions and the surrounding environment.

• Do not use the EX-500(W) series for the purpose of protecting

the human body.

2

Page 3

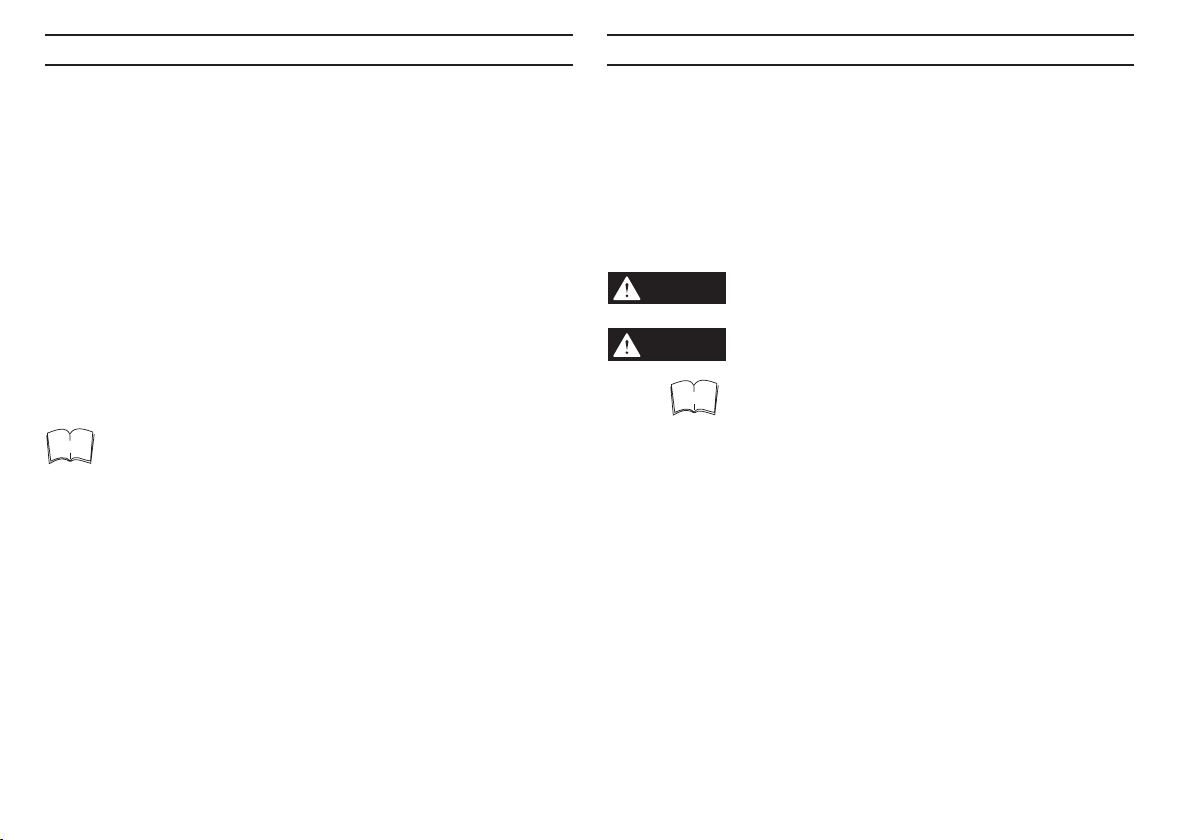

PART NAMES AND FUNCTIONS

1 Sensor head

cable connector

2 Indicators

POWER: Power indicator

OVER: Measurement out-of-range indicator

ALARM: Disconnection alarm indicator

3 Response time selector switch

You can select one of the following four response times.

RESPONSE 1 2 3 4

Response time 0.1 ms 1 ms 10 ms 100 ms

4 Mode selector switch

This switch is used to select the desired mode based on the

target material.

MODE Function

1 MEASUREMENT mode When measuring targets, set the

2 ADJUSTMENT mode

for aluminum

3 ADJUSTMENT mode

for stainless steel

4 ADJUSTMENT mode

for steel

(After completing the adjustment procedure, set the mode selector switch to "1"

to start measurements.)

switch to this position.

When adjusting output voltage

(current), select the ADJUSTMENT

mode based on the target material.

5 Cable length selector switch

Normally set this switch to "3 m" (the lower position).

When an optional extension cable (7 m) is added, set this

switch to "10 m" (the upper position). (7 m cable: model OP-

20708)

6 Lock switch

When this switch is set to LOCK (the lower position), any

output adjustment keys (7) are disabled.

7 Output adjustment keys

The functions are changed by adjusting the Mode selector

switch position.

Mode

Key No.

Zero-point set key

Sets the output to 0 V when the

target is in contact with the

sensor head.

Full-scale set key

Sets the output to 5 V when the

target is at the maximum

measuring distance from the

sensor head.

Linearity compensation key

Sets the output voltage to 2.5 V

to compensate for the linearity of

the output voltage when the

target is placed at half the

maximum measuring distance (1/

2 of F.S.) from the sensor head.

* The auto-span key functions in the range of 2 to 4 V output voltage.

ADJUSTMENT

mode

2. 3. 4

Auto-zero/Auto-span reset key

Resets the auto-zero and autospan functions.

Auto-span key

Changes the input-to-output ratio

and sets the output to 2.5 V when

the target is at any position within

measuring range.

(When current output is used,

pressing this key sets the output

current to 12 mA.)

Auto-zero key

Sets the output to 0 V when the

target is at any position within

measuring range.

(When current output is used,

pressing this key sets the output

current to 4 mA.)

MEASUREMENT

mode

1

3

Page 4

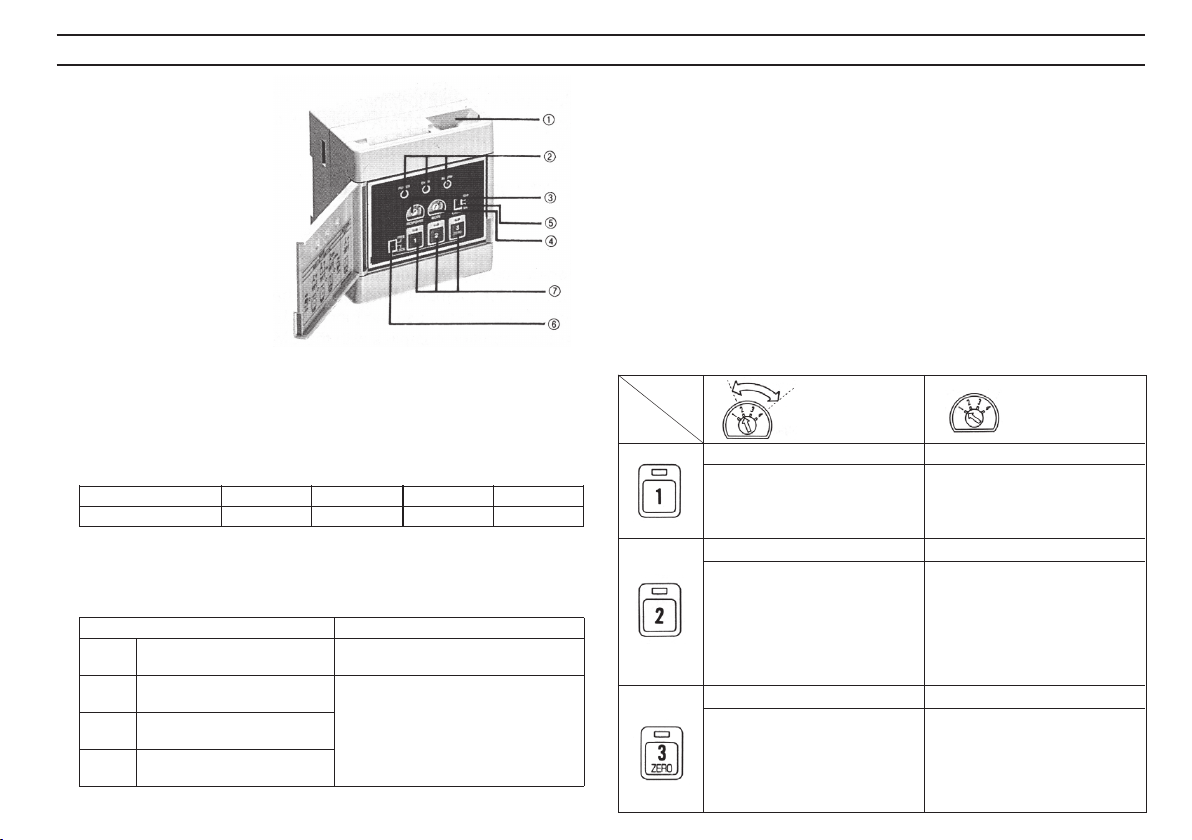

CONNECTIONS

Referring to the following descriptions of terminals, complete

connections before you turn the power ON.

Analog

voltage

output

(V)

Analog

current

output (mA)

8 9 10 11 12

1 2 3 4 5 6 7

12 to 24 VDC

Interference suppression

(CONTROL)

0 V

Auto-zero input

(SYNC)

GND

NPN output

(Disconnection alarm output)

Sensor head

cable connector

GNDNot used

4 Auto-zero input terminal:

Sets the analog output voltage to 0 V when this terminal and

GND terminal (5) are short-circuited. (When current output is

used, the output current is set to 4 mA.) (See p.9.)

6 NPN output (Disconnection alarm output) terminal:

Outputs a signal when the sensor head cable is disconnected.

8 Analog voltage output terminal:

Analog voltage of 0 to 5 V relative to full measuring range is

output.

9 Analog current output terminal:

Analog current of 4 to 20 mA relative to full measuring range is

output.

A & B Interference suppression terminals: (See p.12.)

Note

The interference suppression function is not available with the

EX-500(W) series (compliant model with the EMC directive (CE

marking)). If you want to use the function, be sure to check

whether the operation complies with the EMC directive on your

account.

Input circuit diagram Output circuit diagram

4

Page 5

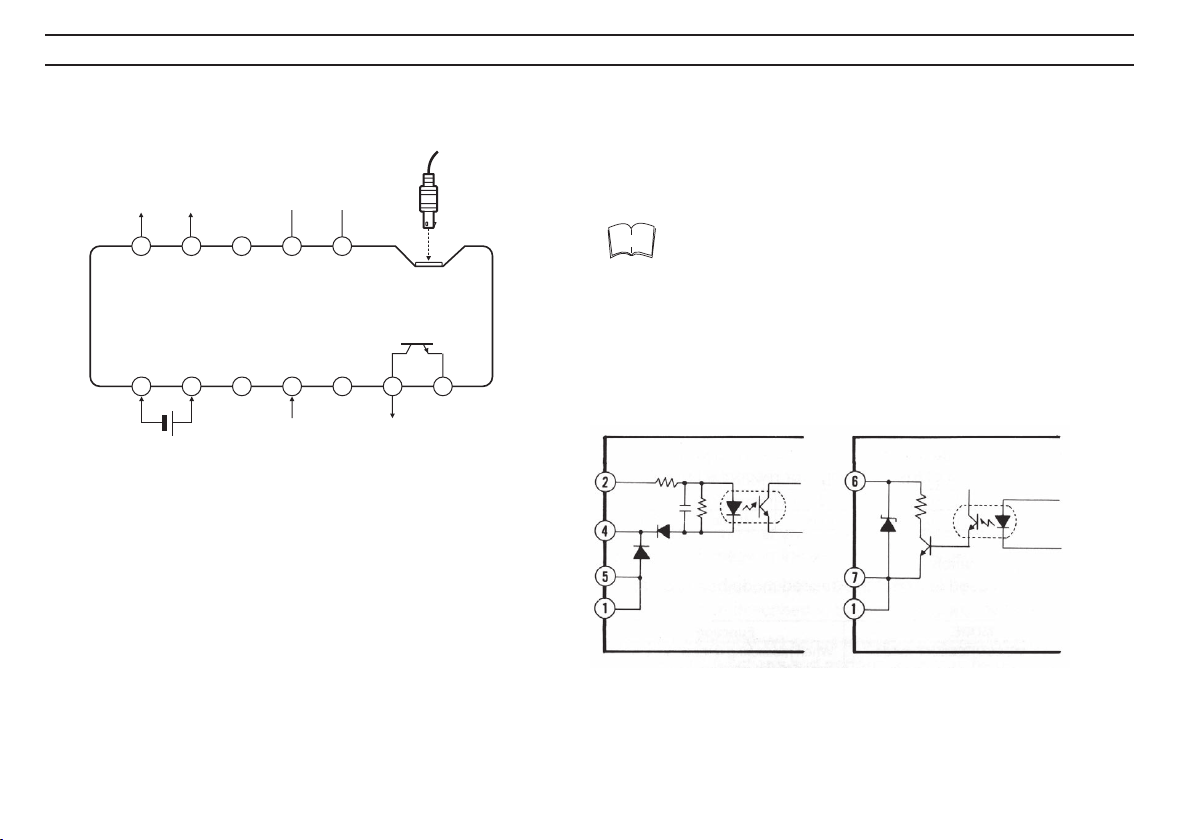

CONNECTIONS

HINTS ON CORRECT USE

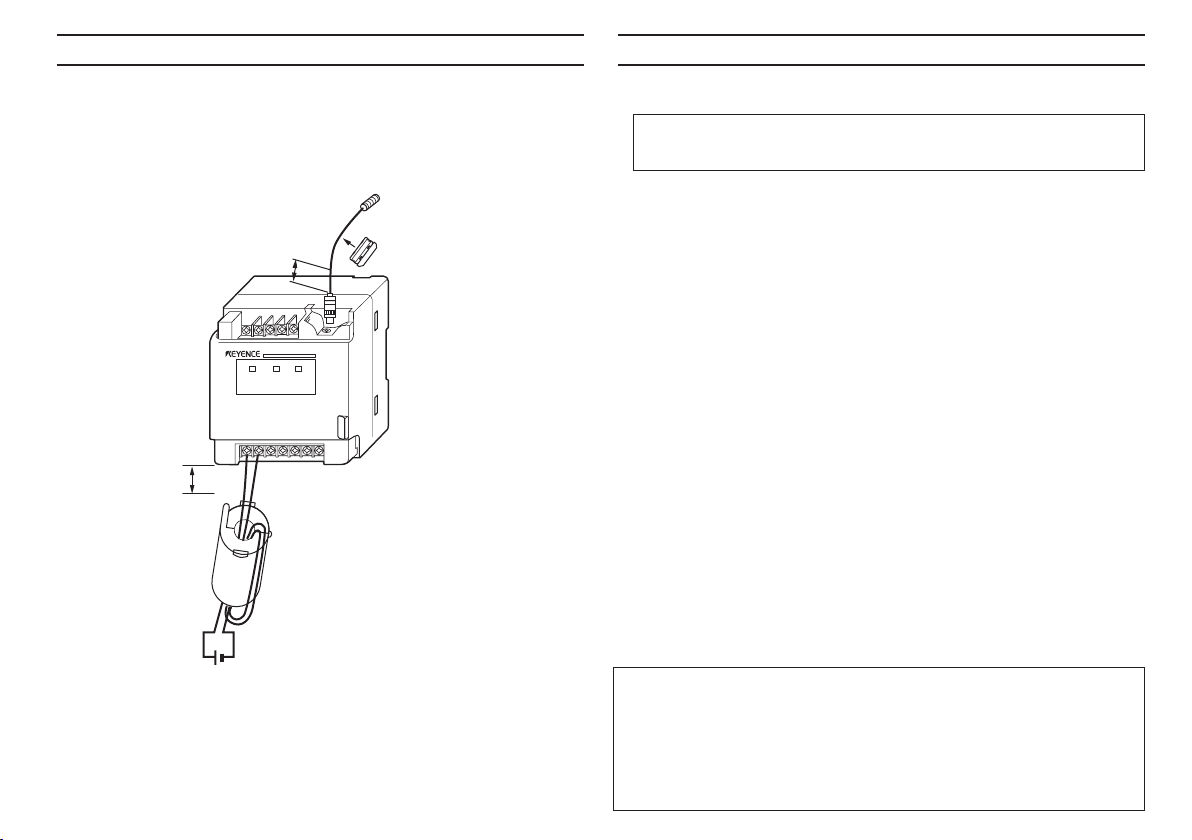

To make the EX-500(W) series comply with the EMC directive

(CE marking), use the attached ferrite cores as shown in the

illustration below.

Sensor head

Ferrite core (smaller one in

the accessory)

ZCAT1325-0530A (TDK)

30 Max.

20 Max.

8 9 10 11 12

POWER OVER ALARM

1

12 to 24 VDC

EX-501

2

3

4 5 6 7

Ferrite core (larger one in the

accessory)

ZCAT2035-0930 (TDK)

Be sure to use a sheathed cable with an

outer diameter of 2.5-mm or less for the

power cable.

■ Noise interference

When using a switching regulator, make sure that the F.G.

terminal or the GND terminal is grounded.

• Keep the wiring and connection cable away from high-voltage

lines or power lines; otherwise noise may affect the performance of the EX-500(W).

• If noise from the power supply line causes the EX-500(W) to

malfunction, use an isolating transformer with the power

supply.

■ Auto-zero input

When the DC 2-wire proximity sensor (KEYENCE EV Series) is

used for auto-zero input, power supply voltage of the EX500(W) Series must be 20 V or higher.

■ Warm-up time

Do not start adjustment/measurement until at least 30 minutes

after the power is turned ON. The circuitry is not stable during

this period and fluctuation in measured values may result.

■ Cable extension

• The standard sensor head cable length is 3 m. It can be

extended to 10 m by connecting 7-m extension cable (Model:

OP-20708).

• Do not change the specified sensor head cable length

(3 or 10 m). If you extend or cut the cable, its characteristics will change.

• The junction connector is grounded through its housing. Make necessary arrangements for insulation.

5

Page 6

INSTALLATION

Controller

The controller can be mounted to a DIN rail. When mounting or

dismounting the controller, pull the claws located at the bottom of

the controller in the direction shown by the arrows. Also, the

controller can be mounted with screws by pulling out the fittings.

When mounted on DIN rail

When mounted with screws

Sensor head

■ Connecting to/disconnecting from the controller

• Plug the sensor head cable into

the connector of the controller until

it clicks. (When connecting an

extension cable to the controller or

the sensor head, follow the same

procedure.)

• When disconnecting the plug, hold

it by the sleeve and pull it out as

shown on the right.

Incorrect

Correct

■ Mounting

Nut tightening position

3mm min

Tighten the nut away from the tip of

the metal case as shown on the right.

Torque values

Tighten the nut according to the

torque values given in the table

below.

EX-008 EX-016 EX-022

(approx. 100 kgf-cm) max. (approx. 200 kgf-cm) max. (approx. 300 kgf-cm) max.

10 Nm 20 Nm 30 Nm

■ Flush-mounting

The diagram and table below shows the dimensions to use when

flush-mounting a sensor head onto a metal plate.

øA

B

EX-008 20 11

EX-016 45 20

EX-022 60 25

A (mm) B (mm)

When connecting and disconnecting the plug, be sure to hold it by

the sleeve. If you forcefully pull on

the cable, the cable may break off

from the plug.

6

Page 7

ADJUSTMENT

Before starting measurements, adjust the analog output with

an actual target using the following procedure.

Connection

1. Connect a panel meter or voltmeter to the analog output

terminal of the controller using a shielded cable.

2. Complete the connections and then turn the power ON. The

POWER indicator of the controller lights and the sensor is in

operation mode.

* Before starting the adjustment procedure, allow the unit to

warm up for at least 30 minutes.

Setting the switches

1. Set the response time selector switch according to the required

measurement accuracy.

RESPONSE 1 2 3 4

Response time 0.1 ms 1 ms 10 ms 100 ms

RESPONSE

2. Select one of the ADJUSTMENT modes based on the target

material.

MODE

* Base material: Iron (SS41),

Plating thickness: 50 µm

Resolution 0.10% 0.06% 0.03% 0.03%

(% of F.S.)

MODE 2 3 4

Reference Aluminum Stainless steel Iron

metal (A5052) (SUS304) (S45C)

Other Copper Iron (SS41)

metals (C1100)

Brass (SUS410)

(C3560) Stainless steel

Metal- Zinc-plated Nickel-

plated* Chromium plated

-plated

Stainless steel

(SUS430)

CABLE

10 m

3 m

FREE

3. Set the cable length selector switch according to the sensor head cable length.

4. Set the lock switch to FREE (the upper

position).

■ Analog output adjustment

LOCK

1. Place the sensor head in contact with the target and press the

<1> key (zero-point set key) to check whether the output

voltage is 0 V.

The LED lights. The LED goes out.

Sensor head in

contact with target.

Hold the sensor head in contact with the target

until the LED of key <1> goes out.

Press the

<1>

key.

Approx. 3 seconds

after pressing the key.

When current output is used .

the output current is set to 4 mA.

2. Set the distance between the sensor head and the target to the

maximum measuring distance. Then press the <2> key (Fullscale set key) to check whether the output voltage is 5 V.

The LED lights.

F.S.(Max.

measuring distance)

Hold the sensor head at the maximum measuring

distance from the target until the LED of <2> key

goes out.

Press the

<2>

key.

The LED goes out.

Approx. 3 seconds

after pressing the key.

When current output is used .

the output current is set to 20 mA.

7

Page 8

ADJUSTMENT

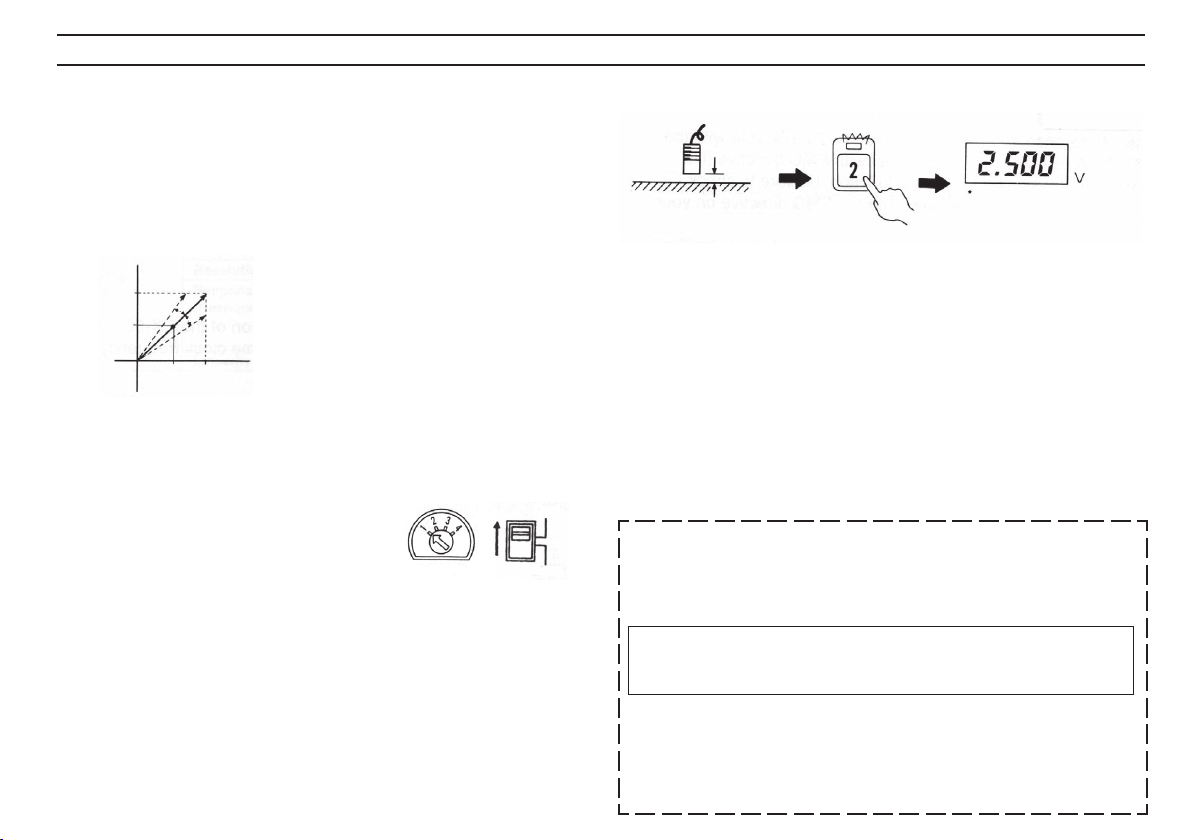

3. Set the distance between the sensor head and the target to

half the maximum measuring distance. Then press the <3> key

(linearity compensation key) to check whether the output

voltage is 2.5 V.

The LED lights.

Harf F.S.(Harf max.

measuring distance)

Hold the sensor head at half the maximum

measuring distance until the LED of <3> key

goes out.

Press the

<3>

key.

The LED goes out.

Approx. 3 seconds

after pressing the key.

When current output is used .

the output current is set to 12 mA.

• If the analog output adjustment cannot be performed during

steps (1) through (3), for example, when any key is pressed

with the target out of the measuring range, the LED of the

corresponding key flashes and the OVER indicator lights.

By pressing the flashing key, the error is reset and the LED

goes out. Re-start the adjustment procedure given in the

previous steps.

(Note: Even if an adjustment error occurs in step (3), the

linearity compensation is performed in the controller.)

• When the response time selector switch is set to RESPONSE

1 (0.1 ms), the linearity and temperature fluctuation of the

analog output voltage is not compensated to reduce the

response time. Although the output voltage is not adjusted to

exactly 2.5 V in step (3), the compensation is completed in the

controller. When a highly accurate measurement is required,

set the response time selector switch to RESPONSE 2, 3 or 4,

then you can start the measurement without re-adjusting the

output voltage.

4. Place the sensor head in contact with the target again as

described in the step (1) to check whether the output voltage is

0 V.

If the output voltage is not 0 V, repeat the steps (1) through (3).

■ Starting measurement

Set the mode selector switch to "1" (MEASUREMENT mode) to start measurement.

Mode

Precautions on analog output adjustment

• When you adjust the analog output voltage (current) using

the adjustment mode switch, be sure to complete steps (1)

through (4). If you interrupt the procedure, the linearity

compensation will not be correct.

• To be within the specifications of the EX-500(W) Series, set

the distance between the sensor head and the target exactly

as described above during the analog output adjustment.

• Making the analog output adjustment resets the auto-zero

and auto-span functions.

8

Page 9

MEASURING RANGE VS. ANALOG OUTPUT

AUTO-ZERO/AUTO-SPAN FUNCTIONS

Each sensor outputs an analog voltage (current) in proportion to the measuring distance.

EX-501(W)/008 EX-502(W)/008

Measuring range Measuring range

F.S. (Full Scale) F.S. (Full Scale)

=1 mm =2 mm

EX-505(W)/016 EX-510(W)/022

Measuring range Measuring range

F.S. (Full Scale) F.S. (Full Scale)

=5 mm =10 mm

Auto-zero function

Using the front panel key or by an external signal, the analog

output voltage can be set to 0 V (analog output current to 4 mA)

when the target is at any position within the measuring range.

This ensures quick adjustment of the output voltage (current) for a

standard target.

■ Procedure

1. The auto-zero function is activated only when the mode

selector switch is set to "1" (MEASUREMENT mode).

FREE

Mode

2. Make sure that the lock switch is set to FREE (the upper

position).

3. Place the sensor head at any position within the measurement

range. Then press the auto-zero key (or short-circuit terminal

4 and GND terminal 5 ) and check whether the output

voltage is reset to 0 V.

LOCK

The standard target is aluminum (A5052, Minimum thickness: 1 mm,

Flat plate 3 times or more larger than the sensor head diameter). When

other metals are detected, the characteristics of each sensor will

change slightly. Make the analog output adjustment using an actual

target to check the characteristics of your sensor.

9

Page 10

AUTO-ZERO/AUTO-SPAN FUNCTIONS

Example: With the EX-501(W), set the distance between the

sensor head and the target to 0.2 mm.

Press the

<3>

key.

to

Ground terminal to √ terminal ➄.

* Even when the lock switch is set to

LOCK (the lower position), the

auto-zero function can be activated

by an external signal.

When the lock switch is set to FREE, the zero-point value is stored in

the controller every time the auto-zero function is used. (The value is

retained even if the power is turned OFF.) When the lock switch is set

to LOCK, the auto-zero function can be activated by external terminal

input, but the zero-point value cannot be stored. To activate the autozero function frequently by external terminal input, set the lock switch

to LOCK.

When current output is used .

the output current is set

to 4 mA.

■ Minimum input time of external signals

ON

OFF

(Auto-zero input)

ON time

OFF

time

Response time

Input time

ON time 1 ms min. 10 ms min.

OFF time 1 ms min. 10 ms min.

RESPONSE

1 2, 3,4

■ Auto-zero process time

10

ON

OFF

(Auto-zero input)

Voltage

0 V

Process time

Response time

Lock switch

LOCK 1 ms max. 15 ms max.

FREE 40 ms max. 50 ms max.

RESPONSE

1 2, 3, 4

■ Auto-zero adjustment range

6 V

5 V

Auto-zero

adjustment range

0

-5 v

F.S.

• The output voltage can be set to 0 V when the target is at any

position within the measuring range. (When current output is

used, the output current is adjusted to 4 mA.)

• If the auto-zero key does not function; for example, if the autozero key is pressed when the sensor head is out of the measuring range, the OVER indicator lights and the LED of the autozero key flashes.

Press the auto-zero key again to reset the alarm, and then restart the procedure described above.

Even if external auto-zero input is activated when the target is out of

the measuring range, the sensor does not receive the auto-zero input

and continues measurement.

Page 11

AUTO-ZERO/AUTO-SPAN FUNCTIONS

Auto-span function

Using the auto-span function, the ratio of the analog output

voltage relative to the measuring distance can be changed. This

function is useful to measure targets having a small diameter or

round surface because with these targets the input-to-output ratio

is variable or is linear only to a limited range. Be sure to calibrate

your sensor for the desired targets.

Set desired distance

Press the

<2>

key.

When current output is used .

the output current is set

to 12 mA.

5 V

2.5 V

0

F.S.

By pressing the auto-span key, the span (inclination) of the output

voltage is automatically changed and the output voltage is set to

2.5 V. (p.16)

■ Procedure

FREE

1. The auto-span function is activated only

when the mode selector switch is set to

"1" (MEASUREMENT mode).

Mode

LOCK

2. Make sure that the lock switch is set to FREE (the upper

position).

3. Set the desired distance within the auto-span adjustment

range. Then press the auto-span key and check whether the

output voltage is set to 2.5 V.

■ Auto-span adjustment range

• The auto-span function can be activated within the range of 2

to 4 V.

(For current output, the auto-span adjustment range is 10.4 to

16.8 mA. )

• If the auto-span function cannot be activated, the OVER

indicator lights and the LED of the auto-span key flashes.

Press the auto-span key again to reset the alarm, and then restart the procedure described above.

Formula for auto-zero/auto-span

The following formula expresses the relationship between the

analog output value and the value just before the auto-zero/

auto-span function is activated.

Analog output value = Span x

(output value just before the auto-zero/

auto-span function is activated - Shift)

Resetting the auto-zero/auto-span functions

Pressing the auto-zero/auto-span reset key (<1>) resets both

functions simultaneously (when the mode selector switch is set

to MEASUREMENT mode and the lock switch is set to FREE).

11

Page 12

INTERFERENCE SUPPRESSION FUNCTION

CAUTION

EX-500W only

The terminals 0 - B for interference suppression function are

indicated as blank terminals with the EX-500W series (compliant

model with EMC directive of CE marking). These terminals can be

used for the interference suppression function as shown below.

However, please note that the EX-500W may not conform to EMC

directive, if you use this function and these terminals. If you want

to use the function, be sure to check whether the operation

complies with the EMC directive on your account.

Interference suppression function

Through a simple wiring change and using the interference

suppression function, up to 5 sensors can be installed side by

side. This enables multi-point measurement in a limited space.

■ Procedure

1. Turn the power OFF.

2. Connect wires as shown below.

Main controller

Sub controller 1

Sub controller 2

Up to 4 sub controllers

can be connected to

the main controller.

3. Make sure that the connections are completed correctly and

then turn the power ON.

Make sure that terminals 0 and A of the sub controllers are

properly connected. If you turn the power ON without connecting these terminals, the controllers may be damaged.

4. After warm-up, make the analog output adjustment under

actual measurement conditions. (See p.7)

5. Start measurement.

* Principle of operation

Using the interference suppression function of the EX-500(W)

Series, all sensors can operate at the same clock frequency.

Connect sensors using shielded cables to shorten the overall

cable length.

12

Page 13

SPECIFICATIONS

Type Threaded, non-shielded type

Size M8 M8 M16 M22

Model

Measuring range 0 to 1 mm 0 to 2 mm 0 to 5 mm 0 to 10 mm

Analog

output

Functions Response time selector function / Preset metal characteristic memory function

Temperature Sensor head 0.03% of F.S./°C

fluctuation Controller

Power supply voltage 12 to 24 VDC ±10%, Ripple (P-P): 10% max.

Current consumption 220 mA max.

Ambient

temperature

Relative humidity 35 to 85%, No condensation

Vibration 10 to 55 Hz, 1.5 mm double amplitude in X, Y and Z directions, 2 hours respectively

Enclosure rating Sensor head: IP-67

Weight

Disconnection alarm output

Sensor head EX-008 EX-008 EX-016 EX-022

Controller EX-501(W) EX-502(W) EX-505(W) EX-510(W)

Output voltage 0 to 5V

Output impedance 100 Ω

Output current 4 to 20 mA (Applicable load: 0 to 350 Ω)

Resolution 0.03 % of F.S. (RESPONSE = 3, 4)

Response time 0.1 ms (RESPONSE = 1)

(Response mode) 1 ms (RESPONSE = 2)

Linearity ±0.3 % of F.S. (RESPONSE = 2, 3, 4)

Cable length selector function / Interference suppression function

Sensor head -20 to +105°C (-4 to 221°F), No freezing

Controller 0 to +50°C (32 to 122°F), No freezing

Sensor head Approx. 50 g Approx. 50 g Approx. 63 g Approx. 80 g

Controller Approx. 360 g

10 ms (RESPONSE = 3)

100 ms (RESPONSE = 4)

Auto-zero function / Auto-span function

1.

0.04% of F.S./°C

NPN open-collector: 100 mA (40 V) max.

Residual voltage: 1 V max. (N.C.)

The above data is obtained using an aluminum target (A5052 t = 1 mm). When measuring steel or stainless steel targets, refer to the characteristics of linearity for these

materials.

1. EX-008: When the distance between the sensor head and target is half the maximum measuring distance and the operating temperature is 10 to 40°C (50 to 104°F).

EX-016, 022: When the distance between the sensor head and target is half the maximum measuring distance and the operating temperature is 0 to 50°C (32 to 122°F).

13

Page 14

TROUBLESHOOTING GUIDE

CHARACTERISTICS

If any trouble occurs with your EX-500(W) Series, check the

following items. If the sensor does not work properly, contact your

distributor or nearest KEYENCE office.

Problem

Analog output does

not change.

Analog output is not

stable.

Fluctuation in

resolution and poor

accuracy.

Key switches are

disabled.

Check items

Is the sensor head

cable tightly connected?

Is noise interference

causing problems?

Is the production line

conveyor vibrating?

Is the response time

selector switch set to

high speed?

Is the output voltage

proportional to the

measuring distance?

Is the lock switch set

to LOCK?

Remedy

Securely connect the

cable into the connector.

Keep the sensor wiring

away from high-voltage

lines and power lines.

Reduce vibration of the

production line conveyor.

If high speed response is

not required, set the

response time selector

switch to low speed.

Adjust the output voltage.

(See p.7 through 9.)

Set the lock switch to

FREE during key

operations.

■ Output voltage for measuring targets of various sizes

(Typical)

EX-502(W)/EX-008 (Target: Aluminum A5052)

• Calibrating analog output voltage

using a standard target (50 x 50 mm)

ø3 ø5 ø8 ø10 ø16

5

Voltage (V)

Distance

0

Measuring distance (mm)

2.0

ø(mm)

• Calibrating analog output voltage using

target of various sizes (diameter)

5

Voltage (V)

0

ø3

ø5

ø8

ø10

Measuring distance (mm)

2.0

ø(mm)

■ Linearity for various metal measurement (Typical)

EX-502(W)/EX-008

Aluminum (Adjustment mode 2)

0.3

Aluminum (A5052)

0

Copper (Cu1100)

-0.3 -0.3

Linearity (% of F.S.)

0 2.0

Iron (Adjustment mode 4)

Measuring distance (mm)

Stainless steel (Adjustment mode 3)

0.3

0

Linearity (% of F.S.)

0 2.0

Stainless steel (SUS304)

1.01.0

Measuring distance (mm)

Distance

14

0.3

0

-0.3

Linearity (% of F.S.)

0 2.0

Iron (S45C)

Iron (SS41)

1.0

Measuring distance (mm)

Page 15

DIMENSIONS

Controller EX-5xx(W) Sensor head

EX-008

ø6.5

M8, P=1

112

136.5

100 90

0 to 180°

60

85

4 x ø5

(mounting

hole)

35.4

652.5

EX-016

ø14

M16, P=1

EX-022

ø20.5

M22, P=1

Expansion cable (OP-20708)

10.4

15.6

20 185.2

Across flats: 12, t = 3

21

25

25

Unit: mm

ø6.4

ø2.8, Cable length: 3 m

18

ø6.4

ø2.8, Cable length: 3 m

Across flats: 21, t = 4

18

ø6.4

ø2.8, Cable length: 3 m

Across flats: 30, t = 4

18

ø6.4

ø2.8, Cable length: 7 m

ø6.4

15

Page 16

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and workmanship for a period of one (1) year from the date of shipment. If any models or samples were shown to

Buyer, such models or samples were used merely to illustrate the general type and quality of the Products and not to represent that the Products would necessarily conform to said models

or samples. Any Products found to be defective must be shipped to KEYENCE with all shipping costs paid by Buyer or offered to KEYENCE for inspection and examination. Upon

examination by KEYENCE, KEYENCE, at its sole option, will refund the purchase price of, or repair or replace at no charge any Products found to be defective. This warranty does not

apply to any defects resulting from any action of Buyer, including but not limited to improper installation, improper interfacing, improper repair, unauthorized modification, misapplication and

mishandling, such as exposure to excessive current, heat, coldness, moisture, vibration or outdoors air. Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products. They are only suggestions, and it is Buyer’s responsibility to ascertain the fitness of the Products for

Buyer’s intended use. KEYENCE will not be responsible for any damages that may result from the use of the Products.

(3) The Products and any samples (“Products/Samples”) supplied to Buyer are not to be used internally in humans, for human transportation, as safety devices or fail-safe systems,

unless their written specifications state otherwise. Should any Products/Samples be used in such a manner or misused in any way, KEYENCE assumes no responsibility, and additionally

Buyer will indemnify KEYENCE and hold KEYENCE harmless from any liability or damage whatsoever arising out of any misuse of the Products/Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER. ALL EXPRESS, IMPLIED, AND STATUTORY WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF

PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED. IN NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES BE LIABLE TO ANY PERSON OR ENTITY FOR ANY

DIRECT, INDIRECT, INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING FROM LOSS OF USE,

BUSINESS INTERRUPTION, LOSS OF INFORMATION, LOSS OR INACCURACY OF DATA, LOSS OF PROFITS, LOSS OF SAVINGS, THE COST OF PROCUREMENT OF SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES, OR FOR ANY MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE OR INABILITY TO USE THE PRODUCTS, EVEN IF

KEYENCE OR ONE OF ITS AFFILIATED ENTITIES WAS ADVISED OF A POSSIBLE THIRD PARTY’S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST BUYER. In some

jurisdictions, some of the foregoing warranty disclaimers or damage limitations may not apply.

BUYER’S TRANSFER OBLIGATIONS: If the Products/Samples purchased by Buyer are to be resold or delivered to a third party, Buyer must provide such third party with a copy of this

document, all specifications, manuals, catalogs, leaflets and written information provided to Buyer pertaining to the Products/Samples.

16

Copyright (c) 1993 KEYENCE CORPORATION. All rights reserved. 0072E 1080-2 96M0368 Printed in Japan

Copyright (c) 1993 KEYENCE CORPORATION. All rights reserved. 0072E 1093-2a 96M0368 Printed in Japan

Loading...

Loading...