Page 1

347GB

PROFIBUS DP Compatible Network Unit

DL-PD1 (GT2)

User's Manual

Read this manual before use.

Keep this manual in a safe place for future reference.

Page 2

Introduction

Important

Point

Reference

WARNING

CAUTION

NOTICE

This manual describes the basic operations and hardware functions of the DL-PD1.

Read the manual carefully to ensure safe performance and function of the DL-PD1.

Keep this manual in a safe place for future reference.

Ensure that the end user of this product receives this manual.

Symbols

The following symbols alert you to matters concerning the prevention of injury and

product damage.

It indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

It indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

It indicates a situation which, if not avoided, could result in product

damage as well as property damage.

It indicates cautions and limitations that must be followed during

operation.

It indicates additional information on proper operation.

It indicates tips for better understanding or useful information.

Page 3

Safety Precautions

WARNING

CAUTION

NOTICE

CAUTION

NOTICE

General Precautions

• Do not use this product for the purpose to protect a human body or

part of a human body.

• This product is not intended for use as an explosion-proof product.

Do not use this product in a hazardous location and/or potentially

explosive atmosphere.

• Before and while operating this product, confirm that it provides its

functions and performance correctly.

• Implement sufficient safety measures to prevent human and

physical damages in case this product fails.

• Do not expose equipment, including peripherals, to rapid

temperature changes. Equipment failure may result from

condensation build up.

• Be aware that the product functions and performance are not

warranted if the product is used outside the range of stated

specifications or is modified by the customer.

• Combining this product with other equipment requires sufficient

consideration because the proper functions and performance may

not be provided depending on the environment.

Precautions for Use

• To avoid injury or failure, turn off the power immediately in the

following cases.

- Water or foreign matter entered the main unit.

- The case is broken, for example if it is dropped.

- Smoke or unusual smell is emitted from the product.

• Use the correct power voltage. Failure to observe may result in

injury, or failure.

• Do not disassemble or modify this product. Failure to observe may

result in injury.

Do not turn off the power while you are setting any item. Doing this

may cause loss of data settings.

347GB

1

Page 4

CAUTION

NOTICE

Precautions for Installation

For safe, trouble-free operation of this product, the product must not

be installed in the following locations:

- Humid, dusty, or poorly ventilated.

- Exposed to direct sunlight or heating source.

- Exposed to corrosive or flammable gases.

- Exposed directly to vibration or shock.

- Exposed to water, oil, or chemical splashes.

- Exposed to static electricity.

If this product is installed in a location near a noise source, e.g.

power source or high-voltage line, it may malfunction or fail. Take

protective measures, such as using a noise filter including a supplied

ferrite core or running the cables separately.

* Use a ferrite core for a power cable of a sensor amplifier with D-bus

support which supplies power for the unit (3 turns).

Precautions for regulations and standards

UL Certificate

This product is an UL/C-UL Listed product.

• UL File No. E207185

• Category NRAQ, NRAQ7

Be sure to consider the following specifications when using this product as an UL/C-UL Listed Product.

•

Use the power supply with Class 2 output defined in NFPA70 (NEC: National Electrical Code).

• Use this product under pollution degree 2.

• This product is an open type device. Therefore, it must be installed in an enclosure

with IP54 or higher. (e.g. Industrial control panel)

CE Marking

Keyence Corporation has confirmed that this product complies with the essential requirements of

the applicable EC Directive, based on the following specifications. Be sure to consider the

following specifications when using this product in the Member State of European Union.

EMC Directive (2004/108/EC)

• Applicable standard EMI: EN55011, Class A, EMS: EN61000-6-2

Remarks: These specifications do not give any guarantee that the end-product with this

product incorporated complies with the essential requirements of EMC Directive. The

manufacturer of the end-product is solely responsible for the compliance on the endproduct itself according to EMC Directive.

2

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 5

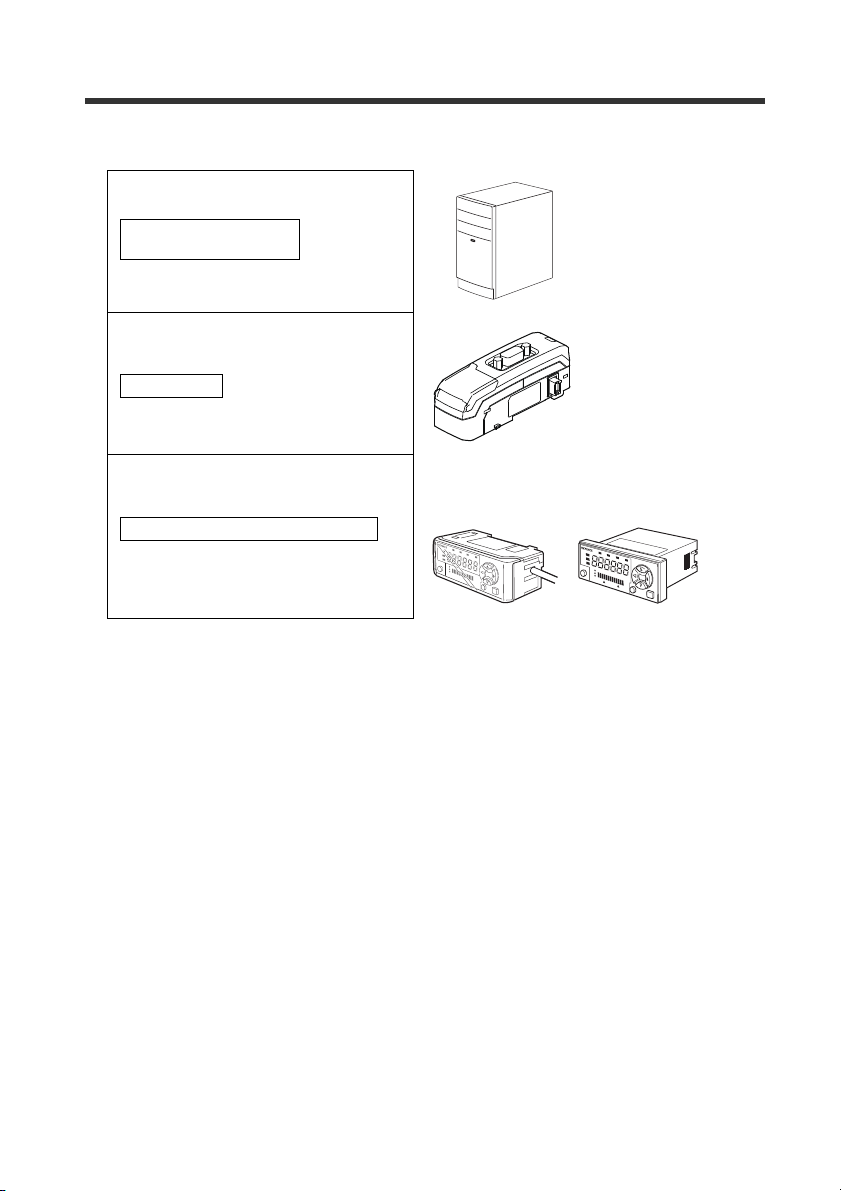

Relevant Manuals

Manuals relevant to

PROFIBUS DP master

PROFIBUS DP master

This manual

DL-PD1

(This unit)

Manuals of sensor amplifier unit

Sensor Amplifier

The manuals to relevant to this document are as follows:

Example: GT2 series user's manual

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3

Page 6

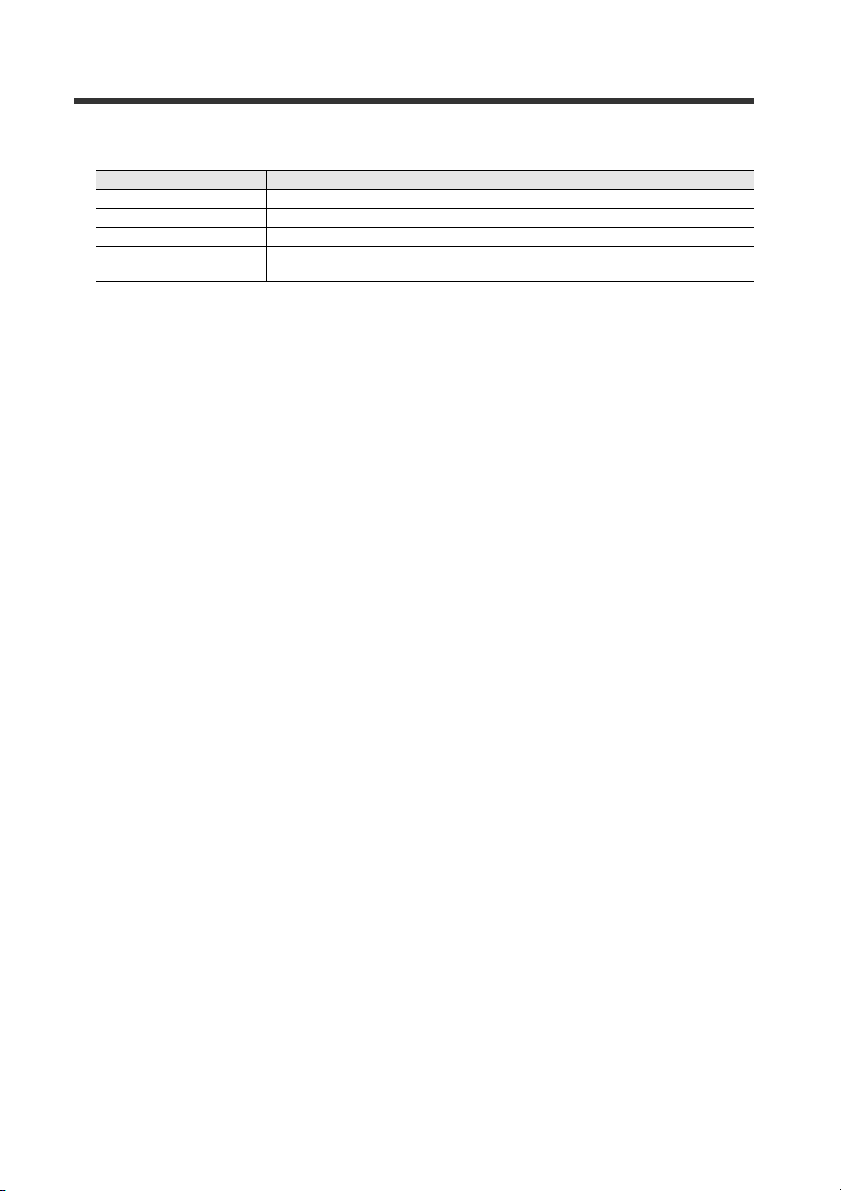

Terms Used in This Document

This document uses the following terms:

Sensor amplifier A sensor amplifier connected to the DL-PD1.

Main unit A sensor amplifier that has a power line and can operate alone.

Expansion unit A sensor amplifier that does not have a power line and must be connected to a main unit.

D-bus The name of KEYENCE's wiring-saving system for sensor amplifiers.

Term Explanation

Supports GT2 Se ries high-accuracy digital contact sensors and others.

4

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 7

Table of Co ntents

Introduction ......................................................................................................... 1

Safety Precautions.............................................................................................. 1

General Precautions............................................................................... 1

Precautions for Use ................................................................................ 1

Precautions for Installation ..................................................................... 2

Precautions for regulations and standards ............................................. 2

Relevant Manuals................................................................................................ 3

Terms Used in This Document .......................................................................... 4

Table of Contents................................................................................................ 5

Chapter 1 Before Using

1-1 Characteristics of the DL-PD1............................................................... 1-2

Types and Number of Connectable Sensor Amplifiers........................ 1-3

1-2 Checking the Package Contents........................................................... 1-4

Package Contents ............................................................................... 1-4

1-3 Names of Each Part................................................................................ 1-5

Chapter 2 Connection and Configuration

2-1 Installation and Connection to a Sensor Amplifier ............................. 2-2

Installation and Connection to Sensor Amplifiers ................................ 2-2

Setting the Station Address ................................................................. 2-6

2-2 Wiring ...................................................................................................... 2-7

Connecting the PROFIBUS ................................................................. 2-7

2-3 Technical data......................................................................................... 2-8

Dimensions.......................................................................................... 2-8

General Specifications......................................................................... 2-9

Chapter 3 Executing Communication

3-1 PROFIBUS communication function of DL-PD1.................................. 3-2

Overview.............................................................................................. 3-2

PROFIBUS Specifications ................................................................... 3-3

Operational flow for test operation....................................................... 3-4

Slot number and ID number assignment............................................. 3-5

3-2 Hardware configuration ......................................................................... 3-6

Operation mode of DL-PD1 ................................................................. 3-6

Input/Output size.................................................................................. 3-7

3-3 Parameterization..................................................................................... 3-8

3-4 Diagnostic Function ............................................................................. 3-10

Slave diagnosis structure................................................................... 3-10

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

5

Page 8

Station status ..................................................................................... 3-11

PROFIBUS DP master address ......................................................... 3-12

Manufacturer ID ................................................................................. 3-12

Identifier-related diagnosis................................................................. 3-13

Module status..................................................................................... 3-13

Channel-related diagnosis ................................................................. 3-15

3-5 Overview of PROFIBUS DP Communication ...................................... 3-17

Cyclic communication ........................................................................ 3-17

Device maps ...................................................................................... 3-18

Communication Methods ...................................................................3-23

3-6 DP-V1 Service........................................................................................ 3-26

DL-PD1 index (Slot 0) ........................................................................3-26

GT2 series index (Slot 1 to 15) ..........................................................3-30

3-7 Other functions ..................................................................................... 3-36

I&M..................................................................................................... 3-36

FREEZE/SYNC/CLEAR command .................................................... 3-37

Chapter 4 Appendix

4-1 Troubleshooting...................................................................................... 4-2

Indicator Specifications ........................................................................ 4-2

Types of error and error code .............................................................. 4-3

4-2 Data update time.....................................................................................4-5

4-3 Comparator Value Property of the Sensor Amplifier...........................4-6

6

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 9

Before Using

This chapter provides an overview of the DL-PD1 and describes its

part names and functions.

1-1 Characteristics of the DL-PD1 ............................ 1-2

1-2 Checking the Package Contents ........................1-4

1-3 Names of Each Part ........................................... 1-5

1

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

1-1

Page 10

1

1-1 Characteristics of the DL-PD1

PROFIBUS DP master

D-bus compatible sensor amplifier I/O etc.

DL-PD1

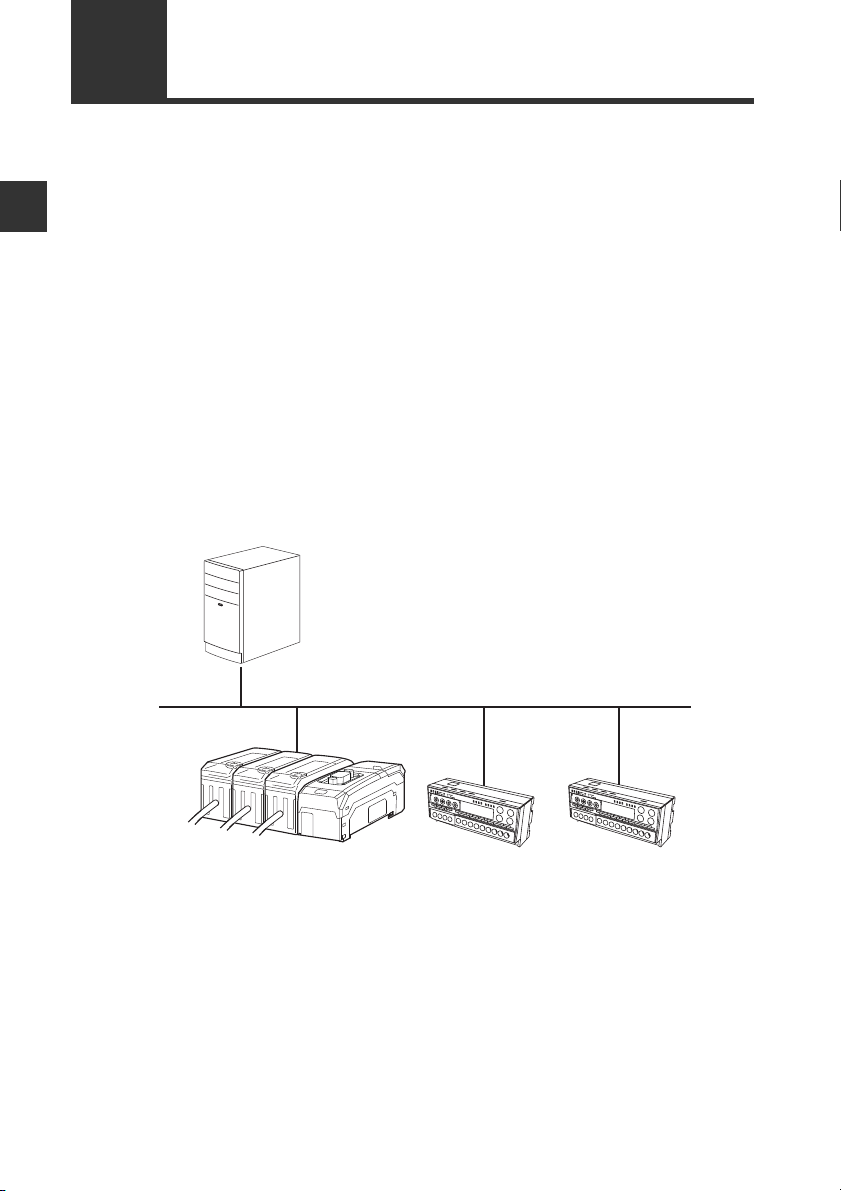

The DL-PD1 is an interface unit, which enables sensor amplifiers or input units to

connect to the PROFIBUS DP. The characteristics of the DL-PD1 are shown below.

Slave unit of the PROFIBUS DP-V1

Before Using

The following features are achieved by connecting the sensor amplifiers, which

are suitable for each application, in the form of a module.

• Reading out the output of the sensor amplifier.

• Reading out the comparator value (the measurement value) of the sensor

amplifier.

• Changing the configuration of the sensor amplifier.

Two selectable operational modes

• Monitor Mode: Input size - MAX 107 bytes, Output size - MAX 16 bytes

• I/O Mode: Input size - 10 bytes, Output size - 10 bytes

Corresponding to the communication speed of 9.6 Kbits/s to 12 Mbits/s

System configuration example

Additional sensor amplifiers corresponding to the D-bus can be connected to the DLPD1. ("D-bus" is the name of KEYENCE's wiring-saving system for sensor amplifiers.)

Any sensor amplifiers corresponding to the D-bus allow different models and up to 15

units of sensor amplifiers to be connected simultaneously.

Connectable quantity depends on the sensor amplifier which is connected to.

1-2

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 11

1-1 Characteristics of the DL-PD1

1

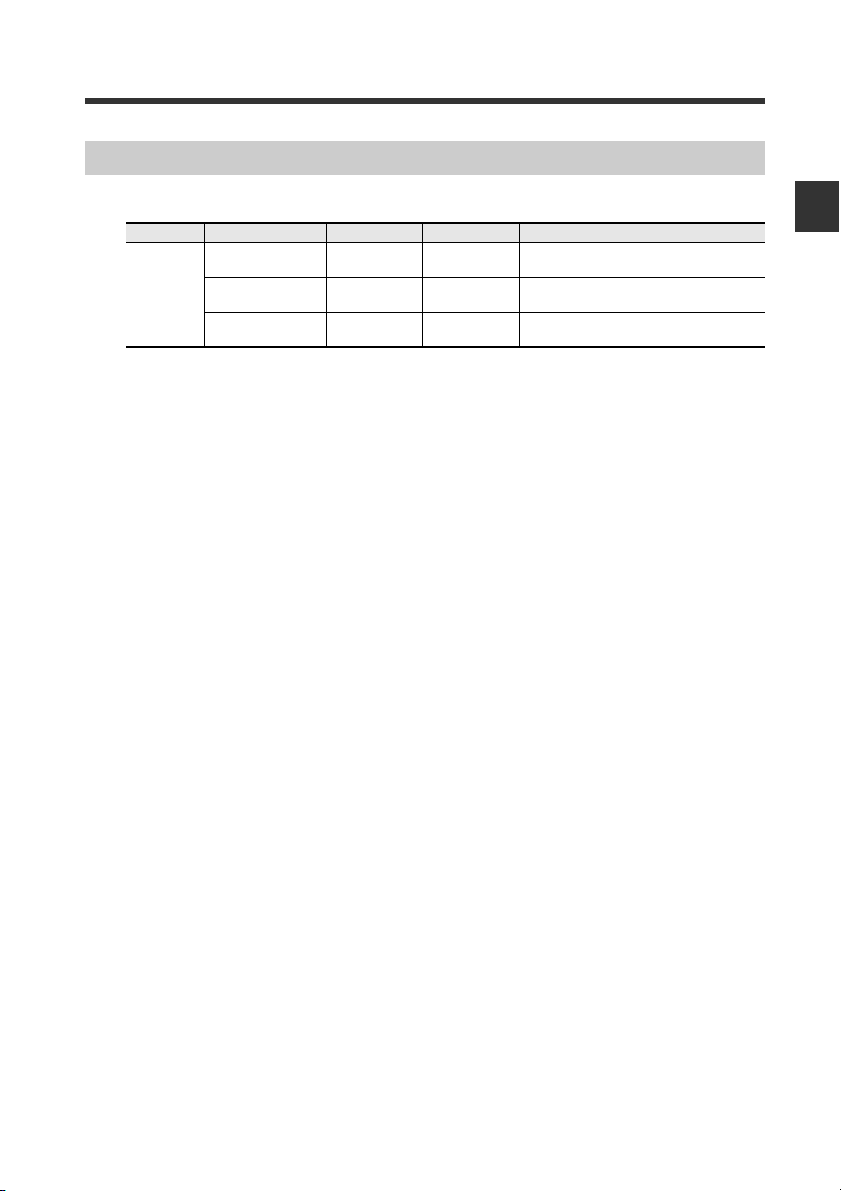

Types and Number of Connectable Sensor Amplifiers

Number of Connectable Sensor Amplifiers

Name Amplifier form Main unit Expansion unit Maximum number of connectable units

DIN rail mounting

type

GT-2 Series

Panel mounting type

Large display type

* Up to 11 sensor heads can be connected by adding a head connection board to the

main unit.

The DL-PD1 can connect to multiple sensor amplifiers (a single main unit and multiple

expansion units) which support D-bus. "D-bus" is the name of KEYENCE's wiring-saving

system for sensor amplifiers.

Different types of sensor amplifiers with D-bus support can be connected to a single DLPD1 unit.

How many and what types of sensor amplifiers can be connected depends on the

sensor amplifiers or units to be connected. Please inquire for details.

GT2-71(M)(C)N

GT2-71(M)(C)P

GT2-75N

GT2-75P

GT2-100N

GT2-100P

GT2-71(M)(C)N

GT2-71(M)(C)P15(1 main unit, 14 expansion units)

GT2-76N

GT2-76P

-

15

(1 main unit, 14 expansion units)

1

(1 main unit)*

Before Using

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

1-3

Page 12

1

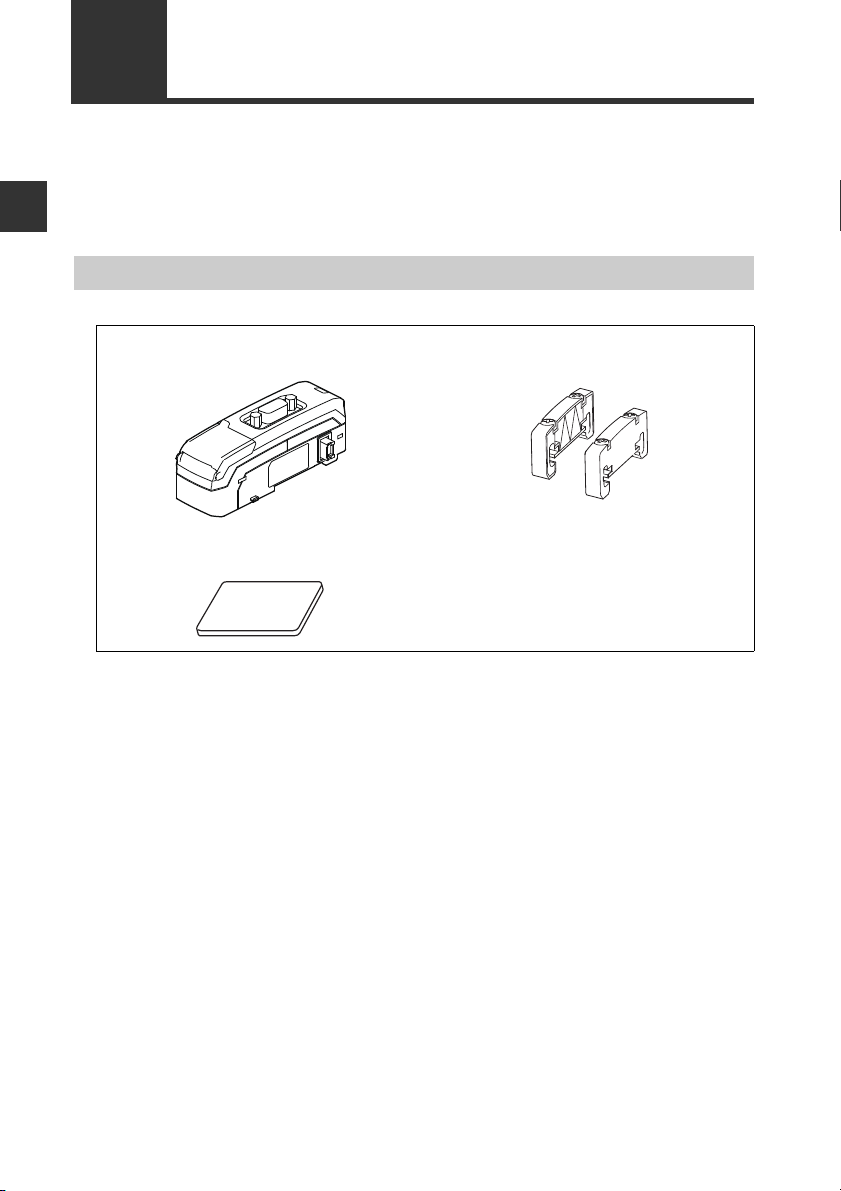

1-2 Checking the Package Contents

Before using the DL-PD1, make sure that the following equipment and accessories are

included in the package.

We have thoroughly inspected the package contents before shipment. However, in the

event of defective or broken items, contact your nearest KEYENCE office.

Before Using

Package Contents

DL-PD1 main unit x 1 End units (OP-26751: a two-unit set) x 1

Expansion connector sticker x 1 Ferrite core x 1

Instruction manual x 1

1-4

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 13

1

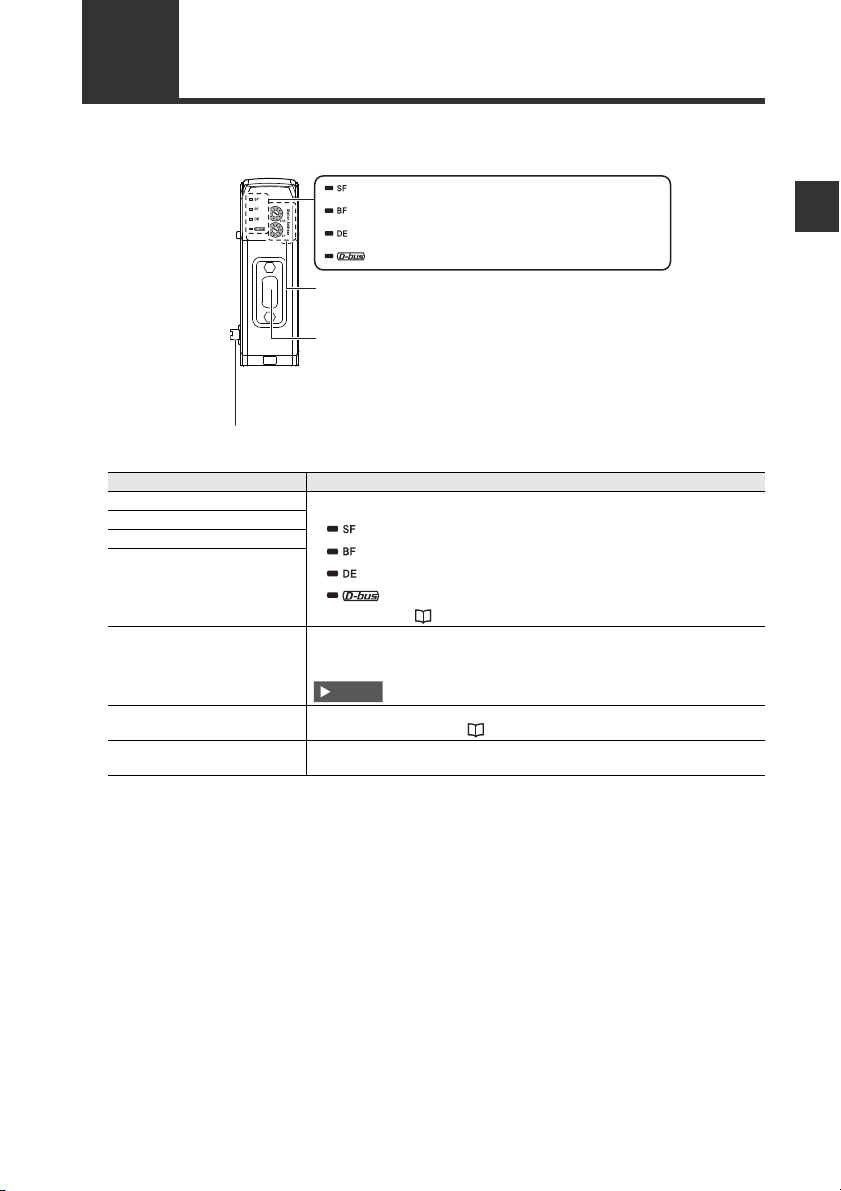

1-3 Names of Each Part

(1) Station Failure Indicator

(2) Bus Failure Indicator

(3) Data Exchange Indicator

(4) Sensor amplifier communication indicator

(5) Station address setting switch

(6) PROFIBUS connector

(7) Sensor amplifier connector

OFF

OFF

Lit in green

Lit in green

Important

This section describes the part names and functions of the DL-PD1.

Before Using

(1) Station Failure Indicator Normal lighting is as below.

(2) Bus Failure Indicator

(3) Data Exchange Indicator

(4) Sensor amplifier

communication indicator

(5) Station address setting switch

(6) PROFIBUS connector

(7) Sensor amplifier connector

Item Description

For details, refer to "Indicator Specifications" (page 4-2).

Set the station address.

The place of x10: 10, the place of x1: 1

[Setting range]: 01 to 99, [Default value]: 11

The station address of the DL-PD1 cannot be set to 00, 100, or more.

D-sub9 pin (socket) connector compliant with the RS-485.

For details on pin layout, see "Connecting the PROFIBUS" (page 2-7).

Attach the sensor amplifier to this connector.

When shipped from the factory, a protection cover is installed.

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

1-5

Page 14

1-3 Names of Each Part

1

Before Using

MEMO

1-6

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 15

Connection and Configuration

This chapter describes installation and wiring for the DL-PD1.

2-1 Installation and Connection to a Sensor Amplifier..2-2

2-2 Wiring ................................................................. 2-7

2-3 Technical data .................................................... 2-8

2

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

2-1

Page 16

2

2-1

Point

Reference

(1)

(3)

(2)

DL-PD1

Sensor amplifier

Expansion connector

This section provides the procedures for installing the DL-PD1 and connecting to sensor

amplifiers.

The DL-PD1 can be connected with the sensor amplifiers which support D-bus. ("D-bus"

is the name of KEYENCE's wiring-saving system for sensor amplifiers.) How many

sensor amplifiers can be connected depends on the sensor amplifiers to be connected.

For specific numbers of connections, refer to the manual of each sensor amplifier.

Installation and Connection to a Sensor Amplifier

Connection and Configuration

Installation and Connection to Sensor Amplifiers

Turn off the power before connecting the DL-PD1 and sensor amplifier.

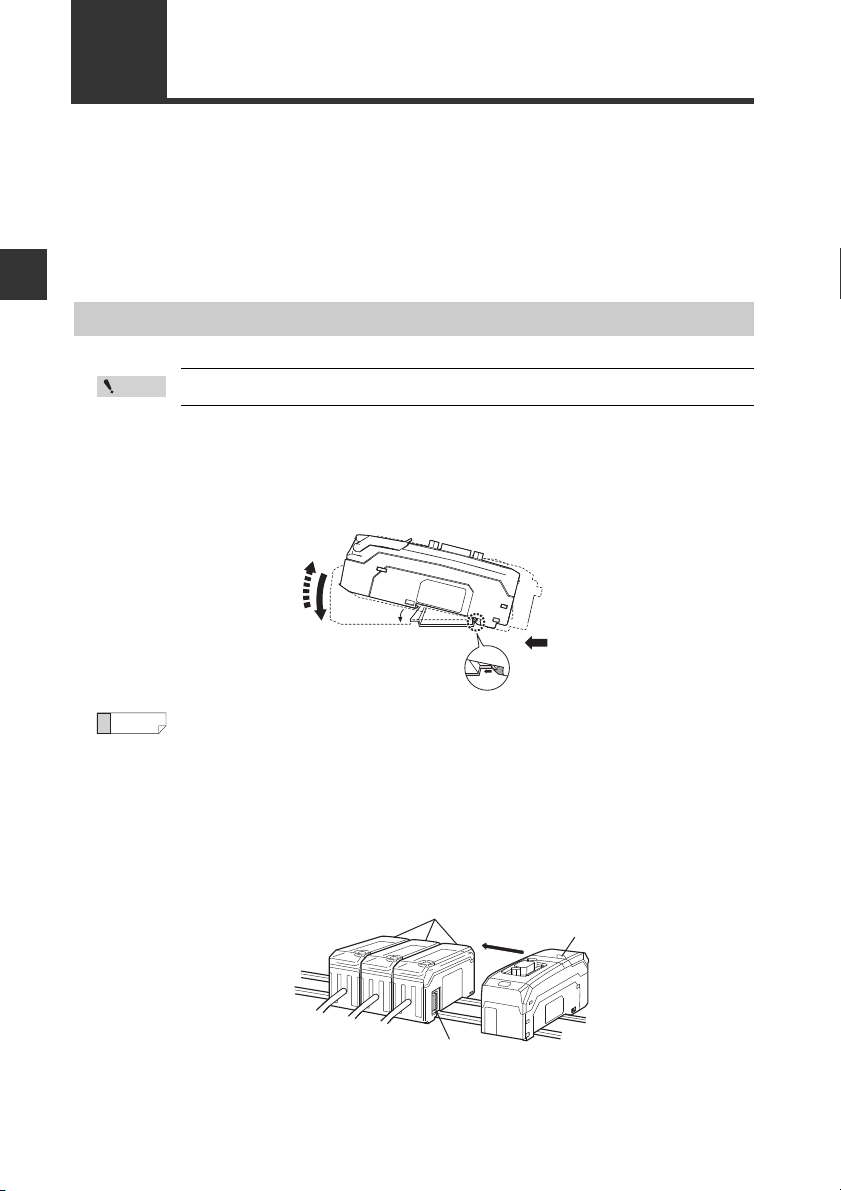

1 Align the claw on the bottom of the DL-PD1 with the DIN rail. While pushing

the amplifier in the direction of arrow (1), press down in the direction of arrow

(2).

To remove the DL-PD1, raise the amplifier in the direction of arrow (3) while

pushing the amplifier in the direction of arrow (1).

2 Repeat step 1 to install additional sensor amplifiers or input units on the DIN

rail and connect them to the DL-PD1.

If the sensor amplifier connector has an expansion protective cover, remove the

cover before connecting the amplifier.

2-2

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 17

2-1 Installation and Connection to a Sensor Amplifier

2

NOTICE

End unit

End unit

NOTICE

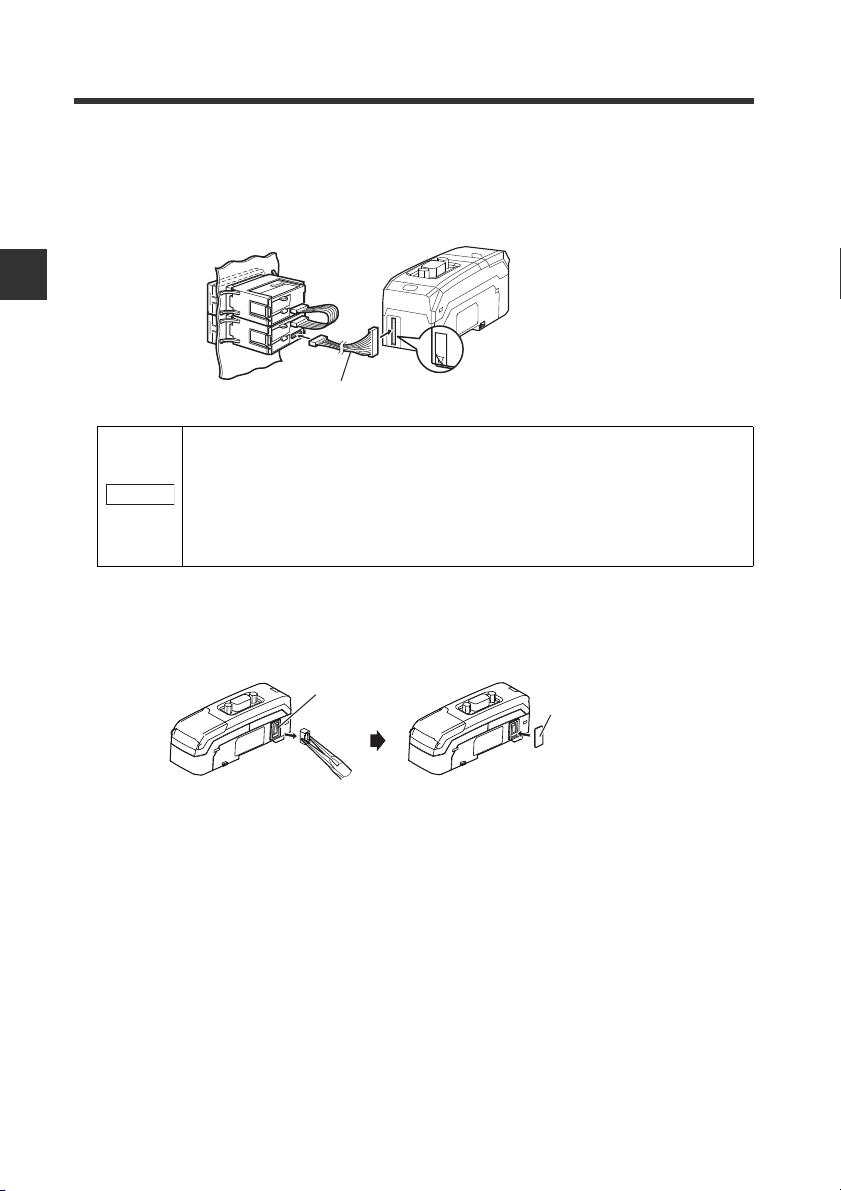

Make sure that the sensor amplifier connector (for DIN rail mounting

type) is not askew on the side face of the DL-PD1, as shown below. If

the connector is askew, the DL-PD1 may become damaged when

connected to the sensor amplifier.

Sensor amplifier connector

DL-PD1

3 Mount the end units (OP-26751: a two-unit set shipped with the DL-PD1) on

both sides of the DL-PD1 and the sensor amplifier. Then, fix the end units

with the screws on the top of each end unit. (Tightening torque: 0.6 N•m or

less)

Mount the end units in the same way as the DL-PD1.

Connection and Configuration

Press the DL-PD1 into full engagement with the sensor amplifier. If

the DL-PD1 is not correctly connected, it may be damaged when the

power is turned on.

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

2-3

Page 18

2-1 Installation and Connection to a Sensor Amplifier

2

Expansion cable (300 mm long)

Peel off the protective sticker.

NOTICE

Sensor amplifier connector

(for DIN rail mounting type)

Expansion

connector sticker

Connecting to sensor amplifiers (panel mounting type)

1 Connect the optional expansion cable (OP-35361) between the sensor

amplifier and the DL-PD1.

Connection and Configuration

• Turn off the power and connect the expansion cable securely. If the

cable is not correctly connected, the DL-PD1 may be damaged

when the power is turned on.

• Do not attach or detach the cable with the power on, as this may

damage the DL-PD1.

2 Remove the sensor amplifier connector (for DIN rail mounting type) from the

DL-PD1, using pliers. In its place, attach the expansion connector sticker

supplied with the DL-PD1.

2-4

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 19

2-1 Installation and Connection to a Sensor Amplifier

2

Detach the

protection sticker.

Detach the

protection

sticker.

Expansion cable (cable length:300 mm)

NOTICE

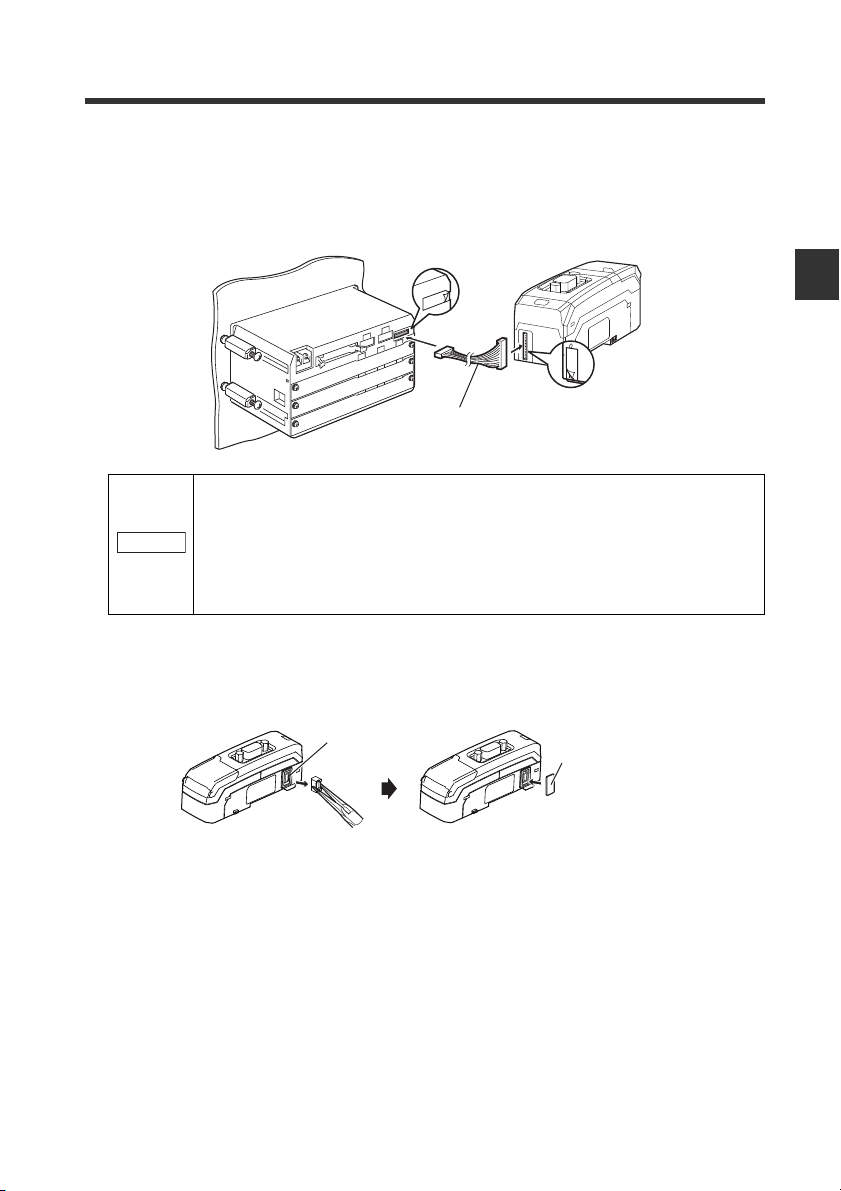

Connecting to a large display type sensor amplifier

1 Connect the optional expansion cable (OP-35361) between the sensor

amplifier and the DL-PD1.

• Turn off the power and connect the expansion cable securely. If the

cable is not correctly connected, the DL-PD1 may be damaged

when the power is turned on.

• Do not attach or detach the cable with the power on, as this may

damage the DL-PD1.

2 Remove the sensor amplifier connector (for DIN rail mounting type) from the

DL-PD1, using pliers. In its place, attach the expansion connector sticker

supplied with the DL-PD1.

Sensor amplifier connector

(for DIN rail mounting type)

Expansion

connector sticker

Connection and Configuration

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

2-5

Page 20

2-1 Installation and Connection to a Sensor Amplifier

2

Point

Station address setting switch Setting range: 01 to 99

Default value: 11

Setting the Station Address

Set the station address of the DL-PD1 with the rotary switch at the top of the DL-PD1.

The station address set here must be the same as the one set through the configuration

software of the PROFIBUS DP.

Connection and Configuration

• The station address of the DL-PD1 cannot be set to 00, 100, or more.

• Set the station address before the DL-PD1 is powered on. When the

station address is changed during operations of the DL-PD1, such

change is reflected after power has been restored to the DL-PD1.

• The station address setting (Set_Slave_Adress) via PROFIBUS DP is

not supported.

2-6

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 21

2

2-2 Wiring

Point

5

1

2

3

4

9

8

7

6

This section describes wiring for the DL-PD1.

Also refer to the Recommendation for Cabling and Assembly published by PROFIBUS

International.

Turn off the power before wiring.

Connecting the PROFIBUS

Use the following procedure to connect the DL-PD1 to the PROFIBUS.

Usable cable

Use the shielded twisted pair cable, which is compliant with the PROFIBUS

specifications.

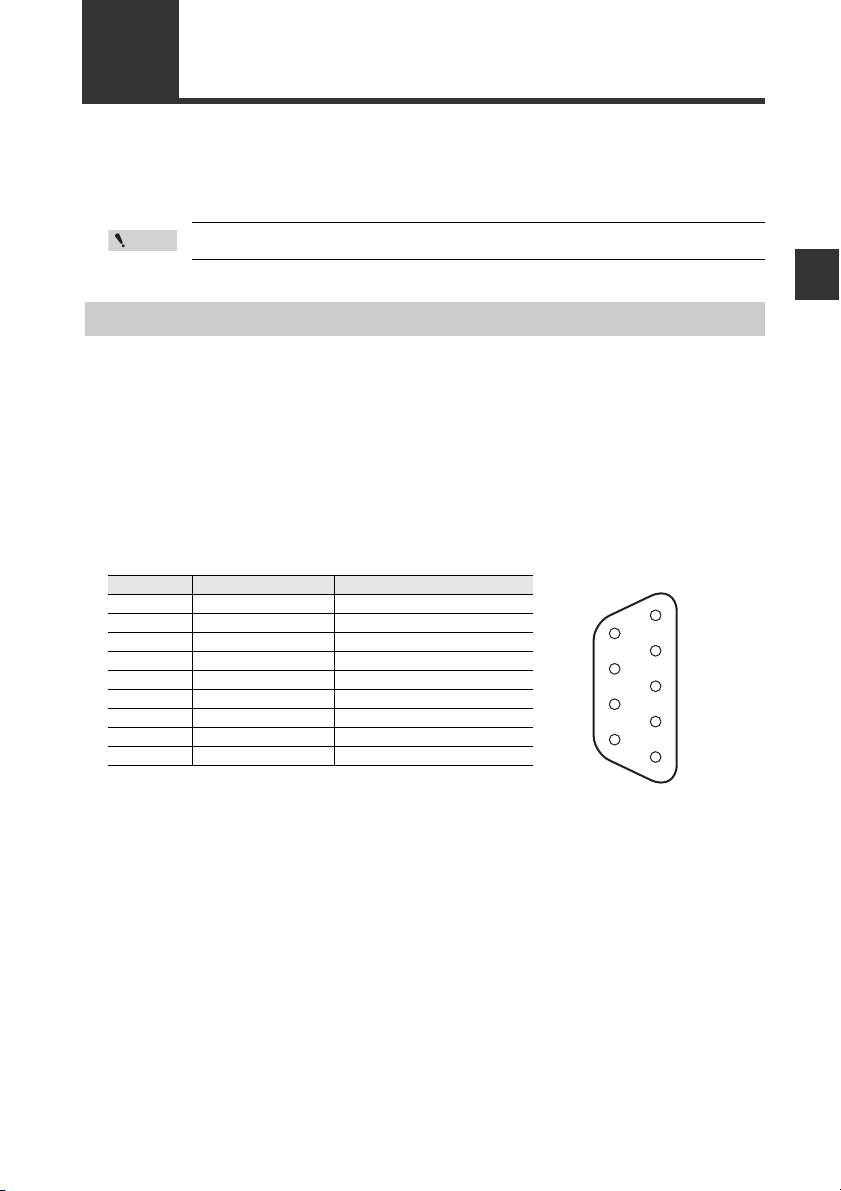

Wiring the PROFIBUS Connector

For the PROFIBUS connector of the DL-PD1, the D-sub 9 pin connector (socket) is

used. Pin arrangement of the connector is as below.

Pin number Signal name Description

1- -

2- -

3 RxD/TxD-P Data line B

4 RTS Request to send

5 M5V2 Data reference potential (Station)

6 P5V2 Power supply: Plus (Station)

7- -

8 RxD/TxD-N Data line A

9- -

Connection and Configuration

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

2-7

Page 22

Connection and Configuration

2

38.1

When cover is opened :

54.7 max.

105° max.

57.4

(0.2)

35.443.5

94.5

(39.0)

34.6 1.8

29.4

Unit : mm

6

9.235.4

53.8

20.8

26.4

2-3 Technical data

Dimensions

DL-PD1

End Unit

2-8

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 23

2

General Specifications

2-3 Technical data

Model DL-PD1

PROFIBUS DP

specifications

Sensor amplifier

connection

specifications

Power vol ta ge

Power consumption 1600 mW or less (65 mA max. at 24 V)

Environmental

resistance

Materials

Weight (including connectors) Approx. 65 g

Device type DP-V1 Slave (D-sub 9 pin, Number of the por ts: 1)

Communication speed 9.6 kbit/s to 12 Mbit/s

Cable length

Connectable Sensor

amplifiers

Number of connectable

Sensor amplifier units

Operating surrounding

air temperature

Operating surrounding

air humidity

Vibration resistance IEC60068-2-6 2G (10 to 500 Hz, 2 hours each in X, Y, Z direction)

Impact resistance IEC60068-2-27 30G (11 ms, 3 times e ach in X, Y, Z direction)

9.6 / 19.2 / 45.45 / 93.75 kbit/s: 1200 m

187.5 kbit/s: 1000 m

500 kbit/s: 400 m

1.5 Mbit/s: 200 m

3 / 6 / 12 Mbit/s: 100 m

Sensor amplifiers with D-bus suppor t

15 units max.

20 to 30 VDC, including ripple (p-p) 10%

(This voltage is supplied from the connected sensor amplifier.)

-20 to +55°C (no freezing)

35 to 85% RH (no condensation)

Main unit case and dust cover: Polycarbonate

PROFIBUS connector: Steel - Nickel plating

*2

*1

*1 "D-bus" is the name of KEYENCE's wiring-saving system for sensor amplifiers.

*2 Varies with the sensor amplifiers connected.

Connection and Configuration

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

2-9

Page 24

2-3 Technical data

2

Connection and Configuration

MEMO

2-10

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 25

Executing Communication

This chapter describes the functions and detailed communication

methods of PROFIBUS DP communication the DL-PD1 supports.

3-1

PROFIBUS communication function of DL-PD1

3-2 Hardware configuration ...................................... 3-6

3-3 Parameterization ................................................ 3-8

3-4 Diagnostic Function.......................................... 3-10

3-5 Overview of PROFIBUS DP Communication ...3-17

3-6 DP-V1 Service.................................................. 3-26

3-7 Other functions ................................................. 3-36

.... 3-2

3

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-1

Page 26

Executing Communication

3

IN area

OUT area

Output

Judgment value

Error information

External Input

PROFIBUS DP

master

DL-PD1

Sensor amplifier

Output

Judgment value

・・・・・・

・・・・・・

Error information

Setting value

Exteral input

Output

Judgment value

・・・・・・

・・・・・・

Error information

Setting value

External Input

Cyclic

communication

Cyclic

communication

DP-V1 service

Output

Judgment value

・・・・・・

・・・・・・

Error information

Setting value

Exteral input

IN area

OUT area

Read/write parameters

・・・・・・

・・・・・・

・・・・・・

3-1

PROFIBUS communication function of DL-PD1

This section describes the overview of the PROFIBUS DP communication functions the

DL-PD1 supports.

Overview

The DL-PD1 operates as a slave unit for PROFIBUS DP. The sensor amplifier output or

comparator value can be read via the cyclic communication, and the sensor amplifier's

external input ON/OFF can be controlled. Also, setting the DL-PD1 or sensor amplifier

connected to DL-PD1 and reading/writing the status of them are possible via the acyclic

communication of the DP-V1 service.

"Overview of PROFIBUS DP Communication" (page 3-17)

"DP-V1 Service" (page 3-26)

3-2

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 27

3

PROFIBUS Specifications

3-1 PROFIBUS communication function of DL-PD1

GSD Revision 5

FMS No

Data transmission rate

Bus protocol PROFIBUS DP

Interface RS-485

Modular Device Yes (Monitor mode only)

module max.15 units

Address

space

PROFIBUS DEVICE ID 0DFD

Redundancy No

P24V signal No

FREEZE capability Yes

SYNC capability Yes

Auto Baudrate Yes

Set_Slave_Adress No

Min_Slave_Interval 600 s

Fail-safe Mode Yes

DP-V1 Ye s

Alarm No

I&M data Compatible with I&M0

Clocking No

Firmware update No

Address 1 to 99

Item Specifications

9.6 / 19.2 / 45.45 / 93.75 / 187.5 / 500 kbit/s

1.5 / 3 / 6 / 12 Mbit/s

I/O Mode inputs: 10 bytes, outputs: 10 bytes

Monitor Mode inputs: max.107 bytes, outputs: max.16 bytes

H

Executing Communication

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-3

Page 28

3-1 PROFIBUS communication function of DL-PD1

3

Operational flow for test operation

The following settings using the PROFIBUS DP configuration software are required for

the DL-PD1 to connect and communicate with the PROFIBUS DP master.

1 Read the GSD file.

The DL-PD1 functions for PROFIBUS DP are defined by the GSD file.

The GSD file can be downloaded from KEYENCE homepage. Read the

downloaded GSD file using the configuration software and install it.

Executing Communication

http://www.keyence.com

2 Add the DL-PD1 to the PROFIBUS DP system.

Reading the GSD file using the configuration software can add the DL-PD1 and

sensor amplifier to the hardware catalog of the configuration software Select the

DL-PD1 from the hardware catalog and add to the PROFIBUS DP system.

"Hardware configuration" (page 3-6)

3 Add the sensor amplifier.

Select the sensor amplifier to connect to the DL-PD1 from the hardware catalog

and add to the PROFIBUS DP system.

"Hardware configuration" (page 3-6)

"Slot number and ID number assignment" (page 3-5)

4 Set the DL-PD1 parameter as necessary.

The parameter setting is not necessary when reading only sensor amplifier output

via cyclic communication.

"Parameterization" (page 3-8)

3-4

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 29

3-1 PROFIBUS communication function of DL-PD1

3

Point

02

...

1501

02

...

1501

Main

unit

Expansion unit

Sensor amplifier

DL-PD1

00

00

ID number

Slot number

Slot number and ID number assignment

When the sensor amplifiers are connected to the DL-PD1, slot numbers are assigned to

each sensor amplifier. When using the acyclic communication with the DP-V1 service or

diagnostic function used, the slot number is used to specify the target sensor amplifier

for communication.

Also, ID numbers are assigned to the control output and external input of each sensor

amplifier in the connection order of sensor amplifiers. ID numbers are used to identify

the control output of the sensor amplifier assigned as cyclic communication data.

(Configuration example)

Executing Communication

Slot numbers and ID numbers are automatically assigned in the

connection order for sensor amplifiers. If the number of connected

sensor amplifiers or connection order is changed, the control program

may have to be changed. Design the sensor amplifier configuration

and control program with this taken into account beforehand.

"Operation mode of DL-PD1" (page 3-6)

If the effective ID setting is changed on the GT2-100N (P), restart the

GT2-100N (P). After restarting the GT2-100N (P), the DL-PD1

recognizes the specified number of units and communication with the

units is possible.

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-5

Page 30

3

3-2

Set the hardware configuration on the configuration software of PROFIBUS DP

according to the physical configuration of the DL-PD1 and sensor amplifier connected to

the DL-PD1. The setting procedure differs depending on the operation mode of DL-PD1.

Operation mode of DL-PD1

There are two types of operation modes for DL-PD1. The operation modes for DL-PD1

are switched on the hardware configuration using the configuration software of

PROFIBUS DP.

Monitor mode

Executing Communication

Use this mode to obtain the comparator value and status of sensor amplifiers via cyclic

communication. The input size and output size for cyclic communication change

depending on the number of sensor amplifiers connected. The maximum sizes for input

and output are 107 bytes and 16 bytes respectively.

When using the monitor mode, assign the "DL-PD1" and each sensor amplifier to the

PROFIBUS DP system on the hardware configuration.

When using the master compatible with the DP-V1, any of the modes can be used to

read or write all information on the sensor amplifier via acyclic communication of DP-V1

service.

DL-PD1 Monitor mode

DL-PD1 (without Sensor

amplifier)

Hardware configuration

Unit assigned on the

configuration

"DP-V1 Service" (page 3-26)

Operation mode

of DL-PD1

I/O mode

Cyclic communication

Control

Comparator

Error

output

value

External

information

input

* When using Class 2 master only

Cannot be used with Class 1 master.

Acyclic

communication

(DP-V1 service)

*

I/O mode

Use this mode to reduce the input/output size of cyclic communication to minimum. The

input size and output size are 10 bytes each regardless of the number of sensor

amplifiers connected. Using the cyclic communication, the control output of sensor

amplifiers can be read and external output to sensor amplifiers can be performed.

When using the I/O mode, assign the "DL-PD1 without sensor amplifier" to the

PROFIBUS DP system on the hardware configuration. Do not assign the sensor

amplifier.

3-6

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 31

3-2 Hardware configuration

3

Input/Output size

When DL-PD1 is in the monitor mode

The input/output size changes according to the number of sensor amplifiers connected.

Assign the "DL-PD1" and each sensor amplifier to the PROFIBUS DP system on the

hardware configuration using the configuration software of PROFIBUS DP.

Slot

* How many sensor amplifiers can be connected depends on the sensor amplifiers to

When DL-PD1 is in the I/O mode

The input/output size is fixed regardless of the number of sensor amplifiers connected.

Assign the "DL-PD1 without sensor amplifier" to the PROFIBUS DP system on the

hardware configuration using the configuration software of PROFIBUS DP.

Slot

Cyclic communication

:

input output

7 bytes 1 byte

0 2 bytes 1 byte

1

15*

be connected. For specific numbers of connections, refer to the manual of each

sensor amplifier.

Cyclic communication

0 10bytes 10bytes

input output

Executing Communication

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-7

Page 32

3

3-3 Parameterization

Set parameters on the configuration software of PROFIBUS DP.

Set as necessary.

Standard parameter

Parameters specified by PROFIBUS DP/DPV1 standard

Octet Name Description Valu e

1 Station Status Station status

Executing Communication

2 WD_Fact_1 Watchdog element 1 -

3 WD_Fact_2 Watchdog element 2 -

4 TSDR Shortest TSDR time -

5 Ident number (H) Manufacturer code (high byte) 0D

6 Ident number (L) Manufacturer code (low byte) FD

7 Group ID

8 DPV1 Status1 DPV1 status 1 (See EN50170.)

9 DPV1 Status2 DPV1 status 2 (See EN50170.)

10 DPV1 Status3 DPV1 status 3 (See EN50170.) 0 (fixed)

Group assignment for broadcast and

multi cast (SYNC,FREEZE, CLEAR)

BIT2-0: reserved

BIT3: Watchdog on

BIT4: Freeze mode request

BIT5: Sync mode request

BIT6: Unlock request

BIT7: Lock request

H

H

-

BIT1-0: reserved

BIT2: Watchdog time base 1 ms

BIT4-3: reserved

BIT5: 0 (fixed)

BIT6: Fail_safe

BIT7: DP-V1_Enable

(Default value: 1100 0000B)

BIT0: Check_Cfg_Mode

BIT1: reserved

BIT7-2: 0 (fixed)

(Default value: 0000 0001B)

3-8

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 33

3

Vender parameter

bit 7

:

:

0

Slot 15 Slot 8

bit 7

:

:

0

Slot 7 Slot 0

bit 7

:

:

0

Slot 15 Slot 8

bit 7

:

:

0

Slot 7 Slot 0

Unique parameters for DL-PD1

Octet Name Description Valu e

11 Reserved - 1 (fixed)

12 Data Format

13 Extended Diagnosis

Selects data storage format when

sending/receiving 2 bytes or larger data.

Selects whether to include information

other than standard diagnosis into slave

diagnosis.

0: Intel (little endian)

1: Motorola (big endian)

0: Disable

1: Enable

3-3 Parameterization

: Default value

14

Indicate error slot

[Sensor Amplifier]

15

16

Indicate warning slot

[Sensor Amplifier]

17

18 Reserved - 0 (fixed)

Selects the sensor amplifier as a target

for slave diagnosis. If the sensor

amplifier is set as a target, set bit

corresponding to the slot number.

"Diagnostic Function" (page 3-10)

Selects whether to include warning

information into slave diagnosis

information. If so, set bit corresponding

to the slot number.

(Default value: 1111 1111B)

(Default value: 1111 1110B)

Slot 0 is fixed to 0.

(Default value: 0)

(Default value: 0)

Executing Communication

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-9

Page 34

Executing Communication

3

1

2

3

4

5

6

7

:

10

11

:

19

20

:

67

:

:

:

Octet

Station status 1 to 3

PROFIBUS DP master address

Manufacturer ID

Identifier-related diagnosis

(Error information)

Module status

Channel-related diagnosis

Minimum 3 bytes

3 bytes increase per slot

Standard Diagnosis

Channel-related

Diagnosis

3-4 Diagnostic Function

Using the slave diagnostic function of PROFIBUS DP, the information of error caused on

the DL-PD1 or sensor amplifier can be sent to the master via PROFIBUS DP.

Slave diagnosis structure

The frame length of the DL-PD1 slave diagnosis is the maximum of 67 bytes. The slave

diagnosis consists of 6-byte standard diagnosis, 4-byte Identifier-related diagnosis, 9byte module status and maximum of 48-byte Channel-related diagnosis. The frame

length of the Channel-related diagnosis changes depending on the number of sensor

amplifiers connected. The minimum length is 3 bytes and the length increases 3 bytes

per sensor amplifier additionally connected.

Also, the diagnostic function can be set to Enable/Disable by slot at the parameter

setting for DL-PD1. When the diagnostic function is set to Disable, the slot information is

deleted from the diagnostic frame.

"Parameterization" (page 3-8)

3-10

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 35

3-4 Diagnostic Function

3

Station status

Information indicating the overview of the DL-PD1 status is stored in Octet 1 to 3. If an

error occurs, each bit for Octet 1 to 3 is set. Refer to the following contents and eliminate

the cause of error.

Station status 1

Octet bit Content Solution

0 Cannot be accessed from the DP master to the DP slave.

1 The DP slave is not ready to exchange data yet. Wait. The DP slave is now starting up.

The configuration data transferred from the DP master to

2

the DP slave does not match with the slave configuration.

31 (fixed) -

40 (fixed) -

1

The DP master cannot decode the response of the DP

5

slave.

The type of DP slave does not match to the software

6

configuration.

Parameters are assigned to the DP slave by the different

7

DP master (not the DP master currently having the

access right to the DP slave).

• Is the correct PROFIBUS address set

to the DP slave?

• Is the bus connector connected?

• Is the RS485 repeater properly set?

• Is the DP slave set?

Check if the slave setting on the

configuration software is correctly made.

Check the configuration of the bus.

Check if the station type set on the

configuration software is correct.

• For example, when accessing to the

DP slave using the programming

device or another DP master, this bit is

always 1.

• The PROFIBUS address of DP master

which assigned parameters to the DP

slave is in the diagnosis byte.

Executing Communication

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-11

Page 36

3-4 Diagnostic Function

3

Station status 2

Octet bit Content

Executing Communication

*1 This bit is updated only when another diagnosis message is updated, too.

Station status 3

Octet bit Content

PROFIBUS DP master address

The PROFIBUS address of PROFIBUS DP master is stored in Octet 4. When the value

is FF

Manufacturer ID

Codes unique for the DL-PD1 status are stored in Octet 5 and 6.

Octet Content Valu e

0 Set the DL-PD1 parameter again.

A diagnosis message is present. The DP slave does not operate until the problem is eliminated.

1

(Static diagnosis message)

2 (1 fixed)

3 The watchdog is enabled.

2

4 The DP slave is in "FREEZE" state.

5 The DP slave is in "SYNC" state.

6 (0 fixed)

7 The DP slave is disabled.

0

:6(0 fixed)

3

7 Diagnosis messages exceed the maximum amount that can be stored. Increase the storing memory.

, the parameter is not assigned.

H

5 Manufacturer ID is stored. (high byte) 0D

6 Manufacturer ID is stored. (low byte) FD

*1

*1

H

H

3-12

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 37

3-4 Diagnostic Function

3

Identifier-related diagnosis

Information to identify the unit where an error occurred is stored in Octet 7 to 10.

Octet Content bit Valu e

Length of the Identifier-related diagnosis

7

Code for Identifier-related diagnosis

BIT corresponding to the module where an error has occurred

8

is set.

(Slot 0 to 7)

BIT corresponding to the module where an error has occurred

9

is set.

(Slot 8 to 15)

10 Reserved

0

00 0100B (fixed) :

5

6

01B (fixed)

7

0 Error in Slot 0 (DL-PD1)

::

7 Error in Slot 7 (Sensor amplifier)

0 Error in Slot 8 (Sensor amplifier)

::

7 Error in Slot 15 (Sensor amplifier)

0

:70000

B

Module status

Error information is stored in Octet 11 to 19 when the hardware configuration on the

configuration software does not coincide with the actual configuration.

Octet Content bit Valu e

Length of the Module status

11

Code for Module status

12 Status Type module Status

13 Reserved

14 Reserved

0

5

6

7

0

7

0

7

0

7

00 1001B (fixed):

00B (fixed)

130D (fixed):

0 (fixed):

0 (fixed):

Executing Communication

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-13

Page 38

3-4 Diagnostic Function

3

DL-PD1

DL-PD1

GT2-71N

GT2-72N

GT2-72N

IL-1050

10234

GT2-71N

GT2-72N

IL-1050

1023

Configuration on the

configuration software

Module status in the state as shown on

the left

Byte Val ue

10 00 00 10 01

B

11 10 00 00 10

B

12 00 00 00 00

B

13 00 00 00 00

B

14

10 00 00 00

B

3210 Slot number

15

00 00 00 11

B

7654 Slot number

::

Slot number

Slot number

Actual configuration

Executing Communication

Octet Content bit Val ue

Slot 0 module status

Slot 1 module status

15

Slot 2 module status

Slot 3 module status

Slot 4 module status

16

Slot 7 module status

Slot 8 module status

17

Slot 11 module status

Slot 12 module status

18

Slot 15 module status

19 Reserved for system

::

::

::

0

1

2

3

4

5

6

7

00B:Normal

0

01B: System error

10B: The unit on the configuration

1

6

7

0

1

6

7

0

1

6

7

0

:70000B (fixed)

does not match the unit

actually connected.

11B: The unit is connected despite

the unit is not assigned on the

configuration, or the unit is not

connected despite the unit is

assigned on the configuration.

Example)

3-14

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 39

3-4 Diagnostic Function

3

Channel-related diagnosis

Information indicating the error content in 3byte per module (sensor amplifier) is stored

in Octet 20 to 67. The frame length of the diagnosis changes depending on the number

of module (sensor amplifier) connected (3 + 3 x [number of module (sensor amplifier)

connected]).

Also, Information of the module (sensor amplifier) for which the diagnostic function is set

to Disable for the parameter settings is deleted from the frame and subsequent data is

offset.

"Parameterization" (page 3-8)

Octet Content bit Valu e

Identifier Number

20

Code for Channel-related diagnosis

Channel Number

21

Slot 0 (DL-PD1)

Slot 1 (Sensor amplifier)

Channel Type

Error Type of Slot 0

22

Channel Type

Identifier Number

23

Code for Channel-related diagnosis

Channel Number

24

Channel Type

Error Type of Slot 1

25

Channel type

::

0

00 0000B (fix):

5

6

10B (fix)

7

0

00 0000B (fix):

5

6

11B (fix) : Input and Output

7

0

:

(page 4-3)

4

5

000B (fix):

7

0

00 0001B (fix):

5

6

10B (fix)

7

0

00 0000B (fix):

5

6

11B (fix) : Input and Output

7

0

:

(page 4-3)

4

5

000B (fix):

7

Executing Communication

"Types of error and error code"

"Types of error and error code"

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-15

Page 40

3-4 Diagnostic Function

3

Executing Communication

Octet Content bit Valu e

Identifier Number

65

Code for Channel-related diagnosis

Channel Number

66

Channel Type

Slot 15 (Sensor amplifier)

Error Type of Slot 15

67

Channel Type

0

00 1111B (fix):

5

6

10B (fix)

7

0

00 0000B (fix):

5

6

11B (fix) : Input and Output

7

0

:

(page 4-3)

4

5

000B (fix):

7

"Types of error and error code"

3-16

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 41

3

3-5

Overview of PROFIBUS DP Communication

The DL-PD1 enables you to read or write various settings and conditions of the sensor

amplifier via PROFIBUS DP.

Examples are shown below.

Item

Reading the sensor amplifier control output

Executing the external input to the sensor amplifier

Reading the sensor amplifier comparator value

Changing the sensor amplifier setting value

Cyclic communication

I/O

Mode

Monitor

Mode

DP-V1

Service

*

Reference

page

3-18

3-18

3-25

3-30

* When the DL-PD1 operation mode is the I/O mode

• When the master is Class 1, the DP-V1 service cannot be used.

• When the master is Class 2, the DP-V1 service can be used.

"Operation mode of DL-PD1" (page 3-6)

For the list of data that can be read or written over the cyclic communication, see

"Device maps" (page 3-18). For the list of data that can be read or written with the DPV1 service, see "DP-V1 Service" (page 3-26).

Cyclic communication

Executing Communication

Information and addresses assigned as the DL-PD1 cyclic communication data differ

depending on the DL-PD1 operation mode. When the DL-PD1 operation mode is the I/O

mode, the cyclic communication data assignment is fixed regardless of the connected

sensor amplifier. When the DL-PD1 operation mode is the monitor mode, assigned

information or addresses differ depending on the number and type of the connected

sensor amplifiers.

"Operation mode of DL-PD1" (page 3-6)

The storage format for 2byte data can be changed on the DL-PD1 parameter settings.

(In this example, data arrangement is shown in the big endian format.)

"Parameterization" (page 3-8)

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-17

Page 42

3-5 Overview of PROFIBUS DP Communication

3

Device maps

Monitor mode

In the monitor mode, the following functions can be performed.

• Reading the control output to the sensor amplifiers: "Parameterization" (page 3-8)

• External input request to the sensor amplifiers: "Parameterization" (page 3-8)

• Reading the comparator value: "Parameterization" (page 3-8)

• Reading the error status: "Parameterization" (page 3-8)

DL-PD1 (Slot 0)

Executing Communication

Input

Octet Bit Function name Description Valu e

0 Reserved for system - -

1 Reserved for system - -

2 Comparator value property Stores the comparator value status.

3 Reserved for system - -

4 Reserved for system - -

0

5 Sensor ready

6 Reserved for system - -

7 Error status

0 External input response 1

1 External input response 2

2 External input response 3

1

3 External input response 4

4 Reserved for system - -

5 Reserved for system - -

6 Reserved for system - -

7 Reserved for system - -

It is output when PROFIBUS DP

communication is established.

Stores the error status of the sensor

amplifiers.

"Types of error and error code"

(page 4-3)

Stores the external input response

to the sensor amplifier.

Stores the external input response

to the sensor amplifier.

Stores the external input response

to the sensor amplifier.

Stores the external input response

to the sensor amplifier.

0: Normal

1: Disabled status

“----”, “FFFF”, or “-FFFF”

0: Starting

1: Ready

0: No error occurred.

1: Error occurred.

0: No input

1: Input reception

0: No input

1: Input reception

0: No input

1: Input reception

0: No input

1: Input reception

3-18

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 43

3

Output

3-5 Overview of PROFIBUS DP Communication

Octet Bit Function name Description Val ue

0 External input request 1

1 External input request 2

2 External input request 3

0

3 External input request 4

4 Reserved for system - -

5 Reserved for system - -

6 Reserved for system - -

7 Reserved for system - -

Requests the external input to the

*1

sensor amplifiers.

Requests the external input to the

*1

sensor amplifiers.

Requests the external input to the

*1

sensor amplifiers.

Requests the external input to the

*1

sensor amplifiers.

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

*1 External input request to the sensor amplifiers connected to the DL-PD1 (Slot 0) can

be executed en bloc. (Smart Access function)

Functions assigned to the external input request 1 to 4 are as follows:

• External input request 1: PRESET input

• External input request 2: TIMING input

• External input request 3: RESET input

• External input request 4: ERROR CLEAR input

Refer to the GT2 series user's manual.

Executing Communication

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-19

Page 44

3-5 Overview of PROFIBUS DP Communication

3

Sensor amplifier (Slot 1 to 15)

Input

Executing Communication

Octet Bit Function name Description Val ue

0High

1Low

2Go

2+7(a-1)*

3+7(a-1)*

4+7(a-1)*

5+7(a-1)* to

8+7(a-1)*

3HH

4LL

5 Reserved for system - -

6 Reserved for system - -

7 Reserved for system - -

0 Reserved for system - -

1 Comparator value invalid Stores the comparator value status.

2 Comparator value under range Stores the comparator value status.

3 Comparator value over range Stores the comparator value status.

4 Reserved for system - -

5 Reserved for system - -

6 Reserved for system - -

7 Error status

0 External input response 1

1 External input response 2

2 External input response 3

3 External input response 4

4 Reserved for system - -

5 Reserved for system - -

6 Reserved for system - -

7 Reserved for system - -

0 to 7 Comparator value box

ON/OFF of the High state of the

sensor amplifiers is output.

ON/OFF of the Low state of the

sensor amplifiers is output.

ON/OFF of the Go state of the

sensor amplifiers is output.

ON/OFF of the HH state of the

sensor amplifiers is output.

ON/OFF of the LL state of the

sensor amplifiers is output.

Stores the error status of the sensor

amplifiers.

"Types of error and error code"

(page 4-3)

Stores the external input response

to the sensor amplifier.

Stores the external input response

to the sensor amplifier.

Stores the external input response

to the sensor amplifier.

Stores the external input response

to the sensor amplifier.

Used when reading the comparator

value (P.V. value).

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: Normal

1: Comparator value invalid

“----”

0: Normal

1: Comparator value under

range “-FFFF”

0: Normal

1: Comparator value over

range “FFFF”

0: No error occurred.

1: Error occurred.

0: No input

1: Input reception

0: No input

1: Input reception

0: No input

1: Input reception

0: No input

1: Input reception

INT32(LITTLE)

* "a" represents a Slot number. For example, the Octet value to Slot 1 is 2, 3, 4, or 5 to

8.

3-20

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 45

3

Output

3-5 Overview of PROFIBUS DP Communication

Octet Bit Function name Description Value

0 External input request 1

1 External input request 2

2 External input request 3

0 to 15

3 External input request 4

4 Reserved for system - -

5 Reserved for system - -

6 Reserved for system - -

7 Reserved for system - -

Requests the external input to the

sensor amplifiers.

Requests the external input to the

sensor amplifiers.

Requests the external input to the

sensor amplifiers.

Requests the external input to the

sensor amplifiers.

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

Functions assigned to the external input request 1 to 4 are as follows:

• External input request 1: PRESET input

• External input request 2: TIMING input

• External input request 3: RESET input

• External input request 4: ERROR CLEAR input

Refer to the GT2 series user's manual.

Executing Communication

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-21

Page 46

3-5 Overview of PROFIBUS DP Communication

3

I/O mode

In the I/O mode, the control output of the sensor amplifiers connected to the DL-PD1

can be read and external input request to the sensor amplifiers can be performed.

DL-PD1 (Slot 0)

Input

Executing Communication

Function

Octet

name

0

1 Slot 7 Slot 6

2

3 Slot 7 Slot 6

4

5 Slot 7 Slot 6

6

7 Slot 7 Slot 6

8

9 Slot 7 Slot 6

High

Low

Go

HH

LL

Description Bit7 Bit6

ON/OFF of the High state of

the sensor amplifiers is

output.

ON/OFF of the Low state

of the sensor amplifiers is

output.

ON/OFF of the Go state

of the sensor amplifiers is

output.

ON/OFF of the HH state

of the sensor amplifiers is

output.

ON/OFF of the LL state of

the sensor amplifiers is

output.

Slot 15 Slot 14

Slot 15 Slot 14

Slot 15 Slot 14

Slot 15 Slot 14

Slot 15 Slot 14

:

Bit1 Bit0 Valu e

:

Slot 9 Slot 8

:

Slot 1

Reserved for system

:

Slot 9 Slot 8

:

Slot 1

Reserved for system

:

Slot 9 Slot 8

:

Slot 1

Reserved for system

:

Slot 9 Slot 8

:

Slot 1

Reserved for system

:

Slot 9 Slot 8

:

Slot 1

Reserved for system

Output

Function

Octet

name

External

0

input

1 Slot 7 Slot 6

request 1

External

2

input

3 Slot 7 Slot 6

request 2

External

4

input

5 Slot 7 Slot 6

request 3

External

6

input

7 Slot 7 Slot 6

request 4

8

Reserved

for system

9 - -

Description Bit7 Bit6

Requests the PRESET

input to the sensor

amplifiers.

Requests the TIMING

input to the sensor

amplifiers.

Requests the RESET

input to the sensor

amplifiers.

Requests the external

input to the sensor

amplifiers.

-

Slot 15 Slot 14

Slot 15 Slot 14

Slot 15 Slot 14

Slot 15 Slot 14

- -

:

Bit1 Bit0 Valu e

:

Slot 9 Slot 8

:

Slot 1

Reserved for system

:

Slot 9 Slot 8

:

Slot 1

Reserved for system

:

Slot 9 Slot 8

:

Slot 1

Reserved for system

:

Slot 9 Slot 8

:

Slot 1

Reserved for system

:

- -

:

- -

* In the big endian format

Functions assigned to the external input request 1 to 4 are as follows:

• External input request 1: PRESET input

• External input request 2: TIMING input

• External input request 3: RESET input

• External input request 4: ERROR CLEAR input

Refer to the GT2 series user's manual.

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

-

3-22

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 47

3-5 Overview of PROFIBUS DP Communication

3

Point

Output

High output of ID01

Sensor amplifier

Master

Slot 1

Bit 0 of the input octet 2

1

0

ON

OFF

(1)

Master

DL-PD1 (Slot 0)

Bit 1 of the input octet 1

Sensor amplifier

Output

High output of ID01

1

0

ON

OFF

(1)

Communication Methods

The following describes how the master cyclically communicates with the DL-PD1

(cyclic communication).

• "Reading an output from a sensor amplifier" (page 3-23)

• "Entering an external input to a sensor amplifier" (page 3-24)

• "Reading comparator values (P.V. values) from sensor amplifiers" (page 3-25)

Reading an output from a sensor amplifier

Available outputs: High, Low, Go, HH, LL

This example shows how to read the High output from Slot 1 (ID01).

In the monitor mode

(1) The output from the sensor amplifier entered into Bit 0 of the input octet 2 via cyclic

communication. (In the big endian format)

This example shows how to read the High output from the sensor amplifier ID01.

To use the HH output and LL output, set "Special Output Setting" of

the sensor amplifier to "5-Output".

In the I/O mode

(1) The output from the sensor amplifier entered into Bit 1 of the input octet 1 via cyclic

communication. (In the big endian format)

Executing Communication

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-23

Page 48

3-5 Overview of PROFIBUS DP Communication

3

Point

Reference

(2)

(1)

Master

External input request

External input response

Sensor amplifier

External input

TIMING input of ID01

1

0

ON

OFF

1

0

Slot 1

Bit 1 of the output octet 0

Slot 1

Bit 1 of the input octet 2

Master

External input request

Sensor amplifier

External input

TIMING input of ID01

ON

OFF

1

0

DL-PD1 (Slot 0)

Bit 1 of the output octet 3

(1)

Entering an external input to a sensor amplifier

Available external inputs: PRESET, TIMING, RESET, error clear

This example shows how to enter the TIMING input from Slot 1 (ID01).

In the monitor mode

Executing Communication

(1) The output octet value to which an external input request was assigned is linked via

cyclic communication and the external input of the sensor amplifier is turned on or

off. (In the big endian format)

(2) You can check the input status of the sensor amplifier with the external input response.

• To use the TIMING input, set "Simultaneous Input Setting" of the

sensor amplifier to "Individual Input".

• To use the TIMING input, set the "Timing Type" of the sensor

amplifier to "External Timing Input".

After the external input is executed, the button operation of the sensor

amplifiers is locked for about 10 seconds. "COM-Lock (comLoc)" is displayed

for about 2 seconds during switching to the locked state or when an attempt

is made to operate a locked button. When button operation is unlocked,

"COM-Unlock (comUnL)" is displayed for about 2 seconds. However, the

initialization screen appears when an initialization reset is executed. If an

external input is repeatedly executed when the initialization screen is being

displayed, the initialization screen is retained.

In the I/O mode

(1) The output octet value to which an external input request was assigned is linked via

3-24

cyclic communication and the external input of the sensor amplifier is turned on or

off. (In the big endian format)

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 49

3-5 Overview of PROFIBUS DP Communication

3

(1)

Master

Comparator value under range

Input octet 3/10/17 Bit 3 of Slot 1/2/3

Comparator value of ID 01

1234 4567 6789

Input octet 5 to 8 (DEX) of Slot 1

Comparator value of ID 02

2345 5678 7890

Input octet 12 to 15 (DEX) of Slot 2

Comparator value of ID 03

3456 8901

Input octet 19 to 22 (DEX) of Slot 3

Sensor amplifier

Comparator value of ID 01

1234 4567 6789

Comparator value of ID 02

2345 5678 7890

Comparator value of ID 03

3456 8901

Comparator value over range

Input octet 3/10/17 Bit 2 of Slot 1/2/3

Comparator value invalid

Input octet 3/10/17 Bit 1 of Slot 1/2/3

1

1

1

0

0

0

(2)

(2)

(2)

Reading comparator values (P.V. values) from sensor amplifiers

Comparator values (P.V. values) can be read only in the monitor mode. They cannot be

read in the I/O mode.

"Operation mode of DL-PD1" (page 3-6)

Example of reading the comparator value (P.V. value) from the sensor

amplifier

Executing Communication

This example shows how to read the comparator values (P.V. values) from the sensor

amplifiers ID01, ID02, and ID03.

(1) When the comparator value of a sensor amplifier is updated, the value of the input

octet is also updated via cyclic communication.

If the comparator value is correct, the parameter range is -199.9999 to +199.9999.

If the comparator value is over range, under range, or invalid, the previous value is

retained without updating the comparator value. To confirm whether the current

value is correct, use the comparator value property.

(2) The comparator value invalid, comparator value over range, or comparator value

under range is entered.

If the comparator value of a sensor amplifier is "invalid", "over", or "under", the bit

corresponding to the ID number of that sensor amplifier flips to 1.

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-25

Page 50

Executing Communication

3

3-6 DP-V1 Service

Setting the DL-PD1 or sensor amplifier connected to DL-PD1 and reading/writing the

status of them are possible via the acyclic communication of the DP-V1 service. Specify

the target sensor amplifier and data for reading/writing by using the slot number and

index.

When the DL-PD1 operation mode is the I/O mode, the DP-V1 service can be used only

when the master is Class2. When the DL-PD1 operation mode is the monitor mode, the

DP-V1 service can be used with Class1 master or Class2 master.

"Operation mode of DL-PD1" (page 3-6)

For sensor amplifier function details, refer to the User's Manual of each sensor amplifier.

This can control multiple sensor amplifiers en bloc or read the statuses of sensor

amplifiers. (Smart access function)

DL-PD1 index (Slot 0)

Index

(DEC)

0Key lock

1 Key unlock

2

3

4 to 14 Reserved for system

15 Initialization request

16 to 31 Reserved for system

32 DL-PD1 error state

33

34 to 63 Reserved for system - - - -

Function name Description

The sensor amplifier enters

the key lock state.

The key lock of the sensor

amplifier is canceled.

Power saving function

(ECO)

Power saving function

(ECO) cancel

Number of connectable

units

The sensor amplifier enters

the eco mode.

The eco mode of the sensor

amplifier is canceled.

Initializes the sensor

amplifier.

Stores the DL-PD1 error

status.

"Types of error and error

code" (page 4-3)

Stores the number of sensor

amplifiers connected to the

DL-PD1.

Data

Attribute Va lue

type

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

INT

W

W

W

W

W

R

R 0 to 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0-4: Error code

bit5-15: 0 (Fixed)

3-26

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 51

3-6 DP-V1 Service

3

Index

(DEC)

64 Error state

65 Warning status

66 Comparator value property

67

68

69 Comparator value Invalid

70 to 77 Reser ved for system

78 Output 1

79 Output 2

80 Output 3

81 Output 4

82 Output 5

83 to 85 Reser ved for system

86 External input response 1

87 External input response 2

Function name Description

Comparator value over

range

Comparator value under

range

When the sensor amplifier is

in the error state, the

corresponding bit is set.

"Types of error and error

code" (page 4-3)

When the sensor amplifier is

in the warning state, the

corresponding bit is set.

When the sensor amplifier

comparator value is invalid or

exceeding the upper or lower

limit, the corresponding bit is

set.

When the sensor amplifier

comparator value is

exceeding the upper limit, the

corresponding bit is set.

When the sensor amplifier

comparator value is

exceeding the lower limit, the

corresponding bit is set.

When the sensor amplifier

comparator value is invalid,

the corresponding bit is set.

When the control output of

sensor amplifier is High, the

corresponding bit is set.

When the control output of

sensor amplifier is Low, the

corresponding bit is set.

When the control output of

sensor amplifier is Go, the

corresponding bit is set.

When the control output of

sensor amplifier is HH, the

corresponding bit is set.

When the control output of

sensor amplifier is LL, the

corresponding bit is set.

When the request reception

to the "External input request

1" is complete, the

corresponding bit is set.

When the request reception

to the "External input request

2" is complete, the

corresponding bit is set.

*1

*1

Data

Attribute Va lue

type

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

R

R

R

R

R

R

R

R

R

R

R

R

R

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

Executing Communication

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

3-27

Page 52

3-6 DP-V1 Service

3

Executing Communication

Index

(DEC)

88 External input response 3

89 External input response 4

90 to

127

128 Product code 1

:: : ::

142 Product code 15

143 Reserved for system

144 Revision 1

:: : :: :

158 Revision 15

159 Reserved for system

160

174

175 Reserved for system

176

:: : ::

190

191 to

194

Function name Description

When the request reception

to the "External input request

3" is complete, the

corresponding bit is set.

When the request reception

to the "External input request

4" is complete, the

corresponding bit is set.

Reserved for system

Stores the product code of ID

number 01 sensor amplifier.

Stores the product code of ID

number 15 sensor amplifier.

Stores the revision of ID

number 01 sensor amplifier.

Stores the revision of ID

number 15 sensor amplifier.

Comparator value 0 (ID

Number 1)

Comparator value 0 (ID

Number 15)

Number of decimal places

(Current value 0, ID

Number 1)

Number of decimal places

(Current value 0, ID

Number 15)

Reserved for system

Used when reading

comparator value (P.V. value)

of ID number 01.

Used when reading

comparator value (P.V. value)

of ID number 15.

Used when reading the

decimal position of ID number

01 comparator value (P.V.

value).

Used when reading the

decimal position of ID number

15 comparator value (P.V.

value).

*2 *3

*2 *3

Data

Attribute Va lue

type

2byte

WORD

*1

2byte

WORD

*1

2byte

WORD

2byte

WORD

2byte

WORD

2byte

WORD

4byte

DINT

4byte

DINT

4byte

DINT

4byte

DINT

bit0 : Reserved for system

bit1 : Slot 1

R

R

R

R

R 0101H to FFFFH

R 0101H to FFFFH

R

R

R

R

:

bit15 : Slot 15

bit0 : Reserved for system

bit1 : Slot 1

:

bit15 : Slot 15

GT2-7** (main unit) : 4006

GT2-7**

(expansion unit) : 4007

GT2-71MC*: 4008

GT2-100* (main unit) : 4010

GT2-100*

(expansion unit) : 4011

-199.9999 to +199.9999:: : ::

3-28

- PROFIBUS DP Compatible Network Unit DL-PD1 User's Manual (GT2) -

Page 53

3-6 DP-V1 Service

3

*1 Functions assigned to the external input request 1 to 4 are as follows:

• External input request 1: PRESET input