Page 1

High-speed, High-capacity Machine Vision System

CV-X Series

Easy Setup Guide

365GB

Control/Communication EtherNet/IP

(KEYENCE KV Series)

Page 2

Contents

Easy Setup Guide: Control/Communication EtherNet/IP (KEYENCE KV Series)

3

1. Before Connecting EtherNet/IP

6

9

2. Outputting the Measured Value/Judged Value

3. Controlling the Controller

15

4. Data Allocation

5. Troubleshooting

17

Page

Page

Page

Page

Page

KEYENCE CORPORATION. Vision System Division

‐ 2 ‐ www.keyence.com

Page 3

1. Before Connecting EtherNet/IP (EtherNet/IP) [Keyence KV Series]

3

This section describes how to establish EtherNet/IP.

[Important]

If it fails, establish a one-to-one connection between the

PLC and CV-X, and follow this manual to configure the

settings and check the operations.

Confirm that it operates properly, and change settings if

necessary.

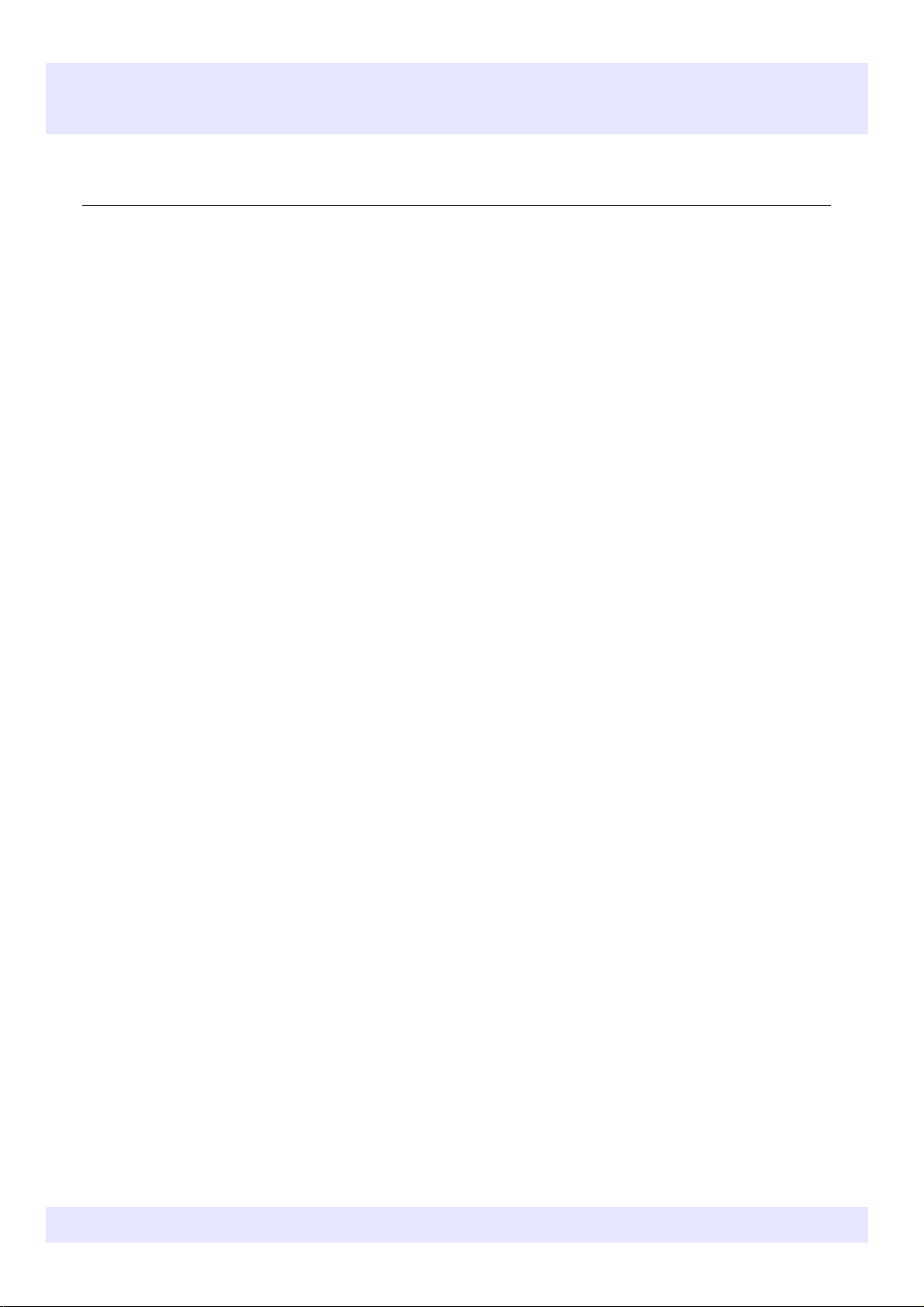

1. Checking the Global Settings of the CV-X100 Series

1

From "Global", select "Communications & I/O" "Network".

2

Change the Ethernet settings and then left-click

"OK".

From "Global", select "Communications & I/O" "EtherNet/IP".

4

Change the EtherNet/IP settings and then left-click

"OK".

In this section, the set values below will be

configured as an example (change the settings

according to the target device).

In this section, the set values below will be configured

as an example (change the settings according to the

target device).

•IP Address: 192.168.0.10

•Subnet Mask: 255.255.255.0

•Enable EtherNet/IP: Check this box.

•Data Size: 496 bytes

•Data Configurations: Set the desired data

allocations and allocation offset for the bit

address and byte address.

•Decimal Point: Fixed‐point

•Process Priority: Image First

5

Restart the controller.

KEYENCE CORPORATION. Vision System Division

365GB

‐ 3 ‐ www.keyence.com

Page 4

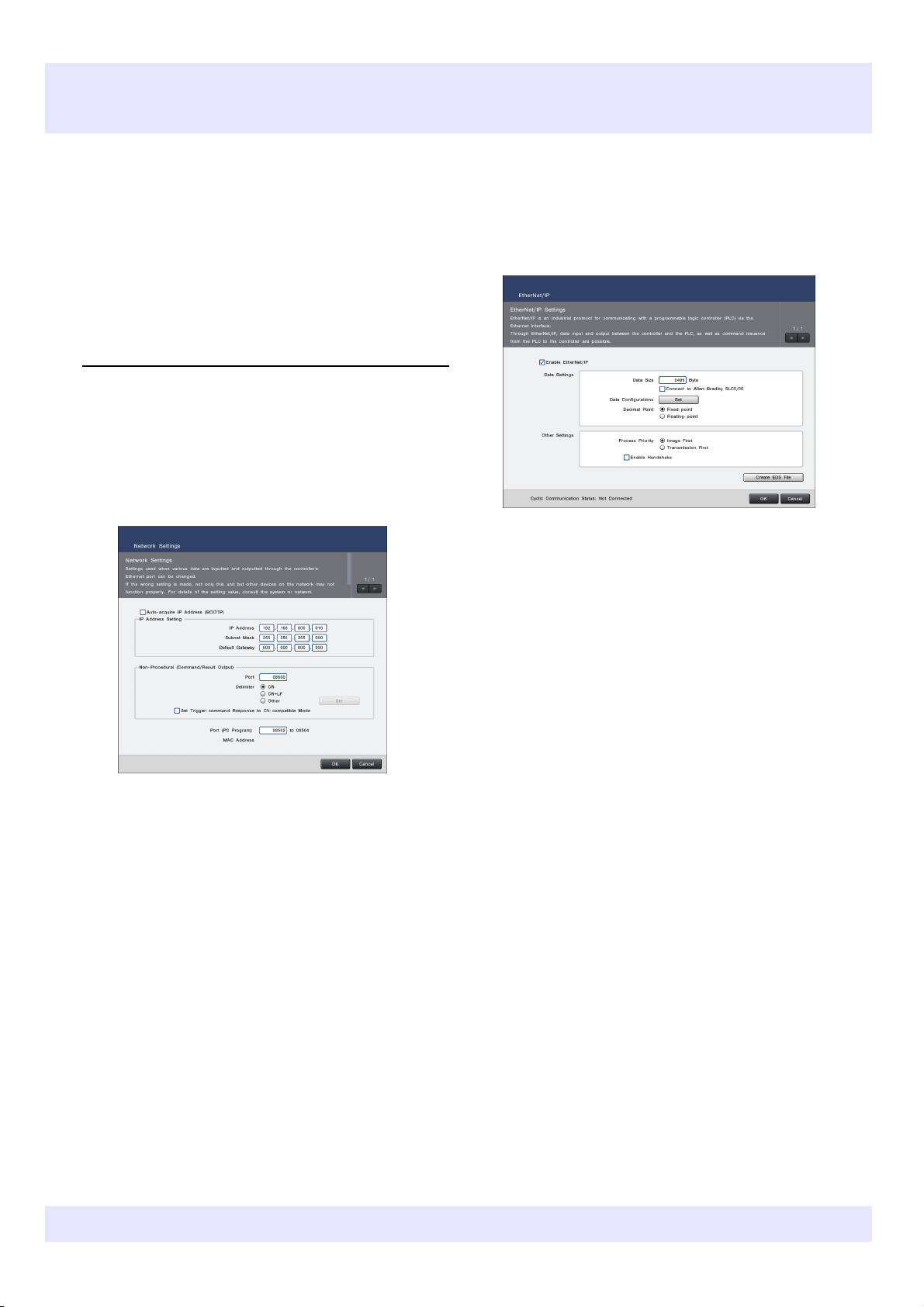

2. Changing the KV-Series settings

2

Enter the "Project name", select the "PLC model",

A "Confirm unit setting information" dialog appears.

3

Click "Read unit setting".

4

In the workspace, click the Ethernet/IP

5

Select "Convert" - "Auto-assign relay/DM" in the

6

Click the icon in "Setup unit (2)" to open

7

Save the changes and exit the "EtherNet/IP

8

Select "Device comment edit window" from the

9

Click "Details".

10

Confirm that the box for "CV-X100" is checked in

Device comments regarding CV‐X100 are

1

Start KV STUDIO with the PLC connected to the

computer, and select "New project" from the

"File" menu.

and then press "OK".

"EtherNet/IP settings". Configure the CV-X100

Series and EtherNet/IP communication settings.

•Drag "CV‐X100" from the "Unit list (1)" tab in

erNet/IP settings" and drop it into the scan list

"Eth

to add it.

•In the "Initial adapter settings" screen that is

displ

ayed after start up, enter the CV

dress (192.168.0.10) that was set in the

IP Ad

CV‐X100

Series global settings.

‐100 S

settings" and Unit Editor.

"Display" menu in KV STUDIO.

The "Device comment edit" screen appears.

eries

communication unit or CPU unit that will be

connected to the CV-X100 Series to start "Unit

Editor". Set up the IP Address of the KV Series in

the "Setup unit (2)" tab.

•IP Address: 192.168.0.20

•Subnet Mask: 255.255.255.0

Unit Editor to allocate a device.

When automatically allocated, the bit device is

allocated to B (link relay) and the byte device is

allocated to W (link register).

The "Register unit device" screen appears.

the "Select unit" list, and then click "Register".

KEYENCE CORPORATION. Vision System Division

automatically registered.

‐ 4 ‐ www.keyence.com

Page 5

11

Select "Transfer to PLC" from the

"Monitor/Simulator" menu in KV STUDIO.

12

Restart both the CV-X100 Series and the KV Series.

If the LINK LED on the KV Series Ethernet port stays lit

When the connection is successful, the LINK LED

(green) will start flashing on the KV Series Ethernet

port.

Successful connection can also be confirmed by

selecting "Communications & I/O"

"Global" on the CV

"Cyclic Communication Status".

(does not flash) or does not light

The EtherNet/IP may not be set up correctly, the cables may

not be connected correctly, or the CV

be started up. Check the connection equipment (if a

crossover cable is being used as a LAN cable when

connected directly, if the HUB is working, etc.)

Series, and checking the

‐X100

‐X100

rNet/IP" in

‐ "Ethe

Series may not

KEYENCE CORPORATION. Vision System Division

‐ 5 ‐ www.keyence.com

Page 6

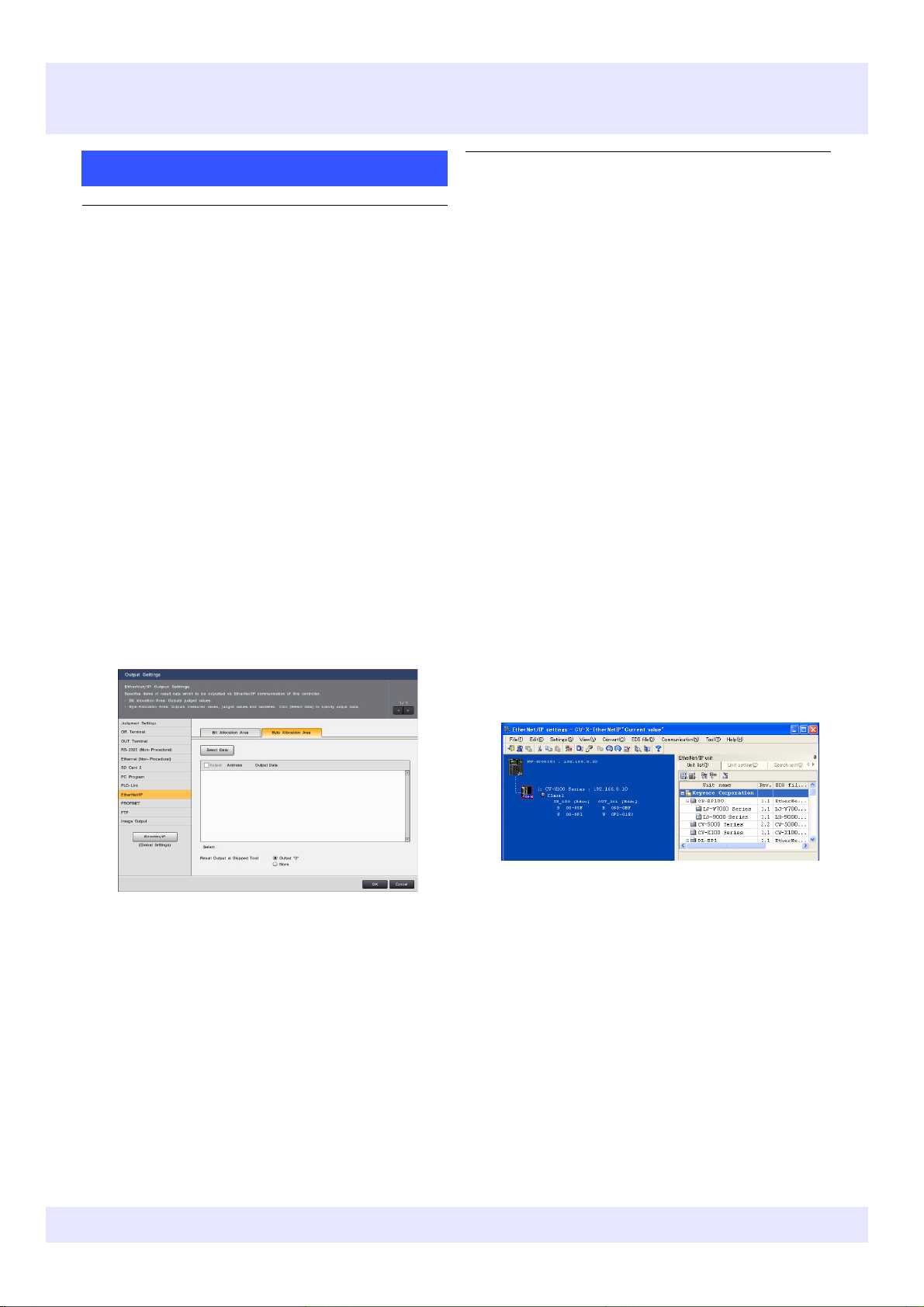

2. Outputting the Measured Value/Judged Value (EtherNet/IP) [Keyence KV Series]

Use the output settings to output the measured values

1

Check an example of result data stored to the

Outputting the Measured Value/Judged

3

Left-click "Select Data", select the items to output,

4

Check the byte address for output.

1

From the "Output Settings" screen, left-click

2

Left-click the "Byte Allocation Area" tab.

2

Check the relationship between the byte address

•Check the range (hexadecimal) of the link relay

2. Checking the format for output to the byte

address, and the relationship between the byte

1. Setting the output data (Output Settings)

address and the link register (W)

and judged values. This section explains how to

allocate the measured/judged values below as an

example.

•Total Status Value

•T100: Position Adjustment with Shading Pattern

(position X)

•T100: Position Adjustment with Shading Pattern

(position XY)

•T101: Area

•T102: OCR (Recognize Strings)

•T100: Position Adjustment with Shading Pattern

(tool judgment value)

•T101: Area (tool judgment value)

•Program Time

•Date & Time

"EtherNet/IP".

The EtherNet/IP output settings screen appears.

byte address.

The EtherNet/IP output settings are set so that the

result data shown below is output.

•Total Status Value

•T100: Position Adjustment with Shading Pattern

(position X)

•T100: Position Adjustment with Shading Pattern

(position XY)

•T101: Area

•T102: OCR (Recognize Strings)

•T100: Position Adjustment with Shading Pattern

(tool judgment value)

•T101: Area (tool judgment value)

•Program Time

•Date & Time

and the link register (W) in KV STUDIO.

Open "EtherNet/IP settings" from the "Setup unit (2)"

tab in KV STUDIO Unit Editor, and click the plus sign

(+) next to "Class1" for the registered CV

check the allocation status of the device. (In the

notation, output from CV

(input)".)

is treated as "IN

‐X100

‐X100

to

and then left-click "Add".

KEYENCE CORPORATION. Vision System Division

•When allocating output data, the destination byte

address is automatically displayed in "Address".

•The byte address starting position is the position

allocated to "Result Data1" on the "Data

igurations"

Conf

he example above, it is byte address 048.)

(In t

‐ "Send‐Data" ‐ "Vie

w List" screen.

(B)/link register (W) allocated to the registered

CV‐X100

changed

•Byte addresses 0000‐0011 are for the link relay

(fro

0012 onwards are for the link register. Allocation

begins at the start from W0000, with 1 register

used for each 2‐byte address.

‐ 6 ‐ www.keyence.com

Series controller. (The range can also be

as desired by clicking "Edit".)

m B0000 onwards), and byte addresses from

Page 7

6

Input the trigger to the CV-X100 Series, then check

3

From "Global", select "Communications & I/O" -

4

Left-click "View List" in "Send-Data".

•By default, "Result Data1" (first result output) is

5

Restart the controller.

•Judged value OK=0, NG=1 is stored using 2 words.

"EtherNet/IP", and left-click "Set" in "Data

Settings".

The "EtherNet/IP Communication Data Structure"

screen appears.

The contents that are allocated to the controller send

set for byte address 0048, and the result data is

allocated there.

•As re

sult data is output in 32

addresses are used for each piece of result data

(1 character in the case of text).

‐bit u

nits, 4

‐byte

the output results in the KV STUDIO registration

monitor.

Check the current value beginning with device W012.

•Decimal fraction data is multiplied by 1000 and

stored using 2 words: 124.121 → 124121

•When XY data is output, it is stored in order XY

using 2 words each.

•Integer data is stored unchanged using 2 words

•Text data is stored in ASCII code using 2 words

per character

‐ When

dev

character string. In this example, because the

OCR unit "Detected String" is output, the character

string is "KEYENCE" (7 characters). However

because 10 is set for "Characters" in "Block Set",

the 20 words (for 10 characters) from W042 to

W054 are used.

‐ When

used changes. If there is a possibility that it might

be changed, it is recommended that it be set at

the end of the output data.

•Judged value OK=0, NG=1 is stored using 2 words.

•System variable: Integer type: Stored using 2 words

as is

Decimal type: Multiplied by 1,000 and stored using

2 words

outputting with "String", the number of

ices used varies depending on the set

the characters setting is changed, the device

KEYENCE CORPORATION. Vision System Division

‐ 7 ‐ www.keyence.com

Page 8

KEYENCE CORPORATION. Vision System Division

‐ 8 ‐ www.keyence.com

Page 9

3. Controlling the Controller (EtherNet/IP) [Keyence KV Series]

5

Restart the controller.

1

From "Global", select "Communications & I/O" -

Controlling the Controller

2

Click "Set" in "Data Settings".

3

Left-click "View List" in "Send-Data" and "Receive-

4

Click "OK".

The changed settings are saved.

1. Checking the Global Settings of the CV-X100 Series

"EtherNet/IP".

The "EtherNet/IP Communication Data Structure"

screen appears.

Data" to check the status of byte address and bit

address allocation for the items that are required

for controller control.

Receive-Data (PLC to Controller: OUT)

•Command request flag: Turns OFF→ON when a

command is executed (bit).

•Command Number: Sets the command No. of the

command to execute (double word).

•Command Parameter#: Sets the No. # argument

for the command (word). (Whether or not there

are arguments depends on the command.)

Send-Data (Controller to PLC: IN)

•Command complete flag: Turns ON when the

command process is completed (bit).

•Command error flag: Turns OFF when the

command process is completed, and ON when

a failure occurs (bit).

•Command ready flag: Turns ON when ready to

receive the command process (bit).

•Command Result: Sets the command execution

results (0: Success, <Error code>: Failure)

(double word).

•Command Data#: Sets the command No. #

response data (word). (Whether or not there is

response data depends on the command.)

KEYENCE CORPORATION. Vision System Division

‐ 9 ‐ www.keyence.com

Page 10

KEYENCE CORPORATION. Vision System Division

‐ 10 ‐ www.keyence.com

Page 11

✎ Command Execution Procedure Example Save Settings (SS)

Here is an example of a command execution procedure. This section shows an example of executing the SS (Save Settings)

Check the SS (Save Settings) command operation.

4.Check if the values of the devices corresponding to

flag, and "0" into Command result.

command which does not use a command parameter. The screens with blue frames show when the "Registration monitor"

function of KV STUDIO is used for confirmation.

1. Enter "12", the SS command No., in the device

corresponding to the PLC Command Number (W0F4

in this example).

2. Enter "1" in the device corresponding to the PLC

Command request flag (B060 in this example).

3. The command is executed.

the PLC Command complete flag and Command

result (B00 and W04 respectively in this example)

have changed.

When the command is successful: CV‐X writes "1" into Command complete

When the command fails: CV‐X writes "1" into Command complete flag, and

an error code into Command result.

KEYENCE CORPORATION. Vision System Division

‐ 11 ‐ www.keyence.com

Page 12

4. Check if the values of the devices corresponding to

✎Command Execution Procedure Example Switch Program Setting No. (PW)

Here is an example of a command execution procedure. This section shows an example of executing the PW (Switch Program

Check the PW (Switch Program Setting No.) command operation.

1. Enter "24", the PW command No., in the device

Setting No.) command which uses command parameters. The screens with blue frames show when the "Registration monitor"

function of KV STUDIO is used for confirmation.

corresponding to the PLC Command number (W0F4 in

this example), and enter the switch target SD drive No.

and program number in the device corresponding to

Command Parameter (W0F6 and W0F8 in this

example).

The figure on the right shows an example of switching

to program number "11" on "SD1".

2. Enter "1" in the device corresponding to the PLC

Command request flag (B060 in this example).

3. The command is executed.

the PLC Command complete flag and Command

result (B00 and W04 respectively in this example)

have changed.

When the command is successful: CV‐X writes "1" into Command complete

flag, and "0" into Command result.

When the command fails: CV‐X writes "1" into Command complete flag, and

an error code into Command result.

KEYENCE CORPORATION. Vision System Division

‐ 12 ‐ www.keyence.com

Page 13

✎ Command Execution Procedure Example Rewrite Judgment Conditions (DW)

Here is an example of a command execution procedure. This section shows an example of executing the DW (Rewrite Judgment

Check the DW (Rewrite Judgment Conditions) command operation.

1. Enter "45", the DW command No., in the device

4. Check if the values of the devices corresponding to

complete flag, and "0" into Command result.

flag, and an error code into Command result.

Conditions) command which uses command parameters and specifies integer and fractional values. The screens with blue frames

show when the "Registration monitor" function of KV STUDIO is used for confirmation.

corresponding to the PLC Command number (W0F4 in

this example), and enter the parameters in order in the

devices corresponding to the Command parameter

(W0F6, W0F8, W0FA and W0FC in this example).

The figure on the right shows an example of rewriting

the lower limit of the area of "T101" to "900".

‐ Parameter 1 101 (Tool ID: 101)

meter 2 105 (judgment condition item ID for

‐ Para

ea")

"Ar

→For information about the judgment condition

i

tem ID, refer to the CV

‐ Parameter 3 1 (lower limit)

‐ Parameter 4 900000 (value)

→If "Decimal Point" is set to "Fixed- point", specify

he value multiplied by 1000 (900000)

t

→If "Decimal Point" is set to "Floating- point",

specify a single precision floating point number

(900.000).

‐X Seri

es user's manual.

2. Enter "1" in the device corresponding to the PLC

Command request flag (B060 in this example).

3. The command is executed.

the PLC Command complete flag and Command result

(B00 and W04 respectively in this example) have

changed.

When the command is successful: CV‐X writes "1" into Command

When the command fails: CV‐X writes "1" into Command complete

KEYENCE CORPORATION. Vision System Division

‐ 13 ‐ www.keyence.com

Page 14

✎Command Execution Procedure Example Rewrite Registered String (CW)

Here is an example of a command execution procedure. This section shows an example of executing the CW (Rewrite

Check the CW (Rewrite Registered String) command operation.

4. Check if the values of the devices

complete flag, and "0" into Command result.

flag, and an error code into Command result.

Registered String) command which uses command parameters and specifies a string. The screens with blue frames

show when the "Registration monitor" function of KV STUDIO is used for confirmation.

1. Enter "43", the CW command No., in the device

corresponding to the PLC Command number

(W0F4 in this example), and enter the parameters

in order in the devices corresponding to the

Command parameter (W0F6 to W0106 in this

example).

T102: To rewrite the registered string of the OCR

tool to "ABCDE", specify the following.

meter 1 102 (Tool ID: 102)

‐ Para

‐ Parameter 2 1 (In the case of "OCR": Always 1)

‐ Para

meter 3 1 (When specifying characters on

th

e PLC side: "1")

meter 4 65 (ASCII code for "A")

‐ Para

meter 5 66 (ASCII code for "B")

‐ Para

‐ Parameter 6 67 (ASCII code for "C")

‐ Para

meter 7 68 (ASCII code for "D")

‐ Para

meter 8 69 (ASCII code for "E")

meter 9 0 (0 at the end of the string)

‐ Para

2. Enter "1" in the device corresponding to the PLC

Command request flag (B060 in this example).

* The device to use is 1 word.

3. The command is executed.

corresponding to the PLC Command complete

flag and Command result (B00 and W04

respectively in this example) have changed.

When the command is successful: CV‐X writes "1" into Command

When the command fails: CV‐X writes "1" into Command complete

KEYENCE CORPORATION. Vision System Division

‐ 14 ‐ www.keyence.com

Page 15

4. Data Allocation

KEYENCE CORPORATION. Vision System Division

‐ 15 ‐ www.keyence.com

Page 16

KEYENCE CORPORATION. Vision System Division

‐ 16 ‐ www.keyence.com

Page 17

5. Troubleshooting

KEYENCE CORPORATION. Vision System Division

‐ 17 ‐ www.keyence.com

Page 18

KEYENCE CORPORATION. Vision System Division

.

from [Image First]

‐ 18 ‐ www.keyence.com

Page 19

Page 20

Copyright (c) 2014 KEYENCE CORPORATION. All rights reserved. 124294E 1084-1 365GB Printed in Japan

Loading...

Loading...