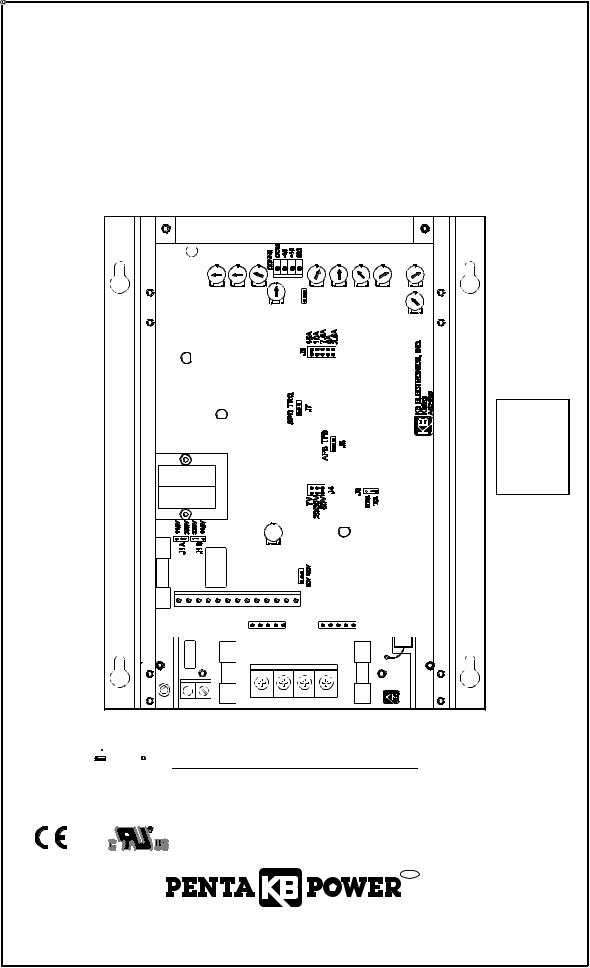

Kb electronics KBRG-225D, KBRG-240D Manual

INSTALLATION AND OPERATING INSTRUCTIONS

REGENERATIVE DRIVE

MODEL KBRG-225D |

MODEL KBRG-240D |

(P/N 8800) |

(P/N 8802) |

FULL WAVE • 4 QUADRANT

FWD |

|

FWD |

REV |

|

|

|

MAX |

IR |

REV |

FWD |

||||

EN |

|

ACCEL ACCEL DB |

|

|

SPD RESP COMP |

CL |

CL |

|||||||

|

|

|

|

|

|

|

|

|

S/LT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NLT |

|

|

|

TCL |

|

|

|

|

|

|

|

|

|

OFFSET |

J8 |

|

|

|

|

|

REV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PWR |

|

|

|

|

|

|

|

|

|

|

This manual |

|

|

|

|

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

applies to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

logic board |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

revision “L” |

|

|

|

|

T1 |

|

|

|

|

|

|

|

|

and newer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

controls |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

only. |

|

|

|

|

|

|

|

|

|

|

|

CL |

|

|

|

|

|

|

|

|

|

|

|

|

R33 |

|

|

|

|

|

F1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J3 |

|

|

|

|

|

TB1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 10 11 12 13 |

|

|

|

|

||

|

|

|

|

|

F1 |

AC LINE |

|

|

ARMATURE |

F2 |

|

|

||

|

|

|

|

|

FUSE |

|

|

FUSE |

|

|

||||

(EARTH) |

TB1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GND |

|

|

|

|

|

|

|

|

|

|

TB2 |

|

|

|

F+ |

|

F- |

|

|

|

|

L1 |

L2 |

M1 |

M2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

See Safety Warning on Page 2

See Safety Warning on Page 2

The information contained in this manual is intended to be accurate. However, the manufacturer retains the right to make changes in design which may not be included herein.

See Page 2

™

A COMPLETE LINE OF MOTOR DRIVES

© 1997 KB Electronics, Inc.

|

TABLE OF CONTENTS |

|

Section |

Page |

|

i. |

Simplified Setup and Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 1 |

ii. |

Safety Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 2 |

I. |

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 2 |

II. |

Setting Mode of Drive (Speed or Torque Control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 4 |

III. |

Setting Selectable Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 6 |

IV. |

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 8 |

V. |

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 8 |

VI. |

Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 12 |

VII. |

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 12 |

VIII. |

Trimpot Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 13 |

IX. |

Function Indicator Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 15 |

X. |

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 22 |

|

TABLES |

|

1. |

Electrical Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 2 |

2. |

General Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 4 |

3. |

Summary of Control Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 5 |

4. |

Jumper J2 Position vs Motor Horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 6 |

5. |

Relationship of AC Line Input and Motor Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 7 |

6. |

Terminal Block Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 8 |

7. |

Field Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 10 |

8. |

Control State vs Relay Contact State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 12 |

9. |

Armature Fuse Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 13 |

10. |

Current Limit Timer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 15 |

11. |

Parts List (Logic Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16, 17 |

12. |

Parts List (Power Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 19 |

|

FIGURES |

|

1. |

Control Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 3 |

2A. |

Linear Torque Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 5 |

2B. |

Non-Linear Torque Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 6 |

3. |

AC Line Voltage Jumper Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 7 |

4. |

Motor Armature Voltage Jumper Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 7 |

5. |

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 9 |

6. |

AC Line and Armature Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 10 |

7A. |

Full Voltage Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 10 |

7B. |

Half Voltage Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 10 |

8. |

Main Speed Potentiometer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

9A. |

Voltage Following . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

9B. |

Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

9C. |

Start/Stop Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

9D. |

Alarm Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

9E. |

Tach-generator Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 12 |

10. |

Accel Trimpot Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 13 |

11. |

Offset Trimpot Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 14 |

12. |

Deadband Trimpot Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 14 |

13. |

Logic Board Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 18 |

14. |

Power Board Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 20 |

ii

i.

KBRG SIMPLIFIED OPERATING INSTRUCTIONS

KBRG SIMPLIFIED OPERATING INSTRUCTIONS

IMPORTANT – You must read these simplified operating instructions before you proceed. These instructions are to be used as a reference only and are not intended to replace the detailed instructions provided herein. You must read the Safety Warning on page 2 before proceeding.

1.CONNECTIONS.

A.AC Line – Wire AC line voltage to terminals L1 and L2. Be sure jumpers J1A and J1B are both set to the correct input line voltage of 115 or 230 VAC. Connect ground wire (earth) to green ground screw.

B.Motor.

1.Permanent Magnet (PM Type). Connect motor armature leads to M1+ and M2-. Be sure jumper J3 is set to the proper position “90" for 90 volt DC motors and “180" for 180 volt DC motors. Note: 180 volt DC motors must be used with 230 VAC line, 90 volt motors can be used with a 230 VAC or 115 VAC line. Note: Motor performance and efficiency, including brush life, may be adversely affected when using 90 volt motors with a 230 VAC line.

2.Shunt Wound Motors. Connect motor armature as above. Connect full voltage shunt field wires (90 volt motors with 100 volt fields and 180 volt with 200 volt fields) to F+ and F-. Connect half voltage field wires (90 volt motors with 50 volt fields and 180 volt motors with 100 volt fields) to F+ and L1.

2.SPEED OR TORQUE MODE.

Jumper J7 is factory set for speed control operation (SPD). For torque control, set J7 to TRQ position. Note: J8 must be set to the “S/LT” position for speed control operation.

3.MOTOR CURRENT.

Jumper J2 is factory set for 15 amp motors (15A) on the KBRG-225D and 10 amp motors (10A) on the KBRG-240D. For lower amperage motors, place J2 in the proper position. If motor amperage is less than 2.5 amps, which is the lowest value on both models, use the 2.5A position and readjust the IR and both CL trimpots according to section VIII D and E on pages 14 and 15 .

Note: The factory setting for Current Limit is 150% of the nominal current setting (e.g., if J2 is selected for 5 amps, the actual CL setting will be 7.5 amps).

4.TRIMPOT SETTINGS.

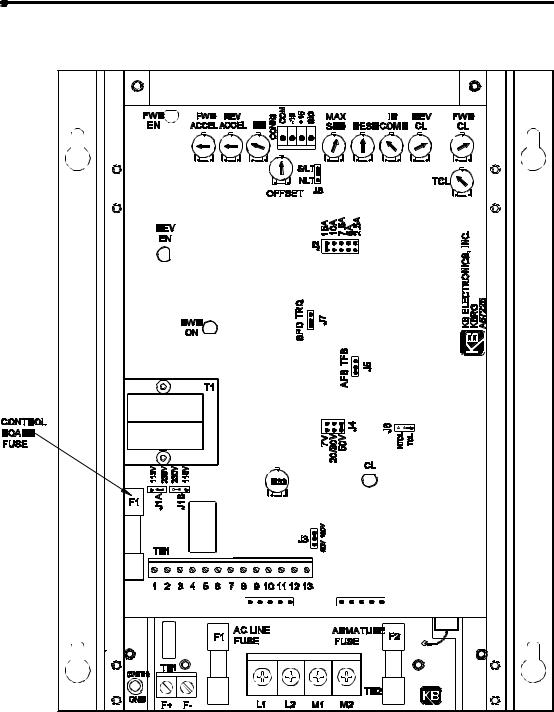

All trimpots have been factory set in accordance with figure 1, page 3.

5.AC LINE FUSE.

The power board on all models contains a single AC line fuse (F1), 25A for KBRG-225D and 20A for KBRG-240D. The AC line fuse protects the unit from catastrophic failure.

6.ARMATURE FUSE.

An armature fuse (F2) is also provided. A 25A armature fuse is installed on the KBRG-225D and a 20A on the KBRG-240D. It is recommended that the correct size armature fuse be installed depending on the rating of the motor and form factor. See table 9, page 13.

7.SIGNAL INPUT.

Connect potentiometer or isolated analog input to terminal “10,” “11,” “12" and “13" according to section V, E and F, on pages 10 and 11. Do not ground (earth) signal inputs. Use a signal isolator when controlling multiple drives from a non isolated signal source.

1

ii. SAFETY WARNING! — PLEASE READ CAREFULLY

ii. SAFETY WARNING! — PLEASE READ CAREFULLY

This product should be installed and serviced by a qualified technician, electrician or electrical maintenance person familiar with its operation and the hazards involved. Proper installation, which includes wiring, mounting in proper enclosure, fusing or other overcurrent protection and grounding, can reduce the chance of electric shocks, fires or explosion in this product or products used with this product, such as electric motors, switches, coils, solenoids and/or relays. Eye protection must be worn and insulated adjustment tools must be used when working with control under power. This product is constructed of materials (plastics, metals, carbon, silicon, etc.) which may be a potential hazard. Proper shielding, grounding and filtering of this product can reduce the emission of radio frequency interference (RFI) which may adversely affect sensitive electronic equipment. If information is required on this product, contact our factory. It is the responsibility of the equipment manufacturer and individual installer to supply this safety warning to the ultimate user of this product. (SW effective 11/92)

This control contains electronic Start/Stop and Inhibit circuits that can be used to start and stop the control. However, these circuits are never to be used as safety disconnects since they are not fail-safe. Use only the AC line for this purpose.

The input circuits of this control (potentiometer, start/stop, Inhibit) are not isolated from AC line. Be sure to follow all instructions carefully. Fire and/or electrocution can result due to improper use of this product.

This product complies with all CE directives pertinent at the time of manufacture. Contact factory for detailed installation instructions and Declaration of

Conformity. Installation of a CE approved RFI filter (KBRF-200A, KB P/N 9945C or equivalent) is required. Additional shielded motor cable and/or AC line cables may be required along with a signal isolator (SI-4X, KB P/N 8801 or equivalent).

I.GENERAL INFORMATION.

The KBRG is a full-wave regenerative control, capable of operating a DC motor (Permanent Magnet or Shunt) in a bidirectional mode. It provides 4-quadrant operation which allows forward and reverse torque in both speed directions. The drive offers excellent controllability, which closely approximates the performance of servo-type drives. Ratings and specifications are presented in tables 1 and 2. Be sure the drive is used within these ratings and specifications.

(Note: Regenerative drives normally produce more motor heating than standard unidirectional SCR speed controls, especially under low speed operation. This should be taken into consideration when specifying motor rating.)

WARNING! Be sure to follow all instructions carefully. Fire or electrocution can result due to improper use of this product. Read Safety Warning.

TABLE 1 – ELECTRICAL RATINGS

|

|

Input |

Max. AC |

Output |

Max. DC |

Max. |

|

Model |

Part No. |

Voltage |

Current |

Voltage |

Output |

Horsepower |

|

|

|

(VAC) |

(RMS) |

(VDC) |

Current (ADC) |

HP, (KW) |

|

KBRG-240D |

8802 |

115 |

16 |

0 – ±90 |

11 |

1, (.75) |

|

230 |

16 |

0 – ±180 |

11 |

2, (1.5) |

|||

|

|

||||||

KBRG-225D |

8800 |

115 |

24 |

0 – ±90 |

16 |

1, (1) |

|

230 |

24 |

0 – ±180 |

16 |

3, (2) |

|||

|

|

2

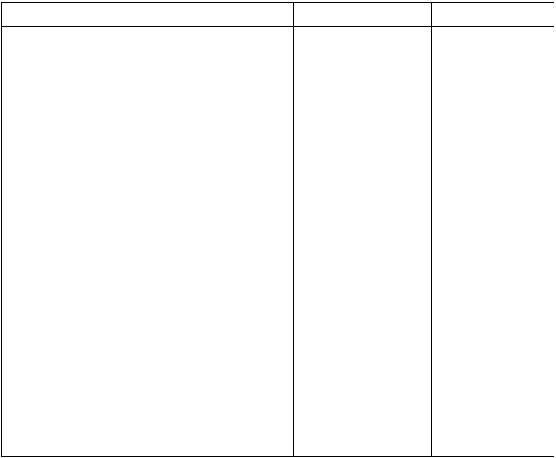

FIG. 1 – CONTROL LAYOUT

Illustrates Factory Setting of Jumpers and Approximate Trimpot Settings

3 |

TABLE 2 – GENERAL PERFORMANCE SPECIFICATIONS

Parameter |

|

Specification |

Factory Setting |

AC Line Input Voltage (VAC ±10%,50/60 Hz) |

115 or 230 |

230 |

|

AC Line Frequency (Hz), # of Phases |

50/60, 1 |

— |

|

Arm Voltage Range at 115VAC Line (VDC) |

0 |

– ±90 |

— |

Arm Voltage Range at 230VAC Line (VDC) |

0 |

– ±180, 0 – ±90 |

0 – ±180 |

Field Voltage at 115VAC Line (VDC) |

100/50 |

— |

|

Field Voltage at 230VAC Line (VDC) |

200/100 |

— |

|

Service Factor |

1.0 |

— |

|

Duty |

Continuous |

— |

|

Max Load Capacity (% for 2 minutes) |

150 |

— |

|

Ambient Temperature Range (ºC) |

0 |

– 50(1) |

— |

Speed Range (Ratio) |

50:1 |

— |

|

Arm Feedback Load Regulation (% Base Speed) |

±1 |

— |

|

Tach Feedback Load Regulation (% Set Speed) |

±1 |

— |

|

Line Regulation (% Base Speed) |

±0.5 |

— |

|

Current Ranges (ADC) |

2.5, 5.0, 7.5, 10, 15(2) |

15 or 10 |

|

FWD and REV Accel Range (Secs.) |

0.1 – 15 |

1 |

|

Dead Band Range (% Base Speed) |

0 |

– ±3 |

0 |

Max Speed Trimpot Range (% Base Speed) |

70 – 110 |

100 |

|

IR Comp Range at 115VAC Line (VDC) |

0 |

– 15 |

5 |

IR Comp Range at 230VAC Line (VDC) |

0 |

– 30 |

10 |

FWD and REV CL Range (% Range Setting) |

0 |

– 150 |

150 |

Timed CL Range (Sec.) |

1 |

– 15 |

5 |

Voltage Following Input Range (VDC) |

0 |

– ±10, 0 – ±15 |

0 – ±15 |

Voltage Following Linearity (% Base Speed) |

±0.5 |

— |

|

Tach-generator Voltage Input (Volts) |

7,20/30,50 |

50 |

|

Notes:

(1)Control mounted in vertical position. Maximum ambient temperature in horizontal position is 45 ºC.

(2)15A current range on KBRG-225D only.

II.SETTING MODE OF DRIVE (SPEED OR TORQUE CONTROL).

The KBRG can be operated as a speed control or torque control by setting the position of jumper J7. The main speed potentiometer controls the magnitude of the mode selected. Set jumper J7 to "SPD" for speed control or to "TRQ" for torque control. (See fig. 1, p. 3.)

A.Speed Control Mode – When jumper J7 is set to the “SPD” position, the KBRG will vary the motor speed as a function of the voltage on input terminals "12" (signal) and "13" (common). IMPORTANT: When J7 is set for speed control (“SPD”), J8 must be set to “S/LT” position (factory setting). The input voltage can be derived from the wiper of the main speed potentiometer or from an isolated analog input (voltage following mode). Since the KBRG is a 4-quadrant regenerative drive, the motor speed will follow both a positive and negative wiper voltage and drive the motor in both the forward direction and reverse direction. In addition, it will apply both forward and reverse torque in order to stabilize motor speed.

To understand the concept of a regenerative drive, the operation of an elevator can be used. If one were to enter the elevator on the first floor and press 10, the motor and control would have to lift the elevator against gravity. In this mode, the drive would operate like a conventional speed control which is called “motoring” (the applied load is opposite to the direction of motor rotation). When the elevator is at floor 10 and floor 1 is pressed, gravity will try to pull the elevator car down faster than the speed for which it is set. The control will then provide reverse torque to keep the car form falling faster than the set speed. This operation is regeneration (the applied load is in the same direction as the direction of motor rotation). Table 3 on page 5 summarizes the different modes of regen operation.

4

Loading...

Loading...