Page 1

• Conveyors • Indexers • Feeders • Positioners

• Textile Equipment • Packaging Machinery

• Web Control • Converting Machinery

DESCRIPTION

The KBMG are ultracompact, full-wave regenerative drives capable of

operating DC PM or Shunt motors in a bidirectional mode. Its (4) quadrant

operation provides forward and reverse torque in both speed directions.

This allows the control to maintain constant speed with overhauling loads

and provides rapid reversing and controlled braking. Because of its excellent controllability and response time, the KBMG can replace servos in

many applications. The control is factory set for armature feedback, which

provides up to 1% load regulation over a motor base speed of 50:1. Tachgenerator feedback is also provided for superior load regulation if required.

A simple jumper setting converts the KBMG to a torque control. In this

mode, motor torque rather than motor speed is controlled.

An important feature of the drive is the factory-calibrated, built-in,

selectable motor current jumper. It eliminates the need to recalibrate IR

Comp and Current Limit for most applications.

The control contains an Enable function that can be used to start and

stop the motor electronically via a contact closure. Through a jumper selection, the motor can be controlled to rapidly “regenerate to stop” or to “coast

to stop.”

KB’s exclusive Auto Inhibit® circuit provides safe, smooth starting

even during rapid cycling of the AC line. The Overspeed Protect Circuit prevents failure of the power bridge in extreme overhauling conditions.

Reliability of the KBMG is further enhanced with the use of a high speed

current limit circuit and MOV transient protection. LED’s, which can be used

for diagnostics, are provided for power on and motor overload. A rugged

extruded aluminum heat sink ensures enhanced heat transfer, which provides a higher control rating while maintaining cooler running SCR’s. The

KBMG contains a finger-safe cover to meet the IP-20 Standard.

Power connections to the KBMG are made via quick connect terminals and signal input connections are made via a removable barrier terminal block. A 5k remote potentiometer and full operating instructions are

supplied.

KBMG SERIES

STANDARD FEATURES

DATA SHEET D-420A

A Complete Line of Motor Drives

1/50 – 1 HP1@ 115 VAC – 50/60 Hz

1/25 – 2 HP

1

@ 230 VAC – 50/60 Hz

ACCESSORIES

• Auxiliary Heat Sink (Part No. 9861) – Increases the control rating to 1 HP at

90 VDC and 2 HP at 180 VDC. Dimensions (L x W x H approx.): 7.0” x 6.3” x 1.9”.

• SIMG Bipolar Signal Isolator (Part No. 8832) – Allows a non-isolated signal

source to be used.

• Multi Speed Board (Part No. 8833) – Provides discrete preset speeds which can

be controlled from a PLC.

• DIN Rail Mounting Kit (Part No. 9995) – Converts control to standard DIN Rail

Mounting.

• Jumper Selectable Features

Operation Mode: Speed, Torque

AC Line Voltage (VAC – 50/60 Hz): 115, 230

DC Armature Voltage (VDC): 90, 180

Tach-generator Voltage (VDC/ 1000 RPM): 7, 50

DC Current Output Ranges (ADC): (0.17 – 1.0, 1.7 – 101)

Analog Input Voltage (VDC): 0 to ±10, 0 to ±15

Enable: Coast to Stop (CTS), Regenerate to Stop (RTS)

• Trimpot Adjustments

Dead Band (DB) • Response (RESP) • IR Compensation (IR)

Forward Current Limit (FCL) • Reverse Current Limit (RCL)

Maximum Speed (MAX) • Forward Acceleration (FACC)

Reverse Acceleration (RACC)

• LEDs

Power On (PWR ON) • Overload (OL)

AC Line Input Voltage (VAC ±10%, 50/60 Hz) . . . . . . . . . . . . . . . . 115 or 230

AC Line Frequency (Hz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50/60

Armature Voltage Range 115 VAC Line (VDC) . . . . . . . . . . . . . . . . . . 0 to ± 90

Armature Voltage Range 230 VAC Line (VDC) . . . . . . . . 0 to ± 90, 0 to ± 180

Field Voltage at 115 VAC Line (VDC) . . . . . . . . . . . . . . . . . . . . . . . . . 100 / 50

Field Voltage at 230 VAC Line (VDC) . . . . . . . . . . . . . . . . . . . . . . . . 200 / 100

Maximum Load Capacity (% for 2 Minutes) . . . . . . . . . . . . . . . . . . . . . . . . 150

Ambient Temperature Operating Range (ºC) . . . . . . . . . . . . . . . . . . . . 0 to 50

Speed Range (Ratio) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50:1

Armature Feedback Load Regulation (% Base Speed) . . . . . . . . . . . . . . . . ±1

3

Tach-generator Feedback Load Regulation (% Set Speed) . . . . . . . . . . . . ±1

3

AC Line Regulation (% Base Speed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±0.5

3

KBMG-21D Current Ranges (Amps DC) . . . . . . . . . . 0.17, 0.25, 0.5, 0.75, 1.0

KBMG-212D Current Ranges (Amps DC) . . . . . . . . . . . 1.7, 2.5, 5.0, 7.5, 10

1

Forward Accel (FACC) and Reverse Accel (RACC) Range (Sec.) . . . . 0.1 to 15

Dead Band Range (% Base Speed) . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 to ±5

Max Speed Trimpot Range (% Base Speed) . . . . . . . . . . . . . . . . . . 55 to 110

3

IR Comp Range at 115 VAC Line (VDC @ Full Load) . . . . . . . . . . . . . . 0 to 20

IR Comp Range at 230 VAC Line (VDC @ Full Load) . . . . . . . . . . . . . . 0 to 40

Forward CL (FCL) and Reverse CL (RCL) Range (% Range Setting) . . 0 to 175

Voltage Following Input Range (VDC)

4

. . . . . . . . . . . . . . . . 0 to ±10, 0 to ±15

Voltage Following Linearity (% Base Speed) . . . . . . . . . . . . . . . . . . . . . . . ±0.5

SPECIFICATIONS

Notes:

1. Maximum rating indicated is with Auxiliary Heat Sink (Part No. 9861). For maximum rating without

Auxiliary Heat Sink see Electrical Rating Chart. 2. CE compliance requires KBRF-200A RFI Filter (or

equivalent) and proper wiring practices. 3. Performance is for 90V PM motors on 115 VAC and 180V PM

motors on 230 VAC. 4. Requires isolated input or SIMG Signal Isolator (Part No. 8832).

ULTRACOMPACT REGENERATIVE DRIVE

FULL-WAVE • 4-QUADRANT • IP-20

SCR Bidirectional Variable Speed and Torque Control

for PM and DC Shunt Motors

Models KBMG-21D, 212D cover:

2

TM

Page 2

KB ELECTRONICS, INC.

12095 NW 39th Street, Coral Springs, FL 33065-2516 • (954) 346-4900 • Fax (954) 346-3377

Outside Florida Call Toll Free (800) 221-6570 • E-mail – info@kbelectronics.com

www.kbelectronics.com

(A42094) – Rev. B – 8/2004

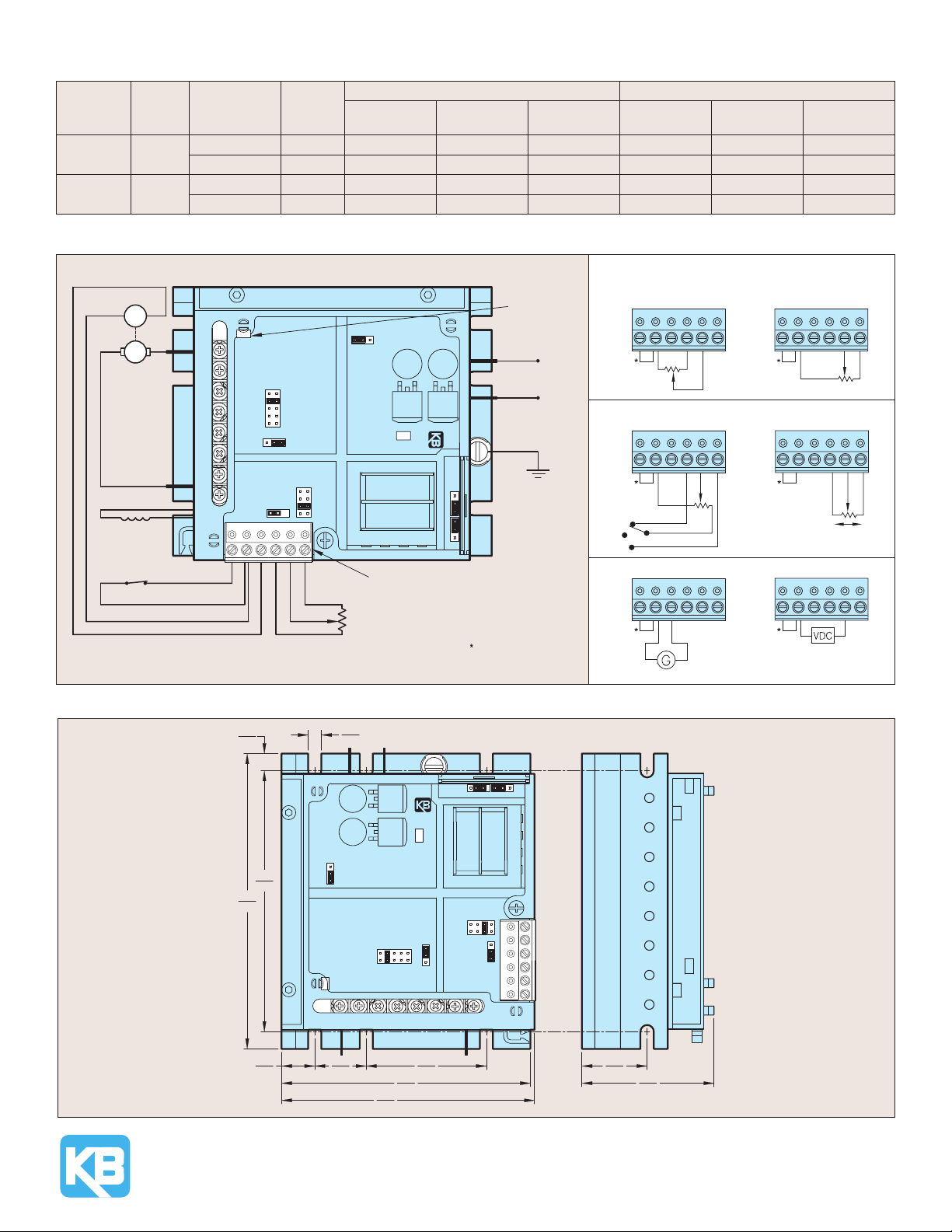

ELECTRICAL RATINGS

CONNECTION DIAGRAMS

Model Part No.

AC Line Voltage

(VAC) ±10%

50/60 Hz

Motor

Voltage

(VDC)

Maximum Rating Without Auxiliary Heat Sink Maximum Rating With Auxiliary Heat Sink

AC Line Current

(RMS Amps)

DC Load Current

(Avg. Amps)

Horsepower

HP, (kW)

AC Line Current

(RMS Amps)

DC Load Current

(Avg. Amps)

Horsepower

HP, (kW)

KBMG-21D 8830

115 0 – ±90 1.5 1.0 .075, (.06) — — —

208 /230 0 – ±180 1.5 1.0 .15, (.11) — — —

KBMG-212D 8831

115 0 – ±90 12.0 8.0 .75, (.6) 16.0 11.0 1.0, (.75)

208 /230 0 – ±180 12.0 8.0 1.5, (1.1) 16.0 11.0 2.0, (1.50)

MECHANICAL SPECIFICATIONS (Inches / mm)

MAIN SPEED POTENTIOMETER CONNECTIONS

(Note: Jumper J4 in “15V” Position)

DATA SHEET D-420A

DC Tach-Generator

G

-

+

-

+

M

M1

Motor Armature

M2

-

+

Motor Field

(shunt motors only)

Enable Switch

(close to run, open to stop)

FORWARD

COMEN TACH +15V SIG –15V

TB1

5k

BIDIRECTIONAL WITH

REVERSING CONTACT

COMEN TACH +15V SIG –15V

TB1

5k

TACH-GENERATOR

COMEN TACH +15V SIG

TB1

DC TACH – GENERATOR

–15V

+–

COMEN TACH +15V SIG –15V

TB1

BIDIRECTIONAL WITH

COMEN TACH +15V SIG –15V

TB1

VOLTAGE FOLLOWING

COMEN TACH +15V SIG –15V

TB1

(NOTE: JUMPER J4 IN "10V"

POSITION. SIGNAL MUST

BE ISOLATED.)

RCL RACCMAX FACCFCLRESP IRDB

F-

F+

J2

5.0

1.7A2.510A 7.5

SPD

TRQ

J5

15V

10V

TB1

EN TACHCOM SIG+15V -15V

J4

Overload LED (OL) is located

below Finger-Safe Cover.

RTS

CTS

J6

L2

AC Line Input

(50/60 Hz)

L1

LED1

PWR

ON

J3

T50

T7

A180

A90

Terminal Block TB1 is removable

Low

Wiper

High

to facilitate wiring.

Bidirectional

Main Speed Potentiometer

(Jumper J4 set to the "15V" position)

230V115V J1B 115VJ1A

Chassis

Ground (Earth)

STOP

Notes:

1. Trimpots and jumpers are

shown in factory set position.

2. For 7V/1000 RPM tach-generator,

set Jumper J3 to the "T7" position.

For 50V/1000 RPM tach-generator,

set Jumper J3 to the "T50" position.

A connection must be made between

"EN" and "COM" for control to operate.

FWD

REV

REVERSE

SPEED POT

FWD

5k

5k

REV

0 – ±10V

0.25

6.35

3.80

96.5

4.30

109

0.49

12.4

0.19

8 Places

4.83

115V115V J1AJ1B 230V

PWR

LED1

ON

J6

CTS

RTS

T50

A180T7A90

J3

RACC

J4

10V

15V

+15V

COM TACH -15VSIG

EN

TB1

0.75

19.1

J5

SPD

J2

RESP IRDB

3.69

93.7

TRQ

2.5 1.7A

7.510A 5.0

RCL

MAX FACCFCL

1.75

44.5

3.63

92.1

0.95

24.1

1.95

49.5

Loading...

Loading...