Page 1

Page 2

Page 3

Page 4

Page 5

Page 6

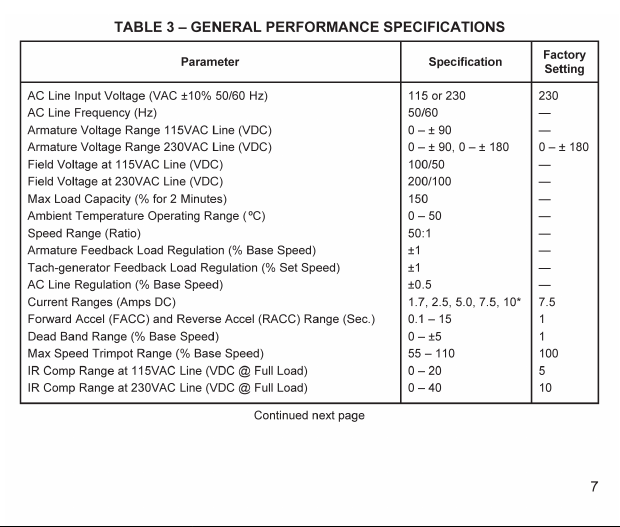

Page 7

Page 8

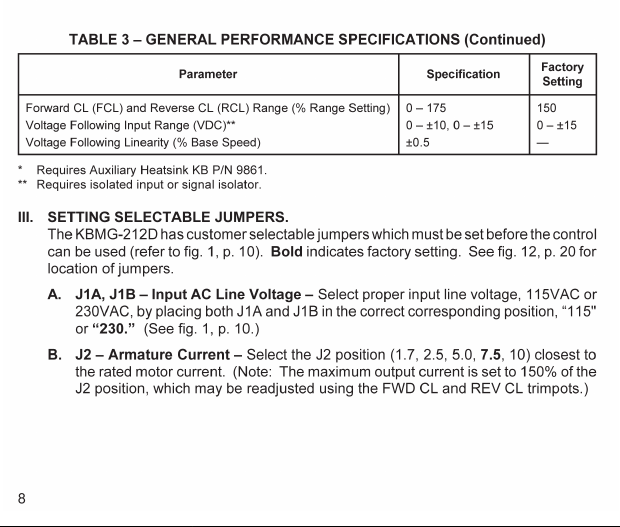

Page 9

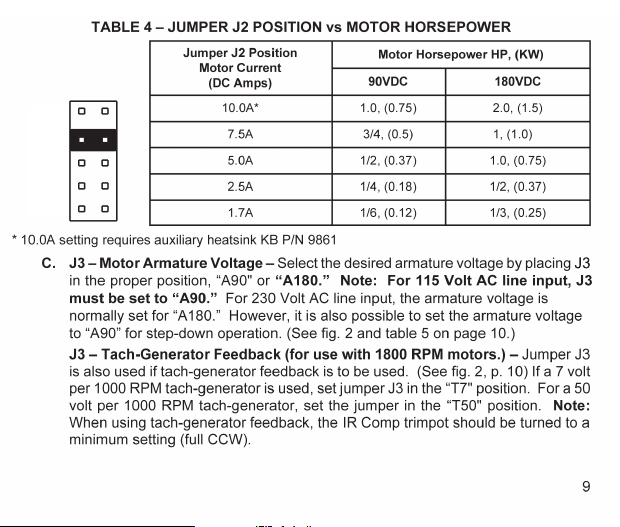

Page 10

Page 11

10A

7.5A

5.0A

2.5A

1.7A

Page 12

J1A J1A

115V

230V

J1B

230V

115V

115V

230V

230V

115V

J1B

T50

J3 J3

T7

A180

A90

T50

T7

A180

A90

Page 13

J4 Set

for 15V

Position

10V

15V

J4 Set

for 10V

Position

10V

10V

15V

J5

SPD

TRQ

J5

SPD

TRQ

Page 14

J6 J6

CTS

RTS

CTS

RTS

Page 15

FIG. 6 – SPEED CONTROL MODE

13

HIGHER

SET SPEED

LOWER

SET SPEED

APPLIED LOAD (TORQUE) (%)

CL

SETPOINT

MOTOR SPEED (%)

00101020203030404050506060707080809090100

100

110 120 130 140 150

Page 16

FIG. 7 – TORQUE CONTROL MODE (Linear)

100

90

80

70

60

50

MOTOR SPEED (%)

40

30

20

10

LOWER TORQUE SETTING

0

0102030405060708090 100

S1

S2

HIGHER TORQUE SETTING

APPLIED LOAD (TORQUE) (%)

14

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

FIG. 13 – MECHANICAL SPECIFICAT IONS (INCHES / [mm])

3.625

[92.08]

0.250

[6.35]

1.75

[44.45]

4.300

[109.22]

0.485

[12.32]

0.750

[19.05]

2.500

[63.50]

0.190

[4.83]

3.800

[96.52]

0.950

[24.13]

21

Page 24

FIG. 14 – VOLTAGE

FOLLOWING CONNECTION

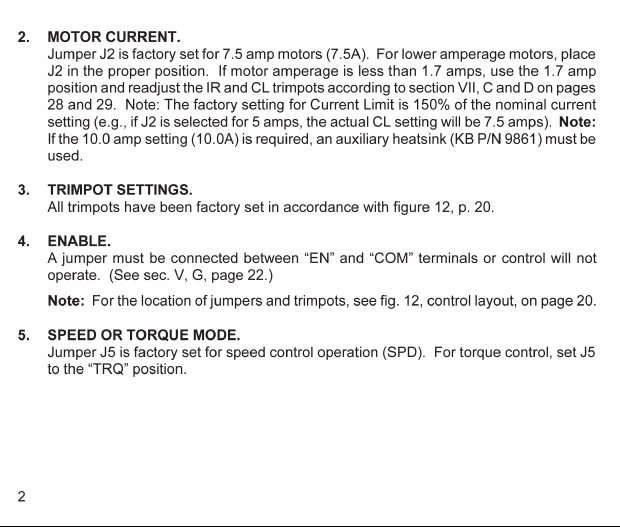

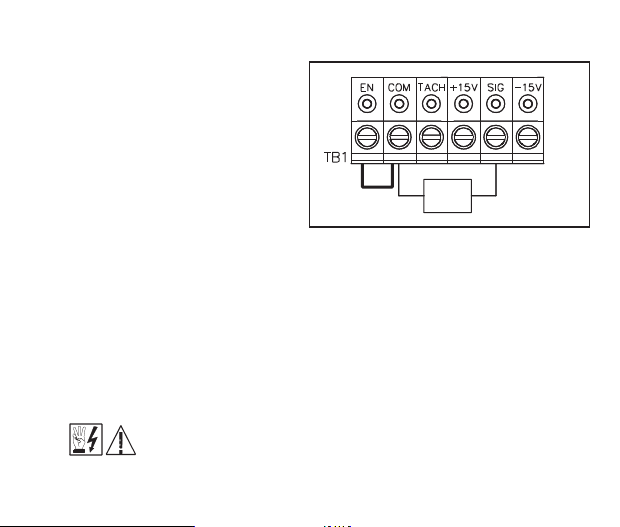

F. Vo ltage Following – An isolated

analog voltage can be used in lieu

of main speed potentiometer.

Connect signal to terminals “SIG"

and “COM.” Note: Te rminal “COM"

is common. A positive signal to

terminal“SIG” will produce a

positive output to motor.

A negative signal to terminal

“SIG" will produce a negative

output. A 0 to ±10VDC is required

to operate control from 0 ± full

output. Note: Jumper J4 must be

in the “10V” position. Note: An isolated signal voltage must be used or

catastrophic failure can result. (A bipolar signal isolator, model SIMG [KB P/N

8832], is available as an option from your distributor. )

G. Enable Start/Stop Circuits – The KBMG-212D contains a 2-wire stop circuit

(Enable), which is used to electronically bring the motor to a “stop.” An isolate

d

single contact closure is required. If an isolated contact is not available, it may be

necessary to use an isolation relay.

*Note: If 2-wire start/stop circuit is not used, a jumper must be wired to EN

and COM or control will not operate.

WARNING! Do not use Start/Stop or Enable functions as a safety

disconnect. Use only an AC line disconnect for that purpose.

22

Jumper*

VDC

0 – ±10V

Page 25

i. Regen to a stop using terminals EN and COM on terminal block TB1 –

When a contact is opened between terminals “EN” and “COM,” with jumper J6

in the “RTS” position, the motor will regeneratively brake to a rapid stop.

Application note (See fig. 15): If controlled regen to stop is required, a contact

can be installed in series with the signal “SIG” connection. T he braking time will

be equal to the REV ACCEL setting when the motor is in the forward direction,

and equal to the FWD ACCEL setting when the motor is in the reverse direction.

Note: J4 must be in the “15V” position. (See fig. 11D, p. 19.)

ii. Coast to a stop using terminals “EN” and “COM” on terminal block TB1 –

If coast to stop operation is required, move jumper J6 to the coast to stop (CTS)

position. When the contact is opened between “EN” and “COM,” the motor will

coast to a stop. See fig. 16.

ENABLE

OPEN TO REGENERATE TO STOP

FIG. 15 – REGENERATE TO STOP

ENABLE

OPEN TO COAST TO STOP

FIG. 16 – COAST TO STOP

*FWD Accel and REV Accel do not affect the stopping time when the enable circuit is opened.

23

J6

CTS

RTS

J6

CTS

RTS

Page 26

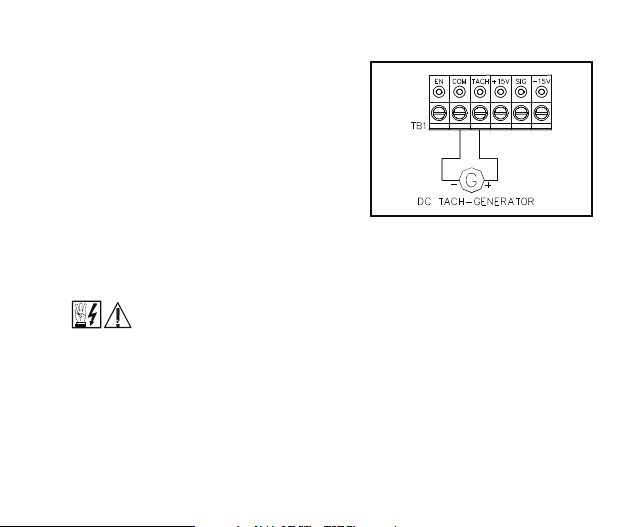

FIG. 17 – TACH-GENERATOR

FEEDBACK

H. Tach-generator Feedback – The KBMG-

212D is factory set for armature feedback,

which provides good load regulation for most

applications. For superior load regulation,

analog tach-generator feedback can be

used.

Wire the tach-generator so that the polarity of

the tach-generator is the same with respect

to the input signal polarity (see fig. 17).

Note: If tach-generator is wired with reverse

polarity, the motor will run at full speed.

Note: Jumper J3 must be set to the proper

position for tach feedback. See sec III, C, p. 9 and fig. 2 on page 10. Note: Check

tach voltage polarity with respect to input signal if polarity does not match reverse

tach leads.

Be sure AC line is disconnected when rewiring tach-generator.

VI.FUSING.

Armature Fuse – It is recommended that the correct size armature fuse be installed,

depending on the rating of the motor and form factor (RMS/AVG current). Fuse type

should be Littelfuse 326 ceramic or Buss ABC, or equivalent. A fuse chart is presented

below which suggests appropriate armature fuse ratings. However, the specific

application may require larger fuse ratings based on ambient temperature, CL set point

and duty cycle of operation (see table 8, p. 25). Fuses may be purchased from your

distributor. Wire fuse in series with armature lead.

24

Page 27

TABLE 8 – ARMATURE FUSE CHART

Motor Horsepower

90VDC 180VDC

Approx. DC

Motor

Current Amps

Fuse Rating

(AC Amps)

1/81/4 1.32

1/61/3 1.72

1/41/2 2.54

1/33/4 3.35

1/215.08

3/417.512

1210.0 20

VII. TRIMPOT ADJUSTMENTS.

The KBMG-212D contains trimpots that have been factory adjusted for most

applications. See specifications for factory settings. (Note: Fig. 12, p. 20, presents the

various trimpots with their location. They are shown in the approximate factory

position.) Some applications may require readjustment of trimpots in order to tailor

control to exact requirements. Readjust trimpots as follows:

25

Page 28

A. Forward Acceleration

FIG. 18 – ACCEL TRIMPOT ADJUSTMENT

(FWD ACCEL) and

Reverse Acceleration

(REV ACCEL) – The FWD

ACCEL trimpot determines

the amount of time it takes

100

(%)

SPEED

the control voltage to reach

full output in the forward

direction. It also determines

the amount of time it takes

0

for the control voltage, in the

reverse direction, to reach

zero output. (FWD ACCEL

is the Reverse Decel.)

The REV ACCEL trimpot

determines the amount of

-100

time it takes the control

voltage to reach full output in the reverse direction and the time it takes for the

control voltage, in the forward direction, to reach zero output. (REV ACCEL is the

Forward Decel.)

The FWD and REV ACCEL trimpots are factory adjusted to approximately 1

second. The acceleration times are adjustable over a range of 0.1 to 15 seconds.

See fig. 18 for graphical representation of ACCEL.

Note: The FWD and REV CL trimpots may override the rapid accel and decel

settings.

26

ACCEL TRIMPOT SETTING

7.5

14.01.0

0.115.0

SECONDS

time

Page 29

FIG. 19 – DEAD BAND TRIMPOT ADJUSTMENT

Note: A 4-quadrant

ACCEL/DECEL accessory

module (KB P/N 8834) is

available as an option.

It provides separate control

of FORWARD acceleration

and deceleration and

REVERSE acceleration

and deceleration.

B. Dead Band Trimpot (DB) –

The DB trimpot sets the

amount of main speed

potentiometer rotation or

analog voltage input

required to initiate control

voltage output. It is factory

adjusted to approximately

25% of rotation.

The DB trimpot also determines the amount of delay that will occur before

regeneration starts. Regeneration occurs when the applied load torque is in the

same direction as the motor rotation.

To readjust the DB to factory setting:

i. Set Main Speed pot to zero speed position.

ii. Set DB trimpot to full CCW position.

27

100

CURVE (a): NO DEAD BAND

CURVE (b): MAX. DEAD BAND

100

-100

-100

(%)

SPEED

a

b

Page 30

iii. Adjust DB trimpot CW until motor hum is eliminated. (See fig. 19, p. 27 for

graphic illustration of the DB trimpot.) Note: If the dead band trimpot is set too

low (CCW direction), the motor may oscillate between forward and reverse.

Adjust dead band trimpot CW until the instability disappears. (Oscillation may

also occur due to RESP and IR COMP trimpot settings. See sec. VII, D & F on

page 29.)

C. Forward Current Limit (FWD CL) and Reverse Current Limit (REV CL)

Trimpots – These trimpots are used to set the maximum amount of DC current that

the motor can draw in both the forward and reverse directions. The amount of DC

current determines the amount of maximum motor torque. They are factory set at

150% of the current established by the jumper J3 setting.

Readjust the CL trimpot as follows:

i. Turn CL trimpot to MIN (CCW) position. Be sure jumper J2 is in the proper

position approximately equal to the motor DC ampere rating.

ii. Wire in a DC ammeter in series with armature lead. Lock shaft of motor.

iii. Apply power. Rotate CL trimpot quickly until desired CL setting is reached

(factory setting is 1.5 times rated motor current). Be sure control is in forward

direction for FWD CL trimpot adjustment and likewise with REV CL.

Warning! To prevent motor damage, do not leave motor shaft locked fo r

more than 2 – 3 seconds.

Caution! Adjusting the CL above 150% of motor rating can cause

overheating and demagnetization of some PM motors. Consult motor

manufacturer.

28

Page 31

Page 32

Page 33

31

Page 34

32

Page 35

33

Page 36

Loading...

Loading...