Page 1

BR 40/10 C

English 3

Français 10

Español 19

59630320 07/12

Page 2

2

Page 3

IMPORTANT SAFETY IN-

English

STRUCTIONS

READ ALL INSTRUCTIONS

BEFORE USING.

WARNING

To reduce the risk of fire, electric

shock, or injury:

– Do not leave appliance when

plugged in. Unplug from outlet

when not in use and before servicing.

WARNING

– TO REDUCE THE RISK OF ELEC-

TRIC SHOCK-USE INDOORS

ONLY

– Do not allow to be used as a toy.

Close attention is necessary when

used by or near children.

– Use only as discribed in this manu-

al. Use only manufacturer`s recommended attachments.

– Do not use with damaged cord or

plug. If appliance is not working as

it should, has been dropped, damaged, left outdoors, or dropprd into

water, return it to a service center.

– Do not pull or carry by cord, use

cord as a handle, close a door on

cord, or pull cord around sharp edges or corners. Do not run appliance

over cord. Keep cord away from

heated surfaces.

– Do not unplug by pulling on cord. To

unplug, grasp the plug, not the

cord.

– Do not handle plug or appliance

with wet hands.

– Do not put any object into openings.

Do not use with any opening

blocked; keep free of dust, lint, hair,

and anything that may reduce air

flow.

– Keep hair, loose clothing, fingers,

and all parts of body away from

openings and moving parts.

– Turn off all controls before unplug-

ging.

– Use extra care when cleaning on

stairs.

– Do not use to pick up flammable or

combustible liquids, such as gasoline, or use in areas where they may

be present.

– Connect to a properly grounded

outlet only. See Grounding Instruction.

SAVE THESE INSTRUCTIONS

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it

should malfunction or breakdown,

grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This appliance is equipped with a cord having an

equipment-grounding conductor and a

grounding plug. The plug must be inserted into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

WARNING

Improper connection of the equipment

grounding conductor can result in a

risk of electric shock. Check with a

qualified electrician or service person if

you are in doubt as to whether the outlet is properly grounded. Do not modify

the plug provided with the appliance-if

it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

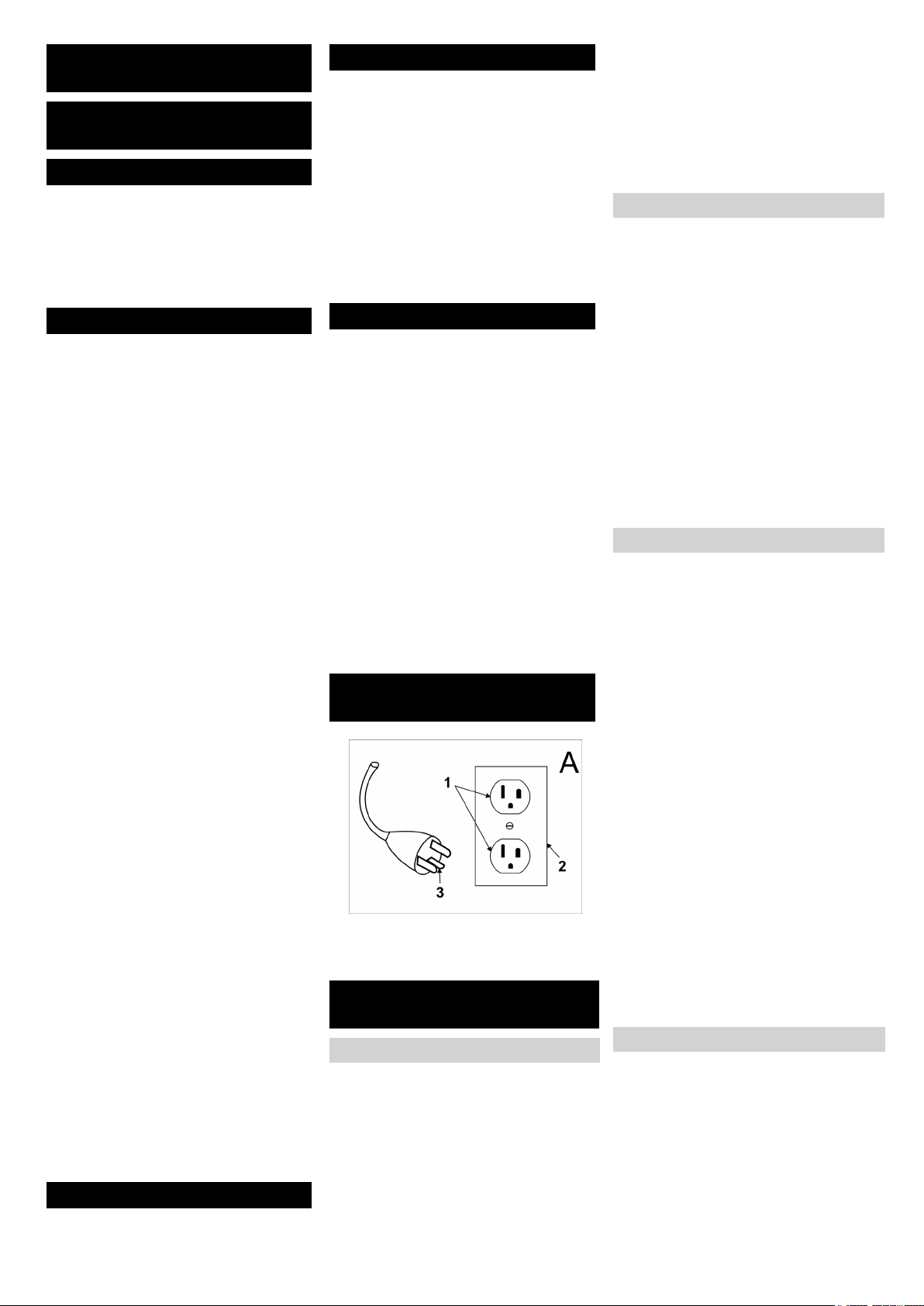

This appliance is for use on a nominal

120-volt circuit and has a grounding attachment plug that looks like the plug

illustrated in sketchpicture A. Make

sure that the appliance is connected to

an outlet having the same configuration as the plug. No adaptor should be

used with this appliance.

CONNECT TO A PROPERLY

GROUNDED OUTLET ONLY

1 Grounded outlet

2 Grounded outlet Box

3 Grounded Pin

OPERATING SAFETY RULES

AND PRACTICES

Operator Responsibility

Save operation is in the responsibility

of the operator.

The operator shall be familiar with the

operation and function of all controls

and instruments before undertaking to

operate the unit.

Before operating the unit, operators

shall have read and be familiar with the

operator’s manual for the particular

unit being operated and they shall also

abide by the safety rules and practices

in the following paragraphs.

Before operating any unit, the operator

shall be familiar with unusual operating

conditions which may require additional safety precautions or special operating instructions.

General

Before starting to operate the unit be in

operating position.

Do not start or operate the unit, any of

its functions or attachments, from any

place other than from the designated

operators position.

Before leaving the operator’s position:

A bring the unit to a complete stop;

B if the unit must be on an incline,

block the wheels.

Maintain a safe distance from the edge

of ramps, platforms, and other similar

working surfaces.

Do not add to, or modify the unit.

Do not block access to fire aisles, stairways or fire equipment.

Travelling

Yield the right of way to pedestrians

and emergency vehicles such as ambulances and fire trucks.

Cross railroad tracks at an angle wherever possible. Do not park closer than

6 ft (1800 mm) to the nearest rail of a

railroad track.

Keep a clear view of the path of travel

and observe for other traffic, personnel, and safe clearances.

Under all travel conditions, operate the

unit at a speed that will pernit it to be

brought to a stop in a safe manner.

Do not indulge in stunt driving or horseplay.

Slow down for wet and slippery floors.

Before driving over a dockboard or

bridge plate, be sure that it is properly

secured. Drive carefully and slowly

across the dockboard or bridge plate,

and never exceed its rated capacity.

When negotiating turns, reduce speed

to a safe level consistent with the operating environment. Make the turns

smoothly.

Operator care of the unit

If the unit is found to be in need of repair or in any way unsafe, or contributes to an unsafe condition, the matter

shall be reported immediately to the

user’s designated authority, and the

unit shall not be operated until it has

been restored to safe operating condition.

If during operation the unit becomes

unsafe in any way, the matter shall be

- 1

3EN

Page 4

reported immediately to the user’s designated authority, and the unit shall not

be operated until it has been restored

to safe operating condition.

Do not make repairs or adjustments

unless specifically authorized to do so.

MAINTENANCE AND REBUILD

PRACTICES

Operation of the unit may be hazardous if maintenance is neglected or repairs, rebuilds, or adjustments are not

performed in accordance with the manufacturer’s design criteria. Therefore,

maintenance facilities (on or off premises), trained personnel, and detailed

procedures shall be provided.

Maintenance and inspection of the unit

shall be performed in conformance

with the following practices:

A a schedules planned maintenance,

lubrication, and inspection system

shall be followed; consult the manufacturer’s recommendations.

B only tranined and authorized per-

sonnel shall be permitted to maintain, repair, adjust, and inspect the

unit, and in accordance with manufacturer’s specifications.

Avoid fire hazards and have fire protection equipment present in the work

area. Do not use open pans of fuel or

flammable cleaning fluids for cleaning

parts.

FIRE SAFETY STANDARD

Any unit not in safe operating condition

shall be removed from service.

Repairs shall not be made in Class I,

Class II, and Class III locations.

Fire Prevention: The unit shall be kept

in a clean condition and reasonably

free of lint, excess oil, and grease.

Noncombustible agents are preferred

for cleaning the unit. Flammable liquids

[those having flash points at or above

100°F (37,8°C)] are not allowed. Precautions regarding toxicity, ventilation,

and fire hazard shall be appropriate for

the agent or solvent used.

Nameplate Visibility: The unit type designations as shown on the nameplate

and the type markers shall not be covered over with paint so that their identification information is obscured.

The unit shall not be used in classified

areas.

Please read and comply

with these instructions prior to the initial operation of your appliance. Retain these operating

instructions for future reference or for

subsequent possessors.

Contents

Function. . . . . . . . . . . . . . . . EN . . . 2

Proper use . . . . . . . . . . . . . . EN . . . 2

Environmental protection. . . EN . . . 2

Operating elements . . . . . . . EN . . . 3

Before Commissioning. . . . . EN . . . 3

Operation. . . . . . . . . . . . . . . EN . . . 4

Maintenance and care . . . . . EN . . . 5

Faults. . . . . . . . . . . . . . . . . . EN . . . 5

Specifications. . . . . . . . . . . . EN . . . 6

Accessories . . . . . . . . . . . . . EN . . . 7

Warranty . . . . . . . . . . . . . . . EN . . . 7

Spare parts . . . . . . . . . . . . . EN . . . 7

Safety instructions

Before using the appliance for the first

time, read and observe these operating instructions and the accompanying

brochure: Safety information for brush

cleaning units and spray-extraction

units, 5.956-251.

Symbols

The following symbols are used in this

operating manual:

Danger

Indicates an immediate threat of danger. Failure to observe the instruction

may result in death or serious injuries.

몇 Warning

Indicates a possibly dangerous situation. Failure to observe the instruction

may result in light injuries or damage to

property.

Note

Indicates useful tips and important information about the product.

Function

The appliance is used for the wet

cleaning or polishing of level floors.

Two brush rollers located opposite of

each other clean the floor by means of

the added detergent liquid. A working

width of 400 mm and a capacity of 10 l

each of the fresh and dirt water reservoirs allow for effective cleaning.

The power supply operation allows a

high capacity without a restriction of

the working time.

Note

The appliance can be equipped with

various accessories depending on the

cleaning task. Please request our catalogue or visit us on the Internet at

www.kaercher.com.

Proper use

Use this appliance only as directed in

these operating instructions.

– The appliance may only be used for

the cleaning of hard surfaces that

are not sensitive to moisture and

polishing operations.

The application temperature ranges

from +5°C to +40°C.

– The appliance is not suited for the

cleaning of frozen grounds (e.g. in

cold stores).

– The appliance may only be

equipped with original accessories

and spare parts.

– The appliance has been designed

for the cleaning of floors inside or or

covered surfaces. With respect to

other applications the usage of alternative brushes must be checked.

– The appliance is not intended for

the cleaning of public traffic routes.

Environmental protection

The packaging materials

are recyclable. Please do

not throw packaging in the

domestic waste but pass it

on for recycling.

Old units contain valuable

recyclable materials. Batteries, oil and similar substances may not be released into

the environment. Therefore

please dispose of old units

through suitable collection

systems.

Notes about the ingredients

(REACH)

You will find current information about

the ingredients at:

www.kaercher.com/REACH

4 EN

- 2

Page 5

25

24

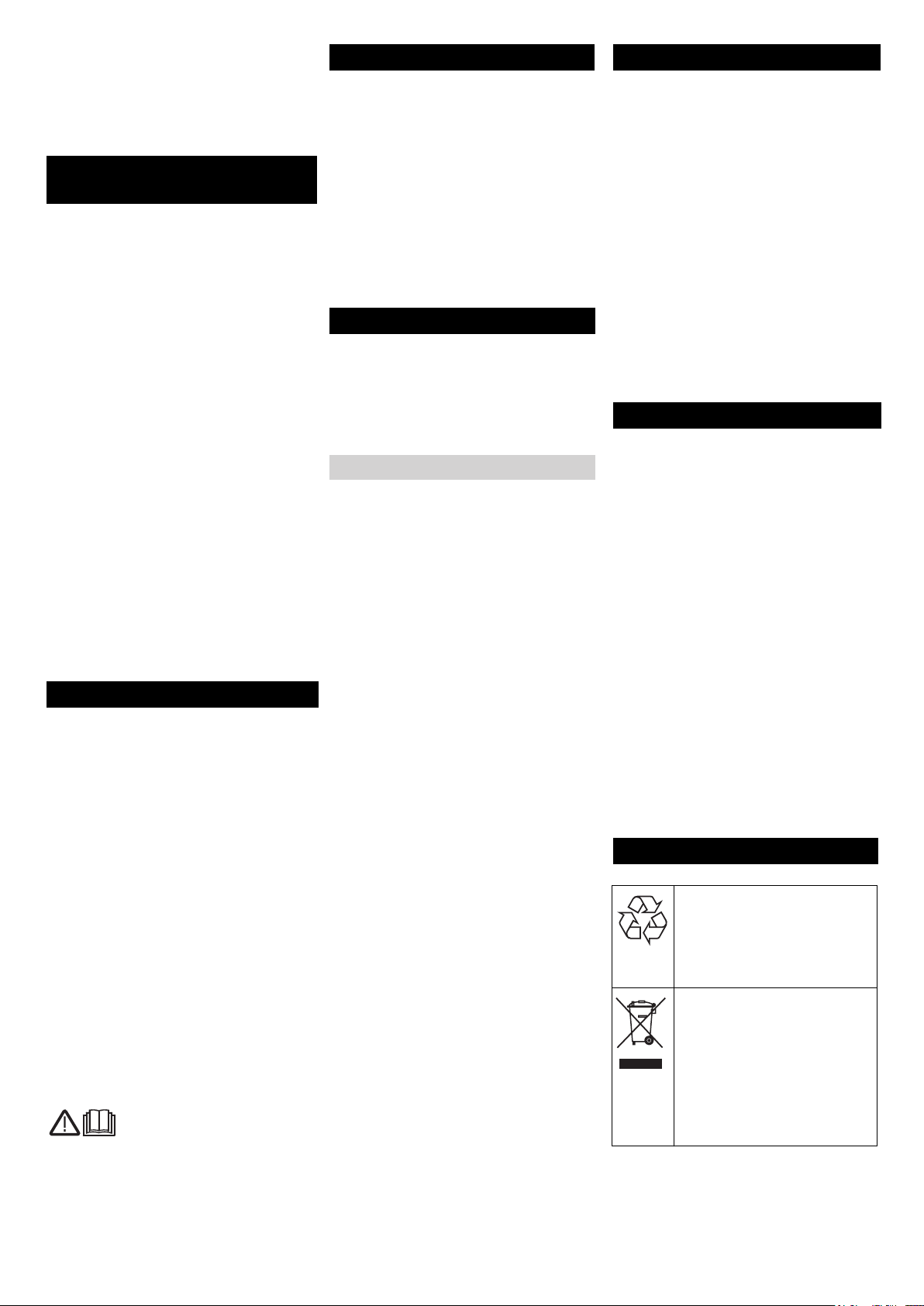

Operating elements

1 Lock for fresh water reservoir

2 Switch for brush drive

3 Switch for detergent solution

4 Hose for detergent solution

5 Lint sieve (suction)

6 Lock of pushing handle

7 Release button for the transport

wheel

8 Bearing wheel

9 Push handle

10 Strain relief clamp

11 Support of the transport wheel

12 Clip

13 Fresh water tank

14 Dirt water reservoir

15 Push-button for vacuum bar

change

16 Float

17 Button for brush change

18 Chassis

19 Vacuum bar

20 Brushing rollers

21 Rotating handle for brush contact

pressure

22 Pedal to lower vacuum bar

23 Mains plug

24 Carrying handle for wastewater res-

ervoir

25 Fresh water tank cover

Before Commissioning

Installing the pushing handle

Slide the upper slider half onto the

lower slider half.

몇 Warning

Risk of damage. Do not pinch the cable

during the installation.

Align the borings (2 possible height

adjustments).

Connect the slider halves to the

lock screws, discs and star grips.

Fasten the cable to the slider using

clips.

Installing the transport wheels

Insert the transport wheel axles into

the borings on the appliance and

lock them.

Installing the Brushes

The brushes must be installed before

the initial operation (see "Maintenance

works").

- 3

5EN

Page 6

Operation

Driving to the Place of Use

Establish mains contact

Note

To take the brush drive out of operation, immediately release brush drive

switch.

Filling in detergents

몇 Warning

Risk of damage. Only use the recommended detergents. With respect to

different detergents the operator bears

the increased risk regarding the operational safety and danger of accident.

Only use detergents that are free from

solvents, hydrochloric acid and hydrofluoric acid.

Note

Do not use highly foaming detergents.

Observe the dosing notes.

Recommended detergents:

Application Detergent

Routine cleaning of all

water resistant floors

Routine cleaning of

glossy surfaces (e.g.

granite)

Routine cleaning and

basic cleaning of industrial floors

Routine cleaning and

basic cleaning of fine

stoneware tiles

Routine cleaning of tiles

in sanitary areas

Cleaning and disinfection in sanitary areas

Removal of coating

from all alkali-resistant

floors (e.g. PVC)

Removal of coating

from linoleum floors

Open the cover of the fresh water

reservoir.

Pour in water/detergent mixture.

Maximum temperature of the liquid

50°C

Note

The fresh water reservoir cover can be

used to meter the detergent. The capacity of the cover up to the mark represents 1% of the fresh water reservoir

capacity.

Close the cover of the fresh water

reservoir.

RM 746

RM 780

RM 755 es

RM 69

ASF

RM 753

RM 751

RM 732

RM 752

RM 754

Short distances on even surfaces

Place the slider vertically.

Position the rotary handle for the

brush contact pressure in the drive

position.

Use the pushing handle to push the

appliance to the place of use.

Longer distances on uneven surfaces

Place the slider vertically and tilt the

lock up.

Install the transport wheels.

몇 Warning

Danger of damage due to leaking water. Remove the waste water and fresh

water reservoirs before tilting the appliance.

Remove the filled waste and fresh

water reservoirs from the appliance

and transport them separately.

Tilt the appliance to the side and

drive it to the place of use on its

transport wheels.

If the transport wheels hinder the use

of the appliance:

Press the transport wheel release

button and pull the transport wheel

out.

Insert the transport wheels into their

holder until they stop.

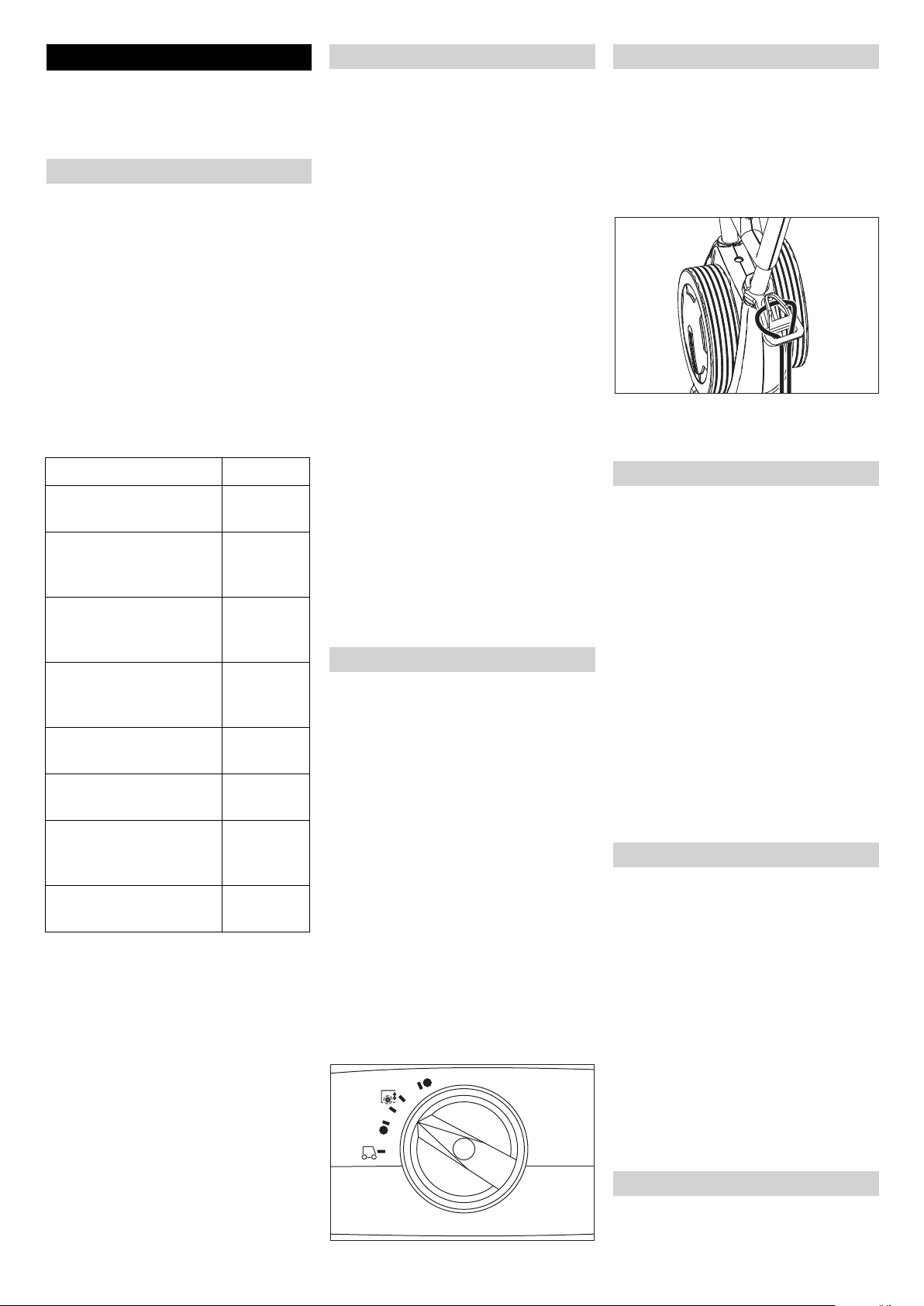

Adjust the brush contact pressure

Place the slider vertically.

Adjust the rotary handle of the

brush contact pressure to the desired value.

Note

Carry out the initial cleaning attempts

with less contact pressure. Increase

contact pressure step-by-step until the

desired cleaning result is achieved. A

correct setting of the contact pressure

reduces the wear and tear of the

brushes.

The brush drive is switched off when

there is overload.

When cleaning with microfibre rollers,

the contact pressure must not be adjusted higher than the position mentioned below. With a higher contact

pressure, there is a danger of destroying the microfibre rollers.

+

-

Danger

Check the mains cables of the machine each time before using the machine to see that it is not damaged.

Never operate a machine with damaged cables. Get the damaged cables

replaced by an electrician.

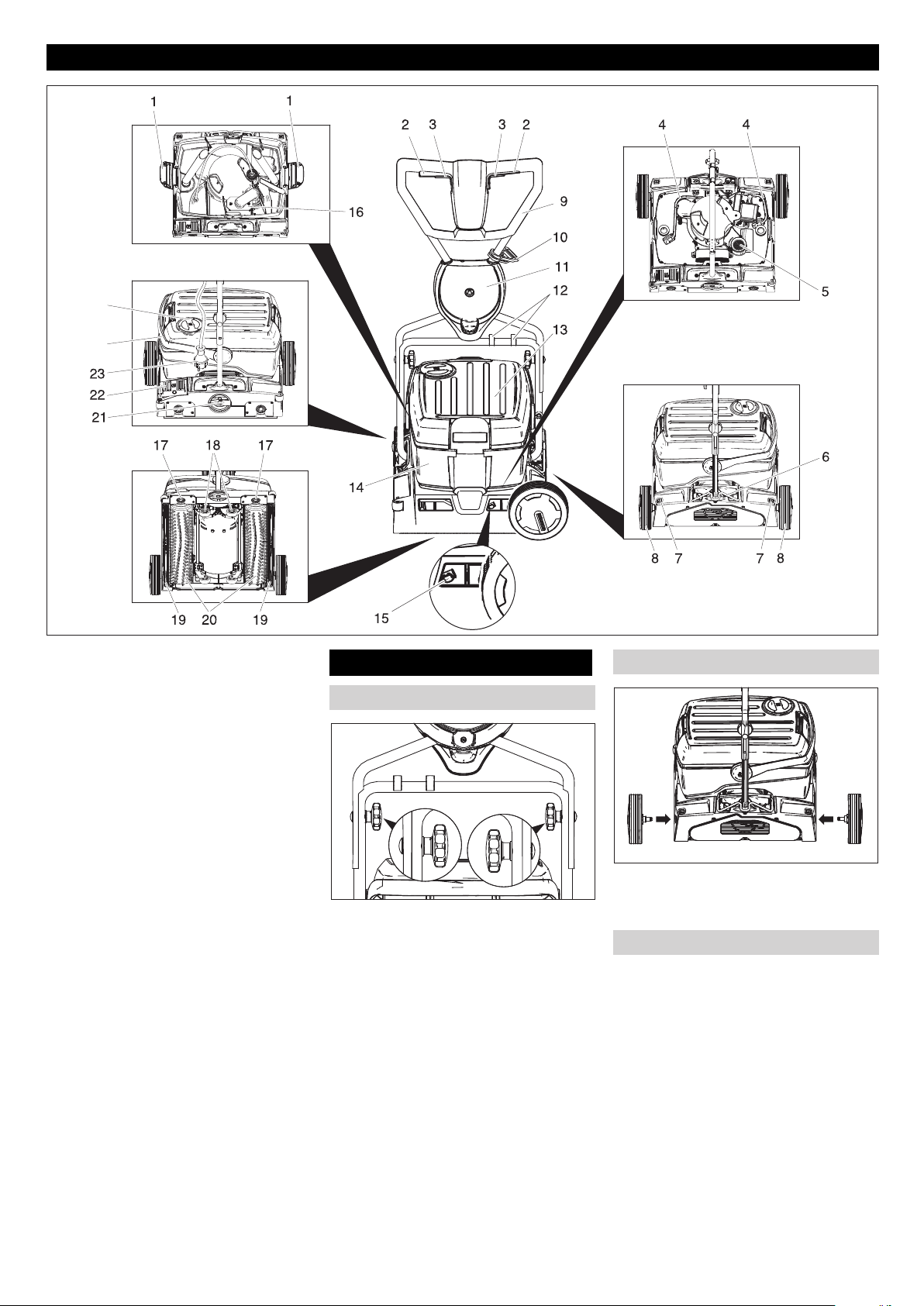

Insert the looped end of the exten-

sion cable in the strain relief hook.

Plug in the mains plug.

Cleaning

If the detergent solution is to be

vacuumed off after the cleaning

process, use the vacuum bar lowering pedal.

Swivel the slider toward the opera-

tor - the chassis is retracted and the

brushes touch the floor.

Turn on the brushes by using the

switch for the brush drive.

Turn on the brush irrigation by us-

ing the switch for the detergent solution.

Move the appliance over the sur-

face to be processed by the slider.

몇 Warning!

Risk of damage to the floor covering.

Do not operate the appliance on the

spot.

Polishing

Swivel the slider toward the opera-

tor - the chassis is retracted and the

brushes touch the floor.

Turn on the brushes by using the

switch for the brush drive.

Move the appliance over the sur-

face to be processed by the slider.

몇 Warning!

Risk of damage to the floor covering.

Do not operate the appliance on the

spot.

Note

To polish furniture, the fresh water and

wastewater reservoirs can be removed.

Shutting Down the Appliance

6 EN

Release the switch for detergent

solution.

- 4

Page 7

Push the appliance forward for an-

other 1-2 m to draw off residual wa-

ter.

Release the brush drive button.

Press the pedal to lower the vacu-

um bar.

Place the slider vertically - the

brushes are elevated.

Disconnect the mains plug.

몇 Warning

Danger of deforming the brushes.

When switching off the appliance, take

the load off the appliance by placing

the slider vertically.

Emptying the Fresh Water Res-

ervoir

Open the locks for the fresh water

reservoir.

Tilt the carrying hanlde for the

wastewater reservoir towards the

side.

Lift up the fresh water reservoir and

carry it to the disposal site.

몇 Warning

Please observe the local provisions regarding the wastewater treatment.

Remove the cover of the fresh wa-

ter reservoir and pour out the liquid

via the notch.

Emptying the Dirt Water Reser-

voir

Note

If the dirt water reservoir is full the float

closes the suction channel. The suction operation is interrupted. Empty the

dirt water reservoir.

Remove the fresh water reservoir,

as described above.

Lift up the wastewater reservoir and

carry it to the disposal site.

몇 Warning

Please observe the local provisions regarding the wastewater treatment.

Pour out dirt water.

Rinse the dirt water tank with clear

water.

Transport

If you want to transport the appli-

ance on a vehicle secure it from

slipping.

To reduce the required space, the

pushing handle can be folded or disassembled:

Release the star grips of the push-

ing handle fastening.

Unscrew the star grips, remove the

screws and take off the upper push

handle half.

Maintenance and care

Danger

Risk of injury!

Pull the plug from the mains before

carrying out any tasks on the appliance.

몇 Warning

Risk of damage to the appliance on account of water leakage. Drain out dirt

water and the remaining free water before wokring at the machine.

Maintenance schedule

After the work

몇 Warning

Risk of damage. Do not wash down the

appliance with water and do not use

aggressive detergents.

Pour out dirt water.

Rinse the dirt water tank with clear

water.

Empty the fresh water reservoir.

Fill the fresh water tank with clear

water and rinse the appliance to

avoid residue buildup.

Remove the remaining water from

the fresh water tank.

Check the seal in the ball valve in

the fresh water reservoir.

Check the fluff filter, clean if re-

quired

Let the reservoirs dry prior to clos-

ing them to prevent odor creation.

Clean the outside of the appliance

with a damp cloth which has been

soaked in mild detergent.

Clean the vacuum lips, check for

wear and replace the vacuum bar if

required.

Check the brushes for wear, re-

place if required.

Clean the water distribution bars

above the brushes.

Monthly

Check the condition of the seals be-

tween the appliance and the wastewater reservoir; replace if required.

Clean the brush tunnel.

Yearly

Have the prescribed inspection car-

ried out by the customer service.

Maintenance Works

Replacing the vacuum bar

Lift the vacuum bar by activating

the pedal for the vacuum bar lowering.

Press the push-button for the vacu-

um bar change toward the inside the vacuum bar will release.

Pull off the vacuum bar downwards.

Remove the screw springs and in-

stall the new vacuum bar.

Align the new vacuum bar so that

the locking nose points toward the

centre of the appliance.

Insert the screw springs into the

pickups on the appliance.

Insert the vacuum bar into the appli-

ance and lock it in.

Repeat process on the second bar.

Note

Regular exchanges of the two vacuum

bars will improve the scraping effect

and will prolong their life.

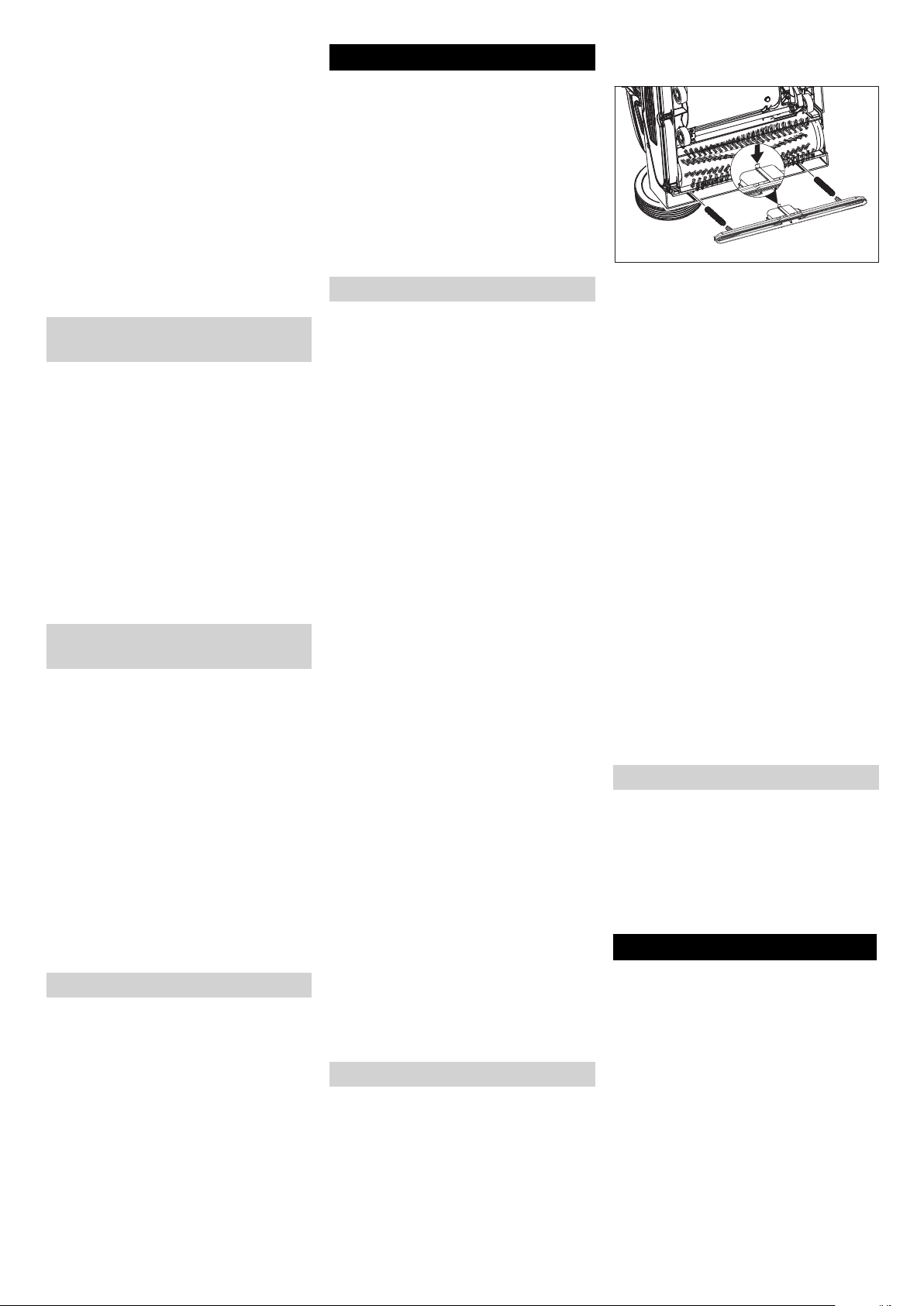

Replacing the brush rollers

Lay the device on its side.

Press the brush change key and si-

multaneously tilt the brush roller

downwards.

Pull out the brush roller.

Place the new brush roller on the

driver and lock into place.

Maintenance contract

To ensure a reliable operation of the

appliance maintenance contracts can

be concluded with the competent

Kärcher sales office.

Frost protection

In case of danger of frost:

Empty the fresh and dirt water res-

ervoirs.

Push the button for detergent solu-

tion until no more water is expelled.

Store the appliance in a frost-pro-

tected room.

Faults

Danger

Risk of injury!

Pull the plug from the mains before

carrying out any tasks on the appliance.

몇 Warning

Risk of damage to the appliance on account of water leakage. Drain out dirt

water and the remaining free water before wokring at the machine.

In case of faults that cannot be remedied using the table below please contact the customer service.

- 5

7EN

Page 8

Faults

Fault Remedy

Appliance cannot be started Check if the mains plug is connected.

Socket fuse rating too low, look for proper socket.

Insufficient water quantity Check fresh water level, refill tank if necessary.

Clean the ball valve in the fresh water reservoir.

Check and ensure that the fresh water reservoir is seated properly on the appliance.

Filter in the fresh water reservoir is plugged, clean filter.

Check hoses for blockages; clean if required.

Insufficient vacuum performance

Insufficient cleaning result Increase brush contact pressure.

Brushes do not turn Check if foreign matters block the brushes; remove foreign matter if required.

Appliance vibrates. Brush rollers are deformed because they were not unloaded by tilting the slider verti-

Empty the wastewater reservoir.

Check and ensure that the fresh water reservoir is seated properly on the wastewater

reservoir.

Check seals on the fresh water reservoir, clean if necessary.

Clean the seals between the appliance and the dirt water reservoir and check for tight-

ness, replace if required.

Clean the fluff filter.

Clean the vacuum lips on the vacuum bar, replace if required

Suction channel plugged, clean.

Check if the vacuum bar is plugged, remove plug if required

Check the brushes for wear, replace if required.

Use brush rollers suited for the type of dirt and floor covering.

Reduce contact pressure.

Overcurrent protective switch was triggered. The overcurrent protective switch will al-

low the operation after max. one minute.

cally when parking the appliance; replace brush rollers.

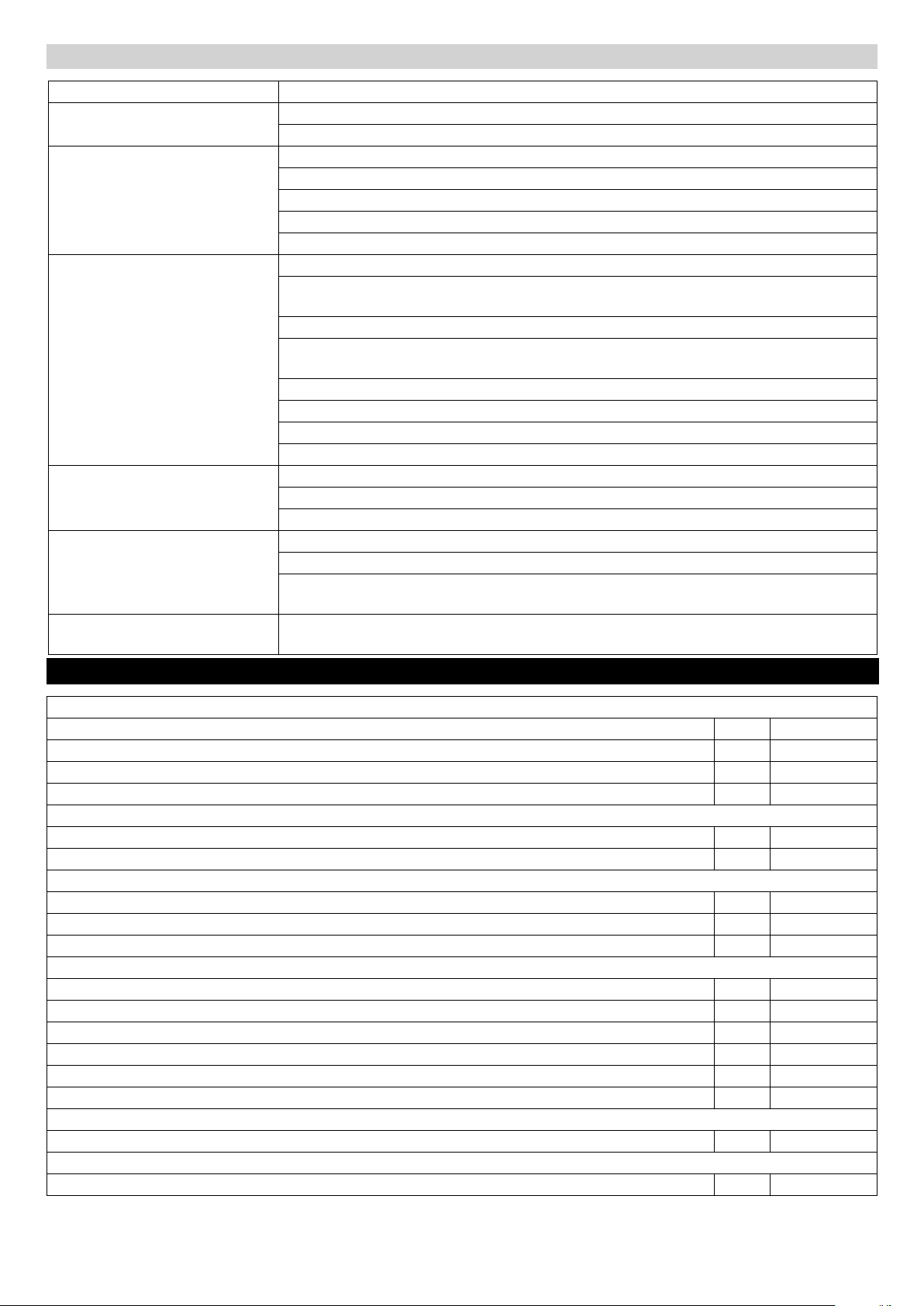

Specifications

Power

Nominal voltage V/Hz 120 / 60

Average power consumption W 1100

Suction engine output W 500

Brush engine output W 1700

Vacuuming

Cleaning power, air quantity l/s 20

Cleaning power, negative pressure kPa 10

Cleaning brushes

Working width mm 400

Brush diameter mm 96

Brush speed 1/min 650

Dimensions and weights

Theoretical surface cleaning performance m²/h 400

Fresh/dirt water reservoir volume l 10

Length (without pushing handle) mm 520

Width (without vacuum bar) mm 470

Height (without pushing handle) mm 380

Weight (without tank contents) kg 30

Noise emission

Sound pressure level (EN 60704-1) dB(A) 71

Machine vibrations

Vibration total value (ISO 5349) m/s² 1,0

8 EN

- 6

Page 9

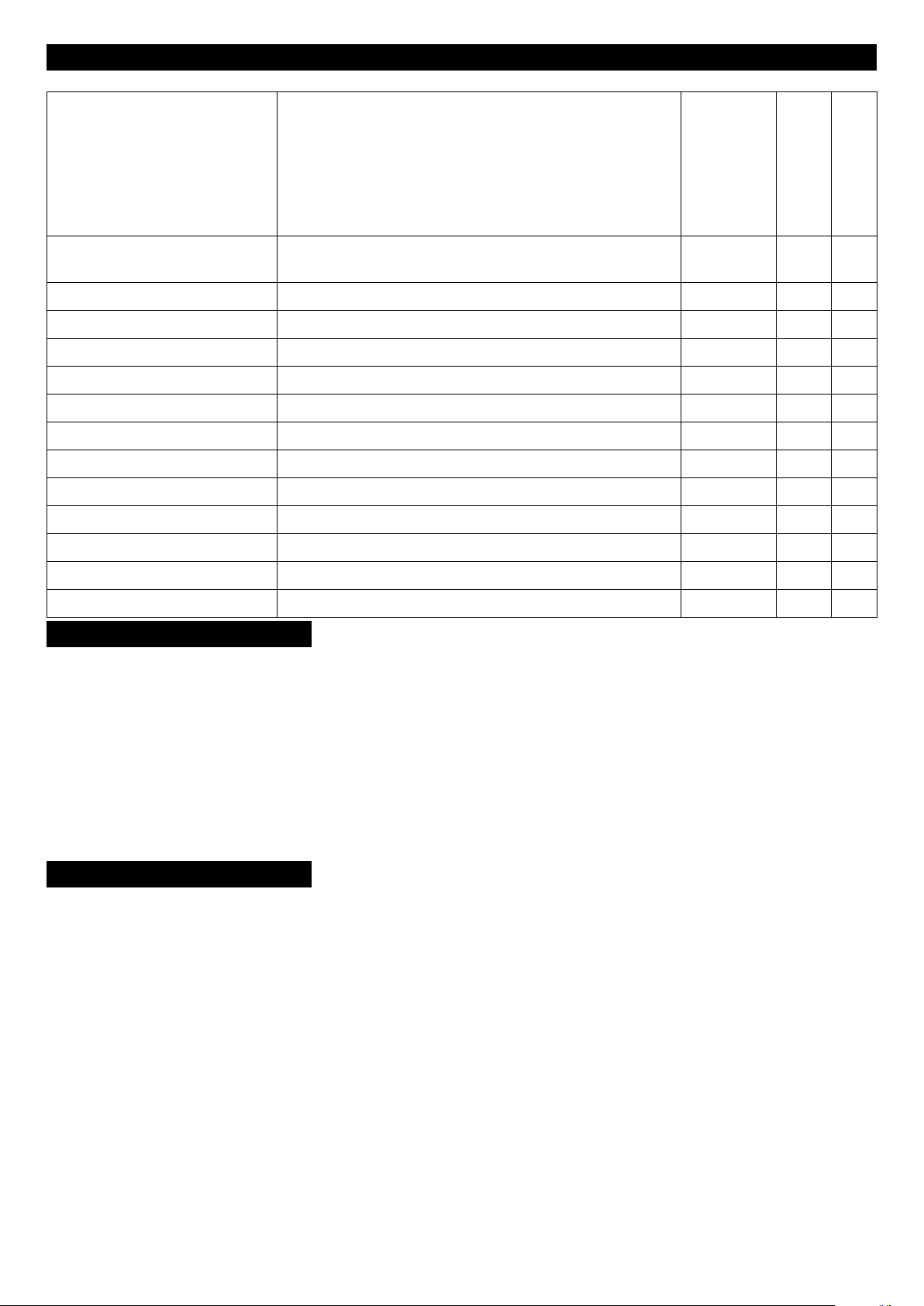

Accessories

Order No.

Piece

Brush roller, red (medium, standard)

Brush roller, green (grit) For cleaning heavily dirtied floors. 4.762-252.0 1 2

Brush roller, orange (high/ low) For scrubbing structured floors (safety tiles, etc.). 4.762-251.0 1 2

Brush roller, white (soft) For polishing floors. 4.762-250.0 1 2

Pad roller shaft For intake of roller pads. 4.762-228.0 1 2

Pad, very soft, white For cleaning and polishing sensitive floorings. 6.369-727.0 1 2

Pad, soft, yellow For polishing floors. 6.369-724.0 1 2

Pad, medium soft, red For cleaning slightly dirtied floors. 6.369-726.0 1 2

Pad, hard, green For cleaning normal to heavily dirtied floors. 6.369-725.0 1 2

Microfibre roller To remove grey tint 4.114-003.0 1 2

Vacuum bar, standard 4.777-323.0 1 2

Vacuum bar, oil-resistant 4.777-322.0 1 2

Extension cable 20 m 6.647-022.0 1 1

For cleaning slightly dirtied or sensitive floors. 4.762-249.0 1 2

Warranty

The warranty terms published by our

competent sales company are applicable in each country. We will repair potential failures of your accessory within

the warranty period free of charge, provided that such failure is caused by

faulty material or defects in fabrication.

In the event of a warranty claim please

contact your dealer or the nearest authorized Customer Service center.

Please submit the proof of purchase.

Machine requires

piece

Spare parts

– Only use accessories and spare

parts which have been approved by

the manufacturer. The exclusive

use of original accessories and

original spare parts ensures that

the appliance can be operated

safely and trouble free.

– At the end of the operating instruc-

tions you will find a selected list of

spare parts that are often required.

– For additional information about

spare parts, please go to the Ser-

vice section at www.kaercher.com.

- 7

9EN

Page 10

INSTRUCTIONS IMPOR-

Français

TANTES EN MATIÈRE DE SÉ-

CURITÉ

LIRE TOUTES LES INSTRUC-

TIONS AVANT DE FAIRE

FONKTIONNER

Attention

Pour réduire les risques d'incendie, de

chok électrique ou de blessure:

– Ne pas laisser l'appareil sans

surveillance lorsqu'il est branché.

Débrancher lorsque l'appareil n'est

pas utilisé et avant l'entretien.

Attention

– Pour réquire les risques de choc

électrique, utiliser à l'interieur

seulement.

– Ne pas permettre aux enfants de

jouer avec l'appareil. Une attention

particulière est nécessaire lorsque

l'appareil est utilisé par des enfants

ou à proximité de ces derniers.

– N'utiliser que conformément à cette

notice avec les accessoires

recommandés par le fabricant.

– Ne pas utiliser si le cordon ou la

fiche est endommagé. Retourner

l'appareil à un atelier de réparation

s'il ne fonctionne pas bien, s'il est

tombé ou s'il a été endommagé,

oublie à l'extérieur ou immergé.

– Ne pas tirer soulever ni traîner

l'appareil par le cordon. Ne pas

utiliser le cordon comme une

poignée, le coincer dans

l'embrasure d'une porte ou

l'appuyer contre des arêtes vives

ou des coins. Ne pas faire rouler

l'appareil sur le cordon. Garder le

cordon à l'écart des surfaces

chaudes.

– Ne pas débrancher en tirant sur le

cordon. Tirer plutôt la fiche.

– Ne pas toucher la fiche ni l'appareil

lorsque vos mains sont humides.

– N'insérer aucun objet dans les

ouvertures. Ne pas utiliser l'appareil

lorsqu'une ouverture est bloquée.

S'assurer que de la poussière, de la

peluche, des cheveux ou d'autres

matières ne réduisent pas le debit

d'air.

– Maintenir les cheveux, les

vêtements amples, les doigts et

toutes les parties du corps à l'écart

des ouvertures et des pièces

mobiles.

– Mettre toutes les commandes à la

position ARRÊT avant de

débrancher l'appareil.

– User de prudence lors du nettoyage

des escaliers.

– Ne pas aspirer des liquides

inflammables ou combustibles,

comme de l'essence, et ne pas faire

functionner dans des endroits où

peuvent se trouver de tels liquides.

– Ne brancher qu'à une prise de

courant avec mise à la terre. Voir

les instructions la mise à la terre.

CONSERVER CES INSTRUC-

TIONS

INSTRUCTIONS VISANT LA

MISE À LA TERRE

Cet appareil doit être mis à la terre. En

cas de défaillance ou de panne, la

mise à la terre fournit au courant un

chemin de moindre résistance qui

réduit le risque de choc électrique. Cet

appareil est pourvu d'un cordon muni

d'un conducteur de terre et d'une fiche

avec broche de terre. La fiche doit être

branchée dans une prise appropriée

correctement installée et mise à la

terre conformément aux règlements et

ordonnances municipaux.

Attention

Un conducteur de terre mal raccordé

peut entraîner un risque de choc électrique. Consulter un électricien ou un

technicien d'entretien qualifié si vous

n'êtes pas certain que la prise est correctement mise à la terre. Ne pas modifier la fiche fournie avec l'appareil - si

elle ne peut être insérée dans la prise,

fair installer une prise adéquate par un

électricien qualifié.

Cet appareil est destiné à un circuit de

120 V et est muni d'une fiche de mise

à la terre semblable à celle illustrée par

le croqui A. S'assurer que l'appareil est

branché à une prise de courant ayant

la même configuration que la fiche. Aucun adaptreur nr devrait être utilisé

avec cet appareil.

NE BRANCHER QU'À UNE

PRISE DE COURANT AVEC

MISE À LA TERRE

1 Sortie avec mise à la terre

2 Boîte avec mise à la terre

3 Fiche avec mise à la terre

REGLES ET PRATIQUES DE

SECURITE DE FONCTION-

NEMENT

Responsabilité de l'opérateur

Un fonctionnement sûr est la responsabilité de l'opérateur.

L'opérateur doit être au courant du

fonctionnement et des fonctions de

toutes les commandes et de tous les

instruments avant d'entreprendre de

faire fonctionner l'unité.

Avant de faire fonctionner l'unité, les

opérateurs doivent avoir lu et bien

connaître le manuel d'utilisation pour

l'unité particulière en fonctionnement

et ils doivent également obéir aux

règles et pratiques de sécurité énoncées dans les paragraphes suivants.

Avant de faire fonctionner l'unité, l'opérateur doit bien connaître les conditions de fonctionnement inhabituelles

qui peuvent nécessiter des précautions de sécurité supplémentaires ou

des instructions de fonctionnement

spéciales.

Généralités

Avant de commencer à faire fonctionner l'unité, soyez dans une position

d'opération.

Ne démarrez pas ou n'opérez pas l'unité, l'une quelconque de ses fonctions

ou accessoires, depuis tout endroit

autre que la position désignée pour les

opérateurs.

Avant de quitter la position de l'opérateur :

A arrêtez complètement l'unité ;

B si l'unité doit se trouver sur un plan

incliné, bloquez les roues.

Conservez une distance de sécurité

depuis le bord des rampes, plateformes et autres surfaces de travail similaires.

N'effectuez aucun ajout ou aucune

modification à l'unité.

Ne bloquez pas l'accès aux couloirs à

incendie, escaliers ou équipement de

lutte contre les incendies.

Déplacements

Donnez la priorité aux piétons et véhicules d'urgence tels que les ambulances et les camions de pompiers.

Traversez les voies ferrées de manière

angulaire si possible. Ne vous garez

pas à moins de 1800 mm du rail le plus

proche d'une voie ferrée.

Conservez une vision claire du chemin

de déplacement et prenez garde au

reste de la circulation, au personnel et

aux dégagements sûrs.

10 FR

- 1

Page 11

Opérez l'unité à une vitesse qui lui permettra d'être arrêtée de manière sûre

dans toutes les conditions de déplacement.

Ne vous adonnez pas aux cascades

ou à la brutalité.

Ralentissez en cas de sols mouillés et

glissants.

Avant de passer sur un bord de quai ou

sur la chaussée d'un pont, assurezvous qu'il/elle est correctement fixé(e).

Conduisez prudemment et lentement

sur le bord de quai ou la chaussée d'un

pont et ne dépassez jamais sa capacité nominale.

Lors de la prise de virages, ralentissez

à une vitesse sûre en correspondance

avec l'environnement de fonctionnement. Prenez les virages en douceur.

Entretien de l'unité par l'opéra-

teur

Si l'unité s'avère nécessiter des réparations ou être dangereuse d'une manière quelconque ou contribue à une

condition dangereuse, le problème doit

être rapporté immédiatement au supérieur désigné de l'utilisateur et l'unité

ne doit pas être opérée jusqu'à ce

qu'elle ait été remise en une condition

de fonctionnement sûre.

Si l'unité devient dangereuse d'une

manière quelconque au cours du fonctionnement, le problème doit être rapporté immédiatement au supérieur

désigné de l'utilisateur et l'unité ne doit

pas être opérée jusqu'à ce qu'elle ait

été remise en une condition de fonctionnement sûre.

N'effectuez pas de réparations ou de

réglages à moins d'y être autorisé spécifiquement.

PRATIQUES D'ENTRETIEN

ET DE RECONSTRUCTION

Le fonctionnement de l'unité peut être

dangereux si l'entretien est négligé ou

si des réparations, reconstructions ou

réglages ne sont pas effectués conformément aux critères de conception du

constructeur. Par conséquent, des installations d'entretien (sur site ou au dehors), du personnel qualifié et des

procédures détaillées doivent être

fournis.

L'entretien et l'inspection de l'unité doivent être réalisés conformément aux

pratiques suivantes :

A un système d'entretien, de lubrifica-

tion et d'inspection planifié doit être

suivi ; consultez les recommanda-

tions du constructeur.

B seul du personnel qualifié et autori-

sé doit être autorisé à effectuer l'en-

tretien, réparer, régler et inspecter

l'unité et ce conformément aux spécifications du constructeur.

Evitez les risques d'incendie et disposez d'un équipement de protection

contre les incendies dans la zone de

travail. N'utilisez pas de récipients ouverts d'essence ou de fluides de nettoyage inflammables pour le nettoyage

des pièces.

NORME DE SECURITE IN-

CENDIE

Toute unité ne se trouvant pas dans

une condition de fonctionnement sûre

doit être mise hors service.

Les réparations doivent être effectuées dans les emplacements de

Classe I, Classe II et Classe III.

Prévention incendie : L'unité doit être

conservée dans une condition propre

et raisonnablement exempte de peluche, d'huile en excès et de graisse.

Des agents non combustibles sont préférés pour le nettoyage de l'unité. Les

liquides inflammables [ceux possédant

des points d'inflammation à ou supérieurs à 100°F (37,8°C)] ne sont pas

permis. Les précautions concernant la

toxicité, la ventilation et les risques

d'incendie doivent être appropriées à

l'agent ou au solvant utilisé.

Visibilité de la plaque signalétique :

Les désignations du type d'unité telles

qu'illustrées sur la plaque signalétique

et les marqueurs de type ne doivent

pas être recouverts par de la peinture

de sorte que les informations concernant leur identification sont obscurcies.

L'unité ne doit pas être utilisée dans

des zones classifiées.

Lisez attentivement ce

mode d’emploi avant la

première utilisation de l’appareil et respectez les conseils y figurant. Conservez ce mode d’emploi pour une

utilisation ultérieure ou un éventuel repreneur de votre matériel.

Table des matières

Fonction . . . . . . . . . . . . . . . FR . . 2

Utilisation conforme . . . . . . FR . . 3

Protection de l’environnement FR . . 3

Eléments de commande. . . FR . . 4

Avant la mise en service. . . FR . . 4

Fonctionnement . . . . . . . . . FR . . 5

Entretien et maintenance . . FR . . 6

Pannes . . . . . . . . . . . . . . . . FR . . 7

Données techniques. . . . . . FR . . 8

Accessoires . . . . . . . . . . . . FR . . 9

Garantie . . . . . . . . . . . . . . . FR . . 9

Pièces de rechange . . . . . . FR . . 9

Consignes de sécurité

Lire la présente notice d'instructions

ainsi que la brochure ci-jointe

Consignes de sécurité pour les nettoyeurs à brosses n° 5.956-251 avant

d'utiliser l'appareil et respecter les instructions.

Symboles

Les symboles suivants sont utilisés

dans ces instructions de service :

Danger

Signalise un danger imminent. Un non

respect de cette consigne peut

conduire à la mort ou entraîner de

graves blessures.

몇 Avertissement

Signalise une situation éventuellement

dangereuse. Un non respect de cette

consigne peut entraîner de légères

blessures ou encore des dégâts matériels.

Remarque

Donne des conseils pour l'utilisation et

d'importantes informations relatives au

produit.

Fonction

L’appareil est employé pour nettoyer

ou pour polir des sols plans par voie

humide.

Deux brosses rotatives opposées nettoient le sol à l'aide du fluide de nettoyage alimenté. Une largeur de travail

de 400 mm et une capacité de 10 l pour

chaque réservoir d'eau propre et d'eau

sale permettent un nettoyage efficace.

Un fonctionnement par courant permet

d'obtenir une capacité élevée sans limitation de la durée de travail.

- 2

11FR

Page 12

Remarque

L'appareil peut être équipé de différents accessoires en fonction de l'application respective. De plus amples

détails figurent dans notre catalogue

ou sur notre site Internet www.kaercher.com.

Utilisation conforme

L'utilisation de l'appareil doit être faite

en conformité avec les consignes figurant dans les instructions de service.

– L'appareil doit uniquement être uti-

lisé pour nettoyer des surfaces

planes non sensibles à l'humidité ni

au polissage.

La plage de température pour l'utilisation est de +5°C à +40°C.

– L'appareil n'est pas approprié pour

nettoyer des sols gelés (par

exemple dans des entrepôts frigorifiques)

– L'appareil doit uniquement être

équipé d'accessoires et de pièces

de rechange d'origine.

– L'appareil est conçu pour le net-

toyage de sols dans le domaine intérieur ou bien de surfaces

couvertes d'un toit. Pour d'autres

domaines d'application, il faut

contrôler l'éventuelle nécessité

d'utiliser d'autres brosses.

– L'appareil n'est pas destiné au net-

toyage de voies publiques.

Protection de l’environne-

ment

Les matériaux constitutifs

de l'emballage sont recyclables. Ne pas jeter les

emballages dans les ordures ménagères, mais les

rendre à un système de recyclage.

Les appareils usés contiennent des matériaux précieux recyclables lesquels

doivent être rendus à un

système de recyclage. Des

batteries, de l’huile et

d'autres substances semblables ne doivent pas être

tout simplement jetées.

Pour cette raison, utiliser

des systèmes adéquats de

collecte pour éliminer les

appareils usés.

Instructions relatives aux ingrédients (REACH)

Les informations actuelles relatives

aux ingrédients se trouvent sous :

www.kaercher.com/REACH

12 FR

- 3

Page 13

25

24

Eléments de commande

1 Verrouillage réservoir d'eau propre

2 Commutateur d'entraînement de

brosse

3 Commutateur solution de net-

toyage

4 Tuyau solution de nettoyage

5 Filtre pour des bouloches de dé-

chets (aspiration)

6 Blocage guidon de poussée

7 Touche de verrouillage roue de

transport

8 Roulette de transport

9 Guidon de poussée

10 Crochet de soulagement de traction

11 Support roue de transport

12 Clip

13 Réservoir d'eau propre

14 Réservoir d'eau sale

15 Poussoir changement de barre

d'aspiration

16 Flotteur

17 Touche changement de brosse

18 Train de roulement

19 Barre d'aspiration

20 Brosses rotatives

21 Poignée rotative pression d'appui

des brosses

22 Pédale abaissement barre d'aspira-

tion

23 Fiche secteur

24 Poignée de transport du réservoir

d'eau sale

25 Couvercle réservoir d'eau fraîche

Avant la mise en service

Monter le guidon de poussée

Pousser la moitié supérieure de

l'étrier de poussée sur la moitié inférieure de l'étrier de poussée.

몇 Avertissement

Risque d'endommagement. Ne pas

coincer le câble lors du montage.

Aligner les alésages (2 réglages en

hauteur possibles).

Connecter les deux moitiés de

l'étrier de poussée avec les boulons

bruts à tête bombée et collet carré,

les rondelles et les poignées en

étoile.

Fixer les câbles avec les clips sur

l'étrier de poussée.

Monter les roues de transport

Enficher les essieux des roues de

transport dans les alésages sur

l'appareil et les enclencher.

Montage des brosses

Les brosses doivent être montées

avant la mise en service (voir 'Travaux

de maintenance').

- 4

13FR

Page 14

Fonctionnement

Remarque

Relâcher l'étrier de commande pour

mettre immédiatement l'entraînement

des brosses hors service.

Remplissage de carburant

몇 Avertissement

Risque d'endommagement. Utiliser

uniquement les détergents recommandés. Pour tout autre détergent, l'exploitant prend des risques plus élevés

quant à la sécurité du travail et au

risque d'accident. Utiliser uniquement

des détergents exempts de solvants,

d'acide chlorhydrique et fluorhydrique.

Remarque

Ne jamais utiliser de détergents extrêmement moussants. Tenir compte des

consignes de dosage.

Détergents recommandés :

Application Produit

détergent

Nettoyage d'entretien

de tous les sols résistants à l'eau

Nettoyage d'entretien

de surfaces brillantes

(par exemple du granite)

Nettoyage d'entretien et

nettoyage minutieux de

sols dans le secteur industriel

Nettoyage d'entretien et

nettoyage minutieux de

carrelages en grès cérame fin

Nettoyage d'entretien

de carrelages dans le

secteur sanitaire

Nettoyage et désinfection dans le secteur sanitaire

Enlèvement d'une

couche sur tous les sols

résistants aux alcalis

(par exemple PVC)

Enlèvement d'une

couche sur des sols en

linoléum

Ouvrir le couvercle du réservoir

d'eau propre.

Remplir de mélange détergent-eau.

Température maximale du liquide,

50°C..

Remarque

Le couvercle du réservoir d'eau propre

peut être utilisé pour le dosage du détergent. Le contenu jusqu'au repère du

RM 746

RM 780

RM 755 es

RM 69

ASF

RM 753

RM 751

RM 732

RM 752

RM 754

couvercle retourné est de 1% du réservoir d'eau propre.

Fermer le couvercle du réservoir

d'eau propre.

Déplacement vers le lieu d'utili-

sation

Voies courtes sur une surface plane

Mettre l'étrier de poussée en posi-

tion verticale.

Mettre la poignée rotative de pres-

sion d'appui des brosses dans la

position déplacement.

Pousser l'appareil sur le lieu d'utili-

sation au moyen du guidon de

poussée.

Voies longues, surfaces inégales

Mettre l'étrier de poussée en posi-

tion verticale et faire basculer le

blocage vers le haut.

Monter les roues de transport.

몇 Avertissement

Risque d'endommagement dû à de

l'eau qui s'écoule ! Retirer les réservoir

d'eau propre et d'eau sale avant de

basculer l'appareil.

Retirer les réservoirs d'eau propre

et d'eau sale de l'appareil et les

transporter séparément.

Basculer l'appareil sur le côté et le

pousser vers le site de mise en

œuvre sur les roues de transport.

Si les roues de transport gênent lors de

la mise en œuvre de l'appareil :

appuyer sur la touche de déver-

rouillage de la roue de transport et

retirer celle-ci.

Enficher les roues de transport jus-

qu'à la butée dans le support de

roue de transport.

Régler la pression de la brosse

Mettre l'étrier de poussée en posi-

tion verticale.

Régler la poignée rotative de pres-

sion d'appui des brosses sur la valeur souhaitée.

Remarque

Effectuer les premiers essais de nettoyage avec une pression d'appui réduite. Augmenter peu à peu la

pression jusqu'à atteindre le résultat

de nettoyage désiré. Un bon réglage

de la pression d'appui diminue l'usure

des brosses.

En cas de surcharge, l'entraînement

de brosse est mis hors service.

Lors du nettoyage avec des brosses à

microfibres, la pression d'appui doit

être réglée sur la position montrée cidessous au maximum. Si la pression

d'appui est supérieure, il existe un

risque de destruction des brosses à

microfibres.

+

-

Établir le raccordement de ré-

seau

Danger

Vérifier le bon état de la conduite de

raccordement de réseau de l'appareil

avant chaque fonctionnement. Ne pas

mettre l'appareil en service avec un

câble endommagé. Laisser changer le

câble endommagé par un électricien.

Accrocher l'extrémité de la rallonge

comme boucle dans le crochet de

soulagement de traction.

Brancher la fiche secteur.

Nettoyage

Si la solution de nettoyage doit être

aspirée après le processus de nettoyage, actionner la pédale d'abaissement de barre d'aspiration.

Basculer l'étrier de poussée vers

l'opérateur, le train de roulement

est rentré et les brosses touchent le

sol.

Mettre les brosses en service en

actionnant le commutateur d'entraînement de brosses.

Mettre l'arrosage des brosses en

service en actionnant le commutateur de solution de nettoyage.

Guider l'appareil sur la surface à

traiter avec l'étrier de poussée.

몇 Avertissement !

Risque d'endommagement pour le revêtement de sol. Ne pas exploiter l'appareil sur place.

Polissage

Basculer l'étrier de poussée vers

l'opérateur, le train de roulement

est rentré et les brosses touchent le

sol.

14 FR

- 5

Page 15

Mettre les brosses en service en

actionnant le commutateur d'entraî-

nement de brosses.

Guider l'appareil sur la surface à

traiter avec l'étrier de poussée.

몇 Avertissement !

Risque d'endommagement pour le revêtement de sol. Ne pas exploiter l'appareil sur place.

Remarque

Pour le polissage sous les objets

d'ameublement, il est possible de retirer le réservoir d'eau propre et le réservoir d'eau sale.

Arrêt et mise hors marche de

l'appareil

Relâcher le commutateur de solu-

tion de nettoyage.

Avancer l'appareil d'encore 1 à 2 m

pour aspirer l'eau restante.

Relâcher le commutateur d'entraî-

nement de brosse.

Actionner la pédale d'abaissement

de barre d'aspiration.

Mettre l'étrier de poussée en posi-

tion verticale, les brosses sont sou-

levées.

Débrancher le câble d'alimentation.

몇 Avertissement

Risque de déformation des brosses.

Lors du rangement de l'appareil, décharger la contrainte de l'étrier de

poussée en mettant les brosses en position verticale

Vidange du réservoir d'eau

propre

Ouvrir les verrouillages du réservoir

d'eau propre.

Basculer la poignée de transport du

réservoir d'eau sale sur le côté.

Soulever le réservoir d'eau propre

et l'emmener au dispositif d'élimina-

tion.

몇 Avertissement

Tenir compte des prescriptions locales

pour le traitement des eaux usées.

Enlever le couvercle du réservoir

d'eau propre et verser le fluide sur

la rainure.

Vidange du réservoir d'eau sale

Remarque

Si le réservoir d'eau sale est plein, le

flotteur ferme le canal d'aspiration.

L'aspiration est alors interrompue. Vider le réservoir d'eau sale.

Réserver le réservoir d'eau propre

de la manière décrite précédem-

ment.

Soulever le réservoir d'eau sale et

l'emmener au dispositif d'élimination.

몇 Avertissement

Tenir compte des prescriptions locales

pour le traitement des eaux usées.

Faire couler l'eau sale.

Rincer le réservoir d'eau sale à

l'eau propre.

Transport

Pour le transport sur un véhicule,

bloquer l'appareil pour l'empêcher

de glisser.

Pour réduire la place nécessaire, il est

possible de rabattre ou de démonter

l'étrier de poussée :

Desserrer les boutons cannelés

pour la fixation du guidon de poussée.

Dévisser les poignées en étoile,

sortir les vis et retirer la moitié supérieure du guidon de poussée.

Entretien et maintenance

Danger

Risque de blessure !

Avant d'effectuer tout type de travaux

sur l'appareil, débrancher la fiche secteur.

몇 Avertissement

Risque de dommage pour l'appareil

par eau que fuit. Vider l'eau sale et

l'eau propre résiduaire avant comencer les travaux à l'appareil.

Plan de maintenance

Après le travail

몇 Avertissement

Risque d'endommagement. Ne pas laver l'appareil au jet d'eau et ne jamais

utiliser de détergents agressifs.

Faire couler l'eau sale.

Rincer le réservoir d'eau sale à

l'eau propre.

Vider le réservoir d'eau propre.

Remplir le réservoir d'eau propre

d'eau claire et rincer l'appareil pour

éviter les dépôts.

Enlever l'eau restante du réservoir

d'eau propre.

Contrôler le joint du robinet sphé-

rique d'arrêt dans le réservoir d'eau

propre.

Contrôler le tamis à peluches et le

cas échéant, le nettoyer.

Laisser sécher les réservoir avant

de les refermer pour éviter la formation d'odeurs.

Nettoyer l'extérieur de l'appareil

avec un chiffon humide et imbibé

de détergent doux.

Nettoyer les lèvres d'aspiration,

puis contrôler leur degré d'usure et

le cas échéant remplacer la barre

d'aspiration.

Contrôler le degré d'usure des

brosses et le cas échéant, les remplacer.

Nettoyer les barres de distribution

de l'eau au-dessus des brosses.

Mensuellement

Contrôler les joints entre le réser-

voir d'eau sale et l'appareil ; le cas

échéant, les remplacer.

Nettoyer le tunnel de brosse.

Tous les ans

L'inspection prescrite doit être ef-

fectuée par le service après-vente.

Travaux de maintenance

Remplacer la barre d'aspiration

Soulever la barre d'aspiration en

actionnant la pédale Abaissement

de la barre d'aspiration.

Presser le poussoir de changement

de barre d'aspiration vers l'intérieur,

la barre d'aspiration se dégage.

Sortir la barre d'aspiration vers le

bas.

Retirer les ressorts cylindriques et

les enficher sur la nouvelle barre

d'aspiration.

Aligner la nouvelle barre d'aspira-

tion de telle manière que le nez

d'enclenchement soit orienté vers

le centre de l'appareil.

Enfiler les ressorts cylindriques

dans les réceptions sur l'appareil.

Enfoncer la barre d'aspiration dans

l'appareil et l'enclencher.

Renouveler le processus pour la

seconde barre d'aspiration.

Remarque

Un replacement régulier des deux

barres d'aspiration améliore l'effet du

raclage et prolonge la durée de vie.

Remplacement des rouleauxbrosses

Disposer l'appareil sur le côté.

Appuyer sur la touche de change-

ment de brosse et basculer simultanément la brosse rotative vers le

bas.

- 6

15FR

Page 16

Retirer le rouleau-brosse.

Enficher la nouvelle brosse rotative

sur l'entraîneur et l'enclencher.

Contrat de maintenance

Afin de pouvoir garantir un fonctionnement fiable de l'appareil, il est possible

de conclure des contrats de maintenance avec le bureau de ventes Kärcher responsable.

Protection antigel

En cas de risque de gel :

Vider le réservoir d'eau propre et le

réservoir d'eau sale.

Actionner le commutateur solution

de nettoyage jusqu'à ce qu'il ne

sorte plus d'eau.

Déposer l'appareil dans une pièce à

l'abri du gel.

Pannes

Danger

Risque de blessure !

Avant d'effectuer tout type de travaux

sur l'appareil, débrancher la fiche secteur.

몇 Avertissement

Risque de dommage pour l'appareil

par eau que fuit. Vider l'eau sale et

l'eau propre résiduaire avant comencer les travaux à l'appareil.

En cas de pannes ne pouvant pas être

résolues grâce aux instructions de ce

tableau, appeler le service aprèsvente.

16 FR

- 7

Page 17

Pannes

Panne Remède

Il est impossible de mettre l'appareil en marche

Quantité d'eau insuffisante Contrôler le niveau d'eau propre et en cas de besoin, remplir le réservoir

Puissance d'aspiration insuffisante

Résultat de nettoyage insuffisant

Les brosses ne se tournent pas Vérifier si des corps étrangers bloquent les brosses et le cas échéant, éliminer les

L'appareil vibre Les brosses rotatives sont ovalisées car elles n'ont pas été déchargées de leur

Vérifier si la fiche secteur est branchée.

Protection par fusible de la prise trop faible, recherche une prise appropriée.

Nettoyer le robinet sphérique d'arrêt dans le réservoir d'eau propre.

Contrôler que le réservoir d'eau propre est correctement fixé sur l'appareil.

Filtre dans le réservoir d'eau propre bouché, nettoyer le filtre.

Contrôler si les flexibles sont bouchés, en cas de besoin nettoyer.

Vider le réservoir d'eau sale.

Contrôler que le réservoir d'eau propre est correctement fixé sur le réservoir d'eau sale.

Contrôler et nettoyer le joint sur le réservoir d'eau propre.

Nettoyer les joints entre le réservoir d'eau sale et l'appareil et vérifier s'ils sont

étanches, en cas de besoin remplacer.

Nettoyer le tamis à peluches.

Nettoyer les lèvres d'aspiration sur la barre d'aspiration et en cas de besoin remplacer.

Canal d'aspiration bouché, le nettoyer.

Vérifier si la barre d'aspiration est colmatée et le cas échéant, éliminer le colmatage

Augmenter la pression d'appui des brosses.

Contrôler le degré d'usure des brosses et le cas échéant, les remplacer.

Utiliser des brosses rotatives adaptées au type d'encrassement et au revêtement de

sol.

corps étrangers.

Diminuer la pression.

Le disjoncteur protecteur de surintensité s’est déclenché. Le disjoncteur protecteur de

surintensité permet de nouveau le service après une minute au maximum.

contrainte par une mise en position verticale de l'étrier de poussée.

Données techniques

Performances

Tension nominale V/Hz 120 / 60

Puissance absorbée moyenne W 1100

Puissance du moteur d'aspiration W 500

Puissance de moteur de brosses W 1700

Aspiration

Puissance d'aspiration, débit d'air l/s 20

Puissance d'aspiration, dépression kPa 10

Brosses de nettoyage

Largeur de travail mm 400

Diamètre des brosses mm 96

Vitesse des brosses t/min 650

Dimensions et poids

Surface théoriquement nettoyable m²/h 400

Volume du réservoir d'eau propre/réservoir d'eau sale l 10

Longueur (sans guidon de poussée) mm 520

Largeur (sans barre d'aspiration) mm 470

Hauteur (sans guidon de poussée) mm 380

Poids (sans contenu du réservoir) kg 30

Emissions sonores

Niveau de pression acoustique (EN 60704-1) dB(A) 71

Vibrations de l'appareil

Valeur globale de vibrations (ISO 5349) m/s² 1,0

- 8

17FR

Page 18

Accessoires

N° de réf.

Pièce

Brosse d'aération, rouge

(moyenne, standard)

Brosse d'aération, verte (grit) Pour le nettoyage des sols très sales. 4.762-252.0 1 2

Brosse d'aération, orange (haut/

bas)

Brosse d'aération, blanche

(douce)

Rouleau de pad Pour la réception de pads de rouleau. 4.762-228.0 1 2

Pad, très doux, blanc Pour le nettoyage et le polissage des sols sensibles. 6.369-727.0 1 2

Pad, doux, jaune Pour le polissage des sols. 6.369-724.0 1 2

Pad, moyenne doux, rouge Pour le nettoyage des sols pas trop sales. 6.369-726.0 1 2

Pad, dur, vert Pour le nettoyage des sols normal ou très sales. 6.369-725.0 1 2

Brosse à microfibres To remove grey tint 4.114-003.0 1 2

Barre d'aspiration, standard 4.777-323.0 1 2

Barre d'aspiration, résistante à

l'huile

Câble de rallonge 20 m 6.647-022.0 1 1

Garantie

Dans chaque pays, les conditions de

garantie en vigueur sont celles publiées par notre société de distribution

responsable. Les éventuelles pannes

sur les accessoires sont réparées gratuitement dans le délai de validité de la

garantie, dans la mesure où celles-ci

relèvent d'un défaut matériel ou d'un

vice de fabrication. En cas de recours

en garantie, adressez-vous à votre revendeur ou au service après-vente

agréé le plus proche munis de votre

preuve d'achat.

Pour le nettoyage des sols pas trop sales ou sensibles. 4.762-249.0 1 2

Pour frotter des sols structurés (carrelage de protection

etc.).

Pour le polissage des sols. 4.762-250.0 1 2

– Plus information sur les pièces de

rechange vous les trouverez sous

www.kaercher.com sous le menu

Service.

4.762-251.0 1 2

4.777-322.0 1 2

L'appareil besoin la pièce

Pièces de rechange

– Utiliser uniquement des acces-

soires et des pièces de rechange

autorisés par le fabricant. Des ac-

cessoires et des pièces de re-

change d’origine garantissent un

fonctionnement sûr et parfait de

l’appareil.

– Une sélection des pièces de re-

change utilisées le plus se trouve à

la fin du mode d'emploi.

18 FR

- 9

Page 19

INSTRUCCIONES IMPOR-

Español

TANTES DE SEGURIDAD

LEA TODAS LAS INSTRUC-

CIONES ANTES DE USAR LA

MÁQUINA

ADVERTENCIA

Para evitar el peligro de incendio, descarga eléctrica o heridas:

– No se aleje de la máquina mientras

esté enchufada. Saque el enchufe

de la base cuando no la esté usan-

do, y antes del mantenimiento.

ADVERTENCIA

– PARA EVITAR PELIGRO DE DES-

CARGAS ELÈCTRICAS, LA

MÀQUINA SÒLO DEBE EM-

PLEARSE EN INTERIORES

– La máquina no es un juguete. Lle-

var mucho cuidado si va a utilizarse

donde hay niños.

– La máquina sólo debe emplearse

tal como se describe en este ma-

nual. Sólo deben usarse los acce-

sorios recomendados por el

fabricante.

– No emplearla si el cable o el enchu-

fe están dañados. Si la máquina no

funciona correctamente, si se ha

caído, si está averiada, si ha per-

manecido al exterior o si ha caído al

agua, devolverla al servicio pos-

venta.

– No tirar de la máquina ni alzarla

con el cable, no emplear el cable

como manija, no aprisionarlo con

una puerta ni pasarlo sobre esqui-

nas o bordes agudos. No pasar la

máquina sobre el cable. Mantener

el cable alejado de fuentes de ca-

lor.

– Al desenchufar, no tirar del cable.

Para desenchufar, tomar el enchu-

fe y no el cable.

– No tocar el enchufe ni la máquina

con las manos mojadas.

– No colocar objetos en las abertu-

ras. No usar la máquina con las

aberturas obstruidas; éstas deben

estar libres de polvo, pelusa, pelos

y cualquier otro objeto que pueda

impedir el paso de aire.

– Mantener el cabello, la ropa, los de-

dos y todas las partes del cuerpo

alejadas de las aberturas y las pie-

zas móviles.

– Apagar la máquina antes de desen-

chufarla.

– Llevar mucho cuidado al trabajar en

escaleras.

– No emplearla para recoger líquidos

inflamables o combustibles, p.ej.

gasolina, ni en zonas donde pueda

haber dichos líquidos.

– Es imprescindible que la toma eléc-

trica esté debidamente puesta a tierra. Véanse las Instrucciones de

Puesta a Tierra.

GUARDE ESTAS INSTRUC-

CIONES

INSTRUCCIONES DE PUES-

TA A TIERRA

La máquina debe ser puesta a tierra.

Si no funciona bien, o si se estropea, la

puesta a tierra constituye una vía de

menor resistencia para la corriente

eléctrica, para disminuir el peligro de

descarga eléctrica. La máquina está

provista de cable con conductor de

puesta a tierra, y enchufe con puesta a

tierra. El enchufe debe insertarse en

una base de enchufe adecuada, debidamente instalada y puesta a tierra,

conforme a la legislación y las normas

válidas en el lugar de utilización.

ADVERTENCIA

Si el conductor de puesta a tierra de la

máquina está mal conectado, puede

haber peligro de descarga eléctrica.

Consulte a un electricista experto o a

un técnico de mantenimiento, si Ud. no

sabe con certeza si la base de enchufe

está correctamente puesta a tierra. No

cambie el enchufe suministrado con la

máquina - no encajará en la base de

enchufe; acuda a un electricista experto.

La máquina está diseñada para emplearla en un circuito de

120 voltios; tiene un enchufe de puesta

a tierra cuyo aspecto es como se ilustra en la Figura A. Cerciórese de conectar la máquina a una base de

enchufe de la misma configuración

que el conector. Con esta máquina no

deben emplearse adaptadores.

CONECTAR SÓLO A UNA

BASE DE ENCHUFE CO-

RRECTAMENTE PUESTA A

TIERRA

1 Enchufe puesto a tierra

2 Caja de enchufe puesta a tierra

3 Pin puesto a tierra

NORMAS Y PROCEDIMIEN-

TOS DE SEGURIDAD DU-

RANTE EL

FUNCIONAMIENTO

Responsabilidad del operario

El operario será responsable de garantizar un funcionamiento seguro.

El operario deberá estar familiarizado

con el manejo y las funciones de todos

los elementos de mando y todos los

instrumentos antes de proceder al manejo de la unidad.

Antes de poner en funcionamiento la

unidad, los operarios deberán haber

leído el manual de instrucciones de la

unidad particular de que se trate y estar familiarizados con él; además, deberán respetar las normas y

procedimientos de seguridad que se

describen a continuación.

Antes de poner en funcionamiento una

unidad cualquiera, el operario deberá

conocer bien las posibles condiciones

inusuales de funcionamiento que requieren la adopción de determinadas

precauciones especiales o para las

que existen unas instrucciones de manejo especiales.

Generalidades

Antes de poner en funcionamiento la

unidad, ésta deberá encontrarse en la

posición de servicio.

No ponga en marcha ni utilice la unidad ni ninguna de sus funciones o sus

aditamentos desde un lugar que no

sea el concebido para el operario.

Antes de abandonar la posición del

operario:

A pare la unidad por completo;

B si es necesario dejar la unidad en

una pendiente, bloquee las ruedas.

Guarde una distancia segura respecto

a los bordes de las rampas y las plata-

- 1

19ES

Page 20

formas, y respecto a los de otras superficies de trabajo similares.

No efectúe ampliaciones ni modificaciones en la unidad.

No bloquee el acceso a las salidas previstas en caso de incendio, las escaleras o los extintores.

Durante la circulación

Ceda el paso a los peatones y a los vehículos de emergencia, como son las

ambulancias y los camiones de bomberos.

Siempre que sea posible, cruce las

vías férreas formando un ángulo con

ellas. No estacione a menos de 6 ft

(1800 mm) de distancia respecto a los

raíles o las vías férreas más cercanos.

Asegúrese de mantener una vista libre

de obstáculos del trayecto a recorrer,

respete las normas de tráfico, tenga

cuidado con las personas y guarde las

distancias de seguridad.

Sean cuales sean las condiciones de

circulación, conduzca la unidad siempre a una velocidad tal que le permita

detenerse por completo de modo seguro.

Durante la conducción, no acceda jamás a realizar acrobacias o competiciones.

Cuando circule por pisos húmedos o

resbaladizos, reduzca la velocidad.

Antes de circular por un muelle o por el

tablero de un puente, asegúrese de

que dichos elementos estén correctamente sujetos. Conduzca con precaución y despacio por el muelle y el

puente, y no sobrepase nunca la capacidad nominal de los mismos.

Cuando tenga que efectuar giros, reduzca la velocidad hasta que sea seguro efectuarlos conforme al entorno

en que esté maniobrando. Realice los

giros con suavidad.

Cuidado de la unidad por parte

del operario

Si se descubre la necesidad de reparar

la unidad o se detecta que ésta resulta

insegura de alguna manera o que contribuye a crear condiciones de inseguridad, se debe informar de inmediato a

la autoridad designada por el usuario.

Además, la unidad no deberá volver a

utilizarse hasta que se la haya devuelto a un estado operativo seguro.

Si, durante el funcionamiento, la unidad se vuelve insegura de alguna manera, se debe informar de inmediato a

la autoridad designada por el usuario.

Además, la unidad no deberá volver a

utilizarse hasta que se la haya devuelto a un estado operativo seguro.

No lleve a cabo reparaciones ni practique ajuste alguno a no ser que haya

sido expresamente autorizado para

ello.

TAREAS DE MANTENIMIEN-

TO Y ACONDICIONAMIENTO

Si se descuida el mantenimiento o se

practican en la unidad reparaciones,

tareas de acondicionamiento o ajustes

en los que no se respeten los criterios

de diseño del fabricante, su manejo

puede resultar peligroso. Por ello, se

debe disponer de servicios de mantenimiento (dentro o fuera de las instalaciones), contar con personal

cualificado y establecer unos modos

de proceder detallados.

El mantenimiento y la inspección de la

unidad deberán llevarse a cabo respetando las tareas que se indican a continuación:

A se deben seguir unos esquemas de

mantenimiento, lubricación e inspección conforme a su planificación; consulte las

recomendaciones del fabricante.

B el mantenimiento, las reparaciones,

los ajustes y las inspecciones de la

unidad sólo podrán ser llevados a

cabo por personal cualificado y autorizado; además, dichas tareas se

realizarán siempre de conformidad

con las especificaciones del fabricante.

Evite las posibles fuentes de peligro de

incendio y disponga siempre de extintores en la zona de trabajo. En la limpieza de las piezas, no use recipientes

de combustible abiertos ni líquidos limpiadores inflamables.

NORMAS DE SEGURIDAD

CONTRA INCENDIOS

Cuando las condiciones operativas de

una unidad no sean seguras, ésta deberá ponerse fuera de servicio.

En los emplazamientos de la clase I, la

clase II y la clase III está prohibido

efectuar reparaciones.

Prevención contra incendios: la unidad

se debe mantener limpia y debe estar

razonablemente libre de pelusas, restos de aceite y grasa. Para limpiar la

unidad, se recomienda usar preferiblemente agentes incombustibles. No

está permitido emplear líquidos inflamables [aquellos cuyo punto de inflamación esté en 100°F (37,8°C) o por

encima]. Se deben adoptar precauciones adecuadas al tipo de agente o disolvente empleado en lo que a la

toxicidad, la ventilación y el peligro de

incendios respecta.

Visibilidad de la placa de características: las denominaciones de tipo y las

marcas de tipo de la unidad indicadas

en la placa de características no deben

cubrirse con pintura que oscurezca la

información identificativa allí contenida.

No se debe utilizar la unidad en zonas

clasificadas.

20 ES

- 2

Page 21

Antes de poner en marcha

por primera vez el aparato,

lea el presente manual de instrucciones y siga las instrucciones que figuran en el mismo. Conserve estas

instrucciones para su uso posterior o

para propietarios ulteriores.

Índice de contenidos

Función . . . . . . . . . . . . . . . . ES . . 3

Uso previsto . . . . . . . . . . . . ES . . 3

Protección del medio ambiente ES . . 3

Elementos de mando . . . . . ES . . 4

Antes de la puesta en marcha ES . . 4

Funcionamiento . . . . . . . . . ES . . 5

Conservación y mantenimiento ES . . 6

Averías . . . . . . . . . . . . . . . . ES . . 7

Datos técnicos . . . . . . . . . . ES . . 8

Accesorios . . . . . . . . . . . . . ES . . 9

Garantía . . . . . . . . . . . . . . . ES . . 9

Piezas de repuesto . . . . . . . ES . . 9

Instrucciones de seguridad

Antes de utilizar por primera vez el

aparato, lea y tenga en cuenta el presente manual de instrucciones y el folleto adjunto relativo a las indicaciones

de seguridad para aparatos de limpieza con cepillos y aparatos pulverizadores, 5.956-251.

Símbolos

En este manual de instrucciones se

emplean los siguientes símbolos:

Peligro

Indica la existencia de un peligro inminente. El incumplimiento de la indicación puede acarrear la muerte o

lesiones de suma gravedad.

몇 Advertencia

Hace alusión a una situación potencialmente peligrosa. El incumplimiento

de la indicación puede provocar lesiones leves o daños materiales.

Nota

Identifica consejos de manejo e información importante sobre el producto.

Función

El aparato sirve para efectuar la limpieza en húmedo o el pulido de pisos llanos.

Dos cepillos rotativos contrarrotantes

limpian el suelo con ayuda del líquido

limpiador añadido. Una anchura de trabajo de 400 mm y una capacidad de

los tanques de agua limpia y sucia de

10 l cada uno permiten una limpieza

eficaz.

El funcionamiento vía red eléctrica permite obtener una elevada capacidad

de rendimiento sin limitar de modo alguno el trabajo.

Nota

En función de la tarea de limpieza de

que se desee realizar, es posible dotar

al aparato de distintos accesorios. Solicite nuestro catálogo o visítenos en la

página de internet www.kaercher.com.

Uso previsto

Utilice el aparato únicamente de conformidad con las indicaciones del presente manual de instrucciones.

– El aparato ha sido concebido exclu-

sivamente para la limpieza de suelos lisos resistentes a la humedad y

al pulido.

El margen de temperaturas de servicio está comprendido entre los

+5°C y los +40°C.

– El aparato no es apto para la limpie-

za de pisos congelados (p. ej., en

almacenes frigoríficos).

– Sólo está permitido dotar al aparato

de accesorios y piezas de repuesto

originales.

– El aparato ha sido concebido para

la limpieza de pisos en interiores o

superficies techadas. Para otros

campos de aplicación, deberá considerarse el uso de cepillos alternativos.

– El presente aparato no es apto para

la limpieza de las vías públicas de

tránsito.

Los aparatos viejos contienen materiales valiosos reciclables que debieran

aprovecharse. Evite el contacto de baterías, aceites y

materias semejantes con el

medioambiente. Deshágase de los aparatos viejos recurriendo a sistemas de

recogida apropiados.

Indicaciones sobre ingredientes

(REACH)

Encontrará información actual sobre

los ingredientes en:

www.kaercher.com/REACH

Protección del medio ambien-

te

Los materiales de embalaje

son reciclables. Por favor,

no tire el embalaje al cubo

de basura; llévelo a un lugar

de reciclaje.

- 3

21ES

Page 22

25

24

Elementos de mando

1 Bloqueo de tanque de agua limpia

2 Interruptor accionamiento de los

cepillos

3 Interruptor solución de limpieza

4 Manguera solución de limpieza

5 Filtro de pelusas (aspiración)

6 Dispositivo de bloqueo estribo de

empuje

7 Tecla de desbloqueo rueda de

transporte

8 Rueda de transporte

9 estribo de empuje

10 Gancho de relajación de esfuerzos

mecánicos

11 Soporte rueda de transporte

12 grapa

13 Depósito de agua limpia

14 depósito de agua sucia

15 Pulsador cambio de barra de aspi-

ración

16 flotador

17 Tecla cambio de cepillos

18 Tren de desplazamiento

19 barra de aspiración

20 Escobillas rotativas

21 Empuñadura giratoria presión de

apriete de cepillo

22 Pedal para bajar la barra de aspira-

ción

23 Clavija de red

24 Asa de transporte depósito de agua

sucia

25 Tapa depósito de agua limpia

Antes de la puesta en marcha

Montar el estribo de empuje

Desplazar la mitad superior del es-

tribo de empuje sobre la mitad inferior del estribo de empuje.

몇 Advertencia

Peligro de daños en la instalación. No

enganchar el cable durante el montaje.

Alinear los orificios (2 ajustes de al-

tura posibles).

Unir las mitades del estribo de em-

puje con tornillos de cierre, arandelas y mangos de estrella.

Fijar el cable con clips al estribo de

empuje.

Montar ruedas de transporte

Insertar los ejes de las ruedas de

transporte en los orificios del aparato y encajarlos.

Montaje de los cepillos

Antes de la puesta en servicio, se tienen que montar los cepillos (véase

"Trabajos de mantenimiento").

Funcionamiento

Nota