Page 1

OPERA T OR'S MANU A L

ROTARY RAKE

RR2109

5PQ990104 (08/28/2012)

Page 2

To the Owner;

Thank-You for choosing a quality product from Frontier Equipment. We strive

to give you the best equipment and the best level of service of any company.

With a little care and maintenance this machine will do your work for you for

many years. In this manual, we make an effort to get you better acquainted

with the machine so you can achieve maximum performance. We design

and build all of our equipment with the end user in mind so we welcome any

suggestions or ideas for improvement. Please note that it is within our rights

to make changes or improvements to our equipment without updating the

equipment that was manufactured before the change took place.

Please take a few minutes to ll out the area below. This information will be

valuable to you when ordering parts or requesting service from your dealer.

Dealer Name:_____________________________

Dealer Phone Number:______________________

Service Manager/Technician:_________________

Model# and Description:_____________________

Serial Number:____________________________

Date of Purchase:__________________________

Page 3

TABLE OF CONTENTS

Introduction ……………………………………………………………… 2

Rake Serial Number ………………………..……………… 2

Specications ………………………………………………… 2

Safety ………………………………………………………...……………… 3

Power Source Safety ………………………………………… 3

Safety Decals …………………….…………..……………… 4

Driveline Safety …………………….…………..…………..… 5

Dealer Setup ……………………………………………..……………… 6

Hitching ……………………………………………………..……………… 8

Tractor Requirements ……………………….……………… 8

Hitching ………………………………………..……………… 8

Transporting ……………………………………………………………… 10

Field Transport ……………………………………………… 10

Road Transport ……………………………………………… 10

Height and Level Adjustment ………………………....………… 11

Height Adjustment ………………………………………..… 11

Leveling the Rake ………………………………………… 11

Hay Curtain Adjustments ………………………………………… 12

Operating ……………………………………………………………….… 13

Field Dangers …………………………………………….… 13

Lubrication …………………………………………………………….… 14

Gearbox Lubrication ……………………………………..… 14

PTO Lubrication …………………………………………..… 15

General Lubrication ……………………………………...… 15

Maintenance …………………………………………………………..… 16

Storing your Rake …………………………………………………… 16

Torque Specications ……………………………………………… 17

Standard Torque Chart …………………………………..… 17

Metric Torque Chart ………………………………………… 18

Warranty ………………………………………………………………...… 19

Illustrated Parts Breakdowns …...……………………………...… 20

Tongue & Main Frame …….……………………………… 21

Guards …………………..…………………………………… 22

Gearbox & Tine Arm …..…………………………………… 23

Axle Assembly ……………………………………………… 24

Rotary Gearbox …….……………………………………… 25

PTO Shaft ……………...…………………………………… 26

Decals & Reectors …..…………………………………… 27

1

Page 4

INTRODUCTION

Thank-You for choosing the Frontier Rotary Rake. Your rake is the result of years of research

and development work. This Operator’s Manual will familiarize the operator with the safety and

operation of the machine. Included are complete instructions for assembly, operation, lubrication,

and maintenance procedures. Understanding and following these procedures will result in years

of maximum performance from your Frontier Rake.

Read entire manual before operating. Failure to follow the instructions outlined in this

manual may result in personal injury and/or damaged equipment, and could void the warranty.

Rake Serial Number

The rake’s serial number can be found near the front on the main frame of the rake. Please use

this number when requesting service, seeking information, or ordering parts. For the operator’s

convenience, space to record the serial number, model number, purchase date, and dealer has

been provided inside the front cover of this manual.

All pictures and instructions in this manual assume that the right and left side

of the machine are that of someone standing behind the rake facing forward.

Specications

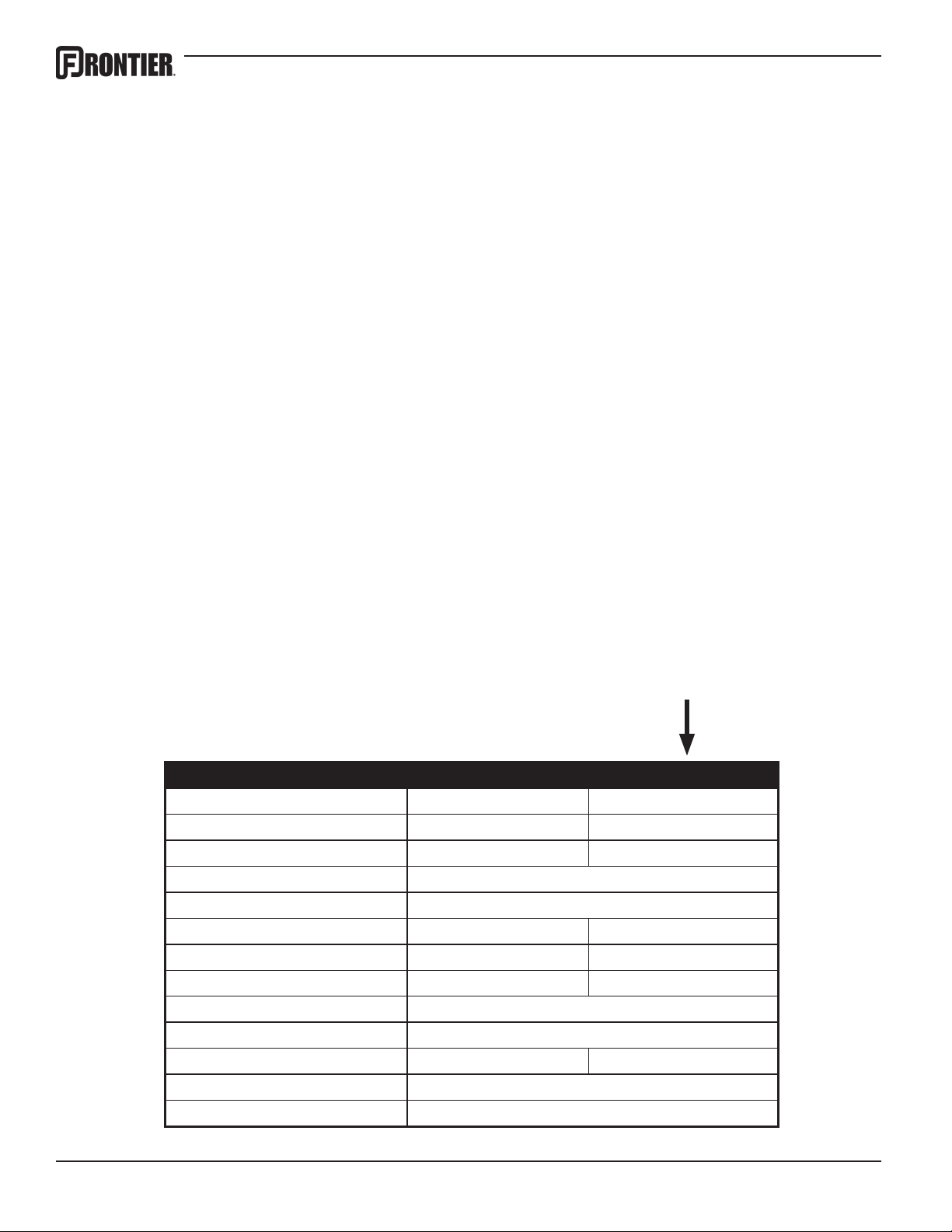

Specications RR2211 RR2109

Working Width 13' (4.3m) 10' 8" (3.2m)

Raking Width 11' (3.3m) 9' (2.7m)

Transport Width 59" (1.5m) 9' 4" (2.8m)

Gear Box Enclosed Oil Bath

Gear Reduction 9.7 to 1

Tine Arms 11 9

Double Tines per Arm 4 3

PTO/HP Required 40 HP - 540 RPM 30 HP - 540 RPM

Direction of Raking Action Left

Hydraulic Requirement 1200 psi

Weight 1550 lbs. 1050 lbs.

Tandem Axle Beam Standard

Tires 18.5 x 8 Flotation Tires on 4-Bolt Painted Wheels

2

Page 5

SAFETY

This symbol precedes specic safety instructions throughout this manual. When reading

the manual pay close attention to the information that follows this symbol.

FAILURE TO FOLLOW INSTRUCTIONS IN THIS MANUAL COULD RESULT IN PERSONAL

INJURY OR DEATH. READ ENTIRE MANUAL BEFORE OPERATING ROTARY RAKE.

Keep hands, feet and clothing away from the machine’s input power take-off (PTO) and any

other moving parts until the machine has been shut down and the power source has been locked

out. (Refer to Power Source Safety)

Do not adjust, unclog, lubricate, or service the machine until it has been shut down and the

power source has been locked out. (Refer to Power Source Safety)

Do not lubricate or adjust the machine while it is in motion.

Support the rake securely while working under it.

Do not stand between the tractor and the rake while attaching or detaching the rake unless the

tractor engine is shut off and the parking brake has been set.

Be certain all bystanders and animals are a safe distance away from the rake before raising or

lowering it. Never allow anyone to ride on the rake or the tractor.

When transporting, never exceed a speed of 20 MPH (32kkm/hr) and avoid sudden turns which

may compromise the operator’s control of the tractor.

Be constantly aware of the location of the ends of the rake to avoid collision with other objects.

When moving the rake on public roads use the proper reectors, lights, and slow moving vehicle

signs required by local government agencies.

Power Source Safety

Do not use a power take-off (PTO) shaft without a rotating shield in good working order. Make

sure drive system safety shields are in place for both the power source and the rake.

The rake input PTO must be securely attached to both the power source and the input shaft.

Do not overextend the input PTO shaft.

Make sure PTO is disengaged before starting power source.

PTO shield chains must be attached to the tractor and the rake to keep the shield from rotating.

3

Page 6

SAFETY CONT’D

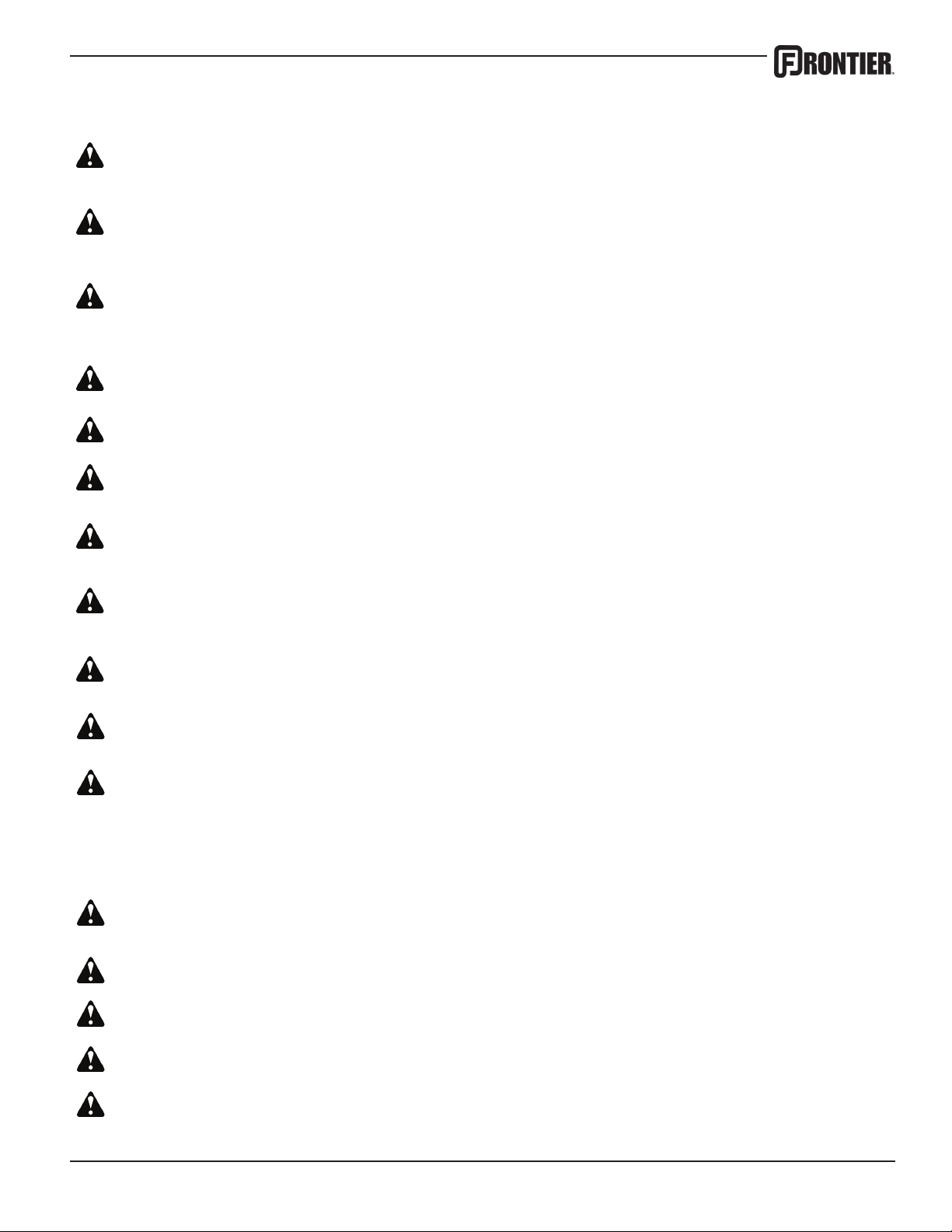

Safety Decals

Decals and reectors are for the protection of yourself and others. If they are missing,

faded, or not readable, get replacements from your dealer immediately.

4

Page 7

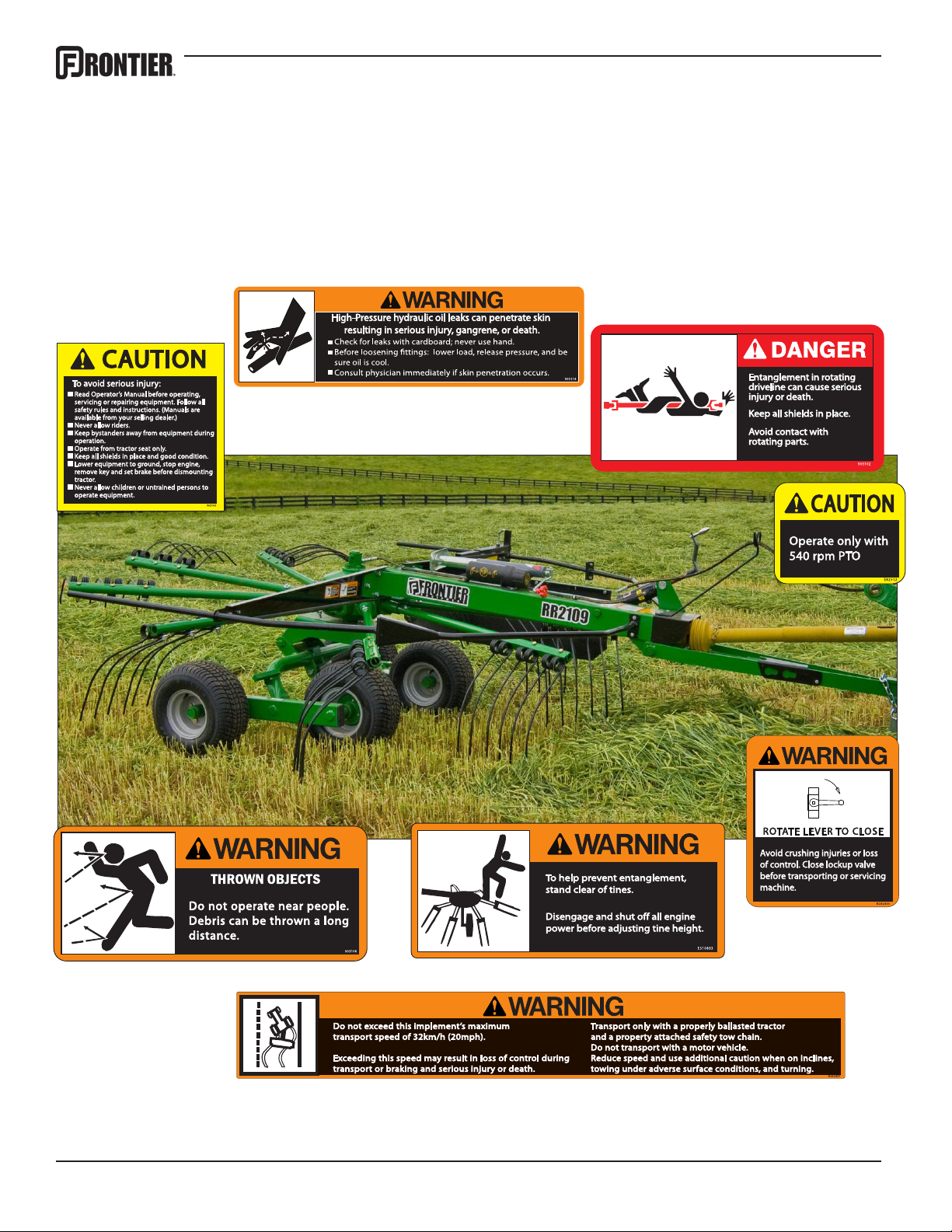

Stay Clear of Rotating Drivelines

master shield shall overlap the end of the splined shaft and the added adaptor

TS1644-UN-22AUG95 H96219-UN-29APR10

Entanglement in rotating driveline can cause serious injury or death.

Keep tractor master shield and driveline shields in place at all times. Make

sure rotating shields turn freely.

Wear close fitting clothing. Stop the engine and be sure that PTO driveline

is stopped before making adjustments, connections, or cleaning out PTO

driven equipment.

Do not install any adapter device between the tractor and the primary

implement PTO drive shaft that will allow a 1000 rpm tractor shaft to power

a 540 rpm implement at speeds higher than 540 rpm.

Do not install any adapter device that results in a portion of the rotating

implement shaft, tractor shaft, or the adapter to be unguarded. The tractor

device as outlined in the table.

PTO Type

1 35 mm (1.378 in.)

Diameter Splines n ± 5 mm (0.20 in.)

6 85 mm (3.35 in.)

2 35 mm (1.378 in.) 21 85 mm (3.35 in.)

3 45 mm (1.772 in.) 20 100 mm (4.00 in.)

5

Page 8

DEALER SETUP

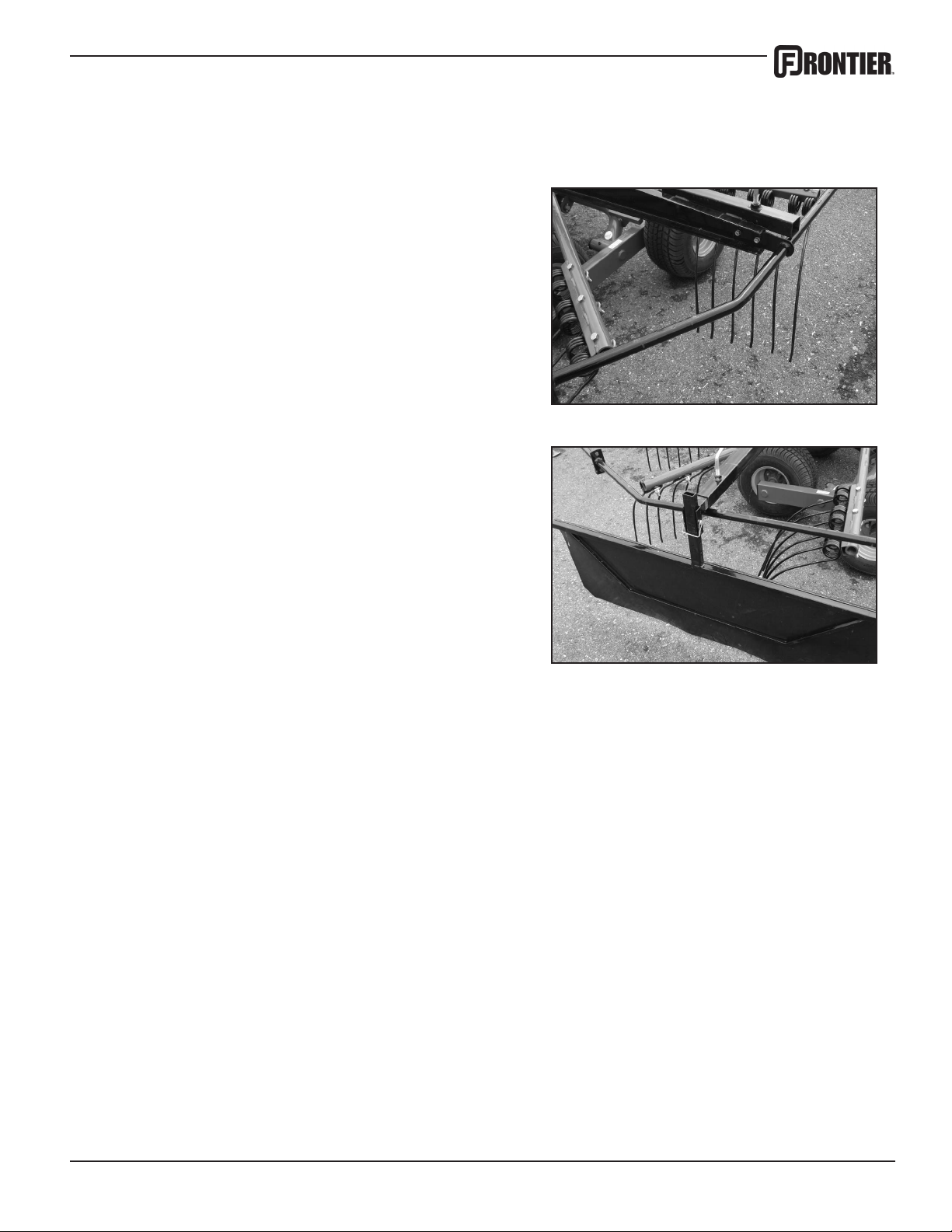

Tine Arms

Remove the rubber cap from the gearbox shaft. Slide

the tine arm onto the shaft. Line up the hole and insert the M10 metric socket head bolt. Place one of

the cupped washers on either side of the tine arm and

tighten the locknut. Repeat for all 9 arms.

Tines

Attach three tines to each arm using the 1/2 x 3-1/4

Grade 8 bolts. Insert bolt from the top and clamp the

tine in place with the 1/2” heavy washer and locknut.

Torque to 60-65 ft.-lbs.

Guard Support Arms

Attach the guard support arms to both sides of the rake

using the 1/2” bolts. NOTE: The guard arm with the

curtain mount tube is for the left side of the rake.

Guards, Front

Attach the front half of the guard to the main frame using the 3/8 x 1 bolts, lockwashers & nuts. Repeat both

sides.

6

Page 9

DEALER SETUP CONT’D

Guards, Rear

Attach the rear half of the guard to the guard support

arm using the 5/16 bolts, lockwashers & nuts. A lso attach to the front guard using 3/8 hardware.

Hay Curtain

Slide the curtain mount tube into the tube on the guard

arm and lock with the locking handle. Attach the curtain and select the desired height. Insert locking pin to

secure.

Note to customer: This setup for the RR2109 is usually done by the dealer, however, the arms and guards

can easily be removed for winter storage if you prefer.

7

Page 10

HITCHING

Tractor Requirements

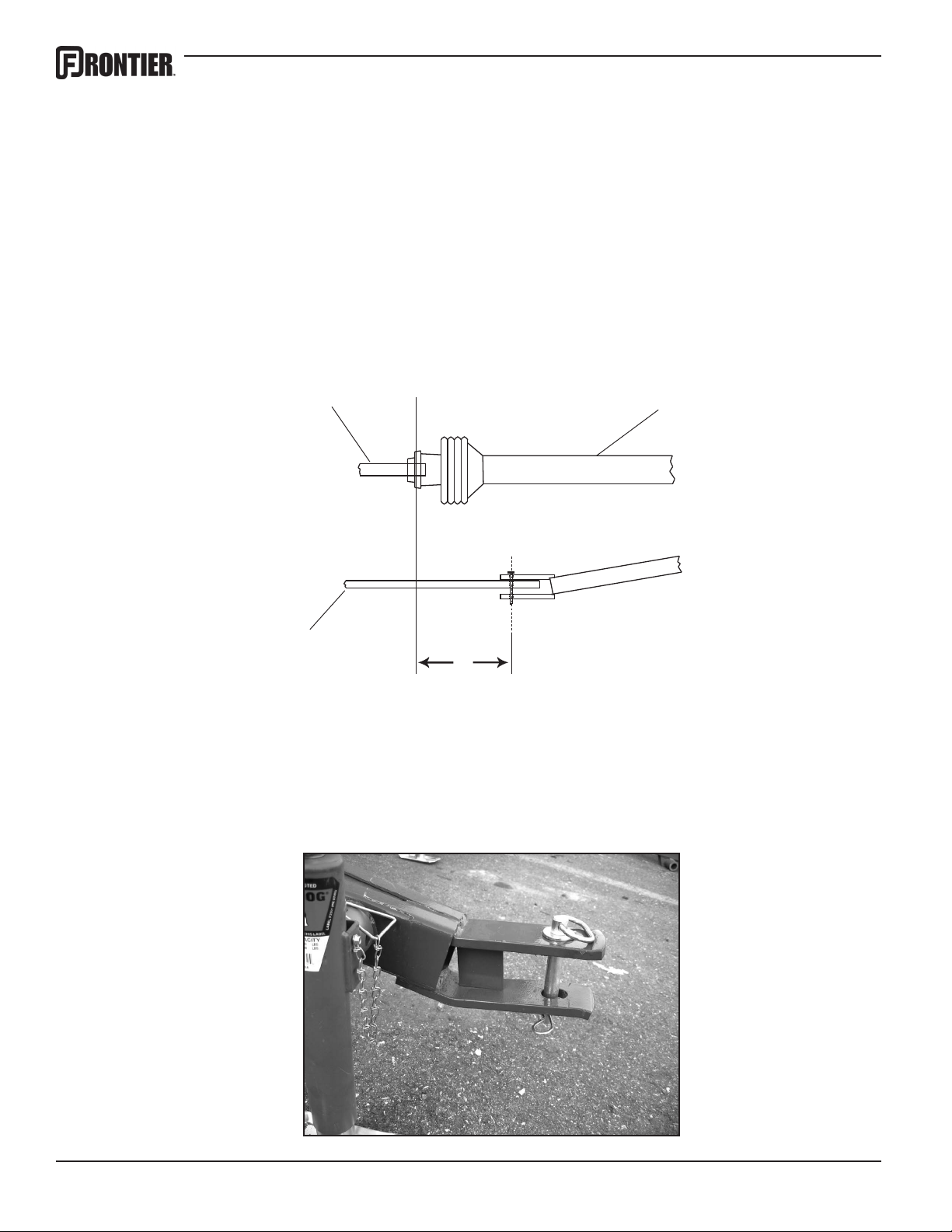

The Frontier Rotary Rake is designed to be used with a tractor having a 540 RPM PTO. The

hitch pin hole on the tractor should be 14” (35cm) from the rear of the groove in the PTO output

shaft. (See illustration below)

NOTE: If the hitch pin hole is located well behind the tractor tires there is the potential of making

a sharp enough turn to damage the rake PTO shaft.

Tractor PTO

Shaft

Rake Driveline

Tractor Drawbar

14”

Center Line of Hitch

Pin Hole

Hitching

Align the hole in the tractor draw bar with the hole in the rake tongue and insert an approved

hitch pin. Lock hitch pin with a safety clip to insure that it cannot work its way out. Attach the

safety chain to the tractor.

8

Page 11

HITCHING, CONT’D

With PTO shaft connected to the rake, slide shaft safety collar back and slide the tractor side of

the PTO shaft onto the tractor drive shaft. Release the shaft safety collar. Insure that the PTO

shaft is securely locked onto the tractor drive shaft. Fold the PTO stand down onto the frame to

avoid damaging the PTO shaft shielding. (See illustration below)

Connect the rake hydraulic line to the tractor implement hydraulic output.

Crank the rake jack off of the ground and remove the locking pin. Pull the jack off of the mount,

place in storage position on the main frame, and reinsert locking pin. (See illustration below)

The jack can also be stored on the hitch beam by simply giving it a quarter turn. This position

is not recommended in the eld though as it increases the risk of damaging the jack with the

tractor wheel when turning.

9

Page 12

TRANSPORTING

Field Transport

• Make sure that the rake is raised into the transport position.

• Never allow anyone to ride on the rake or the tractor other than the operator.

• Avoid tight turns to reduce the possibility of loss of control or PTO shaft damage.

• Remain fully aware of the width of the rake in relation to the objects you are passing, either

stationary or moving.

• Never travel at speeds over 10 MPH (16km/hr.) in the eld.

Road Transport

• Adhere to all suggestions for transport in the eld listed above.

• Follow all local regulations for moving agricultural equipment on public roads, especially those

related to reectors, SMV (slow moving vehicle) symbols and safety markers.

• Never travel at speeds over 20 MPH (32km/hr.) on the road.

10

Page 13

HEIGHT AND LEVEL ADJUSTMENT

Height Adjustment

The RR2109 Rake has an adjustment screw for the rear height adjustment. (See illustration

below) Turn clockwise to raise or counterclockwise to lower the rake. With the rake setting on

level ground, set the height so that the tips of the tines are 1” (25mm) from the ground. This

setting will offer the best performance in most eld and crop conditions, however, in uneven

or rocky areas we recommend setting the tines higher off the ground to reduce tine wear and

stress. There is no advantage to having the tines actually hit the ground. Hitting the ground will

cause unnecessary wear on the tines, and will cause the hay to become contaminated with

dust, resulting in premature wear of other processing equipment. An occasional adjustment will

also be necessary to account for normal tine wear.

Leveling the Rake

Your rake is also equipped with a leveling cylinder. This is on the front of the main frame and

can be adjusted quickly at any time to accommodate different draw bar heights. Simply turn the

handle clockwise to raise or counter-clockwise to lower the front of the rake. NOTE: You will

get the best performance with the front of the rake slightly lower than the rear.

11

Page 14

HAY CURTAIN ADJUSTMENTS

Whenever desired, the hay curtain on your hay rake can easily be adjusted to accommodate

your requirements. The hay curtain adjustment determines the width of the windrow, and is

used when turning a windrow or removed when combining windrows.

The working width of your swath is adjusted by positioning the hay curtain. To change the curtain position, turn the L-shaped rod (1) on the curtain mounting tube. Loosen by turning counter clockwise and tighten by turning clockwise until tight. (Do not overtighten)

The height of the hay curtain is adjusted by removing the stop pins (2) on the curtain frame

and raising or lowering the curtain to the desired height. We recommend setting it so the bottom of the curtain just touches the cut plant.

When combining windrows the curtain may be turned upside down or eliminated completely.

1 2

12

Page 15

OPERATING

Having made adjustments (where necessary) described in the previous sections, drive the

tractor to where you will begin raking. With the tractor standing still, lower the rake to it’s

operating position. Engage the tractor’s PTO at a low RPM, (this is especially important on a

tractor with an electric clutch) and without getting off the tractor seat, visually determine that

the rake is properly adjusted. If further adjustments are required, disengage the PTO and

stop the tractor’s engine and adjust where needed.

When ready, increase PTO speed to the desired RPM and engage the tractor’s forward

gear. Remember, ground speed and PTO speed, along with the proper adjustment for

height and level, will play a large role in making a clean sweep and a nice even windrow. 6

MPH ground speed and 350 PTO RPMs is the ideal combination for uffy windrows. Adhere

to all safety requirements as listed previously for eld operation.

Always operate the rake at the lowest RPM possible that allows you to rake cleanly at your

chosen ground speed. Higher speeds result in more leaf loss and lower quality hay, especially if you are raking dry hay. Higher speeds will also cause more wear on the rake.

When nished, reduce PTO speed before disengaging. Disengage PTO and raise rake into

transport position before leaving eld.

Requirements will change according to eld and crop conditions.

Field Dangers

While operating the rake you must constantly be aware of all your surroundings. The folddown guards are designed for human safety and will not withstand a collision with a stationary object such as a fence post or an electric pole. If such a collision does occur and you

cannot stop before the tine arms hit the obstacle, the safety slip clutch on the PTO shaft will

automatically engage and protect the gearbox from any serious damage. The slip clutch will

not engage fast enough to protect the tine arms.

The rake is also equipped with an anti rollover system for the axle tandem walking beams.

This is a safety feature that will keep the axle tandems from going over center and ipping

up into the tine arms when accidently driving over a washout, sink hole, or animal den. However, this is no excuse for careless driving, as other damage can occur when the wheels hit

a rut or a hole.

13

Page 16

LUBRICATION

It is extremely important to keep your rake properly lubricated at all times. Failure to do so will

greatly decrease the performance and the life of the machine.

Never lubricate or perform any maintenance, adjustments or repairs with the machine running.

The PTO must be disengaged and the tractor’s engine must be shut off.

With a clean cloth wipe off both the grease tting and the tip of the grease gun. This will eliminate any chance of dirt or dust particles getting inside and damaging the bearings.

Do not overgrease the ange bearings. Overgreasing could rupture the seals exposing the

bearing to a lot of dust particles. Roller bearings are sealed and are generally maintenance

free. The friction bearing points cannot be overgreased.

Gearbox Lubrication

The oil level in the gearbox can be checked by removing the check plug on the side of the

gearbox (1) and using a straw to insure that the oil level is near the bottom of the plug hole. If

oil needs to be added, use SAE 85W140 Gear Lube and ll using the plug located on the top of

the gear box (2).

1

2

3

We recommend changing the oil after every 200 hours of use. To do this, remove the plug at

the bottom of the gear box (3) and drain the oil into a container for proper disposal. Always follow local guidelines for disposal of waste oil in an environmentally appropriate manner. Never

drain waste oil directly onto the ground.

14

Page 17

LUBRICATION

PTO Lubrication

There are grease ttings on both the tractor end and the rake end of the PTO shaft. Grease

these after every 8 hours of operation. Use a high quality lithium grease.

General Lubrication

All other grease ttings should be lubricated after every 50 hours of operation. Use a high quality gear grease for the grease ttings on top of the gearbox. For all other bearings, joints, and

pivot points, use either a lithium or a gear grease. In dry, dusty conditions it may be necessary

to grease more than every 50 hours.

15

Page 18

MAINTENANCE

Check and replace any safety decals that are damaged or missing.

After rst use of the rake, we recommend a thorough inspection of all bolts and nuts. Retighten any loose hardware and check periodically thereafter.

Check the air pressure of the tires. They should be inated to approx. 20 psi.

Inspect the tines and replace any broken, missing, or bent tines.

Visually inspect condition of the hay curtain. Replace if necessary.

Periodically pressure wash your equipment and touch up any scratches with high quality rust

resistant paint.

Apply a light weight oil to all moving parts not specied in other lubrication instructions in this

manual.

STORING YOUR RAKE

Before winter storage, perform all lubrication and other maintenance procedures as previously described.

Store in a dry, covered place with the rake lowered into the raking position. Storing in the

raised (transport) position exposes the cylinder rod to dust and other elements that could

cause it to rust.

16

Page 19

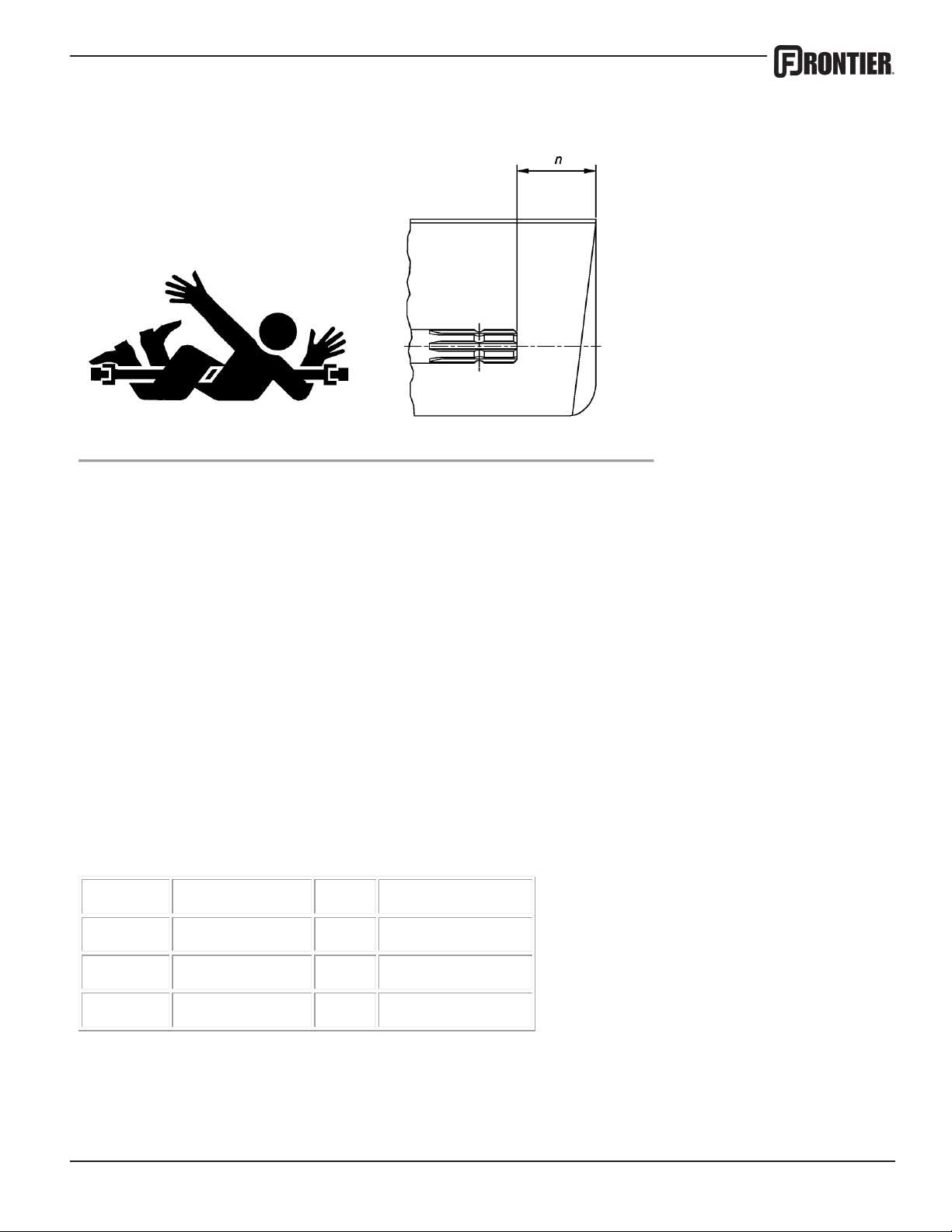

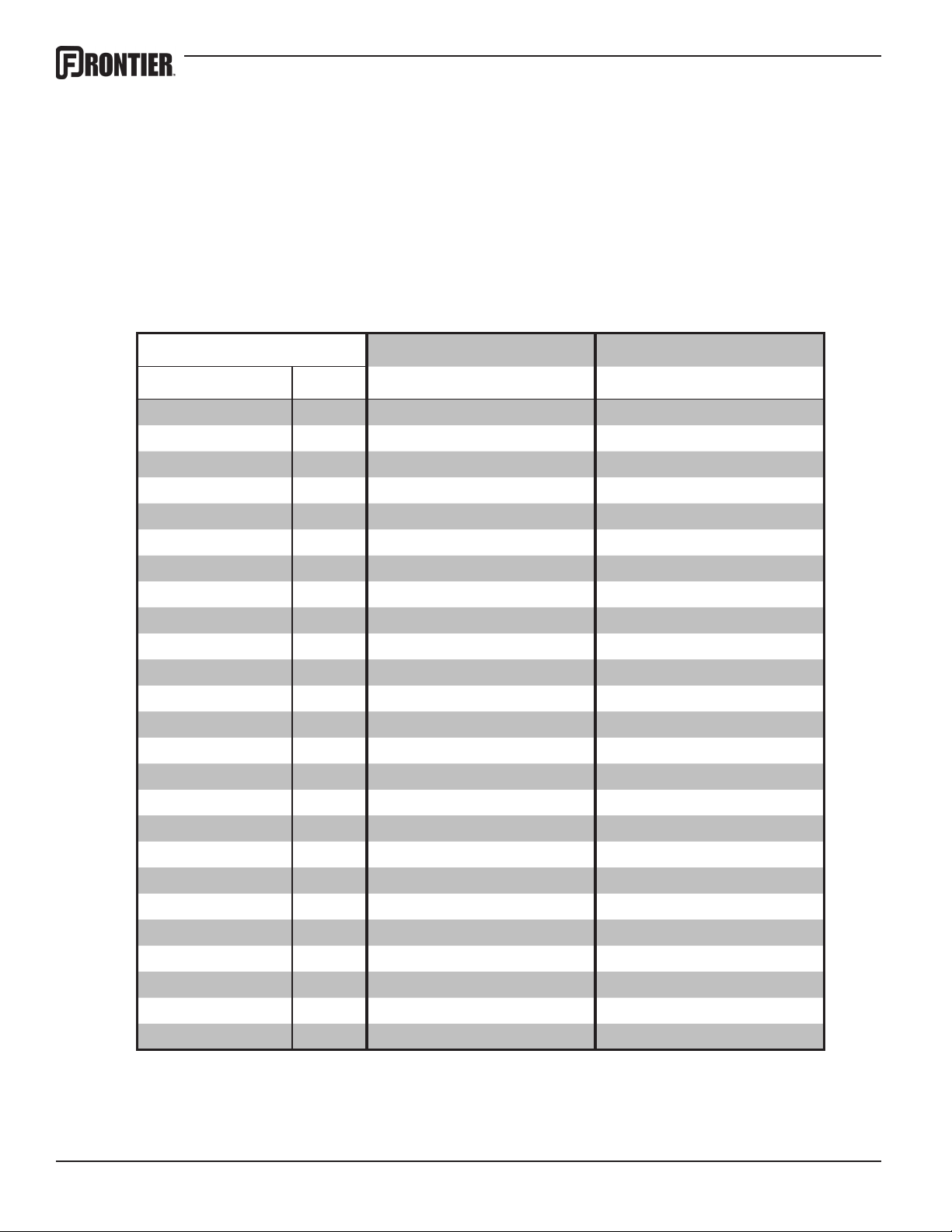

TORQUE SPECIFICATIONS

The torque chart below lists the standard torque values for all attachment hardware on the

rake unless otherwise specied in this manual.

Standard Torque Chart

GRADE 5 BOLTS GRADE 8 BOLTS

BOLT SIZE

1/4 20 8 6 12 9

1/4 28 10 7 14 10

5/16 20 17 13 24 18

5/16 24 19 14 27 20

3/8 16 30 23 45 35

3/8 24 35 25 50 35

7/16 14 50 35 70 50

7/16 20 55 40 80 60

1/2/2 13 75 55 110 80

1/2/2 20 85 65 120 90

9/16 12 110 80 150 110

9/16 18 120 90 170 130

5/8 11 150 110 210 160

5/8 18 170 130 240 180

3/4 10 260 200 380 280

3/4 16 300 220 420 310

7/8 9 430 320 600 450

7/8 14 470 350 670 500

1-8 640 480 910 680

1-14 720 540 1,020 760

TORQUE (DRY)

FT.LBS.

LUBRICATED

FT.LBS.

TORQUE (DRY)

FT.LBS.

LUBRICATED

FT.LBS.

17

Page 20

TORQUE SPECIFICATIONS

BOLT SIZE & PITCH CLASS PLATED UNPLATED PLATED UNPLATED

M4 x .70 8.8 3.10 2.20 2.30 1.65

M5 x .80 8.8 6.10 5.50 4.58 4.13

M6 x 1.00 8.8 10.40 9.50 7.80 7.13

M7 x 1.00 8.8 17.00 15.50 12.75 11.63

M8 x 1.25 8.8 25.00 23.00 18.75 17.25

M8 x 1.00 8.8 27.00 24.50 20.25 18.38

M10 x 1.50 8.8 51.00 46.00 38.25 34.50

M10 x 1.25 8.8 54.00 49.00 40.50 36.75

M10 x 1.00 8.8 57.00 52.00 42.75 39.00

M12 x 1.75 8.8 87.00 79.00 65.25 59.25

M12 x 1.50 8.8 92.00 83.00 69.00 62.25

M12 x 1.25 8.8 96.00 87.00 72.00 65.25

M14 x 2.00 8.8 140.00 125.00 105.00 93.75

M14 x 1.50 8.8 150.00 135.00 112.50 101.25

M16 x 2.00 8.8 215.00 195.00 161.25 146.25

M18 x 2.50 8.8 300.00 280.00 225.00 210.00

M20 x 2.50 8.8 430.00 390.00 322.50 292.50

M22 x 2.50 8.8 580.00 530.00 435.00 397.50

M24 x 3.00 8.8 740.00 670.00 555.00 502.50

M6 x 1.00 10.9 15.50 14.00 11.63 10.50

M8 x 1.25 10.9 37.00 34.00 27.75 25.50

M10 x 1.50 10.9 75.00 68.00 56.25 51.00

M12 x 1.75 10.9 160.00 117.00 97.50 87.75

M14 x 2.00 10.9 205.00 185.00 153.75 138.75

M16 x 2.00 10.9 310.00 280.00 232.50 210.00

Metric Torque Chart

NEWTON METERS (NM) FOOT POUNDS (FT. LBS.)

18

Page 21

WARRANTY

Warranty coverage is provided by John Deere according

to the terms of the Agricultural/Commercial & Consumer

Equipment Warranty Statement. Carefully read the warranty

statement on the back of your original purchase order for

details on coverage and limitations of this warranty.

19

Page 22

Illustrated

Parts

Breakdowns

20

Page 23

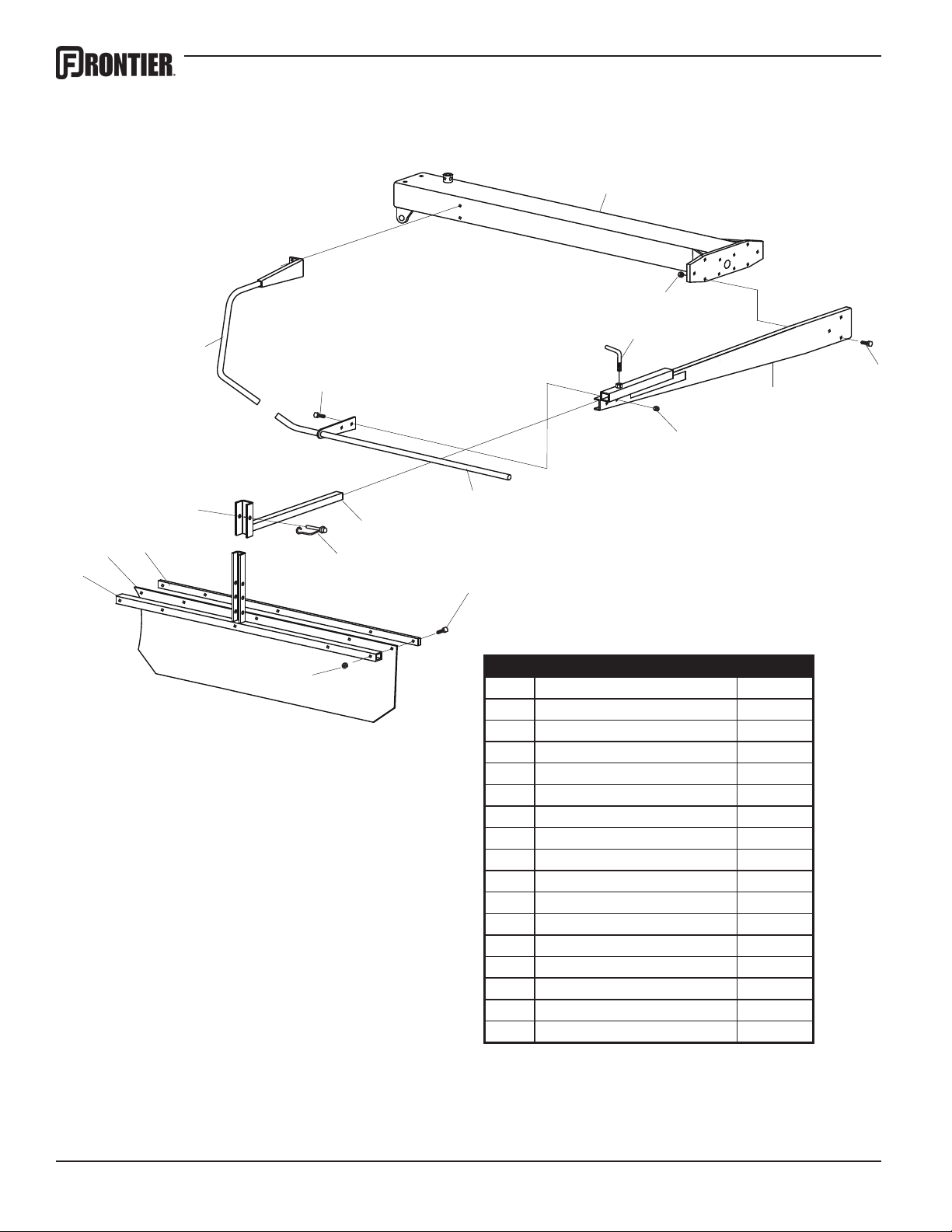

Tongue & Main Frame

4

39

2

1

3

5

40

38

37

6

7

8

9

10

12

11

13

14

26

27

28

41

29

25

24

30

23

22

31

21

20

18

19

17

15

16

32

36

31

33

32

34

35

Ref# Description Part#

Ref# Description Part# 21 Locknut, 5/16 5PQ002999

1 Complete PTO Shaft 5PQ503039 22 1.25-14 Machinery Bushing 5PQ500185

2 Ball Valve 5PQ502322 23 Roll Pin, 1/4 x 2 5PQ500017

3 Hydraulic Hose 5PQ502294 24 Front Cylinder 5PQ502279

4 Hose Support 5PQ502288 25 Front Cylinder Handle 5PQ503037

5 Bolt, 5/16 x 3/4 Truss Head 5PQ000210 26 Tongue Assembly 5PQ502237

6 Bolt, 5/16 x 1 5PQ000221 27 Locknut, 3/8 5PQ003000

7 Hose Support Washer 5PQ502308 28 PTO Stand 5PQ500015

8 PTO Guard 5PQ502234 29 Bolt, 3/8 x 1-1/4 5PQ000275

9 1-3/8 Flange Bearing 5PQ500067 30 Cylinder Mount 5PQ502218

10 Hydraulic Hose 5PQ502281 31 Roll Pin, 1/4 x 2 5PQ500017

11 Jack Mount Bracket 5PQ500005 32 1.25-14 Machinery Bushing 5PQ500185

12 Locknut, 3/8 5PQ003000 33 Tongue Pin 5PQ502225

13 Tunnel Assembly 5PQ502204 34 Pin & Chain 5PQ500012

14 Elbow Fitting, 1502-4-4 5PQ502300 35 Complete Jack 5PQ500009

15 Gearbox Complete 5PQ502264 36 Jack Handle 5PQ500010

16 Splined Yoke 5PQ500269 37 Drive Shaft 5PQ502257

17 Cross & Bearing Kit 5PQ500272 38 Bolt, 1/2 x 1-1/2 5PQ000435

18 Keyed Yoke 5PQ500270 39 Safety Chain 5PQ101200

19 Complete U-Joint 5PQ500268 40 Male Hydraulic Coupler 5PQ290105

20 Nut, 1/2 5PQ000940 41 Handle 5PQ502149

21

Page 24

16

15

Guards

1

5

6

2

3a Left Side

3b Right Side

4

7

12

13

14

11

8

9

10

Ref# Description Part#

1 Tunnel Assembly 5PQ502204

2 Bolt, 1/2 x 1/1-4 5PQ000420

3a Guard Arm, Left 5PQ502246

3b Guard Arm, Right 5PQ502239

4 Nut, 3/8 5PQ000915

5 Nut, 1/2 5PQ000940

6 Curtain Set Bolt 5PQ500148

7 Tine Guard Assembly, Rear 5PQ503096

8 Telescoping Tube 5PQ500149

9 Snapper Pin 5PQ500158

10 Bolt, 1/4 x 1-3/4 5PQ000187

11 Locknut, 1/4 5PQ003001

12 Curtain Mount Assembly 5PQ502251

13 Hay Curtain 5PQ502252

14 Curtain Bar 5PQ502247

15 Bolt 3/8 x 1 5PQ000270

16 Tine Guard Assembly, Front 5PQ503095

22

Page 25

Gearbox & Tine Arm

7

1

2

4

3

6

5

5

8

11

10

9

12

13

18

17

16

14

Ref# Description Part#

1 Hydraulic Hose 5PQ502281

2 Elbow Fitting, 1502-4-4 5PQ502300

3 Complete Gearbox, 9 Arm 5PQ502264

4 M10 x 80 Socket Head Bolt 5PQ001080

5 Radius Washer 5PQ701008

6 Tine Arm 5PQ903147

7 Bolt, 1/2 x 3-1/4 5PQ000478

8 Curved Rake Tine 5PQ500218

9 Locknut, 1/2 5PQ000950

10 Heavy Duty Flat Washer 5PQ000520

11 M10 Nylon Locknut 5PQ002822

12 Hexagon Shaft 5PQ500258

13 Gearbox Stand Assembly 5PQ502241

14 Rear Height Adjustment Lever 5PQ502274

15 Stainless Steel Handle 5PQ502149

16 3/4 x 3/4 Socket Head Bolt 5PQ000693

17 External Tooth Lock Washer 5PQ001087

18 Pipe Plug 5PQ502298

15

23

Page 26

Axle Assembly

15

16

18

17

14

13

12

10

11

8

9

21

7

5

4

2

1

3

32

32

31

33

34

35

30

31

6

26

27

28

29

25

23

22

24

19

23

20

22

36

37

Ref# Description Part# Ref# Description Part#

1 215/60-8 Tire, “C” Ply 5PQ500221 20 Stainless Steel Handle 5PQ502149

2 4-Hole Rim 5PQ500222 21 Elbow Fitting, 1501L-4-4 5PQ502301

3 Cotter Pin 5PQ500208 22 Roll Pin, 1/4 x 2 5PQ500017

4 Complete Hub 5PQ500199 23 1.25-14 Machinery Bushing 5PQ500185

5 Walking Beam Assembly 5PQ502240 24 Axle Assembly 5PQ502243

6 1.50-14 Machinery Bushing 5PQ500197 25 Gear Box Stand/Axle Pin 5PQ502244

7 Roll Pin, 1/4 x 2 5PQ500017 26 Axle/Cylinder Pin 5PQ502212

8 Rear Cylinder 5PQ502278 27 1.00-14 Machinery Bushing 5PQ001008

9 Roll Pin, 1/4 x 2 5PQ500017 28 Roll Pin, 1/4 x 2 5PQ500017

10 1.00-14 Machinery Bushing 5PQ001008 29 Plastic End Cap 5PQ502276

11 Head/Cylinder Pin 5PQ502213 30 Grease Seal 5PQ500201

12 1.00-14 Machinery Bushing 5PQ001008 31 Bearing, LM44643 5PQ500202

13 Roll Pin, 1/4 x 2 5PQ500017 32 Race, LM44610 5PQ500204

14 Hydraulic Hose 5PQ500116 33 Spindle Washer 5PQ500206

15 Hexagon Shaft 5PQ500258 34 Spindle Nut 5PQ500207

16 External Tooth Lock Washer 5PQ001087 35 Dust Cap 5PQ500209

17 3/4 x 3/4 Socket Head Bolt 5PQ000693 36 Lug Bolt, 1/2 x 20 5PQ500210

18 Gearbox Stand Assembly 5PQ502241 37 Rim & Tire Assembly 5PQ500220

19 Rear Height Adjustment Handle 5PQ502274

24

Page 27

Ref# Description Part#

1 Retaining Ring, Internal 5PQ500227

2 Washer 5PQ500228

3 Retaining Ring, External 5PQ500229

4 Bearing 5PQ500230

5 Spacer 5PQ500231

6 Pinion Gear 5PQ500232

7 Grease Fitting 5PQ500233

8 Lock Washer, 9/16 5PQ500234

9 Nut, 9/16 5PQ500235

10 Hexagon Shaft 5PQ500258

11 Bolt, M14 x 110 5PQ500236

12 Lock Washer, M14 5PQ500237

13 Bolt, 9/16 x 3-1/2 5PQ500238

14 Elbow Fitting /w Swivel 5PQ502300

15 Nipple 5PQ502299

16 Hexagon Shaft Cover 5PQ500240

17 Gear Box Cover 5PQ502333

18 Ring Gear 5PQ500242

19 Upper Bearing 5PQ500243

20 Cam Center 5PQ502334

21 Oil Seal 5PQ500245

22 Lower Bearing 5PQ500246

23 Oil Plug 5PQ500247

24 Gear Box Housing 5PQ502335

25 Retaining Ring 5PQ500249

26 Washer 5PQ500250

27 Cam Roller 5PQ500251

28 Crank Arm Shaft 5PQ502336

29 Gasket 5PQ500253

30 Spacer 5PQ502337

31 Cast Arm Support 5PQ500255

32 Bolt, M12 x 30 5PQ500256

33 Oil Seal 5PQ500257

34 Bushing 5PQ500279

35 Socket Head Bolt, M10 x 25 5PQ002426

36 Locknut, M14 5PQ002826

37 Bolt, M14 x 55 5PQ002658

38 NordLock Washer 5PQ000770

39 Oil Plug 5PQ502332

Complete Gear Box 5PQ502264

Rotary Gearbox

4

33

34

6

37

38

27

28

31

32

4

3

2

1

5

10

9

8

7

16

36

35

25

26

29

30

11

15

21

22

12

13

14

17

18

19

20

23

24

39

23

25

Page 28

7

5

4

SHAFT

CLUTCH

17

18

PTO Shaft

1

15

14

13

12

11

10

9

8

7

4

3

2

19

30

20

31

6

5

FRONT 39

24

35

!

!

DANGER

DANGER

25 (6x)

36

19

16

27

21

REAR 40

33

25

34

23

22

16

28

27

26

25

38

22

37

!

DANGER

1

41

29

32

Ref# Description Part # Ref# Description Part #

1 Radial Pin Clutch Assembly 5PQ500028 22 Spring Pin 5PQ500031

2 Retainer Ring 5PQ500048 23 Inner Prole 5PQ500032

3 Flanged Collar 5PQ500047 24 CV Cone & Bearing Assembly 5PQ500055

4 Lock Collar 5PQ500046 25 Screw 5PQ500058

5 Ball 5PQ500044 26 Shield Cone, 3 Rib 5PQ500056

6 Compression Spring 5PQ500045 27 Bearing Ring 5PQ500052

7 Flange Kit 5PQ500050 28 Outer Shield Tube 5PQ500053

8 Retainer Ring 5PQ500043 29 Decal 5PQ500059

9 Thrust Ring 5PQ500042 30 Support Bearing 5PQ500063

10 Seal Ring 5PQ500041 31 Inner Shield Tube 5PQ500054

11 Hub 5PQ500037 32 Safety Chain 5PQ500060

12 Cam 5PQ500038 33 Shield Cone, 4 Rib 5PQ500057

13 Outer Spring 5PQ500039 34 Grease Fitting 5PQ500062

14 Inner Spring 5PQ500040 35 Outer Prole & Sleeve 5PQ500033

15 Clutch Housing 5PQ500036 36 Decal 5PQ500061

16 Grease Fitting 5PQ500049 37 Inboard Yoke 5PQ500029

17 Yoke 5PQ500026 38 Cross & Bearing Kit 5PQ500051

18 Collar Kit 5PQ500064 39 Front Shaft Assembly 5PQ500024

19 Cross & Bearing Kit 5PQ500030 40 Rear Shaft Assembly 5PQ500907

20 Double Yoke 5PQ500027 41 Complete PTO Shaft 5PQ503039

21 Inboard Yoke 5PQ500034

26

Page 29

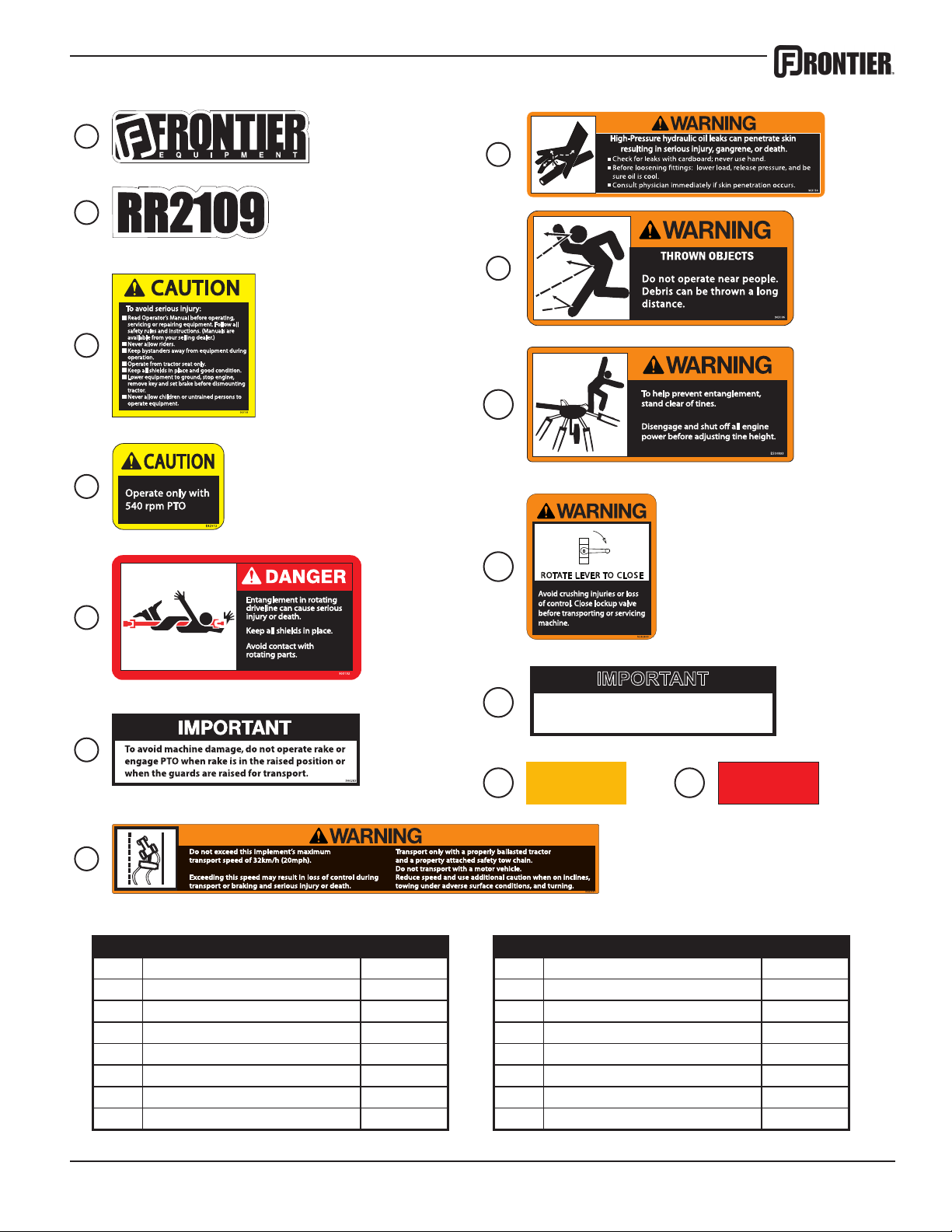

Decals & Reectors

Optimum raking speed is 400-450 PTO RPM.

IMPORTANT

1

8

2

9

3

10

4

11

5

12

6

13 14

7

Ref# Description Part# Ref# Description Part#

1 Frontier Logo 5PQ903110 9 Warning, Thrown Objects 5PQ903106

2 Model Number Decal, RR2109 5PQ903120 10 Warning, Prevent Entanglement 5PQ903123

3 Caution, General Information 5PQ903103 11 Warning, Lock-up Valve 5PQ903125

4 Caution, 540 RPM 5PQ903107 12 Important, Rake Speed 5PQ903116

5 Danger, PTO Entanglement 5PQ903122 13 Decal, Amber Retroreective 5PQ903121

6 Important, Avoid Damage 5PQ903126 14 Decal, Red Retroreective 5PQ903112

7 Warning, Do Not Exceed 5PQ903124 Complete Decal Kit 5PQ903128

8 Warning, Hydraulic Pressure 5PQ903114 French Decal/OM Conversion Kit 5PQ903180

27

Page 30

28

Page 31

Page 32

Loading...

Loading...