Jenn-Air JEC4536BS00, JEC3430BB00, JEC4430BB00, JEC4536BB00, JEC3430BS00 Installation Instructions Manual

...

ELECTRICCOOKTOP INSTALLATIONINSTRUCTIONS

INSTRUCTIONSD'INSTALLATIONDELATABLE

DECUISSONELECTRIQUE

TableofContents / Tabledes mati@res

COOKTOP SAFETY ...................................................................... 1

INSTALLATION REQUIREMENTS ............................................... 2

Tools and Parts........................................................................... 2

Location Requirements ............................................................... 2

Electrical Requirements .............................................................. 3

INSTALLATION INSTRUCTIONS ................................................. 4

Prepare Cooktop for Installation ................................................. 4

Install Cooktop ............................................................................ 4

Make Electrical Connection ........................................................ 6

Attach Cooktop to Countertop ................................................... 8

Complete Installation .................................................................. 8

COOKTOP SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

SI_CURITI_ DE LA TABLE DE CUlSSON .................................... 9

EXIGENCES D'INSTALLATION ................................................... 9

Outils et pieces ........................................................................... 9

Exigences d'emplacement ......................................................... 9

Specifications electriques ........................................................ 11

INSTRUCTIONS D'INSTALLATION .......................................... 12

Preparation de latable de cuisson pour I'installation.............. 12

Installation de la table de cuisson ............................................ 12

Raccordement electrique ......................................................... 14

Fixation de latable de cuisson au plan de travail.................... 16

Achever I'installation................................................................ 16

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

iMPORTANT:

Save for local electrical inspector's use.

iMPORTANT :

A conserver pour consultation par I'inspecteur local des installations 61ectriques.

W10574205A

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

• Tape measure

• 1¼,(6.35 mm) nut driver

Parts supplied

• Foam strip roll • 21/2'' (6.4 cm) clamping

• Clamping brackets (2) screws (2)

Parts needed

• A UL listed or CSA approved connector for 1/2"(1.3 cm)

diameter conduit

• UL listed wire connectors

Check local codes. Check existing electrical supply. See the

"Electrical Requirements" section.

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

• Marker or pencil

• Pliers

• Flat-blade screwdriver

Ovens approved for this type of installation will have an

approval label located on the top of the oven. If you do not

find this label, contact your dealer to confirm that your oven is

approved. Refer to oven manufacturer's Installation

Instructions for approval for built-in undercounter use and

proper cutout dimensions.

The cooktop should be installed away from strong draft

areas, such as windows, doors, fans or strong heating vents.

The cooktop should be located for convenient use in the

kitchen.

• Use the countertop opening dimensions that are given with

these Installation Instructions. Given dimensions are

minimum clearances and provide 0" (0 cm) clearance.

• Grounded electrical supply is required. See "Electrical

Requirements" section.

IMPORTANT: To avoid damage, check with your builder or

cabinet supplier to make sure that the materials used will not

discolor, delaminate or sustain other damage.

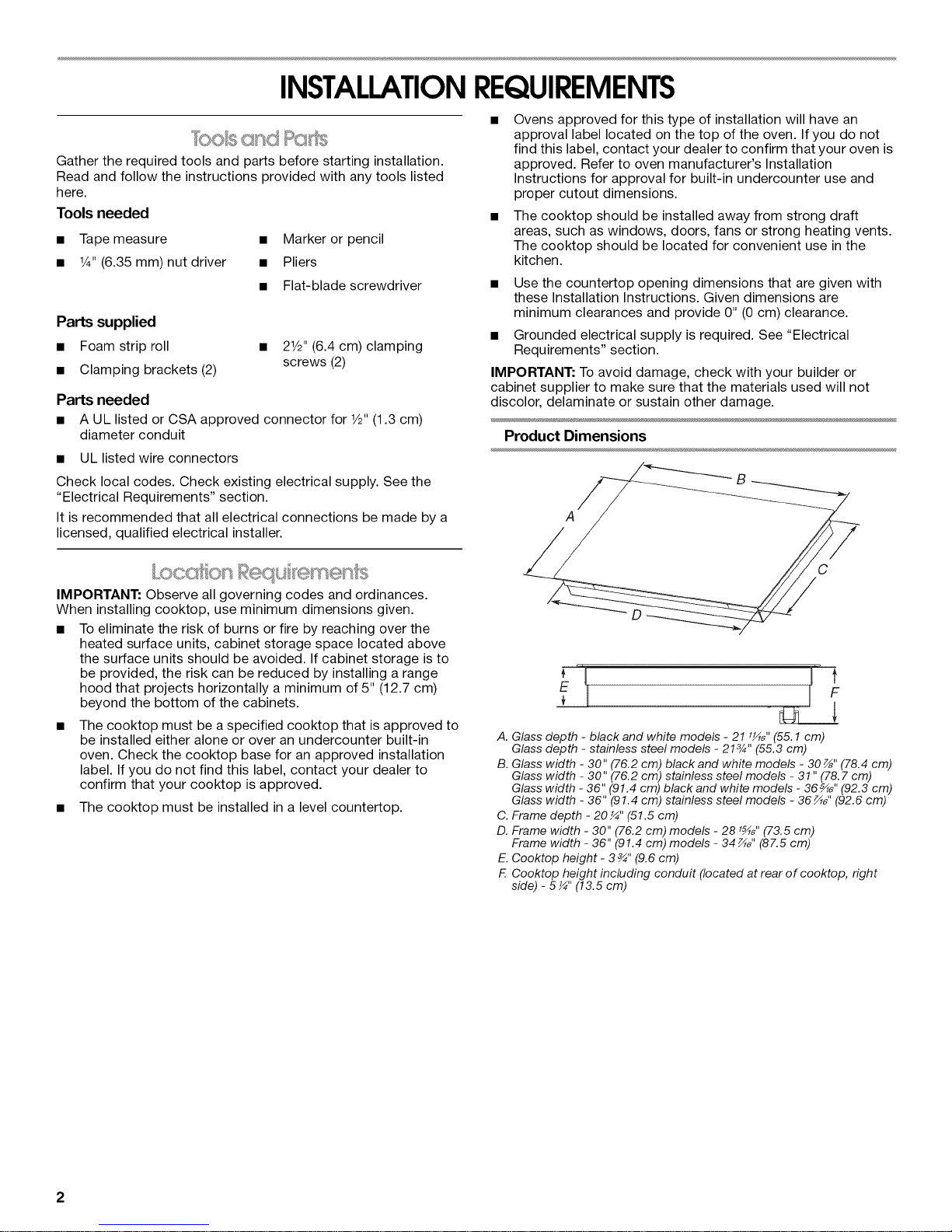

Product Dimensions

B

A

IMPORTANT: Observe all governing codes and ordinances.

When installing cooktop, use minimum dimensions given.

• To eliminate the risk of burns or fire by reaching over the

heated surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage is to

be provided, the risk can be reduced by installing a range

hood that projects horizontally a minimum of 5" (12.7 cm)

beyond the bottom of the cabinets.

The cooktop must be a specified cooktop that is approved to

be installed either alone or over an undercounter built-in

oven. Check the cooktop base for an approved installation

label. If you do not find this label, contact your dealer to

confirm that your cooktop is approved.

• The cooktop must be installed in a level countertop.

C

D

!'iI ir

A. Glassdepth - black and white models - 21 _¼_"(55.1cm)

Glassdepth - stainless steel models - 21_/4'' (55.3 cm)

B. Glasswidth - 30" (76.2cm) black and white models - 30z_,,(78.4 cm)

Glasswidth - 30" (76.2 cm) stainless steel models - 31" (78.7cm)

Glasswidth - 36" (91.4 cm) black andwhite models - 36 _/' (92.3 cm)

Glasswidth - 36" (91.4 cm) stainless steel models - 36 _" (92.6 cm)

C. Framedepth - 20¼" (51.5cm)

D. Framewidth - 30" (76.2cm) models - 28 _5_,,(73.5 cm)

Framewidth - 36" (91.4 cm)models - 34 z_''(87.5 cm)

E.Cooktop height - 3_" (9.6cm)

F Cooktop height including conduit (located atrear of cooktop, right

side) - 5 ¼"(13.5cm)

2

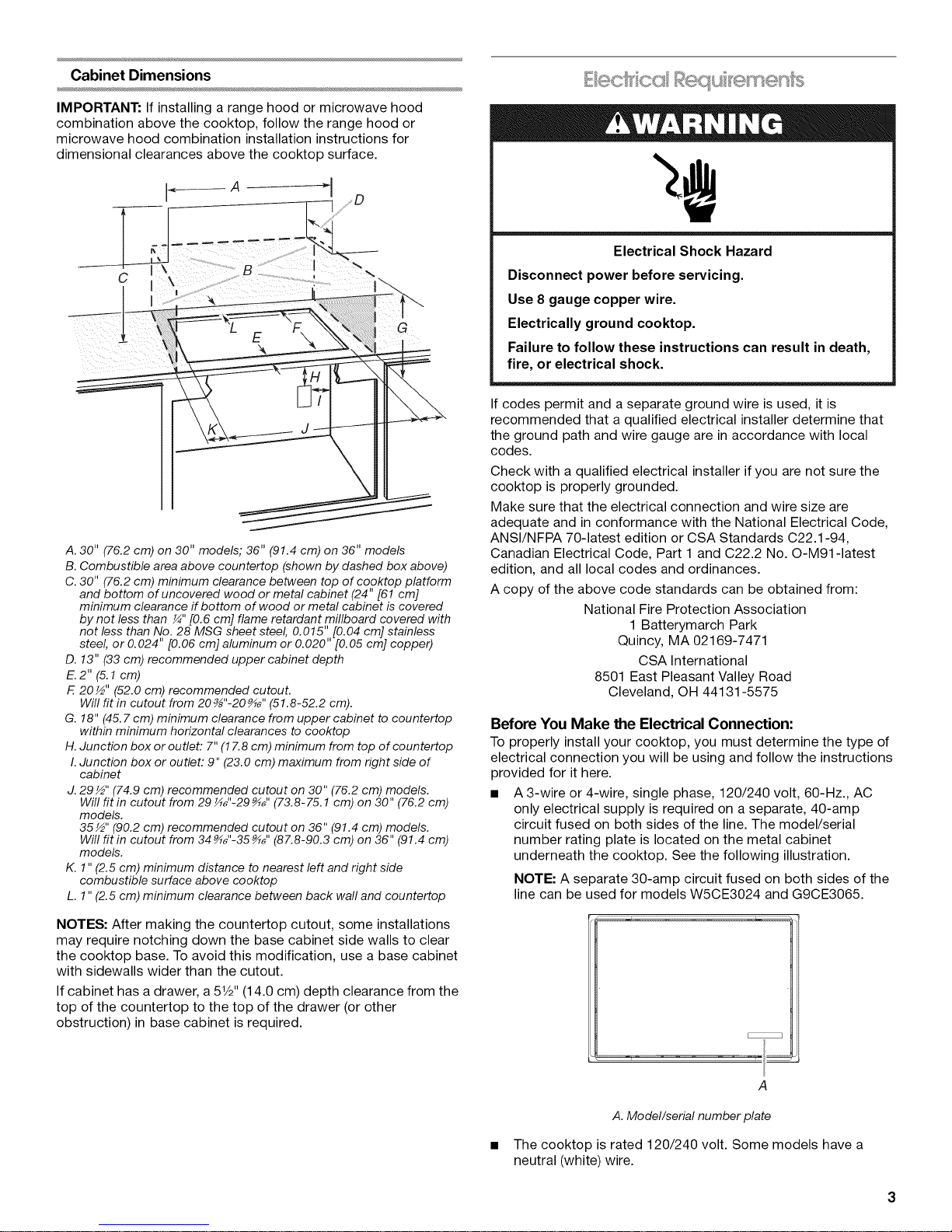

Cabinet Dimensions

IMPORTANT: If installing a range hood or microwave hood

combination above the cooktop, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

A. 30" (76.2 cm) on 30" models; 36" (91.4 cm) on 36" models

B. Combustible area above countertop (shown by dashed box above)

C. 30" (76.2 cm) minimum clearance between top of cooktop platform

and bottom of uncovered wood or metal cabinet (24" [61 cm]

minimum clearance if bottom of wood or metal cabinet is covered

by not less than ¼" [0.6 cm] flame retardant millboard covered with

not less than No. 28 MSG sheet steel, 0.015" [0.04 cm] stainless

steel, or 0.024" [0.06 cm] aluminum or 0.020" [0.05 cm] copper)

D. 13" (33 cm) recommended upper cabinet depth

E. 2" (5.1 cm)

F. 20½" (52.0 cm) recommended cutout.

Will fit in cutout from 20 _"-20 _/' (51.8-52.2 cm).

G. 18" (45.7 cm) minimum clearance from upper cabinet to countertop

within minimum horizontal clearances to cooktop

H. Junction box or outlet: 7" (17.8 cm) minimum from top of countertop

I. Junction box or outlet: 9" (23.0 cm) maximum from right side of

cabinet

J. 29½" (74.9 cm) recommended cutout on 30" (76.2 cm) models.

Will fit in cutout from 29 ¼_"-29 _" (73.8-75.1 cm) on 30" (76.2 cm)

models.

35½" (90.2 cm) recommended cutout on 36" (91.4 cm) models.

Will fit in cutout from 34_"-35_" (87.8-90.3 cm) on 36" (91.4 cm)

models.

K. 1" (2.5 cm) minimum distance to nearest left and right side

combustible surface above cooktop

L. 1" (2.5 cm) minimum clearance between back wall and countertop

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper wire.

Electrically ground cooktop.

Failure to follow these instructions can result in death,

fire, or electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

Check with a qualified electrical installer if you are not sure the

cooktop is properly grounded.

Make sure that the electrical connection and wire size are

adequate and in conformance with the National Electrical Code,

ANSI/NFPA 70-latest edition or CSA Standards C22.1-94,

Canadian Electrical Code, Part 1 and C22.2 No. O-M91-1atest

edition, and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

Before You Make the Electrical Connection:

To properly install your cooktop, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

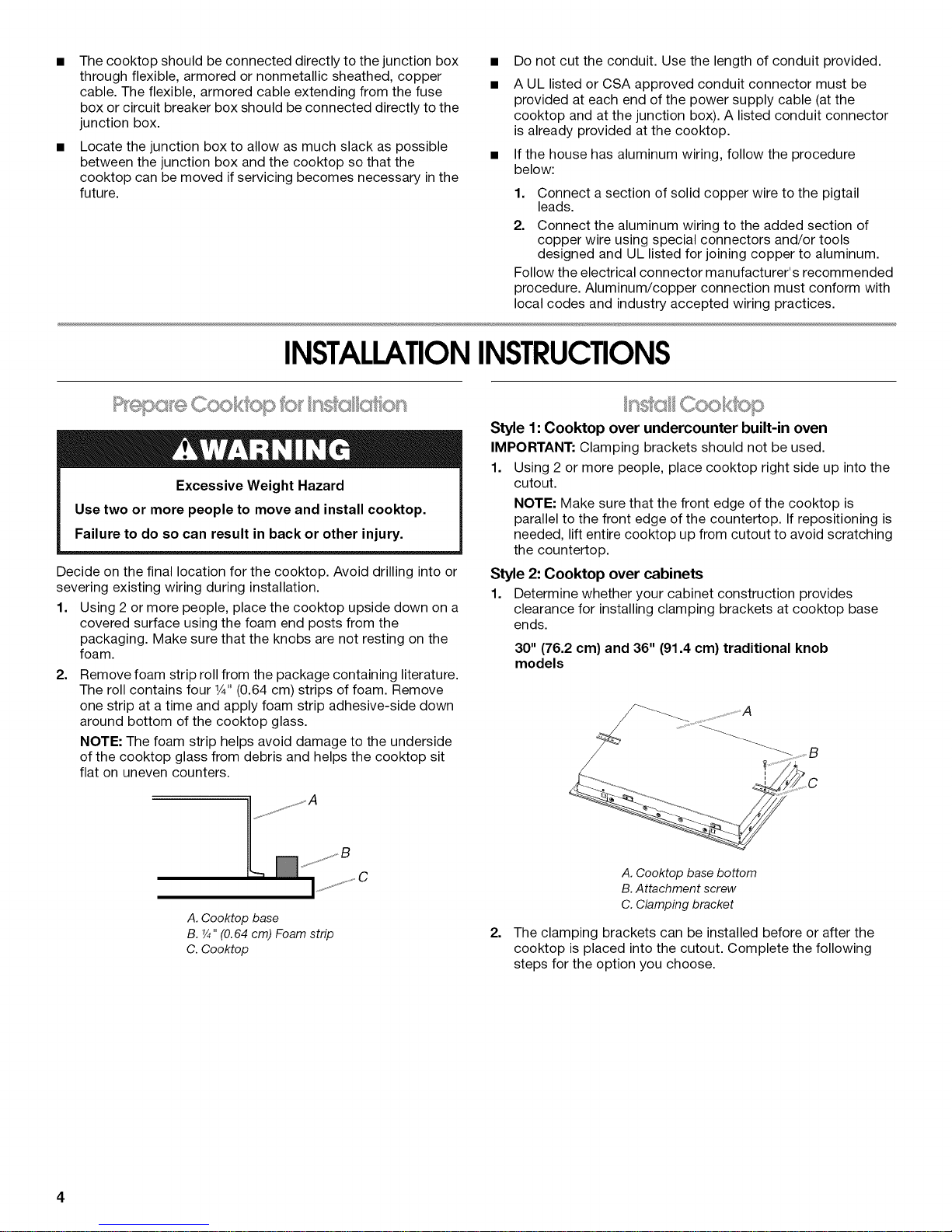

• A 3-wire or 4-wire, single phase, 120/240 volt, 60-Hz., AC

only electrical supply is required on a separate, 40-amp

circuit fused on both sides of the line. The model/serial

number rating plate is located on the metal cabinet

underneath the cooktop. See the following illustration.

NOTE: A separate 30-amp circuit fused on both sides of the

line can be used for models W5CE3024 and G9CE3065.

NOTES: After making the countertop cutout, some installations

may require notching down the base cabinet side walls to clear

the cooktop base. To avoid this modification, use a base cabinet

with sidewalls wider than the cutout.

If cabinet has a drawer, a 51/2"(14.0 cm) depth clearance from the

top of the countertop to the top of the drawer (or other

obstruction) in base cabinet is required.

A

A.Model/serial number plate

The cooktop is rated 120/240 volt. Some models have a

neutral (white) wire.

• Thecooktopshouldbeconnecteddirectlytothejunctionbox

throughflexible,armoredornonmetallicsheathed,copper

cable.Theflexible,armoredcableextendingfromthefuse

boxorcircuitbreakerboxshouldbeconnecteddirectlytothe

junctionbox.

• Locatethejunctionboxtoallowasmuchslackaspossible

betweenthejunctionboxandthecooktopsothatthe

cooktopcanbemovedifservicingbecomesnecessaryinthe

future.

INSTALLATIONINSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install cooktop.

Failure to do so can result in back or other injury.

Decide on the final location for the cooktop. Avoid drilling into or

severing existing wiring during installation.

1. Using 2 or more people, place the cooktop upside down on a

covered surface using the foam end posts from the

packaging. Make sure that the knobs are not resting on the

foam.

2. Remove foam strip roll from the package containing literature.

The roll contains four 1¼,,(0.64 cm) strips of foam. Remove

one strip at a time and apply foam strip adhesive-side down

around bottom of the cooktop glass.

NOTE: The foam strip helps avoid damage to the underside

of the cooktop glass from debris and helps the cooktop sit

flat on uneven counters.

• Donotcuttheconduit.Usethelengthofconduitprovided.

• AULlistedorCSAapprovedconduitconnectormustbe

providedateachendofthepowersupplycable(atthe

cooktopandatthejunctionbox).Alistedconduitconnector

isalreadyprovidedatthecooktop.

• Ifthehousehasaluminumwiring,followtheprocedure

below:

1. Connectasectionofsolidcopperwiretothepigtail

leads.

2. Connectthealuminumwiringtotheaddedsectionof

copperwireusingspecialconnectorsand/ortools

designedandULlistedforjoiningcoppertoaluminum.

Followtheelectricalconnectormanufacturer'srecommended

procedure.Aluminum/copperconnectionmustconformwith

localcodesandindustryacceptedwiringpractices.

Style 1: Cooktop over undercounter built-in oven

IMPORTANT: Clamping brackets should not be used.

1. Using 2 or more people, place cooktop right side up into the

cutout.

NOTE: Make sure that the front edge of the cooktop is

parallel to the front edge of the countertop. If repositioning is

needed, lift entire cooktop up from cutout to avoid scratching

the countertop.

Style 2: Cooktop over cabinets

1. Determine whether your cabinet construction provides

clearance for installing clamping brackets at cooktop base

ends.

30" (76.2 cm) and 36" (91.4 cm) traditional knob

models

/

.......,,,_s'_'_

A. Cooktop base

B. ¼" (0.64 cm) Foam strip

C. Cooktop

A. Cooktop base bottom

B. Attachment screw

C. Clamping bracket

2.

The clamping brackets can be installed before or after the

cooktop is placed into the cutout. Complete the following

steps for the option you choose.

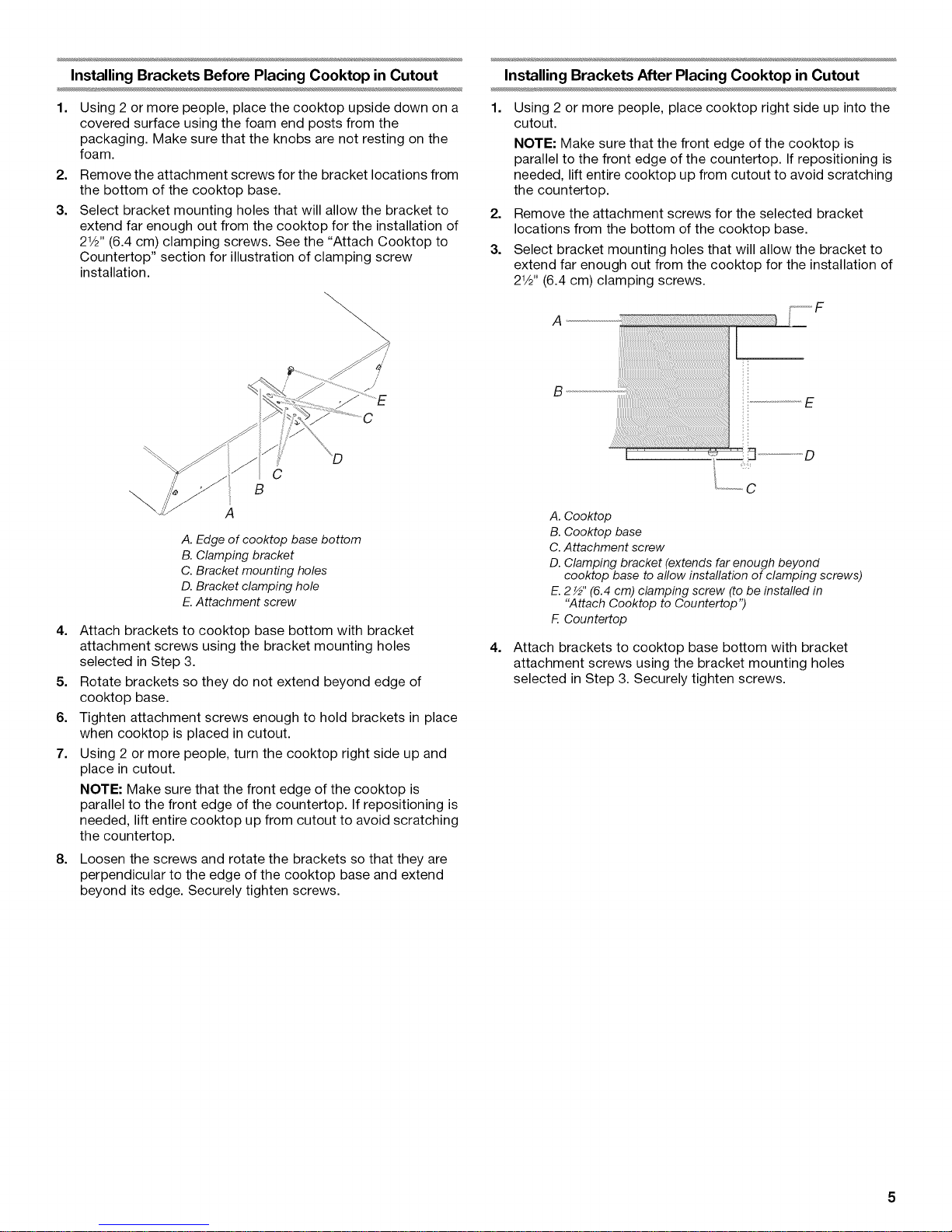

Installing Brackets Before Placing Cooktop in Cutout

Installing Brackets After Placing Cooktop in Cutout

1. Using 2 or more people, place the cooktop upside down on a

covered surface using the foam end posts from the

packaging. Make sure that the knobs are not resting on the

foam.

2. Remove the attachment screws for the bracket locations from

the bottom of the cooktop base.

3. Select bracket mounting holes that will allow the bracket to

extend far enough out from the cooktop for the installation of

21/2"(6.4 cm) clamping screws. See the "Attach Cooktop to

Countertop" section for illustration of clamping screw

installation.

/

/

A. Edge of cooktop base bottom

B. Clamping bracket

C. Bracket mounting holes

D. Bracket clamping hole

E.Attachment screw

4. Attach brackets to cooktop base bottom with bracket

attachment screws using the bracket mounting holes

selected in Step 3.

5. Rotate brackets so they do not extend beyond edge of

cooktop base.

6. Tighten attachment screws enough to hold brackets in place

when cooktop is placed in cutout.

7. Using 2 or more people, turn the cooktop right side up and

place in cutout.

NOTE: Make sure that the front edge of the cooktop is

parallel to the front edge of the countertop. If repositioning is

needed, lift entire cooktop up from cutout to avoid scratching

the countertop.

8. Loosen the screws and rotate the brackets so that they are

perpendicular to the edge of the cooktop base and extend

beyond its edge. Securely tighten screws.

1. Using 2 or more people, place cooktop right side up into the

cutout.

NOTE: Make sure that the front edge of the cooktop is

parallel to the front edge of the countertop. If repositioning is

needed, lift entire cooktop up from cutout to avoid scratching

the countertop.

2. Remove the attachment screws for the selected bracket

locations from the bottom of the cooktop base.

3. Select bracket mounting holes that will allow the bracket to

extend far enough out from the cooktop for the installation of

21/2"(6.4 cm) clamping screws.

B

.......................C

A. Cooktop

B. Cooktop base

C. Attachment screw

D. Clamping bracket (extends far enough beyond

cooktop base to allow installation of clamping screws)

E.2½" (6.4 cm) clamping screw (to be installed in

"Attach Cooktop to Countertop")

F. Countertop

4=

Attach brackets to cooktop base bottom with bracket

attachment screws using the bracket mounting holes

selected in Step 3. Securely tighten screws.

Loading...

Loading...