International VT 365 Service Manual

SERVICE MANUAL

INTERNATIONAL® VT 365

DIESEL ENGINE

2004-2006 Model Years

SERVICE MANUAL

EGES-295-2

INTERNATIONAL® VT 365

DIESEL ENGINE

EGES-295-2

2004-2006 Model Years

© 2006 International Truck and Engine Corporation

Printed in the United States of America

ENGINE SERVICE MANUAL I

Table of Contents

Foreword................................................... .......................................... ......................1

Service Diagnosis.... ...................................... ................................... ...........................2

Safety Information.............................................................. ..........................................3

ENGINE SYSTEMS.......................................................................................................5

MOUNTING ENGINE ON STAND......................................................................................49

ELECTRONICALLY CONTROLLED VARIABLE GEOMETRY TURB

MANIFOLDS AND EXHAUST GAS RECIRCULATION (EGR).....................................................73

CYLINDER HEAD AND VALVE TRAIN................................................................................99

FRONT COVER, VIBRATION DAMPER, and GEROTOR OIL PUMP

OIL PAN, UPPER OIL PAN, and OIL PICKUP TUBE. .. .. ... . . .... . ... . . ... . . . . ... . .. ... . . ... . . ... . . ... . . ... . . ....175

POWER CYLINDERS..................................................................................................183

CRANKCASE, CRANKSHAFT and BEARINGS, CAMSHAFT

OIL COOLER and FILTER HOUSING................................................................................229

ENGINE ELECTRICAL.................................................................. ...............................245

HIGH-PRESSURE OIL PUMP.. ..................... ..................................................................281

FUEL SYSTEM...................................... ....................................................................297

REAR COVER, FLYWHEEL, and POWER STEERIN

IN-CHASSIS PROCEDURES..........................................................................................331

G GEAR DRIVE...........................................309

OCHARGER (VGT)................... ...55

...........................................157

and BUSHINGS............................ ...203

Terminology.............................................................................................................355

Appendix A – Specifications...................................................................... ...................363

Appendix B – Torques.................................................................................................373

Appendix C – Special Service Tools

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

.......................................................... ......................389

EGES295-2

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

II ENGINE SERVICE MANUAL

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

ENGINE SERVICE MANUAL 1

Foreword

International Truck and Engine Corporation is

committed to continuous research and development

to improve products and introduce technological

advances. Procedures, specifications, and parts

defined in published technical service literature may

be altered.

NOTE: Photo illustrations identify specific parts or

assemblies that support text and procedures; other

areas in a photo illustration may not be exact.

This manual includes necessary information

and specifications for technicians to maintain

International® diesel engines. See vehicle manuals

and Technical Service Information (TSI) bulletins fo

additional information.

Technical Service Literature

1171814R2

VT 365 Engine Operation and

Maintenance Manual

EGES-295-2 VT 365 Engine Service Manual

EGES-240

VT 365 Engine Diagnostic Manual

EGED-245 VT 365 Hard Start and No Start

Diagnostic Form

EGED-250 VT 365 Performance Diagnostics

Form

EGED-320-1 VT 365 Electronic Control System

Diagnostic Form

CGE-575 Engine Diagnostic Trouble Codes

r

Technical Service Literature is revised periodically

and mailed automatically to “Revision Service”

subscribers. If a technical publication is ordered, the

latest revision will be supplied.

NOTE: The followingorder information isfor technical

service literature only.

International Truck and Engine Corporation

Printing and Distribution Services

C/O Moore Wallace North America

1750 Wallace Avenue

St. Charles, IL 60174

Telephone: 630-313-7507

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

2 ENGINE SERVICE MANUAL

Service Diagnosis

Service diagno sis is an investigative procedure that

must be followed to find and correct an engine

application problem or an engine problem.

If the problem is engine application, see specific

vehicle manuals for further diagnostic information.

If the problem is the engine, see specific Engine

Diagnostic Manual for further diagnostic information.

Prerequisites for Effective Diagnosis

• Availability of gauges and diagnostic test

equipment

• Availability of current information for engine

application and engine systems

• Knowledge of the principles of operation for

engine application and engine systems

• Knowledge to understand and do procedures in

diagnostic and service publications

Technical Service Literature required for Effective

Diagnosis

• Engine Service Manual

• Engine Diagnostic Manual

• Diagnostics Forms

• Electronic Control Systems Diagnostics Forms

• Service Bulletins

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

ENGINE SERVICE MANUAL 3

Safety Information

This manual provides general and specificservice

proceduresessential for reliable engineoperationand

your safety. Since many variations in procedures,

tools, and service parts are involved, advice for all

possible safety conditions and hazards cannot be

stated.

Read safety instructionsbefore doing any service and

test procedures for the engine or vehicle. See related

application manuals for more information.

DisregardforSafety Instructions, Warnings, Cautio

and Notes in this manual can lead to injury, death or

damage to the engine or vehicle.

SAFETY TERMINOLOGY

Three terms are used to stress your safety and saf

operation of the engine: Warning, Caution, and

Warning: A warning describes actions necessar

prevent or eliminate conditions, hazards, an

practices that can cause personal injury

or death.

Caution: A caution describes actions nec

to prevent or eliminate conditions that c

an cause

damage to the engine or vehicle.

Note: A note describes actions necessar

yforcorrect,

efficient engine operation.

SAFETY INSTRUCTIONS

Vehicle

• Make sure the vehicle is in neutral, th

brake is set, and the wheels are block

doing any work or diagnostic proc

ed before

edures on the

engine or vehicle.

Work area

• Keep work area clean, dry, and org

anized.

• Keep tools and parts off the floor.

• Make sure the work area is ventil

• MakesureaFirstAidKitisavail

ated and well lit.

able.

Safety equipment

• Use correct lifting devices.

• Use safety blocks and stands.

Protective measures

ns,

e

Note

yto

d unsafe

essary

eparking

• Wear appropriate hearing protection.

• Wear correct work clothing.

• Do not wear rings, watches, or other jewelry.

• Restrain long hair.

Fire prevention

• Make sure charged fire extinguishers are in the

work area.

NOTE: Check the classification of each fire

extinguisher to ensure that the following fire types

canbeextinguished.

1. Type A — Wood, paper, textiles, and rubbish

2. Type B — Flammable liquids

3. Type C — Electrical equipment

Batteries

Batteries produce highly flammable gas during and

after charging.

• Always disconnect the main negative battery

cable first.

• Always connect the main negative battery cable

last.

• Avoid leaning over batteries.

• Protect your eyes.

• Do not exposebatteries to openflames orsparks.

• Do not smoke in workplace.

Compressed air

• Limit shop air pressure for blow gun to 207 kPa

(30 psi).

• Use approved equipment.

• Do not direct air at body or clothing.

• Wear safety glasses or goggles.

• Wear hearing protection.

• Use shielding to protect others in the work area.

Tools

• Make sure all tools are in good condition.

• Make sure all standard electrical tools are

grounded.

• Wear protective glasses and sa

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

fety shoes.

EGES295-2

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

4 ENGINE SERVICE MANUAL

• Check for frayed power cords before using power

tools.

Fluids under pressure

• Use extreme caution when working on systems

under pressure.

• Follow approved procedures only.

Fuel

• Do not overfill the fueltank. Over fill creates a fire

hazard.

• Do not smoke in the work area.

• Do not refuelthe tank when the engineis running.

Removal of tools, parts, and equipment

• Reinstall all safety guards, shields, and covers

after servicing the engine.

• Make sure all tools, parts, and service equipment

are removed from the engine and vehicle after all

work is done.

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

ENGINE SYSTEMS 5

Table of Contents

Engine Identification.....................................................................................................7

Engine Serial Number..........................................................................................7

Emission Labels (2004 and 2005 Model Years)............................................................7

Emission Label (2006) Model Year...........................................................................8

Engine Description..............................................................................................9

Engine Component Locations.. .. .... . . . . . .... . .. ... . . . . . . .... . .. ... . . . . . . .... . . . . . .... . .. ... . . . . . . .... . . . . .11

Engine Systems.........................................................................................................16

Air Management System (AMS).............................................................................17

Charge Air Cooler (CAC)................................... .........................................20

Variable Geometry Turbocharger (VGT)............................... ...........................21

Exhaust Gas Recirculation (EGR) System................................................ .......22

Exhaust System......................................................................................24

Fuel Management System.................. ..................................................................25

Fuel Injection..........................................................................................25

Injection Control Pressure (ICP) System.......................................... ...............26

Fuel Injectors....................................................... ............................................28

Fuel Supply System.. . . .... . .. ... . . . . . . ... . . .... . . .... . . . .... . . . . . ... . . . . . . ... . . . . . . ... . . . . .... . . . .... . . ... . . .30

Fuel Flow............................................... .............................................. ...........31

Lubrication System.. . ...... ...................................................................................33

Cooling System................................................................................................37

Electronic Control System.......................................................... ...................................39

Electronic Control System Components ... ...............................................................39

Injection Drive Module (IDM)...................................................... ...........................41

Engine and Vehicle Sensors.. ............................................. ..................................42

Glow Plug Control System.............................................................................................47

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

6 ENGINE SYSTEMS

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

Engine Identification

Engine Serial Number

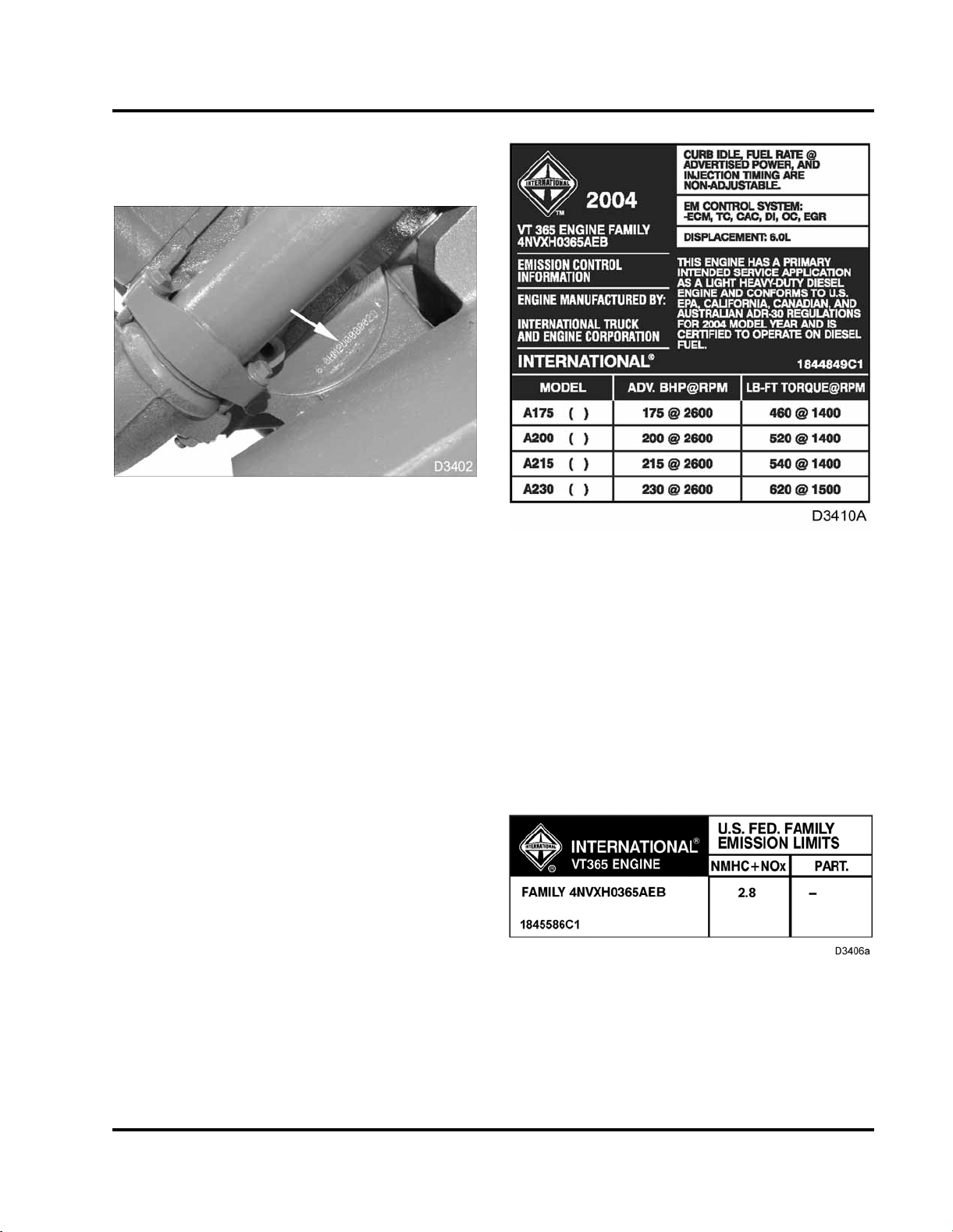

Figure 1 Engine serial number

ENGINE SYSTEMS 7

The engine serial number is stamped on the

crankcase pad on the rear left side of

the crankcase

below the cylinder head.

The engine serial number is also on an

identification

sticker on the valve cover.

Engine serial number examples

6.0HM2Y0000500

6.0HA2U0000508

Engine serial number codes

6.0 – Engine displacement

H–Diesel, turbocharged, Charge

Air Cooled, and

electronically controlled

M2 – Truck

A2 – Service

U–USA

Y–USA Huntsville

7digitsuffix–Engine serial number

Emission Labels (2004 and 2005 M

Twoemissionlabelsareontherig

sequence

odel Years)

ht valve cover:

Figure 2 50 – State Exhaust Emissions Label

(example)

The 50 – State Exhaust Emissions Label includesthe

following:

• Year the engine was certified to meet EPA

emission standards

• Engine model code

• Service applications

• Advertised brake horsepower ratings

Figure 3 U.S. Federal Family Emission Limits

label (example)

• 50 – State Exhaust Emissions Labe

• U.S. Federal Family Emission L

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

imits Label

©2006 International Truck and Engine Corporation

l

The U.S. Federal Family Emission Limits Label

identifies the engine family and emission limits

established by the manufacturer and certified by the

EPA.

EGES295-2

Follow all warnings, cautions, and notes.

8 ENGINE SYSTEMS

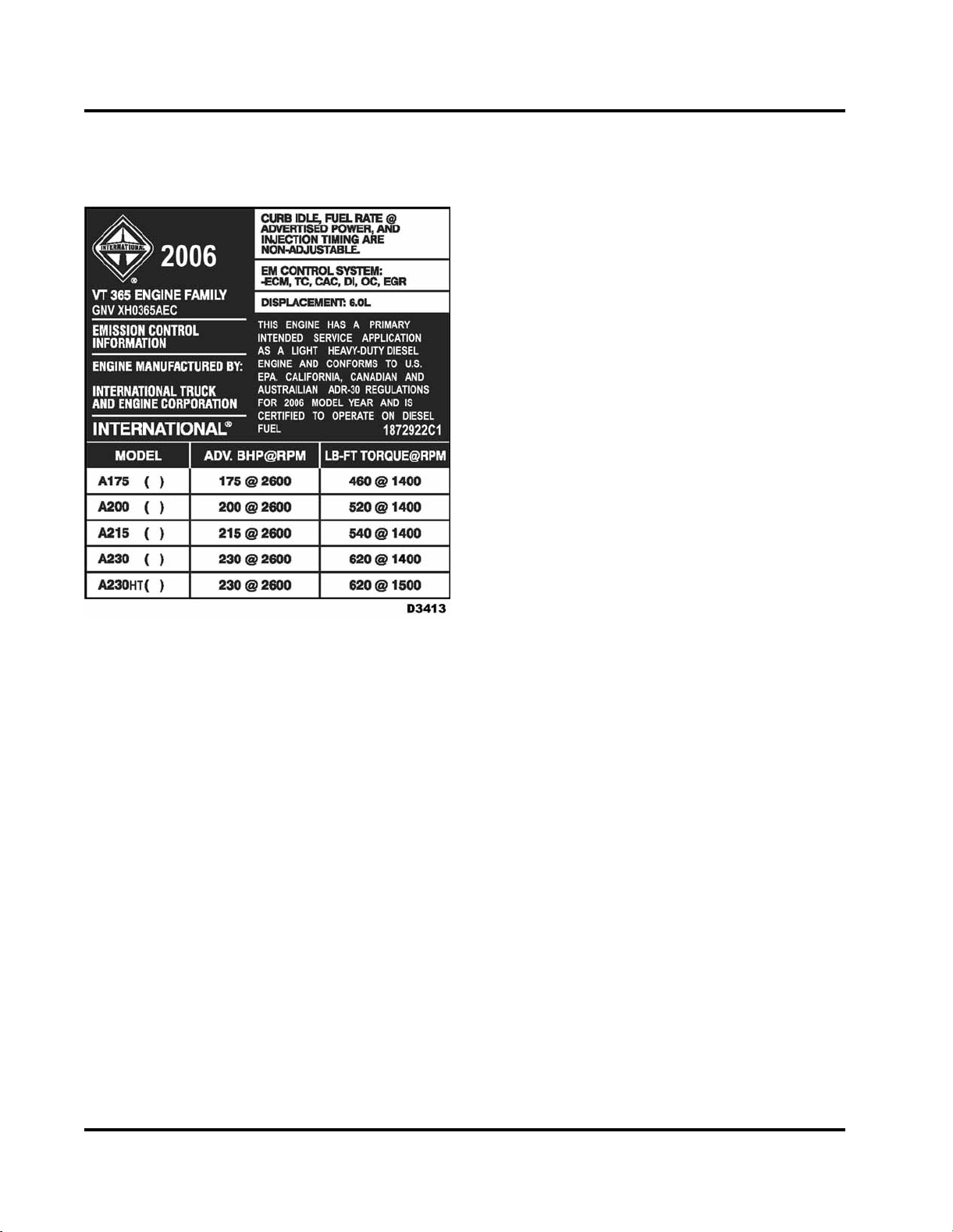

Emission Label (2006) Model Year

One emission label is on the right valve cover.

The 50 – State Exhaust Emissions Label includes the

following:

• Year the engine was certified to meet EPA

emission standards

• Engine model code

• Service applications

• Advertised brake horsepower ratings

Engine accessories

The following engine accessories may have

manufacturer’s labels or identification plates:

• Air compressor (for brake or suspension system )

• Air conditioning compressor

• Alternator

• Cooling fan clutch

• Variable Geometry Turbocharger (VGT)

• Power steering / fuel pump

•Startermotor

Figure 4 50 – State Exhaust Emissions Label

(example)

Labels or identification plates include information

and specifications helpful to vehicle operators and

technicians.

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

ENGINE SYSTEMS 9

Engine Description

Table 1 Engine Features and S pecifications

International® VT 365 engine features and specifications

Engine Diesel, 4 cycle

Configuration 4 OHV/1 Cam-in-Crankcase-V8

Displacement

Bore and stroke

Compression ratio

Aspiration

Rated power @ rpm

Peak torque @ rpm

1

1

365 cu. in (6.0L)

95 mm x 105 mm (3.74 in x 4.134 in)

18.0:1

VGT turbocharged and Charge Air Cooling (CAC)

175 bhp @ 2600 rpm

460 lbf•ft @ 1400 rpm

Engine rotation, facing flywheel Counterclockwise

Combustion system Digital Direct Injection (DDI)

Total engine weight (auto with oil) 459 kg (1094 lb)

Cooling system capacity (engine only) 10.2 liters (10.8 qts)

Lube system capacity (including filter) 18 liters (19 qts)

Lube system capacity (dry) 21.8 liters (23 qts)

Firing order 1–2–7–3–4–5–6–8

1

Base rating shown. See Appendix A for other ratings.

Major features

Air Management System (AMS)

• Variable Geometry Turbocharger (VGT)

• Exhaust Gas Recirculation (EGR) system

• Chassis mounted Charge Air Cooling (CAC)

Digital Direct fuel Injection (DDI)

Two piece crankcase

One piece cylinder head with four valves per cylinder

Dual timing

Rear gear train

Closed crankcase ventilation

Oil cooler

The firing order is 1-2-7-3-4-5-6-8. When viewing the

engine from the rear (flywheel end), the right side

cylinders are numbered 1, 3, 5, and 7. Number one

is the front position. The left side is numbered 2, 4, 6,

and 8 .

A two piece crankcase has been specially designed

to withstand the loads of diesel operation. The lower

crankcase has integral main bearing caps. Coolant

and oil passages are cast and machined in the

crankcase and front cover housing.

The crankshaft has five main bearings with fore and

aft thrust controlled at the upper half of the number 4

main bearing. Two connecting rods are attached to

each crankshaft journal. The piston pin moves freely

inside the piston and rod. Piston pin retaining rings

secure the piston pin within the piston.

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

10 ENGINE SYSTEMS

One piece aluminum alloy pistons are fitted with

one keystone cut compression ring, one rectangular

intermediate compression ring, and a two piece oil

control ring. The combustion bowl (in the piston

crown) reduces exhaust emissions.

The camshaft is supported by five insert bushings

pressed into the crankcase. Two cam lobes, cam

followers, push rods and valve bridges control four

valves per cylinder. The camshaft is gear driven

from the rear end of the crankshaft. A thrust flange

is located between the camshaft gear and the

crankcase. Camshaft thrust iscontrolled with the rear

surface of the number 5 cam journal and the cam

gear.

Hydraulic cam followers maintain zero valve lash

and minimize engine noise. This eliminates periodic

adjustment of valvelash. The hydraulic cam followers

have rollers which provide excellent cam lobe and

cam follower durability.

The lubrication system uses a crankshaft driven

gerotor pump mounted o n the front cover. The oil

pressure regulator is built into the front cover and

is accessible from outside the engine. Lube oil is

routed through an oil cooler equipped with a pressure

controlled b ypass valve. Lube oil moves through

passages in the crankcase to lubricate all internal

components and to supply the piston cooling tubes

and high pressure pump reservoir. The VGT and air

compressor use external oil lines.

The VGT is electronically controlled and hydraulically

actuated. The VGT provides boost control at low and

high speeds for improved throttle response.

An exhaust gas recirculation valve allows water

cooled exhaust gases to be fed into the inlet air

stream to reduce exhaust emissions.

A closed crankcase breather system recirculates

crankcase vapors back into the intake air system.

A chassis mounted Charge Air Cooler (CAC), an

air-to-air heat exchanger, increases the density of the

air charge.

Engine operation is controlledby twoengine mounted

control modules:

• Electronic Control Module (ECM)

• Injector Drive Module (IDM)

The ECM receives signals from engine and chassis

mounted sensors. The ECM controls engine

operation with the following actuators:

•IPR

• VGT control valve

•EGR

• Glow plug relay

The IDM controls fuel injector operation using data

from the ECM.

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

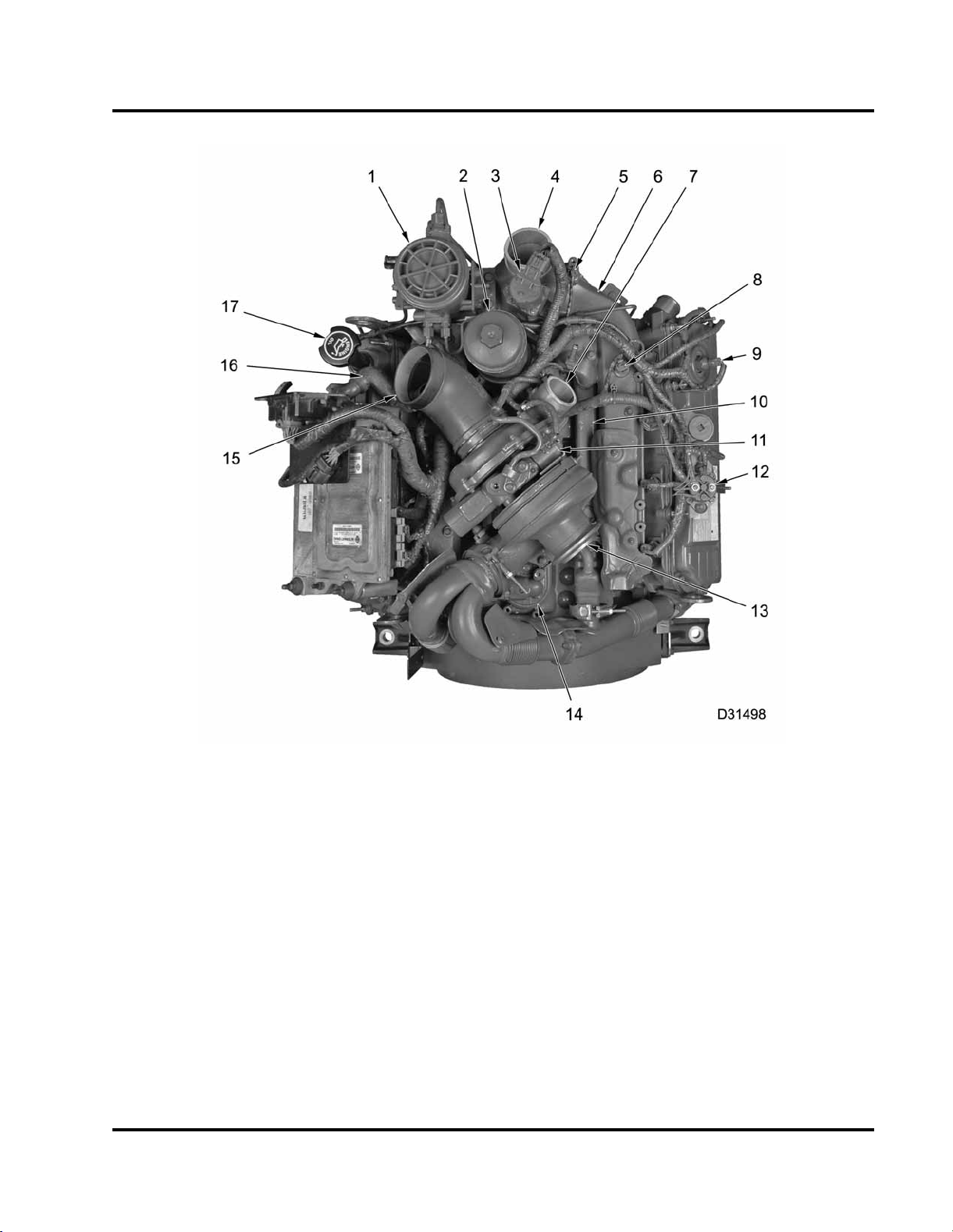

Engine Component Locations

ENGINE SYSTEMS 11

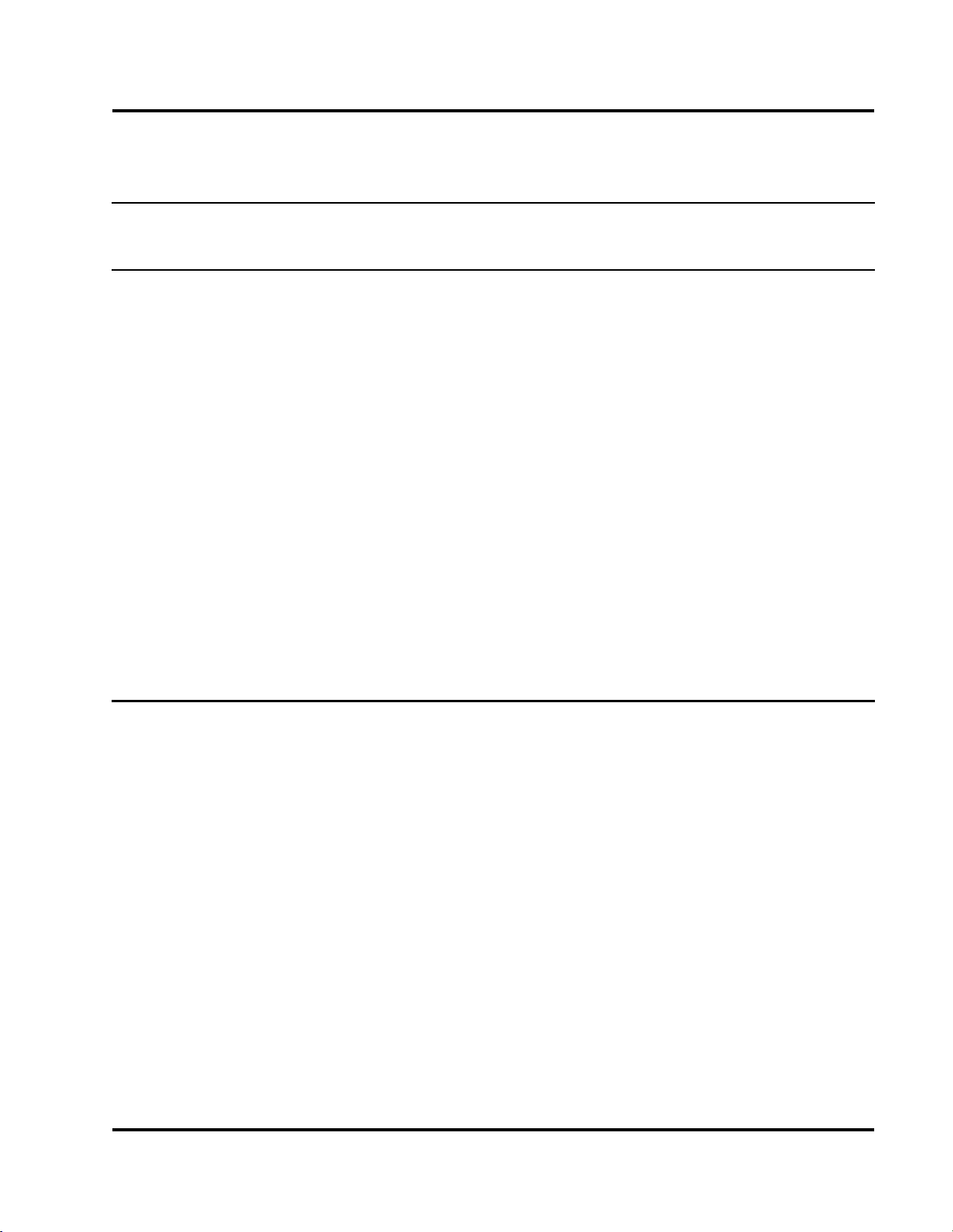

Figure 5 Engine components – Front

1. Manifold Absolute Pressure

(MAP) sensor

2. Lube oil pressure test port

3. Fuel filter assembly

4. Fuel return

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

5. Fuel supply

6. Engine Coolant Temperature

7. Port for coolant deaeration tank

8. Coolant outlet and thermostat

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

(ECT) sensor

EGES295-2

9. Front cover assembly

10. Crankshaft vibration damper

11. Coolant inlet

12. Water pump pulley

12 ENGINE SYSTEMS

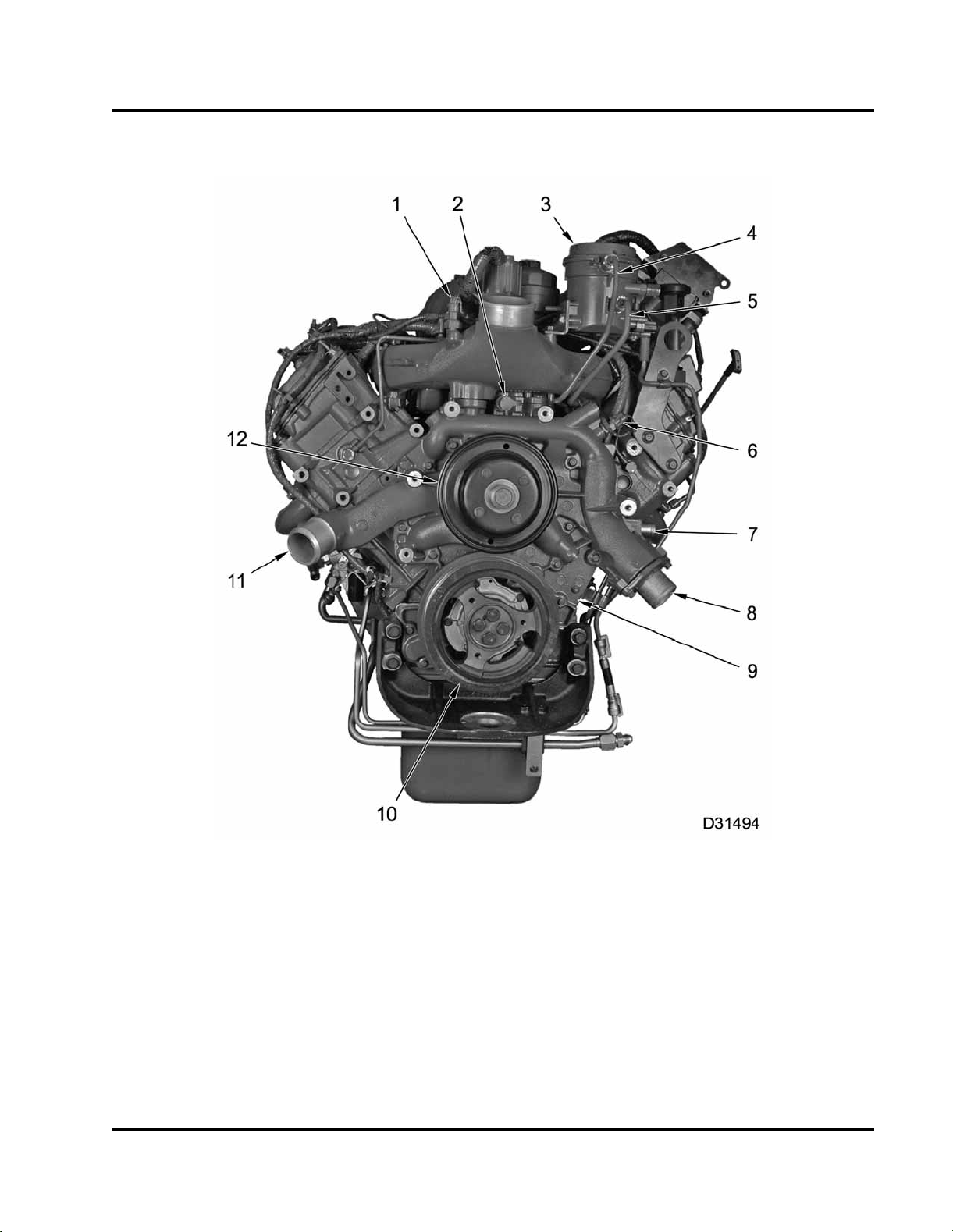

Figure 6 Engine components – Left

1. Fuel filter drain lever

2. Engine Control Module (ECM)

3. Injector Driver Module (IDM)

4. Exhaust Back Pressure (EBP)

sensor

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

©2006 International Truck and Engine Corporation

5. Valve cover

6. Rear cover

7. Exhaust manifold

8. Camshaft Position(CMP)sensor

9. Glow plug harness

EGES295-2

Follow all warnings, cautions, and notes.

10. Engine Coolant Temperature

(ECT) sensor

11. Lube oil fill tube

ENGINE SYSTEMS 13

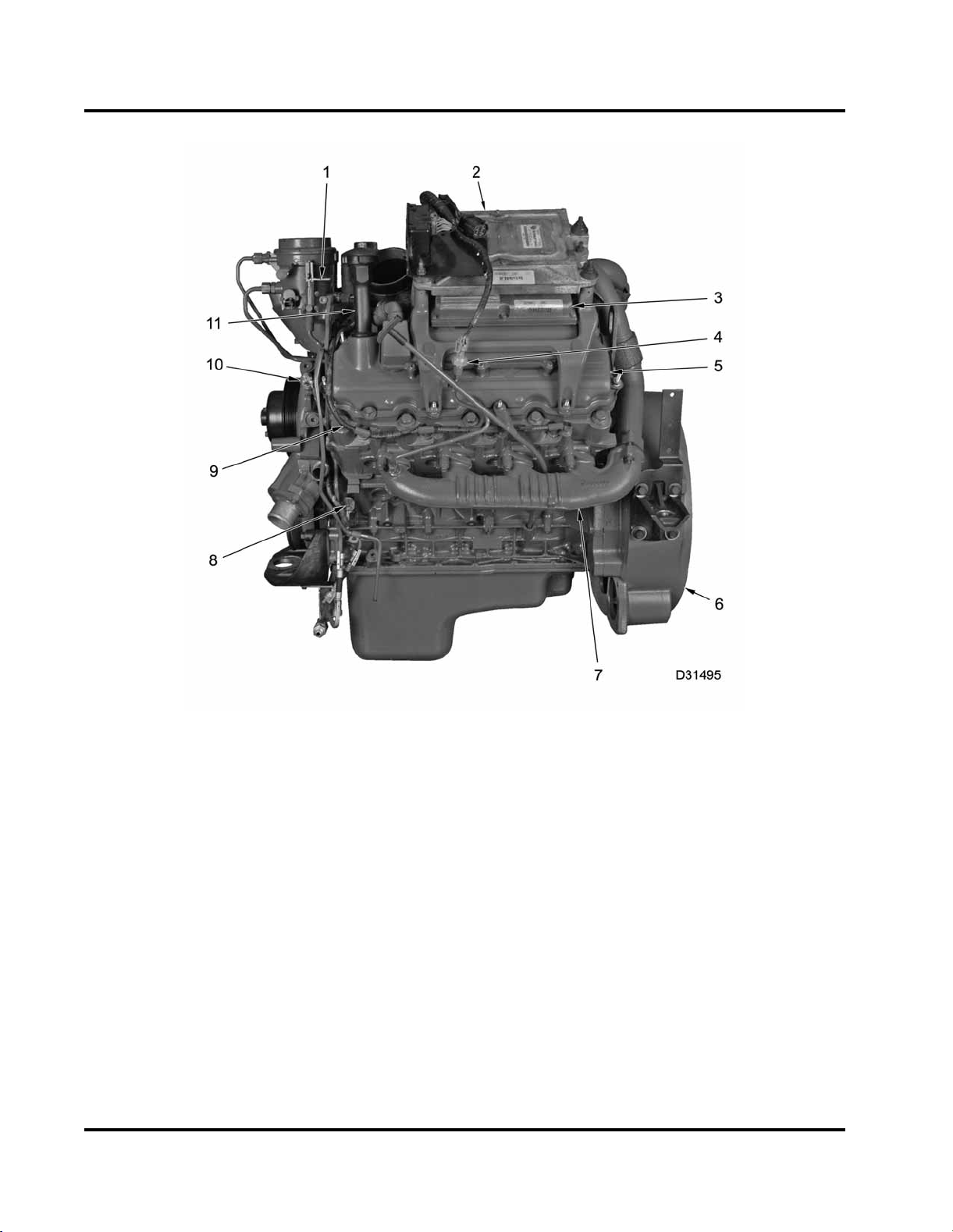

Figure 7 Engine components – R ear

1. Injection Pressure Regulator

(IPR valve)

2. Turbocharger exhaust outlet

3. Exhaust tube assembly, right

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

4. Flywhee l or flexplate assembly

5. Rear cover assembly

6. Reinforcement ring

EGES295-2

7. Shielded exhausttubeassembly,

left

8. Lifting eye (3)

14 ENGINE SYSTEMS

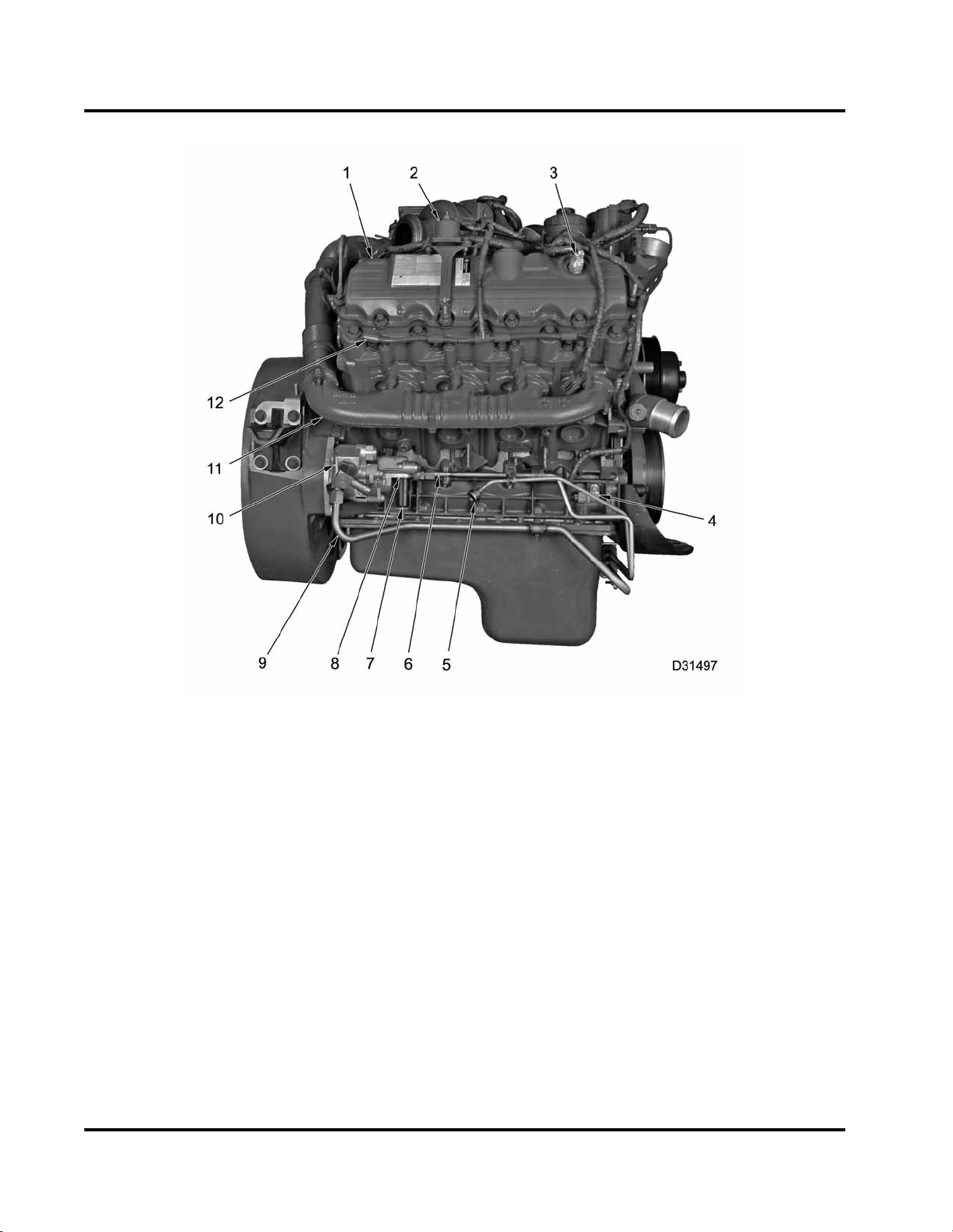

Figure 8 Engine components – Right

1. Valve cover

2. Glow plug relay

3. Injection Control Pressure (ICP)

sensor

4. Crankshaft Position (CKP)

sensor

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

5. Fuel return line

6. Fuel supply line

7. Fuel filter strainer

8. Fuel supply pump (transfer)

9. Power steering line

10. Power steering pump

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

11. Exhaust Manifold

12. Glow plug harness

EGES295-2

ENGINE SYSTEMS 15

Figure 9 Engine compon

1. Fuel filter assembly

2. Oil filter housing

3. Exhaust Gas Recircul

(EGR) valve

4. Intake manifold air i

5. Manifold Absolute Pre

(MAP) sensor

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

ation

nlet

ssure

ents–Top

6. Intake manifold

7. Compressor outlet

8. Manifold Air Tempera

sensor

9. ICP sensor

10. EGR cooler

11. VGT control valve

EGES295-2

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

ture (MAT)

12. Glow plug relay

13. VGT

14. High-pressure oil pu

15. Air inlet duct

16. Breather hose assembl

pitot tube

17. Lube oil fill

mp cover

ywith

16 ENGINE SYSTEMS

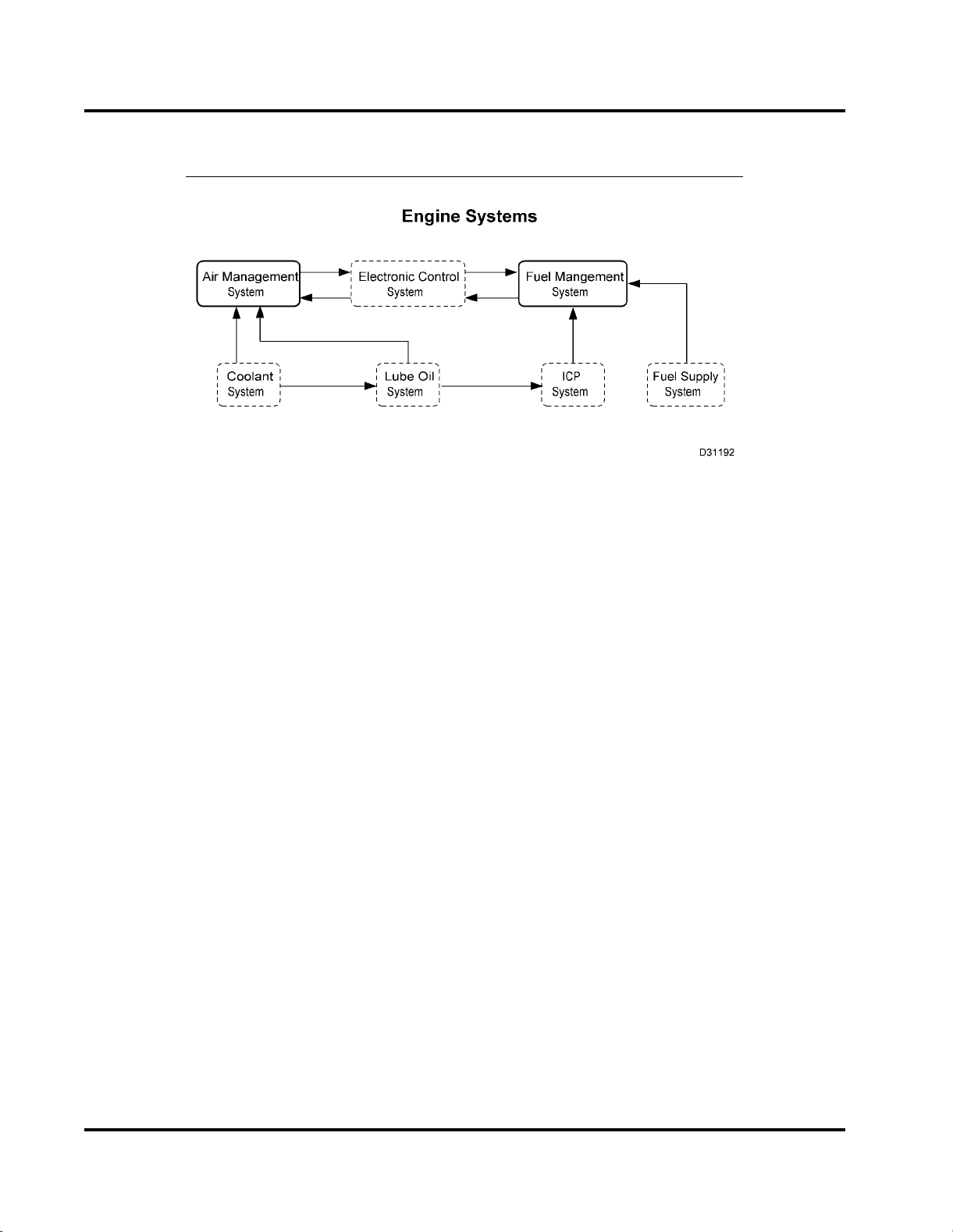

Engine Systems

The primary engine systems are AirManagementand

Fuel Management, which share some subsystems or

have a subsystem that contributes to their operation.

• The Electronic Control System controls the Air

Management System and Fuel Management

System.

• The Coolant System provides heat transfer for

EGR gases and lubrication oil.

• The ICP system uses lube oil for hydraulic fluid to

actuate the fuel injectors.

• The Fuel Supply System pressurizes fuel for

transfer to the fuel injectors.

• The Lube Oil S ystem provides lubrication and

heat transfer to engine components.

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

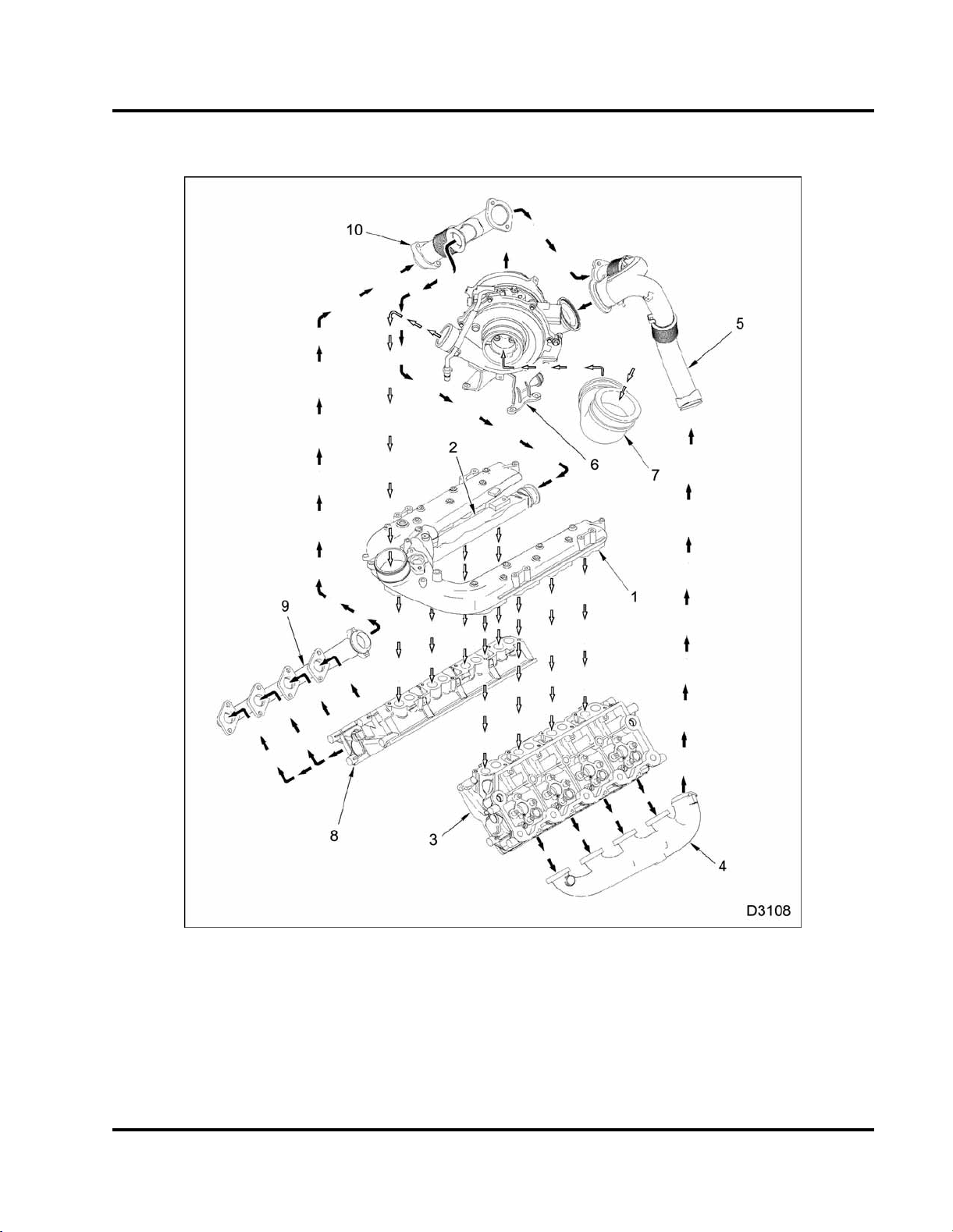

Air Management System (AMS)

ENGINE SYSTEMS 17

Figure 11 Air Management System (AMS)

1. Intake manifold

2. EGR cooler

3. Left cylinder head

4. Left exhaust manifold

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

5. Shielded tube exhaust assembly

6. VGT with mounting bracket

7. Air inlet duct

8. Righ t cylinder head

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

9. Right exhaust manifold

10. Exhaust tube assembly, right

EGES295-2

18 ENGINE SYSTEMS

The Air Management system includes the

following:

•Airfilter assembly

• Closed crankcase breather

• Chassis mounted Charged Air Cooler (CAC)

• Variable Geometry Turbocharger (VGT)

• Intake manifold

• Exhaust Gas Recirculation (EGR) system

• Exhaust system

• Catalytic converter– dependent on application

• Catalyzed Diesel Particulate Filter (CDPF) –

dependent on application

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

ENGINE SYSTEMS 19

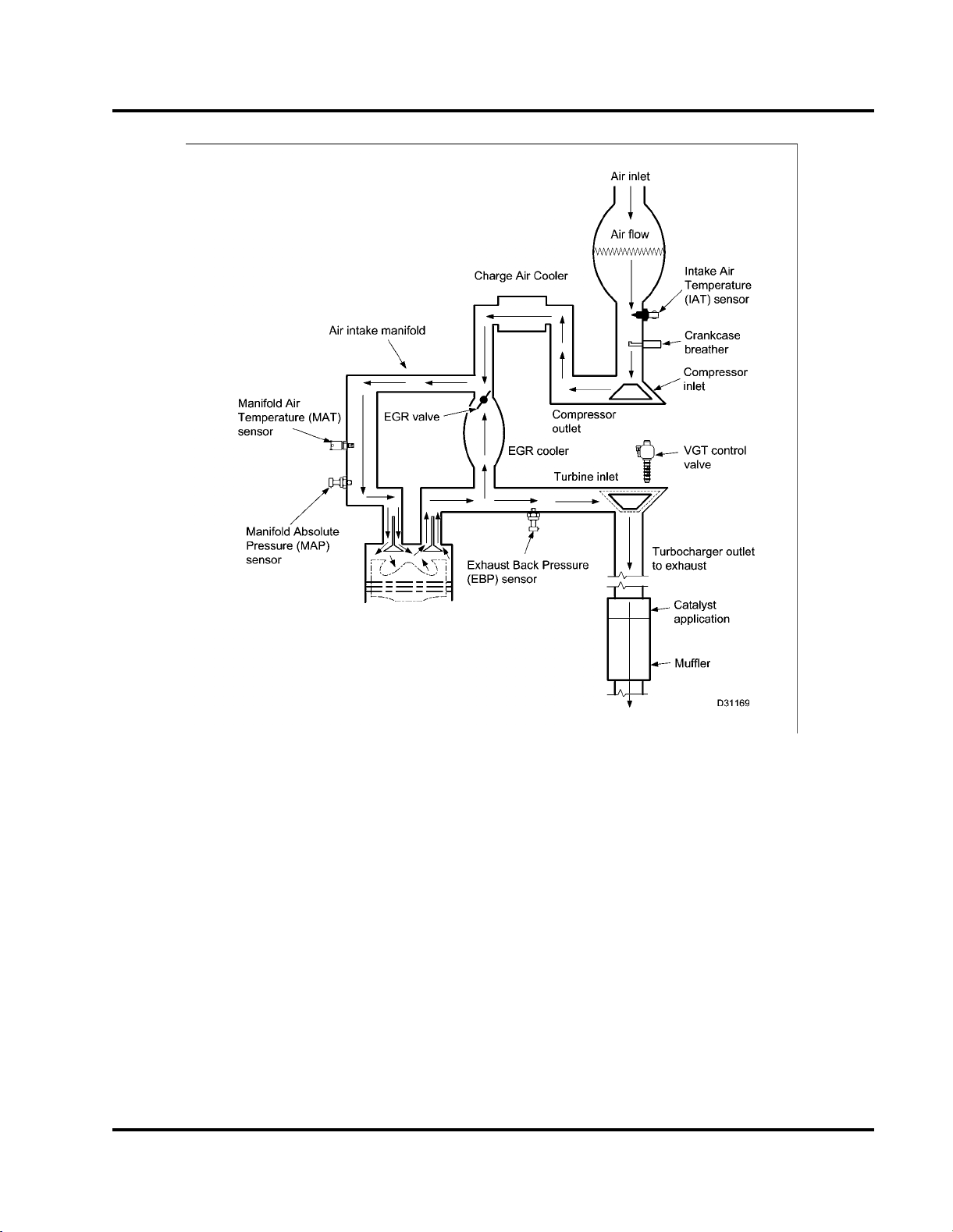

Figure 12 Air flow diagram

Air flow

Airentersand flows throughtheairfilterassembly and

mixes with air from crankcase ventilation. The VGT

compressestheairmixturebeforeitenterstheCharge

Air Cooler (CAC). Cooled compressed air flows from

the CAC into the air intake manifold that directs air to

the intake ports for each cylinder head.

After combustion, hot exhaust gas is forced through

the exhaust manifolds to the EGR cooler and VGT.

• Somehotexhaust gas is cooled intheEGRcooler

and flows through the EGR control valve back

through the air intake manifold to mix with filtered

air. This reduces nitrogen oxide (NOx) emissions

and noise.

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

• Therestof the hot exhaust gas expandsandflows

to the VGT, spins the turbine wheel, and flows

from the VGT outlet to the engine exhaust pipe.

• The VGT compressor wheel, on the same shaft

as the turbine wheel, compresses the mixture of

filtered air and air from crankcase ventilation.

The VGT responds directly to engine loads. During

heavy load, an increased flow of exhaust gases turns

the turbine wheel faster. This increased speed turns

the compressor impeller faster and supplies more air

or greater boost to the intake manifold. Conversely,

when engine load is light, the flow of exhaust gases

decreases and less air is pumped into the intake

manifold.

20 ENGINE SYSTEMS

The VGT modifies more efficient exhaust flow

characteristics.

Charge Air Cooler (CAC)

Figure 13 Charge Air Cooler

1. Air outlet

2. Charge Air Cooler

3. Air inlet

4. Radiator

The CAC cooler is mounted on top of the radiator.

Air from the VGT is pushed through a network of

heat exchanger tubes before entering the air intake

manifold. Outside air flowing over the tubes and

fins cools the charged air. Charged air is cooler and

denser than the uncooled air; cooler and denser

air improves the fuel-to-air ratio during combustion,

resulting in improved emission control and power

output.

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

Variable Geometry Turbocharger (VGT)

ENGINE SYSTEMS 21

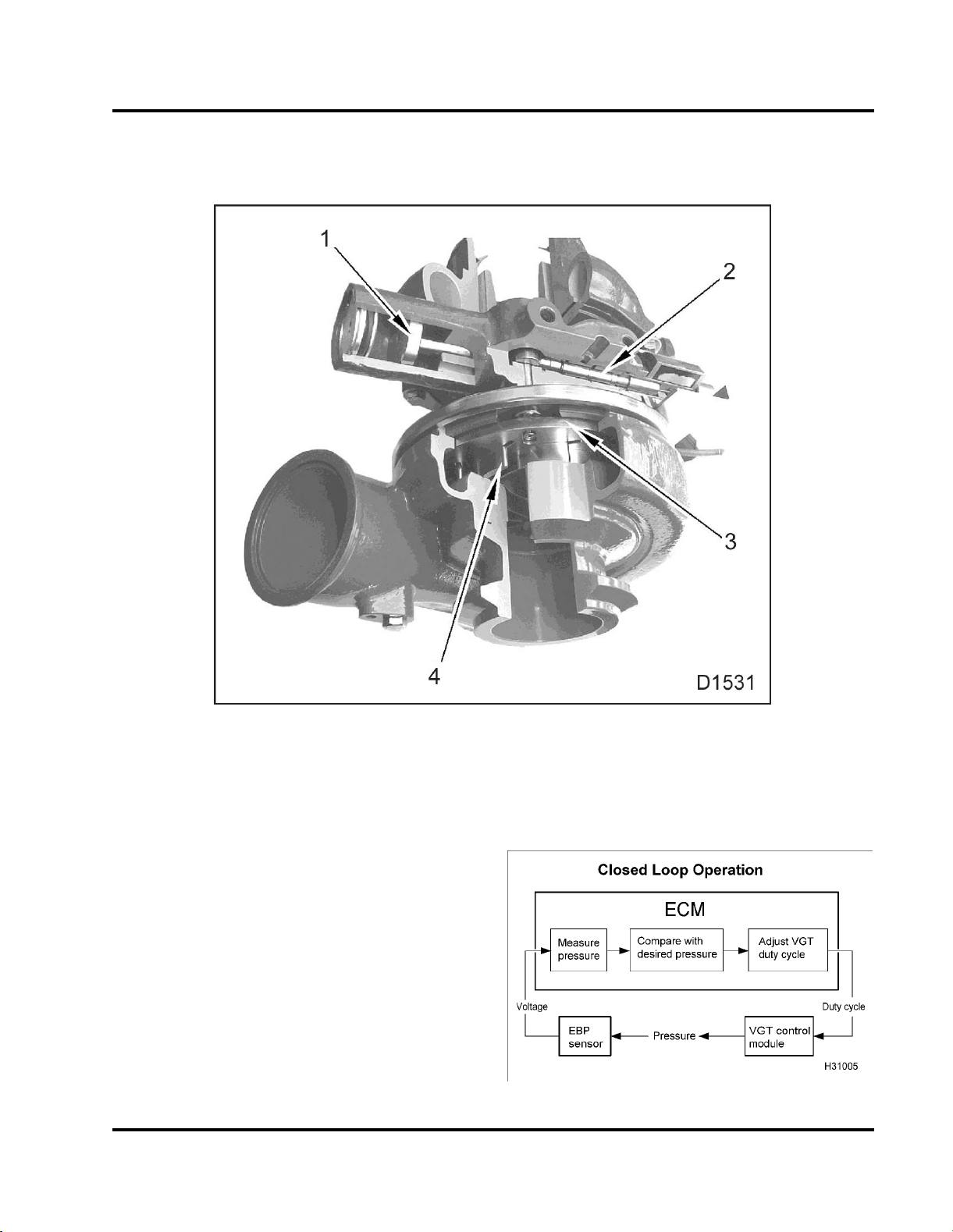

Figure 14 VGT

1. Actuator

2. VGT control valve

3. Unison ring

4. Vanes

The key feature of the VGT is actuated vanes

in the turbine housing. The vanes modify flow

characteristics of exhaust gases through the turbine

housing. The benefit is the ability to con trol boost

pressure needed to accommodate various engine

speeds and load conditions. An additional benefitis

lower exhaust emissions.

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

VGT closed loop system

Figure 15 VGT closed loop system

22 ENGINE SYSTEMS

The V GT is a closed loop system that uses the

Exhaust Back Pressure (EBP) sensor t o provide

feedback to the ECM. The ECM uses the EBP sensor

to continuously monitorEBP and adjust the dutycycle

to the VGT to match engine requirements.

VGT control

links all the vanes. When the unison ring moves,

all vanes move to the same position. Unison ring

movement occurs when either side of the actuator

piston is pressurized by engine oil.

Exhaust gas flow can be regulated depending on

required exhaust back pressure for enginespeed and

load.

Exhaust Gas Recirculation (EGR) System

The EGR system includes the following:

• EGR drive module

•EGRvalve

• EGR cooler

• Air intake manifold

• Exhaust tube assembly, right

The Exhaust Gas Recirculation (EGR) system

reduces Nitrogen Oxide (NOx) emissions.

NO

forms during a reaction between nitrogen and

X

oxygen at high temperature during combustion.

Combustion starts when fu el is injected into the

cylinder before or slightly after the piston reaches

top-dead-center.

Figure 16 VGT control

The solenoid receives a pulse width modulated signal

from the ECM that indicates the on / off time that the

control valve is energized. The control valve directs

lube oil flow to both sides of the piston in the actuator

housing. Directing oil to different sides of the piston

increases or decreases exhaust back pressure.

Actuated vanes are mounted around the inside

circumference of the turbine housing. A unison ring

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

EGR flow

Some exhaust from the right exhaust tube assembly

flows into the EGR cooler. Exhaust from the EGR

cooler flows in to a passage in the air intake manifold

that intersects with the EGR valve.

When EGR is commanded, the EGR control valve

opens allowing cooled exhaust gases to enter the

intake manifold to be mixed with filtered intake air

then recycled through the combustion process.

EGR valve

ENGINE SYSTEMS 23

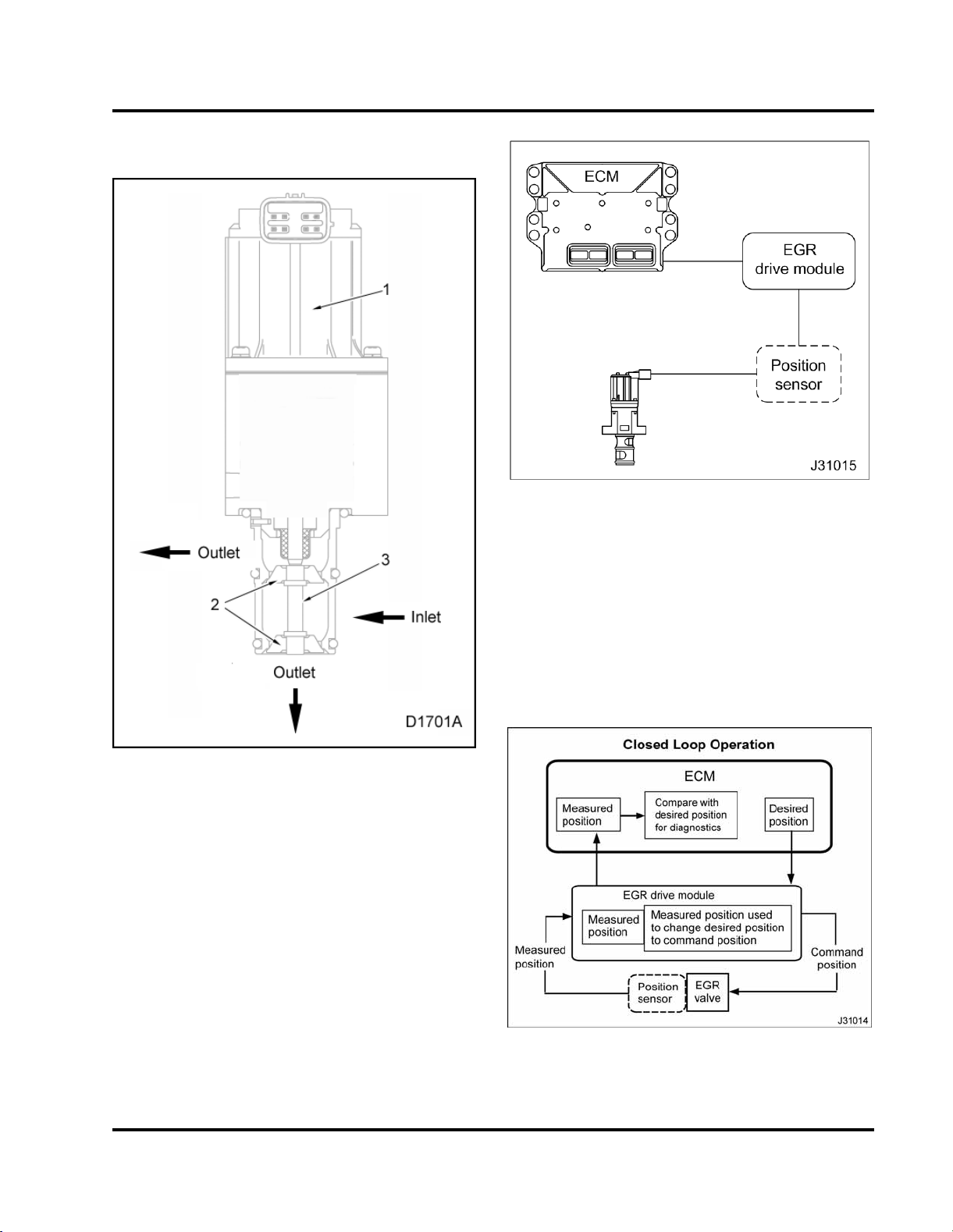

Figure 18 EGR control

Figure 17 EGR valve

1. Ac tuator coil

2. Valve heads (2)

3. Common shaft

A DC motor, in EGR valve, moves and controls the

position of a two head valve assembly.

The EGR valve, installed in the top fron

intake manifold, has th ree major co

head valve assembly, a DC motor, an

Circuit (IC). The IC has three Hal

sensors that monitor valve movem

The EGR drive module, mounted on t

module mounting bracket abov

assembly, controls the DC mo

mponents: a two

d an Integrated

l effect position

ent.

he EGR drive

e the ECM/IDM

tor.

toftheair

Figure 19 EGR closed loop operation

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

24 ENGINE SYSTEMS

The EGR system is closed loop control, using EGR

position signals.

The EGR drive module receives the desired EGR

valve position from the ECM across the CAN 2

datalink to activate the EGR valve for exhaust gas

recirculation. The EGR drive module provides

feedback to the ECM on the valve position, interprets

the ECM command, and sends the command using

three pulse width modulated signals to the DC motor.

Exhaust System

The exhaust system includes the following:

• Exhaust valves

• Exhaust manifolds

• Turbocharger

• Exhaust piping

•Muffler and catalytic converter – dependent on

application

• Catalyzed Diesel Particulate Filter (CDPF) – if

equipped.

The exhaust s ystem rem o ves exhaust gases from

the engine. Exhaust gases exit from exhaust ports,

through exhaust valves, and flow into the exhaust

manifolds. Expanding exhaust gases are directed

through the exhaust tubes. The right exhaust tube

directs some exhaust gases into the Exhaust Gas

Recirculation (EGR) cooler. Exhaust gases flowing

into the VGT drive the turbine wheel. Exhaust gases

exit the VGT and flow into the exhaust piping, through

the muffler and catalytic converter or CDPF, and out

the discharge pipe to the atmosphere.

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

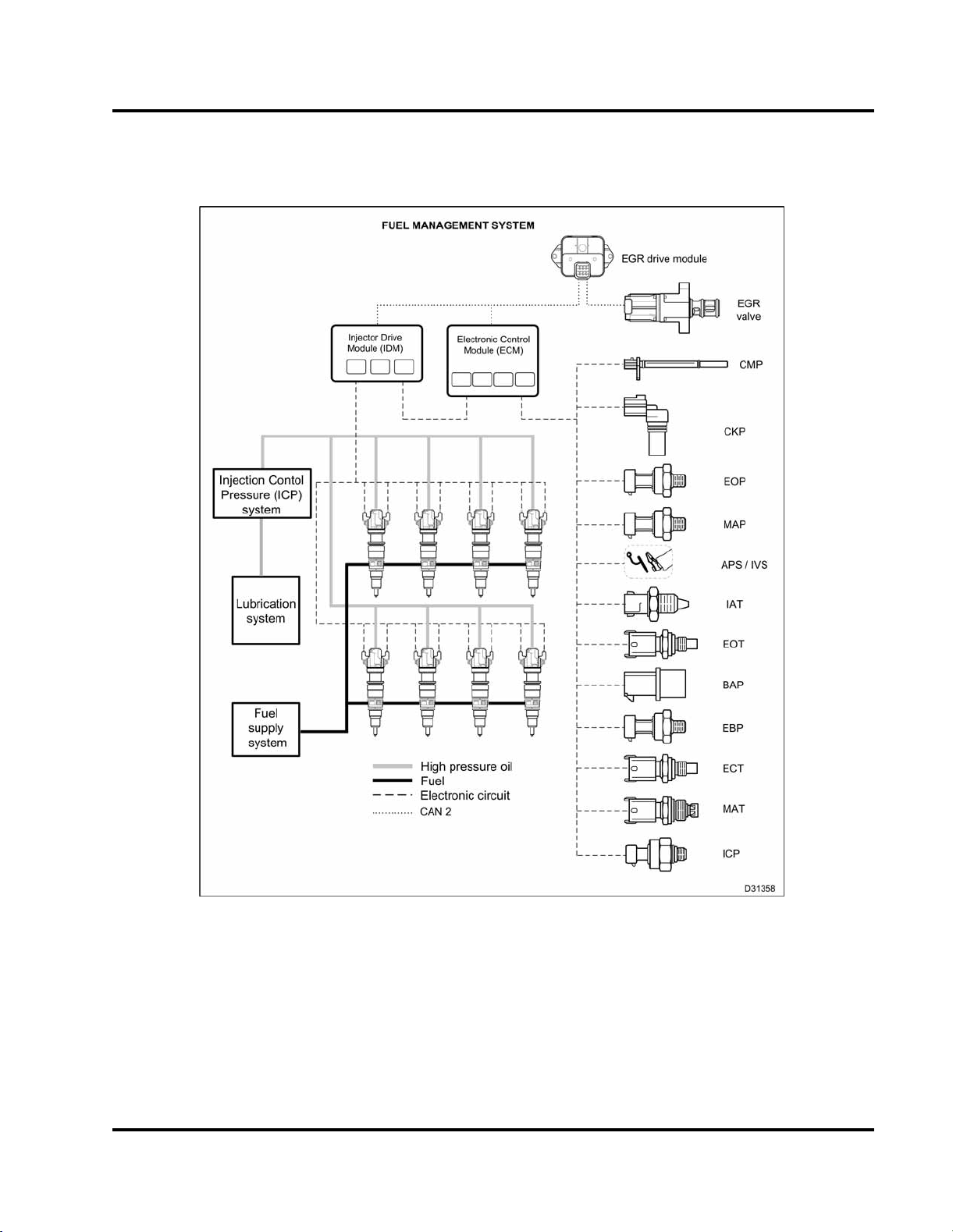

Fuel Managem ent System

Fuel Injection

ENGINE SYSTEMS 25

Figure 20 Fuel management system

The fuel management system includes the following:

• Injection Control Pressure (ICP) system

• Fuel injectors

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

• Electronic control system

• Lubrication system

• Fuel supply system

26 ENGINE SYSTEMS

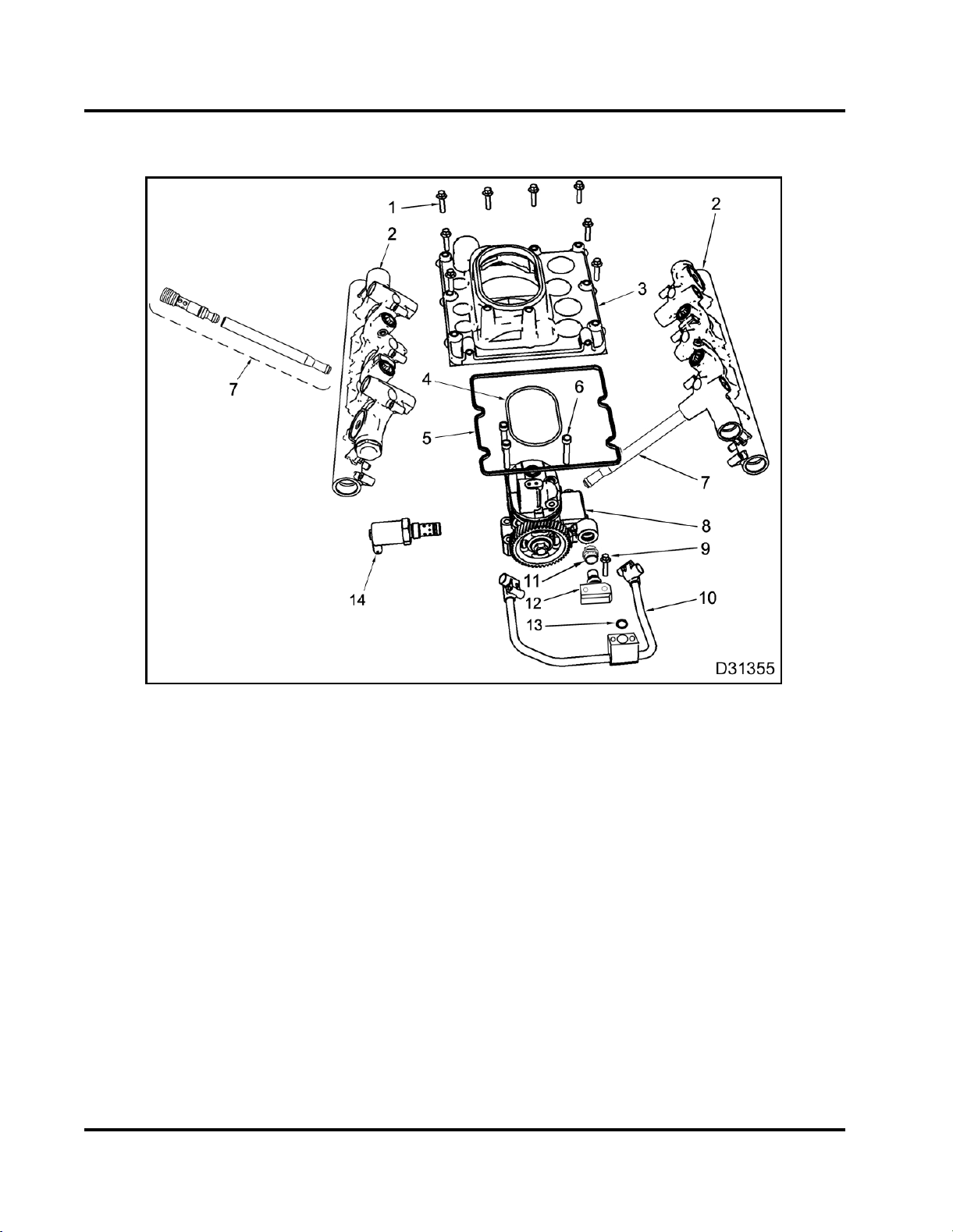

Injection Control Pressure (ICP) System

Figure 21 High-pressure o

1. High-pressure oil pump c

fasteners (8)

2. Oil rail assembly (2)

3. High-pressure oil pump co

4. Pump-to-cover seal ring

5. High-pressure oil pump c

seal

il system

over

ver

over

6. High-pressure oil pump

fasteners (3)

7. Case-to-head tube assem

8. High-pressure oil pump

assembly

9. Branch tube adapter bol

10. Branch tube assembly

High-pressure Oil Flow

A gear driven, high-pressure oil pump draws

oil through a screen in the oil reservoir for the

high-pressure oil pump. The oil reservoir, in the top

of the crankcase below the oil cooler, is kept full by

the engine lubrication system.

TheIPR valve maintains the ICP pressurebydumping

excess oil back to the crankcase.

EGES295-2

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

©2006 International Truck and Engine Corporation

fitting

bly (2)

t(2)

11. Snap to Connection (STC)

12. Branch tube adapter

13. O-ring

14. IPR valve

High-pressure oil from the pump flows through a

branch tube assembly to each case-to-head tube

assembly to each high-pressure oil rail.

High-pressure oil in the oil rails enter the fuel injectors

through sealed ports in the top of the fuel injectors.

When the OPEN coilfor each injectoris energized, the

injector uses high-pressure oil to inject and atomize

fuel into the combustion chamber. The CLOSE coils

are energized to end injection. Exhaust oil exits

through two ports in the top of the injector and drains

back to the crankcase.

Loading...

Loading...