International HS 2.8L Service Manual

SERVICE MANUAL

International HS 2.8L

International HS 2.8L Presentation

1

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

PRESENTATION

This Service Manual has technical specifications necessary to a correct maintenance and repairing of the

International HS 2.8L engines.

As a strictly technical literature, it has been avoided the inclusion of theory concepts and basic definitions,

due to this publication purpose.

It is important to learn how to correctly operate, to maintain and to repair these engines, as well to know

the issues that may cancel warranty due to a bad operation, unauthorized adaptations, unoriginal parts

use or any other procedures that affect it way any.

Following the instructions and specifications of this manual, the maintenance and repairing will be made

in the most correct and safety way possible.

INTERNATIONAL ENGINES SOUTH AMERICA LTDA reserves the right of changing the content of this

publication without warning, whenever innovations are necessary to be introduced in its products.

INTERNATIONAL ENGINES SOUTH AMERICA LTDA

Strategic Planning and Control Management

After Sales Department

Estrada dos Casa, 3155

S.B. do Campo - SP - Brazil

ZIP 09840-000 - Post Office Box 951

Phone: 55 (1 1) 4358-8522 - Fax (1 1) 4358-5710

site: www.nav-international.com.br

Publication Nr . 8120081 - 05/02.

International HS 2.8LIndex

2

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

INDEX

Safety Precautions......................................................................................................................................3

Environment ................................................................................................................................................5

Technical Features......................................................................................................................................8

Operation and Maintenance Recommendations.......................................................................................11

Cooling System.........................................................................................................................................20

Fuel System ..............................................................................................................................................27

Lubrication System ...................................................................................................................................41

Cylinder Head............................................................................................................................................47

Engine Block .............................................................................................................................................63

Pistons and Connecting Rods ..................................................................................................................68

Crankshaft.................................................................................................................................................76

Crankshaft Pulley ......................................................................................................................................83

Engine Timing............................................................................................................................................89

Flywheel ....................................................................................................................................................97

Accessories ............................................................................................................................................101

Technical Specifications..........................................................................................................................106

Tightening S pecifications.........................................................................................................................113

Additional Instructions .............................................................................................................................119

Special Tools ...........................................................................................................................................125

3

International HS 2.8L

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

SAFETY PRECAUTIONS

International HS 2.8L

4

Safety Precautions

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

SAFETY PRECAUTIONS

Warning: The texts emphasized with the symbol means direct or indirect personal injuries

risk.

Read carefully this manual and keep it always on hand to clarify any doubts.

Do not try to operate the equipment without knowing all controls and understanding the

operation of the main systems.

Take all precautions of safety indicated next, because they are your protection during

the work.

• Do not change the original features of the engine.

• Do not smoke while filling fuel tank.

• Clean immediately all and any spilled fluid. Put the material used on cleaning in a safe position and

discard according the Local Legislation.

• Do not fill, while engine is running, unless it is absolutely necessary.

• Never clean, lubricate or adjust an engine in operation.

• Do not adjust anything, if you do not know how to do it correctly.

• Do not operate the engine in closed rooms, because the exhaust gases are extremely “prejudicial” to

the health.

• Do not allow people or animals to stay close to the engine, vehicle or equipment while in operation.

• Do not allow people with loose clothes or long and loose hair to stay close to the mobile parts.

• Stay away from the rotary parts. Remember that helices, for example, cannot be well seen while the

engine is running.

• Do not remove radiator cap if the engine is still hot, because cooling water, under pressure, is

extremely dangerous, and may spill and cause serious injuries.

• Do not use salty water or any other substance that can cause corrosion in the cooling system.

• Avoid sparks or fire near batteries, especially while they are charging, because they can cause

explosions. The solution of the batteries could boil and its contact with the skin and eyes is dangerous.

• Disconnect battery terminals before doing any repair in the electric system.

• Seek medical assistance if diesel fuel, under high pressure, penetrates the skin.

5

International HS 2.8L

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

ENVIRONMENT

International HS 2.8LEnvironment

6

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

ENVIRONMENT

ENVIRONMENT AL POLICY

INTERNATIONAL ENGINES SOUTH AMERICA LTDA is committed with the continuous search of the

environment preservation in Diesel engines production for the worldwide market, through an efficient

administration of its resources, processes and products.

GUIDELINES:

To attend the legislation, applicable environmental rules and other requirements that the Company has

joined.

To develop products and procedures to reduce environmental impact s and to avoid pollution.

To apply an efficient administration system that promotes the continuous improvement to reach

environmental objectives and targets.

To promote, in the Company , the sense of individual responsibility in relation with the environment.

To involve its suppliers and service suppliers in the development of habits which cooperate in the

preservation of the environment.

ENVIRONMENT

The environment preservation is a basic point in the managerial philosophy of INTERNATIONAL

ENGINES SOUTH AMERICA LTDA.

It has been approved a program of actuation that includes activities as natural resources conservation,

elimination and residues recycling, water protection, noise reduction and acoustic isolation, air purity

conservation and contaminants residues elimination.

All these subjects constitute the mark of a wide environment protection program, which is considered

since the beginning of a new product project.

The International HS 2.8L engine was released in the market and accomplishes without problems all

these requirements.

The systematical accomplishment of this philosophy can be appreciated especially in the main aspects,

like disassembly easiness, less number of materials, usage of plastics of easy recycling.

It means, equally , that materials harmful to the environment are not used, like amianthus, cadmium and

hydro-carbide fluor-chlorined.

In the same field, gases and acoustics emissions reduction are considered, as well as the improvement

of the active and passive safety.

This environment protection program is not limited only to the production process, because it is extended

to the complete cycle of useful life of the engine, considering also its wear after a long operation period.

We have assumed a commitment with the planet we live in. A commitment that we take very seriously.

International HS 2.8L Environment

7

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

ENVIRONMENT AL POLLUTION CONTROL

INTERNATIONAL ENGINES SOUTH AMERICA LTDA, through its Environmental Administration

System, has improved more and more its engines contributing to pollution reduction (Program of Air

Pollution Control for Auto-Motorized Vehicles - PROCONVE) and attending, in this way , to the resolutions

of CONAMA (National Council of the Environment).

Warning: The engine adjustment values specified in this manual, must be strictly observed,

because, besides to offer a better performance to the vehicle, also reduce noises and

harmful gases emissions to the atmosphere.

Warning: Any change in the fuel injection or air intake system, or even the exhaust system, may

affect directly the homologated values.

DESTINA TION OF THE USED COMPONENTS OF THE ENGINE

INTERNA TIONAL ENGINES SOUTH AMERICA L TDA is applying in its engines, more and more, materials

of easy recycling, making easy this way , in the end of the component life, its sale or re-fusion.

Plastic and Metallic Components / Packing

This type of component must be sent to a Scrap Trade where the parts will be sold and re-melted.

Lubricant Oil

This fluid has a high polluting potential and it cannot be discarded, never, in the sewer. Send it to

companies that make the re-process (re-refine).

International HS 2.8L

8

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

TECHNICAL FEA TURES

International HS 2.8L Technical Features

9

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

TECHNICAL FEA TURES

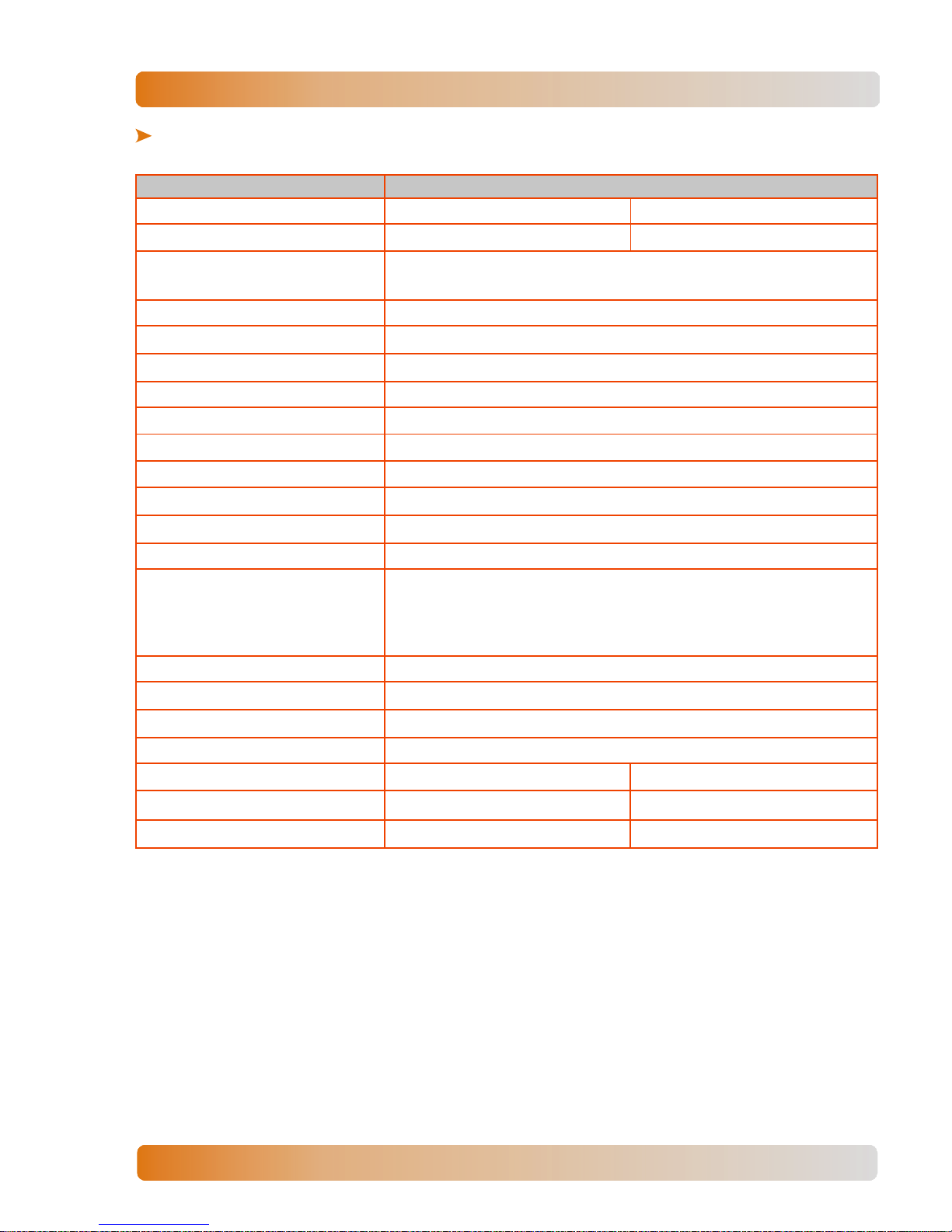

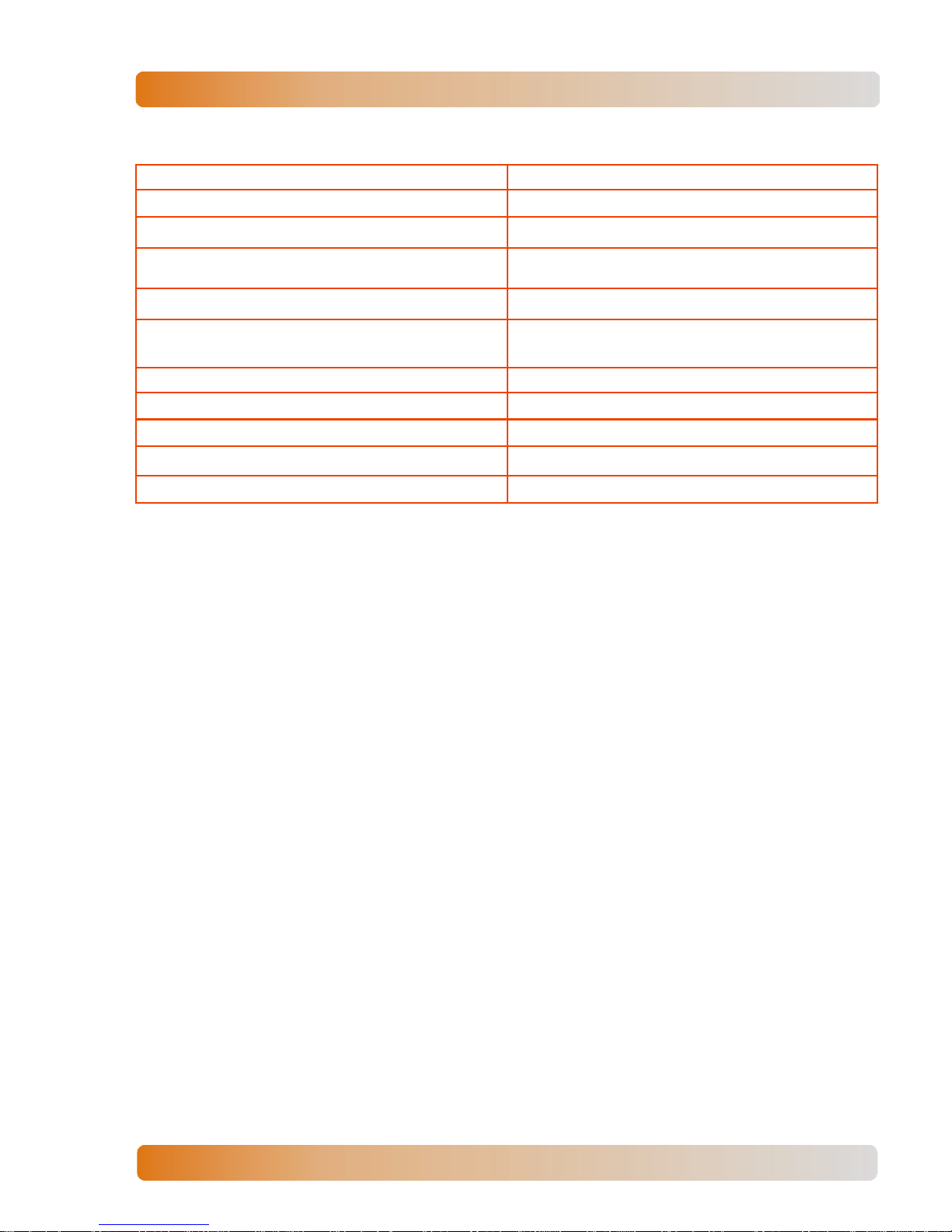

ENGINE TYPE INTERNA TIONAL HS 2.8L

PL number

8B60 8B61

Turbocharger

V ariable Nozzle (VNT) With Wastegate

Number and Cylinder

Arrangement

4 in line

Cylinder Nominal Bore

93.0 mm

Stroke

102.50 mm

Cycle

Diesel, 4 stroke

Compression Relation

19.5 : 1

Total Displacement

2,8 Liters

Combustion System

Direct Injection

Rotation Sense (front view)

Clockwise

Firing Order

1 - 3 - 4 - 2

Opening Beginning

86 - 90 ºC

Operation Temperature

86 -102 ºC

Lubricant oil Pressure (at

Maximum Specified Speed With

the Engine at Normal Operation

Temperature)

3.5 bar

Maximum Speed Unload 4640 rpm

Idle Speed

800 rpm ± 20

St atic Injection Beginning at TDC

0º

Engine Cooling

Liquid

Power (NBR5454) 135 hp (99 kW) at 3800 rpm 133 hp (97 kW) at 3800 rpm

Torque (NBR5454) 38.2 kgfm (375 Nm) at 1400 rpm 36.2 kgfm (355 Nm) at 1600 rpm

Weight (basic unit) 208 kg 205 kg

International HS 2.8LTechnical Features

10

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

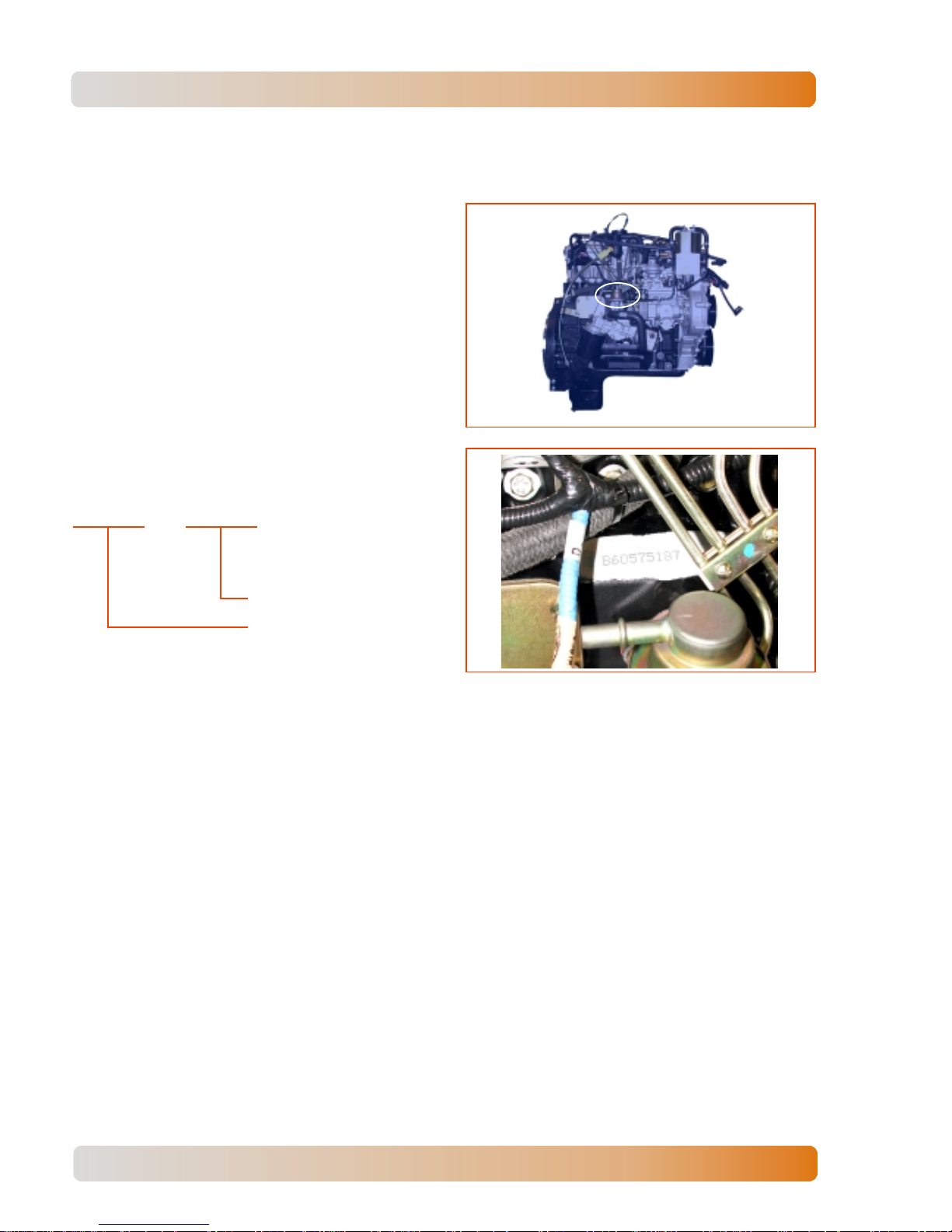

LOCA TION AND IDENTIFICA TION OF THE

ENGINE NUMBER

Location

Identification

B61 (WG)

B60 (VNT) 536265

SERIAL NUMBER

P ARTS LIST NUMBER

• For engines manufactured in Brazil nr 000001 to 499999.

• For engines manufactured in Argentina nr from 500000 on.

PS: (WG) - Wastegate Version

(VNT) - V ariable Nozzle Turbocharger V ersion

Left side view

Front

11

International HS 2.8L

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

OPERATION AND MAINTENANCE

RECOMMENDATIONS

International HS 2.8L

12

Operation and Maintenance Recommendations

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

OPERATION AND MAINTENANCE

RECOMMENDA TIONS

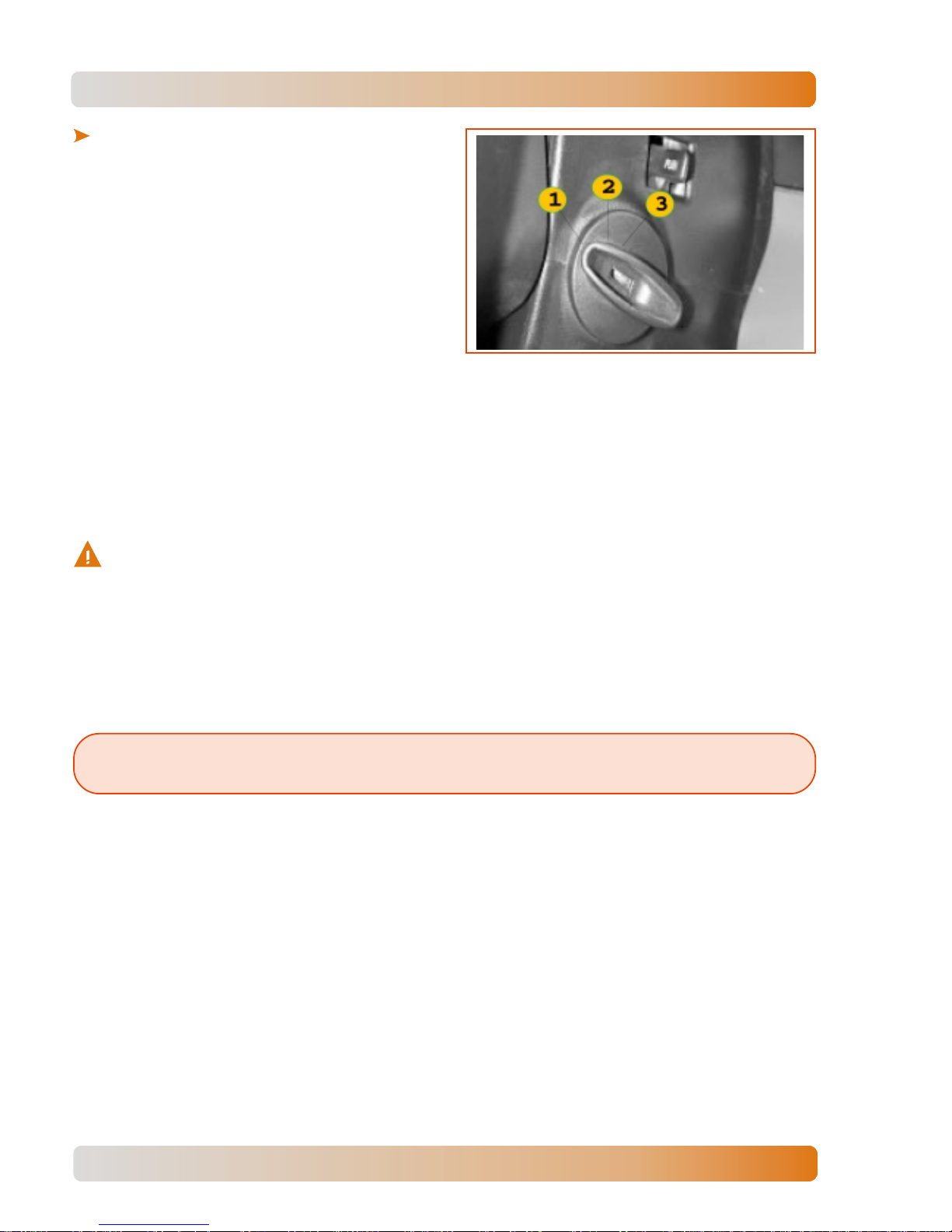

ST ART AND STOP

Before starting the engine

1. Check “Daily Maintenance” items, see

PERIODIC MAINTENANCE.

2. Turn start key to contact position and check if

battery charge and engine oil pressure

indicator lamps are switched on.

If the engine has been stayed inactive for a long

period, bleed the fuel system.

Key Positions

1. Off

2. Contact

3. Start

Start

Warning: POSITION TRANSMISSION

LEVER TO NEUTRAL.

1. Position key in start position for seven

seconds, at the maximum.

If engine doesn’t work, repeat operation after 30

(thirty) seconds.

Note: Do not keep the key turned too much long, because it will damage the starter .

In turbocharged engines, after to start, do not

accelerate over than 1000 rpm, during the firsts

30 (thirty) seconds. This allows turbocharger

lubrication line pressure equalization avoiding

damages to this equipment.

13

International HS 2.8L Operation and Maintenance Recommendations

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

2. Check the panel instruments, engine noise

and exhaust gases.

In case of any irregularity , stop the engine

and immediately look for our Distributors

Network and / or Authorized Services.

Note: Do not extremely load the engine, while it is not at the normal operation temperature.

Stop

Warning: Let the engine in idle speed and

transmission lever in neutral.

In turbocharged engines, in order to do not

damage the turbocharger shaft, the engine must

run during 30 (thirty) seconds under 1000 rpm

before stopped.

• Do not accelerate the engine.

• Turn key to “off” position.

RUNNING-IN

The technology that INTERNA TIONAL ENGINES

SOUTH AMERICA L TDA uses on it s engines

production, as well as on tests in dynamometer,

eliminate the necessity of large run-in periods.

Generally , it is considered the firsts 2500 km

(1550 mi) of work as the necessary period for the

run-in, which can vary according to each

application that each product is used.

International HS 2.8L

14

Operation and Maintenance Recommendations

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

During running-in follow these recommendations:

• DO NOT OPERATE THE ENGINE AT OVER

THAN 85% OF THE MAXIMUM SPECIFIED

SPEED (3800 rpm), see TECHNICAL

SPECIFICATIONS.

• WHEN IN A TRIP, V ARY THE ROT A TION T O

A VOID CONST ANT SPEEDS DURING LONG

PERIODS. DO NOT BRUSQUELY

ACCELERA TE THE ENGINE.

During useful life of the engine:

• Before starting, check lubricant oil, cooling

system water and fuel levels.

• Do not warm the engine up in idle speed but

varying its speed.

• To reach the normal operation temperature,

move the vehicle without extremely loading

and without exceeding 3800 rpm.

• Do not let the engine running in idle speed

without need.

• Keep the engine operation temperature

between 86 and 102 °C (187 and 216 °F)

engine.

Note: It is operator responsibility the correct use of the product during the running-in. The not

execution of the recommendations above mentioned will provoke the decrease of the

product useful life, with consequent increase of the lubricant oil consumption to higher

levels than the ones defined by the project.

REVISION PROGRAMS

The engine warranty is conditioned to the

accomplishment of the delivery revisions, and

more the revisions mentioned in the Warranty

Certificate.

Our Distributors and / or Authorized Services Net

must make all obligatory and periodic revisions

operations according to the instructions of this

Manual.

Optional equipment installation, not originals from

factory, will cancel warranty and may cause

serious damages to the engine, with consequent

decrease of its useful life.

For a better engine performance, always use

genuine parts.

15

International HS 2.8L Operation and Maintenance Recommendations

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

INST ALLATION REVISION

ITEM CHECK

Alternator belt T ension

Water and lubricant oil Level (complete if necessary)

General performance

Operation temperature and speed at

maximum load

Intake system Intake air temperature and restriction

Fuel system circuit

If the piping is unobstructed and free of vibrations,

extreme heat areas and leakages occurrences

Exhaust system If there isn’t restriction to the exhaust gases

Command system

Accelerator course

Engine fixation

Alignment among engine and transmition

Instrument panel Indicators, warning lamps and sensors functioning

Cooling system

Radiator, hoses, piping and clamp conditions

International HS 2.8L

16

Operation and Maintenance Recommendations

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

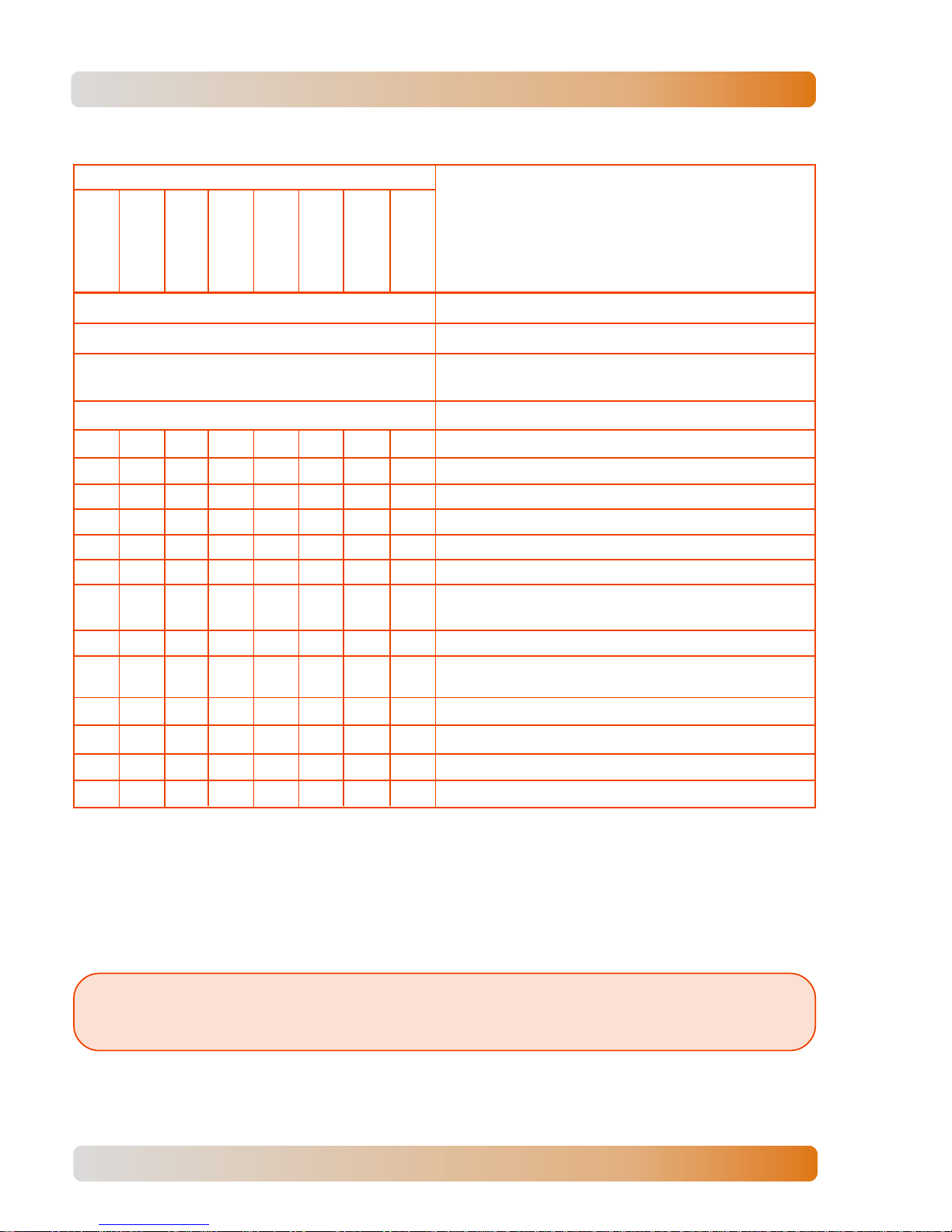

PERIODIC MAINTENANCE

PERIODS

CHECK

15,000 km

(9,300 mi)

Check engine oil level (complete if necessary).

30,000 km

(18,600 mi)

45,000 km

(27,900 mi)

60,000 km

(37,300 mi)

75,000 km

(46,600 mi)

90,000 km

(55,900 mi)

105,000 km

(65,200 mi)

120,000 km

(74,600 mi)

Daily

Check water “reservoir” level (complete if necessary).Daily

Drain impurities from the fuel filter and

sedimentation filter.

Daily

Check air filter hoses and connections conditions.Daily

Retighten engine rubber pads.

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

Replace lubricant oil and filter.

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

Replace fuel filter element.

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

Adjust valves clearance.

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

Check idle speed*.

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

Check teeth belt conditions, through the inspection

lateral plug.

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

Check external belts conditions.

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

Cooling system: check anti-freezing

(replace at each 2 years).

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

Check oil - fuel - cooling piping conditions.

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

Replace external belts.

••

••

•

Replace toothed belt.

••

••

•

Evaluate starter, alternator and turbocharger**.

••

••

•

••

••

•

After the first change at 15.000 km (9,300 mi) lubricant oil and oil filter must be obligatory changed at

each 15.000 km (9,300 mi) or 6 months maximum (which one first occurs). Fuel filter must be replaced

and fuel tank clean (maximum) at each 6 months, even without reached the limit of 15.000 km (9,300 mi)

(recommended for the fuel filter change).

* Services that have to be made by Distributors / Authorized Services Net.

** Services that have to be made by part manufacturer.

Remark: For vehicles that work predominantly in regions where sulfur index in fuel is over than

1%, lubricant oil change intervals must be at each 7.500 km.

Check the terminals and battery level.

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

••

••

•

17

International HS 2.8L Operation and Maintenance Recommendations

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

TURBOCHARGER

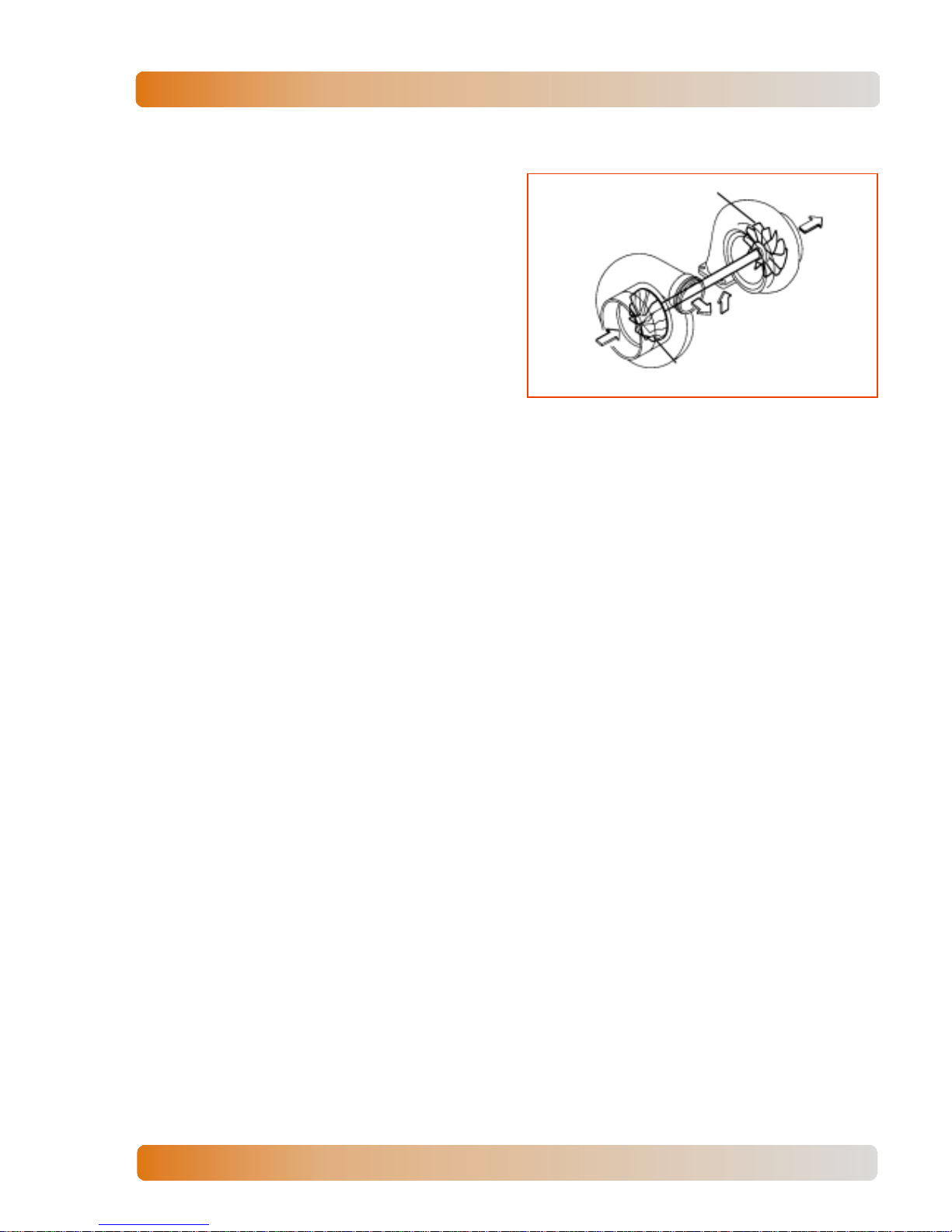

The turbocharger is compound of a rotary turbine

and a air compressor, located in opposite sides

of a same shaft. The compressor and turbine

rotors are covered by housing denominated

compressor and turbine, which function is to

direct the gases flow through the rotors shovels.

These gases having energy in pressure,

temperature and speed form, cause the rotation

of the turbine rotor and consequently of the

compressor rotor.

With the rotation, the atmospheric air (that must

be properly filtrate) is aspired, and later on,

compressed to the compressor rotor from where

goes to turbocharging (in turbocharged

International HS 2.8L engines) and later on to the

engine cylinders. Having a higher pressure in the

intake, the work done by the cylinders is positive,

in other words, the cylinders spent a smaller

amount of energy in the intake.

In turbocharged International HS 2.8L engine, the

turbocharger is also composed by a Wastegate

valve or VNT, which controls the maximum

pressure to be provided by the compressor, to

avoid damages in the engine.

Other advantage:

Existing a larger mass of air, we can fire a larger

amount of fuel, besides we get a better

combustion of the mixture.

The operation of an engine equipped with

turbocharger does not require any special

procedure.

Anyway , to assure the maximum durability of the

turbocharger, take care of these items:

To accelerate the engine immediately after

starting damages the turbocharger, because it

gets a high speed without the oil flow need on its

shaft.

To accelerate the engine before stop it, also

damages the turbocharger, because it stops the

lubrication but, on the other hand, the turbo shaft

still has a high speed.

Filtrate air

Exhaust

gases

Turbine rotor

Compressed air

Compressor rotor

Exhaust

gases from

the engine

International HS 2.8L

18

Operation and Maintenance Recommendations

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

The intake of strange objects, even smalls, will

damage the rotor of the compressor, damaging

the operation of the turbocharger, this way,

between the recommended periods check the air

filtering system.

By working at high speeds and temperatures, the

turbo requires a lubricant oil that accomplish to

these requirements, and never should be used a

lubricant oil that does not attend to API / ACEA

specification (5th class - multi-viscous).

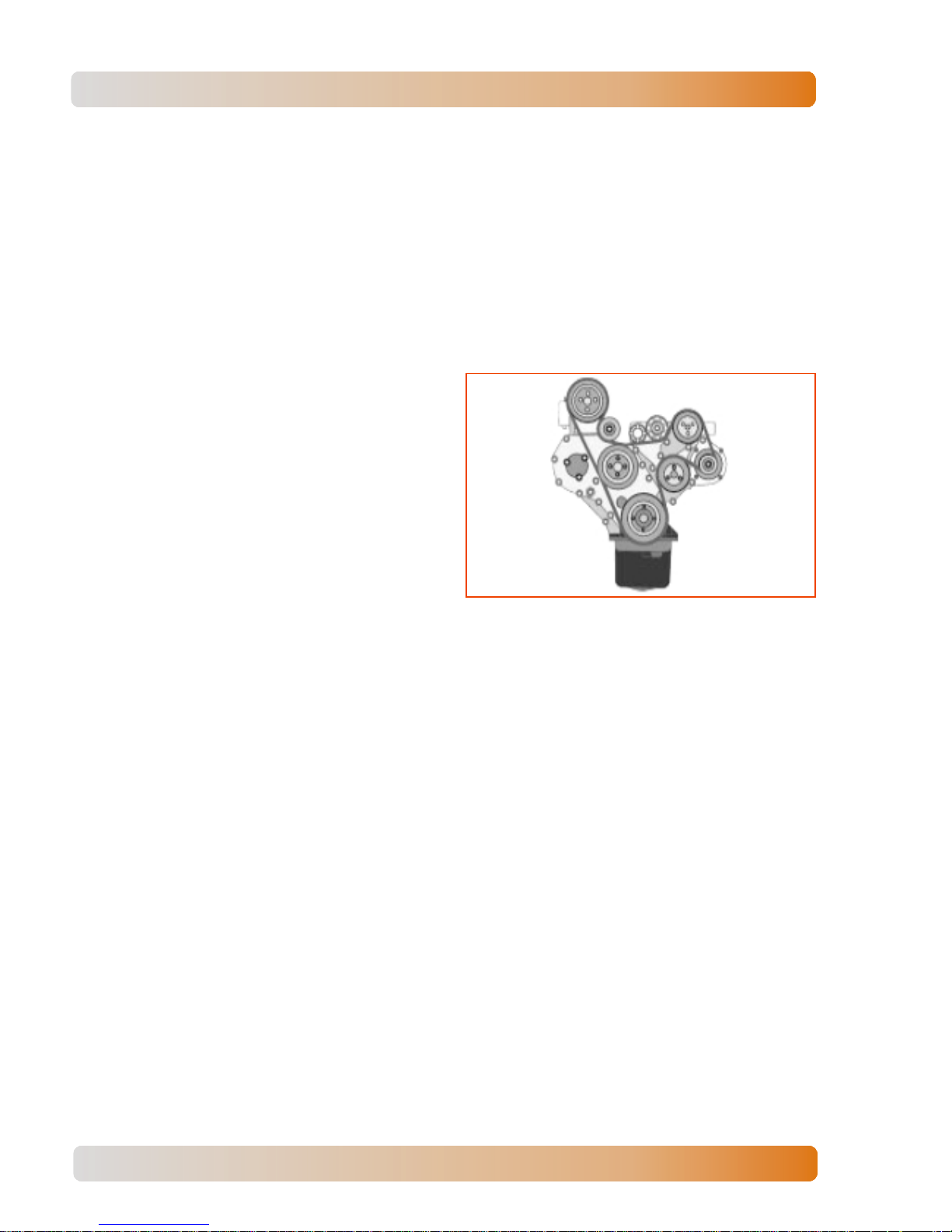

ACCESSORIES BEL TS

If the panel of the equipment accuses high

temperature and / or battery low charge, check if

the belt is loose or ruptured.

Two belts equip the turbocharged International HS

2.8L engine. It is very important that the belts be

installed exactly as shown in the illustration.

Two tensors adjust automatically the belts

tension, eliminating this way the necessity of

individual adjustment.

The belts must be checked at each service and

replaced when necessary.

Off-road use

Belts regular checks are essential if the vehicle is

used off-road. When executing service in the

vehicle, the owner must be contacted to identify

the way in that the vehicle’s mileage has been

get.

After each off-road use, the owner must check

the belts for cuts and damages caused by

stones. If one of the belts gets loose, it must be

repositioned correctly , replacing in the next

service or before, depending on the damage

level.

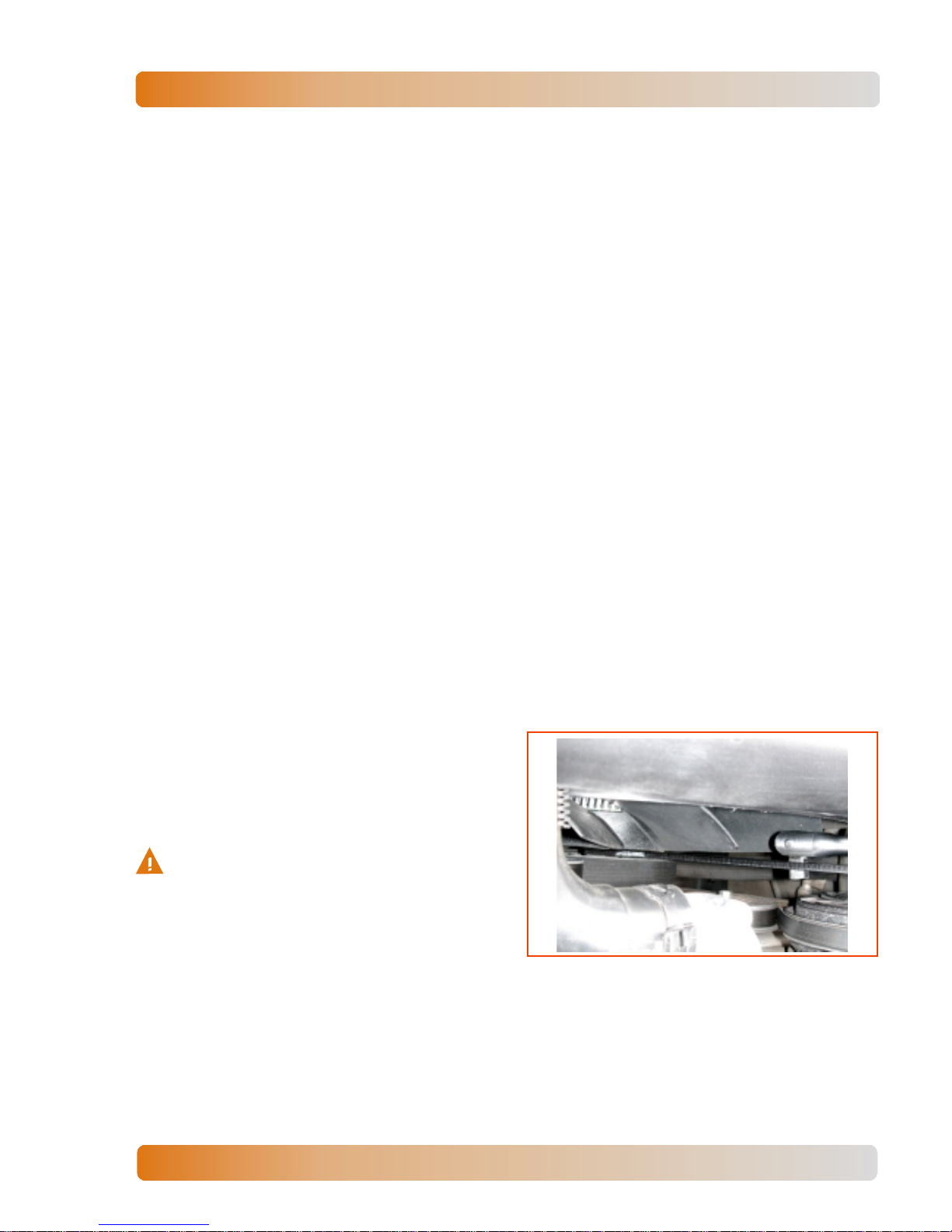

Belts conditions check

Check belts conditions, replacing them if they

present waste, cracks or contamination with oil.

19

International HS 2.8L Operation and Maintenance Recommendations

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

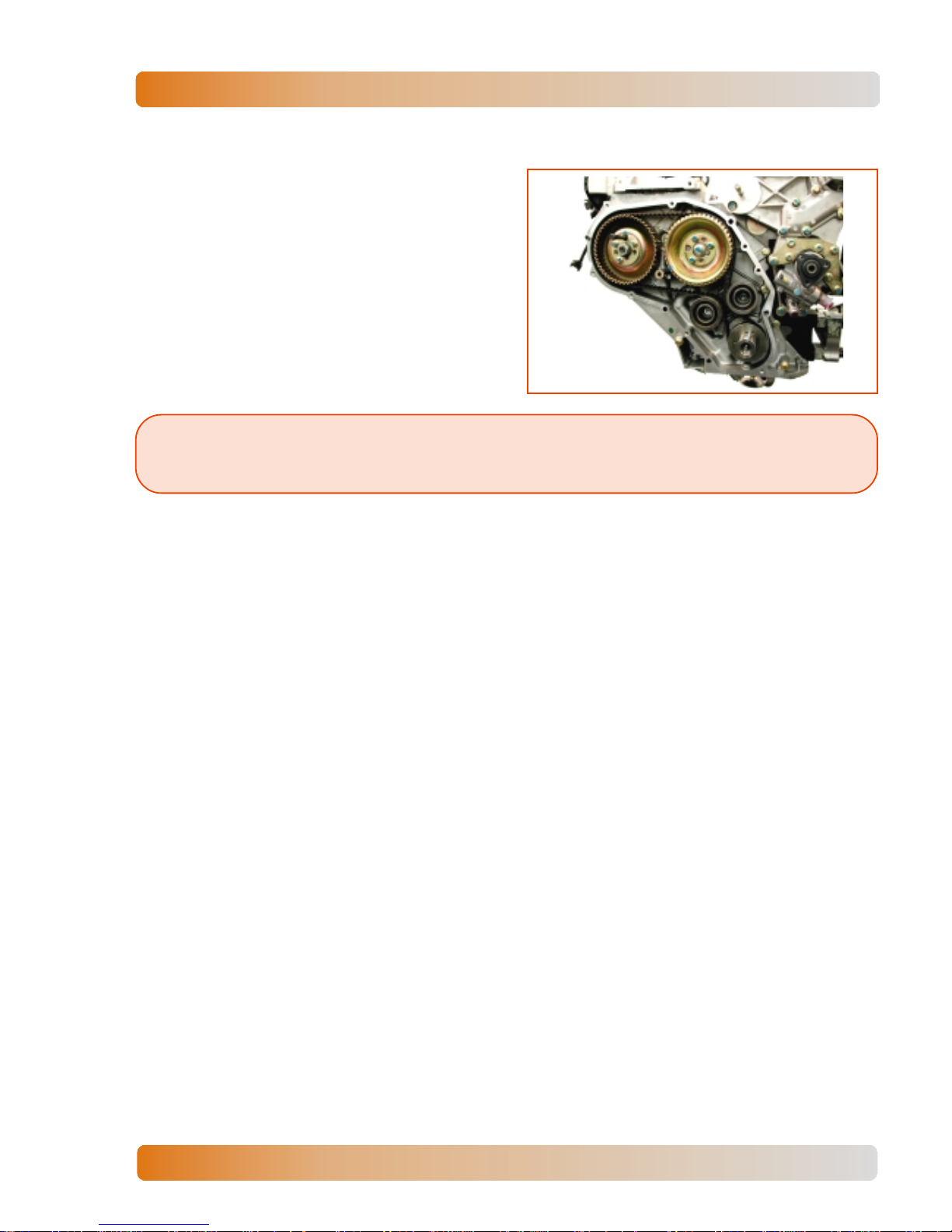

CAMSHAFT BEL T

The engine timing pulleys are moved by a flexible

rubber belt, which must be replaced in

predetermined intervals depending on the use

conditions severity .

Follow strictly the specifications of belt tensor

tightening, guaranteeing its useful life, according

the recommendation.

Note: If the belt is not replaced within the correct intervals, it may present failures, causing

serious damages to the engine.

International HS 2.8L

20

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

COOLING SYSTEM

21

International HS 2.8L Cooling System

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

COOLING SYSTEM

Circuit drainage

If it is necessary to totally drain the coolant water ,

follow the instructions below:

Warning: Do not drain cooling water while

the engine is still hot and the

system pressurized.

1. Remove lower and upper radiator hoses.

2. Remove engine block drainage plug M14

(right side of the engine, front view). Make

sure that the drainage hole is not obstructed.

3. Remove radiator hoses from the engine, and

fan.

4. Drain all the coolant water from the block.

5. Check hoses condition and replace them if

they are damaged or deformed.

System filling

1. Install plug in the block and tighten it within

13 to 17 Nm.

2. Install all cooling system hoses in the inverse

order of the removal, according to the vehicle

Owner’s Manual.

3. Check in the Owner’s Manual, the level

(capacity) of the cooling system (engine +

radiator + expansion reservoir - if existent).

Warning: Never check the water level

immediately after the engine

stop. This may cause burnings.

International HS 2.8L

22

Cooling System

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

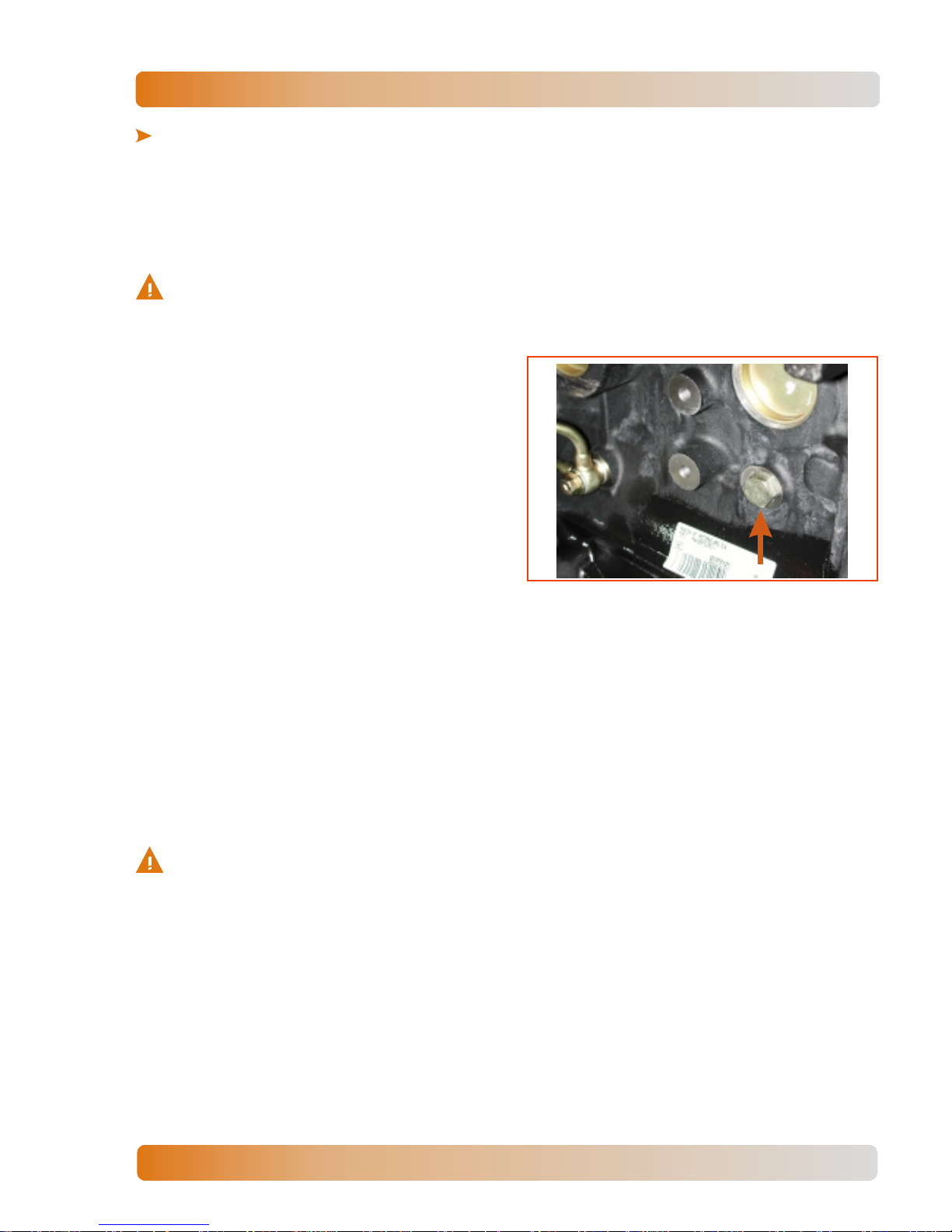

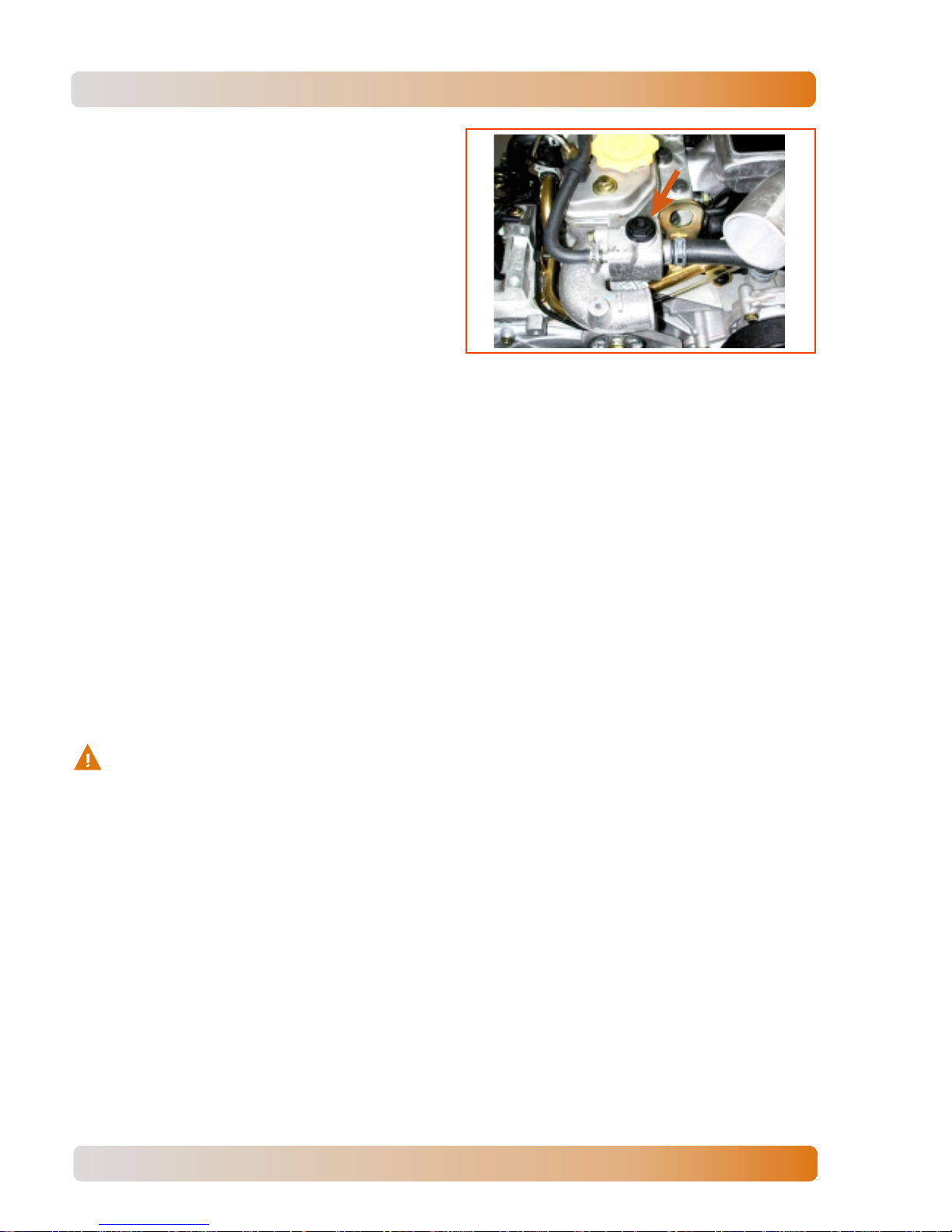

4. Remove cooling system expansion reservoir

cover (tank).

5. Remove disaeration plug, located in the

upper part of the thermostat housing.

6. With the engine stopped, fill the system

through expansion reservoir, until liquid leaks

through the disaeration plug (see illustration).

Always using additives diluted in clean water ,

keeping the mix proportion (1/3 of addictive,

2/3 of water).

In regions of more intense cold, use 1/2 of

addictive and 1/2 of clean water, free of

residues.

7. Press radiator upper hose to help the air

elimination and fill the system until only

coolant water leaks free from bubbles

through the thermostat-housing hole.

Recommended additives:

Radiex Química Ltda - Fluid for radiator Radiex.

Mobil Oil do Brasil Ind. e Com. Ltda. - Mobil

Permazone.

Promax Products Máximos S.A. - Bardhal Rad

Cool.

Shell Brasil S.A. - Fluid for radiators

Warning: Carefully read the instructions

on the product packing before

using it.

Do not add soluble oil to the cooling circuit water ,

because it attacks and damages the rubber

hoses.

The above mentioned additives usage is very

important to guarantee the cooling system

efficiency , being the engine operating at low or

high temperatures.

23

International HS 2.8L Cooling System

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

8. Manually reinstall thermostat housing

disaeration plug, just to seal the liquid outlet

hole.

A. Fill system until reaching the maximum level

of the tank.

B. Tighten expansion reservoir cover and check

for leakages.

C. Run engine at idle speed for 10 seconds and

let the liquid spill through the disaeration plug,

eliminating all air bubbles from the system.

D. S top engine and tighten the disaeration plug

within 13 to 17 Nm.

E. Run engine at 2000 rpm, approximately

medium acceleration, for five minutes.

F. Increase speed up to 3500 rpm,

approximately 3/4 of the maximum

acceleration, for four minutes more.

G. Slow down engine speed again to 2000 rpm,

for three minutes more.

H. Check coolant water level in the expansion

reservoir, if necessary complete to the

maximum level.

FAN

Removal

1. Remove radiator shield.

2. Using tool nr. 8130632 to lock flywheel, use

tool nr. 8130643 to viscous clutch.

Warning: To remove the viscous clutch

and fan is necessary to rotate

the fixation nut clockwise.

Reinstallation

1. Reinstall in inverse order of removal.

2. Using tool nr. 8130632 to lock flywheel, fix

viscous clutch and fan with the tool nr.

8130643, counter clockwise; tighten nut.

International HS 2.8L

24

Cooling System

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

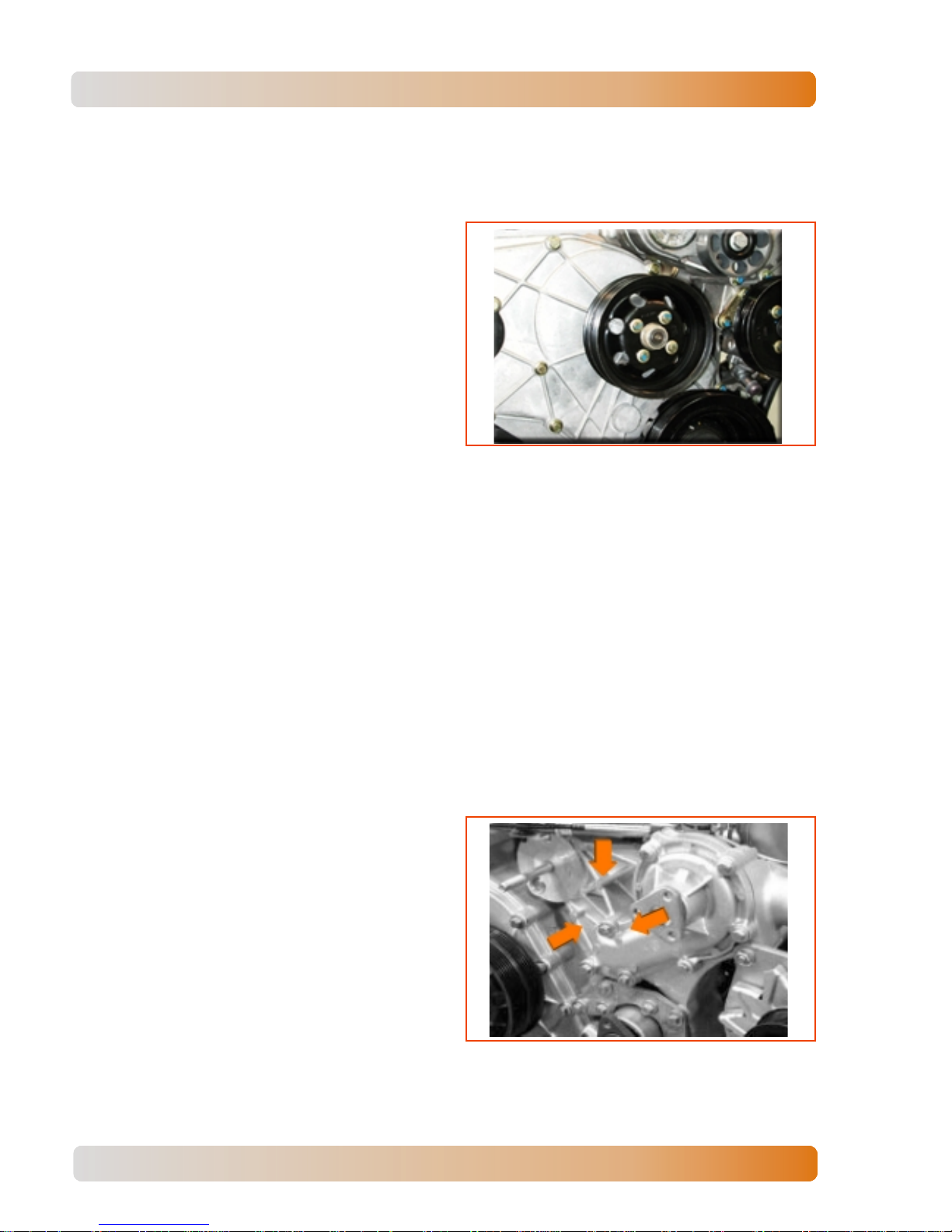

FAN PULLEY

Removal

1. Remove fan, see FAN - Removal.

2. Loosen pulley fixation bolts.

3. Remove accessories belt, see

ACCESSORIES BELTS.

4. Remove pulley.

Reinstallation

1. Reinstall in the inverse order, tightening bolts

within 22 to 28 Nm.

WA TER PUMP

Removal

1. Drain cooling system.

2. Remove radiator upper hose from the

thermostat.

3. Loosen fixation bolts of the power steering

pump pulley .

4. Loosen fixation bolts of the water pump

pulley.

5. Remove belt tensor.

6. Remove accessories belt, see

ACCESSORIES BELTS - Removal.

7. Remove water pump pulley.

8. Remove power steering pump pulley.

9. Remove the 8 fixation bolts of the water

pump, marking the position of the 3 passing

bolts in the engine block.

10. Remove pump and gasket and clean the

contact surfaces.

25

International HS 2.8L Cooling System

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

Reinstallation

1. Reinstall water pump in the inverse order of

the removal, using a new gasket.

2. Use two prisoners as guide to position the

new gasket, reinstall the assembly support in

the inverse order.

3. Apply Loctite 242 and tighten the bolts with

the specified torque (See TIGHTENING

SPECIFICA TIONS ) .

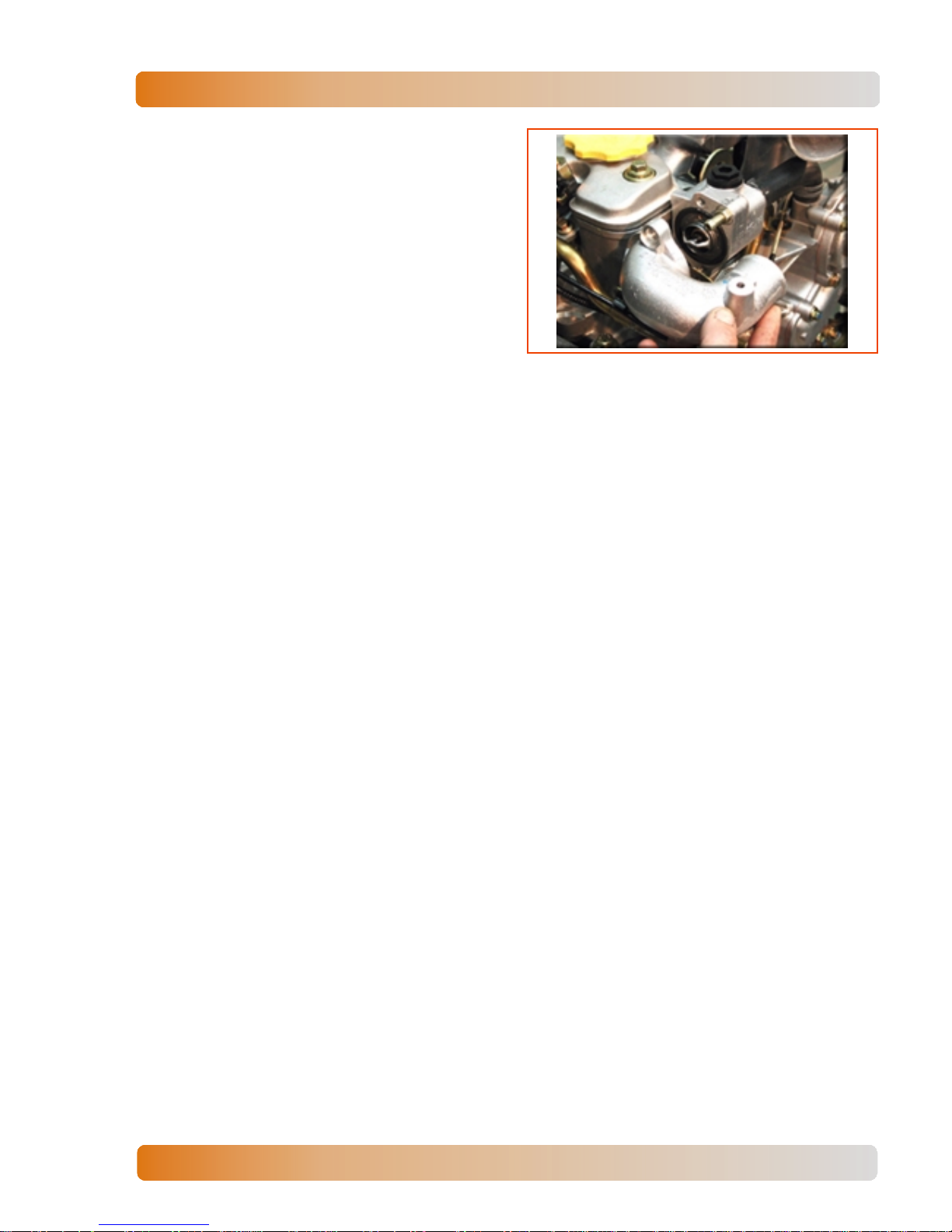

THERMOSTAT

Removal

1. Partially drain cooling system, until the level

of the coolant water is below the thermostat

housing.

2. Disconnect hose from thermostat housing.

3. Disconnect electric connections of the water

temperature switch.

4. Remove outlet elbow.

5. Remove thermostat.

6. Pay attention that the initial scale for the

thermostat operation evaluation test is

88 °C (190 °F). Install the thermostat in a

recipient with water . Heat the water up and

check the temperature in which the

thermostat begins to open. The thermostat

will be satisfactory if it opens between

86 and 90 °C (187 and 194 °F).

Reinstallation

1. Put the thermostat with the breathe guide /

hole pin totally upwards (12 o-clock position).

2. Install the outlet elbow and a new sealing

washer. Tighten bolts within 22 to 28 Nm.

3. Invert the removal operations.

4. Tighten bolts within 22 to 28 Nm.

5. Check for coolant water leakages around all

the connections and gaskets.

International HS 2.8L

26

Cooling System

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

Note: The preliminary specified test in this manual for the thermostat evaluation helps the

diagnosis of a possible failure in the engine. Therefore, it is recommended to send the

thermostat to laboratorial analysis after the tests (if positive).

27

International HS 2.8L

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

FUEL SYSTEM

International HS 2.8LFuel System

28

Service Manual - 8120081 - 05/02

INTERNATIONAL ENGINES

FUEL SYSTEM

PREVENTIVE MAINTENANCE

Fuel is an important factor to ensure the good

operation of the engine for a long time and without

failures.

The fuel must be clean, free of water and

impurities.

If the fuel used in the engine has to be stored, see

FUEL STORAGE.

During the engine operation, be aware to the fuel

indicator.

Fill the tank before the volume reaches the

minimum, because sedimented impurities in the

bottom of the tank can be suctioned, damaging

the filter.

Filling

1. Clean filling inlet duct cover whenever

necessary.

2. Every end of working day, fill the tank in order

to avoid the condensation of the air humidity .

Warning: After tank filling, keep it very well

closed. Never improvise. If the

cap presents any problem,

replace it to a genuine spare

part.

Warning: Bleed the system every time

the engine stops due of a fuel

lack.

Warning: Do not smoke or get close any

type of exposed blame or

sparks while filling the tank,

because diesel fuel is very

inflammable.

International HS 2.8L Fuel System

29

8120081 - 05/02 - Service Manual

INTERNATIONAL ENGINES

3. In periods of intense cold (under 0 ºC)

(32 °F), 20% of aviation kerosene can be

added to the diesel fuel. This procedure will

avoid that the existence of paraffin in the

diesel fuel obstruct the fuel piping. In the

filling, first put the kerosene and then the fuel.

Note: Only use aviation kerosene in situations when the ambient temperature is under zero.

(0 °C) (32 °F).

Fuel Filter

The filter has the function to retain the impurities

to make that the system receives a clean fuel,

avoiding this way damages in the engine fuel

injection pump and the nozzles.

Note: Use only genuine filter element.

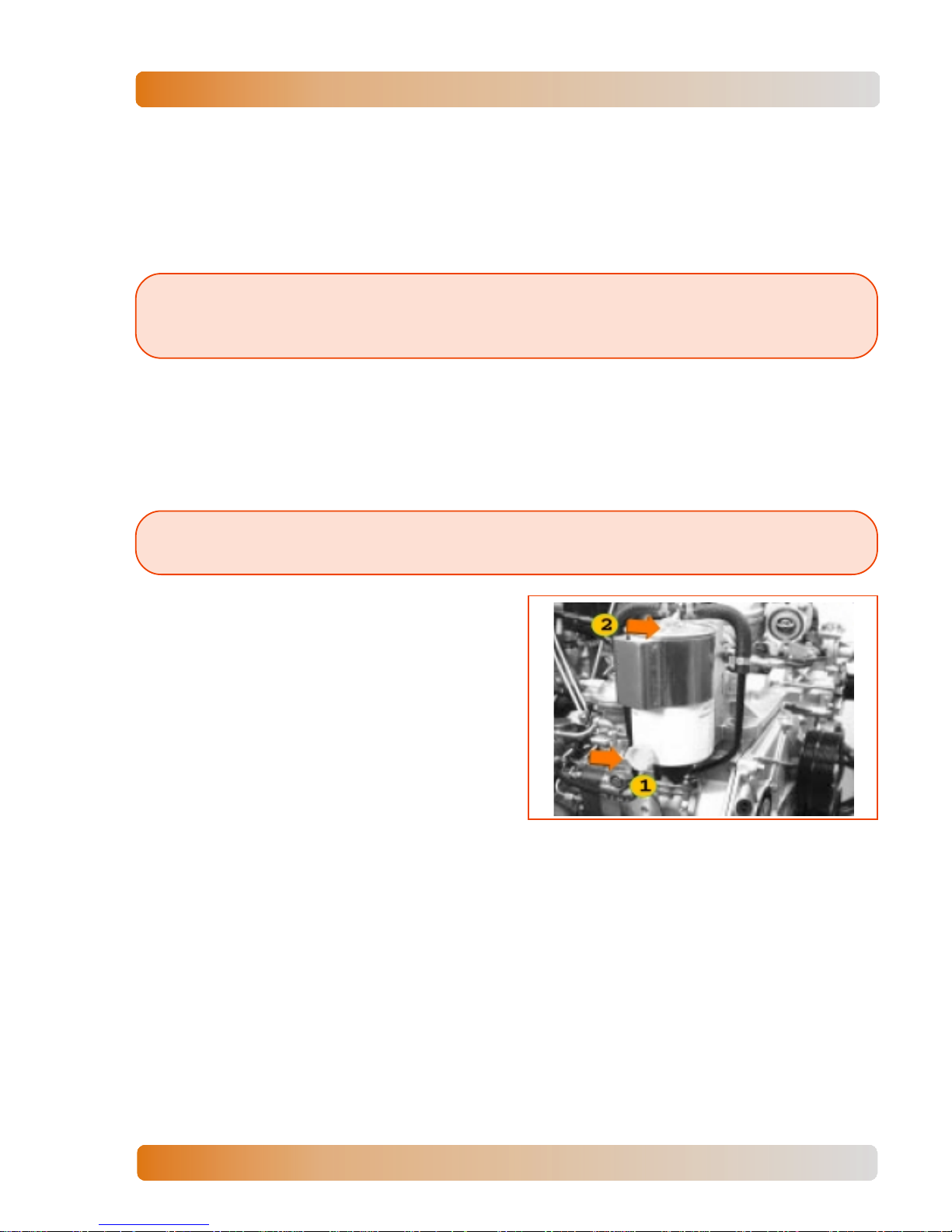

Filter drainage

Daily , in order to avoid the premature obstruction

of the filter and to guarantee the fuel injection

pump and nozzles durability, it is necessary drain

it before the initial start, according to the Periodic

Maintenance table.

1. Open filter drainage lateral plug.

2. Open filter upper plug.

3. As soon as the fuel flows clean, through the

side plug, close the drain plug.

4. Close upper plug.

5. Check for leakages.

Loading...

Loading...