International CF500, CF600 Wiring Diagram

CF 500, CF 600 Circuit Diagrams

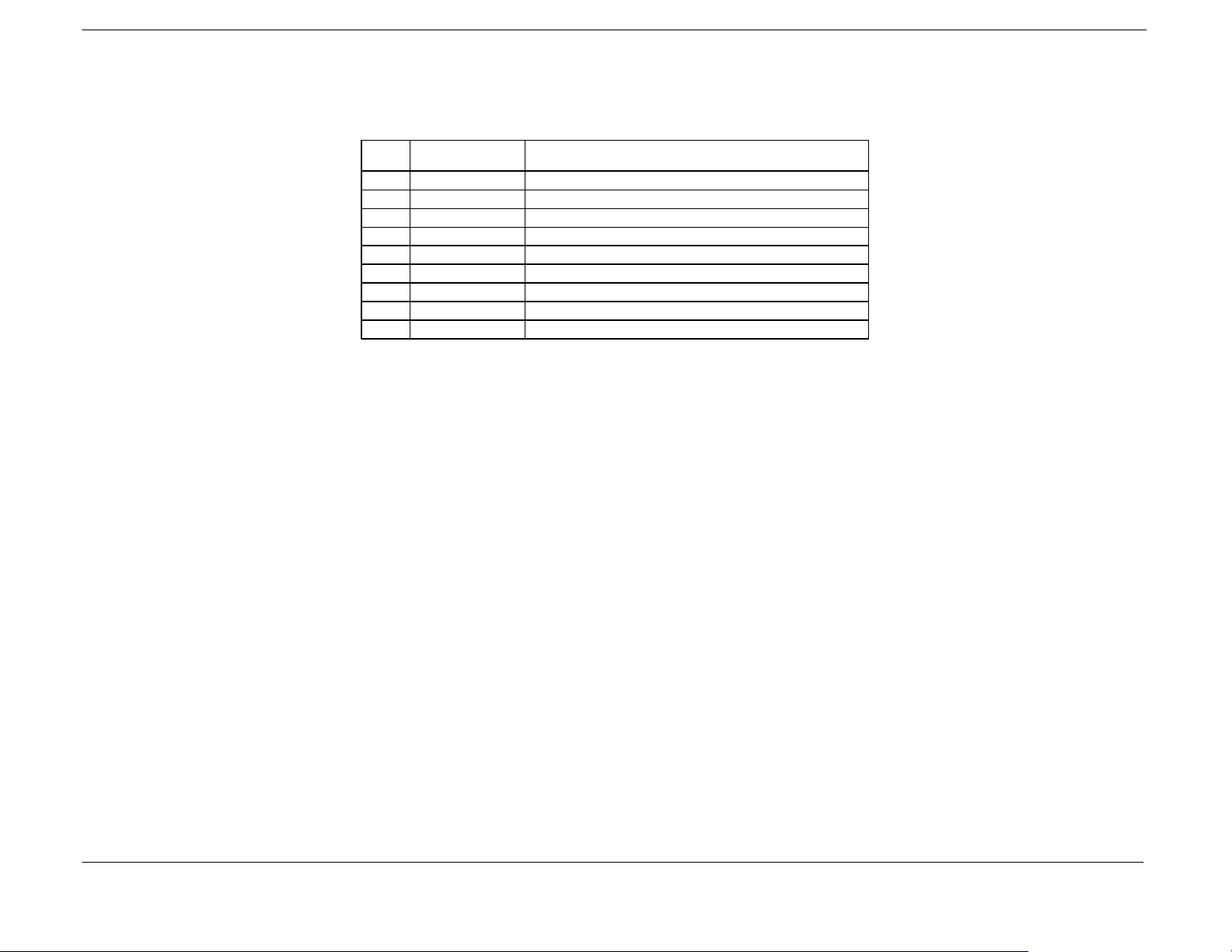

Table of Contents 1-1

Table of Contents 1-1..............................................

Introduction 3-1..................................................

Symbols 4-1.....................................................

Connector Repair Procedures 5-1....................................

Wiring Harness Overview 9-1.......................................

Grounds 10-1....................................................

Fuse and Relay Information 11-1......................................

Charging System 12-1.............................................

Power Distribution 13-1............................................

Module Communications Network 14-1...............................

Starting System 20-1..............................................

Electronic Engine Controls 23-1.....................................

Transmission Controls 29-1.........................................

Speed Control 31-1...............................................

Vehicle Dynamic Systems 42-1......................................

Horn/Cigar Lighter 44-1...........................................

Fuel Tank Selector 49-1............................................

Manual Climate Control System 54-1.................................

Instrument Cluster 60-1............................................

Cluster and Panel Illumination 71-1..................................

Front Wipers and Washers 81-1......................................

Headlamps 85-1..................................................

Fog Lamps 86-1..................................................

Interior Lamps 89-1...............................................

Turn Signal/Stop/Hazard Lamps 90-1.................................

Parking, Rear and License Lamps 92-1................................

Reversing Lamps 93-1.............................................

Trailer Adapter 95-1...............................................

Daytime Running Lamps 97-1.......................................

Power Windows 100-1.............................................

Power Door Locks 110-1............................................

Remote Keyless Entry and Alarm 117-1................................

Audio System 130-1..............................................

Customer Access 140-1............................................

Component Testing 149-1..........................................

Connector Views 150-1............................................

Component Location Views 151-1...................................

Component Location Charts 152-1...................................

Vehicle Repair Location Charts 160-1.................................

NOTE: The descriptions and specifications contained in this manual were in effect at the time this manual was approved for printing. International Truck and Engine Corporation reserves the right to change specifications or design without notice and

without incurring any obligation.

S08311

p

3-1

Introduction

Note

All wiring connections between components are shown exactly as they exist

in the vehicles. It is important to realize, however, that no attempt has been

made on the schematic to represent components and wiring as they

physically appear on the vehicle. For example, a 4-foot length of wire is

treated no differently in a schematic from one which is only a few inches

long. Furthermore, to aid in understanding electrical (electronic) operation,

wiring inside complicated components has been simplified.

Complete Circuit Operation

Each circuit is shown completely and independently in one cell. Other

components which are connected to the circuit may not be shown unless

they influence the circuit operation.

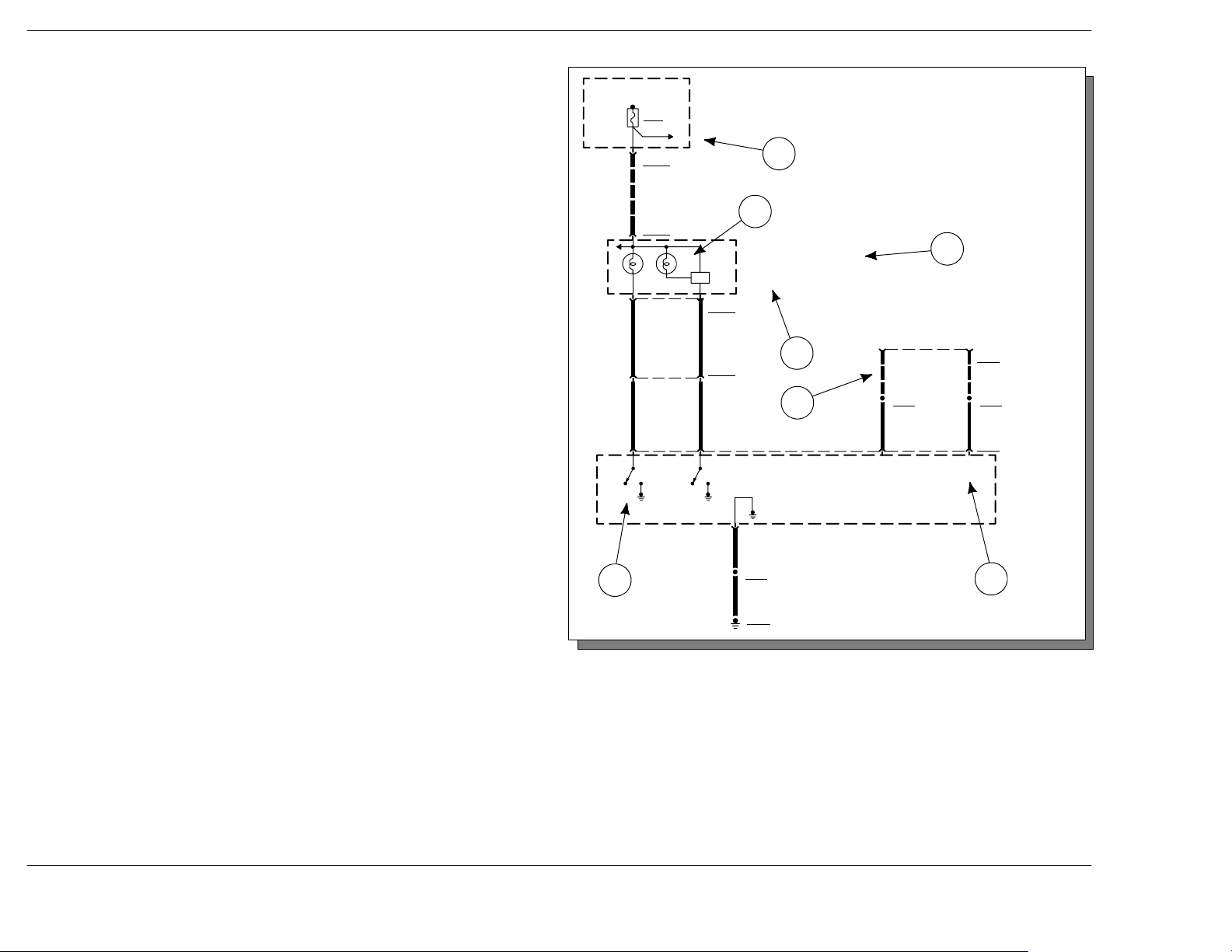

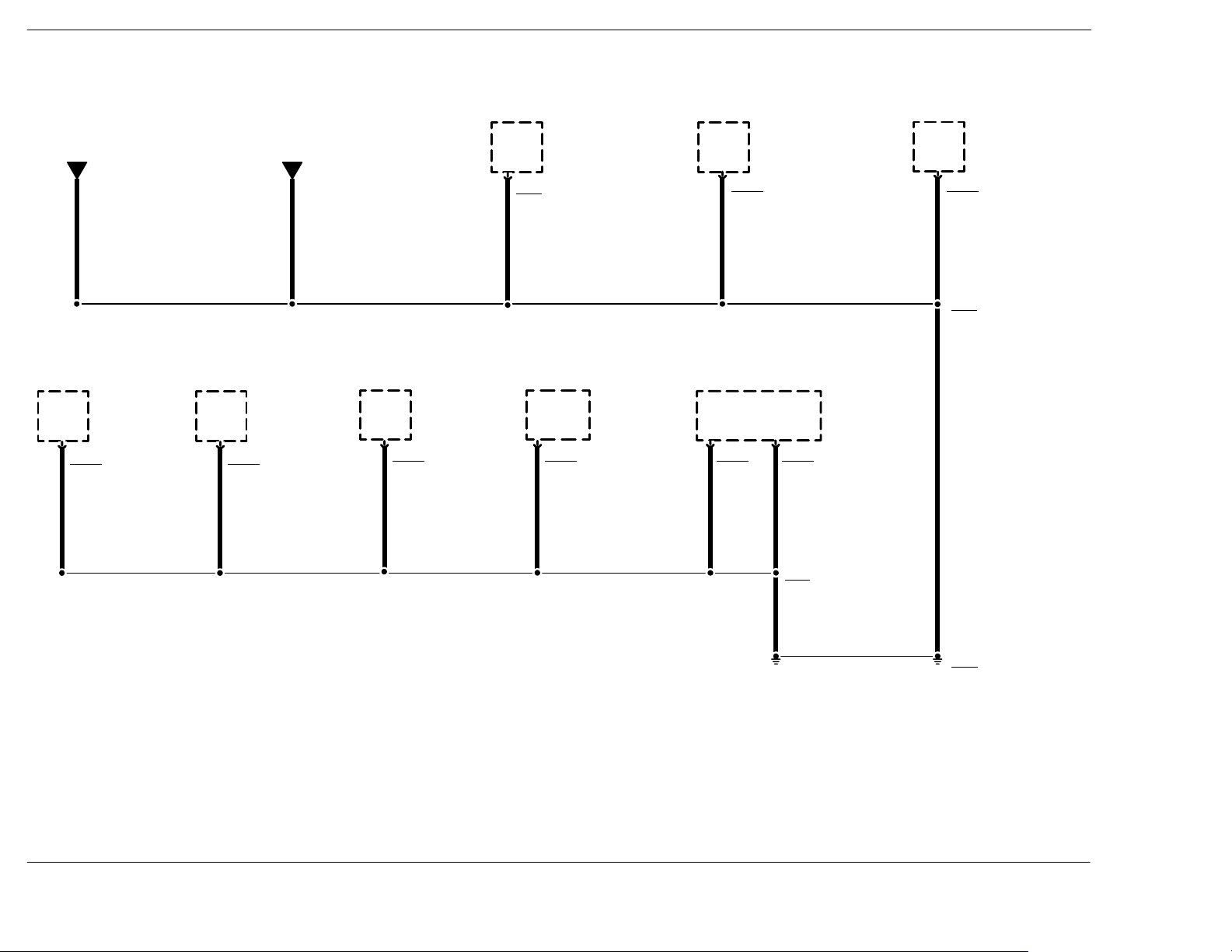

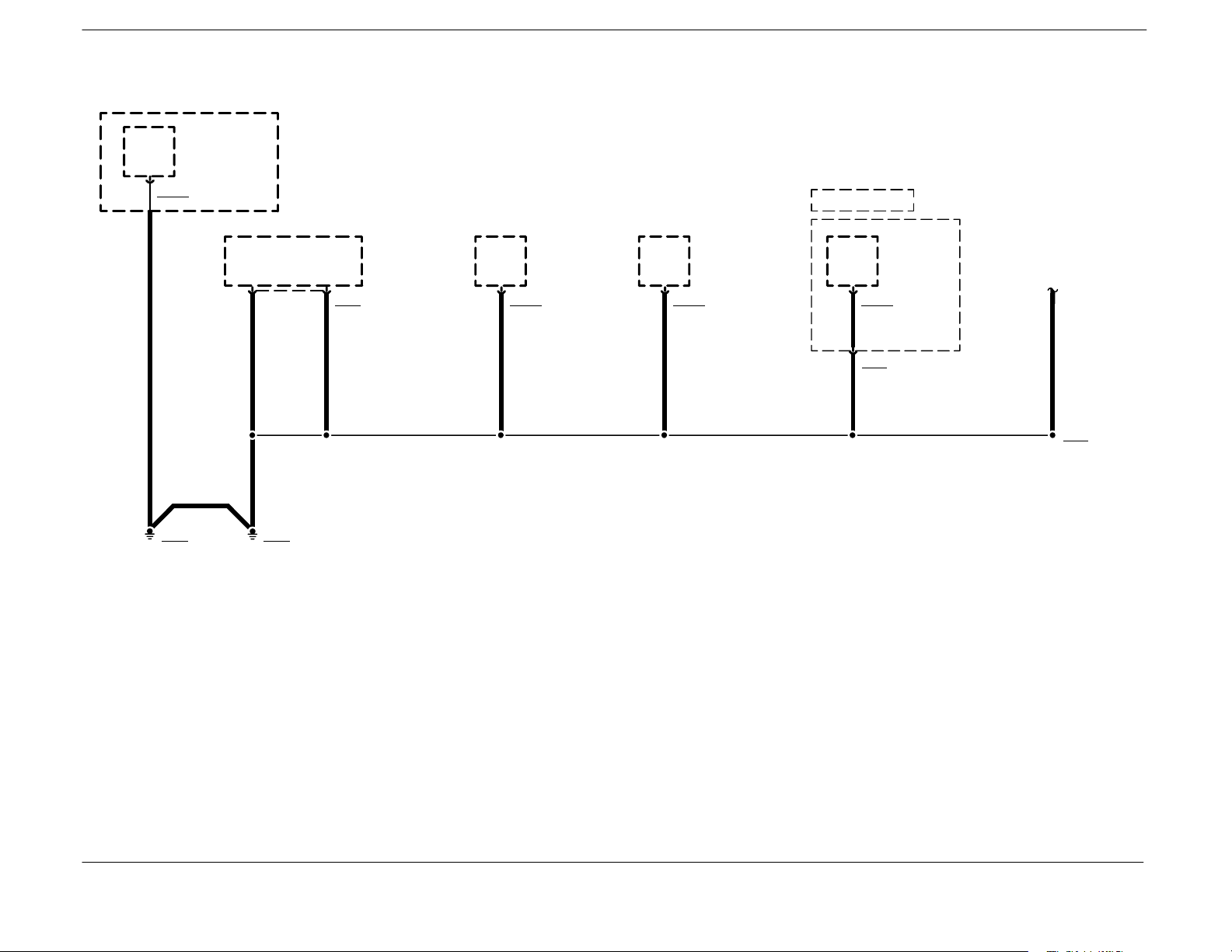

Current Flow (1)

Each cell normally starts with the component that powers the circuit, such

as a fuse or the ignition switch. Current flow is shown from the power

source at the top of the page to ground at the bottom of the page. In order to

concentrate on the essential parts, power supply and ground connections are

sometimes simplified by a dashed line in the schematics. A full

representation of the power supply of a fuse or the power distribution from

a f use to various components is given in cell 13 “Power Distribution”. Full

representation of the ground connections are shown in cell 10 “Grounds”.

Switch Positions (2)

Hot in run

F2.6

5A

C270a31

LB/BK1405

See page

13−8

11 C220a

1

4

VT939

15

VT939

7

2

Central Junction Box (CJB)

(14A067)

13−4

12

16

C220a

DG603

C1019

27

DG603

15

1

6

Instrument cluster (10849)

1) Traction control

12) ABS

62−3

4

3

8

LG/YE530

S200

LG/YE530

G104

5

Data Link Connector (DLC)

(14489)

2

See page

14−3

S157

TN/OG914

3

SCP + SCP −

11 C135

C25110

See page

14−3

S156

PK/LB915

ABS control

module (2C219)

151−5

7

Within the schematic, all switches, sensors and relays are shown “at rest”

(as i f the Ignition Switch were OFF).

Splices (3)

A dashed line indicates that the splice is not shown completely. A reference

is given to the page where the splice appears in full. It is also listed in the

Index.

p

Component Referencing (4)

Each component on a schematic has a reference to the component location

view or the page where it is shown completely. It is located to the right of

each component.

Component Names, Notes and Base Part Numbers (5)

Component names are placed on the r ight hand side of each component.

Any notes that describe switch positions or operating conditions follow the

name. Descriptions of the internals of the component are also included here.

The page where the component appears in full is listed in the Index. The

base part number for a component is listed in parentheses next to or under a

component. These part numbers will appear any place the component name

appears i n the publication.

Internal Name and Function Identification Numbers (6)

Some components on each page have internal symbols with an

identification number l ocated to the right. You can identify the internal

symbol or function by finding the corresponding number under the

component name.

Introduction

3-2

Circuit Function Identifiers (7)

Some components without internal schematics use symbols or text to

describe the function of a circuit in a system.

p

3-3

Introduction

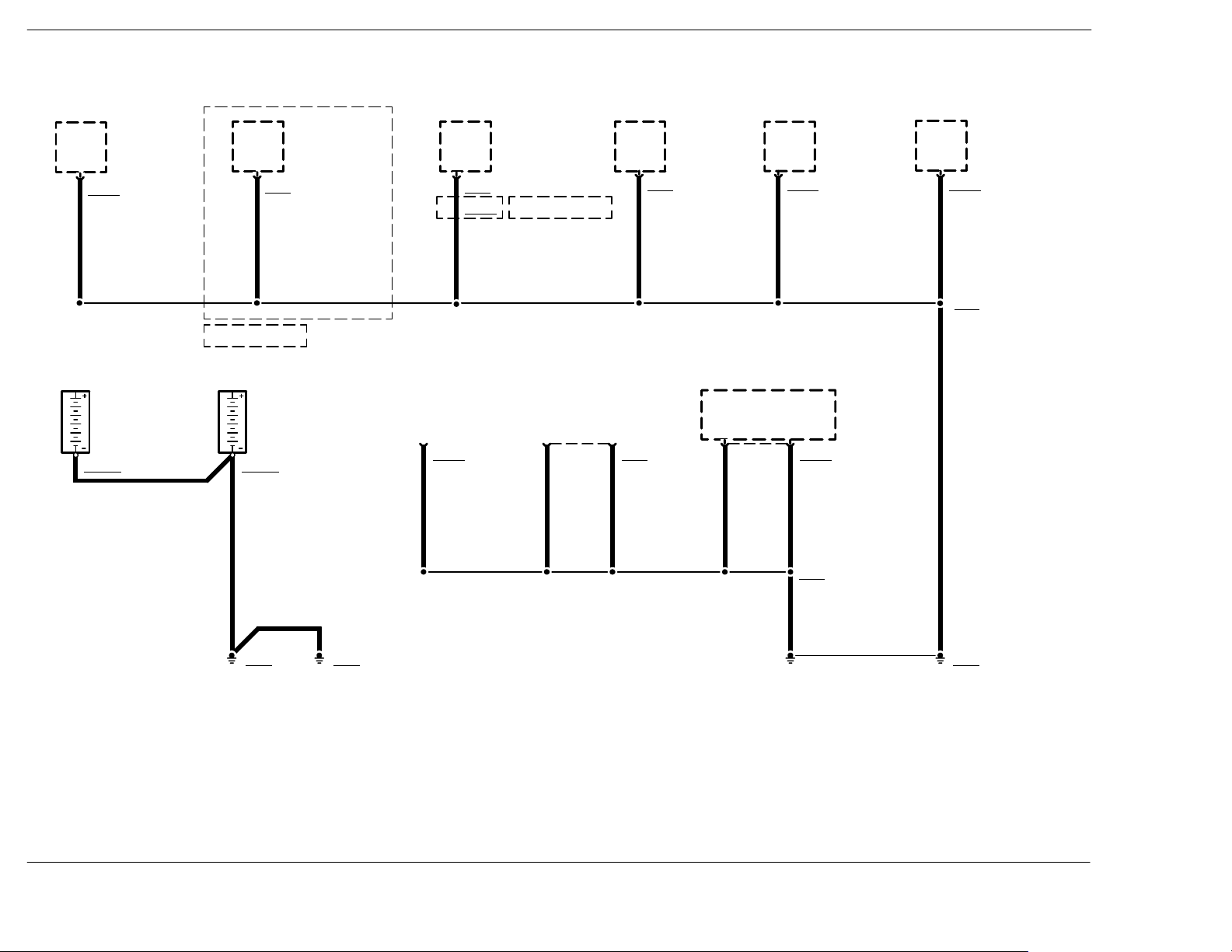

Fuse and Relay Information

Cell 11 “Fuse and Relay Information” contains a view of the fuse-/relay

box in which all fuses and relays are identified.

Fuse and Relay Numbering and Naming

Fuse and relay numbering and naming follow the indication of the fuse

panel cover. In addition, a prefix precedes the fuse number to facilitate

finding the fuse in the Component Location Charts, e.g. “F1.” precedes

Power Distribution Center fuses, and “F2.” precedes Central Junction Box

fuses.

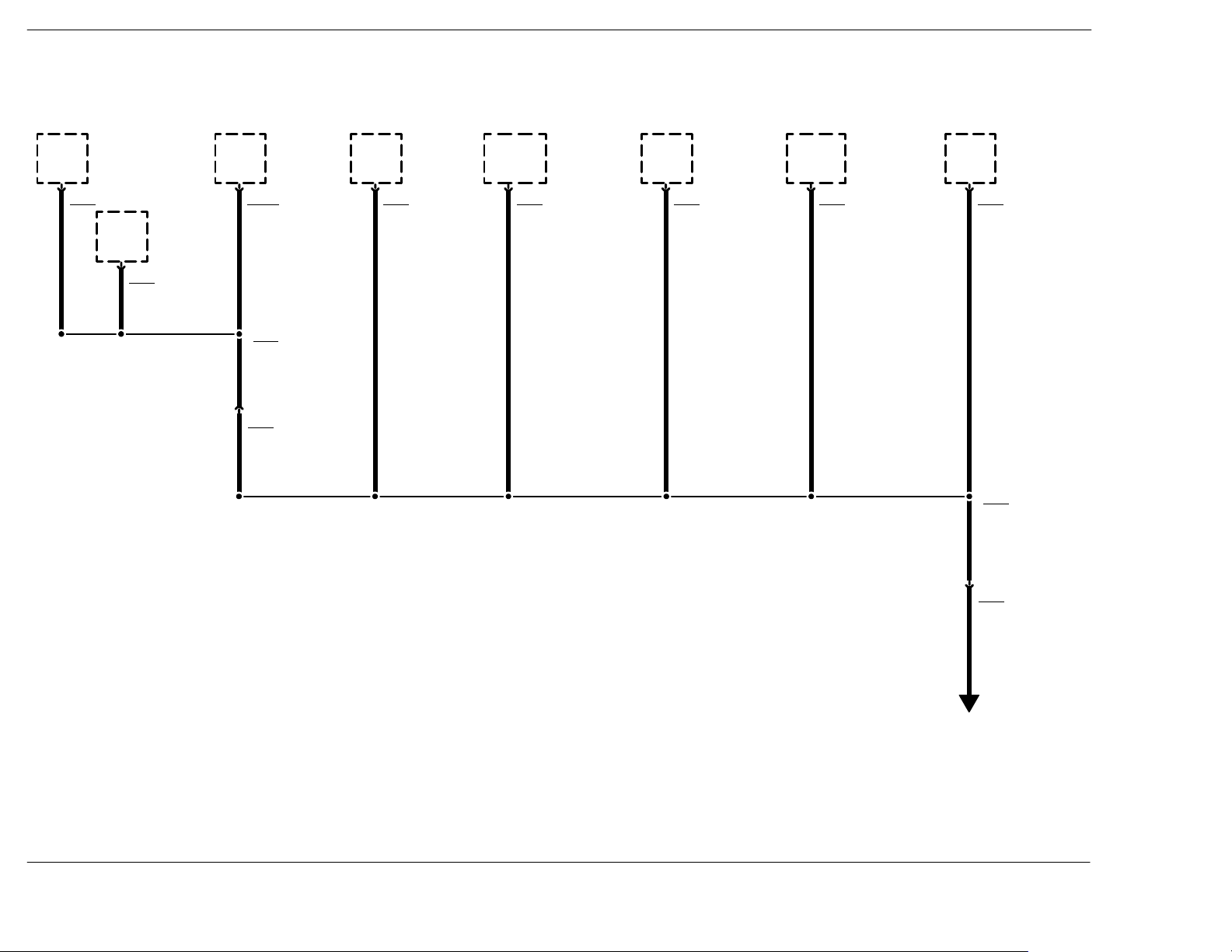

Power Distribution

Cell 13 “Power Distribution” shows the current feed circuit. The current

path is shown from the battery to the ignition switch and to all fuses. It also

shows the circuits protected by each fuse. The circuit is traced from the fuse

to the component. All details (wires, splices, connectors) between the fuse

and t he first component are shown.

F1.12

F1.13

F1.14

F1.15

F1.1

F1.2

F1.3

F1.4

57 BK

F1.24

Battery

G1002

S130

Fusible Link A

1) 12 gauge

2) gray

S131

F1.20

10A

F1.21

20A

F1.23

Power

Distributi

on Center

(PDC)

F1.2

20A

DB/OG

Power

Distributio

nCenter

(PDC)

Instrument

cluster

60−1

Hot at all times Hot at all times

F1.1

30A

RD RD

932

C1041 C1021 C220

Headlamp,

right

85−1

932

Headlamp,

left

85−1

196

711

Introduction

p

3-4

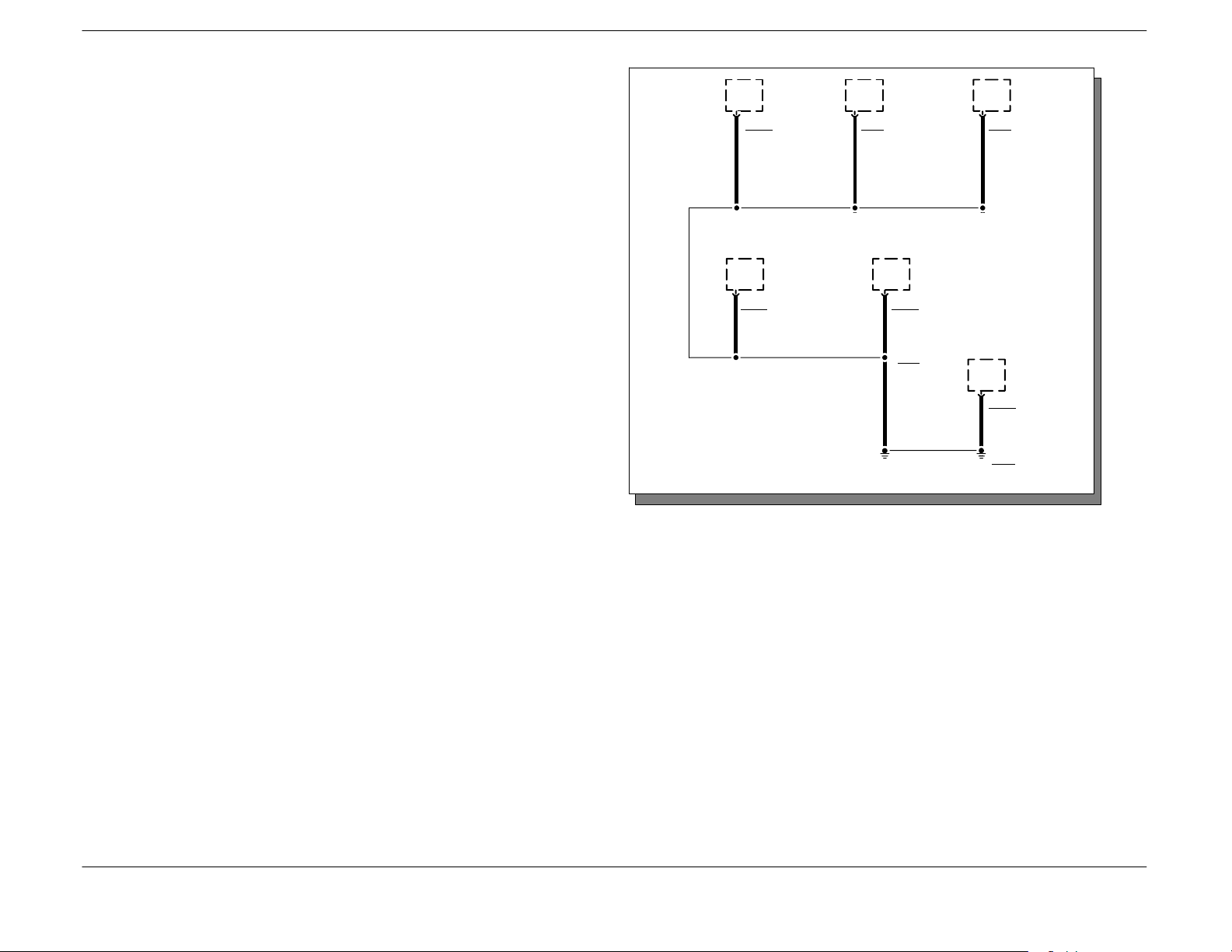

Ground Distribution

Cell 10 “Grounds” contains the schematics that show the complete details

for each ground connection or main ground splice. This is useful in

diagnosing a problem affecting several components at once (poor ground

connection or ground splice). All details (wires, splices, connectors)

between the ground point and the components are shown. These ground

connection details are shown here in order to keep the individual cell

schematics as uncluttered as possible.

Headlamp,

right (13008)

85−2

C1041 C162 C152

21 1

BK BK57 57BK57

Side lamp , left

front (13411)

92−1

22

BK

57

Fog lamp,

right front

(15200)

86−1

Headlamp,

left (13008)

85−2

C1021C1127

BK57

S102

BK BK

57 57

2

Fog lamp,

front left

(15200)

86−1

Side lamp, right

front (13411)

92−1

C1126

G100

151−3

p

3-5

Introduction

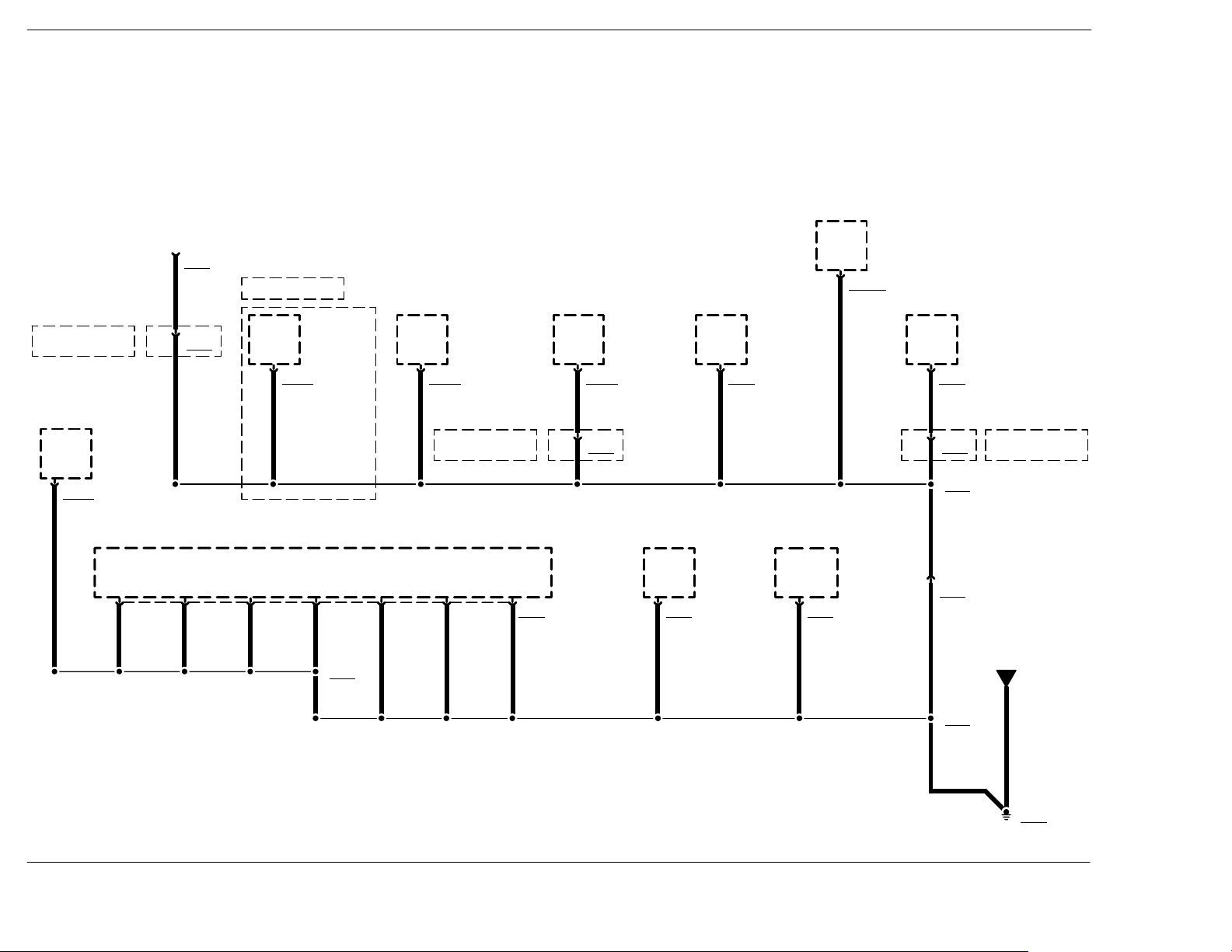

Component and Connector Information

Cell 152 “Component Location Charts” helps the user find where the

various items depicted on the schematic can physically be found on the

vehicle. A brief written description of the location is given, along with a

reference t o the component location views.

Cell 151 “Component Location Views” show the components and their

connecting wires as they can be found on the vehicle.

Cell 150 “Connector Views” show the views of the pins and/or cavities of

all connectors. The pin and cavity sides are shown separately as if the

connector were disconnected. The color of the connector housing is

indicated next to the connector number when available. The harness causal

number is located above the component name and below the connector

number or above the connector face itself. Wiring harness designations are

listed in cell 152 “Component Location Charts”. Circuit function charts are

located below each connector.

C150

(BK)

12A581

Wheel speed sensor, left front

(2C205)

Pin Circuit Circuit Function

1 522 (TN/BK) Wheel speed sensor, left front (2C205) −

2 521 (TN/OG) Wheel speed sensor, left front (2C205) +

2

FEMALE

1

C1033

(BK)

(1) −

(2) 1102 (YE/LG)

12B637

42

31

FEMALE

14B102

2

1

MALE

(3) 359 (GY/RD)

(4) −

4

3

p

WARNINGS

!

D Always wear safety glasses for eye protection.

D Use safety stands whenever a procedure requires being under a

vehicle.

D Be sure that the Ignition Switch is always in the OFF position, unless

otherwise required by the procedure.

D Set the parking brake when working on any vehicle. An automatic

transmission should be in PARK. A manual transmission should be in

NEUTRAL.

D Operate the engine only in a well-ventilated area to avoid danger of

carbon monoxide.

D Keep away from moving parts, especially the fan and belts, when the

engine is running.

D To prevent serious burns, avoid contact with hot metal parts such as

the radiator, exhaust manifold, tail pipe, catalytic converter and muffler.

D Do not allow flame or sparks near the battery. Gases are always pres-

ent in and around the battery cell. An explosion could occur.

D Do not smoke when working on a vehicle.

D To avoid injury, always remove rings, watches, loose hanging jewelry

and avoid wearing loose clothing.

Introduction

3-6

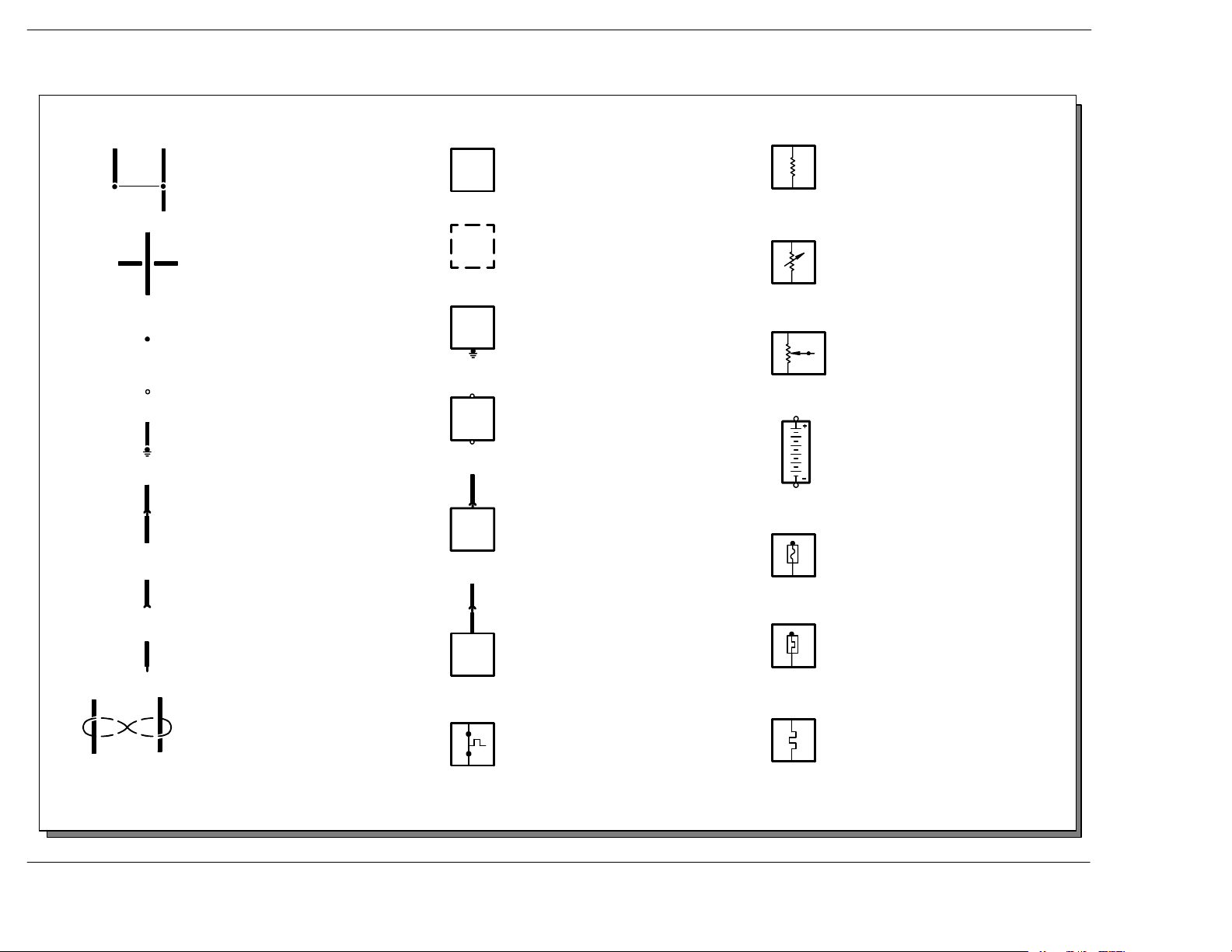

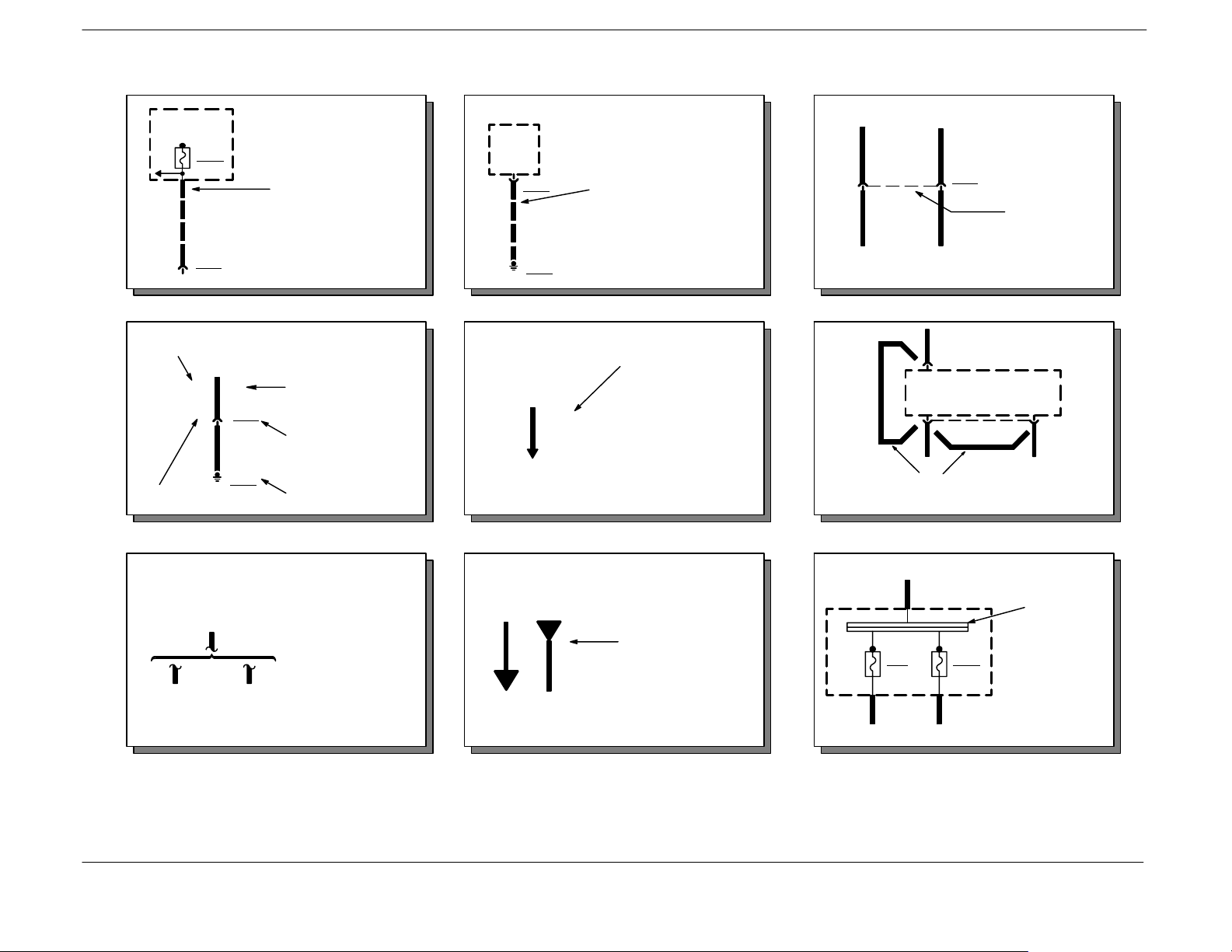

Symbols4-1

Distributed splice

Crossed wiring without

connection

Splice

Removable connection

Ground

Connector

Female connector

Male connector

Entire component Resistor

Part of a component

Potentiometer (pressure

or temperature)

Component case directly attached to metal part of vehicle

(ground)

Component with screw

terminals

Connector attached to

component

Connector attached to component lead (pigtail)

Potentiometer (outside influence)

Battery

Fuse

Circuit breaker

Twisted pair

Positive Temperature Coefficient (PTC)

Heating element, Conductor loop

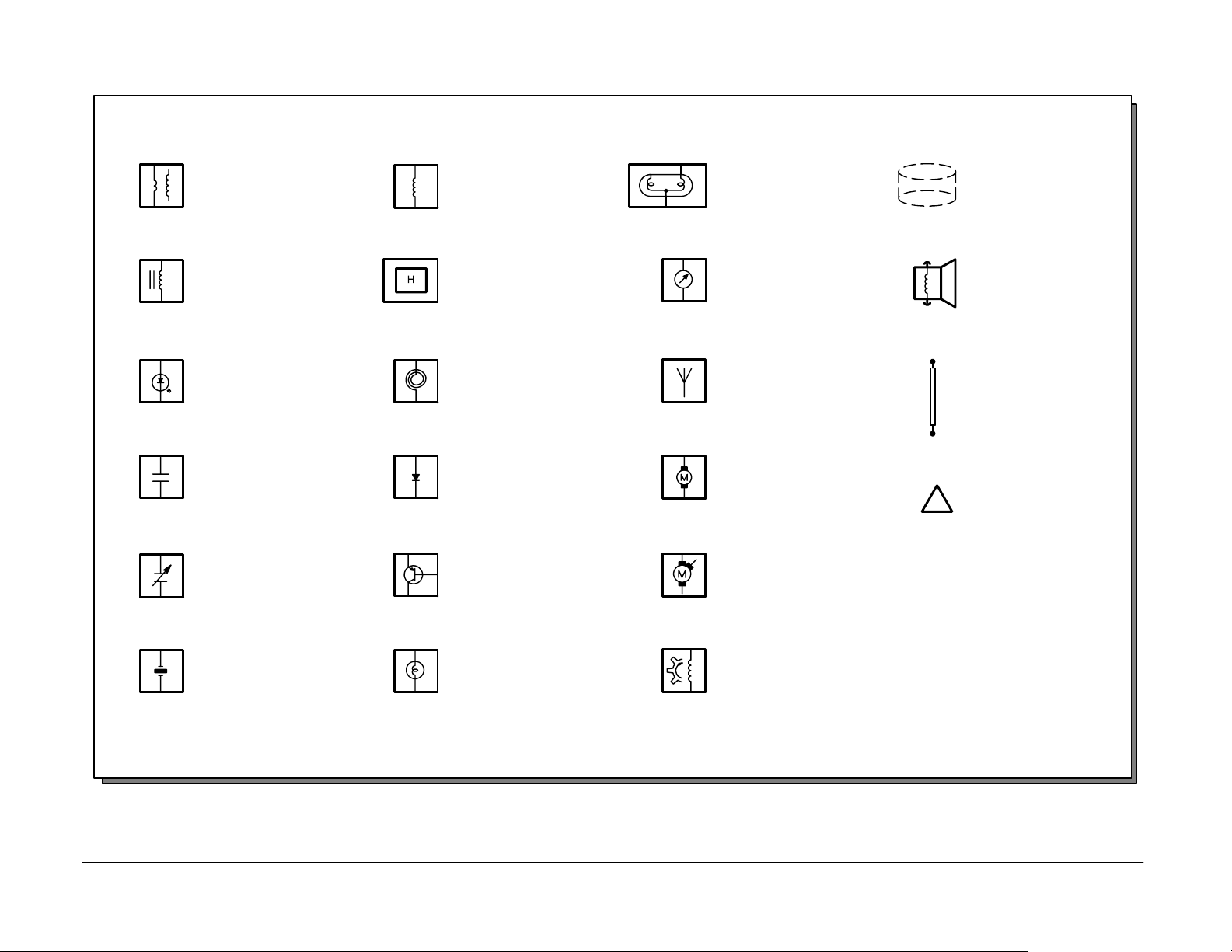

Symbols 4

-2

Ignition coil assembly

Solenoid controlled valve

or clutch solenoid

Light emitting diode

(LED)

Capacitor

Variable capacitor

Coil

Hall sensor

Air bag sliding contact

(14A664)

Diode, current flows in

direction of arrow

Transistor

Bifilament lamp

Gauges

Antenna

Permanent magnet,

one−speed−motor

Permanent magnet,

two−speed−motor

Shield

Horn or speaker

Fusible link

Warning

!

Piezoelectric sensor

Lamp

Rotational sensor

Symbols4-3

Wire colors

BK

Black

BN Brown

BU Blue

DB Dark blue

DG Dark green

GN Green

GY Gray

LB Light blue

LG Light green

NA Natural

OG Orange

PK Pink

RD Red

SR Silver

TN Tan

VT Violet

WH White

YE Yellow

VREF

Reference voltage

PWR

VBATT VPWR SCP + SCP −

Switched power

signal signal Signal return

Joint connector

Battery voltage Switched or

+ −

−

module voltage

SIG

RTN

Standard Corporate Protocol (SCP)

data +

Standard Corporate Protocol

(SCP) data −

ground

C1201

GY/RD359

C2003

ISO

Data bus ISO

9141 (K−line)

Groundsignal Signal return Switched

jumper

C2004

GY/RD359

C1202

Symbols 4

-4

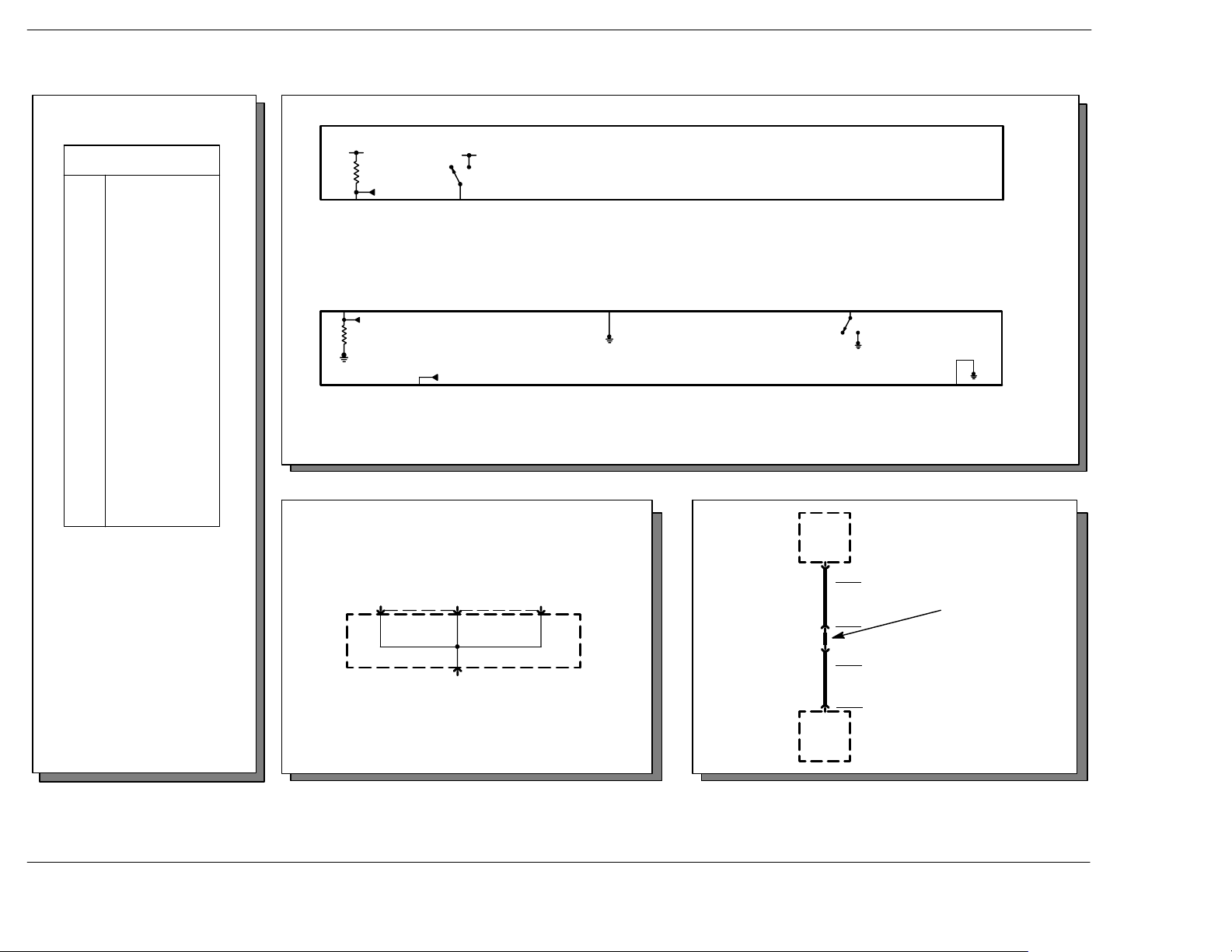

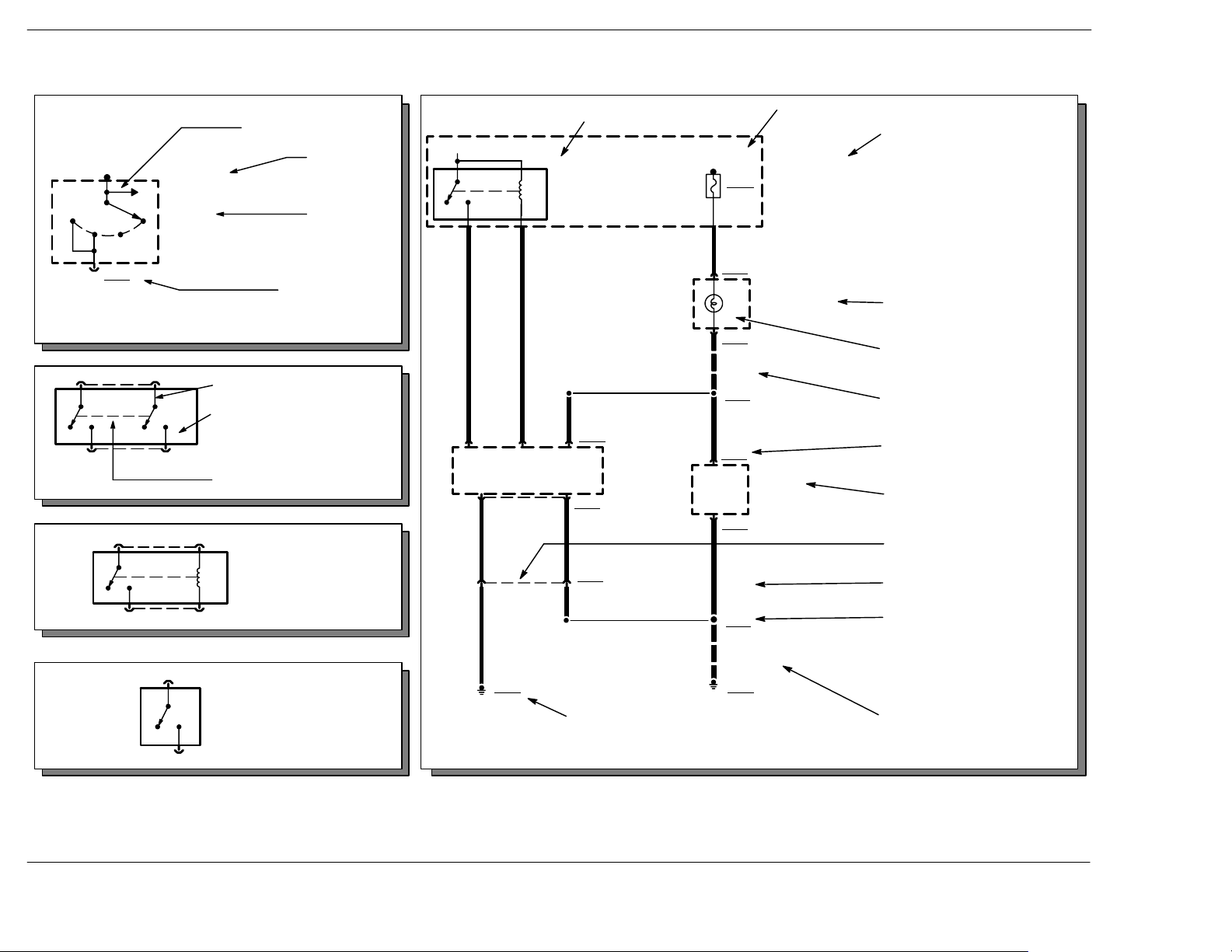

Hot in Start

or Run

910 GY/BK

53 C240

Circuit number

Pin number

F1.18

15A

See page

13-1

PK329

4 C100

57

BK

G100

Power Distribution

Center (PDC)

(14A003)

Other circuits which share

fuse 18, but are not shown,

can be referenced in Power

Distribution

Wire insulation is one

color

Connector reference

number for component

location chart

Ground numbered for

reference to component

location chart

1 C125

57 BK

See page

10-1

G100

29−1

Transmission

Controls

Windshield wiper

motor (17508)

Other circuits which are also

grounded at G100, but are not

shown, can be referenced in

Grounds

GN/WH329

Wire insulation is one

color with another

color stripe (green

with white)

Reference to another

cell where circuit is

shown completely

359

359

3

GY/RD

GY/RD

Shorting bar

PK329

4 C103

Two connections

(pins) in the

same connector

Dashed line indicates terminals

for the same connector

A choice bracket

shows wiring differences between models, countries or options

A

See page

46−2

See page

46−1

A

Cut wires referenced between pages. Arrows

show current flow from

power to ground.

F1.3

10A

Busbar

F1.14

10A

Symbols4-5

Indicates incomplete

internal bussing

Name of com-

Ignition switch

(11572)

3

C3003

12

0) Off

0

1) Acc

12

2) Run

3) Start

Switches that move together

Reference number indicates

12

switch position

Dashed line shows a mechanical connection between

switches

Normally open contact

When coil is energized,

switch is activated

ponent

Details about

component or

operation

Component connector number

non−serviceable components

Hot in Start or Run

Fuel pump relay

DG/YE238

LB/OG238

16

18

33

BK57

4

19

57

LB/RD19

C17517

C175

BK

C2012

Engine

Control

Module (ECM)

(12A650)

Hotatalltimes

F2.23

3A

720

RD/YE

C2205

6

C2204

See page

13−1

S100

LB/RD19

C1351

C1352

BK57

Fuse conditionRelays shown without a connector number are

Central Junction

Box (CJB)

Instrument cluster

6) Illumination

ABS control

module

(2C219)

Name of component

Details about component or

operation

Reference number for internal

component name

Referencetopagewhere

circuit is shown complete

Component connector number

Base service part number

Dashed line indicates terminals for the same connector

Wire insulation is one color

One pole, two position switch

12

G102

Ground numbered for reference to component location

chart

S101

See page

10−1

G101

Splice numbered for reference in component location

chart

Other circuits which are

also grounded at G100,

butarenotshown,canbe

found using the reference

The first digit of every connector, ground,

and splice number used in this publication references

its location within the vehicle.

The chart below describes the different sections of the vehicle, and lists the number associated

with each.

Symbols 4

-6

Number

100−199

1000−1999

200−299

2000−2999

300−399

3000−3999

400−499

4000−4999

500−599 left front door

600−699 right front door

700−799 left rear door

800−899 right rear door

900−999 A, B, C pillars Above door trim panel and

Location

front fascia, hood, front fenders, front axle, Engine compartment, Powertrain (including: axle/

differential/transmission/exhaust system)

Instrument Panel and Center Stack Console,

Steering wheel assembly, front kick panels,

cowl panel (body side)

From instrument panel to rear seat, A, B, C

pillars below door trim panel, center console

behind rear seats, to rear bumper; Truck bed,

Tailgate, Liftgate, Rear fenders

headliner

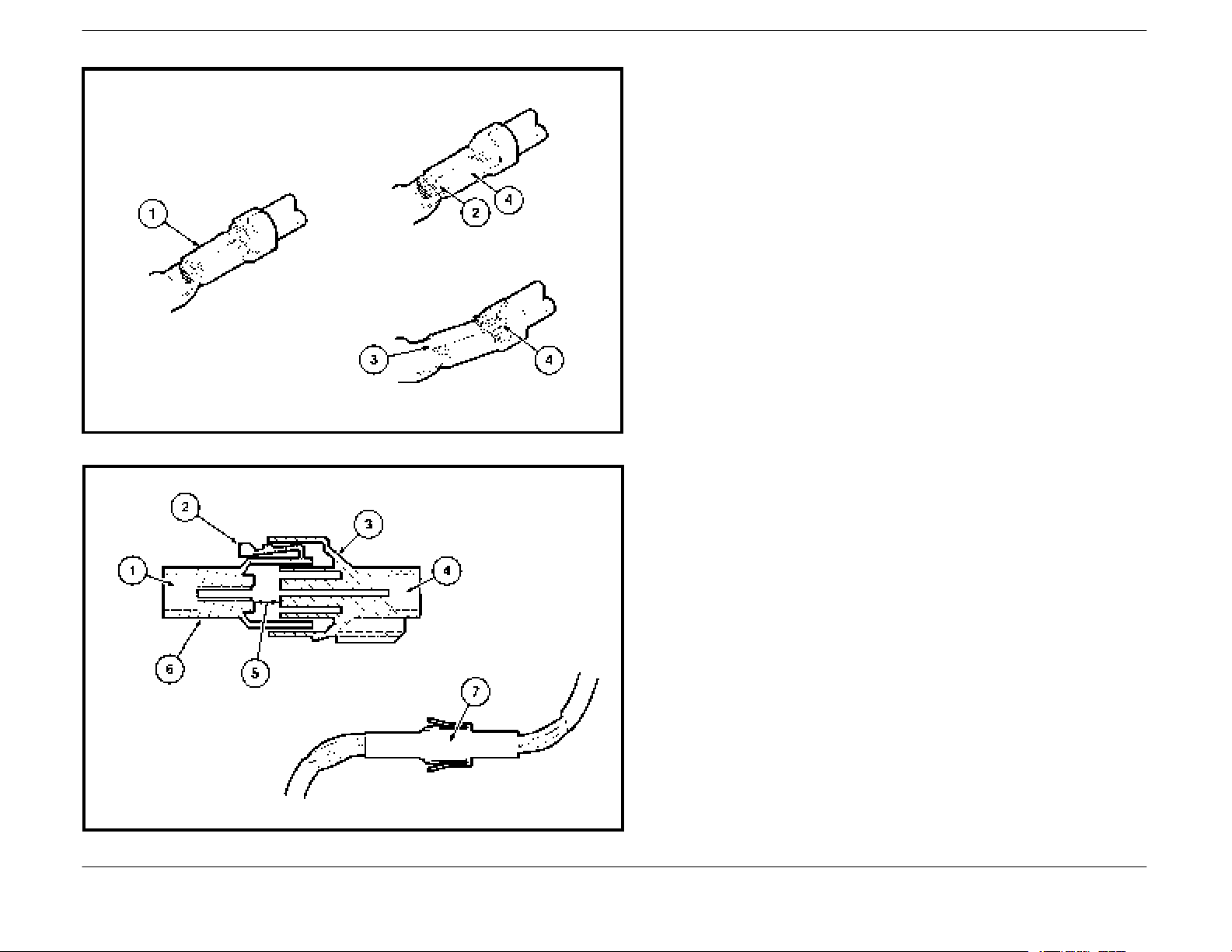

Connector Repair Procedures5-1

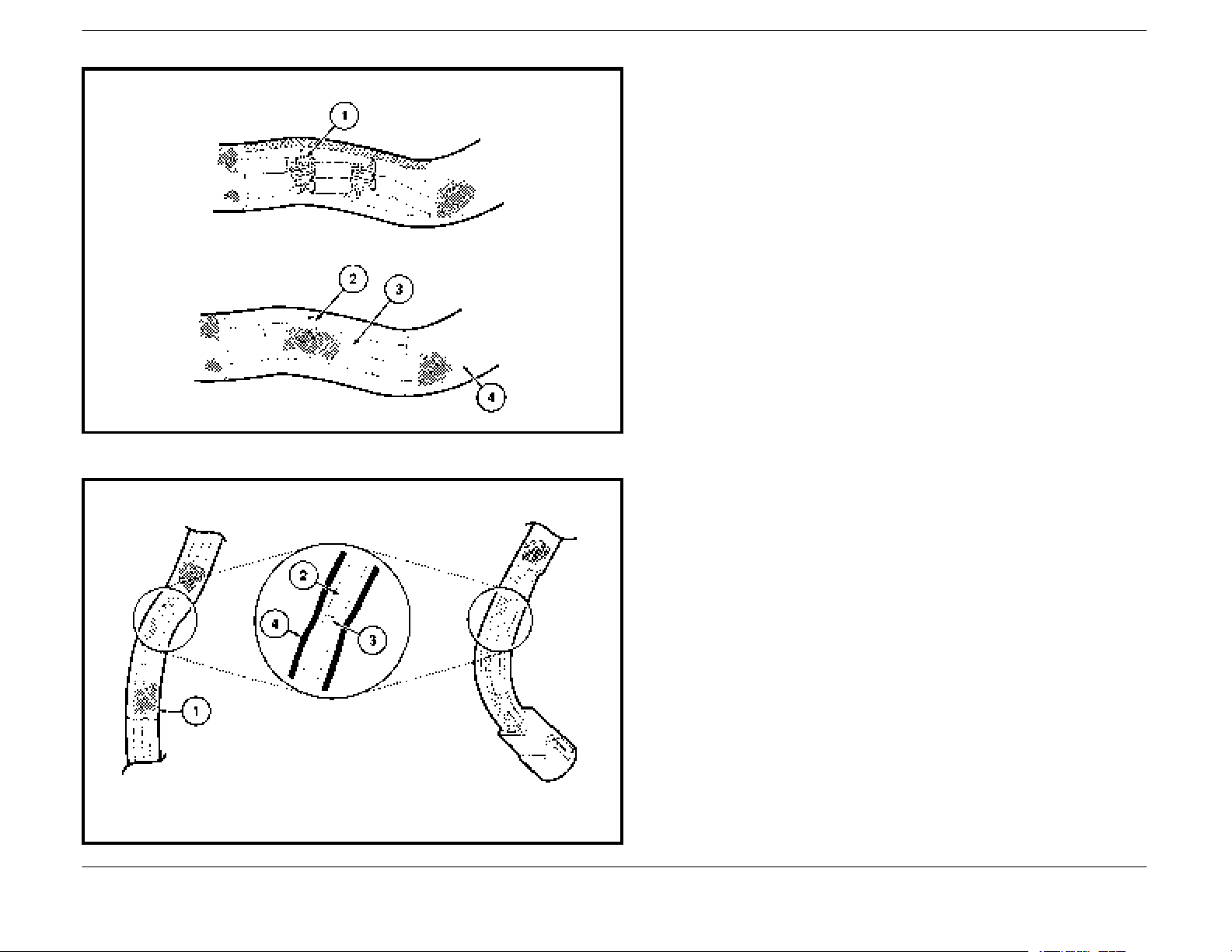

Troubleshooting wiring harness and connector hidden concerns

The following illustrations are known examples of wiring harness, splices

and connectors that will create intermittent electrical concerns. The

concerns are hidden and can only be discovered by a physical evaluation as

shown in each illustration.

NOTE: Several components, such as the ECM, utilize gold plated

terminals in t heir connections to the wiring harness. If those terminals need

to be replaced, they must be replaced with a gold plated terminal.

Terminal not properly seated

1 = Locked terminal

2 = Male half

3 = Female half

4 = Seal

5 = Intermittent contact

6 = Unlocked terminal (Hidden by wire seal)

7 = Seal

Check for unlocked terminals by pulling each wire

at the e nd of the connector.

Connector Repair Procedures 5-2

Defective insulation stripping

1 = Proper crimp

2 = Insulation not removed

3 = Wire strands missing

4 = Intermittent signals through pierced insulation

Partially mated connectors

1 = Seal

2 = Displaced tab

3 = Female half

4 = Seal

5 = Intermittent contact

6 = Male half

7 = Intermittent contact

Lock may be displaced into an unlocked

position; pull on the connector to verify the lock.

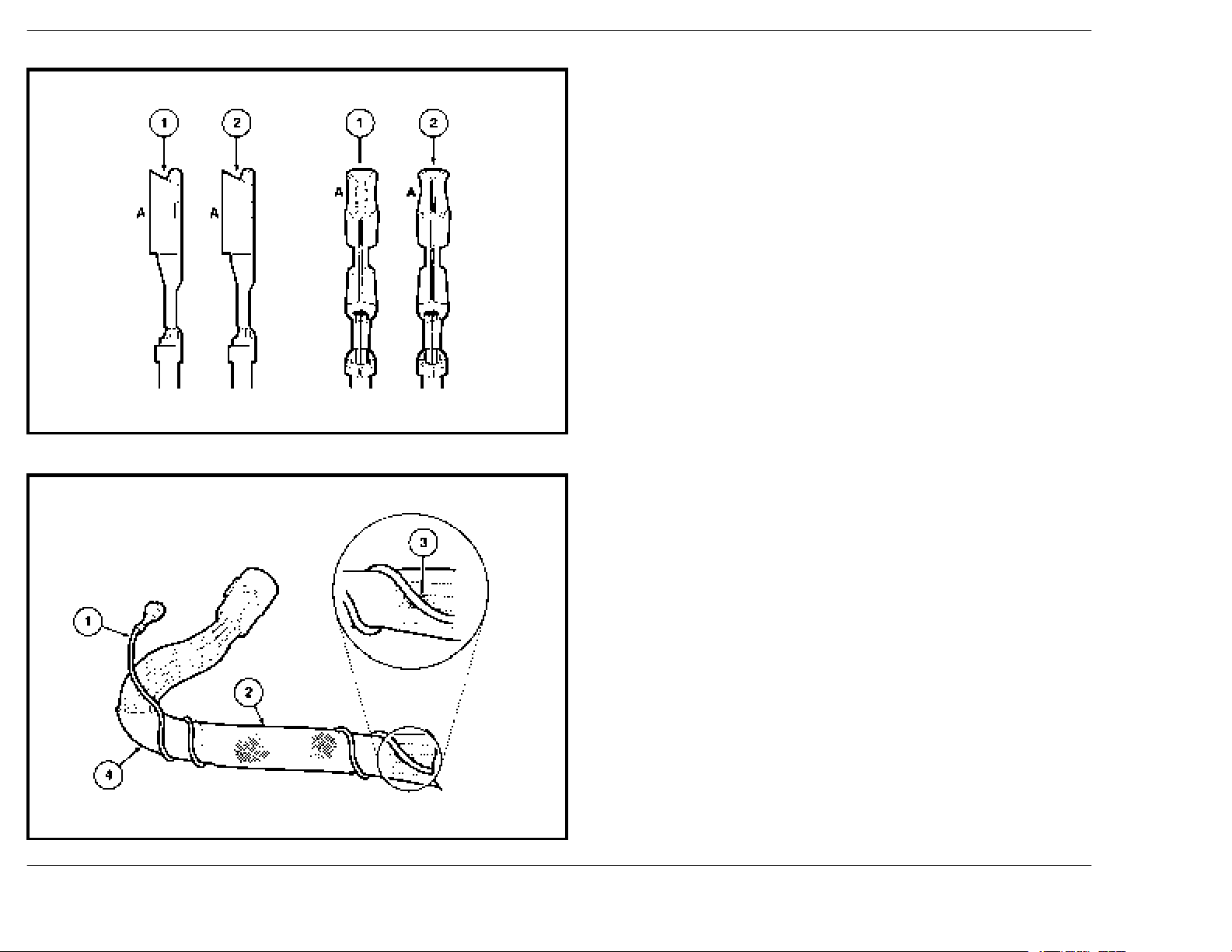

Connector Repair Procedures5-3

Deformed (enlarged) female terminals

1= Enlarged

2= Normal

Any probe entering the terminal may enlarge the contact spring opening

creating an intermittent signal. Insert the correct mating terminal

(Location A) from the service kit and feel for a loose fit.

Electrical s hort inside the harness

1 = Solder coated wire to ground

2 = Harness protective tape

3 = Intermittent short

Solder coated wire pierced through the insulation of

another circuit

4 = Grounding foil

Connector Repair Procedures 5-4

Electrical short within the harness

Splicetaperemoved

1 = Intermittent short

Splice covered

2 = Wire strand

3 = Splice tape

4 = Harness tape

Broken wire strands in harness

1 = Wiring harness tape

2 = Wiring strand

3 = Broken strands intermittent signal

4 = Circuit insulation

Remove the tape and flex/feel each circuit for a reduction in

diameter at break.

Connector Repair Procedures5-5

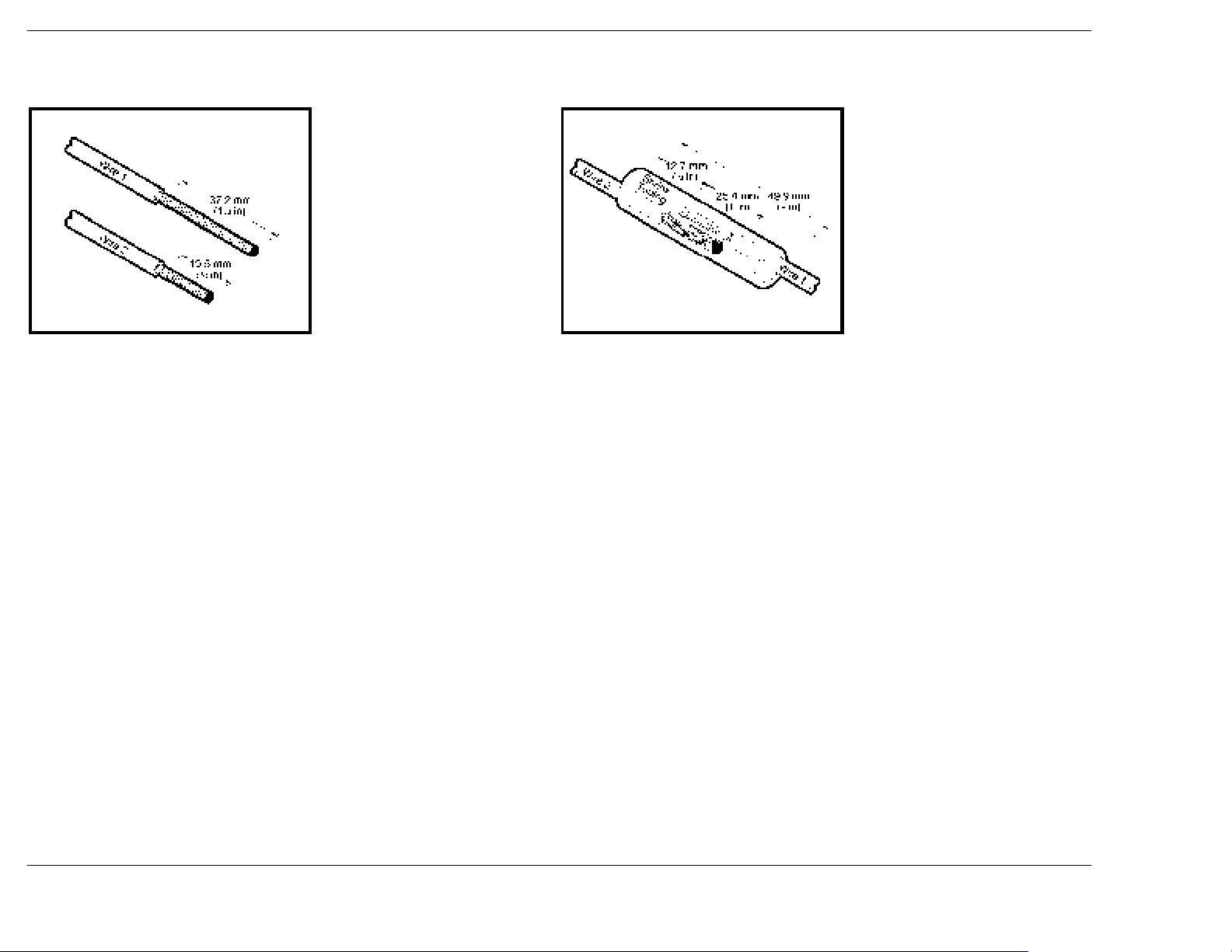

Recommended splicing method − Solder (For 16 AWG and Smaller Diameter Wire Only)

1. Disconnect battery ground

cable.

2. Strip wires to appropriate

length.

3. Install heat shrink tubing.

4. Twist wires together.

5. Solder wires together.

NOTE: Use rosin core

mildly-activated (RMA) solder.

Do not use acid core solder.

7. Evenly position heat shrink

tubing over wire repair.

NOTE: Overlap tubing on

both wires.

8. Use shielded heat gun to heat the

repaired area until adhesive flows

out of both ends of heat shrink

tubing.

9. Reconnect battery ground

cable.

6. Bend wire 1 back in a

straight line.

NOTE: Wait for solder to

cool before moving wires.

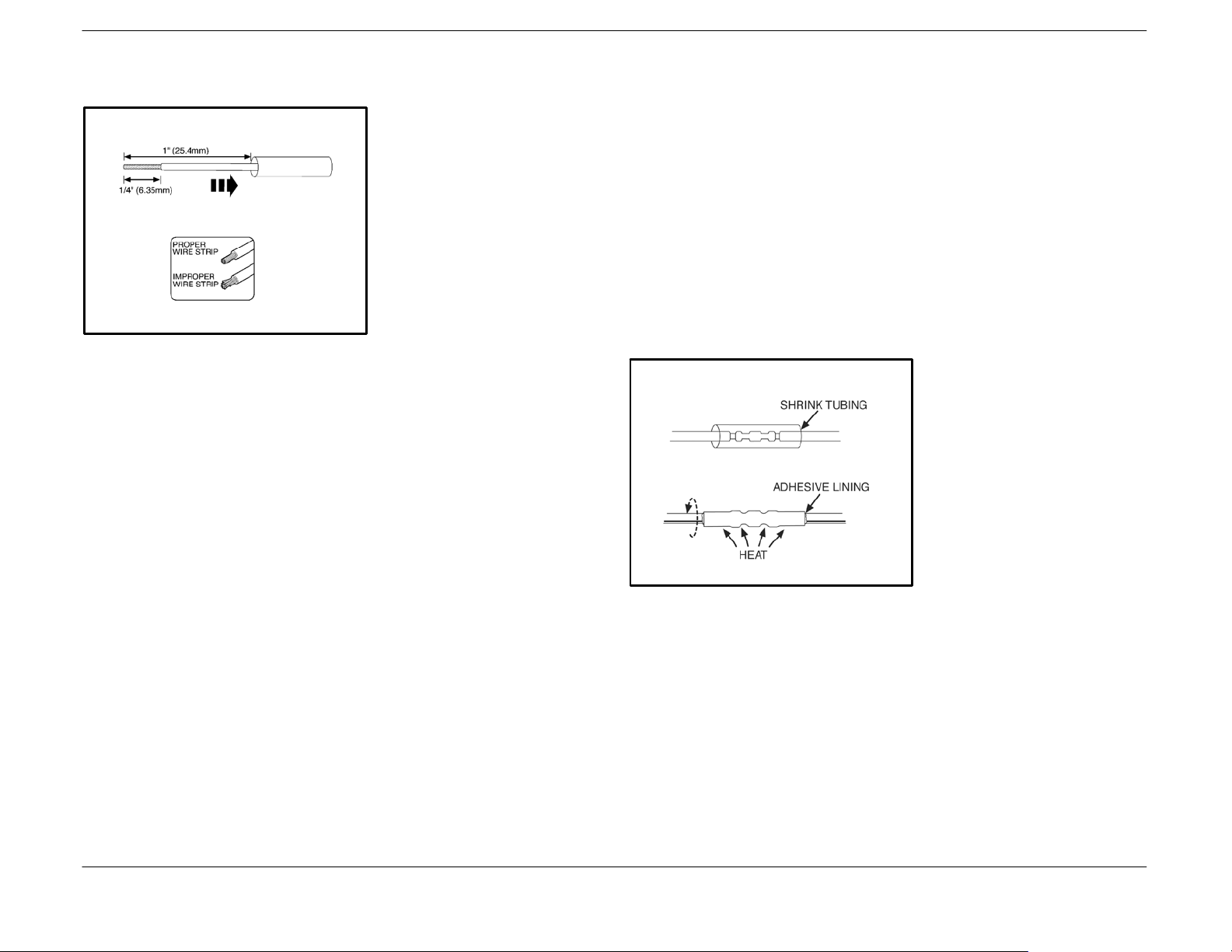

Connector Repair Procedures 5-6

Recommended splicing method − Crimp (For 10−22 AWG Diameter Wire to Like Wire Diameter)

1. Disconnect battery ground

cable.

2. Remove proper amount of

insulation from each wire end,

taking care not to nick or cut

wire strands.

3. Install heat shrink tubing.

4. Select appropriate wire splice

for the wires to be spliced.

5. Install the wire ends into the splice,

making sure the ends of the wires

are fully inserted.

6. Using the proper crimping tool for

the splice, hand crimp the wires and

splice.

7. Gently tug on the wires to be sure

they are secure.

8. Electrically check the circuit for

continuity through the splice.

9. Evenly position supplied heat

shrink tubing over wire repair.

10. Use shielded heat gun to heat

the repaired area until adhesive

flows out of both ends of the

heat shrink tubing.

11. Reconnect battery ground cable.

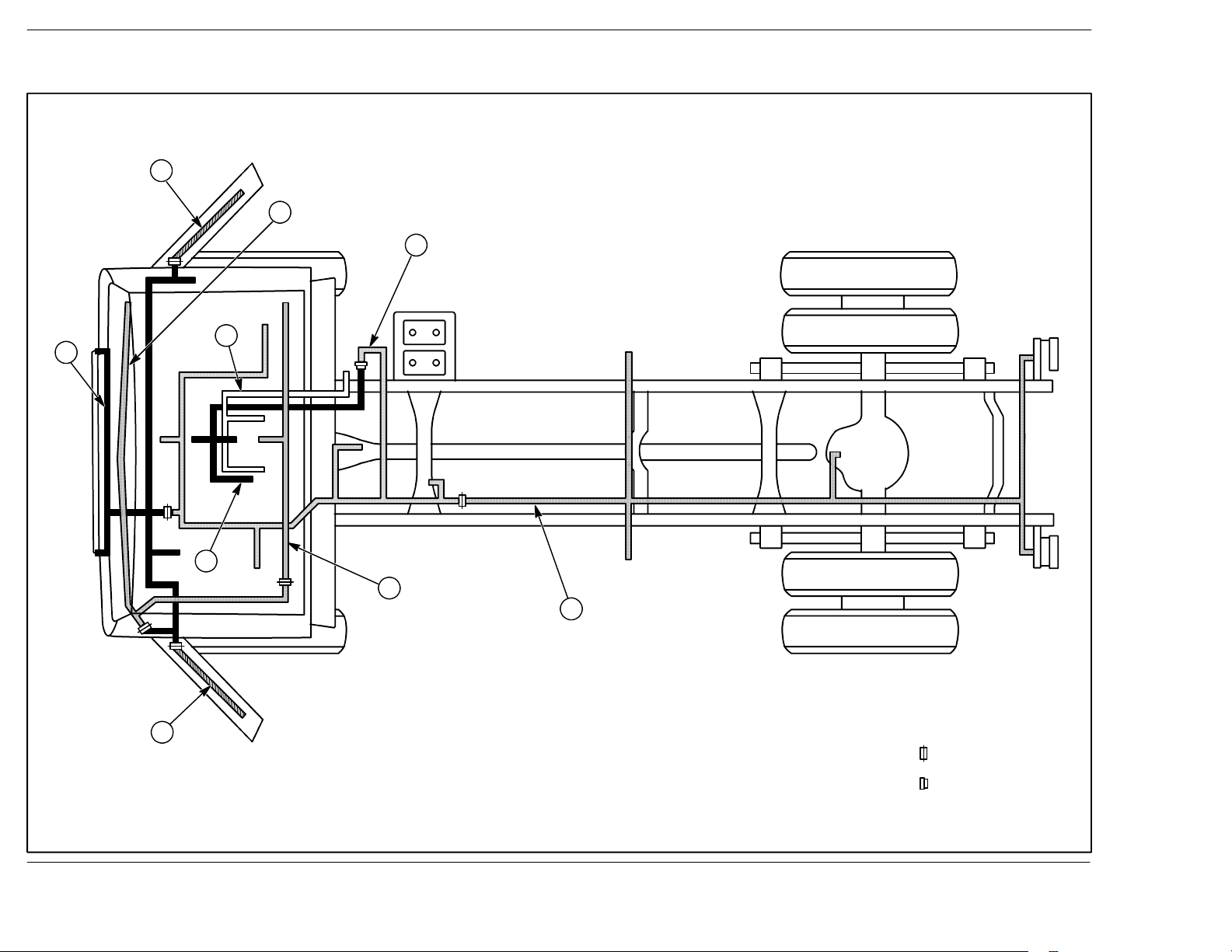

Wiring Harness Overview9-1

9

1

4

2

5

3

7

6

8

Connector

Grommet

Wiring Harness Overview 9

DescriptionPart NumberItem

-2

1

2

3

4

5

6

7

8

9

14335 Wiring harness − Interior illumination

9D930 Wiring harness − Fuel charge

12B637 Wiring harness − Engine control sensor

12A581 Wiring harness − Main

14401 Wiring harness − Instrument panel

14405 Wiring harness − Rear Chassis

14A005 Wiring harness − Floor

14631 Wiring harness − driver door

14630 Wiring harness − passenger door

G100

Grounds10 -1

57

B

57

See page

10−2

A

BK

C1041

BK

Headlamp, right

(13008)

85−2

C137

BK

1

57

Windshield

washer pump

motor (17618)

81−1

Function selec-

tor switch assembly

C294a

BK

(19B888)

54−2

12

57

57

See page

10−3

B

A

BK

57

Pusher fan relay

54−4

C2346

2

BK

57

C

57

Cigar lighter,

front (15055)

44−1

C2031

BK

57

C2333

BK

C202a

BK

Door lock timer

110 −1

C202b

516

BK

57

S202

57

Multifunction

switch

81−1, 85−1, 92−1

57

C2047

5

BK

S203

BK

Indicator flasher

relay (13350)

90−1

BK

57

G100

151−12

Grounds 10

-2

Auxiliary relay

box 1

11−3, 151−9

2

Power window

relay

100−1

C2218

BK

Speed control

On/Off switch

31−2

C2178

BK

S204

Ashtray illumi-

nation lamp

71−1

C294c

C2246

B

BK

57

Ashtray illumi-

nation lamp

71−1

C2014

B

BK

57

9

57

Hazard flasher

switch

90−1

C2039

BK

2

BK

57

Function selec-

tor switch assembly

(19B888)

54−1

C2177

G

BK

57

86

57

Speed control

Set/Resume

switch

31−2

57

57

A

See page

10−1

BK

Grounds10 -3

3

Roof marker

lamp, left

92−2

C970

BK

Roof marker

lamp, left center

92−2

C971

3

BK

57

57

Parking brake

switch (15A851)

60−2

C306

A

Safety belt

buckle switch

BK

57

57

(10B924)

60−2

C323

3

BK

57

57

A

57

F

Floor shifter

29−4

C3245

57

BK

S300

BK

C300

BK

3

Roof marker

lamp, center

92−2

C972

BK

3

Roof marker

lamp, right

92−2

C974

BK

S900

BK

Roof marker

lamp, right center

92−2

C973

3

BK

57

57

57

1

57

B

See page

10−1

C210

BK

G101

Grounds 10

-4

ends in harness

BK

57

C1043

3

B

57

Park/turn lamp,

right front

(13411)

90−4

Brake fluid level

switch (2L414)

60−2

C124

BK

Master window

adjust switch

100−1

C504

3

BK

C211

1

BK

Run/Accessory

relay

60−3

Function selec-

tor switch assembly

(19B888)

C294b

A

57

54−1

BK

S206

C552

6

BK

BK

BK

Door lock actua-

tor, left front

110 −1

S207

57

57

C2312

2

Speed control

On/Off switch

31−2

C2178

7

BK

57

Fog lamp, right

front (15200)

86−1

C162

2

C152

2

B

57

Fog lamp, left

front (15200)

86−1

Headlamp, left

(13008)

85−2

C1021

BK

57

13

57

57

Park/turn lamp,

left front (13411)

90−4

C1023

3

BK

57

BK

57

BK

57

BK

57

BK

57

S205

BK

57

BK

57

G101

151−12

G102, G400

Grounds10 -5

with 137” wheelbase

C1529

B

BK

57

Pusher fan

54−4

BK

57

not used

4

4

57

57

C431

C423

BK

BK

with dual tanks

B

57

BK

57

Fuel sender,

secondary

49−2

C3263

BK

65838485

57

57

BK

BK

S109

License plate

lamp (13550)

92−1

C4046b

1

Fuel sender,

primary

49−2, 49−3

C3262

B

BK

57

with 137” wheelbase

BK

333

57

62

BK

57

57

B

57

B

Automatic

transmission

module (7G422)

29−2

C168

BK

Reversing

alarm speaker

93−1

C4015

BK

C422

57

Output Shaft

Speed (OSS)

sensor

(7H103)

C193

3

57

29−2

BK

1

Tail lamp, left

90−3

C412

BK

Tail lamp,

right

90−3

C415

1

BK

57

Speed sen-

sor assembly

(7M101)

29−2

C143

2

BK

57

BK

57

C421

1

S401

BK

57

C311

9

BK

57

S108

with 137” wheelbase

See page

10−6

C

BK

57

BK

57

G102

151−16

G105

Grounds 10

-6

Windshield wiper relay

81−1

C1491

BK

BK

2

51

Transmission

relay

29−1

C1520

BK

D

BK/WH

3027

3

A/C Compres-

sor clutch diode

54−3

C1086

RD/WH

S102

See page

10−7

57

57

E

BK

Fuel heater

relay

49−1

C1329

2

BK

57

Horn (13832)

44−1

C131

2

3027

BK

57

3027

1

A/C clutch field

coil (19D798)

54−3

C100

RD/WH

RD/WH

57

See page

10−7

2

Fog lamp relay

86−1

C1007

BK

6

BK/PK

574

574

86

57

Engine Control Module

(ECM)

23−1

C175b

7

BK/PK

57

Power Distribution Center

(PDC)

11−1, 151−22

S104

BK

57

574

574

C140

41

BK/PK

S105

BK/PK

S101

BK

57

C

See page

10−5

G105

151−22

7

BK/PK

574

BK

57

Grounds10 -7

C1450

BK

BK

E

EGR system

module

23−2

C1245d

1

BK

57

Manifold in-

take air heater

relay

23−3

57

Injector Driver Module

(IDM)

23−4

C1174c

BK/WH

3

BK/WH

51

51

21

BK/WH

51

51

BK/WH

See page

10−6

2622

BK/WH

51

S106

BK/WH

51

D

2

57

57

See page

10−6

1

C1084d

BK

Glow plug

relay

23−9

1

57

C1515

BK

C

Boost control

solenoid

23−5

57

C128

BK

S107

Mass Air Flow

(MAF) sensor

(12B579)

23−6

G103, G104

Grounds 10

-8

Body builder

relay #1

140−1

C1519

2

16

BK

57

G104

151−23

530

57

57

BK

Power Distribution Center

(PDC)

11−1, 151−22

45

LG/YE

BK

G103

151−16

with dual tanks

D

Fuel transfer

pump

49−2

C3264

BK

C311

BK

ends in harness

BK

57

S100

ABS control

module

(2C219)

42−1

C135

BK

57

57

Fuel pump

49−3

C1253

2

BK

57

Fuel heater

49−1

C1076

1

BK

57

23

57

Grounds10 -9

G107, G108, G200

C220b

1

BK

BK

Instrument clus-

ter (10849)

60−2

S200

Daytime Run-

ning Lamps

(DRL) module

97−2

C1030

D

BK

57

Battery 2

151−18

BK

C

57

premium radio

C1

BK

Audio unit

(18808)

130−1

C290

BK

Battery (10655)

151−18

100bC1249b

8

5

57

Engine diagnostic

connector

14−1

C2173

A

BK

57

C240

C2188

BK

Audio unit

(18808)

130−1

Cassette

Data Link Connector

(DLC) (14489)

14−2

57

BK

14

57

C251

54

BK

57

Remote keyless

entry module

(15K602)

117 −1

C272

BK

Door lock timer

117 −2

C2333

5

BK

57

Instrument cluster (10849)

60−2

C220b

32

BK

57

BK

57

S201

57

57

G107

BK

G108

BK

57

G200

151−12

Loading...

Loading...