Page 1

R

Intel® 815EG Chipset Platform

For Use with Universal Socket 370

Design Guide

August 2002

Document Number: 298301-002

Page 2

R

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY

ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN

INTEL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER, AND INTEL

DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR

WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT,

COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for use in medical, life saving, or life sustaining

applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked "reserved" or "undefined." Intel reserves these for

future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to them.

The Intel

Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

I

Implementations of the I

Corporation.

Alert on LAN is a result of the Intel-IBM Advanced Manageability Alliance and a trademark of IBM.

Intel, Celeron, Pentium, MMX and the Intel logo are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States

and other countries.

*Other names and brands may be claimed as the property of others.

Copyright

815 chipset may contain design defects or errors known as errata which may cause the product to deviate from published specifications.

2

C is a two-wire communications bus/protocol developed by Philips. SMBus is a subset of the I2C bus/protocol and was developed by Intel.

©

2001-2002, Intel Corporation

2

C bus/protocol may require licenses from various entities, including Philips Electronics N.V. and North American Philips

®

2 Intel

815EG Chipset Platform Design Guide

Page 3

R

Contents

1 Introduction ........................................................................................................................13

1.1 Design Guide and Chipset Basic Information .......................................................13

1.2 Terminology ..........................................................................................................14

1.3 Reference Documents ..........................................................................................16

1.4 System Overview ..................................................................................................17

1.4.1 System Features ...................................................................................18

1.4.2 Component Features.............................................................................19

1.4.2.1 Intel® 82815EG GMCH Features .........................................19

1.4.2.2 Intel® 815 to 815G/EG Signal Name Changes ....................20

1.4.2.3 Intel® 82801BA I/O Controller Hub 2 (ICH2) ........................21

1.4.2.4 Firmware Hub (FWH)...........................................................21

1.4.3 Platform Initiatives .................................................................................21

1.4.3.1 Universal Motherboard Design ............................................21

1.4.3.2 Intel® PC 133........................................................................22

1.4.3.3 Accelerated Hub Architecture Interface ...............................22

1.4.3.4 Internet Streaming SIMD Extensions...................................22

1.4.3.5 Integrated LAN Controller ....................................................22

1.4.3.6 Ultra ATA/100 Support .........................................................22

1.4.3.7 Expanded USB Support .......................................................22

1.4.3.8 Manageability and Other Enhancements ............................. 23

1.4.3.9 AC ’97 6-Channel Support ...................................................23

1.4.3.10 Low-Pin-Count (LPC) Interface ............................................26

2 General Design Considerations.........................................................................................27

2.1 Nominal Board Stack-Up ......................................................................................27

2.2 Future Designs Require Pull-Ups and Pull-Downs on Any Unused Input and

I/O Pins .................................................................................................................28

2.3 Support For P-MOS Kicker “ON”: SMAA[9] Is Strapped High by an Internal

50 kΩ Pull-Up Resistor .........................................................................................28

2.4 Electrostatic Discharge Platform Recommendations ...........................................28

3 Component Layouts...........................................................................................................31

4 Universal Socket 370 Design ............................................................................................35

4.1 Universal Socket 370 Definitions ..........................................................................35

4.2 Processor Design Requirements ..........................................................................37

4.2.1 Use of Universal Socket 370 Design with Incompatible GMCH............37

4.2.2 Identifying the Processor at the Socket .................................................38

4.2.3 Setting the Appropriate Processor VTT Level .......................................39

4.2.4 VTT Processor Pin AG1 ........................................................................40

4.2.5 Identifying the Processor at the GMCH.................................................41

4.2.6 Configuring Non-VTT Processor Pins ...................................................42

4.2.7 VCMOS Reference................................................................................43

4.2.8 Processor Signal PWRGOOD...............................................................44

4.2.9 APIC Clock Voltage Switching Requirements .......................................45

4.2.10 GTLREF Topology and Layout..............................................................46

®

815EG Chipset Platform Design Guide 3

Intel

Page 4

4.3

Power Sequencing on Wake Events ....................................................................47

4.3.1 Gating of Intel® CK-815 to VTTPWRGD ...............................................47

4.3.2 Gating of PWROK to Intel® ICH2 ..........................................................48

5 System Bus Design Guidelines .........................................................................................49

5.1 System Bus Routing Guidelines ...........................................................................49

5.1.1 Initial Timing Analysis ............................................................................ 49

5.2 General Topology and Layout Guidelines.............................................................52

5.2.1 Motherboard Layout Rules for AGTL/AGTL+ Signals ...........................53

5.2.1.1 Ground Reference ...............................................................53

5.2.1.2 Reference Plane Splits ........................................................53

5.2.1.3 Processor Connector Breakout............................................53

5.2.1.4 Minimizing Crosstalk ............................................................54

5.2.2 Motherboard Layout Rules for Non-AGTL/AGTL+ (CMOS) Signals .....55

5.2.3 THRMDP and THRMDN .......................................................................56

5.2.4 Additional Routing and Placement Considerations ...............................56

5.3 Electrical Differences for Universal PGA370 Designs ..........................................57

5.3.1 THERMTRIP Circuit ..............................................................................57

5.3.1.1 THERMTRIP Timing ............................................................58

5.3.1.2 THERMTRIP Support for 0.13 Micron Technology

Processors, A-1 Stepping ....................................................58

5.4 PGA370 Socket Definition Details ........................................................................59

5.5 BSEL[1:0] Implementation Differences.................................................................62

5.6 CLKREF Circuit Implementation ...........................................................................63

5.7 Undershoot/Overshoot Requirements ..................................................................64

5.8 Processor Reset Requirements ............................................................................65

5.9 Processor PLL Filter Recommendations ..............................................................66

5.9.1 Topology................................................................................................ 66

5.9.2 Filter Specification .................................................................................66

5.9.3 Recommendation for Intel® Platforms ...................................................68

5.9.4 Custom Solutions ..................................................................................70

5.10 Voltage Regulation Guidelines..............................................................................70

5.11 Decoupling Guidelines for Universal PGA370 Designs ........................................70

5.11.1 VCC

Decoupling Design.................................................................70

CORE

5.11.2 VTT Decoupling Design ........................................................................71

5.11.3 VREF Decoupling Design......................................................................71

5.12 Thermal Considerations........................................................................................72

5.12.1 Heatsink Volumetric Keep-Out Regions................................................72

5.12.2 Fan Heatsink Keep-Out Adherence for Future Boxed Intel® Celeron®

Processors ............................................................................................74

5.13 Debug Port Changes ............................................................................................75

R

6 System Memory Design Guidelines...................................................................................77

6.1 System Memory Routing Guidelines.....................................................................77

6.2 System Memory 2-DIMM Design Guidelines ........................................................78

6.2.1 System Memory 2-DIMM Connectivity ..................................................78

6.2.2 System Memory 2-DIMM Layout Guidelines.........................................79

6.3 System Memory 3-DIMM Design Guidelines ........................................................81

6.3.1 System Memory 3-DIMM Connectivity ..................................................81

6.3.2 System Memory 3-DIMM Layout Guidelines.........................................82

6.4 System Memory Decoupling Guidelines ...............................................................83

®

4 Intel

815EG Chipset Platform Design Guide

Page 5

R

6.5

Compensation.......................................................................................................85

7 Display Cache Design Guidelines .....................................................................................87

7.1 Display Cache Interface........................................................................................87

7.2 GPA Card Considerations.....................................................................................87

7.3 GPA Mechanical Considerations ..........................................................................87

7.4 Display Cache Clocking ........................................................................................88

7.5 VDDQ Generation.................................................................................................88

8 Integrated Graphics Display Output...................................................................................89

8.1 Analog RGB/CRT..................................................................................................89

8.1.1 RAMDAC/Display Interface ...................................................................89

8.1.2 Reference Resistor (Rset) Calculation ..................................................91

8.1.3 RAMDAC Board Design Guidelines ......................................................91

8.1.4 RAMDAC Layout Recommendations ....................................................93

8.1.5 HSYNC/VSYNC Output Guidelines....................................................... 93

8.2 Intel® Digital Video Out..........................................................................................94

8.2.1 Intel® DVO Interface Routing Guidelines...............................................94

8.2.2 Intel® DVO I2C Interface Considerations ...............................................94

8.2.3 Leaving the Intel® DVO Port Unconnected............................................94

9 Hub Interface .....................................................................................................................97

9.1.1 Data Signals ..........................................................................................98

9.1.2 Strobe Signals .......................................................................................98

9.1.3 HREF Generation/Distribution...............................................................98

9.1.4 Compensation .......................................................................................99

10 I/O Controller Hub 2 (Intel® ICH2)....................................................................................101

10.1 Decoupling ..........................................................................................................101

10.2 Power Sequencing on Wake Events ..................................................................102

10.3 Power Supply PS_ON Considerations................................................................ 103

11 I/O Subsystem .................................................................................................................105

11.1 IDE Interface .......................................................................................................105

11.1.1 Cabling ................................................................................................105

11.2 Cable Detection for Ultra ATA/66 and Ultra ATA/100.........................................105

11.2.1 Combination Host-Side/Device-Side Cable Detection ........................106

11.2.2 Device-Side Cable Detection...............................................................107

11.2.3 Primary IDE Connector Requirements ................................................108

11.2.4 Secondary IDE Connector Requirements ...........................................109

11.3 AC ’97 .................................................................................................................110

11.3.1 Communications Network Riser (CNR)...............................................111

11.3.2 AC ’97 Audio Codec Detect Circuit and Configuration Options...........112

11.3.2.1 Valid Codec Configurations ...............................................115

11.3.3 SPKR Pin Considerations....................................................................115

11.3.4 AC ’97 Routing ....................................................................................116

11.3.5 Motherboard Implementation ..............................................................117

11.4 USB.....................................................................................................................118

11.4.1 Using Native USB Interface.................................................................118

11.4.2 Disabling the Native USB Interface of ICH2........................................119

11.5 I/O APIC Design Recommendation ....................................................................119

11.5.1 PIRQ Routing Example .......................................................................120

®

815EG Chipset Platform Design Guide 5

Intel

Page 6

R

11.6

SMBus/SMLink Interface ....................................................................................121

11.6.1 SMBus Architecture and Design Considerations ................................122

11.6.1.1 General Design Issues and Notes .....................................122

11.7 PCI ......................................................................................................................125

11.8 RTC.....................................................................................................................126

11.8.1 RTC Crystal.........................................................................................126

11.8.2 External Capacitors .............................................................................127

11.8.3 RTC Layout Considerations ................................................................127

11.8.4 RTC External Battery Connection .......................................................127

11.8.5 RTC External RTCRST Circuit ............................................................129

11.8.6 Power-Well Isolation Control Requirements .......................................129

11.8.7 RTC Routing Guidelines...................................................................... 130

11.8.8 VBIAS DC Voltage and Noise Measurements ....................................131

11.9 LAN Layout Guidelines .......................................................................................131

11.9.1 Intel® ICH2 – LAN Interconnect Guidelines .........................................132

11.9.1.1 Bus Topologies ..................................................................133

11.9.1.2 Point-to-Point Interconnect ................................................133

11.9.1.3 LOM/CNR Interconnect......................................................134

11.9.1.4 Signal Routing and Layout .................................................135

11.9.1.5 Crosstalk Consideration.....................................................135

11.9.1.6 Impedances .......................................................................135

11.9.1.7 Line Termination ................................................................136

11.9.2 General LAN Routing Guidelines and Considerations ........................136

11.9.2.1 General Trace Routing Considerations..............................136

11.9.2.2 Power and Ground Connections........................................138

11.9.2.3 A 4-Layer Board Design.....................................................139

11.9.2.4 Common Physical Layout Issues .......................................139

11.9.3 Intel® 82562EH Home/PNA* Guidelines..............................................141

11.9.3.1 Power and Ground Connections........................................141

11.9.3.2 Guidelines for Intel® 82562EH Component Placement......141

11.9.3.3 Crystals and Oscillators .....................................................142

11.9.3.4 Phoneline HPNA Termination ............................................142

11.9.3.5 Critical Dimensions ............................................................143

11.9.4 Intel® 82562ET / Intel® 82562EM Guidelines ......................................144

11.9.4.1 Guidelines for Intel® 82562ET / Intel® 82562EM Component

Placement ..........................................................................144

11.9.4.2 Crystals and Oscillators .....................................................145

11.9.4.3 Intel® 82562ET / Intel® 82562EM Termination Resistors...145

11.9.4.4 Critical Dimensions ............................................................145

11.9.4.5 Reducing Circuit Inductance ..............................................147

11.9.5 Intel® 82562ET/82562EM Disable Guidelines .....................................148

11.9.6 Intel® 82562ET / Intel® 82562EH Dual Footprint Guidelines ...............149

11.10 LPC/FWH............................................................................................................151

11.10.1 In-Circuit FWH Programming ..............................................................151

11.10.2 FWH VPP Design Guidelines ...............................................................151

11.10.3 FWH Decoupling .................................................................................152

12 Clocking ...........................................................................................................................153

12.1 2-DIMM Clocking ................................................................................................153

12.2 3-DIMM Clocking ................................................................................................155

12.3 Clock Routing Guidelines.................................................................................... 157

12.4 Clock Driver Frequency Strapping ......................................................................159

®

6 Intel

815EG Chipset Platform Design Guide

Page 7

R

12.5

Clock Skew Assumptions ...................................................................................160

12.6 Intel® CK-815 Power Gating On Wake Events ...................................................161

13 Power Delivery.................................................................................................................163

13.1 Power Delivery Guidelines..................................................................................163

13.1.1 5V Dual Switch ....................................................................................165

13.1.2 VTT......................................................................................................165

13.1.3 1.85 V ..................................................................................................165

13.1.4 VDDQ ..................................................................................................165

13.1.5 3.3VSB ................................................................................................166

13.1.6 1.85VSB ..............................................................................................166

13.1.7 VCMOS ...............................................................................................166

13.2 Thermal Design Power .......................................................................................167

13.2.1 Pull-Up and Pull-Down Resistor Values ..............................................167

13.3 ATX Power Supply PWRGOOD Requirements..................................................168

13.4 Power Management Signals ...............................................................................168

13.4.1 Power Button Implementation .............................................................169

13.4.2 1.85 V/3.3 V Power Sequencing..........................................................170

13.4.3 V5REF/3.3 V Sequencing....................................................................171

13.5 Power Plane Splits ..............................................................................................172

13.6 Glue Chip 3 (ICH2 Glue Chip) ............................................................................173

14 System Design Checklist ................................................................................................. 175

14.1 Design Review Checklist ....................................................................................175

14.2 Processor Checklist ............................................................................................175

14.2.1 GTL Checklist......................................................................................175

14.2.2 CMOS Checklist ..................................................................................176

14.2.3 TAP Checklist for 370-Pin Socket Processors ....................................176

14.2.4 Miscellaneous Checklist for 370-Pin Socket Processors ....................177

14.3 GMCH Checklist .................................................................................................178

14.3.1 System Memory Interface Checklist....................................................178

14.3.2 Hub Interface Checklist .......................................................................178

14.3.3 Digital Video Output Port Checklist .....................................................179

14.4 Intel® ICH2 Checklist...........................................................................................179

14.4.1 PCI Interface .......................................................................................179

14.4.2 Hub Interface.......................................................................................179

14.4.3 LAN Interface ......................................................................................180

14.4.4 EEPROM Interface..............................................................................180

14.4.5 FWH/LPC Interface ............................................................................. 180

14.4.6 Interrupt Interface ................................................................................180

14.4.7 GPIO Checklist....................................................................................182

14.4.8 USB .....................................................................................................182

14.4.9 Power Management ............................................................................183

14.4.10 Processor Signals ...............................................................................184

14.4.11 System Management ..........................................................................184

14.4.12 RTC ...........................................................................................184

14.4.13 AC ’97 ...........................................................................................185

14.4.14 Miscellaneous Signals ......................................................................... 186

14.4.15 Power ...........................................................................................187

14.4.16 IDE Checklist .......................................................................................188

14.5 LPC Checklist .....................................................................................................190

14.6 System Checklist ................................................................................................191

®

815EG Chipset Platform Design Guide 7

Intel

Page 8

14.7

FWH Checklist .................................................................................................... 191

14.8 Clock Synthesizer Checklist................................................................................192

14.9 System Memory Checklist ..................................................................................193

14.10 Power Delivery Checklist ....................................................................................193

15 Third-Party Vendor Information .......................................................................................195

R

®

8 Intel

815EG Chipset Platform Design Guide

Page 9

R

Figures

Figure 1. System Block Diagram .......................................................................................18

Figure 2. Component Block Diagram ................................................................................19

Figure 3. AC ’97 Audio and Modem Connections .............................................................25

Figure 4. Board Construction Example for 60 Ω Nominal Stack-up .................................. 27

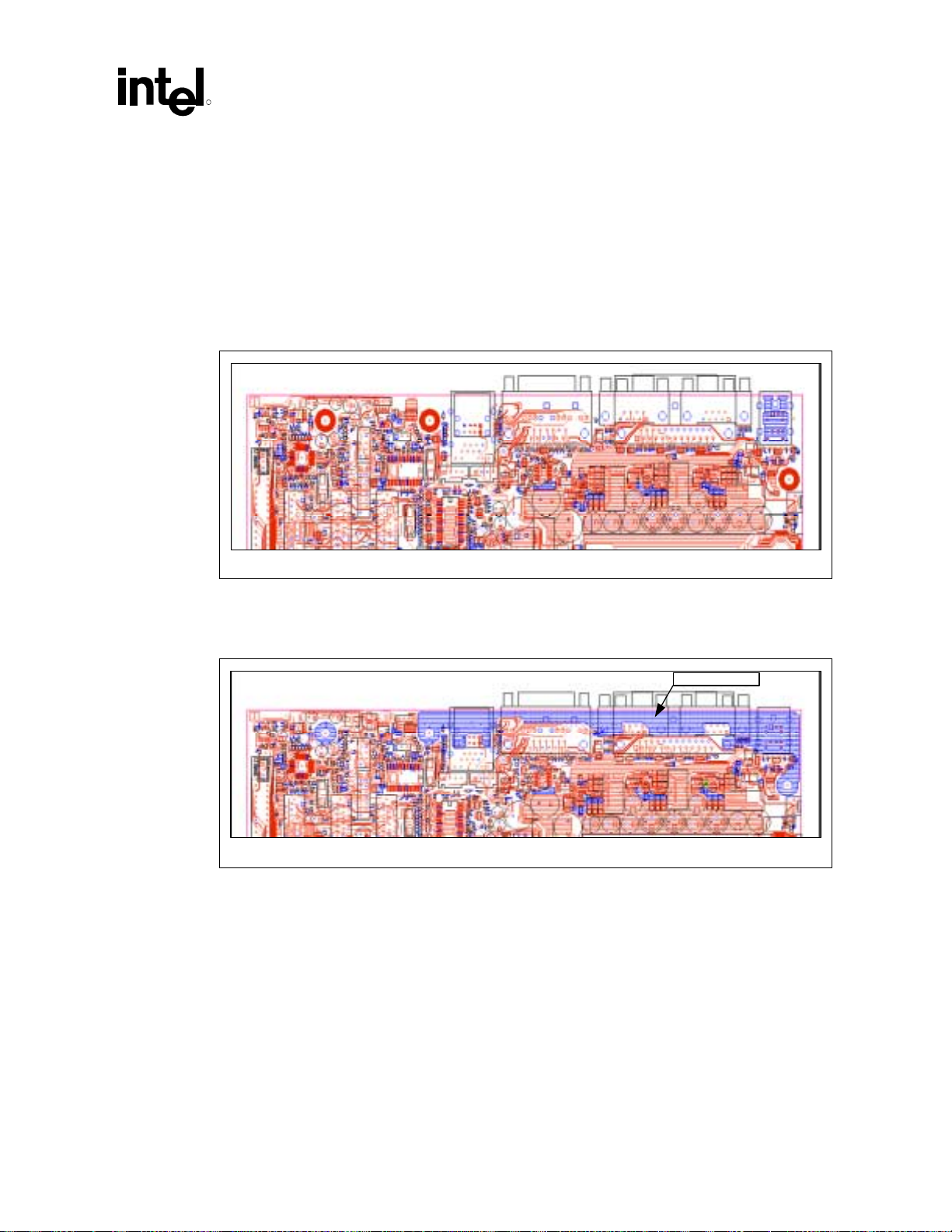

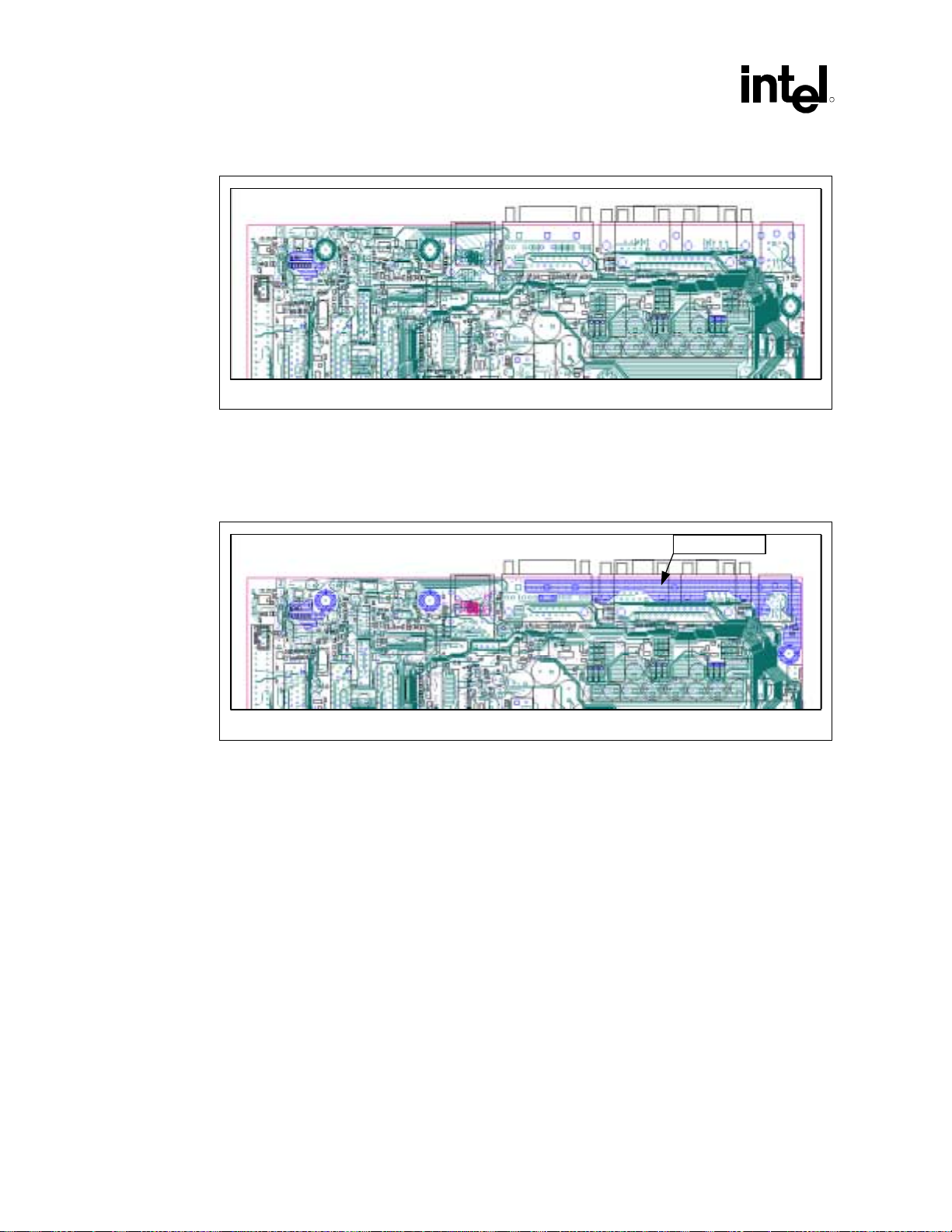

Figure 5. Top Signal Layer before the Ground Fill Near the I/O Layer ..............................29

Figure 6. Top Signal Layer after the Ground Fill Near the I/O Layer .................................29

Figure 7. Bottom Signal Layer before the Ground Fill Near the I/O Area ..........................30

Figure 8. Bottom Signal Layer after the Ground Fill Near the I/O......................................30

Figure 9. GMCH 544-Ball µBGA* CSP Quadrant Layout (Top View)................................31

Figure 10. ICH2 360-Ball EBGA Quadrant Layout (Top View) ..........................................32

Figure 11. Firmware Hub (FWH) Packages ......................................................................33

Figure 12. Future 0.13 Micron Socket 370 Processor Safeguard for Universal Socket 370

Designs Using A-2 GMCH..........................................................................................37

Figure 13. Processor Detect Mechanism at Socket/TUAL5 Generation Circuit ................38

Figure 14. VTT Selection Switch ........................................................................................39

Figure 15. Switching Pin AG1............................................................................................40

Figure 16. Processor Identification Strap on GMCH .........................................................41

Figure 17. VTTPWRGD Configuration Circuit ...................................................................42

Figure 18. GTL_REF/VCMOS_REF Voltage Divider Network ..........................................43

Figure 19. Resistor Divider Network for Processor PWRGOOD....................................... 44

Figure 20 Voltage Switch for Processor APIC Clock .........................................................45

Figure 21. GTLREF Circuit Topology ................................................................................46

Figure 22. Gating Power to Intel® CK-815 .........................................................................47

Figure 23 PWROK Gating Circuit for Intel® ICH2..............................................................48

Figure 24. Topology for 370-Pin Socket Designs with Single-Ended Termination (SET)..52

Figure 25. AGTL/AGTL+ Trace Routing............................................................................53

Figure 26. Routing for THRMDP and THRMDN................................................................56

Figure 27. Example Implementation of THERMTRIP Circuit ............................................57

Figure 28 Thermtrip Support for A-1 Stepping 0.13 Micron Technology Processors........59

Figure 29. BSEL[1:0] Circuit Implementation for PGA370 Designs...................................63

Figure 30. Examples for CLKREF Divider Circuit..............................................................64

Figure 31. RESET#/RESET2# Routing Guidelines ...........................................................65

Figure 32. Filter Specification ............................................................................................67

Figure 33. Example PLL Filter Using a Discrete Resistor .................................................69

Figure 34. Example PLL Filter Using a Buried Resistor ....................................................69

Figure 35. Core Reference Model .....................................................................................70

Figure 36. Capacitor Placement on the Motherboard........................................................71

Figure 37. Heatsink Volumetric Keep-Out Regions ...........................................................73

Figure 38 Motherboard Component Keep-Out Regions .................................................... 73

Figure 39. Keep-Out Requirements for the 370-pin (Top View) ........................................ 74

Figure 40. TAP Connector Comparison ............................................................................75

Figure 41. System Memory Routing Guidelines ................................................................77

Figure 42. System Memory Connectivity (2 DIMM) ...........................................................78

Figure 43. System Memory 2-DIMM Routing Topologies..................................................79

Figure 44. System Memory Routing Example ...................................................................80

Figure 45. System Memory Connectivity (3 DIMM) ...........................................................81

Figure 46. System Memory 3-DIMM Routing Topologies..................................................82

Figure 47. Intel 815 Chipset Platform Decoupling Example ............................................83

Figure 48. Intel® 815 Chipset Decoupling Example...........................................................84

Figure 49. Display Cache Input Clocking...........................................................................88

®

815EG Chipset Platform Design Guide 9

Intel

Page 10

R

Figure 50. Schematic of RAMDAC Video Interface...........................................................90

Figure 51. Cross-Sectional View of a Four-Layer Board ...................................................91

Figure 52. Recommended RAMDAC Component Placement and Routing ......................92

Figure 53. Recommended RAMDAC Reference Resistor Placement and Connections ..93

Figure 54. Hub Interface Signal Routing Example ............................................................97

Figure 55. Single Hub Interface Reference Divider Circuit ................................................99

Figure 56. Locally Generated Hub Interface Reference Dividers ......................................99

Figure 57. Intel® ICH2 Decoupling Capacitor Layout.......................................................102

Figure 58. Combination Host-Side / Device-Side IDE Cable Detection ..........................106

Figure 59. Device-Side IDE Cable Detection...................................................................107

Figure 60. Connection Requirements for Primary IDE Connector...................................108

Figure 61. Connection Requirements for Secondary IDE Connector.............................. 109

Figure 62. Intel® ICH2 AC ’97– Codec Connection .........................................................110

Figure 63. CNR Interface.................................................................................................111

Figure 64. CDC_DN_ENAB# Support Circuitry for a Single Codec on Motherboard......112

Figure 65. CDC_DN_ENAB# Support Circuitry for Multi-Channel Audio Upgrade..........113

Figure 66. CDC_DN_ENAB# Support Circuitry for Two-Codecs on Motherboard /

One-Codec on CNR .................................................................................................114

Figure 67. CDC_DN_ENAB# Support for Two-Codecs on Motherboard /

Two-Codecs on CNR ...............................................................................................114

Figure 68. Example Speaker Circuit................................................................................116

Figure 69. USB Data Signals...........................................................................................119

Figure 70. Example PIRQ Routing ..................................................................................120

Figure 71. SMBus/SMLink Interface ................................................................................121

Figure 72. Unified VCC_Suspend Architecture ...............................................................123

Figure 73. Unified VCC

Figure 74. Mixed VCC_Suspend/VCC

Architecture......................................................................... 123

CORE

Architecture .................................................124

CORE

Figure 75. PCI Bus Layout Example................................................................................125

Figure 76. External Circuitry for the ICH2 RTC ...............................................................126

Figure 77. Diode Circuit to Connect RTC External Battery..............................................128

Figure 78. RTCRST External Circuit for ICH2 RTC ........................................................129

Figure 79. RTC Power Well Isolation Control..................................................................130

Figure 80. Intel® ICH2 / LAN Connect Section ................................................................132

Figure 81. Single-Solution Interconnect...........................................................................133

Figure 82. LOM/CNR Interconnect ..................................................................................134

Figure 83. LAN_CLK Routing Example ...........................................................................135

Figure 84. Trace Routing .................................................................................................137

Figure 85. Ground Plane Separation ...............................................................................138

Figure 86. Intel® 82562EH Termination ...........................................................................142

Figure 87. Critical Dimensions for Component Placement..............................................143

Figure 88. Intel® 82562ET/Intel® 82562EM Termination .................................................145

Figure 89. Critical Dimensions for Component Placement..............................................146

Figure 90. Termination Plane ..........................................................................................148

Figure 91. Intel® 82562ET/82562EM Disable Circuit.......................................................148

Figure 92. Dual-Footprint LAN Connect Interface ...........................................................149

Figure 93. Dual-Footprint Analog Interface .....................................................................149

Figure 94. FWH VPP Isolation Circuitry ..........................................................................151

Figure 95. Platform Clock Architecture for a 2-DIMM Solution........................................154

Figure 96. Platform Clock Architecture for a 3-DIMM Solution........................................156

Figure 97. Clock Routing Topologies ..............................................................................157

Figure 98. Power Delivery Map........................................................................................164

Figure 99. Pull-Up Resistor Example ..............................................................................167

Figure 100. Example 1.85 V/3.3 V Power Sequencing Circuit ........................................170

Figure 101. V5REF/3.3 V Sequencing Circuitry ..............................................................171

®

10 Intel

815EG Chipset Platform Design Guide

Page 11

R

Tables

Figure 102. Power Plane Split Example ..........................................................................172

Figure 103. USB Data Line Schematic ............................................................................183

Figure 104. Intel® ICH2 Oscillator Circuitry......................................................................185

Figure 105. SPKR Circuitry..............................................................................................186

Figure 106. V5REF Circuitry............................................................................................187

Figure 107. Host/Device Side Detection Circuitry............................................................189

Figure 108. Device Side Only Cable Detection ...............................................................189

Table 1. Intel® 82815 to Intel® 82815G Pin Name Changes..............................................20

Table 2. Processor Considerations for Universal Socket 370 Design...............................35

Table 3. GMCH Considerations for Universal Socket 370 Design ....................................36

Table 4. Intel® ICH2 Considerations for Universal Socket 370 Design .............................36

Table 5. Clock Synthesizer Considerations for Universal Socket 370 Design ..................37

Table 6. Determining the Installed Processor via Hardware Mechanisms ........................41

Table 7. Intel® Pentium® III Processor AGTL/AGTL+ Parameters for Example

Calculations ................................................................................................................50

Table 8. Example T

Table 9. Example T

Calculations for 133 MHz Bus ................................................51

FLT_MAX

Calculations (Frequency Independent) ....................................51

FLT_MIN

Table 10. Trace Guidelines for Figure 24..........................................................................52

Table 11. Trace Width: Space Guidelines ......................................................................... 52

Table 12. Routing Guidelines for Non-AGTL/AGTL+ Signals ...........................................55

Table 13. Processor Pin Definition Comparison................................................................ 59

Table 14. Resistor Values for CLKREF Divider (3.3 V Source)......................................... 64

Table 15. RESET#/RESET2# Routing Guidelines (see Figure 31)...................................65

Table 16. Component Recommendations – Inductor........................................................68

Table 17. Component Recommendations – Capacitor .....................................................68

Table 18. Component Recommendation – Resistor .........................................................68

Table 19. System Memory 2-DIMM Solution Space..........................................................79

Table 20. System Memory 3-DIMM Solution Space..........................................................82

Table 21. Decoupling Capacitor Recommendation .........................................................101

Table 22. Signal Descriptions ..........................................................................................115

Table 23. Codec Configurations ......................................................................................115

Table 24. IOAPIC Interrupt Inputs 16 thru 23 Usage.......................................................120

Table 25. Pull-Up Requirements for SMBus and SMLink................................................122

Table 26. LAN Connect ...................................................................................................131

Table 27. Single-Solution Interconnect Length Requirements (See Figure 81) ..............133

Table 28. LOM/CNR Length Requirements (See Figure 82)...........................................134

Table 29. Critical Dimensions for Component Placement (Refer to Figure 87) ..............143

Table 30. Critical Dimensions for Component Placement (see Figure 89) .....................146

Table 31. Intel® 82562ET Operating States.....................................................................149

Table 32. Intel® CK-815 (2-DIMM) Clocks ....................................................................... 153

Table 33. Intel® CK-815 (3-DIMM) Clocks ....................................................................... 155

Table 34. Simulated Clock Routing Solution Space ........................................................158

Table 35. Simulated Clock Skew Assumptions ...............................................................160

Table 36. Power Delivery Definitions...............................................................................163

®

815EG Chipset Platform Design Guide 11

Intel

Page 12

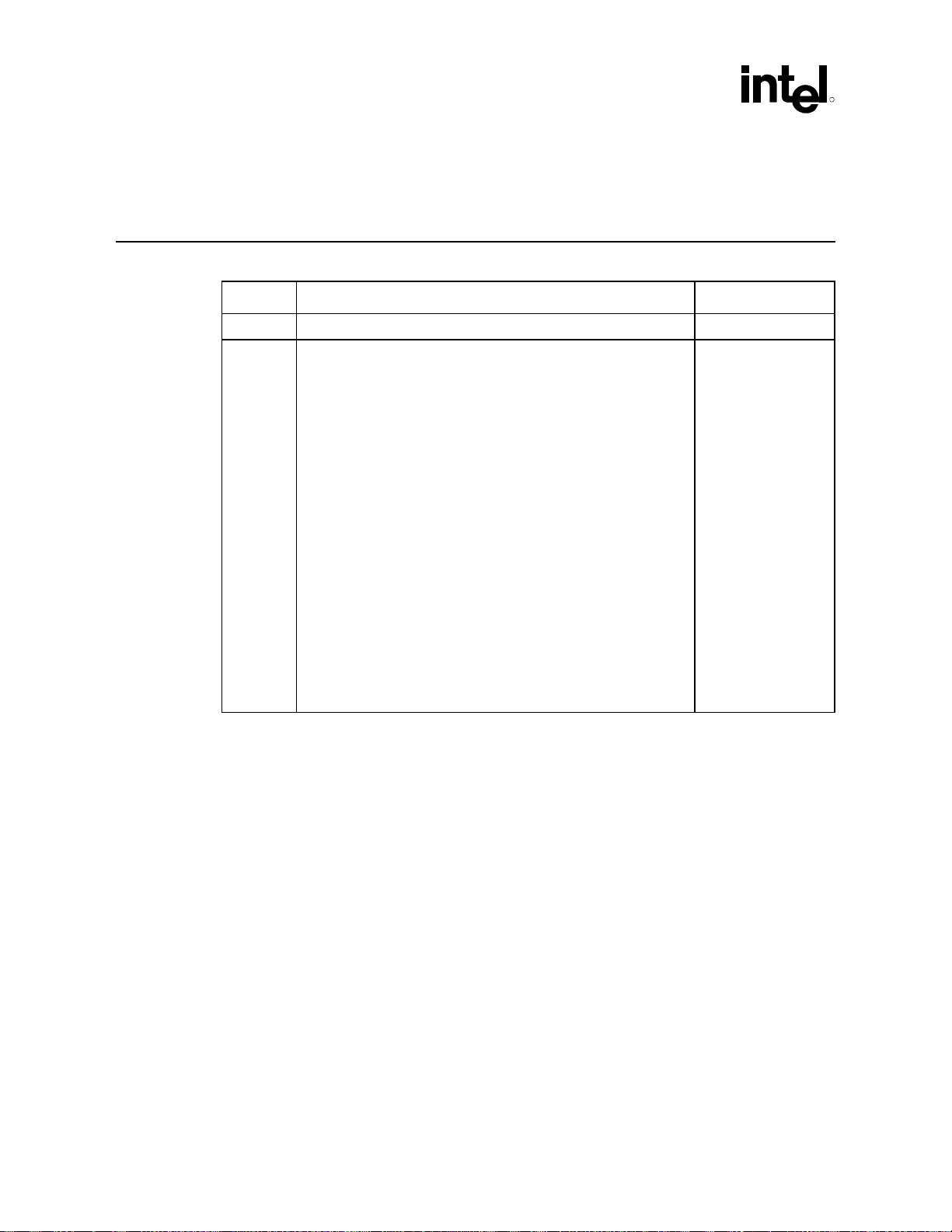

Revision History

Rev. No. Description Rev. Date

-001 • Initial Release. Sept 2001

-002 • Added Section 2.4, Electrostatic Discharge Platform

Recommendations

• Replaced Figure 98, Power Delivery Map, in Section 13, Power

Delivery

• Revised Section 13.4.3, 3.3V/V5REF Sequencing

• Revised Table 33. Intel

(3-DIMM) Clocks, in Section 12.2, 3-DIMM Clocking

• Revised Table 32, Intel

12.1, 2-DIMM Clocking

• Replaced Figure 79, RTC Power Well Isolation Control, in Section

11.8.6, Power Well Isolation Control Requirements

• Replaced Figure 84, Trace Routing, in Section 11.9.2.1, General

Trace Routing Considerations

• Revised Section 13.4.3, 3.3V/V5REF Sequencing

• Revised Checklist Recommendations for 5V_REF_SUS in

Section 14.4.15, Power

• Added SUSCLK to the RTC Checklist in Section 14.4.12

• Added Section 10.3 Power Supply PS_ON Considerations

®

CK-815 (3-DIMM) Clocks, Intel® CK-815

®

CK-815 (2-DIMM) Clocks, in Section

Aug 2002

R

®

12 Intel

815EG Chipset Platform Design Guide

Page 13

Introduction

R

1 Introduction

1.1 Design Guide and Chipset Basic Information

This design guide organizes Intel design recommendations for the Intel® 815EG chipset platform

for use with universal socket 370. In addition to providing motherboard design recommendations

(e.g., layout and routing guidelines), this document also addresses system design issues (e.g.,

thermal requirements) for the chipset platform.

This design guide contains design recommendations, debug recommendations, and a system

checklist. These design guidelines are developed to ensure maximum flexibility for board

designers while reducing the risk of board-related issues.

Consult the debug recommendations when debugging your design. However, these debug

recommendations should be understood before completing board design to ensure that the debug

port, in addition to other debug features, are implemented correctly.

There is no AGP port capability in the Intel

®

82815EG GMCH. The 82815EG uses internal

graphics only.

There are six chipsets in the Intel

®

• Intel

• Intel

• Intel

82815 chipset: This chipset contains the Intel 82815 and the Intel® 82801AA ICH.

®

82815E chipset: This chipset contains the Intel 82815E and the Intel® 82801BA ICH2.

®

82815P chipset: This chipset contains the Intel 82815P and the 82801AA ICH. There is

815 chipset family:

no internal graphics capability. This GMCH uses an AGP port only.

®

• Intel

82815EP chipset: This chipset contains the Intel 82815EP and the 82801BA ICH2.

There is no internal graphics capability. This GMCH uses an AGP port only.

®

• Intel

82815G chipset: This chipset contains the 82815G GMCH and 82801AA ICH. There is

no AGP port capability. This GMCH uses internal graphics only.

®

• Intel

82815EG chipset. This chipset contains the 82815EG GMCH and Intel 82801BA

ICH2. There is no AGP port capability. This GMCH uses internal graphics only.

The only component difference between the 82815 GMCH and the 82815E GMCH is the I/O

Controller Hub. The only component difference between the 82815P GMCH and the 82815EP

GMCH is the I/O Controller Hub. The only component difference between the 82815G GMCH

and the 82815EG GMCH is the I/O Controller Hub.

The Intel 815EG chipset platform supports the following processors:

®

• Intel

• Intel

Pentium® III processor based on 0.18 micron technology (CPUID = 068xh).

®

Celeron® processor based on 0.18 micron technology (CPUID = 068xh). This applies to

Celeron 533A MHz and ≥566 MHz processors

• Future 0.13 micron socket 370 processors

®

815EG Chipset Platform Design Guide 13

Intel

Page 14

Introduction

The system bus speed supported by the design is based on the capabilities of the processor,

chipset, and clock driver.

The 815 chipset for use with the universal socket 370 is not compatible with the

®

Intel

Pentium® II processor (CPUID = 066xh) 370-pin socket.

1.2 Terminology

This section describes some of the terms used in this document. Additional power delivery term

definitions are provided at the beginning of Chapter13, “Power Delivery”.

Term Description

AGP Accelerated Graphics Port

R

AGTL/AGTL+ Refers to processor bus signals that are implemented using either Assisted

Bus Agent A component or group of components that, when combined, represent a single load

Crosstalk The reception on a victim network of a signal imposed by aggressor network(s)

GMCH Graphics and Memory Controller Hub. A component of the Intel 815 chipset

ICH Intel 82801AA I/O Controller Hub component.

ISI Inter-symbol interference is the effect of a previous signal (or transition) on the

Gunning Transceiver Logic (AGTL+) or its lower voltage variant (AGTL), depending

on which processor is being used.

on the AGTL+ bus.

through inductive and capacitive coupling between the networks.

• Backward Crosstalk–coupling that creates a signal in a victim network that travels

in the opposite direction as the aggressor’s signal.

• Forward Crosstalk–coupling that creates a signal in a victim network that travels

in the same direction as the aggressor’s signal.

• Even Mode Crosstalk–coupling from single or multiple aggressors when all the

aggressors switch in the same direction that the victim is switching.

• Odd Mode Crosstalk–coupling from single or multiple aggressors when all the

aggressors switch in the opposite direction that the victim is switching.

platform for use with the Universal Socket 370

interconnect delay. For example, when a signal is transmitted down a line and the

reflections due to the transition have not completely dissipated, the following data

transition launched onto the bus is affected. ISI is dependent upon frequency, time

delay of the line, and the reflection coefficient at the driver and receiver. ISI can

impact both timing and signal integrity.

Network Length The distance between agent 0 pins and the agent pins at the far end of the bus.

Pad The electrical contact point of a semiconductor die to the package substrate. A pad

Pin The contact point of a component package to the traces on a substrate such as the

14 Intel

is only observable in simulation.

motherboard. Signal quality and timings can be measured at the pin.

®

815EG Chipset Platform Design Guide

Page 15

Introduction

R

Term Description

Ringback The voltage that a signal rings back to after achieving its maximum absolute value.

Ringback may be due to reflections, driver oscillations, or other transmission line

phenomena.

Setup Window The time between the beginning of Setup to Clock (T

) and the arrival of a

SU_MIN

valid clock edge. This window may be different for each type of bus agent in the

system.

SSO Simultaneous Switching Output (SSO) Effects refers to the difference in electrical

timing parameters and degradation in signal quality caused by multiple signal

outputs simultaneously switching voltage levels (e.g., high-to-low) in the opposite

direction from a single signal (e.g., low-to-high) or in the same direction (e.g., highto-low). These are respectively called odd-mode switching and even-mode

switching. This simultaneous switching of multiple outputs creates higher current

swings that may cause additional propagation delay (or “push-out”), or a decrease

in propagation delay (or “pull-in”). These SSO effects may impact the setup and/or

hold times and are not always taken into account by simulations. System timing

budgets should include margin for SSO effects.

Stub The branch from the bus trunk terminating at the pad of an agent.

System Bus The system bus is the processor bus.

Trunk The main connection, excluding interconnect branches, from one end agent pad to

the other end agent pad.

Undershoot Minimum voltage observed for a signal to extend below VSS at the device pad.

Universal Socket 370 Refers to the Intel 815EG chipset using the “universal” PGA370 socket. In general,

these designs support 66/100/133 MHz system bus operation, Intel

guidelines for future 0.13 micron processors, and Celeron

(CPUID=068xh), Pentium

®

III processor (CPUID=068xh), and future Celeron and

®

®

VRM

processors

Pentium III processors using 0.13 micron technology in single-microprocessor

based designs.

Victim A network that receives a coupled crosstalk signal from another network is called

the victim network.

®

815EG Chipset Platform Design Guide 15

Intel

Page 16

Introduction

1.3 Reference Documents

R

Document Document Number /

Intel® 815 Chipset Family: 82815G/82815EG Graphic s and Memory Controller

Hub (GMCH) for use with the Univ ersal Socket 370 Datasheet

Intel® 82802AB/82802AC Firmware Hub (FWH) Datasheet Doc 290658

Intel® 82801BA I/O Controller Hub (ICH2) and Intel® 82801BAM I/O Controller

Hub (ICH2-M) Datasheet

Intel® Pentium® III Processor Specification Update (latest revision from website) http://developer.intel.co

AP 907 Intel® Pentium® III Processor Power Distribution Guidelines Doc 245085

AP-585 Intel® Pentium® II Processor AGTL+ Guidelines Doc 243330

AP-587 Intel® Pentium® II Processor Power Distribution Guidelines Doc 243332

Accelerated Graphics P ort Interface Specification, Revision 2.0 http://www.intel.com/te

Graphics Performance Accel erator Specification ftp://download.intel.co

PCI Local Bus Specification, Revision 2. 2 http://www.pcisig.com/s

AC ’97 Component Specification, Revision 2.2

Communication Network Riser Specification, Revision 1.1 http://developer.intel.co

Universal Serial Bus, Revision 2.0 Specification http://www.usb.org/dev

(1)

http://developer.intel.co

Location

Doc 290714

Intel developer website

Intel developer website

Doc 290687

Intel developer website

m/design/PentiumIII/sp

ecupdt/

Intel developer website

Intel developer website

Intel developer website

chnology/agp/agp_inde

x.htm)

m/technology/agp/dow

nloads/agp20.pdf

pecifications/conventio

nal_pci

m/ial/scalableplatforms

/audio/index.htm

m/technology/cnr/

elopers/usb20/

NOTES:

1. Throughout this document, this specification will be referred to as AC ’97 v2.2.

®

16 Intel

815EG Chipset Platform Design Guide

Page 17

Introduction

R

1.4 System Overview

The 815EG chipset platform for use with the universal socket 370 contains a Graphics and

Memory Controller Hub (GMCH) component and I/O Controller Hub 2 (ICH2) component for

desktop platforms.

The GMCH provides the processor interface (optimized for future 0.13 micron Celeron processors

and Pentium III processors (socket 370) and the Pentium III processors (CPUID = 068xh), DRAM

interface, hub interface, and internal graphics. It does not provide support for an external AGP

port. This product provides flexibility and scalability in memory subsystem performance. PC100

SDRAM system memory may be scaled to PC133 system memory.

The Accelerated Hub Architecture interface (i.e., the chipset component interconnect) is designed

into the chipset to provide an efficient, high-bandwidth communication channel between the

GMCH and the I/O controller hub. The chipset architecture also enables a security and

manageability infrastructure through the Firmware Hub component.

An ACPI-compliant 815EG chipset platform can support the Full-on (S0), Stop Grant (S1),

Suspend to RAM (S3), Suspend to Disk (S4), and Soft-off (S5) power management states. The

chipset also supports wake-on-LAN for remote administration and troubleshooting. The chipset

architecture removes the requirement for the ISA expansion bus that was traditionally integrated

into the I/O subsystem of PCIsets/AGPsets. This removes many of the conflicts experienced when

installing hardware and drivers into legacy ISA systems. The elimination of ISA provides true

plug-and-play for the platform. Traditionally, the ISA interface was used for audio and modem

devices. The addition of AC ’97 allows the OEM to use software-configurable AC ’97 audio and

modem coder/decoders (codecs), instead of the traditional ISA devices.

®

815EG Chipset Platform Design Guide 17

Intel

Page 18

Introduction

1.4.1 System Features

The 815EG chipset platform contains two components: the 82815EG Graphics and Memory

Controller Hub (GMCH) and the 82801BA I/O Controller Hub 2 (ICH2). The GMCH integrates a

66/100/133 MHz, P6 family system bus controller, integrated 2D/3D graphics accelerator,

100/133 MHz SDRAM controller, and a high-speed accelerated hub architecture interface for

communication with the ICH2. The ICH2 integrates an UltraATA/100 controller, 2 Universal

Serial Bus (USB) host controllers with a total of 4 ports, Low Pin Count (LPC) interface

controller, Firmware Hub (FWH) interface controller, PCI interface controller, AC-link, integrated

LAN controller, and a hub interface for communication with the GMCH.

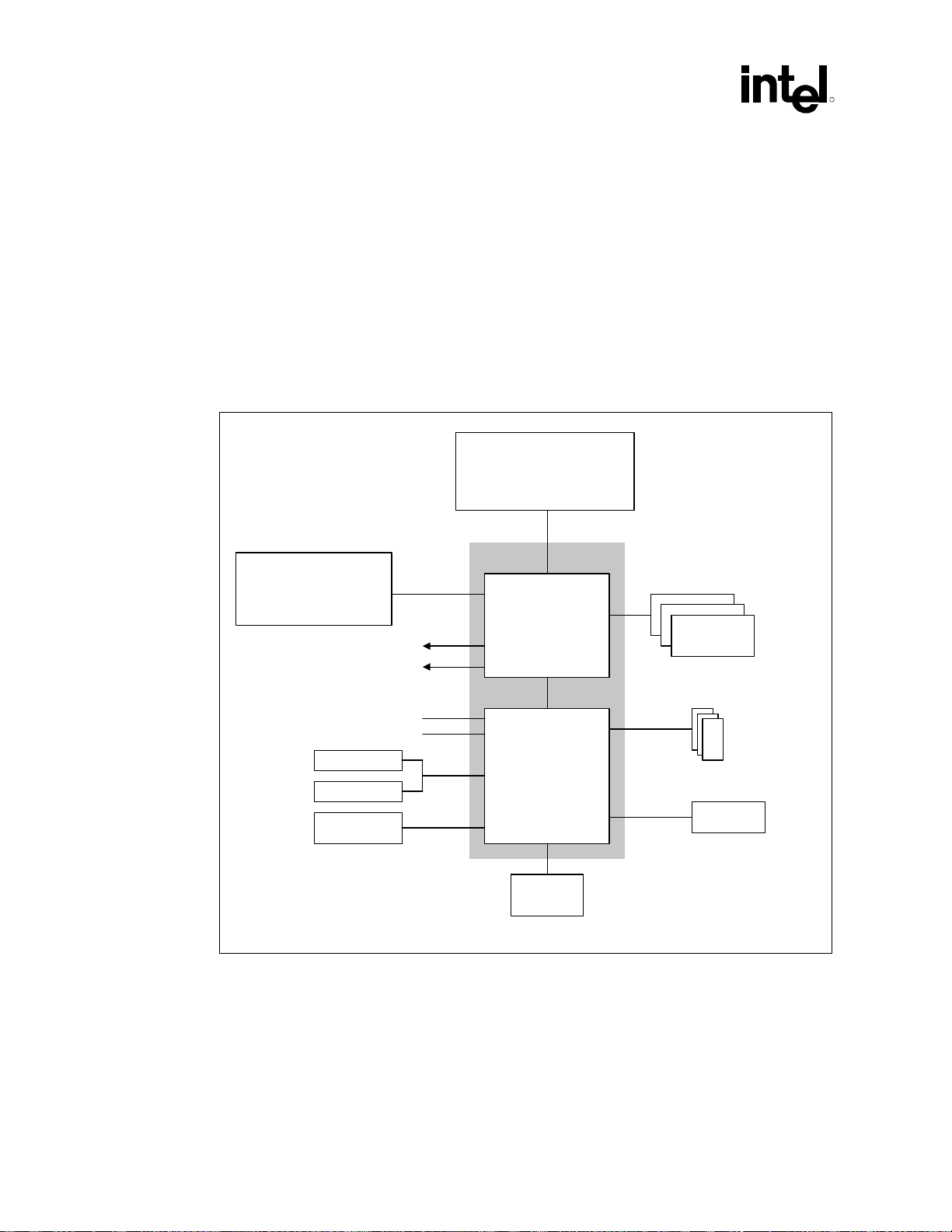

Figure 1. System Block Diagram

Intel Celeron and Pentium III

Processors Using 0.13 Micron

Technology

R

Display Cache

AIMM

(AGP in-line memory module)

Analog display out

Digital video out

Audio codec

Modem codec

LAN connect

component

4x USB

2x IDE

AC97

LAN

connect

815EG

Chipset

82815EG B-0

GMCH

82801BA ICH2

FWH

Flash BIOS

66/100/133 MHz system bus

Hub interface

PCI bus

LPC I/F

Sys_Blk_815E_B0

100/133 MHz

SDRAM

PCI slots

KBC/SIO

®

18 Intel

815EG Chipset Platform Design Guide

Page 19

Introduction

R

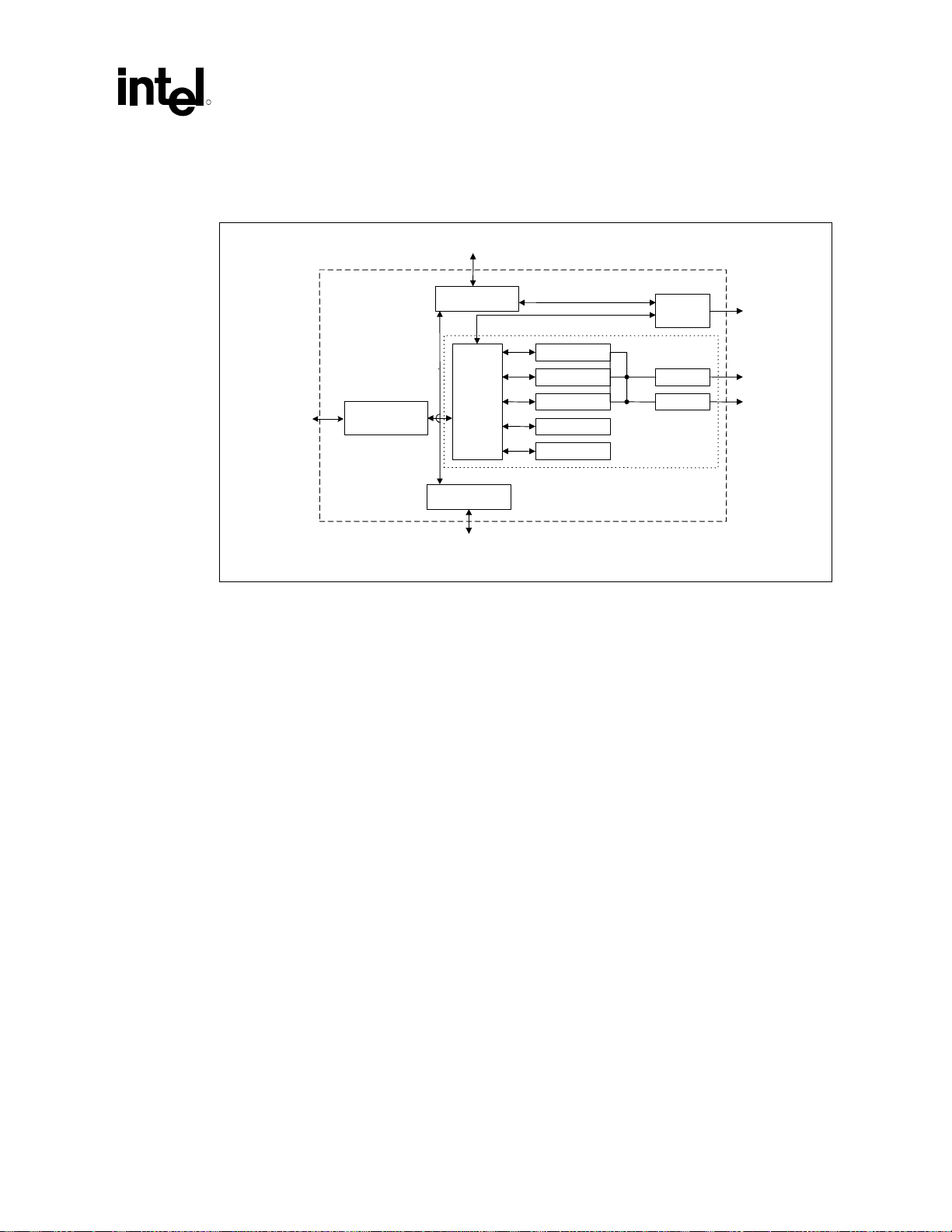

1.4.2 Component Features

Figure 2. Component Block Diagram

System bus (66/100/133 MHz)

Processor I/F

Data

stream

GPA or AIMM

Card

Local memory I/F

control &

dispatch

Hub I/F

Hub

1.4.2.1 Intel® 82815EG GMCH Features

• Processor/System Bus Support

Optimized for Celeron and Pentium III processors which use 0.13 micron technology at

133 MHz system bus frequency

Support for Celeron and Pentium III processors (CPUID = 068xh); at 66 MHz system bus

frequency

Supports 32-bit AGTL or AGTL+ bus addressing

Supports uniprocessor systems

Utilizes AGTL and AGTL+ bus driver technology (gated AGTL/AGTL+ receivers for

reduced power)

Primary display

Overlay

H/W cursor

3D pipeline

2D (blit engine)

System

memory I/F

RAMDAC

FP / TVout

Internal graphics

comp_blk_1

SDRAM

100/133

MHz, 64 bit

Monitor

Digital

video out

• Integrated DRAM controller

32 MB to 512 MB using 16-Mb/64-Mb/128-Mb technology

Supports up to three double-sided DIMMS (6 rows)

100 MHz, 133 MHz SDRAM interface

64-bit data interface

Standard Synchronous DRAM (SDRAM) support (x-1-1-1 access)

Supports only 3.3 V DIMM DRAM configurations

No registered DIMM support

Support for symmetrical and asymmetrical DRAM addressing

Support for x8, x16 DRAM device widths

Refresh mechanism: CAS-before-RAS only

Support for DIMM serial PD (presence detect) scheme via SMbus interface

Suspend-To-RAM (STR) power management support via self-refresh mode using CKE

®

815EG Chipset Platform Design Guide 19

Intel

Page 20

Introduction

• Integrated Graphics Controller

Full 2D/3D/DirectX acceleration

Texture-mapped 3D with point sampled, bilinear, trilinear, and anisotropic filtering

Hardware setup with support for strips and fans

Hardware motion compensation assist for software MPEG/DVD decode

Digital Video Out interface for support of digital displays and TV-Out

PC99A/PC2001 compliant

Integrated 230 MHz DAC

• Integrated Local Graphics Memory Controller (Display Cache)

0 MB to 4 MB (via Graphics Performance Accelerator) using zero, one or two parts

32-bit data interface

133 MHz memory clock

Supports only 3.3 V SDRAMs

• Packaging/Power

544-ball mBGA CSP with local memory port

1.85 V core and mixed 3.3 V, 1.5 V, and AGTL+ IO. Note that the 82801BA ICH2 has a

1.8 V requirement and the 82815EG GMCH has a 1.85 V requirement. Instead of using

separate voltage regulators to meet these requirements, a single voltage regulator can be

set to 1.795 V to 1.910 V. See Figure 98. Power Delivery Map.

R

1.4.2.2 Intel® 815 to 815G/EG Signal Name Changes

Intel 82815G/EG pins associated with AGP signals have name changes. The following table shows

the old Intel 82815 signal name, the ball number, and the new Intel 82815G/EG signal name. New

designs for new 815G/EG boards should use pull-ups or pull-downs as indicated by the 815G/EG

signal name. 815 boards using 815GEG devices may leave the associated 815 pins in the original

815 configuration.

Table 1. Intel

NOTES:

®

82815 to Intel® 82815G Pin Name Changes

Intel® 815 Signal

Name

WBF# AB24 PU

AD_STB0 M22 PD

AD_STB0# L23 PU

AD_STB1 U22 PD

AD_STB1# V23 PU

SB_STB Y23 PD

SB_STB# AA24 PU

GRCOMP J26 PD40

AGPREF J24 0.5VDDQ

G_GNT# AD25 NC

G_AD[24] V25 PD

NC = No Connect. These pins should float

PU = Pull-up to 3.3 V through a weak pull-up resistor. (8.2 kΩ to 10 kΩ resistor.)

PD = Pull-down. These pins should be pulled down to ground through a weak pull- down resistor.

(8.2 kΩ to 10 kΩ resistor.)

PD40 = Pull-down to VSS using a 40 resistor.

0.5VDDQ = Set to 50% of the VDDQ voltage supply level.

Ball# Intel® 815G/EG

Signal Name

®

20 Intel

815EG Chipset Platform Design Guide

Page 21

Introduction

R

1.4.2.3 Intel® 82801BA I/O Controller Hub 2 (ICH2)

The Intel® I/O Controller Hub 2 allows the I/O subsystem to access the rest of the system, as

follows:

• Upstream accelerated hub architecture interface for access to the GMCH

• PCI 2.2 interface (6 PCI Request/Grant pairs)

• 2 channel Ultra ATA/100 Bus Master IDE controller

• USB controller (Expanded capabilities for 4 ports)

• I/O APIC

• SMBus controller

• FWH interface

• LPC interface

• AC ’97 Component Specification, Revision 2.2 interface

• Integrated system management controller

• Alert-on-LAN*

• Integrated LAN controller

• Packaging/Power

360 EBGA

1.8 V (± 3% within margins of 1.795 V to 1.9 V) core and 3.3 V standby

1.4.2.4 Firmware Hub (FWH)

The hardware features of the firmware hub include:

• An integrated hardware Random Number Generator (RNG)

• Register-based locking

• Hardware-based locking

• Five General Purpose Interrupts (GPI)

• Packaging/Power

40L TSOP and 32L PLCC

3.3 V core and 3.3 V / 12V for fast programming

1.4.3 Platform Initiatives

1.4.3.1 Universal Motherboard Design

The 815EG chipset platform for use with the universal socket 370 allows systems designers to

build one system that is compatible with the Pentium III processor (CPUID=068xh), Celeron

processor (CPUID=068xh), and future 0.13 micron socket 370 processors. When implemented,

the 815EG chipset universal socket 370 platform can detect which processor is present in the

socket and function accordingly.

®

815EG Chipset Platform Design Guide 21

Intel

Page 22

Introduction

1.4.3.2 Intel® PC 133

The PC133 initiative provides the memory bandwidth necessary to obtain high performance from

the processor and AGP graphics controller. The platform’s SDRAM interface supports 100 MHz

and 133 MHz operation. The latter delivers 1.066 GB/s of theoretical memory bandwidth

compared with the 800 MB/s theoretical memory bandwidth of 100 MHz SDRAM systems.

1.4.3.3 Accelerated Hub Architecture Interface

As I/O speeds increase, the demand placed on the PCI bus by the I/O bridge becomes significant.

With the addition of AC ’97 and Ultra ATA/100, coupled with the existing USB, I/O requirements

could impact PCI bus performance. The 815EG platform’s accelerated hub architecture ensures

that the I/O subsystem, both PCI and the integrated I/O features (IDE, AC ’97, USB, LAN),

receives adequate bandwidth. By placing the I/O bridge on the accelerated hub architecture

interface instead of PCI, I/O functions integrated into the ICH2 and the PCI peripherals are

ensured the bandwidth necessary for peak performance.

1.4.3.4 Internet Streaming SIMD Extensions

R

The Pentium III processors provide 70 new SIMD (single instruction, multiple data) instructions.

The new extensions are floating-point SIMD extensions. Intel

integer SIMD instructions. The Internet Streaming SIMD extensions complement the MMX

technology SIMD instructions and provide a performance boost to floating-point-intensive 3D

applications.

1.4.3.5 Integrated LAN Controller

The 815EG chipset platform incorporates an ICH2 integrated LAN Controller. Its bus master

capabilities enable the component to process high-level commands and perform multiple

operations; this lowers processor utilization by off-loading communication tasks from the

processor.

The ICH2 functions with several options of LAN connect components to target the desired market

segment. The 82562EH provides a HomePNA 1 Mbit/sec connection. The 82562ET provides a

basic Ethernet 10/100 connection. The 82562EM provides an Ethernet 10/100 connection with the

added flexibility of Alert on LAN. More advanced LAN solutions can be implemented with the

82550 or other PCI based product offerings.

1.4.3.6 Ultra ATA/100 Support

The 815EG chipset platform incorporates an IDE controller with two sets of interface signals

(primary and secondary) that can be independently enabled, tri-stated or driven low. The

component supports Ultra ATA/100, Ultra ATA/66, Ultra ATA/33, and multiword PIO modes for

transfers up to 100 MB/sec.

®

MMX™ technology provides

1.4.3.7 Expanded USB Support

The 815EG chipset platform contains two USB Host Controllers. Each Host Controller includes a

root hub with two separate USB ports each, for a total of 4 USB ports. The addition of a second

USB Host Controller expands the functionality of the platform.

®

22 Intel

815EG Chipset Platform Design Guide

Page 23

Introduction

R

1.4.3.8 Manageability and Other Enhancements

The 815EG chipset platform integrates several functions designed to manage the system and lower

the total cost of ownership (TCO) of the system. These system management functions are designed

to report errors, diagnose the system, and recover from system lockups, without the aid of an

external microcontroller.

SMBus

The ICH2 integrates an SMBus controller. The SMBus provides an interface for managing

peripherals such as serial presence detection (SPD) and thermal sensors. The slave interface allows

an external microcontroller to access system resources.

Interrupt Controller

The interrupt capabilities of the platform expand support for up to 8 PCI interrupt pins and

PCI 2.2 message-based interrupts. In addition, the ICH2 supports system bus interrupt delivery.

Firmware Hub (FWH)

The platform supports firmware hub BIOS memory sizes up to 8 MB for increased system

flexibility.

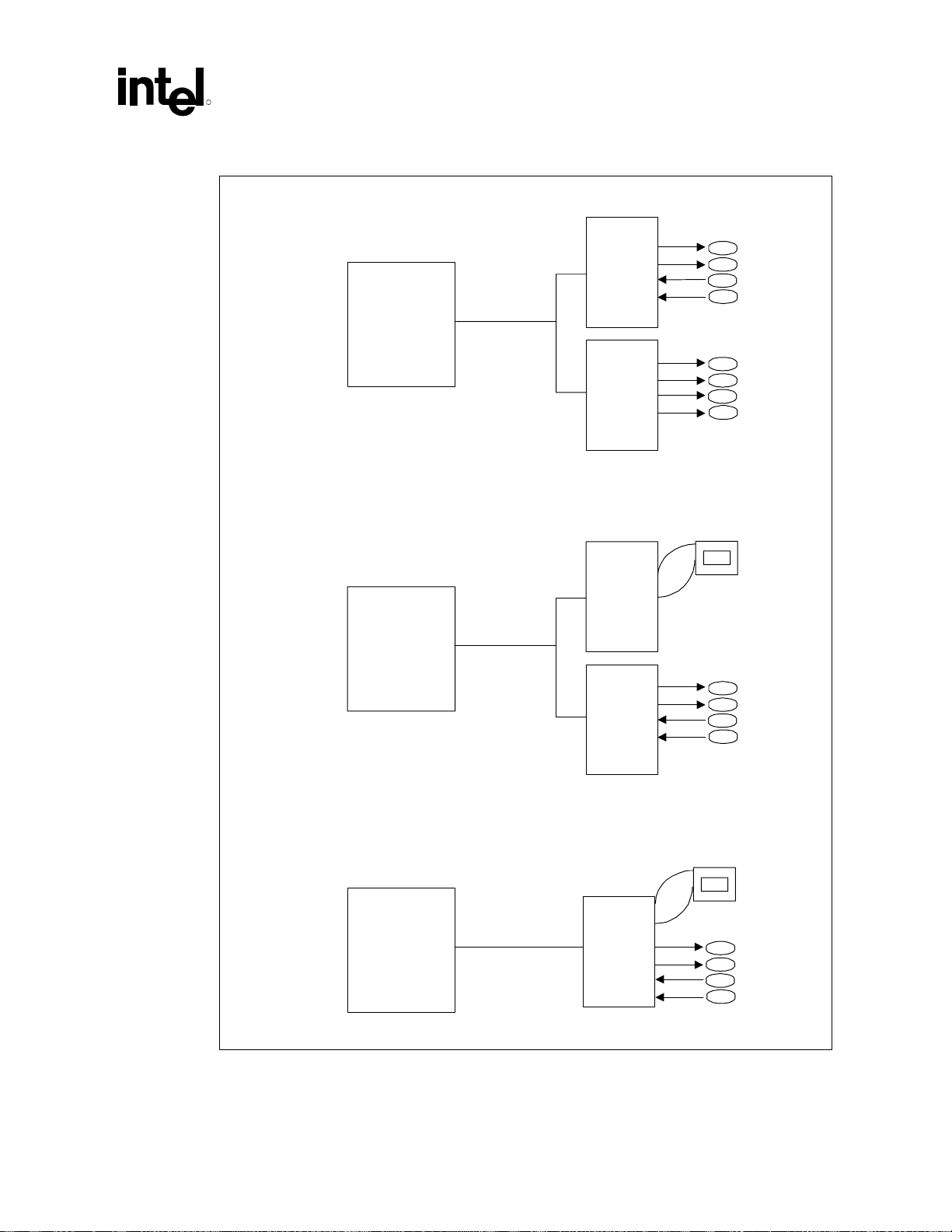

1.4.3.9 AC ’97 6-Channel Support

The AC ’97 v2.2 defines a digital interface that can be used to attach an audio codec (AC), a

modem codec (MC), an audio/modem codec (AMC), or both an AC and an MC. The AC ’97 v2.2

defines the interface between the system logic and the audio or modem codec known as the “AClink.”

The 815EG chipset platform’s AC ’97 (with the appropriate codecs) not only replaces ISA audio

and modem functionality, but also improves overall platform integration by incorporating the AClink. Using the platform’s integrated AC-link reduces cost and eases migration from ISA.

By using an audio codec, the AC-link allows for cost-effective, high-quality, integrated audio. In

addition, an AC ’97 soft modem can be implemented with the use of a modem codec. Several

system options exist when implementing AC ’97. The 815EG chipset platform’s integrated digital

link allows several external codecs to be connected to the ICH2. The system designer can provide

audio with an audio codec, a modem with a modem codec, or an integrated audio/modem codec

(Figure 3c). The digital link is expanded to support two audio codecs (Figure 3a) or a combination

of an audio and modem codec (Figure 3b).

®

815EG Chipset Platform Design Guide 23

Intel

Page 24

Introduction

Modem implementation for different countries must be taken into consideration, as telephone

systems may vary. By implementing a split design, the audio codec can be on board, and the

modem codec can be placed on a riser. is developing an AC-link connector. With a single

integrated codec, or AMC, both audio and modem can be routed to a connector near the rear panel

where the external ports can be located.

The digital link in the ICH2 is AC ’97 v2.2 compliant, supporting two codecs with independent

PCI functions for audio and modem. Microphone input and left and right audio channels are

supported for a high-quality, two-speaker audio solution. Wake-on-ring-from-suspend also is

supported with the appropriate modem codec.

The 815EG chipset platform expands audio capability with support for up to six channels of PCM

audio output (i.e., full AC3 decode). Six-channel audio consists of Front Left, Front Right, Back

Left, Back Right, Center and Woofer, for a complete surround sound effect. ICH2 has expanded

support for two audio codecs on the AC-link.

R

®

24 Intel

815EG Chipset Platform Design Guide

Page 25

Introduction

®

®

R

Figure 3. AC ’97 Audio and Modem Connections

a) AC'97 with Audio C odecs ( 4-Channel Secondary)

AC’97

Audio

Codec

ICH2

Intel

360 EBGA

AC-link

AC’97

Audio

Codec

Audio Port

Audio Port

b) AC'97 with Modem and Audio Codecs

Intel® ICH2

360 EBGA

c) AC'97 with Audio/Modem Codec

ICH2

Intel

360 EBGA

AC-link

AC-link

Modem Port

AC’97

Modem

Codec

AC’97

Audio

Codec

Audio Port

Modem Port

AC’97

Audio/

Modem

Codec

Audio Port

®

815EG Chipset Platform Design Guide 25

Intel

Page 26

Introduction

1.4.3.10 Low-Pin-Count (LPC) Interface

In the 815EG chipset platform, the Super I/O (SIO) component has migrated to the Low-PinCount (LPC) interface. Migration to the LPC interface allows for lower-cost Super I/O designs.

The LPC Super I/O component requires the same feature set as traditional Super I/O components.

It should include a keyboard and mouse controller, floppy disk controller, and serial and parallel

ports. In addition to the Super I/O features, an integrated game port is recommended because the

AC ’97 interface does not provide support for a game port. In systems with ISA audio, the game

port typically existed on the audio card. The fifteen-pin game port connector provides for two

joysticks and a two-wire MPU-401 MIDI interface. Consult your preferred Super I/O vendor for a

comprehensive list of the devices offered and the features supported.

In addition, depending on system requirements, specific system I/O requirements may be

integrated into the LPC Super I/O. For example, a USB hub may be integrated to connect to the

ICH2 USB output and extend it to multiple USB connectors. Other SIO integration targets include

a device bay controller or an ISA-IRQ-to-serial-IRQ converter to support a PCI-to-ISA bridge.

Contact your Super I/O vendor to ensure the availability of desired LPC Super I/O features.

R

®

26 Intel

815EG Chipset Platform Design Guide

Page 27

General Design Considerations

R

2 General Design Considerations

This design guide provides motherboard layout and routing guidelines for systems based on the

815EG chipset for use with the universal socket 370. The document does not discuss the functional

aspects of any bus or the layout guidelines for an add-in device.

If the guidelines listed in this document are not followed, it is very important that thorough signal

integrity and timing simulations be completed for each design. Even when the guidelines are

followed, critical signals should be simulated to ensure the proper signal integrity and flight time.

As bus speeds increase, it is imperative that the guidelines documented are followed precisely.

Any deviation from these guidelines should be simulated.

The trace impedance typically noted (i.e., 60 Ω ± 15%) is the “nominal” trace impedance for a

5 mil-wide trace. That is, it is the impedance of the trace when not subjected to the fields created

by changing current in neighboring traces. When calculating flight times, it is important to

consider the minimum and maximum impedance of a trace, based on the switching of neighboring

traces. The use of wider spaces between the traces can minimize this trace-to-trace coupling. In

addition, these wider spaces reduce crosstalk and settling time.

Coupling between two traces is a function of the coupled length, the distance separating the traces,

the signal edge rate, and the degree of mutual capacitance and inductance. To minimize the effects

of trace-to-trace coupling, follow the routing guidelines documented in this section.

The routing guidelines in this design guide have been created using a PCB stack-up similar to that

shown in Figure 4. If this stack-up is not used, extremely thorough simulations of every interface

must be completed. Using a thicker dielectric (prepreg) will make routing very difficult or

impossible.

2.1 Nominal Board Stack-Up

The 815EG chipset platform requires a board stack-up yielding a target impedance of 60 Ω ± 15%

with a 5-mil nominal trace width. Figure 4 shows an example stack-up that achieves this. It is a 4layer printed circuit board (PCB) construction using 53%-resin FR4 material.

Figure 4. Board Construction Example for 60 ΩΩΩΩ Nominal Stack-up

Component-side layer 1: ½ oz. Cu

4.5-mil prepreg

Power plane layer 2: 1 oz. Cu

~48-mil core

Ground layer 3: 1 oz. Cu

4.5-mil prepreg

Solder-side layer 4: ½ oz. Cu

Total thickness:

62 mils

board_4.5mil_stackup

®

815EG Chipset Platform Design Guide 27

Intel

Page 28

General Design Considerations

2.2 Future Designs Require Pull-Ups and Pull-Downs on Any Unused Input and I/O Pins