Page 1

Intel Corporation assum es no responsibility for the use of any circui try other than ci rcuitry embodied in an Intel product. No other circuit patent

li

censes are implied. Information contained herein supersedes previously published specifications on these devices from Intel.

© INTEL CORPORATION, 2004 August 2004 Order Number: 272206-003

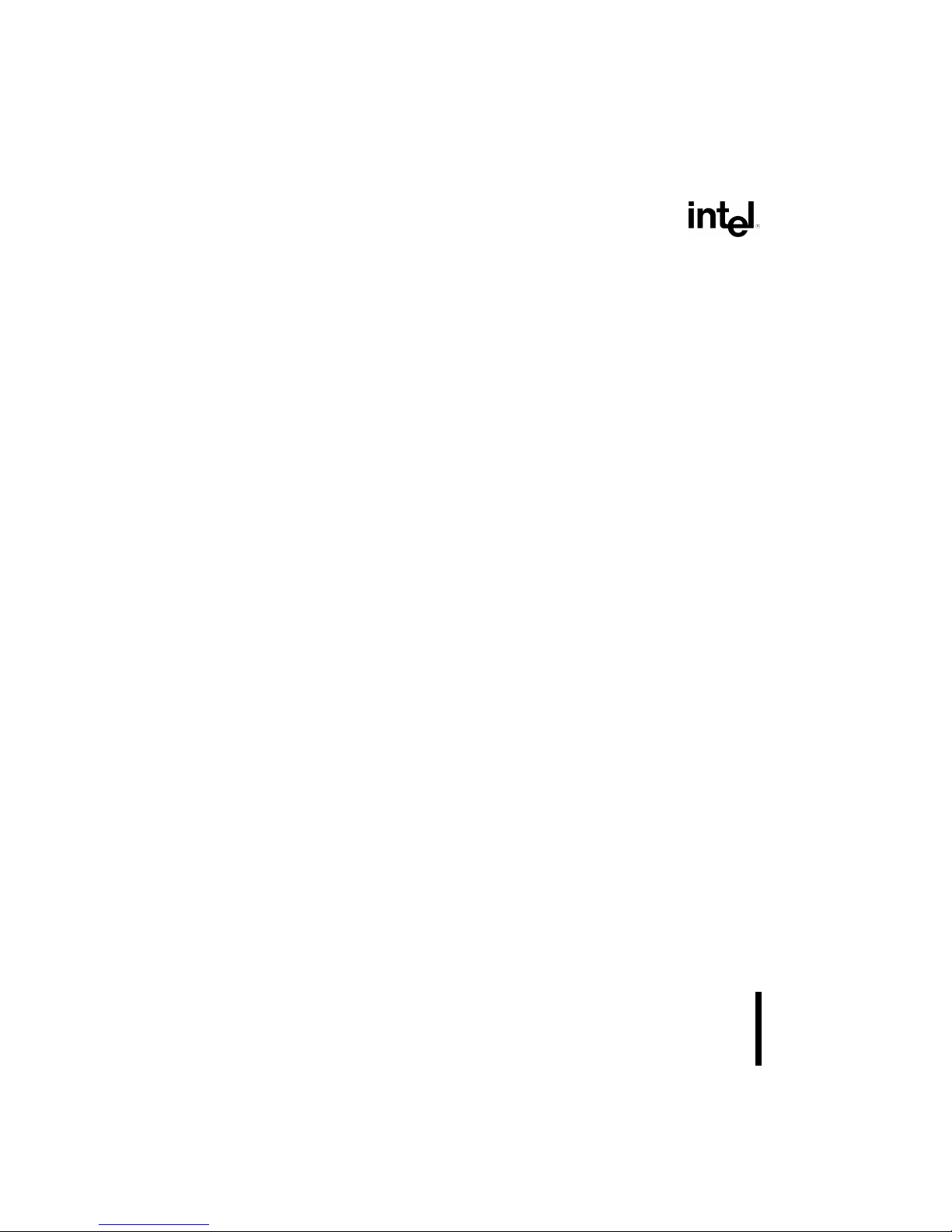

80960SA

EMBEDDED 32-BIT MICROPROCESSOR

WITH

16-BIT BURST DATA BUS

The 80960SA is a member of Intel’s i960® 32-bit processor family, which is designed especially for low cost

embedded

applications. It includes a 512-byte instruction cache and a built-in interrupt controller. The 80960SA

ha

s a large register set, multiple parallel execution units and a 16-bit burst bus. Using advanced RISC

technology, this high performance processor is capable of execution rates in excess of 7.5 million instructions

per

second

*

. The 80960SA is well-suited for a wide range of cost sensitive embedded applications including

non-impact

printers, network adapters and I/O controllers.

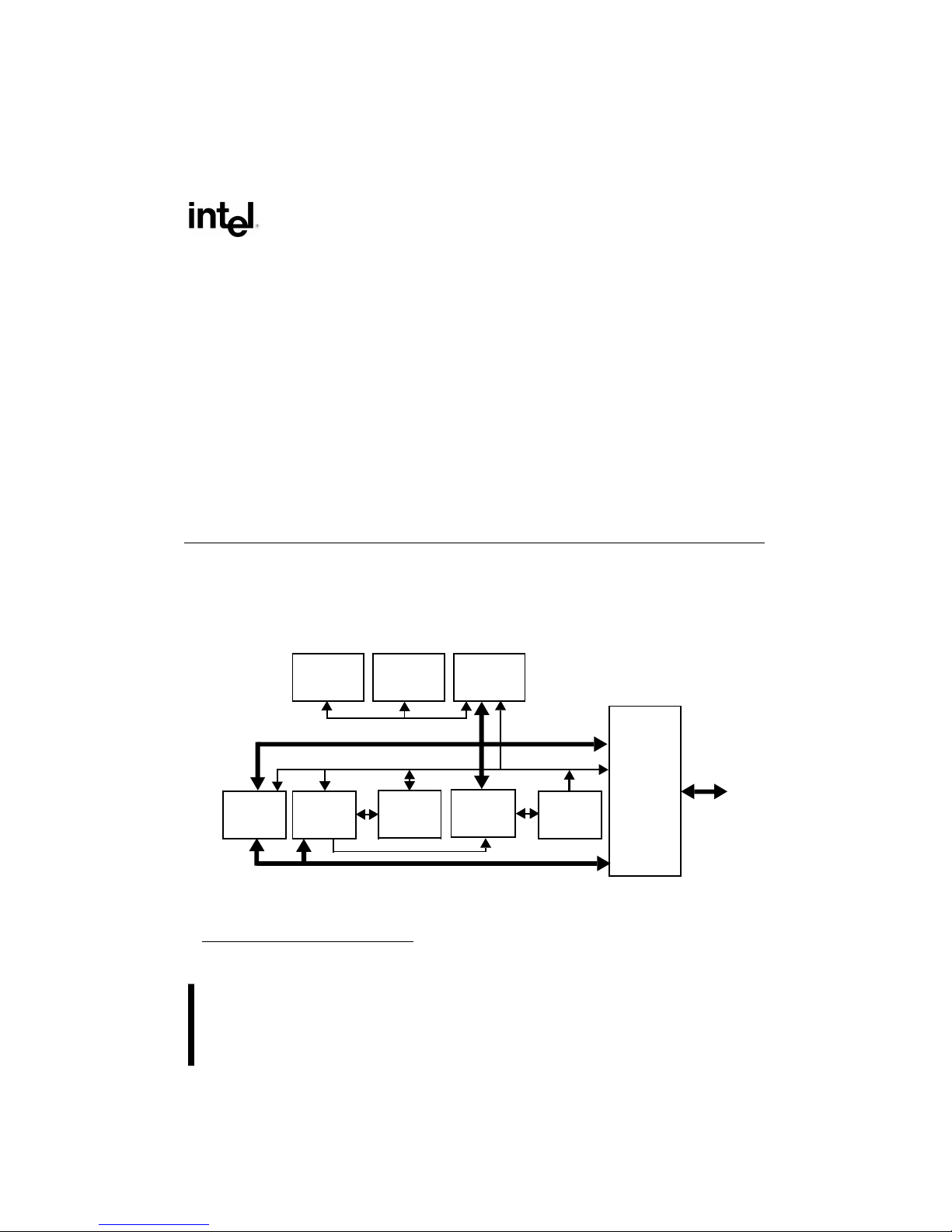

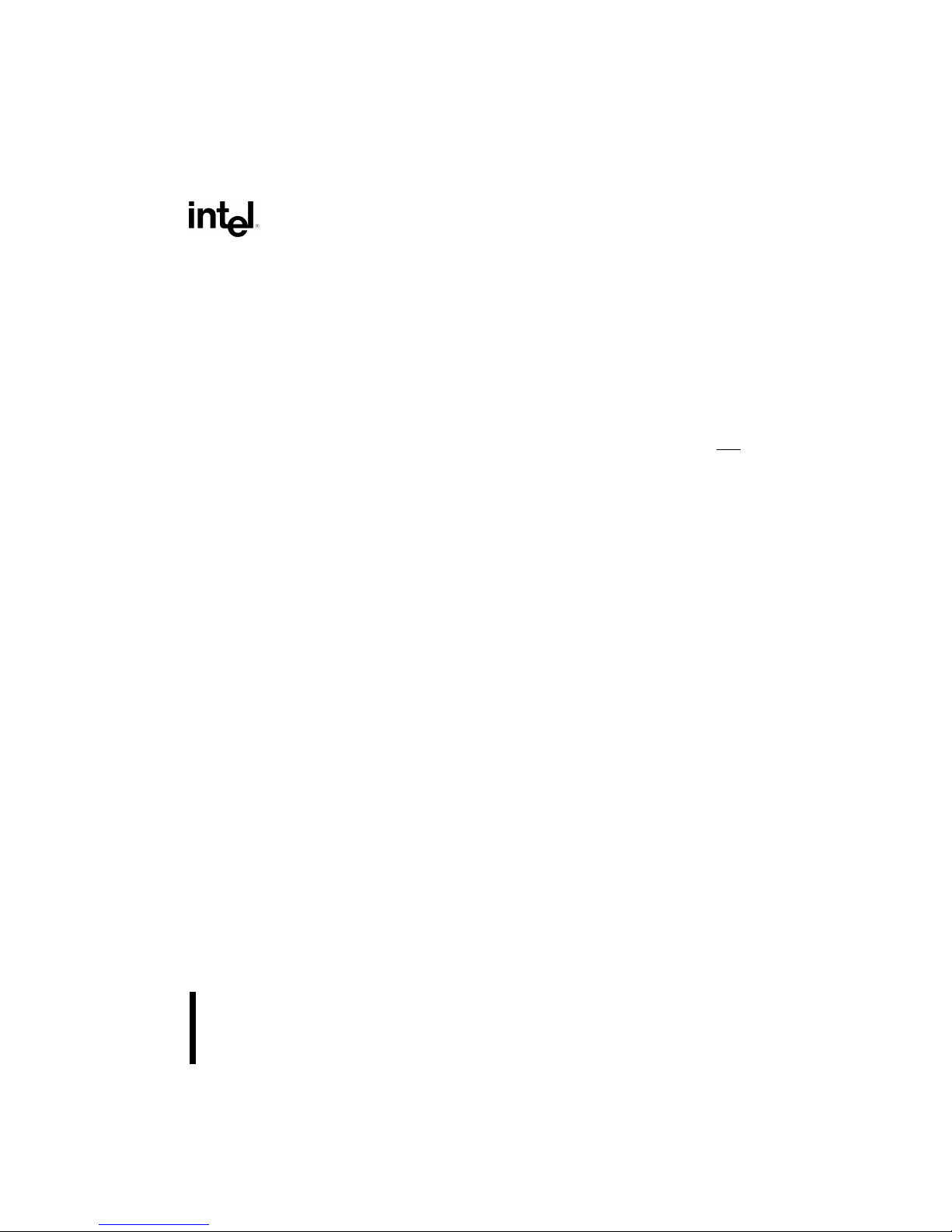

Figure

1. The 80960SA Processor’s Highly Parallel Architecture

* Relative to Digital Equipment Corporation’s VAX-11/780 at 1 MIPS (VAX-11™ is a trademark of Digital Equipment

Co

rporation)

■ High-Performance Embedded

Architectu

re

— 20 MIPS* Burst Execution at 20 MHz

— 7.5 MIPS Sustained Execution

at 20 MHz

■ 512-Byte On-Chip Instruction Cache

— Direct Mapped

— Parallel Load/Decode for Uncached

Instr

uctions

■ Multiple Register Sets

— Sixteen Global 32-Bit Registers

— Sixteen Local 32-Bit Registers

— Four Local Register Sets Stored

On-Chip

— Register Scoreboarding

■ Pin Compatible with 80960SB

■ Built-in Interrupt Controller

— 4 Direct Interrupt Pins

— 31 Priority Levels, 256 Vectors

■ Easy to Use, High Bandwidth 16-Bit Bus

— 32 Mbytes/s Burst

— Up to 16 Bytes Transferred per Burst

■ 32-Bit Address Space, 4 Gigabytes

■ 80-Lead Quad Flat Pack (EIAJ QFP)

— 84-Lead Plastic Leaded Chip Carrier

(PL

CC)

■ Software Compatible with

80960KA/KB/CA/CF

Processors

INSTRUCTION

FETCH UNI

T

512-BYTE

INSTRUCTIO

N

CACH

E

INSTRUCTION

DECODER

MICRO

-

INSTRUCTION

SEQ

UENCER

MICRO

-

INSTRUCTION

ROM

32-BIT

BU

S

CONTROL

LOGI

C

32-BIT

INSTRUCTIO

N

EXECUTIO

N

UNI

T

64-

BY 32-BIT

LOCAL

REGISTE

R

CACH

E

SIXTEEN

32-BIT

GLOBAL

REGISTERS

32-BIT

ADDRES

S

16-BIT

BURS

T

BUS

Page 2

ii

CONTENTS PAGE

1.0 THE i960® PROCESSOR ...........................................................................................................................1

1.1 Key Performance Features .................................................................................................................2

1.1.1 Memory Space And Addressing Modes ...................................................................................4

1.1.2 Data Types ...............................................................................................................................4

1.1.3 Large Register Set ...................................................................................................................4

1.1.4 Multiple Register Sets ..............................................................................................................5

1.1.5 Instruction Cache .....................................................................................................................6

1.1.6 Register Scoreboarding ........................................................................................................... 6

1.1.7 High Bandwidth Bus ................................................................................................................6

1.1.8 Interrupt Handling ....................................................................................................................6

1.1.9 Debug Features ....................................................................................................................... 6

1.1.10 Fault Detection .......................................................................................................................7

1.1.11 Built-in Testability ....................................................................................................................7

1.1.12 CHMOS ..................................................................................................................................7

2.0 ELECTRICAL SPECIFICATIONS............................................................................................................. 11

2.1 Power and Grounding .......................................................................................................................11

2.2 Power Decoupling Recommendations .............................................................................................. 11

2.3 Connection Recommendations ......................................................................................................... 11

2.4 Characteristic Curves ....................................................................................................................... 11

2.5 Test Load Circuit ...............................................................................................................................13

2.6 ABSOLUTE MAXIMUM RATINGS* ..................................................................................................14

2.7 DC Characteristics ............................................................................................................................14

2.8 AC Specifications ..............................................................................................................................15

3.0 MECHANICAL DATA................................................................................................................................21

3.1 Packaging .........................................................................................................................................21

3.2 Pin Assignment .................................................................................................................................21

3.3 Pinout ................................................................................................................................................23

3.4 Package Thermal Specifications ......................................................................................................27

3.5 Stepping Register Information ..........................................................................................................27

4.0 WAVEFORMS...........................................................................................................................................28

5.0 REVISION HISTORY ................................................................................................................................34

80960SA

EMBEDDED 32-BIT MICROPROCESSOR

WITH 16-BIT BURST DATA BUS

Page 3

iii

LIST OF FIGURES PAGE

Figure 1 The 80960SA Processor’s Highly Parallel Architecture ................................................................0

Figure 2 80960SA Programming Environment ...........................................................................................1

Figure 3 Instruction Formats ......................................................................................................................4

Figure 4 Multiple Register Sets Are Stored On-Chip ..................................................................................5

Figure 5 Connection Recommendation for LOCK

....................................................................................11

Figure 6 Typical Supply Current vs. Case Temperature ...........................................................................12

Figure 7 Typical Current vs. Frequency (Room Temp) ............................................................................. 12

Figure 8 Typical Current vs. Frequency (Hot Temp) ................................................................................. 13

Figure 9 Capacitive Derating Curve ......................................................................................................... 13

Figure 10 Test Load Circuit for Three-State Output Pins ............................................................................ 13

Figure 11 Drive Levels and Timing Relationships for 80960SA Signals ..................................................... 15

Figure 12 Processor Clock Pulse (CLK2) ...................................................................................................19

Figure 13 RESET

Signal Timing .................................................................................................................19

Figure 14 HOLD Timing ..............................................................................................................................20

Figure 15 80-Lead EIAJ Quad Flat Pack (QFP) Package ..........................................................................21

Figure 16 84-Lead Plastic Leaded Chip Carrier (PLCC) Package .............................................................22

Figure 17 Non-Burst Read and Write Transactions Without Wait States ....................................................28

Figure 18 Quad Word Burst Read Transaction With 1, 0, 0, 0, 0, 0, 0, 0 Wait States ................................29

Figure 19 Burst Write Transaction With 2, 1, 1, 1 Wait States (6-8 Bytes Transferred) ..............................30

Figure 20 Accesses Generated by Quad Word Read Bus Request,

Misaligned One Byte from Quad Word Boundary 1, 0, 0, 0, 0, 0, 0, 0 Wait States.....................31

Figure 21 Interrupt Acknowledge Cycle ......................................................................................................32

Figure 22 Cold Reset Waveform ................................................................................................................ 33

LIST OF TABLES

Table 1 80960SA Instruction Set ..............................................................................................................3

Table 2 Memory Addressing Modes .........................................................................................................4

Table 3 80960SA Pin Description: Bus Signals ........................................................................................8

Table 4 80960SA Pin Description: Support Signals ................................................................................ 10

Table 5 DC Characteristics .....................................................................................................................14

Table 6 80960SA AC Characteristics (10 MHz) ...................................................................................... 16

Table 7 80960SA AC Characteristics (16 MHz) ...................................................................................... 17

Table 8 80960SA AC Characteristics (20 MHz) ...................................................................................... 18

Table 9 80960SA QFP Pinout — In Pin Order ........................................................................................ 23

Table 10 80960SA QFP Pinout — In Signal Order ...................................................................................24

Table 11 80960SA PLCC Pinout — In Pin Order ......................................................................................25

Table 12 80960SA PLCC Pinout — In Signal Order ................................................................................. 26

Table 13 80960SA QFP Package Thermal Characteristics ...................................................................... 27

Table 14 80960SA PLCC Package Thermal Characteristics .................................................................... 27

Table 15 Die Stepping Cross Reference ...................................................................................................27

Page 4

Page 5

1

80960SA

1.0 THE i960® PROCESSOR

The 80960SA is a member of the 32-bit architecture

from Intel known as the i960 processor family. These

microprocessors were especially designed to serve

the needs of embedded applications. The embedded

market includes applications as diverse as industrial

automation, avionics, image processing, graphics

and networking. These types of applications require

high integration, low power consumption, quick

interrupt response times and high performance.

Since time to market is critical, embedded microprocessors need to be easy to use in both hardware and

software designs.

All members of the i960 processor family share a

common core architecture which utilizes RISC

technology so that, except for special functions, the

family members are object-code compatible. Each

new processor in the family adds its own special set

of functions to the core to satisfy the needs of a

specific application or range of applications in the

embedded market.

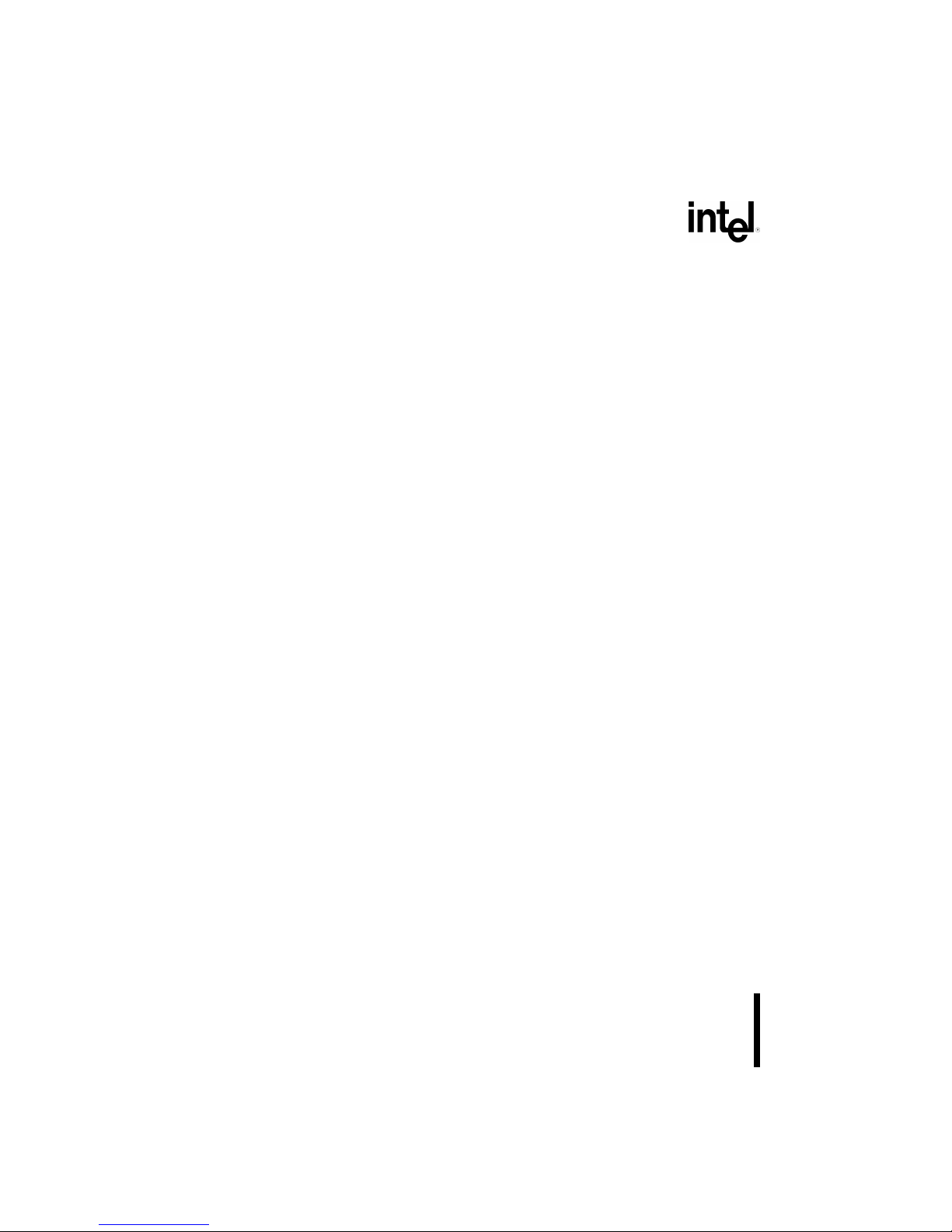

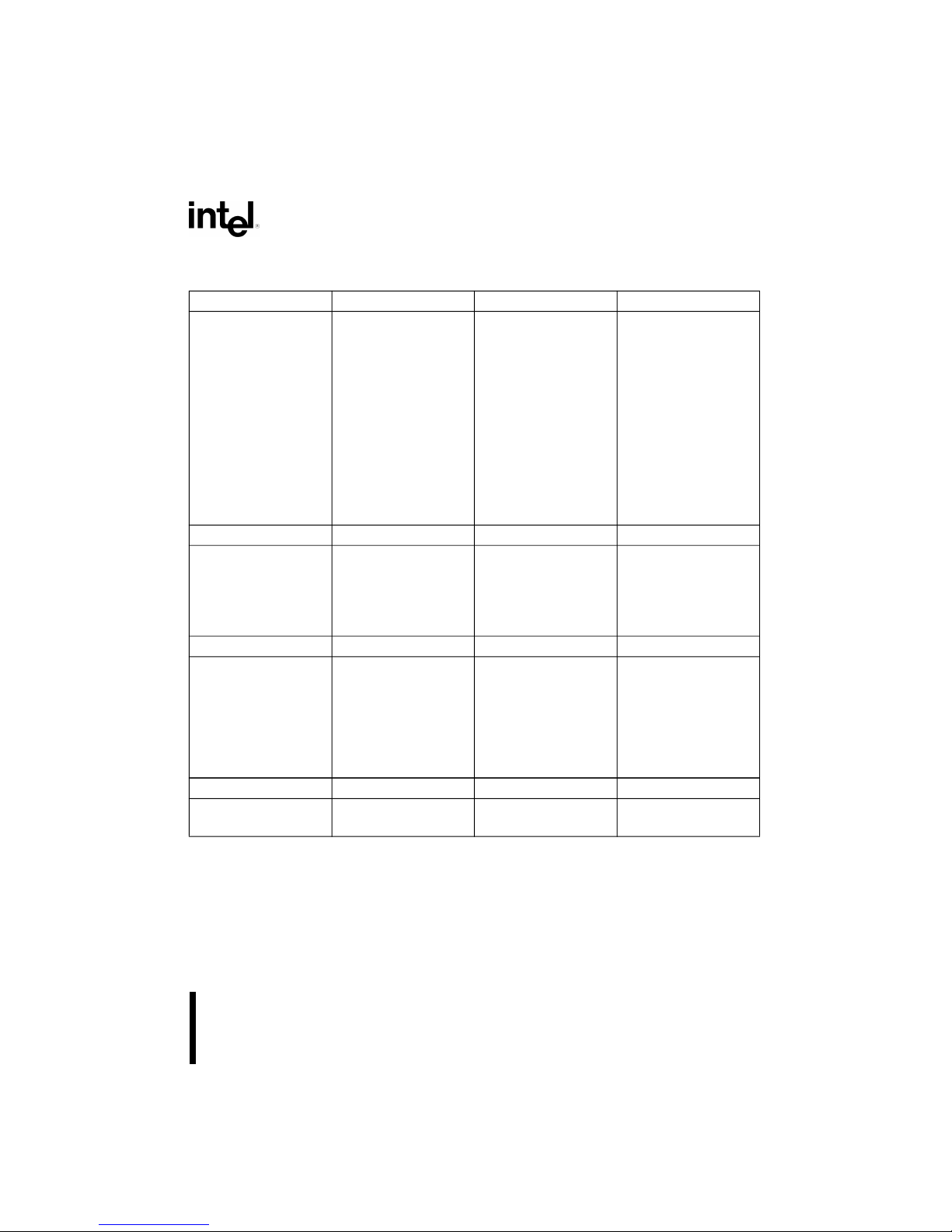

Figure 2. 80960SA Programming Environment

ARCHITECTURALLY

DEFINED

DATA STRUCTURES

FFFF FFFFH

INSTRUCTION

STREAM

INSTRUCTION

EXECUTION

PROCESSOR STATE

REGISTERS

INSTRUCTION

POINTER

ARITHMETIC

CONTROLS

PROCESS

CONTROLS

TRACE

CONTROLS

ADDRESS SPACE

SIXTEEN 32-BIT

GLOBAL REGISTERS

SIXTEEN 32-BIT

LOCAL REGISTERS

g0

g15

r0

r15

LOAD STORE

0000 0000H

INSTRUCTION

CACHE

FETCH

FOUR 80-BIT

CONTROL REGISTERS

FLOATING POINT REGISTERS

Page 6

2

80960SA

1.1 Key Performance Features

The 80960SA architecture is based on the most

recent advances in microprocessor technology and

is grounded in Intel’s long experience in the design

and manufacture of embedded microprocessors.

Many features contribute to the 80960SA’s exceptional performance:

1. Large Register Set. Having a large number of

registers reduces the number of times that a

processor needs to access memory. Modern

compilers can take advantage of this feature to

optimize execution speed. For maximum flexibility, the 80960SA provides thirty-two 32-bit

registers. (See Figure 2.)

2. Fast Instruction Execution. Simple functions

make up the bulk of instructions in most

programs so that execution speed can be

improved by ensuring that these core instructions are executed as quickly as possible. The

most frequently executed instructions — such

as register-register moves, add/subtract,

logical operations and shifts — execute in one

to two cycles. (Table 1 contains a list of instructions.)

3. Load/Store Architecture. One way to improve

execution speed is to reduce the number of

times that the processor must access memory

to perform an operation. As with other

processors based on RISC technology, the

80960SA has a Load/Store architecture. As

such, only the LOAD and STORE instructions

reference memory; all other instructions

operate on registers. This type of architecture

simplifies instruction decoding and is used in

combination with other techniques to increase

parallelism.

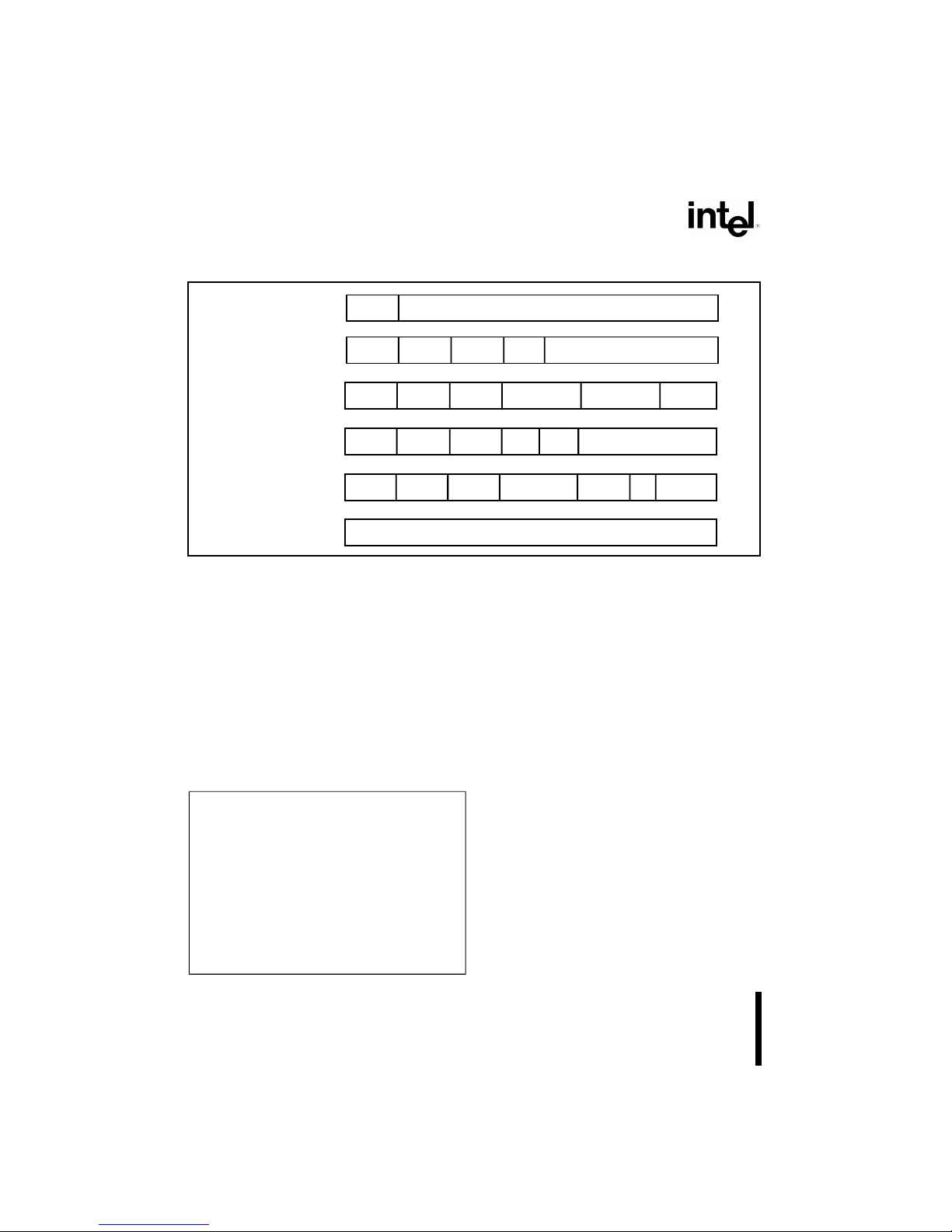

4. Simple Instruction Formats. All instructions

in the 80960SA are 32 bits long and must be

aligned on word boundaries. This alignment

makes it possible to eliminate the instruction

alignment stage in the pipeline. To simplify the

instruction decoder, there are only five

instruction formats; each instruction uses only

one format. (See Figure 3.)

5. Overlapped Instruction Execution. Load

operations allow execution of subsequent

instructions to continue before the data has

been returned from memory, so that these

instructions can overlap the load. The

80960SA manages this process transparently

to software through the use of a register scoreboard. Conditional instructions also make use

of a scoreboard so that subsequent unrelated

instructions may be executed while the conditional instruction is pending.

6. Integer Execution Optimization. When the

result of an arithmetic execution is used as an

operand in a subsequent calculation, the value

is sent immediately to its destination register.

At the same time, the value is put on a bypass

path to the ALU, thereby saving the time that

otherwise would be required to retrieve the

value for the next operation.

7. Bandwidth Optimizations. The 80960SA gets

optimal use of its memory bus bandwidth

because the bus is tuned for use with the onchip instruction cache: instruction cache line

size matches the maximum burst size for

instruction fetches. The 80960SA automatically

fetches four words in a burst and stores them

directly in the cache. Due to the size of the

cache and the fact that it is continually filled in

anticipation of needed instructions in the

program flow, the 80960SA is relatively insensitive to memory wait states. The benefit is that

the 80960SA delivers outstanding performance

even with a low cost memory system.

8. Cache Bypass. If a cache miss occurs, the

processor fetches the needed instruction then

sends it on to the instruction decoder at the

same time it updates the cache. Thus, no extra

time is spent to load and read the cache.

Page 7

3

80960SA

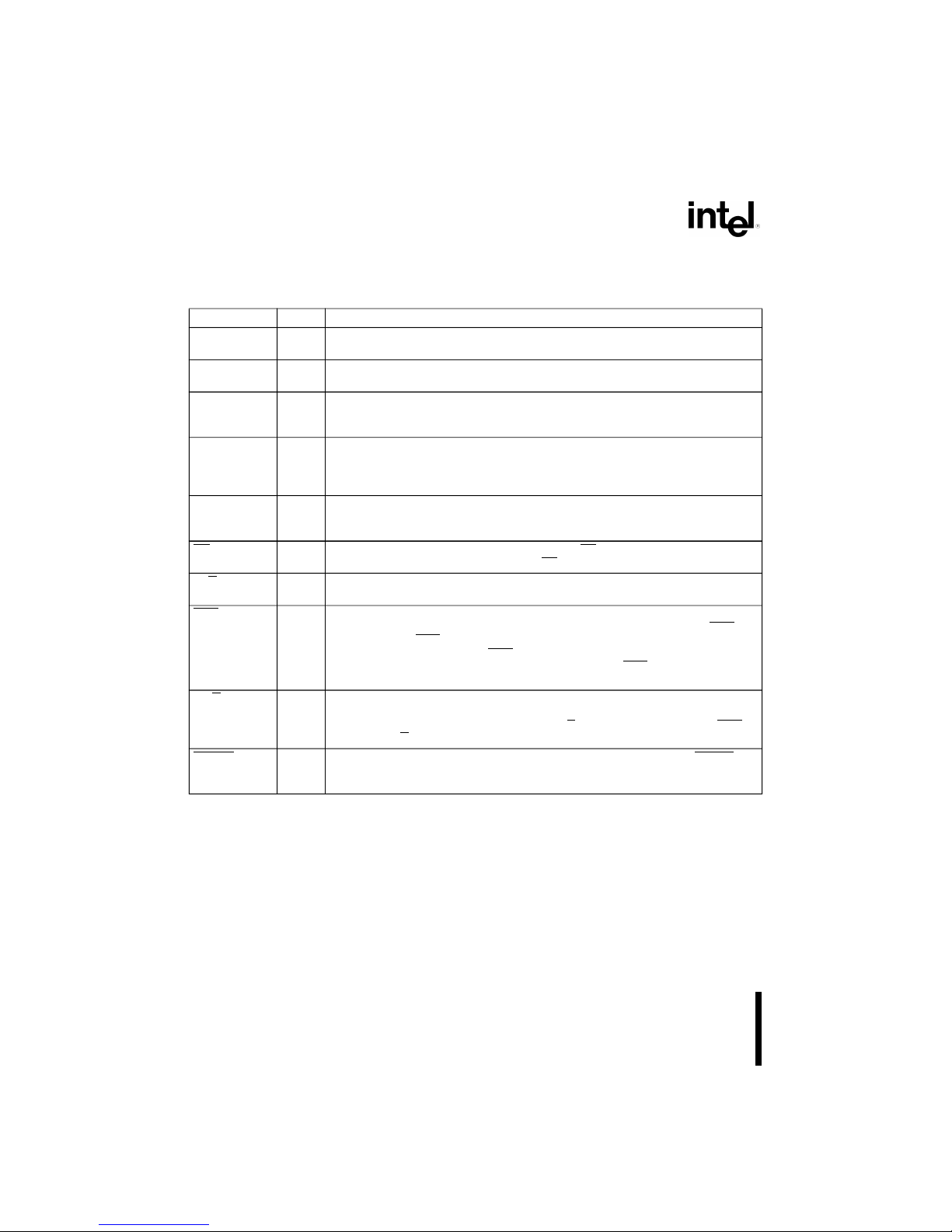

Table 1. 80960SA Instruction Set

Data Movement Arithmetic Logical Bit and Bit Field

Load

Store

Move

Load Address

Add

Subtract

Multiply

Divide

Remainder

Modulo

Shift

Extended Multiply

Extended Divide

And

Not And

And Not

Or

Exclusive Or

Not Or

Or Not

Nor

Exclusive Nor

Not

Nand

Rotate

Set Bit

Clear Bit

Not Bit

Check Bit

Alter Bit

Scan For Bit

Scan Over Bit

Extract

Modify

Comparison Branch Call/Return Fault

Compare

Conditional Compare

Compare and Increment

Compare and Decrement

Unconditional Branch

Conditional Branch

Compare and Branch

Call

Call Extended

Call System

Return

Branch and Link

Conditional Fault

Synchronize Faults

Debug Miscellaneous Decimal

Modify Trace Controls

Mark

Force Mark

Atomic Add

Atomic Modify

Flush Local Registers

Modify Arithmetic

Controls

Scan Byte for Equal

Test Condition Code

Move

Add with Carry

Subtract with Carry

Synchronous

Synchronous Load

Synchronous Move

Page 8

4

80960SA

Figure 3. Instruction Formats

Control

Compare and

Branch

Register to

Register

Memory Access--Short

Memory Access--Long

Opcode Displacement

Opcode DisplacementReg/Lit Reg M

Displacement

Opcode

Opcode

Opcode Reg

Reg

Reg Reg/Lit

Base

Base

M

Modes

Mode

Ext’d Op Reg/Lit

X Offset

Scale xx Offset

1.1.1 Memory Space And Addressing Modes

The 80960SA offers a linear programming

environment so that all programs running on the

processor are contained in a single address space.

Maximum address space size is 4 Gigabytes (2

32

bytes).

For ease of use the 80960SA has a small number of

addressing modes, but includes all those necessary

to ensure efficient execution of high-level languages

such as C. Table 2 lists the memory addressing

modes.

Table 2. Memory Addressing Modes

• 12-Bit Offset

• 32-Bit Offset

• Register-Indirect

• Register + 12-Bit Offset

• Register + 32-Bit Offset

• Register + (Index-Register x Scale-Factor)

• Register x Scale Factor + 32-Bit Displacement

• Register + (Index-Register x Scale-Factor) + 32Bit Displacement

Scale-Factor is 1, 2, 4, 8 or 16

1.1.2 Data Types

The 80960SA recognizes the following data types:

Numeric:

• 8-, 16-, 32- and 64-bit ordinals

• 8-, 16-, 32- and 64-bit integers

Non-Numeric:

• Bit

• Bit Field

• Triple Word (96 bits)

• Quad-Word (128 bits)

1.1.3 Large Register Set

The 80960SA programming environment includes a

large number of registers. In fact, 32 registers are

available at any time. The availability of this many

registers greatly reduces the number of memory

accesses required to perform algorithms, which

leads to greater instruction processing speed.

There are two types of general-purpose register:

local and global. The global registers consist of

sixteen 32-bit registers (g0 though g15). These

registers perform the same function as the general-

Page 9

5

80960SA

purpose registers provided in other popular microprocessors. The term global refers to the fact that

these registers retain their contents across

procedure calls.

The local registers, on the other hand, are procedure

specific. For each procedure call, the 80960SA

allocates 16 local registers (r0 through r15). Each

local register is 32 bits wide.

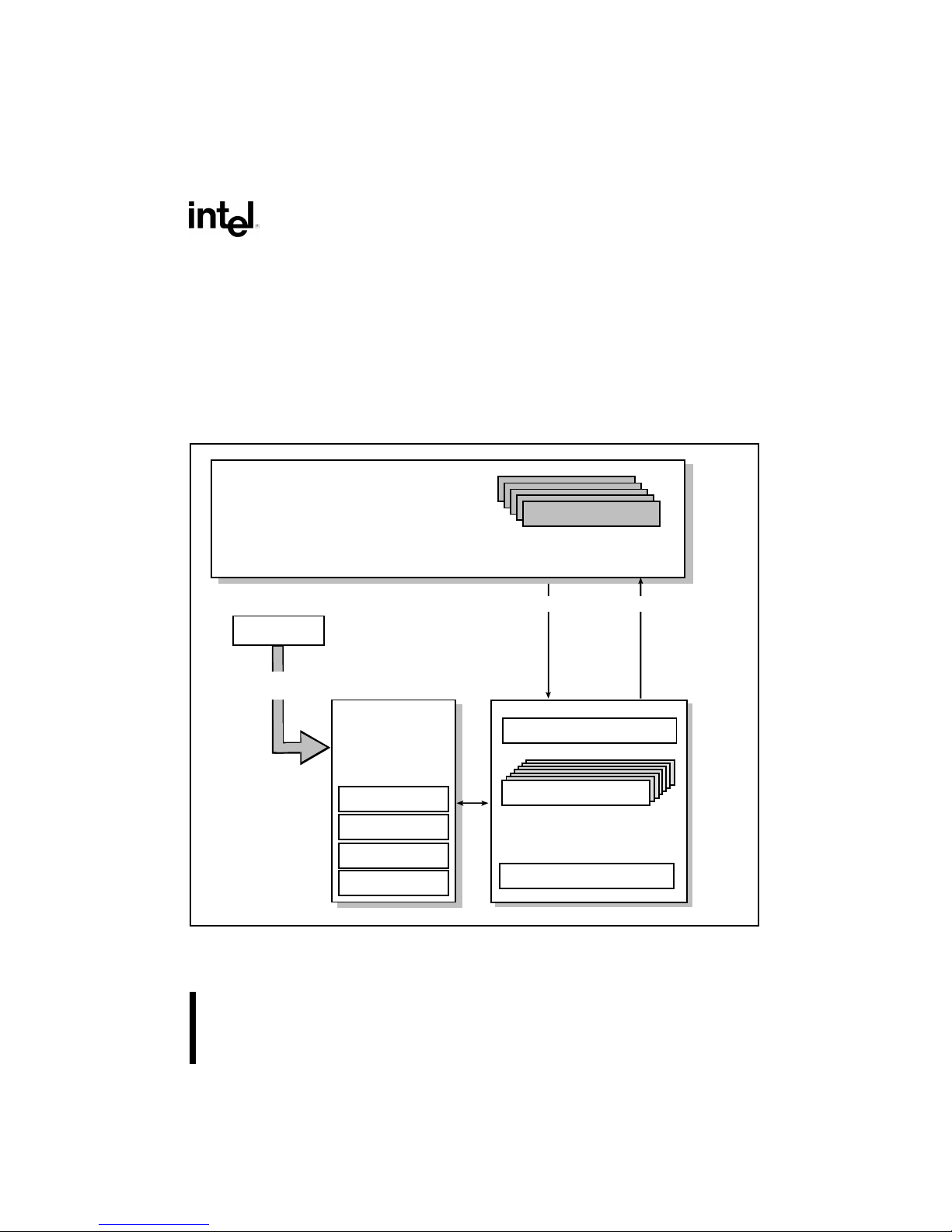

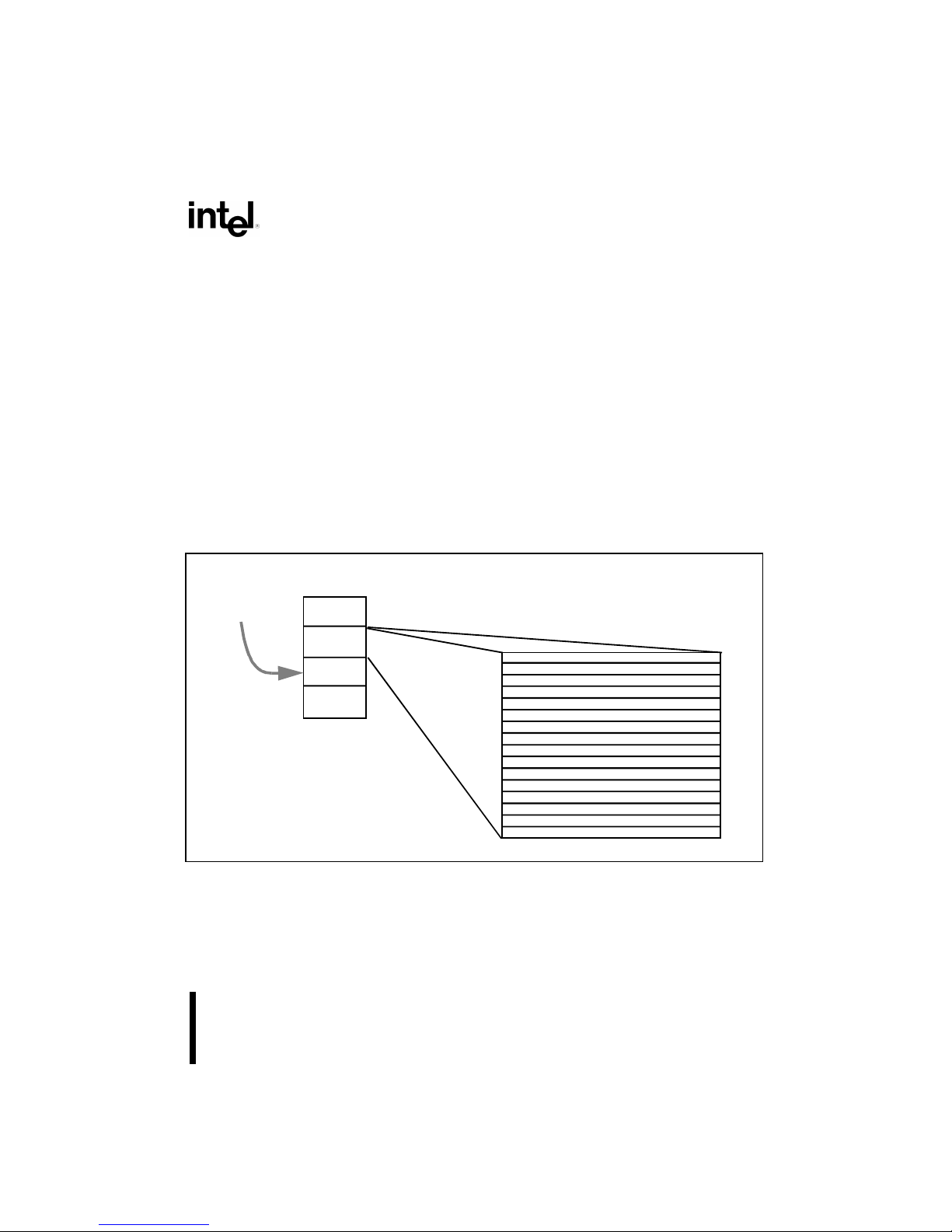

1.1.4 Multiple Register Sets

To further increase the efficiency of the register set,

multiple sets of local registers are stored on-chip

(See Figure 4). This cache holds up to four local

register frames, which means that up to three

procedure calls can be made without having to

access the procedure stack resident in memory.

Although programs may have procedure calls nested

many calls deep, a program typically oscillates back

and forth between only two to three levels. As a

result, with four stack frames in the cache, the probability of having a free frame available on the cache

when a call is made is very high. In fact, runs of

representative C-language programs show that 80%

of the calls are handled without needing to access

memory.

If four or more procedures are active and a new

procedure is called, the 80960SA moves the oldest

local register set in the stack-frame cache to a

procedure stack in memory to make room for a new

set of registers. Global register g15 is the frame

pointer (FP) to the procedure stack.

Global registers are not exchanged on a procedure

call, but retain their contents, making them available

to all procedures for fast parameter passing.

Figure 4. Multiple Register Sets Are Stored On-Chip

r

15

r

0

31

0

ONE OF FOUR

LOCAL

REGISTER SETS

REGISTER

CACHE

LOCAL REGISTER SET

Page 10

6

80960SA

1.1.5 Instruction Cache

To further reduce memory accesses, the 80960SA

includes a 512-byte on-chip instruction cache. The

instruction cache is based on the concept of locality

of reference; most programs are not usually

executed in a steady stream but consist of many

branches, loops and procedure calls that lead to

jumping back and forth in the same small section of

code. Thus, by maintaining a block of instructions in

cache, the number of memory references required to

read instructions into the processor is greatly

reduced.

To load the instruction cache, instructions are

fetched in 16-byte blocks; up to four instructions can

be fetched at one time. An efficient prefetch

algorithm increases the probability that an instruction

will already be in the cache when it is needed.

Code for small loops often fits entirely within the

cache, leading to a great increase in processing

speed since further memory references might not be

necessary until the program exits the loop. Similarly,

when calling short procedures, the code for the

calling procedure is likely to remain in the cache so it

will be there on the procedure’s return.

1.1.6 Register Scoreboarding

The instruction decoder is optimized in several ways.

One optimization method is the ability to overlap

instructions by using register scoreboarding.

Register scoreboarding occurs when a LOAD moves

a variable from memory into a register. When the

instruction initiates, a scoreboard bit on the target

register is set. Once the register is loaded, the bit is

reset. In between, any reference to the register

contents is accompanied by a test of the scoreboard

bit to ensure that the load has completed before

processing continues. Since the processor does not

need to wait for the LOAD to complete, it can execute

additional instructions placed between the LOAD

and the instruction that uses the register contents, as

shown in the following example:

ld data_2, r4

ld data_2, r5

Unrelated instruction

Unrelated instruction

add r4, r5, r6

In essence, the two unrelated instructions between

LOAD and ADD are executed “for free” (i.e., take no

apparent time to execute) because they are

executed while the register is being loaded. Up to

three load instructions can be pending at one time

with three corresponding scoreboard bits set. By

exploiting this feature, system programmers and

compiler writers have a useful tool for optimizing

execution speed.

1.1.7 High Bandwidth Bus

The 80960SA CPU resides on a high-bandwidth

address/data bus. The bus provides a direct communication path between the processor and the

memory and I/O subsystem interfaces. The

processor uses the bus to fetch instructions,

manipulate memory and respond to interrupts. Bus

features include:

• 16-bit data path multiplexed onto the lower bits of

the 32-bit address path

• Eight 16-bit half-word burst capability which

allows transfers from 1 to 16 bytes at a time

• High bandwidth reads and writes with 32

Mbytes/s burst (at 20 MHz)

Table 3 defines bus signal names and functions;

Table 4 defines other component-support signals

such as interrupt lines.

1.1.8 Interrupt Handling

The 80960SA can be interrupted in one of two ways:

by the activation of one of four interrupt pins or by

sending a message on the processor’s data bus.

The 80960SA is unusual in that it automatically

handles interrupts on a priority basis and can keep

track of pending interrupts through its on-chip

interrupt controller. Two of the interrupt pins can be

configured to provide 8259A-style handshaking for

expansion beyond four interrupt lines.

1.1.9 Debug Features

The 80960SA has built-in debug capabilities. There

are two types of breakpoints and six trace modes.

Debug features are controlled by two internal 32-bit

registers, the Process-Controls Word and the TraceControls Word. By setting bits in these control words,

a software debug monitor can closely control how

the processor responds during program execution.

Page 11

7

80960SA

The 80960SA provides two hardware breakpoint

registers on-chip which, by using a special

command, can be set to any value. When the

instruction pointer matches either breakpoint register

value, the breakpoint handling routine is automatically called.

The 80960SA also provides software breakpoints

through the use of two instructions: MARK and

FMARK. These can be placed at any point in a

program and cause the processor to halt execution

at that point and call the breakpoint handling routine.

The breakpoint mechanism is easy to use and

provides a powerful debugging tool.

Tracing is available for instructions (single step

execution), calls and returns and branching. Each

trace type may be enabled separately by a special

debug instruction. In each case, the 80960SA

executes the instruction first and then calls a trace

handling routine (usually part of a software debug

monitor). Further program execution is halted until

the routine completes, at which time execution

resumes at the next instruction. The 80960SA’s

tracing mechanisms, implemented completely in

hardware, greatly simplify the task of software test

and debug.

1.1.10 Fault Detection

The 80960SA has an automatic mechanism to

handle faults. Fault types include trace and

arithmetic faults. When the processor detects a fault,

it automatically calls the appropriate fault handling

routine and saves the current instruction pointer and

necessary state information to make efficient

recovery possible. Like interrupt handling routines,

fault handling routines are usually written to meet the

needs of specific applications and are often included

as part of the operating system or kernel.

For each of the fault types, there are numerous

subtypes that provide specific information about a

fault. The fault handler can use this specific information to respond correctly to the fault.

1.1.11 Built-in Testability

Upon reset, the 80960SA automatically conducts an

exhaustive internal test of its major blocks of logic.

Then, before executing its first instruction, it does a

zero check sum on the first eight words in memory to

ensure that the memory image was programmed

correctly. If a problem is discovered at any point

during the self-test, the 80960SA asserts its FAIL

pin

and will not begin program execution. Self test takes

approximately 24,000 cycles to complete.

System manufacturers can use the 80960SA’s selftest feature during incoming parts inspection. No

special diagnostic programs need to be written. The

test is both thorough and fast. The self-test capability

helps ensure that defective parts are discovered

before systems are shipped and, once in the field,

the self-test makes it easier to distinguish between

problems caused by processor failure and problems

resulting from other causes.

1.1.12 CHMOS

The 80960SA is fabricated using Intel’s CHMOS IV

(Complementary High Speed Metal Oxide Semiconductor) process. The 80960SA is available at 10 and

16 MHz in the QFP package and at 10, 16 and 20

MHz in the PLCC package.

Page 12

8

80960SA

Table 3. 80960SA Pin Description: Bus Signals (Sheet 1 of 2)

NAME TYPE DESCRIPTION

CLK2 I SYSTEM CLOCK provides the fundamental timing for 80960SA systems. It is

divided by two inside the 80960SA to generate the internal processor clock.

A31:16 O

T.S.

ADDRESS BUS carries the upper 16 bits of the 32-bit physical address to memory.

It is valid throughout the burst cycle; no latch is required.

AD15:1, D0 I/O

T.S.

ADDRESS/DATA BUS carries the low order 32-bit addresses and 16-bit data to

and from memory. AD15:4 must be latched since the cycle following the address

cycle carries data on the bus.

A3:1 O

T.S.

ADDRESS BUS carries the word addresses of the 32-bit address to memory.

These three bits are incremented during a burst access indicating the next word

address of the burst access. Note that A3:1 are duplicated with AD3:1 during the

address cycle.

ALE O

T.S.

ADDRESS LATCH ENABLE indicates the transfer of a physical address. ALE is

asserted during a T

a

cycle and deasserted before the beginning of the Td state. It is

active HIGH and floats to a high impedance state during a hold cycle (T

h

).

AS

O

T.S.

ADDRESS STATUS indicates an address state. AS is asserted every Ta state and

deasserted during the following T

d

state. AS is driven HIGH during reset.

W/R

O

T.S.

WRITE/READ specifies, during a Ta cycle, whether the operation is a write or read.

It is latched on-chip and remains valid during T

d

cycles.

DEN

O

T.S.

DATA ENABLE is asserted during Td cycles and indicates transfer of data on the

AD lines. The AD lines should not be driven by an external source unless DEN

is

asserted. When DEN

is asserted, outputs from the previous cycle are guaranteed

to be three-stated. In addition, DEN

deasserted indicates inputs have been

captured; therefore input hold times can be disregarded. DEN

is driven HIGH

during reset.

DT/R

O

T.S.

DATA TRANSMIT / RECEIVE indicates the direction of data transfer to and from

the bus. It is low during T

a

and Td cycles for a read or interrupt acknowledgment; it

is high during T

a

and Td cycles for a write. DT/R never changes state when DEN is

asserted. DT/R

is driven HIGH during reset.

READY

I READY indicates that data on AD lines can be sampled or removed. If READY is

not asserted during a T

d

cycle, the Td cycle is extended to the next cycle by

inserting a wait state (T

w

).

I/O = Input/Output, O = Output, I = Input, O.D. = Open Drain, T.S. = Three-state

Page 13

9

80960SA

LOCK I/O

O.D.

BUS LOCK prevents bus masters from gaining control of the bus during

Read/Modify/Write (RMW) cycles. The processor or any bus agent may assert

LOCK

.

At the start of a RMW operation, the processor examines the LOCK

pin. If the pin is

already asserted, the processor waits until it is not asserted. If the pin is not

asserted, the processor asserts LOCK

during the Ta cycle of the read transaction.

The processor deasserts LOCK

in the Ta cycle of the write transaction. While LOCK

is asserted, a bus agent can perform a normal read or write but not a RMW

operation. The processor also asserts LOCK

during interrupt-acknowledge transac-

tions.

Do not leave LOCK

unconnected. It must be pulled high for the processor to

function properly.

ONCE MODE: The LOCK

pin is sampled during reset. If it is asserted LOW at the

end of reset, all outputs will be three-stated until the part is reset again. ONCE

mode is used in conjunction with an in-circuit emulator.

BE1:0

O

T.S.

BYTE ENABLE LINES specify which data bytes (up to two) on the bus take part in

the current bus cycle. BE1

corresponds to AD15:8; BE0 corresponds to AD7:1, D0.

The byte enable lines are asserted appropriately during each data cycle.

INITIALIZATION FAILURE indicates that the processor has failed to initialize

correctly. The failure state is indicated by a combination of BLAST

asserted and

BE1:0

not asserted. This condition occurs after RESET is deasserted and before

the first bus transaction begins. FAIL

is asserted while the processor performs a

self-test. If the self-test completes successfully, FAIL

is deasserted. The processor

then performs a zero checksum on the first eight words of memory, If it fails, FAIL

is

asserted for a second time and remains asserted; if it passes, system initialization

continues and FAIL

remains deasserted.

HOLD I HOLD indicates a request from an external bus master to acquire the bus. When

the processor receives HOLD and grants bus control to another master, it floats its

three-state bus lines, then asserts HLDA and enters the T

h

state. When HOLD is

deasserted, the processor deasserts HLDA and enters the T

i

or Ta state.

HLDA O

T.S.

HOLD ACKNOWLEDGE notifies an external bus master that the processor has

relinquished control of the bus. This signal is always driven. At reset it is driven

LOW.

BLAST

/FAIL O

T.S.

BURST LAST indicates the last data cycle (Td) of a burst access. It is asserted low

during the last T

d

and associated with Twcycles in a burst access.

INITIALIZATION FAILURE indicates that the processor has failed to initialize

correctly. The failure state is indicated by a combination of BLAST

asserted and

BE1:0

not asserted. This condition occurs after RESET is deasserted and before

the first bus transaction begins. FAIL

is asserted while the processor performs a

self-test. If the self-test completes successfully, FAIL

is deasserted. The processor

then performs a zero checksum on the first eight words of memory, If it fails, FAIL

is

asserted for a second time and remains asserted; if it passes, system initialization

continues and FAIL

remains deasserted.

Table 3. 80960SA Pin Description: Bus Signals (Sheet 2 of 2)

NAME TYPE DESCRIPTION

I/O = Input/Output, O = Output, I = Input, O.D. = Open Drain, T.S. = Three-state

Page 14

10

80960SA

Table 4. 80960SA Pin Description: Support Signals

NAME TYPE DESCRIPTION

RESET

I RESET clears the processor’s internal logic and causes it to reinitialize.

During RESET

assertion, the input pins are ignored (except for INT0, INT1, INT3,

LOCK

), the three-state output pins are placed in a HIGH impedance state (except

for DT/R

, DEN, and AS) and other output pins are placed in their non-asserted

states.

RESET

must be asserted for at least 41 CLK2 cycles for a predictable reset.

Optionally, for a synchronous reset, the LOW and HIGH transition of RESET

should occur after the rising edge of both CLK2 and the external bus CLK and

before the next rising edge of CLK2.

The interrupt pins indicate the initialization sequence executed. Typical initialization requires driving only INT0

and INT3 to a HIGH state. The reset conditions

follow:

INT0

INT1 INT3 LOCK Action Taken

1 x 1 1 Run self test (core initialization)

0 0 1 1 Disable self-test

0 1 x x Reserved

x x 0 x Reserved

x x x 0 ONCE mode (see LOCK

pin)

INT0

I INTERRUPT 0 indicates a pending interrupt. To signal an interrupt in a

synchronous system, this pin — as well as the other interrupt pins — must be

enabled by being deasserted for at least one bus cycle and then asserted for at

least one additional bus cycle. In an asynchronous system, the pin must remain

deasserted for at least two system clock cycles and then asserted for at least two

more system clock cycles. The interrupt control register must be programmed with

an interrupt vector before using this pin.

INT0

is sampled during reset to determine if the self-test sequence is to be

executed.

INT1 I INTERRUPT 1, like INT0

, provides direct interrupt signaling. INT1 is sampled

during reset to determine if the self-test sequence is to be executed.

INT2/INTR I INTERRUPT2/INTERRUPT REQUEST: The interrupt control register determines

how this pin is interpreted. If INT2, it has the same interpretation as the INT0

and

INT1 pins. If INTR, it is used to receive an interrupt request from an external

interrupt controller.

INT3

/INTA I/O

T.S.

INTERRUPT3/INTERRUPT ACKNOWLEDGE: The interrupt control register

determines how this pin is interpreted. If INT3

, it has the same interpretation as

the INT0

and INT1 pins. If INTA, it is used as an output to control interrupt

acknowledge transactions. The INTA

output is latched on-chip and remains valid

during T

d

cycles; as an output, it is open-drain. INT3 must be pulled HIGH during

reset.

NC N/A NOT CONNECTED indicates pins should not be connected. Never connect any

pin marked NC; these pins may be reserved for factory use.

I/O = Input/Output, O = Output, I = Input, O.D. = Open Drain, T.S. = Three-state

Page 15

11

80960SA

2.0 ELECTRICAL SPECIFICATIONS

2.1 Power and Grounding

The 80960SA is implemented in CHMOS IV

technology and therefore has modest power requirements. Its high clock frequency and numerous output

buffers (address/data, control, error and arbitration

signals) can cause power surges as multiple output

buffers simultaneously drive new signal levels. For

clean on-chip power distribution, V

CC

and VSS pins

separately feed the device’s functional units. Power

and ground connections must be made to all

80960SA power and ground pins. On the circuit

board, all V

CC

pins must be strapped closely

together, preferably on a power plane; all V

SS

pins

should be strapped together, preferably on a ground

plane.

2.2 Power Decoupling

Recommendations

Place a liberal amount of decoupling capacitance

near the 80960SA. When driving the bus the

processor can cause transient power surges, particularly when connected to a large capacitive load.

Low inductance capacitors and interconnects are

recommended for best high frequency electrical

performance. Inductance is reduced by shortening

board traces between the processor and decoupling

capacitors as much as possible.

2.3 Connection Recommendations

For reliable operation, always connect unused inputs

to an appropriate signal level. In particular, if one or

more interrupt lines are not used, they should be

pulled up. No inputs should ever be left floating.

The LOCK

open-drain pin requires a pullup resistor

whether or not the pin is used as an output. Figure 5

shows the recommended resistor value.

Do not connect external logic to pins marked NC.

Figure 5. Connection Recommendation

for LOCK

2.4 Characteristic Curves

Figure 6 shows typical supply current requirements

over the operating temperature range of the

processor at supply voltage (V

CC

) of 5V. Figure 7

shows the typical power supply current (I

CC

) that the

80960SA requires at various operating frequencies

when measured at three input voltage (V

CC

) levels.

For a given output current (I

OL

) the curve in Figure 8

shows the worst case output low voltage (V

OL

).

Figure 9 shows the typical capacitive derating curve

for the 80960SA measured from 1.5V on the system

clock (CLK) to 0.8V on the falling edge and 2.0V on

the rising edge of the bus address/data (AD) signals.

910Ω

V

CC

OPEN-DRAIN

OUTPUT

Page 16

12

80960SA

Figure 6. Typical Supply Current vs. Case Temperature

Figure 7. Typical Current vs. Frequency (Room Temp)

VCC = 5.0V

POWER SUPPLY CURRENT (mA)

CASE TEMPERATURE (°C)

20 MHz

16 MHz

10 MHz

100

150

200

250

300

350

-10 0 10 20 30 40 50 60 70 80 90 100 110

0 5 10 15 20 25

OPERATING FREQUENCY (MHz)

4.5V

5.0V

5.5V

TYPICAL SUPPLYCURRENT (mA)

TEMP = +22°C

250

225

200

175

150

125

100

Page 17

13

80960SA

Figure 8. Typical Current vs. Frequency

(Hot Temp)

0 5 10 15 20 25

OPERATING FREQUENCY (MHz)

TYPICAL SUPPLYCURRENT (mA)

TEMP = +85°C

4.5V

5.0V

5.5V

300

250

200

150

100

50

0

Figure 9. Capacitive Derating Curve

0 20 40 60 80 100

30

25

20

15

10

THREE-STATE OUTPUT

CAPACITIVE LOAD (pF)

(TEMP = +85°C, V

CC

= 4.5V)

5

0

RISING

FALLING

X

X

X

VALID DELAY (NS)

2.5 Test Load Circuit

Figure 10 illustrates the load circuit used to test the 80960SA’s output pins.

Figure 10. Test Load Circuit for Three-State Output Pins

THREE-STATE OUTPUT

C

L

= 50 pF for all signals

C

L

Page 18

14

80960SA

2.6 ABSOLUTE MAXIMUM RATINGS*

Parameter Maximum Rating

Operating Temperature (PLCC) ........... 0°C to +85°C Case

Operating Temperature (QFP)............ 0°C to +100°C Case

Storage Temperature .............................. –65°C to +150°C

Voltage on Any Pin (PLCC)................. –0.5V to VCC +0.5V

Voltage on Any Pin (QFP)............... –0.25V to VCC +0.25V

Power Dissipation ....................................... 1.9W (20 MHz)

NOTICE: This is a production data sheet. The

specifications are subject to change without notice.

*WARNING: Stressing the device beyond the

“Absolute Maximum Ratings” may cause

permanent damage. These are stress ratings only.

Operation beyond the “Operating Conditions” is not

recommended and extended exposure beyond the

“Operating Conditions” may affect device reliability.

2.7 DC Characteristics

80960SA (10 and 16 MHz QFP) T

CASE

= 0°C to +100°C, VCC = 5V ± 5%

80960SA (10 and 16 MHz PLCC) T

CASE

= 0°C to +85°C, VCC = 5V ± 10%

80960SA (20 MHz PLCC) T

CASE

= 0°C to +85°C, VCC = 5V ± 5%

Table 5. DC Characteristics

Symbol Parameter Min Max Units Notes

V

IL

Input Low Voltage –0.3 +0.8 V

V

IH

Input High Voltage 2.0 VCC + 0.3 V

V

CL

CLK2 Input Low Voltage –0.3 +0.8 V

V

CH

CLK2 Input High Voltage 0.7 V

CC

VCC + 0.3 V

V

OL

Output Low Voltage 0.45

0.45

VVIOL = 4.0 mA

I

OL

= 6 mA, LOCK Pin

V

OH

Output High Voltage 2.4 V All TS, -2.5 mA(1)

I

CC

Power Supply Current:

10 MHz-QFP

10 MHz-PLCC

16 MHz-PLCC

20 MHz-PLCC

240

240

300

340

mA

mA

mA

mA

T

CASE

= 00C

T

CASE

= 00C

T

CASE

= 00C

T

CASE

= 00C

I

LI1

Input Leakage Current,

Except INT0

, LOCK

±15 µA 0 ≤ VIN≤ V

CC

I

LI2

Input Leakage Current,

INT0

, LOCK

–300 µA VIN= 0.45V (2)

I

OL

Output Leakage Current ±15 µA

C

IN

Input Capacitance 10 pF fC = 1 MHz (3)

C

O

Output Capacitance 12 pF fC = 1 MHz (3)

C

CLK

Clock Capacitance 10 pF fC = 1 MHz (3)

NOTES:

1. Not measured for open-drain output.

2. INT0

and LOCK have internal pullup devices.

3. Input, output and clock capacitance are not tested.

Page 19

15

80960SA

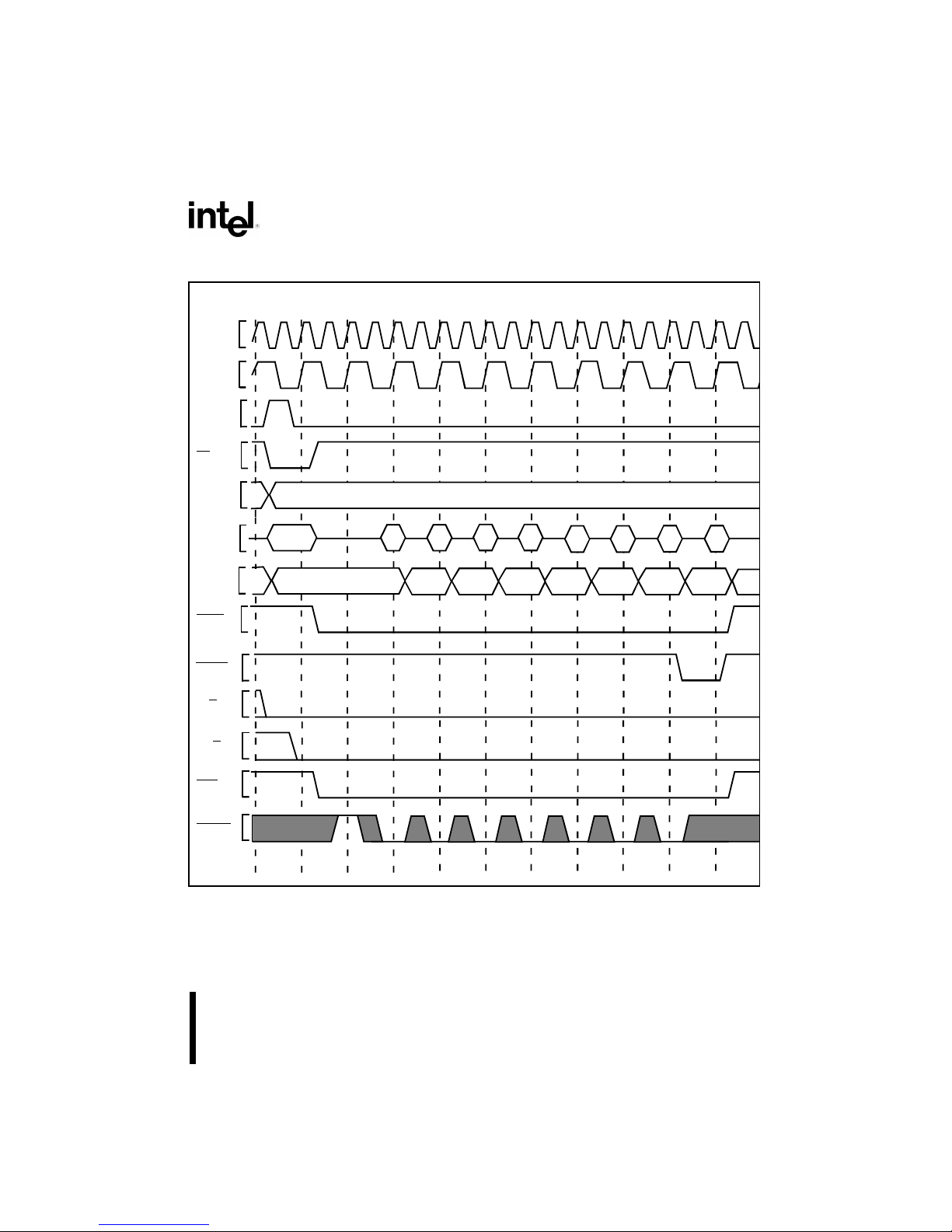

2.8 AC Specifications

This section describes the AC specifications for the

80960SA pins. All input and output timings are

specified relative to the 1.5V level of the rising edge

of CLK2 and refer to the time at which the signal

crosses 1.5V (for output delay and input setup). All

AC testing should be done with input voltages of

0.4V and 2.4V, except for the clock (CLK2) which

should be tested with input voltages of 0.45V and 0.7

x V

CC

. See Figure 11 and Tables 6, 7 and 8 for timing

relationships for the 80960SA signals.

Figure 11. Drive Levels and Timing Relationships for 80960SA Signals

A B C D A B C

1.5V

1.5V 1.5V 1.5V

T

6

1.5V

1.5V

T

7

1.5V 1.5VVALID OUTPUT

T

6

T

8

T

8

T

13

T

14

1.5V 1.5V

VALID OUTPUT

T

9

2.0V 2.0V

2.0V 2.0V

0.8V 0.8V

0.8V 0.8V

EDGE

CLK2

OUTPUTS:

AD15:1, A3:1, D0,

W/R

, DEN, BLAST,

HLDA, LOCK

, INTA

ALE

DT/R

INPUTS:

AD15:1, D0,

INT2, INT3

HOLD

LOCK

READY

T

9

T

10

T

11

T

12

T

11

A 31:16, BE1:0,

INT0, INT1,

AS

T

6AS

T

6AS

VALID INPUT

Page 20

16

80960SA

Table 6. 80960SA AC Characteristics (10 MHz)

Symbol Parameter Min Max Units Notes

Input Clock

T

1

Processor Clock Period (CLK2) 50 125 ns VIN= 1.5V

T

2

Processor Clock Low Time (CLK2) 8 ns VT= 10% Point

= V

CL

+ (VCH – VCL) x 0.1

T

3

Processor Clock High Time

(CLK2)

8 ns VT= 90% Point

= V

CL

+ (VCH – VCL) x 0.9

T

4

Processor Clock Fall Time (CLK2) 10 ns VT= 90% to 10% Point (1)

T

5

Processor Clock Rise Time (CLK2) 10 ns VT= 10% to 90% Point (1)

Synchronous Outputs

T

6

Output Valid Delay 2 31 ns

T

6AS

AS Output Valid Delay 2 25 ns

T

7

ALE Width T1 - 11 ns

T

8

ALE Output Valid Delay 4 33 ns

T

9

Output Float Delay 2 20 ns (2)

Synchronous Inputs

T

10

Input Setup 1 10 ns

T

11

Input Hold 2 ns

T

12

Input Setup 2 13 ns

T

13

Setup to ALE Inactive 10 ns

T

14

Hold after ALE Inactive 8 ns

T

15

RESET Hold 3 ns (3)

T

16

RESET Setup 5 ns (3)

T

17

RESET Width 2050 ns 41 CLK2 Periods Minimum

NOTES:

1. Processor clock (CLK2) rise time and fall time are not tested.

2. A float condition occurs when the maximum output current becomes less than I

LO

. Float delay is not tested, but should be

no longer than the valid delay.

3. Meeting RESET

setup and hold times is an optional method of synchronizing your clocks. If you decide to use an asyn-

chronous reset, synchronizing the clock can be accomplished by using AS

.

Page 21

17

80960SA

Table 7. 80960SA AC Characteristics (16 MHz)

Symbol Parameter Min Max Units Notes

Input Clock

T

1

Processor Clock Period (CLK2) 31.25 125 ns VIN= 1.5V

T

2

Processor Clock Low Time (CLK2) 8 ns VT= 10% Point

= V

CL

+ (VCH – VCL) x 0.1

T

3

Processor Clock High Time

(CLK2)

8 ns VT= 90% Point

= V

CL

+ (VCH – VCL) x 0.9

T

4

Processor Clock Fall Time (CLK2) 10 ns VT= 90% to 10% Point (1)

T

5

Processor Clock Rise Time (CLK2) 10 ns VT= 10% to 90% Point (1)

Synchronous Outputs

T

6

Output Valid Delay 2 25 ns

T

6AS

AS Output Valid Delay 2 21 ns

T

7

ALE Width T1 - 11 ns

T

8

ALE Output Valid Delay 2 22 ns

T

9

Output Float Delay 2 20 ns (2)

Synchronous Inputs

T

10

Input Setup 1 10 ns

T

11

Input Hold 2 ns

T

12

Input Setup 2 13 ns

T

13

Setup to ALE Inactive 10 ns

T

14

Hold after ALE Inactive 8 ns

T

15

RESET Hold 3 ns (3)

T

16

RESET Setup 5 ns (3)

T

17

RESET Width 1281 ns 41 CLK2 Periods Minimum

NOTES:

1. Processor clock (CLK2) rise time and fall time are not tested.

2. A float condition occurs when the maximum output current becomes less than I

LO

. Float delay is not tested, but should be

no longer than the valid delay.

3. Meeting RESET

setup and hold times is an optional method of synchronizing your clocks. If you decide to use an asyn-

chronous reset, synchronizing the clock can be accomplished by using AS

.

Page 22

18

80960SA

Table 8. 80960SA AC Characteristics (20 MHz)

Symbol Parameter Min Max Units Notes

Input Clock

T

1

Processor Clock Period (CLK2) 25 125 ns VIN= 1.5V

T

2

Processor Clock Low Time (CLK2) 6 ns VT= 10% Point

= V

CL

+ (VCH – VCL) x 0.1

T

3

Processor Clock High Time (CLK2) 6 ns VT= 90% Point

= V

CL

+ (VCH – VCL) x 0.9

T

4

Processor Clock Fall Time (CLK2) 10 ns VT= 90% to 10% Point (1)

T

5

Processor Clock Rise Time (CLK2) 10 ns VT= 10% to 90% Point (1)

Synchronous Outputs

T

6

Output Valid Delay 2 20 ns

T

6AS

AS Output Valid Delay 2 20 ns

T

7

ALE Width T1 - 11 ns

T

8

ALE Output Valid Delay 2 18 ns

T

9

Output Float Delay 2 17 ns (2)

Synchronous Inputs

T

10

Input Setup 1 7 ns

T

11

Input Hold 2 ns

T

12

Input Setup 2 13 ns

T

13

Setup to ALE Inactive 10 ns

T

14

Hold after ALE Inactive 8 ns

T

15

RESET Hold 3 ns (3)

T

16

RESET Setup 5 ns (3)

T

17

RESET Width 1025 ns 41 CLK2 Periods Minimum

NOTES:

1. Processor clock (CLK2) rise time and fall time are not tested.

2. A float condition occurs when the maximum output current becomes less than I

LO

. Float delay is not tested, but should be

no longer than the valid delay.

3. Meeting RESET

setup and hold times is an optional method of synchronizing your clocks. If you decide to use an asyn-

chronous reset, synchronizing the clock can be accomplished by using AS

.

Page 23

19

80960SA

Figure 12. Processor Clock Pulse (CLK2)

Figure 13. RESET

Signal Timing

HIGH LEVEL (MIN) 0.7V

CC

LOW LEVEL (MAX) 0.8V

T

1

T

3

T

5

T

4

T

2

90%

10%

1.5 V

CLK2

CLK

RESET

OUTPUTS

A B C D A

B C

T

15

T

16

INT0, INT1,

INT3

, LOCK

INITIALIZATION PARAMETERS

T

17

NOTE: Initialization parameters must be set up at least four CLK2 periods before the first CLK2 “A” edge.

Page 24

20

80960SA

Figure 14. HOLD Timing

T

h

T

h

T

h

CLK2

CLK

HOLD

HLDA

T

12

T

11

T

6

T

6

Page 25

21

80960SA

3.0 MECHANICAL DATA

3.1 Packaging

The 80960SA is available in two package types:

• 80-lead quad flat pack (EIAJ QFP). Shown in

Figure

15.

• 84-lead plastic leaded chip carrier (PLCC).

Shown

in Figure 16.

Dimensions

for both package types are given in the

Inte

l Packaging handbook (Order #240800).

3.2 Pin Assignment

The QFP and PLCC have different pin assignments.

The QFP pins are numbered in order from 1 to 80

around

the package perimeter. The PLCC pins are

numbered

in order from 1 to 84 around the package

perime

ter. Tables 9 and 10 list the function of each

QFP

pin; Tables 11 and 12 list the function of each

PLCC

pin.

V

CC

and GND connections must be made to multiple

V

CC

and GND pins. Each VCC and GND pin must be

connected

to the appropriate voltage or ground and

externally

strapped close to the package. It is recom-

mended

that you include separate power and ground

plane

s in your circuit board for power distribution.

Pins

identified as NC (No Connect) should never be

connected

.

Figure 15. 80-Lead EIAJ Quad Flat Pack (QFP) Package

AS

AD1

AD

2

V

SS

AD3

AD

4

AD

5

AD

6

A

D

7

AD

8

A

D

9

AD

1

0

AD

1

1

AD

1

2

AD

1

3

A

D

1

4

AD

1

5

A

16

A17A

18

A1

9

A20

A2

1

A2

2

V

SS

A23

A2

4

A25

BLAST

H

O

LD

V

S

S

R

ESET

V

CC

CLK

2

I

N

T3/INT

A

I

N

T

2

/

I

N

T

R

INT1

INT0

V

C

C

V

C

C

NC

V

SS

V

S

S

V

C

C

V

CC

V

S

S

V

SS

V

CC

V

CC

NC

V

SS

V

SS

V

SS

V

CC

V

CC

V

CC

HL

DA

ALE

A1

A2

A3

D0

W

/

R

READY

D

T

/R

B

E0

BE1

V

S

S

LO

CK

D

EN

V

S

S

V

SS

V

C

C

V

C

C

66

65

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41

40

39

38

37

36

35

34

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

80

79

78

77

76

75

74

73

72

71

70

69

68

67

22 23 24

25

26

27

28

29

30

31

32

33

A26

A2

7

A2

8

A2

9

A3

0

A3

1

x80960SA-20

XXXXXXXX

XXXXX

X

XXXXX

X

NOTE: To address the fact that many of the package prefix variables have changed, all

package prefix variables in this document are now indicated with an "x".

Page 26

22

80960SA

.

Figure

16. 84-Lead Plastic Leaded Chip Carrier (PLCC) Package

AS

AD1

AD

2

V

SS

AD

3

AD

4

AD5

AD

6

AD7

AD

8

AD

9

AD10

AD1

1

AD1

2

AD1

3

AD1

4

AD1

5

A1

6

A17

A1

8

A19

A2

0

A21

A2

2

V

SS

A23

A

2

4

A25

BLAST

HOLD

V

SS

RESET

V

C

C

CLK2

INT3

/INTA

INT2/INTR

INT1

INT0

V

CC

V

C

C

N

C

V

S

S

V

SS

V

CC

V

C

C

V

SS

V

SS

V

CC

V

CC

NC

V

SS

V

SS

NC

V

SS

V

CC

V

CC

V

CC

HLDA

ALE

A

1

A2A

3

D0

W/R

READY

DT/R

B

E

0

B

E

1

V

SS

LOCK

DEN

N

C

N

C

V

S

S

V

S

S

N

C

V

C

C

V

C

C

66

65

64

63

62

61

60

59

58

57

56

55

54

5352515049484746454443424140393837363534

1234567891011

12

13

14

15

16

17

18

19

20

21

84 83 82 81 80 79 78 77 76 75

74

73

72

71

70

69

68

67

22

23

24

25

26

27

28

29

30

31

32

33

A26

A27

A28

A29

A30

A31

x80960SA-20

XXXXXXXX

XXXXX

X

XXXXX

X

NOTE: To address the fact that many of the package prefix variables have changed, all

package prefix variables in this document are now indicated with an "x".

Page 27

23

80960SA

3.3 Pinout

Table 9. 80960SA QFP Pinout — In Pin Order

Pin Signal Pin Signal Pin Signal Pin Signal

1 A22 21 V

CC

41 BE0 61 V

CC

2 A21 22 V

SS

42 V

CC

62 V

SS

3 A20 23 V

CC

43 V

SS

63 NC

4 A19 24 V

SS

44 CLK2 64 AS

5 A18 25 AD6 45 RESET 65 V

SS

6 A17 26 AD5 46 INT0 66 ALE

7 A16 27 AD4 47 INT1 67 READY

8 V

CC

28 AD3 48 INT2/INTR 68 A31

9 V

SS

29 AD2 49 INT3/INTA 69 A30

10 AD15 30 AD1 50 HLDA 70 A29

11 AD14 31 D0 51 V

CC

71 A28

12 V

CC

32 V

SS

52 V

SS

72 V

SS

13 V

SS

33 V

CC

53 HOLD 73 V

CC

14 AD13 34 A3 54 W/R 74 A27

15 AD12 35 A2 55 DEN

75 A26

16 AD11 36 V

CC

56 DT/R 76 A25

17 AD10 37 V

SS

57 BLAST 77 V

CC

18 AD9 38 A1 58 LOCK 78 V

SS

19 AD8 39 NC 59 V

CC

79 A24

20 AD7 40 BE1

60 V

SS

80 A23

NOTES:

Do not connect any external logic to any pins marked NC.

Page 28

24

80960SA

Table 10. 80960SA QFP Pinout — In Signal Order

Signal Pin Signal Pin Signal Pin Signal Pin

A1 38 A18 5 D0 31 V

CC

51

A2 35 A19 4 DEN

55 V

CC

59

A3 34 A20 3 DT/R

56 V

CC

61

AD1 30 A21 2 HLDA 50 V

CC

73

AD2 29 A22 1 HOLD 53 V

CC

77

AD3 28 A23 80 INT0

46 V

CC

8

AD4 27 A24 79 INT1 47 V

SS

13

AD5 26 A25 76 INT2/INTR 48 V

SS

22

AD6 25 A26 75 INT3

/INTA 49 V

SS

24

AD7 20 A27 74 LOCK 58 V

SS

32

AD8 19 A28 71 NC 39 V

SS

37

AD9 18 A29 70 NC 63 V

SS

43

AD10 17 A30 69 READY

67 V

SS

52

AD11 16 A31 68 RESET

45 V

SS

60

AD12 15 ALE 66 V

CC

12 V

SS

62

AD13 14 AS

64 V

CC

21 V

SS

72

AD14 11 BE0

41 V

CC

23 V

SS

78

AD15 10 BE1

40 V

CC

33 V

SS

9

A16 7 BLAST

57 V

CC

36 V

SS

65

A17 6 CLK2 44 V

CC

42 W/R 54

NOTES:

Do not connect any external logic to any pins marked N.C.

Page 29

25

80960SA

Table 11. 80960SA PLCC Pinout — In Pin Order

Pin Signal Pin Signal Pin Signal Pin Signal

1 V

CC

22 V

SS

43 V

SS

64 HOLD

2 NC 23 NC 44 V

CC

65 NC

3 A27 24 AD13 45 A3 66 W/R

4 A26 25 AD12 46 A2 67 DEN

5 A25 26 AD11 47 V

CC

68 DT/R

6 V

CC

27 AD10 48 V

SS

69 BLAST

7 V

SS

28 AD 9 49 A1 70 LOCK

8 A24 29 AD8 50 NC 71 V

CC

9 A23 30 AD7 51 BE1 72 V

SS

10 A2 2 31 V

CC

52 BE0 73 V

CC

11 A2 1 32 V

SS

53 V

CC

74 V

SS

12 A2 0 33 V

CC

54 V

SS

75 NC

13 A1 9 34 V

SS

55 CLK 2 76 AS

14 A1 8 35 AD6 56 RESET 77 V

SS

15 A1 7 36 AD5 57 INT0 78 ALE

16 A1 6 37 AD4 58 INT1 79 READY

17 V

CC

38 AD 3 59 INT2/INTR 80 A31

18 V

SS

39 D2 60 INT3/INTA 81 A30

19 AD1 5 40 D1 61 HLDA 82 A29

20 AD1 4 41 D0 62 V

CC

83 A28

21 V

CC

42 NC 63 V

SS

84 V

SS

NOTES:

Do not connect any external logic to any pins marked NC.

Page 30

26

80960SA

Table 12. 80960SA PLCC Pinout — In Signal Order

Signal Pin Signal Pin Signal Pin Signal Pin

A1 49 A18 14 DT/R

68 V

CC

44

A2 46 A19 13 HLDA 61 V

CC

47

A3 45 A20 12 HOLD 64 V

CC

53

D0 41 A21 11 INT0

57 V

CC

6

AD1 40 A22 10 INT1 58 V

CC

62

AD2 39 A23 9 INT2/INTR 5 9 V

CC

71

AD3 38 A24 8 INT3

/INTA 60 V

CC

73

AD4 37 A25 5 LOCK

70 V

SS

18

AD5 36 A26 4 NC 2 V

SS

22

AD6 35 A27 3 NC 23 V

SS

32

AD7 30 A28 83 NC 42 V

SS

34

AD8 29 A29 82 NC 50 V

SS

43

AD9 28 A30 81 NC 65 V

SS

48

AD10 27 A31 80 NC 75 V

SS

54

AD11 26 ALE 78 READY

79 V

SS

63

AD12 25 AS

76 RESE T 56 V

SS

7

AD13 24 BE0

52 V

CC

1 V

SS

72

AD14 20 BE1

51 V

CC

17 V

SS

74

AD15 19 BLAST

69 V

CC

21 V

SS

77

AD16 16 CLK2 55 V

CC

31 V

SS

84

A17 15 DEN

67 V

CC

33 W/R 66

NOTES:

Do not connect any external logic to any pins marked NC.

Page 31

27

80960SA

3.4 Package Thermal Specifications

The 80960SA is specified for operation when case

temperature is within the range 0°C to +85°C (PLCC)

or 0°C to 100°C (QFP). Measure case temperature

at the top center of the package. Ambient temperature can be calculated from:

T

J

= TC + P*θ

JC

TA = TJ - P*θ

JA

TC = TA + P*[θJA−θJC]

Compute P by multiplying the maximum voltage by

the typical current at maximum temperature. Values

for

θJA and θJC for various airflows are given in Table

13 for the QFP package and in Table 14 for the

PLCC package. I

CC

at maximum temperature is

typically 80 percent of specified I

CC

maximum (cold).

Table 13. 80960SA QFP Package Thermal Characteristics

Thermal Resistance — °C/Watt

Parameter

Airflow — ft./min (m/sec)

0 50 100 200 400 600 800

θ Junction-to-Ambient (Case

measured in the middle of the

top of the package)

(No Heatsink)

59 57 54 50 44 40 38

θ Junction-to-Case

11 11 11 11 11 11 11

NOTES:

This table applies to 80960SA QFP soldered directly to board.

Table 14. 80960SA PLCC Package Thermal Characteristics

Thermal Resistance — °C/Watt

Parameter

Airflow — ft./min (m/sec)

0 50 100 200 400 600 800 1000

θ Junction-to-Ambient

(No Heatsink)

34 32 29.5 28 25 23 21 20.5

θ Junction-to-Case

12 12 12 12 12 12 12 12

NOTES:

This table applies to 80960SA PLCC soldered directly to board.

3.5 Stepping Register Information

Upon reset, register g0 contains die stepping information. Table 15 shows the relationship between the

number in g0 and the current die stepping

The current numbering pattern in g0 may not be

consistent with past or future steppings of this

product.

Table 15. Die Stepping Cross Reference

Register g0 Die Stepping

01010101H C-1

Page 32

28

80960SA

4.0 WAVEFORMS

Figures 17, 18, 19, 20 and 21 show waveforms for various transactions on the 80960SA’s bus. Figure 22 shows

a cold reset functional waveform.

Figure 17. Non-Burst Read and Write Transactions Without Wait States

T

a

T

d

T

r

T

a

T

d

T

r

CLK2

CLK

ALE

AS

A31:16

W/R

DT/R

DEN

READY

BLAST

BE1:0

VALID VALID

INVALID

A3:1

ADDR

ADDR

DATA

D

A15:4,

D15:0

VALID

VALID

Page 33

29

80960SA

Figure 18. Quad Word Burst Read Transaction With 1, 0, 0, 0, 0, 0, 0, 0 Wait States

T

a

T

w

T

d

T

d

T

d

T

d

T

d

T

d

T

d

T

d

T

r

CLK2

CLK

ALE

AS

BE1:0

W/R

DT/R

DEN

READY

BLAST

D D D D D D D D

A3:1

A15:4,

D15:0

A31:16

VALID

000 001 010 011 100 101 110 111

ADDR

Page 34

30

80960SA

Figure 19. Burst Write Transaction With 2, 1, 1, 1 Wait States (6-8 Bytes Transferred)

T

a

T

w

T

w

T

d

T

w

T

d

T

w

T

d

T

w

T

d

T

r

CLK2

CLK

ALE

AS

BE1:0

W/R

DT/R

DEN

READY

BLAST

A3:1

A15:4,

D15:0

A31:16

VALID

ADDR

DATA

DATA

DATA DATA

VALID

VALID VALID

VALID

00 00 x0

0x

Page 35

31

80960SA

Figure 20. Accesses Generated by Quad Word Read Bus Request,

Misaligned One Byte from Quad Word Boundary 1, 0, 0, 0, 0, 0, 0, 0 Wait States

T

a

T

w

T

d

Td Td T

d

T

d

T

d

T

d

T

d

T

r

CLK2

CLK

ALE

AS

BE1

W/R

DT/R

DEN

BLAST

A3:1

A15:4,

D15:0

A31:16

VALID

ADDR

T

a

T

w

T

d

T

r

BE0

ADDR

D D D D D D D D

D

VALID

000

001 010 011 100 101 110 111 000

READY

Page 36

32

80960SA

Figure 21. Interrupt Acknowledge Cycle

CLK2

TaTdTrT

i

TiTiTiTiTaT

w

TdT

r

A15:4,

ALE

AS

INTA

DT/R

DEN

LOCK

CLK

W/R

BLAST

A31:16

D15:0

ADDR

ADD

DATA

A3:1

1 1 0

BE1:0

READY

1 0

1 0

Page 37

33

80960SA

Figure 22. Cold Reset Waveform

RESET

CLK2

CLK

V

CC

AS, DT/R,

DEN,

LOCK (O)

HLDA

BLAST/FAIL

ALE, A31:16,

A15:4, A3:1,

D15:0,

BE1:0, W/R

INT0, INT1,

INT3,

LOCK (I)

VCCand CLK2 stable to RESET high, minimum 41 CLK2 periods

Initialization parameters

set up to first A edge,

minimum 4 CLK2 periods

First

Bus

Activity

Internal self-test,

approximately 94,000 CLK2

periods (if selected)

A B C D T

a

A B C D A B C D

A B C D

A B C D

A B C D

48,000

VALID

Page 38

34

80960SA

5.0 REVISION HISTORY

This data sheet supersedes data sheet 272206-001 and applies only to those devices identified as the current

stepping in section 3.

5. The sections significantly changed since the previous revision are:

Data

sheet 270917-004 applied to both the 80960SA and the 80960SB. The 80960SA was then documented

alone

in data sheet 272206-001. The sections significantly changed between revisions -004 of the SA/SB data

sheet and 272206-001 of the SA data sheet were:

Section

Las

t

Re

v.

Description

2.3

Connection Recommendations (pg. 11) -001 Removed two LOCK

pin Connection Recommendation

figures and added Figure 5 to reflect the new LOCK

pin

connection

recommendation of a single 910

Ω pullup

resistor

.

2.5 Test Load Circuit (pg. 13) -001 Obsolete figure (Test Load Circuit for Open-Drain

Output

Pins) removed to reflect current test conditions.

2.7

DC Characteristics (pg. 14) -001 I

OL

value at 0.45V improved.

WAS

: 2.5 mA IS: 4.0 mA

LOCK

pin IOL value at 0.45V relaxed.

WAS

: 12 mA IS: 6 mA

LOCK

pin IOL value at 0.60V deleted.

80960SA

16 MHz QFP added to product list.

3.5

Stepping Register Information (pg. 27) -001 New section added.

Secti

on

La

st

Re

v.

Descripti

on

2.3 Connection Recommendations

(pg.

11)

-0

04 Deleted corresponding graph of open drain voltage vs. out-

put

current.

Figure 6. Typical Supply Current vs.

Cas

e Temperature (pg. 11)

Figure 7. Typical Current vs. Frequency

(Room Temp) (pg. 12)

Figure 8. Typical Current vs. Frequency

(Hot Temp) (pg. 12)

-0

04 Regraphed new data in three graphs instead of two.

Table 5. DC Characteristics (pg. 15) -004 Input Leakage Current (I

LI2

) Specification added to accu-

rately

describe leakage of INT0 and LOCK as inputs.

ICC max reduced:

Power Supply Current: Was: Is:

10

MHz 280 240

16

MHz 350 300

NOTES:

Page numbers re

fer to 80960SA data sheet number 272206-001.

Overall

To address the fact that many of the package prefix

variables have changed, all package prefix variables

in this document are now indicated with an "x".

-003

Page 39

35

80960SA

Table 6. 80960SA AC Characteristics

(10 MHz) (pg. 17)

Table 7. 80960SA AC Characteristics

(16 MHz) (pg. 18).

-004 T7 minimum specification improved:

Power Supply Current: Was: Is:

10 MHz 24 ns T

1

- 11 ns

16 MHZ 15 ns T

1

- 11 ns

Table 8. 80960SA AC Characteristics

(20 MHz) (pg. 19)

-004 New 20 MHz specification table added for 80960SA C-step.

Table 11. 80960SA PLCC Pinout — In

Pin Order (pg. 26)

-004

θJA increased to reflect smaller die size and lower ICC.

Table 11. 80960SA PLCC Pinout — In

Pin Order (pg. 26)

-004

θJA and θJCincreased to reflect smaller die size and lower

I

CC

.

The sections significantly changed between revisions -003 and -004 of the 80960SA/SB Data Sheet were:

Section

Last

Rev.

Description

DC Characteristics -003 Operating temperature for PLCC package changed:

WAS: T

CASE

= 0°C to +100°C

IS: T

CASE

= 0°C to +85°C

The test program has not changed.

Table 9. 80960SA and 80960SB QFP

Pinout — In Pin Order

-003 Signal A12 incorrectly shown as Pin 28; is now correctly shown as Pin 38. Note added to clarify No Connect Pins.

Section

Last

Rev.

Description

NOTES:

Page numbers refer to 80960SA data sheet number 272206-001.

Loading...

Loading...