Page 1

Intel® 6 Series Chipset

Thermal Mechanical Specifications and Design Guidelines (TMSDG)

January 2011

324647-001

Page 2

Legal Lines and Disclaimers

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED,

BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS

PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER

AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING T O SALE AND/OR USE OF INTEL PRODUCT S INCLUDING

LIABILITY OR WARRANTIES RELA TING T O FITNES S FOR A PARTICULAR PURPOSE, MERCHANT ABILITY, OR INFRINGEMENT OF ANY

PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS OTHERWISE AGREED IN WRITING BY INTEL, THE INTEL PRODUCTS ARE NOT DESIGNED NOR INTENDED FOR ANY

APPLICATION IN WHICH THE FAILURE OF THE INTEL PRODUCT COULD CR EA TE A SITUA TION WHERE PERSONAL INJURY OR DEATH

MAY OCCUR.

Intel may make changes to specifications and product descriptions at any time, without notice. Designers must not rely on the

absence or characteristics of any features or instructions marked "reserved" or "undefined." Intel reserves these for future

definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to them. The

information here is subject to change without notice. Do not finalize a design with this information.

The products described in this document may contain design defects or errors known as errata which may cause the product to

deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

All products, platforms, dates, and figures specified are preliminary based on current expectations, and are subject to change

without notice. All dates specified are target dates, are provided for planning purposes only and are subject to change.

This document contains information on products in the desig n phase of development. Do not finalize a design with this information.

Revised information will be published when the product is available. Verify with your local sales office that you have the latest

datasheet before finalizing a design.

®

No computer system can provide absolute securit y under all co nditions. Intel

a computer system with Intel

Modules and an Intel TXT-compatible measured launched environment (MLE). The MLE could consist of a virtual machine monitor,

an OS or an application. In addition, Intel TXT requires the system to contain a TPM v1.2, as defined by the Trusted Computing

Group and specific software for some uses. For more information, see http://www.intel.com/technology/security/

®

Virtualization Technology requires a computer system with an enabled Intel® processor, BIOS, virtual machine monitor

Intel

(VMM) and, for some uses, certain computer system software enabled for it. Functionality, performance or other benefits will vary

depending on hardware and software configur ations and may re quire a BIOS update. S oftware applicatio ns may not be compatible

®

Virtualization Technology, an Intel TXT-enabled processor, chipset, BIOS, Authenticated Code

Tr usted Execution Technology (Intel® TXT) requires

with all operating systems. Please check with your application vendor.

®

Active Management Technology requires the computer system to have an Intel® AMT-enabled chipset, network hardware

Intel

and software, as well as connection with a power source and a corpor ate netwo rk connection . Setup req uires c onfigur atio n by the

purchaser and may require scripting with the management console or further integration into existing security frameworks to

enable certain functionality. It may also require modifications of implementation of new business processes. With regard to

notebooks, Intel AMT may not be available or certain capabilities may be limited over a host OS-based VPN or when connecting

wirelessly, on battery power, sleeping, hibernating or powered off. For more information, see http://www.intel.com/technology/

platform-technology/intel-amt/

Intel processor numbers are not a measure of performance. Processor numb ers differentia te features withi n each processo r family,

not across different processor families. See www.intel.com/products/processor_number for details.

Copies of documents which have an order number and are referenced in this document, or other Intel literature, may be obtained

at: http://www.intel.com/design/literature.h tm

Intel and the Intel logo are trademarks of Intel Corporation in the U.S. and other countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2011, Intel Corporation. All rights reserved.

2 Thermal Mechanical Specifications and Design Guidelines

Page 3

Contents

1Introduction..............................................................................................................7

1.1 Related Documents .............................................................................................8

1.2 Terminology .......................................................................................................8

2 Packaging Mechanical Specifications .........................................................................9

2.1 PCH Package for Single Processor Desktop..............................................................9

2.2 Solder Balls......................................................................................................11

2.3 Package Mechanical Requirements................................................ .. .....................12

3 Thermal Specifications ............................................................................................13

3.1 Thermal Design Power (TDP) ..............................................................................13

3.2 Thermal Specifications.......................................................................................13

3.3 Storage Specifications........................................................................................16

4 Thermal Simulation .................................................................................................17

5 Thermal Metrology ..................................................................................................19

5.1 Tcase Temperature Measurements.............. .......................... .. .. ......................... ..19

5.1.1 Heatsink Thermocouple Attach Methodology ..............................................19

5.2 Ambient Temperature and Airflow Measurement....................................................21

6 ATX Reference Thermal Solution..............................................................................23

6.1 Reference Solution ........ .. .. ................................................... .. .. .. .......................23

6.2 Environmental Reliability Requirements................................................................24

A Thermal Solution Compon ent Vendors.....................................................................25

B Mechanical Drawings for Package and Reference Thermal Solution .........................27

Thermal Mechanical Specifications and Design Guidelines 3

Page 4

Figures

2-1 Package Dimensions (Top View) .................................................................................. 9

2-2 Package Dimensions (Side View) ................................................... ........................... ..10

2-3 Package (Land Side View)..........................................................................................11

5-1 Thermal Solution Decision Flow Chart..........................................................................19

5-2 Heatsink Modifications...............................................................................................20

5-3 Top View of Package.................................................................................................20

5-4 Airflow & Temperature Measurement Locations.............................................................21

6-1 Reference Thermal Solution............................ ......................... ... .. ......................... .. ..24

Tables

3-1 PCH Thermal Specifications........................................................................................13

3-2 PCH TDP Workload Running Simultaneously.................................................................14

3-3 PCH TDP Configuration..............................................................................................14

3-4 PCH Idle Power Configuration.....................................................................................15

3-5 Storage Conditions ...................................................................................................16

6-1 Reference Thermal Solution Environmental Reliability Requirements................................24

4 Thermal Mechanical Specifications and Design Guidelines

Page 5

Revision History

Revision

Number

001 Initial release January 2011

Description

Revision

Date

§

Thermal Mechanical Specifications and Design Guidelines 5

Page 6

6 Thermal Mechanical Specifications and Design Guidelines

Page 7

Introduction

1 Introduction

The goals of this document are to:

• Outline the thermal and mechanical operating limits and specifications for the the

Intel® 6 Series Chipset for use in single processor systems for the desktop.

• Describe reference thermal solutions that meet the specifications of the Intel

Series Chipset.

®

The Intel

•Intel® P67 Express Chipset

•Intel

•Intel® B65 Express Chipset

•Intel® Q67 Express Chipset

Note: Unless otherwise specified, the term “Platform Controller Hub” or “PCH” will be used to

refer to any version of the chipset for the Desktop platform. Only where required will a

specific product code be used.

6 Series Chipset components supported in this document are:

®

H67 Express Chipset

®

6

Properly designed thermal solutions provide adequate cooling to maintain the Platform

Controller Hub case temperatures at or below thermal specifications. This is

accomplished by providing a low local-ambient temperature, ensuring adequate local

airflow, and minimizing the case to local-ambient thermal resistance. By maintaining

the PCH case temperature at or below the specified limits, a system designer can

ensure the proper functionality, performance, and reliability of the PCH. Operation

outside the functional limits can cause data corruption or permanent damage to the

component.

The simplest and most cost-effective method to improve the inherent system cooling

characteristics is through careful chassis design and placement of fans, vents, and

ducts. When additional cooling is required, component thermal solutions may be

implemented in conjunction with system thermal solutions. The size of the fan or

heatsink can be varied to balance size and space constraints with acoustic noise.

Thermal Mechanical Specifications and Design Guidelines 7

Page 8

1.1 Related Documents

The reader of this specification should also be familiar with material and concepts

presented in the following documents.

Title Location

®

Intel

6 Series Chipset Datasheet www.intel.com/Assets/PDF/

®

Intel

6 Series Chipset Specification Update www.intel.com/Assets/PDF/

nd

Generation Intel® Core™ Processor and LGA1155 Socket Thermal

2

Mechanical Specifications and Design Guidelines

Thermally Advantaged Chassis Design Guidelines http://www3.intel.com/cd/

Various system thermal design suggestions http://www.formfactors.org

1.2 Terminology

Item Description

BLT

CTE

FC-BGA

MD

PCH

SMD

TDP

TIM

Bond Line Thickness. Final settled thickness of the thermal interface material

after installation of the heatsink.

Coefficient of Thermal Expansion. The relative rate a material expands during a

thermal event.

Flip Chip Ball Grid Array. A package type defined by a plastic substrate where a

die is mounted using an underfill C4 (Controlled Collapse Chip Connection)

attach style. The primary electrical interface is an array of solder balls attached

to the substrate opposite the die. Note that the device arrives at the customer

with solder balls attached.

Metal Defined pad is one where a pad is individually etched into the PCB with a

minimum width trace exiting it

Platform Controller Hub. The PCH is connected to the processor via the Direct

Media Interface (DMI) and the Intel

The Solder Mask Defined pad is typically a pad in a flood plane where th e solder

mask opening defines the pad size for soldering to the component.

Thermal design power. Thermal solutions shou ld be designed to dissipate this

power level. TDP is not the peak power that the PCH can dissipate.

Thermal Interface Material. A conductive material used between the component

and heatsink to improve thermal conduction.

Introduction

specupdate/324645.pdf

specupdate/324646.pdf

http://download.intel.com/

design/processor/specupdt/

324644.pdf

channel/reseller/asmo-na/eng/

products/53211.htm

®

Flexible Display Interface (Intel® FDI)

§ §

8 Thermal Mechanical Specifications and Design Guidelines

Page 9

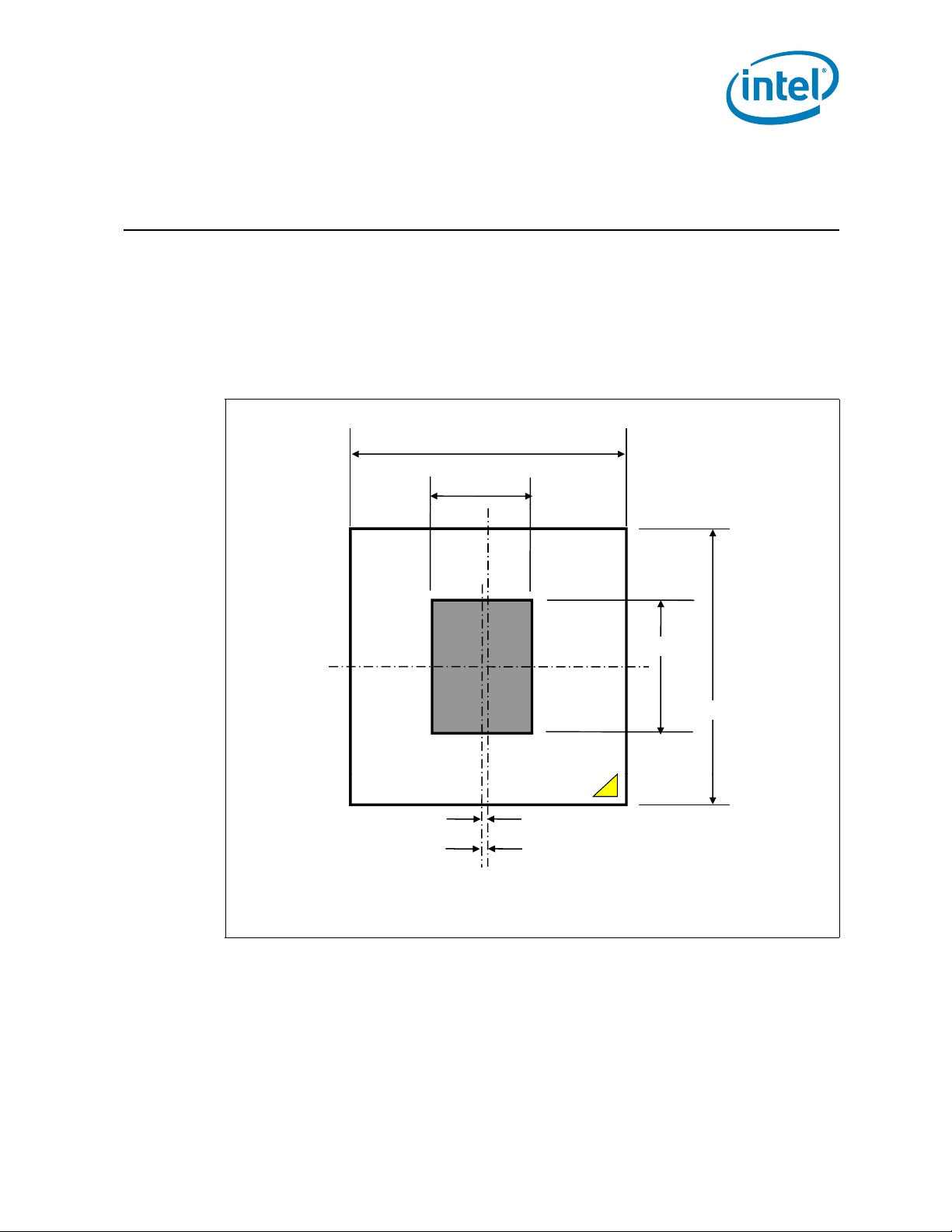

Packaging Mechanical Specifications

27.000

9.525

10.574

27.000

0.440

Package CenterlineDie Centerline

2 Packaging Mechanical

Specifications

2.1 PCH Package for Single Processor Desktop

The Platform Controller Hub uses a 27 mm square flip chip ball grid array (FC-BGA)

package (see Figure 2-1 through Figure 2-3). The complete package drawing can be

found in Appendix B.

Figure 2-1. Package Dimensions (Top View)

Note:

1. All dimensions in mm

Thermal Mechanical Specifications and Design Guidelines 9

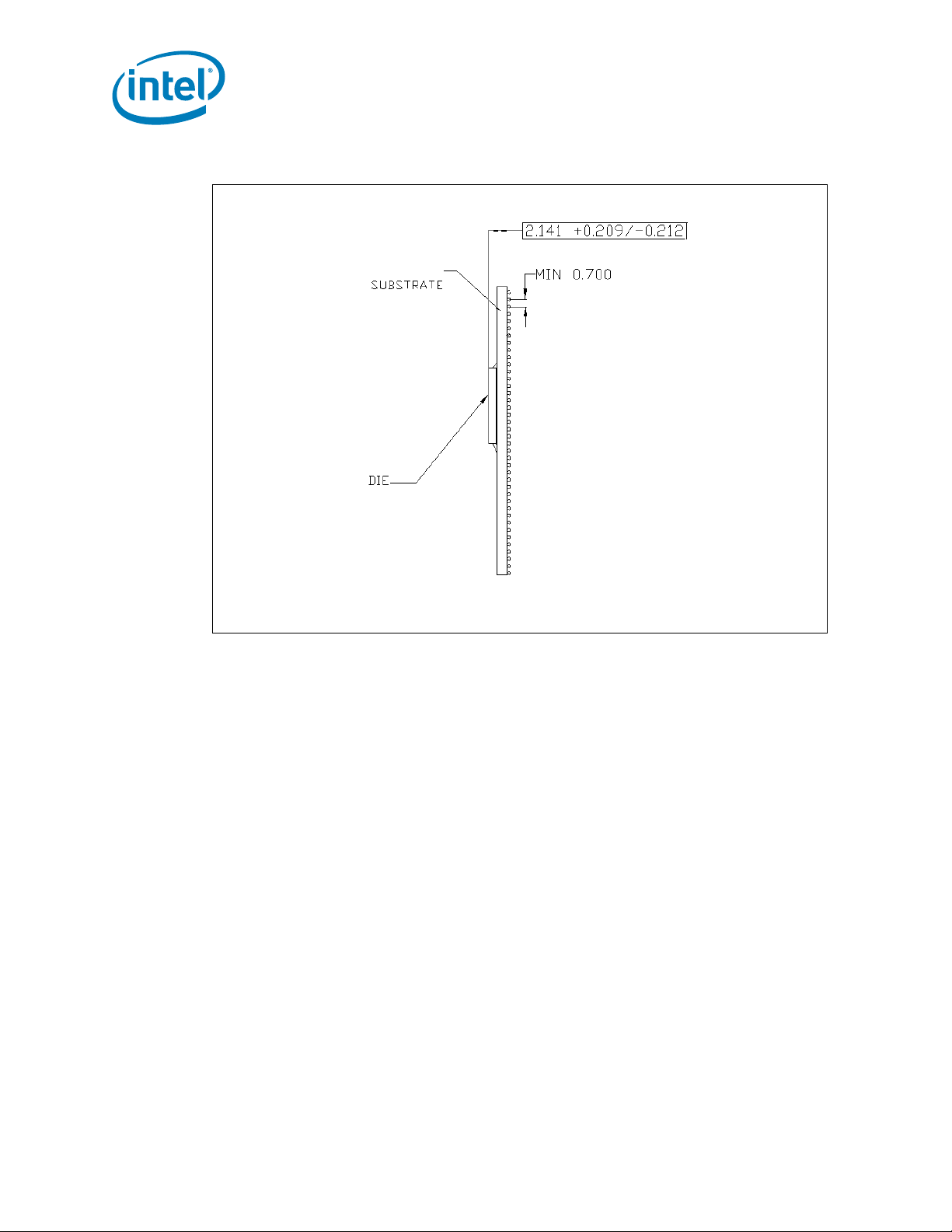

Page 10

Figure 2-2. Package Dimensions (Side View)

Packaging Mechanical Specifications

Note: All dimensions in mm

10 Thermal Mechanical Specifications and Design Guidelines

Page 11

Packaging Mechanical Specifications

$

%8

Figure 2-3. Package (Land Side View)

Note: All dimensions in mm

2.2 Solder Balls

A total of 942 solder balls corresponding to the lands are on the bottom of the PCH

package for surface mounting with the motherboard. The package solder ball has the

following characteristics:

• Lead free SAC (SnAgCu) 405 solder alloy with a silver (Ag) content between 3%

and 4% and a melting temperature of approximately 217 °C. The alloy is

compatible with immersion silver (ImAg) and Organic Solderability Protectant

(OSP) motherboard surface finishes and a SAC alloy solder paste.

• Solder ball diameter 17 mil [0.4138 mm], before attaching to the package.

Thermal Mechanical Specifications and Design Guidelines 11

Page 12

Packaging Mechanical Specifications

2.3 Package Mechanical Requirements

The package has a bare die that is capable of sustaining a maximum static normal load

of 15 lbf (67 N).

Note: The heatsink attach solutions must not induce continuous stress to the package with

Note: These specifications apply to uniform compressive loading in a direction perpendicular

Note: These specifications are based on limited testing for design characterization. Loading

the exception of a uniform load to maintain the heatsink-to-package thermal interface.

to the die top surface.

limits are for the package only.

§ §

12 Thermal Mechanical Specifications and Design Guidelines

Page 13

Thermal Specifications

3 Thermal Specifications

To ensure proper operation and reliability of the PCH, the case (or junction)

temperature must be at or below the maximum value specified in Table 3-1. System

and/or component level thermal solutions are required to maintain these temperature

specifications. Chapter 5 provides the thermal metrology guidelines for case

tempearture measurements.

3.1 Thermal Design Power (TDP)

Real applications are unlikely to cause the PCH component to consume maximum

power dissipation for sustained time periods. Therefore, in order to arrive at a more

realistic power level for thermal design purposes, Intel characterizes power

consumption to reach a Thermal Design Power (TDP). TDP is the target power level to

which the thermal solutions should be designed. TDP is not the maximum power that

the PCH can dissipat e , see Table 3-1.

TDP condition is a set of applications when run simultaneously, would stress all its

features and dissipate power equivalent to TDP in the worst leakage scenario, see

Table 3-2. The configuration of PCH TDP is in Table 3-3.

3.2 Thermal Specifications

The data in Table 3-1 is based on post-silicon power measurements for the PCH. The

TDP, Idle, S3 and S5 (deep Sx) values are based on system configuration, see the

notes of Table 3-1. Intel recommends designing the PCH thermal solution to the TDP

for maximum flexibility and reuse. The PCH package has poor heat transfer capability

into the board and has minimal thermal capability without thermal solutions. Intel

requires that system designers plan for an attached heatsink when using the PCH. The

reference thermal solution is described in Chapter 6.

Table 3-1. PCH Thermal Specifications (Sheet 1 of 2)

Parameter Value Notes

Tcase-max 104 °C

Tcase-min 0 °C

Tj,max 108 °C

Tcontrol 104 °C

1. The value is based on system configuration and applications running

TDP 6.1 W

Idle 2.77 W

Idle

(configuration 2)2.65 W

simultaneously, see Table 3-2 and Table 3-3.

2. The value measurement is based on a core voltage of 1.05V and Tj of Tj,max

1. The value is based on system configuration, see Table 3-4

2. The value measurement is based on a core voltage of 1.05 V and Tj of 50 °C

1. The value is based on system configuration, see Table 3-4 but disconnected

one Gen 2 SATA HDD

2. The value measurement is based on a core voltage of 1.05 V and Tj of 50 °C

Thermal Mechanical Specifications and Design Guidelines 13

Page 14

Table 3-1. PCH Thermal Specifications (Sheet 2 of 2)

Parameter Value Notes

Idle

(configuration

3)

S3 0.128 W The value measurement is based on Tj of 35°C

S5/ deep Sx <0.009 W The value measurement is based on Tj of 35°C

2.41 W

1. The value is based on system configuration, see Table 3-4

one Gen 2 SATA HDD and disabled integrated graphic and then installed an

external graphic card.

2. The value measurement is based on a core voltage of 1.05 V and Tj of 50 °C

Table 3-2. PCH TDP Workload Running Simultaneously

TDP Workload Description (Applications running concurrently)

Windows* 7 system back up (Video, Pictire, Music, etc...) to USB HDD

Printer emulation (print ASCII test file to USB thumbdrive)

NetBlast over LAN to emulate heavy web traffic (Local network, system 1)

Media download from digital camera

Large file copy from HDD to USB thumbdrive

NetBlast over WLAN to emulate heavy web traffic (Local network, system 2)

1080P HD Video Recording over PCIE

NetBlast over PCI-LAN card to emulate heavy web traffic (Local network, system 3)

Large file copy from USB thumbdrive to USB HDD

Web Camera 1600 x 1200 @ 30 fps active (running Skype)

Thermal Specifications

but disconnected

Table 3-3. PCH TDP Configuration (Sheet 1 of 2)

PCH Interfaces Connected and Active Notes

USB Port 0 Flash Drive High-speed

USB Port 1 External USB HDD High-speed

USB Port 2 Digital Camera High-speed

USB Port 3 Media Card Reader High-speed

USB Port 4 USB Keyboard Low-speed

USB Port 5 USB Mouse Low-speed

USB Port 6 MP3 Player High-speed

USB Port 7 Gaming Controller Low-speed

USB Port 10 WebCam (640x480) High-speed

USB Port 13 Printer High-speed

SATA Port 0 HDD Non-Raid OS Gen 3

SATA Port 1 HDD Raid Array Gen 3

SATA Port 2 HDD Raid Array Gen 2

SATA Port 3 HDD Raid Array Gen 2

SATA Port 4 DVD/CD RW ODD Gen 1

SATA Port 5 BD ODD Gen 1

PCIE Port 1 Lewisville Gbe

PCIE Port 3 HDMI* HDTV Recorder

PCIE Port 5 USB3 Dongle

PCIE Port 6 WiFi (Mini PCIE)

Display Link 1 DP 1920 x 1200, 60 Hz, 24bpp

14 Thermal Mechanical Specifications and Design Guidelines

Page 15

Thermal Specifications

Table 3-3. PCH TDP Configuration (Sheet 2 of 2)

PCH Interfaces Connected and Active Notes

Display Link 2 VGA 1920 x 1200, 60 Hz, 24bpp

Platform Audio Jacks Headphone/Microphone Combination

FDI x 2 x2 for each 1920x1200, 60 Hz, 24bpp

DMI x 4 Active

LPC I/F Active

PCI 1394 Controller Active

Table 3-4. PCH Idle Power Configuration

PCH Interfaces Link Utilization Notes

High Definition Audio Idle External Codec

USB Port 1 EHCI1 (Idle, ports in suspend) Low-speed Keyboard

USB Port 2 Low-speed Mouse

SATA Port 2 Windows 7 system Idle, LPM disabled Gen 2 HDD

SATA Port 3 Windows 7 system Idle, LPM disabled Gen 2 HDD

SATA Port 5 Windows 7 system Idle, LPM disabled Gen 1 ODD

PCIE Port 1 100% L1 x 1 device Lewisville Gbe

PCIE Port 2 100% L1 x 1 device (IEEE-1394b Controller)

Display Link 1 Active VGA 1920 x 1200, 60 Hz, 24bpp

FDI x 2 1920x1200, 60 Hz, 24bpp

Thermal Mechanical Specifications and Design Guidelines 15

Page 16

3.3 Storage Specifications

Table 3-5 includes a list of the specifications for device storage in terms of maximum

and minimum temperatures and relative humidity. These conditions should not be

exceeded in storage or transportation.

Table 3-5. Storage Conditions

Parameter Description Min Max Notes

The non-operating device storage temperature.

T

ABSOLUTE STORAGE

T

SUSTAINED STORAGE

RH

SUSTAINED STORAGE

TIME

SUSTAINED STORAGE

Note:

1. Refers to a component device that is not assembled in a board or socket that is not to be electrically

connected to a voltage reference or I/O signals.

2. Specified temperatures are based on data collected. Exceptions for surface mount reflow are specified in by

applicable JEDEC standard. Non-adherence may affect component reliability.

3. T

ABSOLUTE STORAGE

moisture barrier bags or desiccant.

®

4. Intel

5. The JEDEC, J-JSTD-020 moisture level rating and associated handling practices apply to all moisture

6. Nominal temperature and humidity conditions and durations are given and tested within the constraints

branded board products are certified to me et th e fol lowing temperat ure and humidity limits that are

given as an example only (Non-Operating Temperature Limit: -40 °C to 70 °C & Humidity: 50% to 90%,

non-condensing with a maximum wet bulb of 28 °C). Post board attach storage temperature limits are not

specified for non-Intel

sensitive devices removed from the moisture barrier bag.

imposed by Tsustained and customer shelf life in applicable Intel

Damage (latent or otherwise) may occur when

subjected to for any length of time.

The ambient storage temperature limit (in shipping

media) for a sustained period of time.

The maximum device storage relative humidity for

a sustained period of time.

A prolonged or extended period of time; typically

associated with customer shelf life.

applies to the unassembled component only and does not apply to the shipping media,

®

branded boards.

Months6 Months

®

box and bags.

Thermal Specifications

-55 °C 125 °C 1, 2, 3

-5 °C 40 °C 4, 5

60% @ 24 °C 5, 6

0

6

§ §

16 Thermal Mechanical Specifications and Design Guidelines

Page 17

Thermal Simulation

4 Thermal Simulation

Intel provides thermal simulation models of the PCH and associated users’ guides to aid

system designers in simulating, analyzing, and optimizing their thermal solutions in an

integrated, system-level environment. The models are for use with the commercially

available Computational Fluid Dynamics (CFD)-based thermal analysis tool FLOTHERM*

(version 5.1 or higher) by Flomerics, Inc. and Icepak* by Fluent. Contact your Intel

field sales representative to order the thermal models and users’ guides.

§ §

Thermal Mechanical Specifications and Design Guidelines 17

Page 18

Thermal Simulation

18 Thermal Mechanical Specifications and Design Guidelines

Page 19

Thermal Metrology

Start

End

Attach

thermocouple.

Setup the system

in the desired

configuration

Revise

Heatsink or

Boundary

Conditions

Run representative

workload for the

configuration and

monitor the device

temperature

Temperature >

Specification?

Attach the

device to the

board using

normal reflow

process

Yes

No

Start

End

Attach

thermocouple.

Setup the system

in the desired

configuration

Revise

Heatsink or

Boundary

Conditions

Run representative

workload for the

configuration and

monitor the device

temperature

Temperature >

Specification?

Attach the

device to the

board using

normal reflow

process

Yes

No

5 Thermal Metrology

The system designer must make temperature measurements to accurately determine

the thermal performance of the system. Intel has established guidelines for proper

techniques to measure the PCH case and junction temperatures. The flowchart in

Figure 5-1 offers useful guidelines for thermal performance and evaluation.

Figure 5-1. Thermal Solution Decision Flow Chart

5.1 Tcase Temperature Measurements

To ensure functionality and reliability, the T

between the maximum/minimum operating range of the temperature specification as

noted in Table 3-1. The surface temperature at the geometric center of the die

corresponds to T

. Measuring T

case

requires special care to ensure an accurate

case

temperature measurement.

T emperature differences between the surface and the surrounding local ambient air can

introduce errors in the measurements. The measurement errors could be due to a poor

thermal contact between the thermocouple junction and the surface of the package,

heat loss by radiation and/or convection, conduction through thermocouple leads, and/

or contact between the thermocouple cement and the heatsink base (if a heatsink is

used). For maximum measurement accuracy, only the following thermocouple attach

approach is recommended.

5.1.1 Heatsink Thermocouple Attach Methodology

1. Mill a 3.3 mm (0.13 in.) diameter and 1.5 mm (0.06 in.) deep hole centered on the

bottom of the heatsink base.

2. Mill a 1.3 mm (0.05 in.) wide and 0.5 mm (0.02 in.) deep slot from the centered

hole to one edge of the heatsink. The slot should be parallel to the heatsink fins

(see Figure 5-2).

3. Attach thermal interface material (TIM) to the bottom of the heatsink base.

of the PCH must be maintained at or

case

Thermal Mechanical Specifications and Design Guidelines 19

Page 20

4. Cut out portions of the TIM to make room for the thermocouple wire and bead. The

Cement +

Thermocouple Bead

Die

Thermocouple

Wire

Substrate

cutouts should match the slot and hole milled into the heatsink base.

5. Attach a 36 gauge or smaller calibrated K-type thermocouple bead or junction to

the center of the top surface of the die using a high thermal conductivity cement.

During this step, ensure no contact is present between the thermocouple cement

and the heatsink base because any contact will affect the thermocouple reading. It

is critical that the thermocouple bead makes contact with the die (see Figure 5-3).

6. Attach heatsink assembly to the package and route thermocouple wires out

through the milled slot.

Figure 5-2. Heatsink Modifications

Thermal Metrology

Note: Not to Scale

Figure 5-3. Top View of Package

20 Thermal Mechanical Specifications and Design Guidelines

Page 21

Thermal Metrology

5.2 Ambient Temperature and Airflow Measurement

Figure 5-4 describes the recommended location for air temperature measurements

measured relative to the component. For a more accur ate measurement of the av erage

approach air temperature, Intel recommends averaging temperatures recorded from

two thermocouples spaced about 25 mm [1.0 in] apart. Locations for both a single

thermocouple and a pair of thermocouples are presented.

Airflow velocity should be measured using industry standard air velocity sensors.T ypical

airflow sensor technology may include hot wire anemometers.

Figure 5-4 provides guidance for airflow velocity measurement locations. These

locations are for a typical JEDEC test setup and may not be compatible with all chassis

layouts due to the proximity of the PCI and PCI Express* add-in cards to the

component. The user may have to adjust the locations for a specific chassis. Be aware

that sensors may need to be aligned perpendicular to the airflow velocity vector or an

inaccurate measurement may result. Measurements should be taken with the chassis

fully sealed in its operational configuration to achieve a representative airflow profile

within the chassis.

Figure 5-4. Airflow & Temperature Measurement Locations

§ §

Thermal Mechanical Specifications and Design Guidelines 21

Page 22

Thermal Metrology

22 Thermal Mechanical Specifications and Design Guidelines

Page 23

ATX Reference Thermal Solution

6 ATX Reference Thermal

Solution

Note: The reference thermal mechanical solution information shown in this document

represents the current state of the design. The data is subject to modification and

represents design targets, not commitments by Intel.

The design strategy for the PCH thermal solution is to reuse the z-clip heatsink

originally designed for the I/O Controller Hub 6 (ICH6) Family and used on subsequent

ICH designs through ICH10 and also for Intel® 5 Series Chipset design.

This section describes the overall requirements for the A TX heatsink reference thermal

solution including critical-to-function dimensions, operating environment, and

validation criteria. Other chipset components may or may not need attached thermal

solutions depending on your specific system local-ambient operating conditions.

6.1 Reference Solution

The reference solution is an extruded aluminum heatsink with pre-applied phase

change thermal interface material (TIM). The TIM is a Chomerics T710. The reference

solution is provided as an assembly with the clip, TIM and extrusion. See Appendix B

for the complete set of mechanical drawings including the motherboard keep-out zone.

The reference design z-clip centers the load on the die and by design will keep the

heatsink flush and parallel with the top surface of the die. The TIM size in the reference

design is larger than the die area. The resistivity of the TIM is 5 x 10^16 Ohm-cm. Any

TIM material that comes in contact with die side capacitors (DSC) will not cause a

short.

During the heatsink assembly process the heatsink may come in contact with DSC. The

maximum spring force allowed for the reference design z-clip has not been shown to

cause damage to DSC during assembly.

Thermal Mechanical Specifications and Design Guidelines 23

Page 24

Figure 6-1. Reference Thermal Solution

ATX Reference Thermal Solution

6.2 Environmental Reliability Requirements

The reference solution heatsink will be evaluated to the reliability requirements in

Table 6-1. The mechanical loading of the component may vary depending on the

heatsink, and attach method used. The customer should define a validation test suite

based on the anticipated use conditions and resulting reliability requirements. Thermal

cycling, bake and humidity tests were performed on original design and are not being

repeated. The designer should select appropriate thermal / humidity tests for the

expected use conditions.

Table 6-1. Reference Thermal Solution Environmental Reliability Requirements

Test Requirement Pass / Fail Criteria

3 drops for + and - directions in each of 3 perpendicular

Mechanical Shock

Random Vibration

axes (that is, total 18 drops).

Profile: 50 G trapezoidal waveform, 170 inches/sec.

minimum velocity change.

Setup: Mount sample board on test fixture

Duration: 10 min/axis, 3 axes

Frequency Range: 5 Hz to 500 Hz

Power Spectral Density (PSD) Profile: 3.13 g RMS

§ §

Visual\Electrical Check

Visual\Electrical Check

24 Thermal Mechanical Specifications and Design Guidelines

Page 25

Thermal Solution Component Vendors

A Thermal Solution Component

Vendors

Note: These vendors and devices are listed by Intel as a convenience to Intel's general

customer base, but Intel does not make any representations or warranties whatsoever

regarding quality, reliability, functionality, or compatibility of these devices. This list

and/or these devices may be subject to change without notice.

Table A-1. Reference Heatsink Enabled Components

Item Intel PN AVC CCI Foxconn Wieson

Heatsink

Assembly

Anchor A13494-008 HB9703E-DW G2100C888-064H

Table A-2. Supplier Contact Information

C46655-001 S702C00001 00C855802B 2Z802-009

Supplier Contact Phone

AVC

(Asia Vital Corporation)

CCI(Chaun Choung

Technology

Foxconn

Wieson

Kai Chang

Monica Chih

Harry Lin

Jack Chen

Wanchi Chen

Chary Lee

Henry Liu

+86 755 3366 8888

x63588

+886-2-2995-2666

(714) 739-5797

(408) 919-6121

(408) 919-6135

+886-2-2647-1896 ext. 6684

+886-2-2647-1896 ext.6330

kai_chang@avc.com.tw

monica_chih@ccic.com.tw

hlinack@aol.com

jack.chen@foxconn.com

wanchi.chen@foxconn.com

chary@wieson.com

henry@wieson.com

§ §

Thermal Mechanical Specifications and Design Guidelines 25

Page 26

Thermal Solution Component Vendors

26 Thermal Mechanical Specifications and Design Guidelines

Page 27

Mechanical Drawings for Package and Reference Thermal Solution

B Mechanical Drawings for

Package and Reference

Thermal Solution

The following mechanical drawings are included in this appendix:

Figure B-1, “Desktop Platform Controller Hub Package Drawing” on page 28

Figure B-2, “Motherboard Keep-Out for ATX Reference Heatsink” on page 29

Figure B-3, “ATX Reference Heatsink Assembly” on page 30

Figure B-4, “ATX Reference Heatsink Extrusion” on page 31

Figure B-5, “ATX Reference Heatsink Clip” on page 32

Thermal Mechanical Specifications and Design Guidelines 27

Page 28

Mechanical Drawings for Package and Reference Thermal Solution

Figure B-1. Desktop Platform Controller Hub Package Drawing

28 Thermal Mechanical Specifications and Design Guidelines

Page 29

Mechanical Drawings for Package and Reference Thermal Solution

13

4

5678

B

C

D

A

123

4

5678

B

C

D

A

THIS DRAWING CONTAINS INTEL CORPORATION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONTENTS

MAY NOT BE DISCLOSED, REPRODUCED, DISPLAYED OR MODIFIED, WITHOUT THE PRIOR WRITTEN CONSENT OF INTEL CORPORATION.

SHEET 1 OF 1DO NOT SCALE DRAWINGSCALE: 1

1.0C45961 D

REVDRAWING NUMBERCAGE CODESIZE

ICH 6 KEEPOUT DRAWING

TITLE

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

CORP.

R

TMD

DEPARTMENT

NA

FINISH:NAMATERIAL:

06/02/03D.CARTER

DATEAPPROVED BY

06/02/03F.ANDERS

DATECHECKED BY

06/01/03P. JOHNSON

DATECHECKED BY

5/30/03S.LOFLAND

DATEDESIGNED BY

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS.

INTERPRET DIMENSIONS AND TOLERANCES

PER ANSI Y14.5M-1994

THIRD ANGLE PROJECTION

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPROVED

*** 0.5 PRELIMINARY RELEASE 06/02/03 PJ

1.0 CHANGED REV FROM 0.5 TO 1.0 09/28/04 D.CARTER

C45961 1 1.0

DWG. NO SHT. REV

2X 22.39

.882[]

2X 5.08

.200[]

2X 4.19

.165[]

2X 8.76

.345[]

2X 2.11

.083[]

2X 1.85

.073[]

33

1.299[]

33

1.299[]

2X 27.43

1.080[]

2X 18.29

.720[]

4X PLATED THRU HOLE0.97 .038[]

2X 5

.197[]

5

.197[]

1.5 [ .059]

MAX COMPONENT HEIGHT

(NON-ICH COMPONENTS)

3.25 [ .125]

MAX COMPONENT HEIGHT

NO COMPONENTS THIS AREA

4X 1.42[.056] TRACE KEEPOUT

DETAIL A

DO NOT SCALE

SEE DETAIL A

COMPONENT CENTER

NOTES:

1 . HOLE PLACEMENT FABERICATION

TOLERANCE PER INTEL 454979, CLASS 1,2,3.

1

Figure B-2. Motherboard Keep-Out for ATX Reference Heatsink

Thermal Mechanical Specifications and Design Guidelines 29

Page 30

Mechanical Drawings for Package and Reference Thermal Solution

Figure B-3. ATX Reference Heatsink Assembly

30 Thermal Mechanical Specifications and Design Guidelines

Page 31

Mechanical Drawings for Package and Reference Thermal Solution

Figure B-4. ATX Reference Heatsink Extrusion

Thermal Mechanical Specifications and Design Guidelines 31

Page 32

Mechanical Drawings for Package and Reference Thermal Solution

Figure B-5. ATX Reference Heatsink Clip

§ §

32 Thermal Mechanical Specifications and Design Guidelines

Loading...

Loading...