Integrated

Circuit

Systems, Inc.

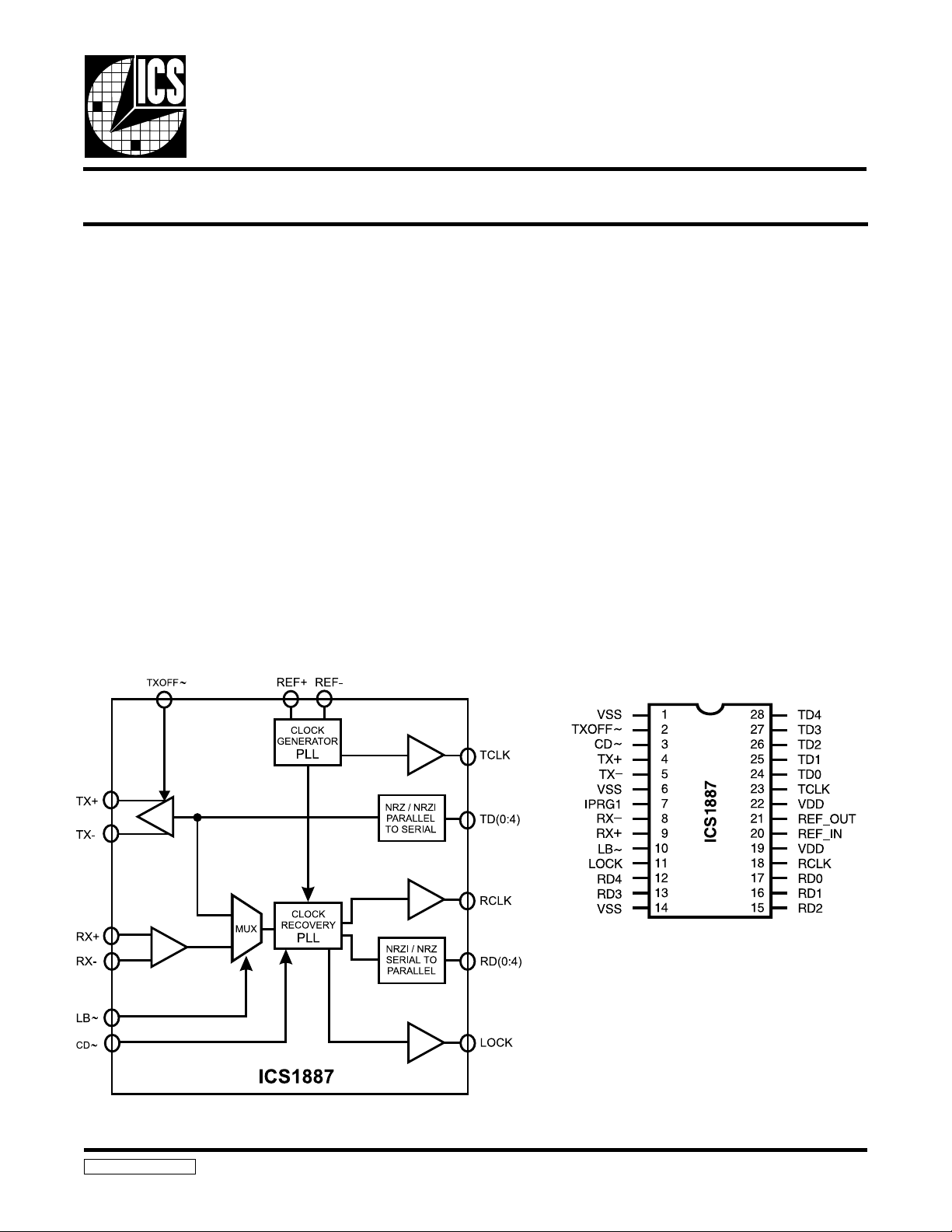

ICS18 87

FDDI / Fast Ethernet PHYceiver

TM

General Description Features

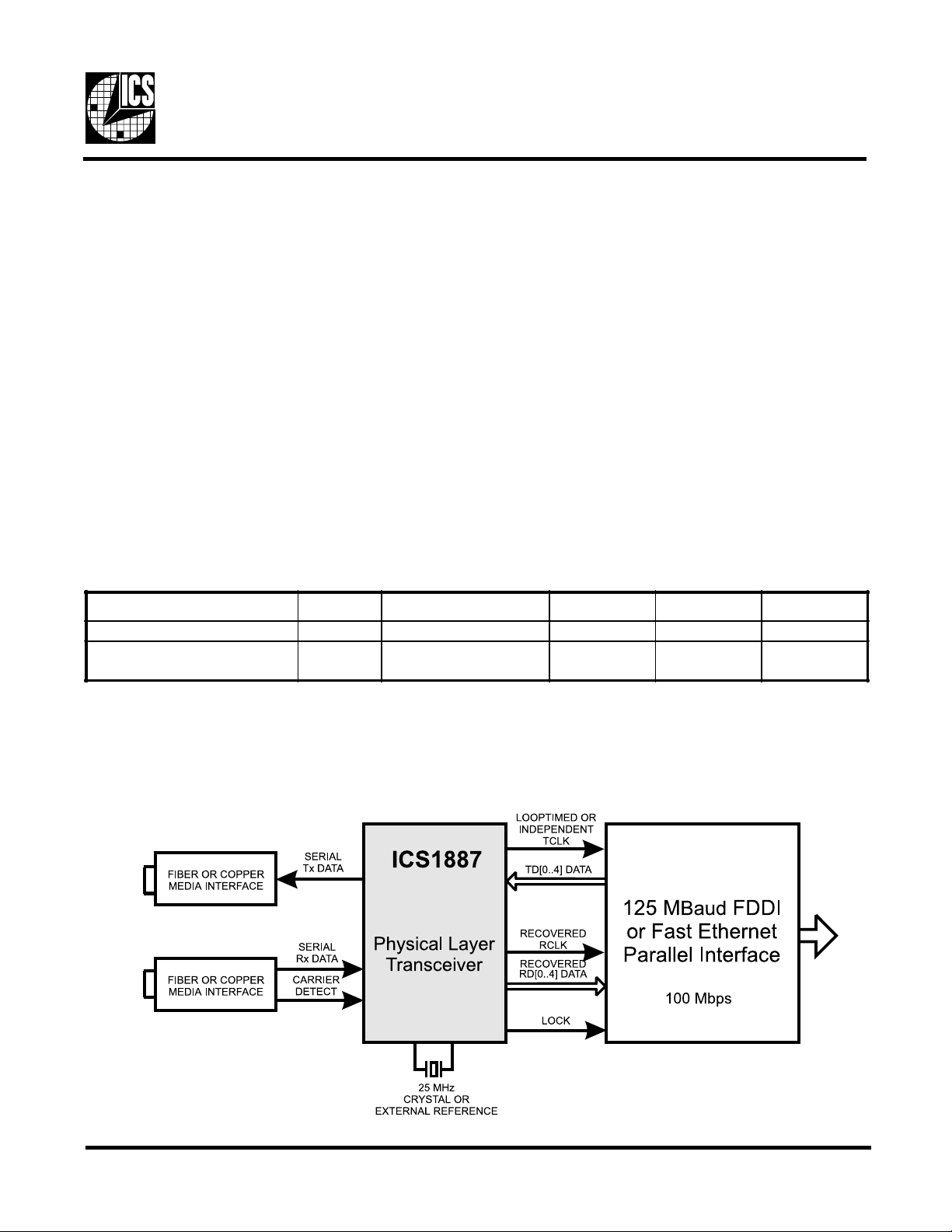

The ICS1887 is designed to provide high performance clock

recovery and generation for 125 MHz serial data streams. The

ICS1887 is ideally suited for LAN transceiver applications in

either FDDI or Fast Ethernet environments. The ICS1887

converts NRZ to/from NRZI data in addition to providing a

5-bit parallel digital data transmit and receive interface.

Clock and data recovery is performed on an input serial data

stream or the buffered transmit data depending upon the state

of the loopback input. A continuous clock source will

continue to be present even in the absence of input data.

All internal timing is derived from either a low cost crystal,

differential or single-ended source.

The ICS1887 utilizes advanced CMOS phase-locked loop

technology which combines high performance and low power

at a greatly reduced cost.

• Single IC solution to existing designs requiring

multiple devices

• Data and clock recovery for 125 MBaud FDDI or Fast

Ethernet applications

• Clock multiplication from either a crystal, differential

or single-ended timing source

• Continuous clock in the absence of data

• No external PLL components

• Lock/Loss status indicator output

• Loopback mode for system diagnostics

• Selectable loop timing mode

• PECL driver with settable sink current

• Parallel digital transmit and receive data interface

• NRZ to/from NRZI data conversion

• Consult ICS for optional configurations and data rates

Block Diagram

Pin Configuration

28-Pin SOIC

ICS1887RevF112596

PHYceiver is a trademark of Integrated Circuit Systems, Inc.

ICS1887

Pin Descriptions

PIN

NUMBER

PIN NAME TYPE DESCRIPTION

1 VSS Negative Supply Voltage

2 TXOFF~

3 CD~ TTL-Compatible

2

TTL-Compatible Transmitter Off*

1

Carrier Detect input*

4 TX+ PECL Positive Tr ansmit serial data output

5 TX– PECL Negative Transmit serial data outpu t

6 VSS Negative supply voltage

7 IPRG1 PECL Output stage current set (TX)

8 RX– PECL Negative Receive serial data input

9 RX+ PECL Positive Receive serial data input

10 LB~ TTL-Compatible Loop Back mode select*

11 LOCK TTL-Compatible Lock detect output

12 RD4 T TL-Compatible Recovered data output 4

13 RD3 T TL-Compatible Recovered data output 3

14 VSS Negative supply voltage

15 RD2 T TL-Compatible Recovered data output 2

16 RD1 T TL-Compatible Recovered data output 1

17 RD0 T TL-Compatible Recovered data output 0

18 RCLK T TL-Compatible Recovered Receive clock output

19 VDD Positive supply volta ge

20 REF_IN Positive reference clock/crystal input

21 REF_OUT Negative reference clock/crystal output

22 VDD Positive supply volta ge

23 TCLK TTL-Compatible Transmit clock output

24 TD0 TTL-Compatible Transmit data input 0

25 TD1 TTL-Compatible Transmit data input 1

26 TD2 TTL-Compatible Transmit data input 2

27 TD3 TTL-Compatible Transmit data input 3

28 TD4 TTL-Compatible Transmit data input 4

* Active Low Input.

Note:

1. A running production change will be made to this input in the June 1996 time frame to convert this

input from the TTL-compatible to PECL to more closely match applications requirements. See

Substituting the ICS1887 for the AMD PDR & PDT applications note for more information.

2. This pin was formerly used for Loop-Timed operation. If your design did not use loop timing, this

change does not affect you. If your application requires loop timing, please contact ICS.

2

ICS1887

Input Pin Descriptions

Parallel Transmit Data (TD0 .. TD4)

Five bit TTL compatible digital input, which is received by

the ICS1887 on the positive edge of TCLK. High impedance

input drivers routed to the serial NRZ to NRZI converter. In

loopback testing mode, this NRZI data is multiplexed to the

input of the device clock recovery section.

Differential ECL Receive Data Input (RX+ & RX-)

The clock recovery and data regenerator from the receive

buffer are driven from this PECL input. During loopback testing mode this input is ignored.

Carrier Detect (CD~)

Active low input which forces the VCO to free run. Upon

receipt of a loss of input signal (such as from an optical-toelectrical transducer), the internal phase-lock loop will

free-run at the selected operating frequency. Also, when

asserted, CD will set the lock output low.

Transmitter Off (TXOFF~)

Active low input which, when low, forces TX+ low and

TX-high. When high, data passes through TX+ and TXunaffected. This input has an internal pull-up resistor.

Loopback Mode (LB~)

Active low input which causes the clock recovery PLL to

operate using the transmit input data reference and ignore the

receive RX± data. Utilized for system loopback testing.

External Crystal or Reference Clock

(REF_IN and REF_OUT)

This oscillator input can be driven from either a fundamental

mode crystal or a stable reference. For either method, the reference frequency is 25.00 MHz.

Output Pin Descriptions

Differential ECL Transmit Data (TX+ and TX-)

This differential output is converted TD[0..4] serial data. This

output remains active during loopback mode.

Receive Clock (RCLK)

A 25 MHz digital clock recovered with the internal clock

recovery PLL. In loopback mode this clock is recovered from

the transmit data.

Lock/Loss Detect (LOCK)

Set high when the clock recovery PLL has locked onto the

incoming data. Set low when there is no incoming data, which

in turn causes the PLL to free-run. This signal can be used to

indicate or ‘alarm’ the next receive stage that the incoming

serial data has stopped.

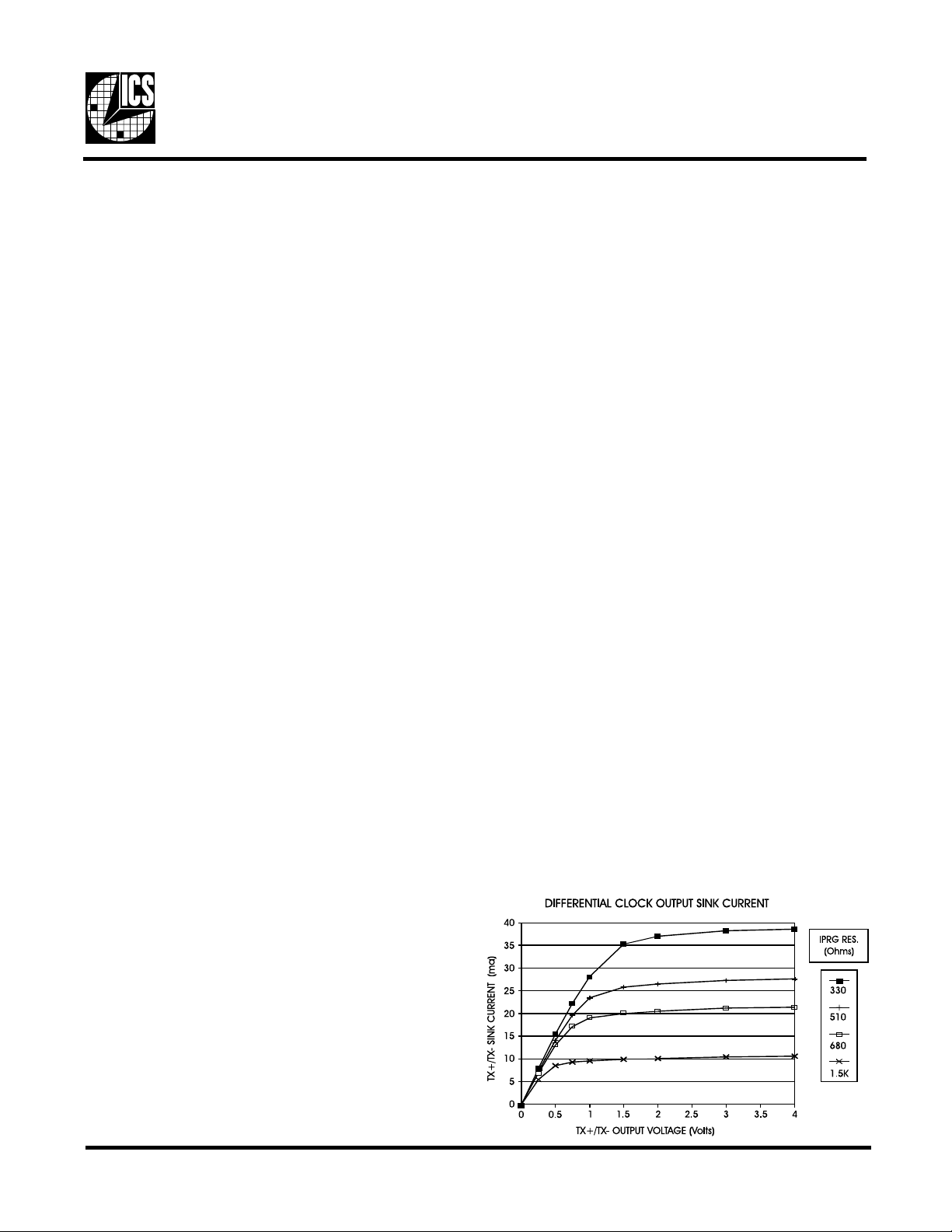

Output Description

The differential driver for the TX± is current mode and is designed to drive resistive terminations in a complementary

fashion. The output is current-sinking only, with the amount

of sink current programmable via the IPRG1 pin. The sink

current is equal to four times the IPRG1 current. For most

applications, an 910Ω resistor from VDD to IPRG1 will set

the current to the necessary precision.

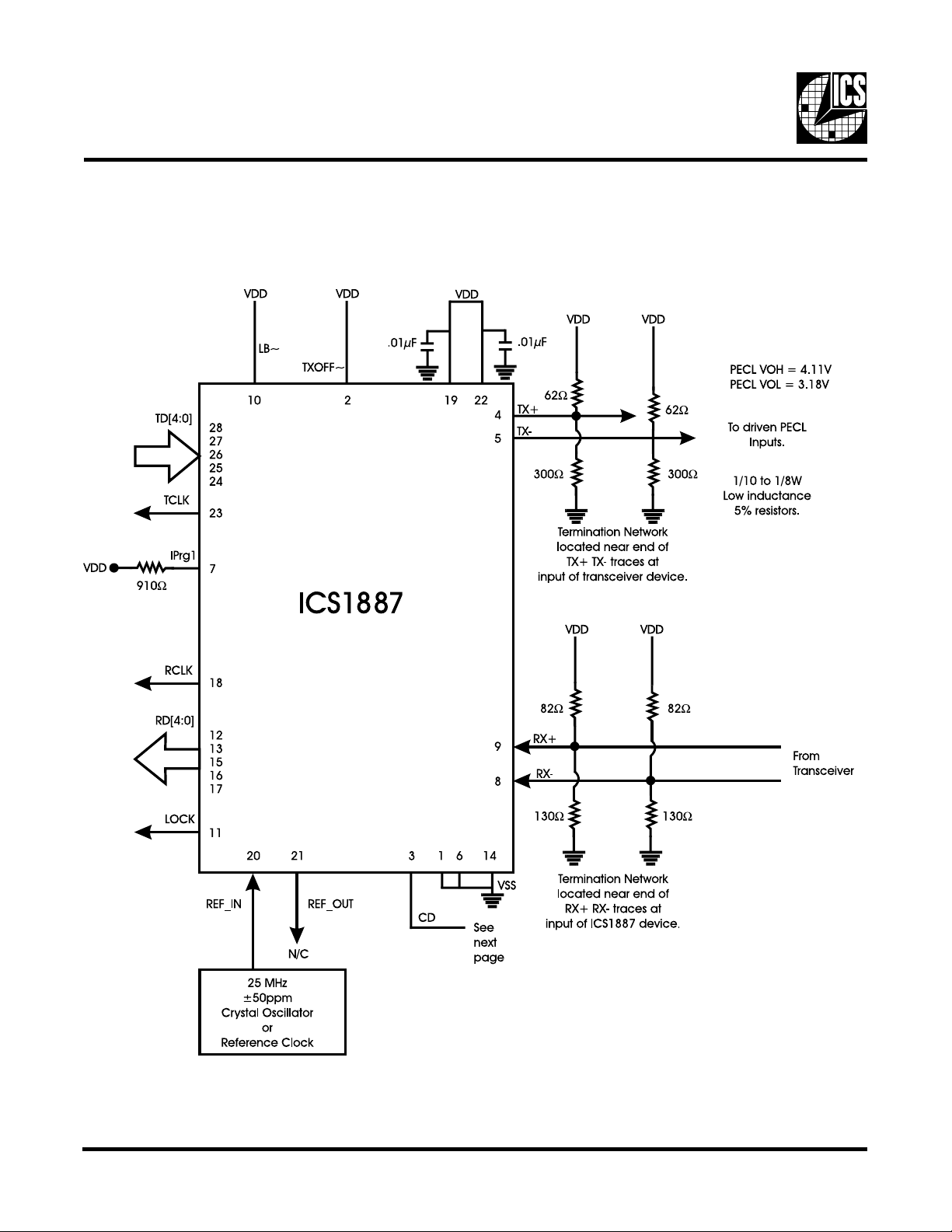

The TX± pins are incapable of sourcing current, so VOH must

be set by the ratios of the Thevenin termination resistors for

each of these lines. R1 is a pull-up resistor connected from the

PECL output to VDD. R2 is a pull-down resistor connected

from the PECL output to VSS. R1 and R2 are electrically in

parallel from an AC standpoint. If we pick a target impedance

of 50Ω for our transmission line impedance, a value of 62Ω

for R1 and a value of 300Ω for R2 would yield a Thevinin

equivalent characteristic impedance of 50Ω and a VOH value

of VDD-.88 volts, compatible with PECL circuits.

To set a value for VOL, we must determine a value for I

will cause the output FET’s to sink an appropriate current. We

desire VOL to be VDD-1.81 or greater . Setting up a sink current

of 19 milliamperes would guarantee this through our output

terminating resistors. As this is controlled by a 4/1 current

mirror, 4.75 mA into I

910Ω resistor from VDD to I

should set this current properly. An

prg

should work fine.

prg

prg

that

Transmit Clock (TCLK)

TTL compatible 25 MHz clock used by the parallel processor

transmitter for clocking out transmit data. This clock can be

derived from either an independent clock source or from the

recovered data clock (system loop time mode).

Parallel Receive Data (RD0 .. RD4)

The regenerated five bit parallel data derived from the serial

data input. In loopback mode this data is regenerated from the

transmit data. This data is phase-aligned with the negative

edge of RCLK clock output.

3

ICS1887

ICS1887 System Diagram

(PECL Termination for 50

ΩΩ

Ω Transmission Lines)

ΩΩ

4

Substituting the ICS1887

for the AMD PDR & PDT

This note describes the issues involved in replacing the AMD PDR & PDT with the

ICS1887.

There are a number of implementation differences between AMD’s PDR & PDT and the

ICS1887. This note describes the differences

and how they affect an application.

Signal Detect

Many twisted pair and fiber optic transceivers

provide a signal detect indication that becomes

active when the amount of energy being received reaches a threshold that makes it appear

to be data and not ambient noise.

The AMD PDR device has a single ended

PECL input (SDI) and provides a TTL level

output (SDO) that tracks the input. The input

controls the source that the PLL locks to. When

signal detect is asserted, the PLL locks to the

incoming receive data. When signal detect is

deasserted, the PLL locks to the LSCLK input

to prevent locking to an off center frequency.

ICS1887

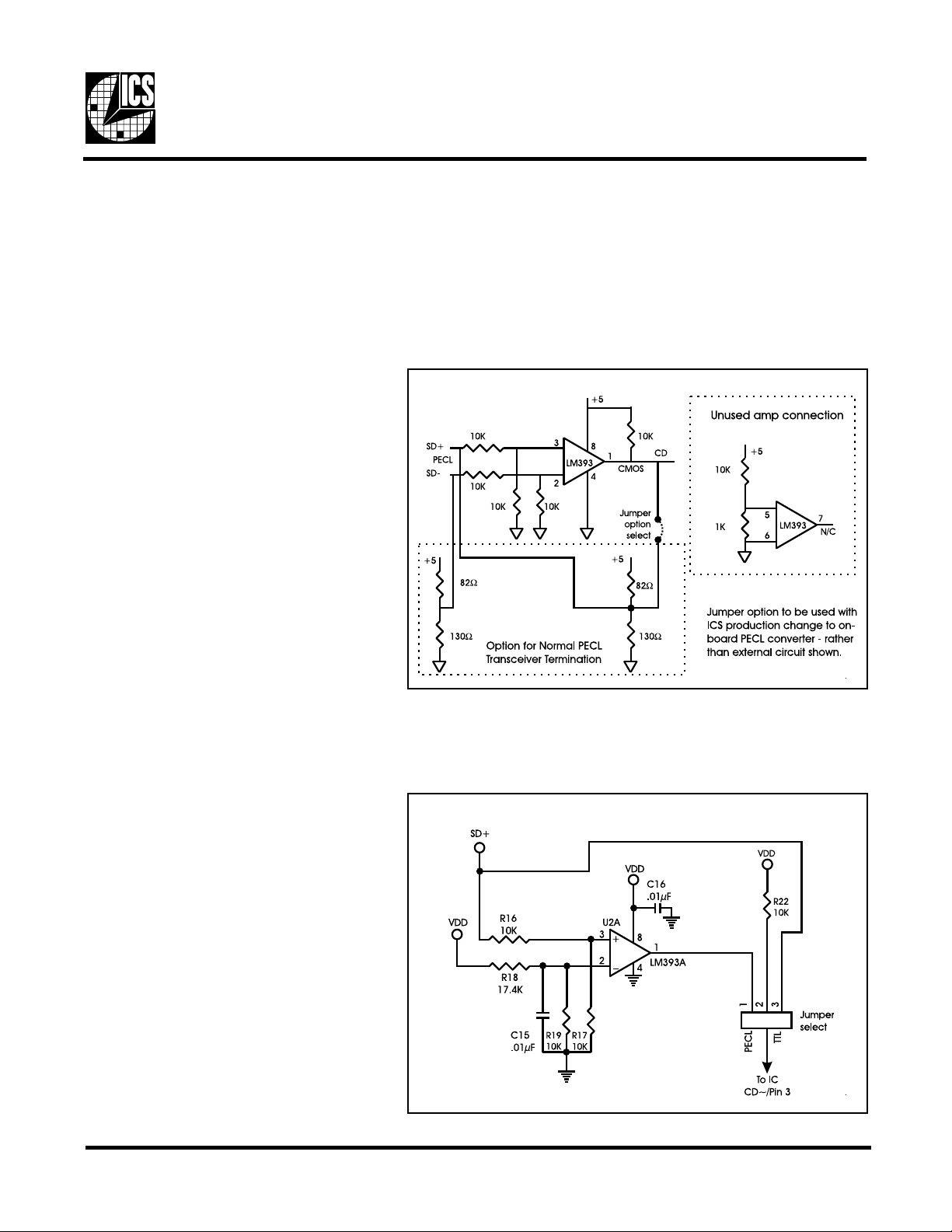

CD PECL Input: Board Layout Options

Option 1

Differential PECL to CMOS Conversion Circuit

The current ICS1887 device provides a single

TTL-compatible input, carrier detect (CD ~).

When carrier detect is asserted, the ICS1887

locks to the incoming receive data. When carrier detect is deasserted, or if carrier detect is

asserted and no data is present on the receive

inputs, the PLL will free run and continue to

provide RXCLK at the nominal 25 MHz

frequency. This allows the carrier detect input

to always be tied to an asserted level (ground).

If a true signal detect is required by a chip that

connects to the ICS1887 , a simple, low cost

PECL to CMOS converter can be used. The

following circuit implements this function:

Option 2

Single-Ended PECL to CMOS Conversion Circuit

5

ICS1887

This circuit provides the PECL to CMOS conversion for less

than $0.80 in single unit quantities. Note that the LM393 has

two amplifiers, so the unused one is tied inactive.

A running production change will be made to the ICS1887 to

change the CD input to PECL. Therefore, boards should be

laid out with a direct normal PECL termination connection

stuffing option. This allows either version of the part to be

used by stuffing one of two sets of external components. A

version of this circuit is shown in the diagram on the previous

page.

With ICS1887 devices that have a TTL-compatible CD input,

the “Differential PECL to CMOS Conversion Circuit” components need to be placed on the PCB and the “Normal PECL

Transceiver T ermination” resistors (82 Ω and 130Ω ) as well as

the option select jumper should NOT be placed.

When the final ICS1887 device with the PECL CD input is

used, none of the components in the “Differential PECL to

CMOS Conversion Circuit” or the “Unused amp connection”

circuits should be used. Only the four termination resistors

(87Ω and 130Ω) and the option select jumper are needed.

Note that these resistors should be located near the ends of the

transmission lines.

Loopback

The AMD PDR & PDT chips have an external loopback connection between the two chips. The ICS1887 also has a

loopback function, but it is totally internal to the device.

Optical Transmitter Off Control

The PDT chip has an input (FOTOFF) which can force an

optical transceiver to be off. The ICS1887 performs the same

behavior with the TXOFF~ pin.

Test Mode

Both the AMD PDR & PDT have a test mode that allows automated testers to test internal logic without the PLL clock

multiplier. The ICS1887 does not have a similar test mode.

T ransmit Current Selection

The ICS1887 allows the PECL transmit current level to be set

externally. An 887Ω resistor to the VDD supply is recommended.

Clocking

Parallel data that is to be serialized for transmission must be

presented to the data transmitter device with a certain amount

of setup and hold time to a given clock.

The PDT chip expects data to setup relative to the 25 MHz

Local Symbol Clock (LSCLK). This clock is an input to the

device.

The ICS1887 expects data to be setup relative to the 25 MHz

Reference In Clock (REF_IN). This clock is an input to the

ICS1887 device. Note that the REF_IN pin of the ICS1887 is

a CMOS input with a switching point of 50% of VDD. If this

pin is driven by a TTL output, a pull-up resistor to VDD must

be used. The ICS1887 device also provides a Transmit Clock

(TXC) output, which is a 50% duty cycle (nominal) copy of

the REF_IN input. The ICS1887 is designed to provide a very

low skew between the REF_IN and the TCLK.

6

ICS1887

Absolute Maximum Ratings

VDD (measured to VSS) . . . . . . . . . . . . . . . . . . 7.0 V

Digital Inputs/Outputs . . . . . . . . . . . . . . . . . . V

Ambient Operating Temperature . . . . . . . . . . – 55°C to +125°C

Storage Temperature . . . . . . . . . . . . . . . . . . . . – 65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . . 175°C

Soldering Temperature . . . . . . . . . . . . . . . . . . 260°C

Stresses above those listed under Absolute Maximum Ratings above may cause permanent damage to the device. This is a stress

rating only and functional operation of the device at these or any other conditions above those listed in the operational sections

of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may affect product

reliability.

Recommended Operating Conditions

–0.5 V to VDD +0.5 V

SS

PARAMETER SYMBOL TEST CONDITIONS MIN MAX UNITS

V

A

SS

DD

Ambient Operating Temp. T

Using a Positive Supply V

ICS1887 FDDI / Fast Ethernet Application

0+70ºC

0.0

+4.50

0.0

+5.50

V

V

7

ICS1887

DC Characteristics

VDD = V

Supply Current I

ECL Input / Output

ECL Input High Voltage V

ECL Input Low Voltage V

ECL Di fferent ial

Threshold Voltage Range

ECL Input Common

Mode Voltage

ECL Outp ut H igh Vol tage V

ECL Outp ut Low Vol tage V

TTL Input / Output

MIN

to V

, VSS = 0V, TA = T

MAX

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

PA RAMETER SYMBO L CONDIT IONS MIN MAX UNITS

V

V

DD

IH

IL

TH

CM

OH

OL

MIN

to T

MAX

V

= +5. 0V, VSS = 0.0V — 80 mA

DD

V

V

DD

DD

-1.16 V

-1.81 V

-0.88 V

DD

-1.47 V

DD

— 150 mV

1.3 V

V

-1.02 — V

DD

—V

-.4 V

DD

-1.62 V

DD

PA RAMETER SYMBOL CONDITIONS MIN MAX UNITS

TTL Input High Voltage V

TTL In put Low Volta ge V

TTL Output High Voltage V

TTL Output Low Voltage V

TTL Dr i vin g CM OS

Output High Voltage

TTL Dr i vin g CM OS

Output Low Voltage

TTL / CMOS Output

Sink Current

TTL / CMOS Output

Source Current

V

V

I

I

IH

IL

OH

OL

OH

OL

OL

OH

VDD = 5.0V, VSS = 0.0V 2.0 — V

VDD = 5.0V, VSS = 0.0V — 0.8 V

VDD = 5.0V, VSS = 0.0V 2.4 — V

VDD = 5.0V, VSS = 0.0V — 0.4 V

VDD = 5.0V, VSS = 0.0V 3.68 — V

VDD = 5.0V, VSS = 0.0V — 0.4 V

VDD = 5.0V, VSS = 0.0V 8 — mA

VDD = 5.0V, VSS = 0.0V — -0.4 mA

REF_IN Input

PA RAMETER SYMBO L CONDIT IONS MIN MAX UNITS

Input High Voltage V

Input Low Voltage V

Note: REF_IN Input switch point is 50% of VDD.

IH

IL

VDD = 5.0V, VSS = 0.0V 3.5 — V

VDD = 5.0V, VSS = 0.0V — 1.5 V

8

AC Characteristics

Clocks – Reference In (REF_IN) to Transmit Clock (TCLK)

ICS1887

T# PA RAMETE R (conditio ns) MIN TYP MAX UNIT S

t1 REF_IN Duty Cycle 45 50 55 %

t 2 REF_IN Per iod — 40 — n s

t3 REF_IN rise to TCLK rise 0 1.5 3.0 ns

9

ICS1887

Clocks — T ransmit Clock T olerance

T# PA RAMETE R (conditio ns) MIN TYP MAX UNIT S

t1 TCLK Duty Cycle 40 50 60 %

t 2 TCLK Period — 40 — ns

Note: TCLK Duty cycle = REF_IN Duty cycle ±5%.

Clocks — Receive Clock Tolerance

T# PA RAMETE R (conditio ns) MIN TYP MAX UNIT S

t1 RCLK Duty Cycle 45 50 55 %

t 2 RCLK Period — 40 — ns

10

ICS1887

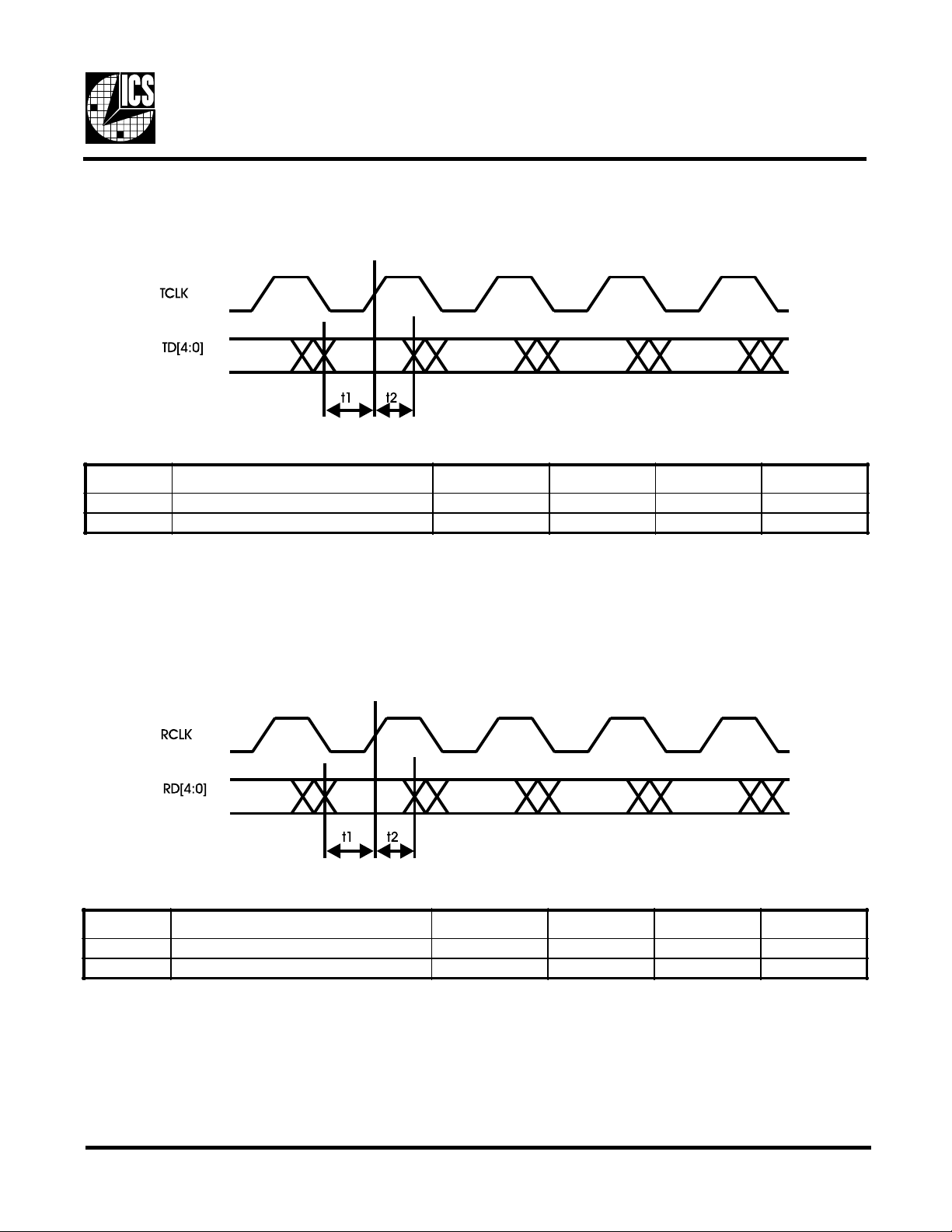

5-Bit Interface – Synchronous Transmit Timing

T# PA RAMETE R (conditio ns) MIN TYP MAX UNIT S

t 1 TD[4:0] Setup to TCLK rise 10 — — n s

t 2 TD[4:0 ] Hold after TCLK ris e 0 — — n s

5-Bit Interface – Synchronous Receive Timing

T# PARAMETER (conditions) MIN TYP MAX UNITS

t 1 RD[4:0] Setup to RCLK rise 13.0 — — n s

t 2 RD[4:0] Hold after RCLK rise 12.5 — — ns

11

ICS1887

Transmit Latency

T# PA RAMETE R (conditio ns) MIN TYP MAX UNITS

t 1 TD[4:0] sampled to T X+ Output of 1st bit — — 5 bits

Receive Latency

T# PARAMETER (conditions) MIN TYP MAX UNITS

t 1 MSbit into RX+ to MSb on RD[4:0] — — 8 bits

12

Clock Recover y

ICS1887

T# PA RAMETE R (conditio ns) MIN TY P MAX UNITS

t 1 Ideal data recovery window — — 8 n s

t 2 Actual data recove ry window 6 — 8 ns

t 3 Data recovery window truncation 0 — 1 ns

t4 CD assert to data acquired — — 5 µs

13

ICS1887

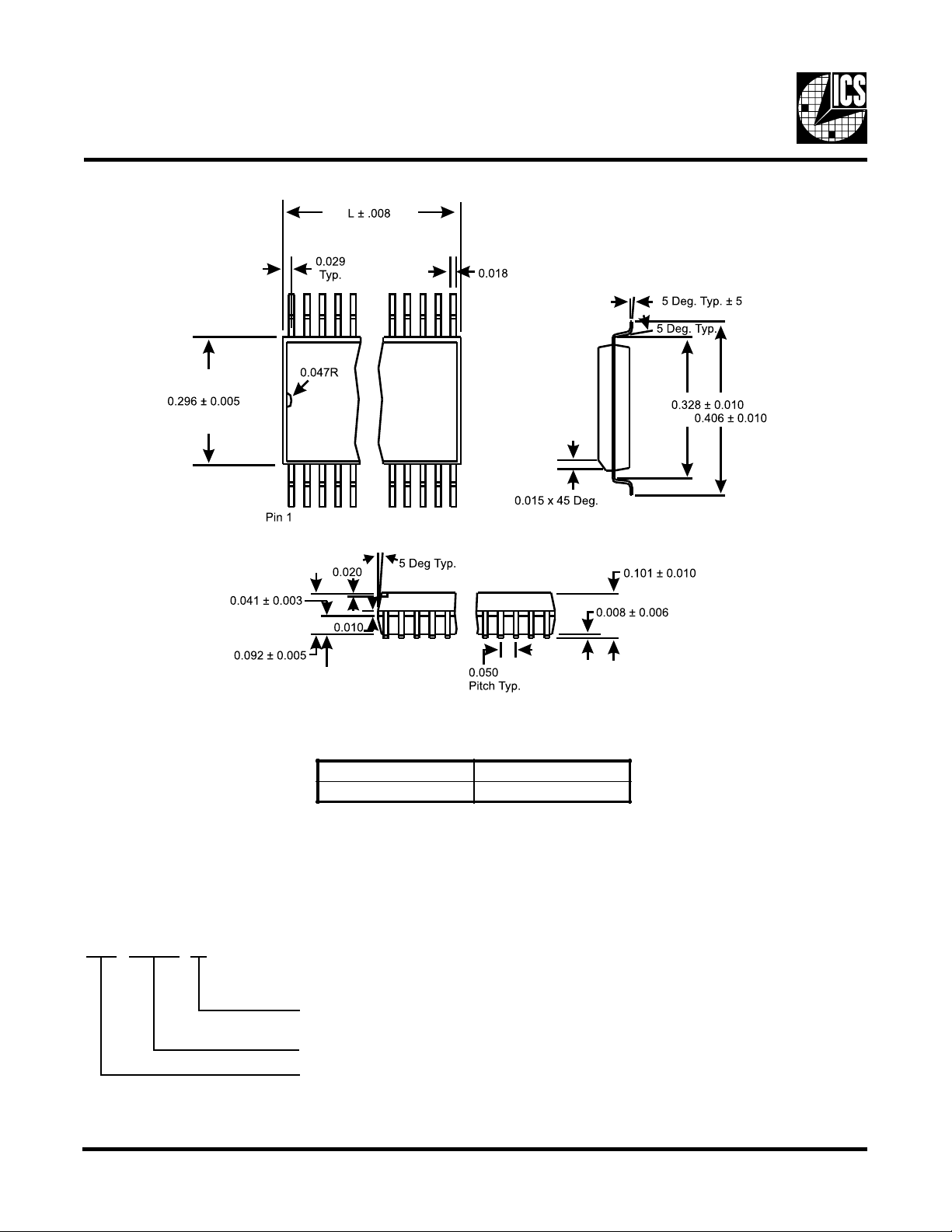

Ordering Information

ICS 18 87 M

Example:

ICS XXXX M

SOIC PACKAGE

LEAD COUNT 2 8 L

DIMENSION L 0.704

Package Type

M = SOIC

Device Type (consists of 3 or 4 digit numbers)

Prefix

ICS, AV = Standard Device

14

Loading...

Loading...