Page 1

Service Manual

HP OmniBook 800CS/CT

Page 2

Please check out our eBay auctions for more great

deals on Factory Service Manuals:

Page 3

Notice

In a continuing effort to improve the quality of our products,

technical and environmental information in this document is

subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to

this material, including, but not limited to, the implied warranties

of merchantability and fitness for a particular purpose. HewlettPackard shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the

furnishing, performance, or use of this material.

Hewlett-Packard assumes no responsibility for the use or

reliability of its software on equipment that is not furnished by

Hewlett-Packard.

As an ENERGY STAR partner, HP has determined that these

products meet the ENERGY STAR guidelines for energy

efficiency.

All Certifications may not be completed at product introduction.

Please check with your HP reseller for certification status.

This equipment is subject to FCC rules. It will comply with the

appropriate FCC rules before final delivery to the buyer.

ENERGY STAR is a service mark of the U.S. Environmental

Protection Agency. IBM and OS/2 are registered trademarks

and TrackPoint is a trademark of International Business

Machines Corporation. Pentium and the Intel Inside logo are

registered trademarks and MMX is a trademark of Intel

Corporation. Photo CD is a registered trademark of Kodak

Corporation. Microsoft, MS-DOS, and Windows are registered

trademarks, and the Genuine Microsoft Products logo is a

trademark of Microsoft Corporation in the United States of

America and in other countries. Sound Blaster is a trademark of

Creative Technology Ltd.

Hewlett-Packard Company 1997.

All Rights Reserved. Reproduction, adaptation, or translation

without prior written permission is prohibited except as allowed

under copyright laws.

Printed in U.S.A.

F1360-90049

Page 4

Table of Contents

List of Figures.............................................................................................................................iii

List of Tables..............................................................................................................................iv

Introduction .................................................................................................................................v

Product Overview........................................................................................................................ 1

What’s New ............................................................................................................................. 2

Product Features .....................................................................................................................3

Product at a Glance.................................................................................................................4

Product Comparisons...............................................................................................................6

Troubleshooting...........................................................................................................................3

Power-On Self-Test .................................................................................................................4

Beep Codes..........................................................................................................................4

Display Codes ......................................................................................................................5

OmniBook Diagnostics............................................................................................................. 7

Running the diagnostics program..........................................................................................7

Main diagnostic screen.........................................................................................................7

Special test hardware requirements......................................................................................9

Loop Back Connectors........................................................................................................10

Command line options ........................................................................................................12

User interface commands ...................................................................................................13

Details on using the diagnostic tests................................................................................... 17

Desktop Management Interface (DMI).................................................................................... 28

Description of DMI ..............................................................................................................28

Contents of the DMI Package.............................................................................................28

Setup and Configuration ........................................................................................................ 31

SCU Main Screen...............................................................................................................31

System Menu Screen .........................................................................................................32

Password Configuration ......................................................................................................34

Input/Output Menu Screen..................................................................................................35

Power Menu Screen...........................................................................................................37

Default Menu Screen ..........................................................................................................38

Exit Menu Screen...............................................................................................................39

Troubleshooting Tips..............................................................................................................40

OmniBook Components......................................................................................................40

CD ROM Drive Troubleshooting.........................................................................................45

Resolving Docking Station Operating Problems.................................................................. 46

Resolving OmniBook Docking Problems ............................................................................47

Hardware Repair ....................................................................................................................... 49

Battery (End User Replaceable).............................................................................................50

Memory (End User Replaceable) ...........................................................................................51

Hard Disk Drive (End User Replaceable) .............................................................................. 53

Hard Disk Drive Breather Holes..........................................................................................57

Mouse (End User Replaceable).............................................................................................. 58

Small Parts (End User Replaceable)......................................................................................59

Battery Latch......................................................................................................................59

I/O Door ............................................................................................................................. 59

Memory Cover....................................................................................................................59

PCMCIA Card Tray.............................................................................................................59

Rubber Feet .......................................................................................................................59

Keyboard (HP Authorized Service Providers Only) ................................................................60

Display (HP Authorized Service Providers Only)....................................................................62

CPU (HP Authorized Service Providers Only)........................................................................67

Heat Transfer Disk..............................................................................................................68

Logic PCA Board (HP Authorized Service Providers Only).....................................................70

i

Page 5

Electronic Serial Number ....................................................................................................70

Paw Active (HP Authorized Service Providers Only)..............................................................73

Other Components and Accessories (HP Authorized Service Providers Only)........................74

Appendix A - Technical Specifications .......................................................................................78

Mass Storage Specifications..................................................................................................78

Hard Disk Drive..................................................................................................................78

Floppy Disk Drive...............................................................................................................78

CD-ROM Drive...................................................................................................................79

System Resources.................................................................................................................80

System Interrupts (IRQs)....................................................................................................80

DMA Channels ...................................................................................................................81

Memory Map......................................................................................................................81

I/O Addresses.....................................................................................................................82

Appendix B - Hewlett-Packard Password Removal Policy..........................................................83

Appendix C - Hewlett-Packard TFT Display Quality Statement..................................................85

Appendix D - OmniBook Diagnostics BIOS Checksums ............................................................86

Appendix E - OmniBook Diagnostics Error Messages ................................................................87

Hewlett-Packard supplied test messages............................................................................87

Watergate Software supplied test messages ......................................................................90

Appendix F - Part Numbers....................................................................................................... 95

ii

Page 6

List of Figures

Figure 1 - OmniBook 800 External Features ................................................................................3

Figure 2 - OmniBook 800 External Features (continued) .............................................................3

Figure 3 - Exploded Diagram....................................................................................................... 4

Figure 4 - Main Diagnostic Screen............................................................................................... 8

Figure 5 - Serial Loop Back Connector...................................................................................... 10

Figure 6 - Parallel Loop Back Connector ................................................................................... 10

Figure 7 - SCSI Loop Back Connector.......................................................................................10

Figure 8 - SyCard Solder Bridges.............................................................................................. 11

Figure 9 - Sycard Test Results ..................................................................................................19

Figure 10 - Keyboard Test Screen.............................................................................................21

Figure 11 - Mouse Test Screen (text mode)...............................................................................23

Figure 12 - Mouse Test Screen (graphics mode) ....................................................................... 24

Figure 13 - Dock Keyboard Test Screen.................................................................................... 27

Figure 14 - DMI Components.....................................................................................................29

Figure 15 - Removing the Battery ..............................................................................................50

Figure 16 - 8- and 16-MB Memory Modules ...............................................................................51

Figure 17 - New and Old 32-MB Memory Module (respectively) ................................................51

Figure 18 - Removing the Memory Module ................................................................................52

Figure 19 - Hard Drive Screws...................................................................................................53

Figure 20 - Folding the Keyboard Open.....................................................................................54

Figure 21 - Hard Drive Removal ................................................................................................54

Figure 22 - Hard Drive Removal (continued) ............................................................................. 55

Figure 23 - Hard Drive Insulator Flap......................................................................................... 55

Figure 24 - Inserting the Hard Drive........................................................................................... 56

Figure 25 - Proper Keyboard Flex Cable Position...................................................................... 56

Figure 26 - IBM and Toshiba Hard Drive Breather Holes (respectively) ..................................... 57

Figure 27 - Removing the Mouse...............................................................................................58

Figure 28 - Keyboard Screws.....................................................................................................60

Figure 29 - Folding the Keyboard Open.....................................................................................60

Figure 30 - Keyboard Flex Cables .............................................................................................61

Figure 31 - Keyboard Flex Cable Placement ............................................................................. 61

Figure 32 - Bottom Case Screws and Rubber Feet.................................................................... 62

Figure 33 - Keyboard Support Plate Screws .............................................................................. 63

Figure 34 - Display Flex Cables.................................................................................................64

Figure 35 - Top Case and Display Removal ..............................................................................65

Figure 36 - Intel Inside Sticker Placement ................................................................................. 66

Figure 37 - Removing the CPU..................................................................................................67

Figure 38 - Heat Transfer Disk and Keyboard Support Insulator ................................................68

Figure 39 - CPU Thermal Coupling............................................................................................ 68

Figure 40 - Logic PCA Removal................................................................................................ 71

Figure 41 - Grommet and Bushing Placement...........................................................................72

Figure 42 - Paw Active Removal...............................................................................................73

iii

Page 7

List of Tables

Table 1 - Parts Identification ........................................................................................................5

Table 2 - POST Beep Codes.......................................................................................................4

Table 3 - POST Display Codes ....................................................................................................5

Table 4 - Diagnotic Command Line Options .............................................................................. 12

Table 5 - Diagnostic Test Selection Commands ........................................................................13

Table 6 - Diagnostic Commands for Toggling Settings ..............................................................14

Table 7 - Diagnostic Hidden Commands.................................................................................... 15

Table 8 - Diagnostic Test Parameters........................................................................................16

Table 9 - System Menu Settings ................................................................................................32

Table 10 - System Password Matrix ..........................................................................................34

Table 11 - Input/Output Menu Settings ......................................................................................35

Table 12 - Power Menu Settings ................................................................................................37

Table 13 - Default Menu Settings .............................................................................................. 38

Table 14 - Exit Menu Settings....................................................................................................39

Table 15 - OmniBook Troubleshooting Tips...............................................................................40

Table 16 - CD-ROM Troubleshooting Tips.................................................................................45

Table 17 - Hard Disk Drive Specifications..................................................................................78

Table 18 - Floppy Disk Drive Specifications...............................................................................79

Table 19 - CD-ROM Drive Specifications ..................................................................................79

Table 20 - Interrupts for F1171 - F1175..................................................................................... 80

Table 21 - Interrupts for F1360.................................................................................................. 80

Table 22 - DMA Channels for F1171 - F1175, and F1360..........................................................81

Table 23 - Memory Map for F1171 - F1175 ............................................................................... 81

Table 24 - Memory Map for F1360 ............................................................................................ 81

Table 25 - I/O Address for F1171 - F1175 .................................................................................82

Table 26 - I/O Addresses for F1360...........................................................................................82

Table 27 - OmniBook F1171 - F1175 BIOS Checksums............................................................86

Table 28 - OmniBook F1360 BIOS Checksums.........................................................................86

iv

Page 8

Introduction

This document provides reference information for the HP OmniBook 800. It is intended to be

used by HP-qualified service personnel to help with the installation, servicing, and repair of these

HP OmniBook PCs.

It is a self-paced guide designed to train you to install, configure, and repair the OmniBook

Notebook PC. You can follow it without having any equipment available.

The following table lists additional sources where supplementary information can be obtained:

Resource Number/Address Comments

HP External Web http://hpcc998.external.hp.com/mcd/ No usage restriction

HP-MCD Internal Web http://webmcd.cv.hp.com Restricted to HP internet

access only

HP MCD Service

Engineer

svc-eng_mcd@om.cv.hp.com Email address for service

related questions and

issues

v

Page 9

Page 10

Part 1

Product Overview

• What’s New

• Product Features

• Product at a Glance

• Product Comparisons

Page 11

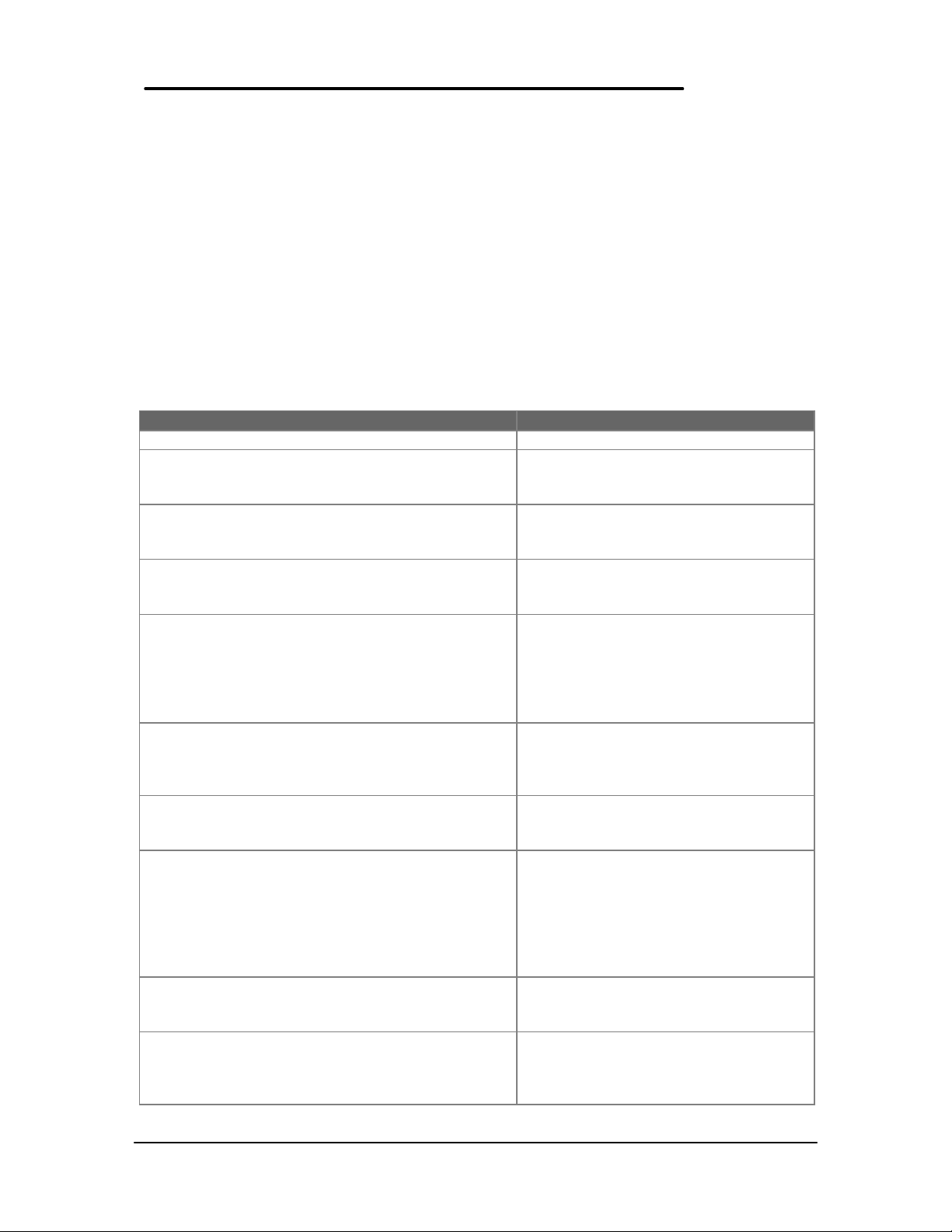

What’s New

This version of the HP OmniBook 800 Service Manual has been updated to include the HP

OmniBook 800 with MMX Technology (F1360A). The following is a list comparing the

technologies of the various models of the OmniBook 800.

Feature OmniBook 800 with MMX

(F1360)

Processor

Cache 512-KB L2 256-KB L2

Video NeoMagic NM2093 128-bit

PC Card CardBus support No CardBus support

Desktop Management

Interface

Advanced Power

Management

Intel Pentium 166-MHz with

MMX Technology

accelerated controller with

2MB video RAM and Zoom

Video

Pre-installed DMI 1.1 software No DMI software installed

APM 1.2 APM 1.1

OmniBook 800

(F1171 - F1175)

Intel Pentium 100- and 133MHz processor

NeoMagic NM2070 128-bit

accelerated controller with

1MB RAM

2

Page 12

Product Features

1

2

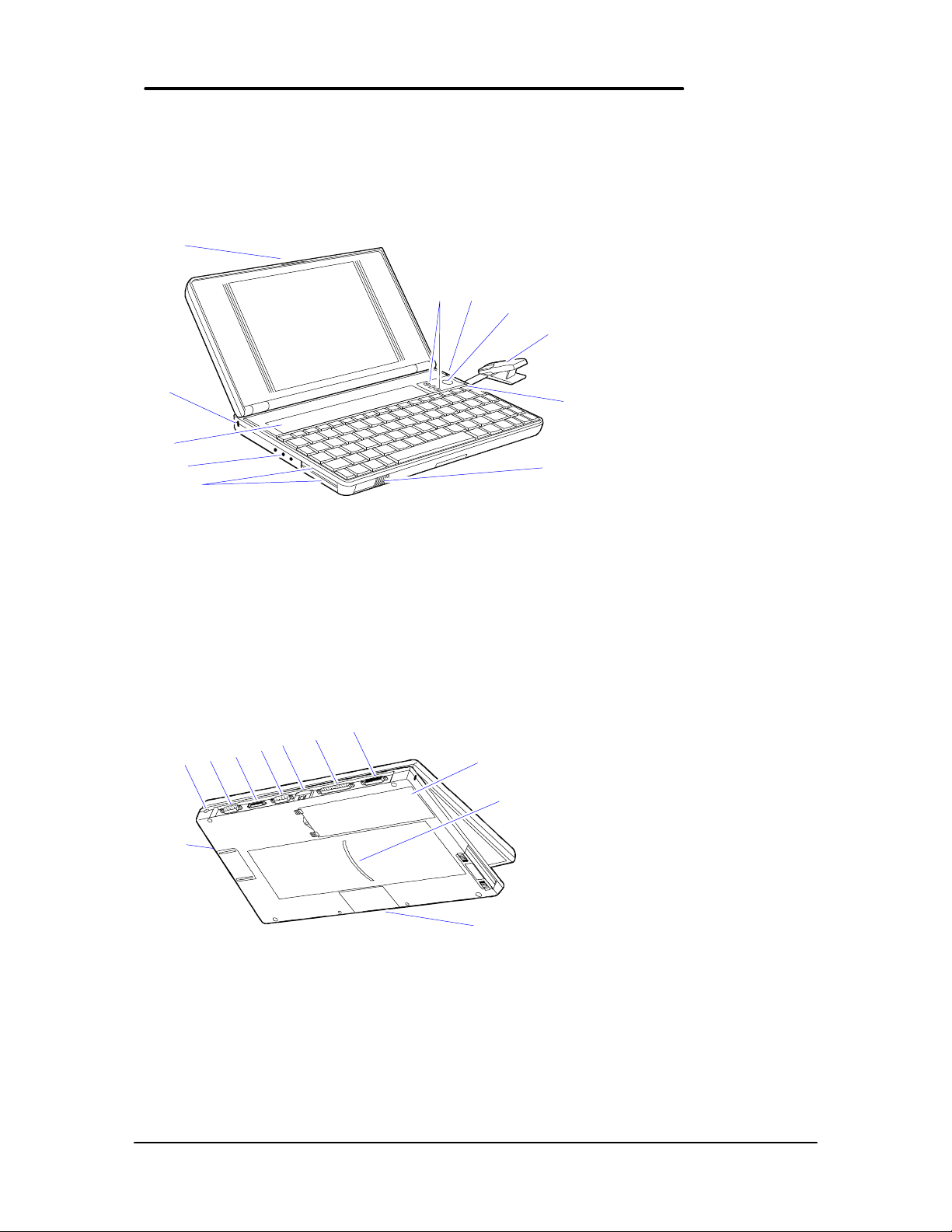

The following two illustrations point out the key external features of the OmniBook 800.

1 1110

2

3

4

5

Figure 1 - OmniBook 800 External Features

1. Latch

2. Kensington security connector

3. Fn-key icon strip

4. Sound jacks

5. Card slots

6. Card-eject lever

13

14

15

16

17

18

9

8

7

6

7. On/Off key

8. Mouse

9. Mouse-eject button

10. Charging light

11. Display adjustments

22

21

19

20

Figure 2 - OmniBook 800 External Features (continued)

12. Docking/SCSI port

13. Parallel port connector

14. Infrared port (IrDA)

15. Serial port connector

16. Floppy drive port

17. VGA output connector

18. AC adapter socket

19. Reset button

20. Memory-expansion slot

21. Identification pocket

22. Battery

3

Page 13

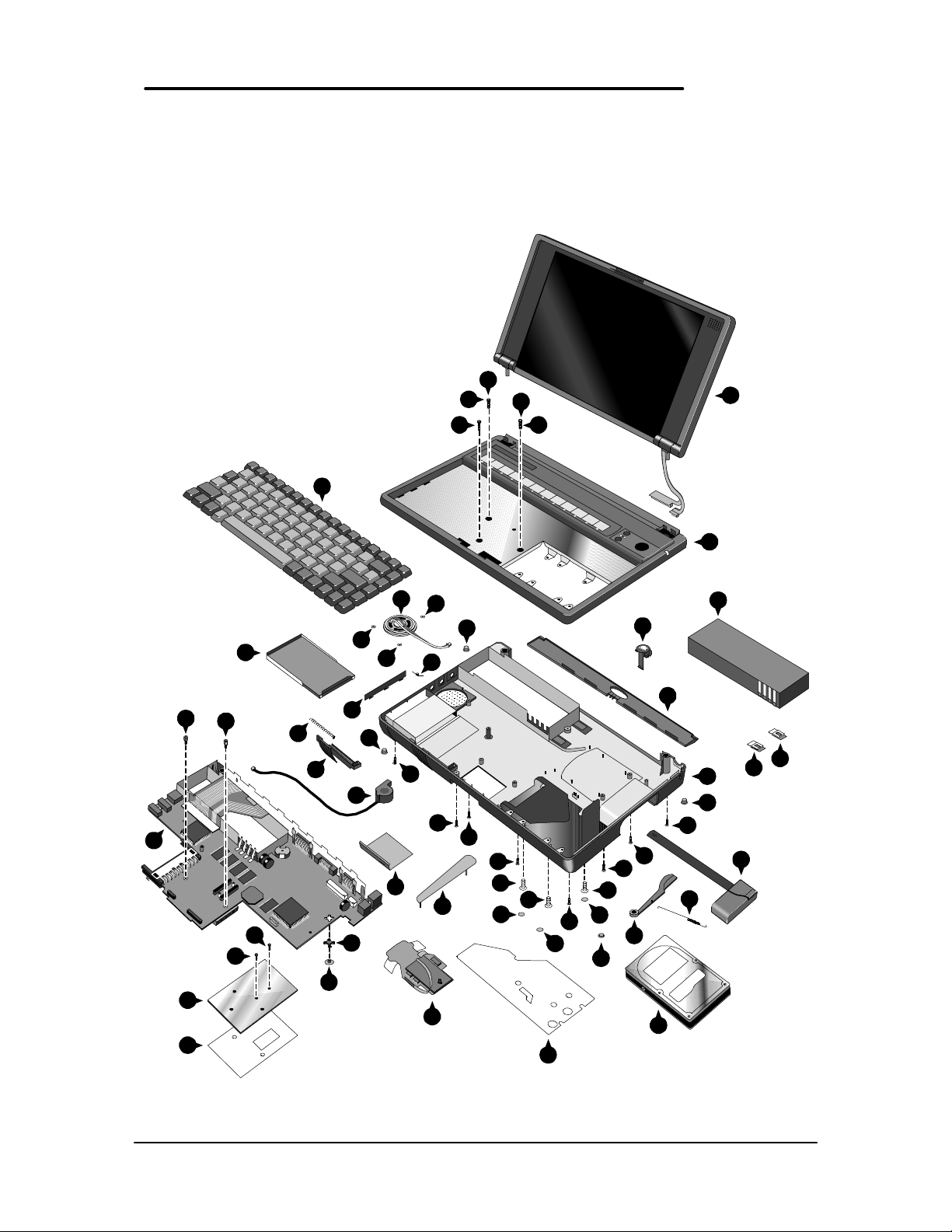

Product at a Glance

The following diagram represents all models of the OmniBook 800. Use Table 1 to identify each

part for the F1171 - F1175, and F1360 OmniBooks. Refer to the corresponding repair

procedure(s) in Part 3 for the exact placement of each component.

33

32

34

14

33

32

6

16

37

40

4

39

39

17

31

5

13

38

31

40

40

7

28

9

18

3

10

30

26

28

25

30

35

30

36

8

19

36

29

30

29

24

21

12

30

35

36

29

20

27

11

1

2

2

15

28

30

22

23

Figure 3 - Exploded Diagram

4

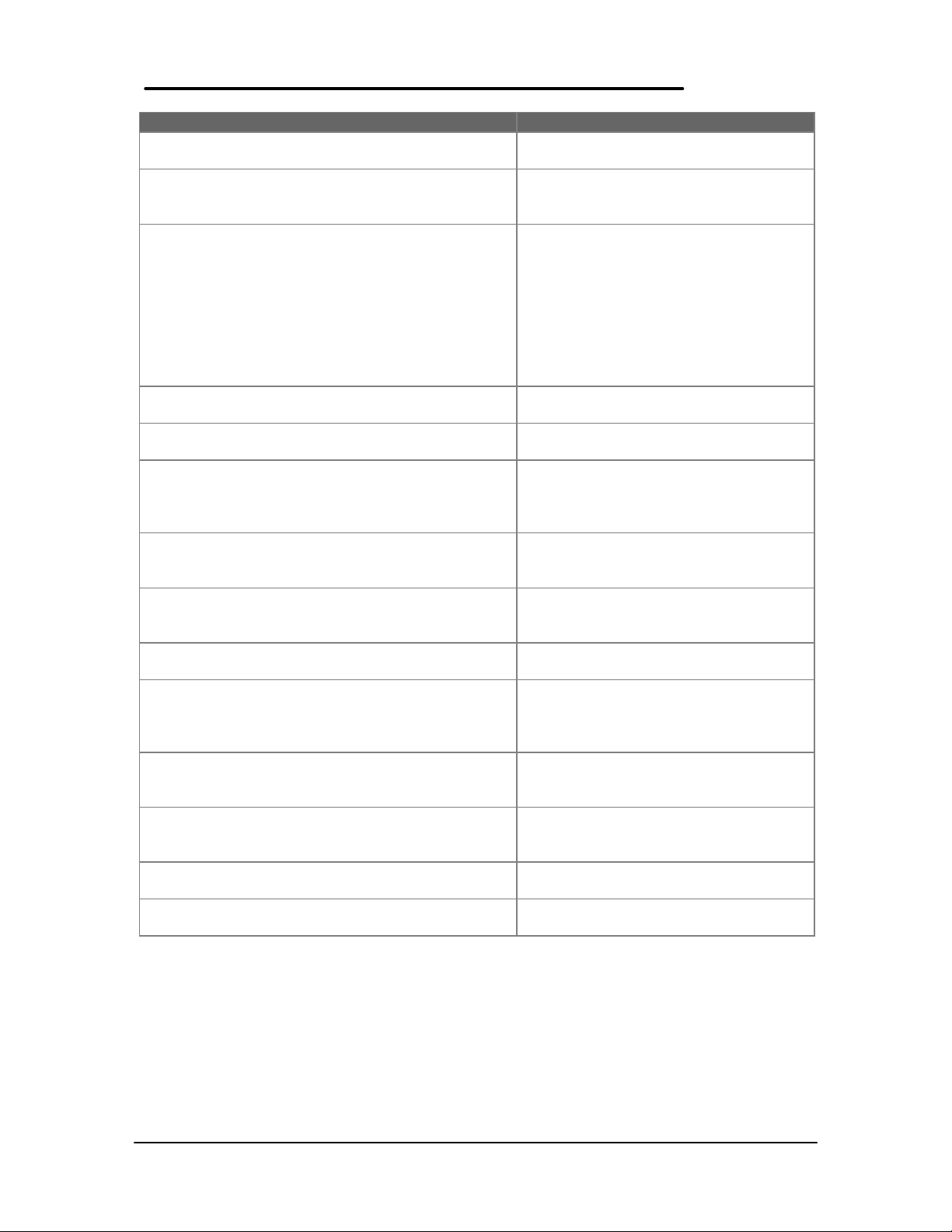

Page 14

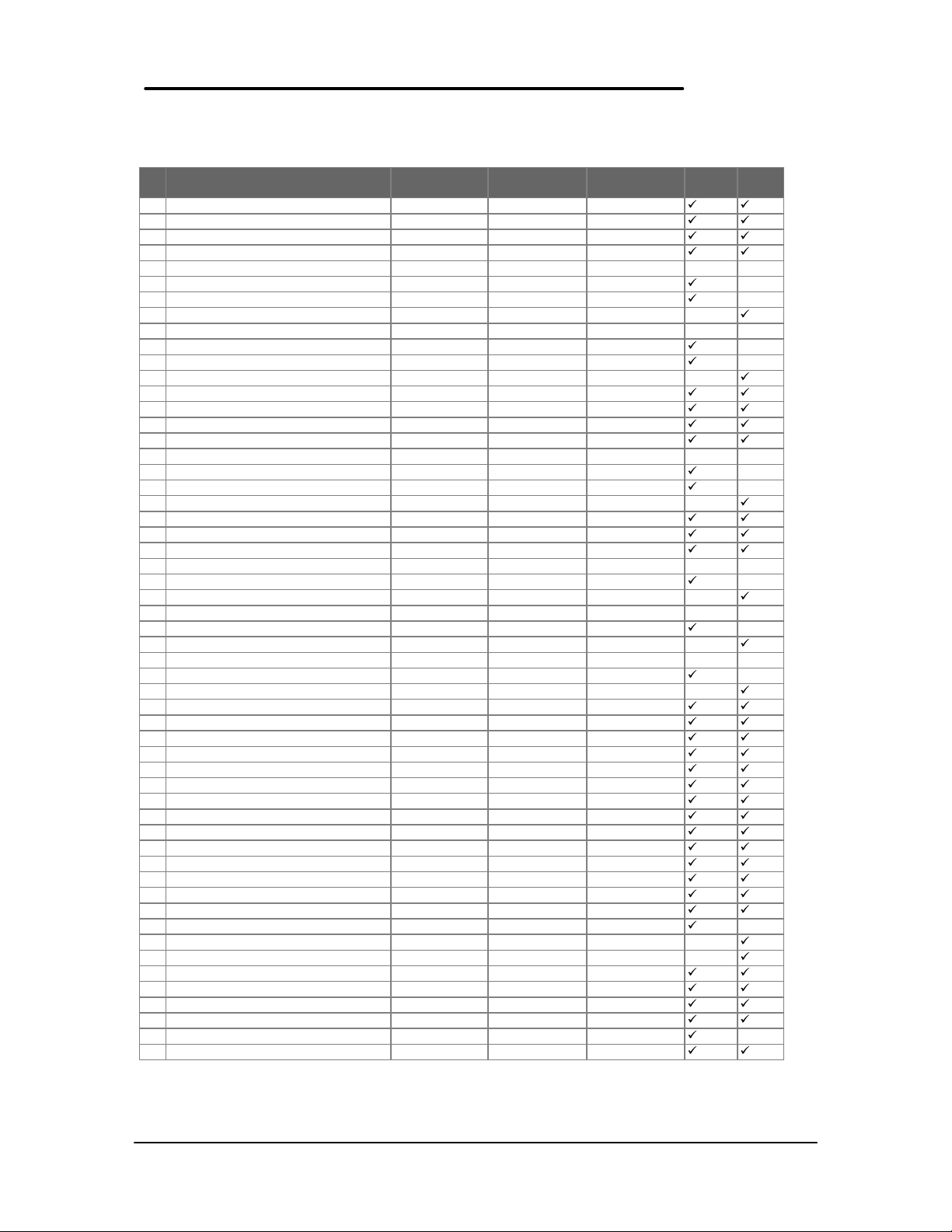

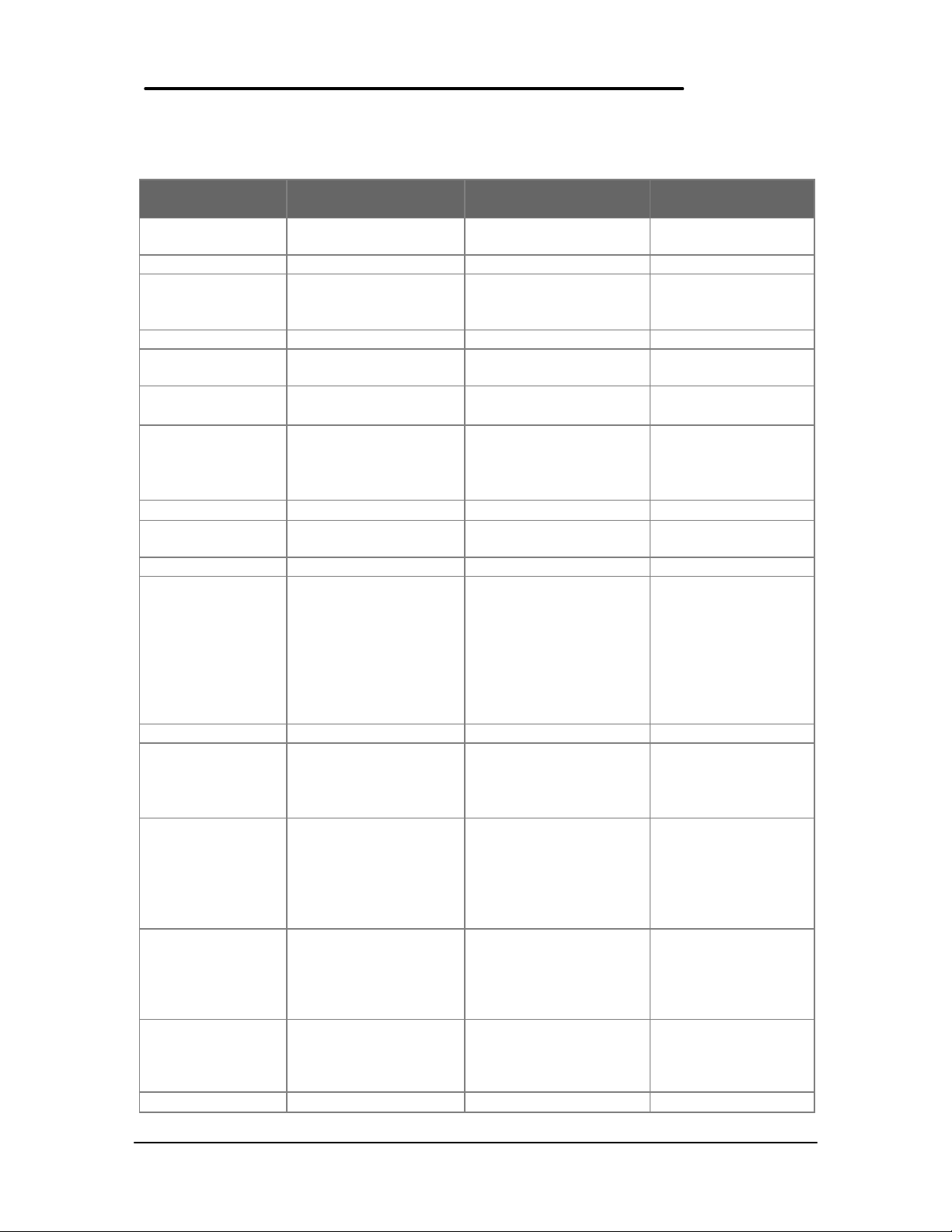

Table 1 - Parts Identification

DESCRIPTION PART

NUMBER

1 BATTERY - LI-ION F1121-80002 yes

2 BATTERY LATCH F1170-40006 yes

3 BUSHING F1170-40025 no

4 CARD TRAY ASSY F1052-60005 yes

5 CPU

CPU 100MHZ F1170-60919 F1170-69019 no

CPU 133MHZ F1170-60920 1170-69020 no

CPU 166MHZ F1360-60911 1360-69011 no

6 DISPLAY

DISPLAY CSTN F1170-60902 F1170-69002 no

DISPLAY TFT F1170-60901 F1170-69001 no

DISPLAY TFT F1360-60901 F1360-69001 no

7 DOOR - PIVOT LEFT F1052-40007 no

8 EJECT ARM LEFT F1360-40005 no

9 EJECT BUTTON LEFT F1170-40030 no

10 GROMMET F1360-40004 no

11 HARD DISK DRIVE

810MB HDD 0950-3084 F1191-69001 yes

1.44GB HDD 0950-3133 F1170-69012 yes

2.1GB HDD 0950-3193 F1360-69012 yes

12 I/O DOOR F1170-40010 yes

13 INSULATOR - CPU F1360-20007 no

14 KEYBOARD * no

15 KEYBOARD BOTTOMCASE

KEYBOARD BTMCASE F1170-60904 no

KEYBOARD BTMCASE F1360-60904 no

16 KEYBOARD TOPCASE

KEYBOARD TOPCASE F1170-60903 no

KEYBOARD TOPCASE F1360-60903 no

17 LOGIC PCA

LOGIC PCA 16MB F1170-60906 F1170-69006 no

LOGIC PCA 16MB F1360-60906 F1360-69006 no

18 MICROPHONE ASSY F1067-60012 no

19 PAW ACTIVE F1170-60909 no

20 PAW EJECT ARM F1170-40008 no

21 PAW EJECT BUTTON F1170-40005 no

22 PAW EJECT SPRING F1030-00016 no

23 PAW MECHANICAL 5061-4390 yes

24 PAW SHIELD F1170-00009 no

25 PIVOT DOOR SPRING F1030-00026 no

26 RAM DOOR F1170-40007 yes

27 RUBBER FEET - FALSE FOOT F1170-40009 yes

28 RUBBER FEET-SCREW COVER F1030-40018 yes

29 RUBBER HDD HOLE PLUG F1170-40018 yes

30 SCREW 2.0 X.4 6MM 0515-2396 yes

31 SCREW M1.6X.35X4 0515-2852 no

32 SCREW M2X.40X4.5WH 0515-2853 no

33 SCREW M2X.4X11.5WH 0515-2920 no

34 SCREW M2X.4X3.5WH 0515-2921 no

35 SCREW M2X.4X7PH T6 0515-2846 yes

36 SCREW M3X.5X5WH T6 0515-2847 yes

37 SPEAKER 9164-0422 no

38 SPRING EJECT LATCH F1030-00029 no

39 STANDOFF - HEX 0380-4606 no

40 TOPY SPRING NUT 0510-1634 no

Note, this is a partial parts list. For a complete parts list, please refer to Appendix F or the Product Support Plan.

* For a complete listing of localized keyboards, please refer to Appendix F or the Product Support Plan.

EXCHANGE

PART NUMBER

CUSTOMER

REPLACEABLE

F1171 F1175

F1360

Only

5

Page 15

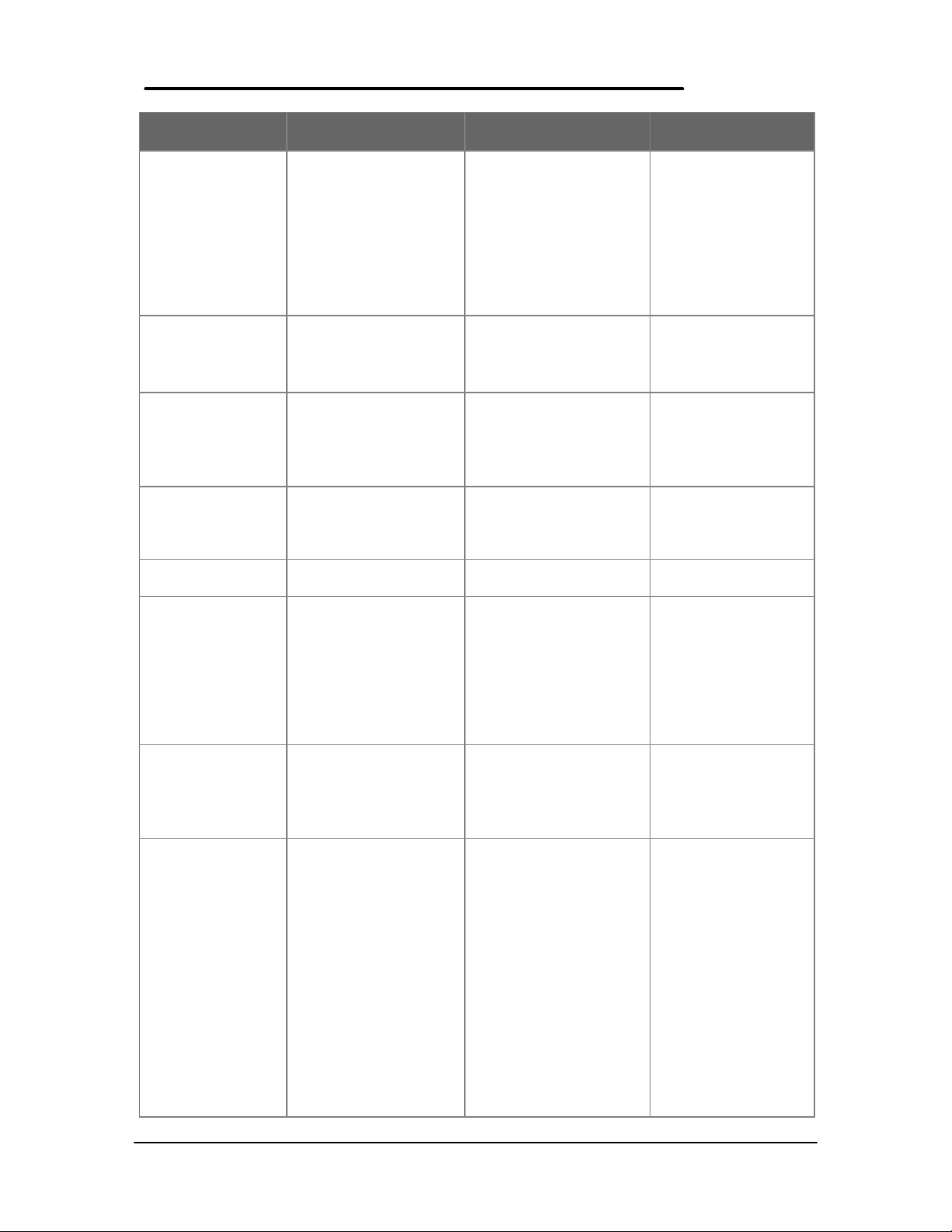

Product Comparisons

HP OmniBook 800

HP OmniBook 800 HP OmniBook 5700

with MMX Technology

Size Closed 18.49 × 28.24 × 3.99 cm

(7.28 × 11.12 × 1.57 in)

18.49 × 28.24 × 3.99 cm

(7.28 × 11.12 × 1.57 in)

29.5 x 22.6 x 4.9 cm

(11.6 x 8.9 x 1.93 in)

Weight 1.77 kg (3.90 lb) 1.70 kg (3.75 lb) 3.27 kg (7.2 lb)

Processor

166-MHz Intel Pentium

with MMX Technology

100-, 133-MHz Intel

Pentium

166- or 150-MHz Intel

Pentium with MMX

technology

Bus Architecture 32-bit PCI bus 32-bit PCI bus 32-bit PCI bus

Cache 512-KB external L2

cache

Display Size

• 10.4-inch TFT • 10.0-inch CSTN

256-KB external L2

cache

512-KB burst-

synchronous L2 cache

• 12.1-inch TFT

• 10.4-inch TFT

Display Resolution

Pointing Device pop-up mouse pop-up mouse

Video Bus Accelerated 128-bit PCI

• SVGA TFT 800 x 600

x 64K colors

bus

• SVGA CSTN 800 x 600

x 256 colors

• SVGA TFT 800 x 600 x

256 colors

Accelerated 128-bit PCI

bus

• XGA TFT 1024 x

768 x 64k colors

• SVGA TFT 800 x

600 x 16M colors

TrackPoint III

32-bit PCI bus

Video RAM 2MB 1MB 2MB

VGA-out Support

• SVGA-out supports

1024×768×256 at 75

Hz and 800x600x64k

at 85 Hz

• MPEG software

• SVGA-out supports up

to 1024×768×256

colors

• MPEG software support

• SVGA-out supports

up to 1024 x 768 x

64k colors

• Zoomed Video

enabled

support

• Zoomed Video

enabled

Video Controller NeoMagic NM2093 NeoMagic NM2070 C&T 65554

Power

• AC adapter 100 to 240

Vac (50 to 60 Hz) input

• 12 Vdc, 3.3 A output

• AC adapter 100 to 240

Vac (50 to 60 Hz) input

• 12 Vdc, 3.3 A output

• AC adapter 100 to

240 Vac (50 to 60

Hz) input

• 12 Vdc, 3.3 A output

Battery Type

• 7.2 Vdc rechargeable

Lithium Ion battery

• 7.2 Vdc rechargeable

Lithium Ion battery

• 14.4-Vdc, 2.5-AH

rechargeable

Lithium-Ion battery

• Optional, 14.4-Vdc,

3.75-AH enhanced

Lithium Ion battery

Battery Life Battery life up to 3.0

hours.

Battery life up to 3.0

hours.

1.75 to 2.5 hours with

one LiIon battery

(enhanced LiIon

battery adds 2.5 to

3.75 hours)

Recharge Rate Battery pack recharges

to high level in less than

2.5 hours using AC

adapter

Advanced Power

• Instant-on maintains • Instant-on maintains • Instant-on maintains

Battery pack recharges to

high level in less than 2.5

hours using AC adapter

Battery recharges to

high level in 4 hours

using AC adapter

while PC is on or off

6

Page 16

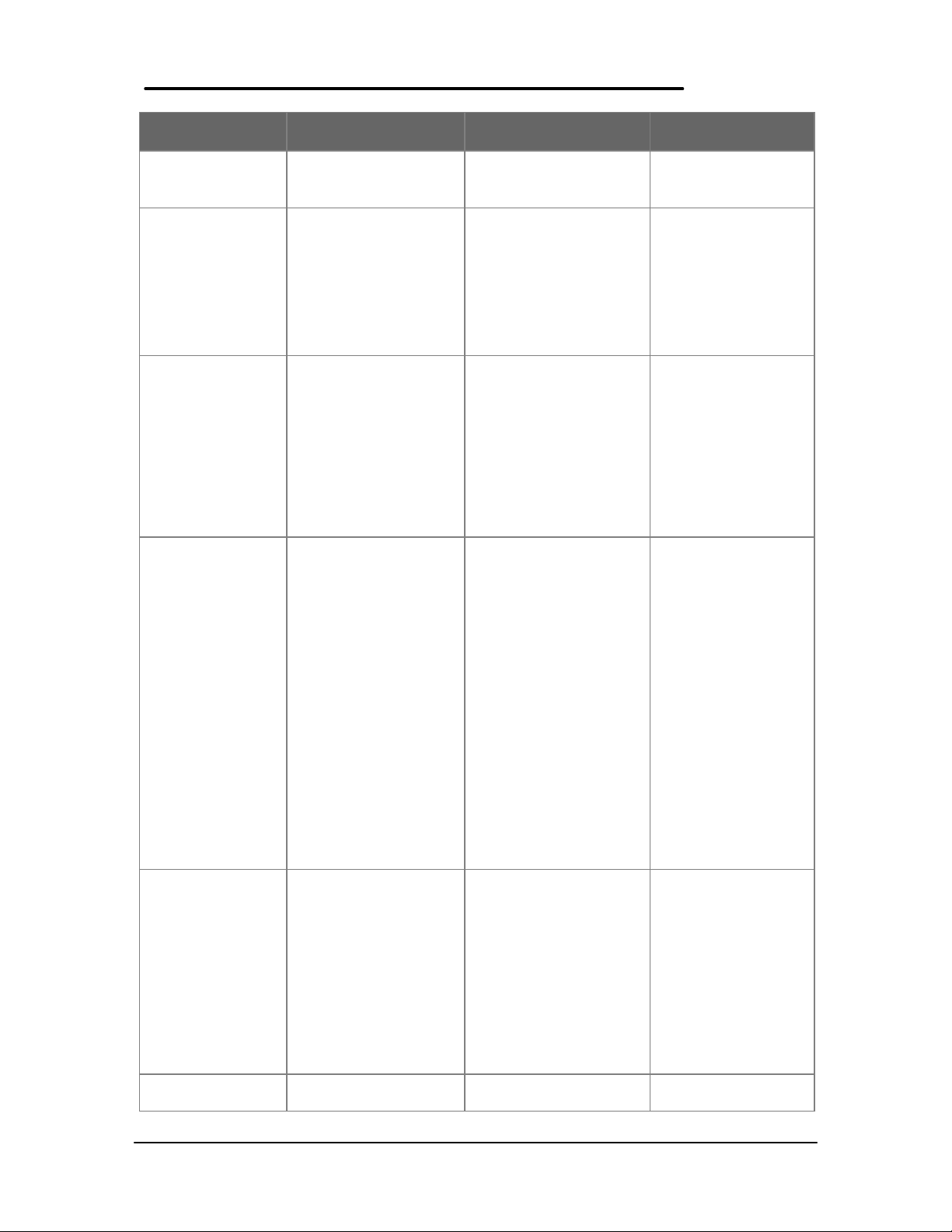

HP OmniBook 800

with MMX Technology

Management computer in ready-to-

work state for months

on a charge. Turn it on

again, and you're

instantly back where

you were.

• 2-minute low-battery

warning

• APM 1.2

Removable

Modules

• Hard disk drive

• RAM

• Battery

Hard Disk Drive

• 2.1-billion-byte

enhanced-IDE

• mode-4, PCI-bus

• 12.7 mm

Floppy Disk Drive External ultra-thin,

three-mode floppy disk

drive (included with

product)

CD-ROM Drive Optional, external 8x

speed

Memory

• 16 MB standard VEDO

DRAM

• 60 ns

• upgradable to 80 MB

• 16-, 32-, 64-MB RAM

expansion cards

Audio

• 16-bit Sound Blaster

Pro stereo compatible.

• Two built-in speakers

(not stereo sound)

IO Ports

• 9-pin, 115,200-b/s,

RS-232 port

• 25-pin EPP/ECP

parallel port

• SVGA-out (up to 1024

× 768 × 256)

• 4 Mbps Fast IRDA

• Docking system

connector (dock is

optional)

• SCSI-2 port available

with accessory cable

(fits in docking port)

• Floppy drive port

• Headphone/stereo-out

HP OmniBook 800 HP OmniBook 5700

computer in ready-towork state for months

on a charge. Turn it on

again, and you're

instantly back where

you were.

• 2-minute low-battery

warning

• APM 1.1

• Hard disk drive

• RAM

• Battery

computer in readyto-work state for

weeks on a full

charge; returns you

to your application or

file instantly

• 2-minute low-battery

warning

• APM 1.2

• Floppy disk drive

• Hard disk drive

• RAM

• Battery

• 810-million-byte, 1.44-

billion-byte enhancedIDE

• 3.0 billion-byte or 2.0

billion byte

enhanced- IDE

• mode-4, PCI-bus

• 12.7 mm

External ultra-thin, threemode floppy disk drive

Internal 3.5-inch, 1.44MB, standard

(included with product)

Optional, external 8x

Optional, internal, 10x

speed

• 16 MB standard VEDO

DRAM

• 60 ns

• upgradable to 80 MB

• 8-, 16-, 32-, 64-MB

RAM expansion cards

• Self-refreshed FPM

DRAM

• 16 or 32-MB models,

expandable to 128

MB

• 8-, 16-, 32-, and 64MB RAM cards

available

• 16-bit Sound Blaster

Pro stereo compatible.

• Two built-in speakers

(not stereo sound)

• 16-bit with Sound

Blaster and MIDI

support

• Stereo sound via two

built-in speakers

• 9-pin, 115,200-b/s,

RS-232 port

• 25-pin EPP/ECP

parallel port

• SVGA-out (up to 1024 ×

768 × 256)

• 4 Mbps Fast IRDA

• Docking system

connector (dock is

optional)

• SCSI-2 port available

with accessory cable

(fits in docking port)

• Floppy drive port

• Headphone/stereo-out

• 9-pin, 115,200-bps,

RS-232 port

• 25-pin bidirectional

ECP/EPP parallel

port

• SVGA-out (up to

1024 x 768 x 64K)

• Fast-IR-IRDA

compliant @ 4Mbps

• Expansion bus

connector

• PS/2

keyboard/mouse port

• Headphone/stereoout port

7

Page 17

HP OmniBook 800

with MMX Technology

port

• Stereo-in and

microphone ports

PCMCIA

• One Type III PCMCIA

slot (or use as two

Type II slots)

• Zoomed video support

in upper slot

• CardBus-ready

Docking Optional docking system

with EPP/ECP parallel,

serial, VGA-out (up to

1024 × 768), keyboard,

PS/2 or Microsoft

mouse, and SCSI-2

ports; external floppy

connector; stereo out;

and standard half-length

ISA/PCI slot.

Pre-installed

Software

• Microsoft Windows

for Workgroups 3.11

and MS-DOS 6.22

dual-loaded with

Windows 95

• User upgradable Plug

and Play BIOS

• APM 1.2

• Diagnostic Software

• HP PIM and Financial

Calculator

• DMI 1.1 under

Windows 95 with

TopTOOLS

• On-line documentation

Security Features

• 2-level password

protection

• Hardware-based hard

drive password

• Kensington lock slots

• System administrator

password

• PC ID

• EEPROM-based serial

number for DMI

tracking

Warranty Free three-year world-

wide warranty (1-year on

HP OmniBook 800 HP OmniBook 5700

port

• Stereo-in and

microphone ports

• One Type III PCMCIA

slot (or use as two Type

II slots)

• Stereo-in and

microphone ports

• MIDI/joystick port

• One Type III

PCMCIA slot (or use

as two Type II slots)

with 3.3-V or 5-V

support

• Zoomed video

support for lower slot

• CardBus support

Optional docking system

with EPP/ECP parallel,

serial, VGA-out (up to

1024 × 768), keyboard,

PS/2 or Microsoft mouse,

and SCSI-2 ports;

external floppy

connector; stereo out;

and standard half-length

Optional docking

system with one

PCI/ISA and one ISA

slot, parallel, serial,

SVGA-out (up to 1024

x 768 x 64k),

keyboard, PS/2

mouse, MIDI/joystick,

audio and SCSI-2

ISA/PCI slot.

• Microsoft Windows

for Workgroups 3.11

and MS-DOS 6.22

dual-loaded with

Windows 95

• User upgradable Plug

and Play BIOS

• APM 1.1

• Diagnostic Software

• HP PIM and Financial

Calculator

• SystemSoft CardLite

and Monarch PC card

software

• On-line documentation

• Microsoft

Windows for

Workgroups 3.11

and MS-DOS 6.22

co-loaded with

Microsoft Windows

95*

• User upgradable

Plug and Play BIOS

• Advanced Power

Management 1.2

• DMI 1.1 under

Windows 95 with

TopTools

• HP PIM and

Financial Calculator

• On-line

documentation

• 2-level password

protection

• Optional hardwarebased hard drive

password

• Kensington lock slots

• System administrator

password

• PC ID

Free three-year worldwide warranty (1-year on

• 2-level password

protection

• Hardware-based

hard drive password

• Electronic serial

number

• PC ID (tattooing)

• Drive lock

• Kensington lock slots

Free three-year worldwide warranty (1-year

8

Page 18

HP OmniBook 800

with MMX Technology

battery and accessories) battery and accessories) on battery and

HP OmniBook 800 HP OmniBook 5700

accessories)

9

Page 19

Page 20

Page 21

Page 22

Part 2

Troubleshooting

• Power-On Self-Test

• OmniBook Diagnostics

• Desktop Management Interface

• System Configuration Utility

• Troubleshooting Tips

Page 23

Power-On Self-Test

The OmniBook 800 BIOS includes a Power-On Self-Test (POST) facility that tests a number of

hardware and firmware items in the unit at each cold-start (BOOT or RESET).

The OmniBook self-test alone should not be used to diagnose a hardware problem. If the selftest results are absolutely clear and repeatable, confirm the results with at least two other nonself-test failure symptoms.

Within POST, there are three kinds of messages:

• Error Messages – These messages appear when there is a failure in hardware,

software, or firmware.

• Informational Messages – These messages provide information to the user but

require no action.

• Beep Codes – This kind of warning sounds when POST errors occur and the screen

is not yet available.

Beep Codes

These multiple beep codes indicate a failure in a simple test of:

• a portion of base memory

• flash BIOS checksum

• a portion of conventional memory

• a portion of extended memory

If the unit fails to boot, ensure that

• all accessories are removed, including:

memory, floppy drive, docking station, modems and other PC Cards, printers,

external displays, pointing devices, and keyboard

• clean AC power is provided (no “chained” battery chargers or auto adapters), and

press reset.

If the unit still fails to boot, it requires service.

Beep codes are used to identify a POST error that occurs when the screen is not available.

Once the screen is operating, diagnostic messages are reported to the screen. There are beep

codes for both fatal and non-fatal system board errors.

Table 2 - POST Beep Codes

Beep Code Description

S-S-S-P-S-S-L-P The DMA page registers are faulty.

S-S-S-P-S-L-S-P The refresh circuitry is faulty

S-S-S-P-S-L-L-P The ROM checksum is incorrect

S-S-S-P-L-S-S-P The CMOS RAM test failed

S-S-S-P-L-S-L-P The DMA controller is faulty

S-S-S-P-L-L-S-P The interrupt controller failed

S-S-S-P-L-L-L-P The 8042 keyboard controller failed

S-S-L-P-S-S-S-P No video adapter was found

S-S-L-P-S-S-L-P No RAM installed. No message is displayed.

4

Page 24

Display Codes

There are a number of Power On Self Test (POST) tests that are performed after the Beep Code

tests. Failure of one or more of these tests will result in a displayed failure code (such as

03044). It is extremely important not to interpret a failure code immediately as a hardware

failure. The failure should be confirmed with a clean boot. A clean boot is defined as pressing

the reset button after removing all accessories (including additional memory, floppy drive,

modems, PC cards, and printers) and providing a reliable power source. Note, make sure the

display is adjusted to be visible.

The following tables lists common PC error messages. Not all of these messages will appear on

every model of the OmniBook 800.

Table 3 - POST Display Codes

Message Possible Cause

CLOCK NOT TICKING CORRECTLY The real time clock is not ticking.

COLOR/MONO SWITCH INCORRECT The COLOR/MONO switch on the system

board is incorrect for the installed

hardware.

CMOS CHECKSUM INVALID - RUN SCU CMOS RAM information has been

corrupted and needs to be reinitialized via

the System Configuration Utility.

CMOS FAILURE - RUN SCU CMOS RAM has lost power and needs to

be reinitialized via the System

Configuration Utility.

FLOPPY CONTROLLER FAILED The floppy controller failed to respond to

the reset command. Power down the

system and check all appropriate

connections. It the floppy controller

continues to fail, you may need to replace

it.

FLOPPY DISK TRACK 0 FAILED The floppy drive cannot read track 0 of

the floppy disk in the drive. Try another

diskette. If the problem persists, you may

need to replace the floppy drive.

FLOPPY INFORMATION INVALID - RUN SCU The drive parameters stored in CMOS do

not match the floppy drives detected in

the system.

HARD DISK CONTROLLER ERROR The hard disk controller failed to respond

to the reset command. Possible

solutions: 1) Check the drive parameters.

2) Power down the system and check all

appropriate connections. If the problem

persists, you may need to replace the

hard disk controller.

HARDWARE INFO DOES NOT MATCH VIDEO

CARD - RUN SCU

KEYBOARD CONTROLLER FAILURE The keyboard failed the self-test

The video adapter type specified in

CMOS RAM does not match the installed

hardware.

command. Check to see if the keyboard

controller is properly installed. If the

problem continues, replace the controller.

5

Page 25

Message Possible Cause

KEYBOARD FAILURE The keyboard failed to respond to the

RESET ID Command.

MACHINE IS LOCKED - TURN KEY The system will not continue the boot

sequence until you insert the key into the

key lock and turn it.

NO BOOTABLE FLOPPY DRIVE 0 INSTALLED No bootable floppy drive was detected.

Possible solutions: 1) Power down the

system and check all appropriate

connections, cables, etc. 2) In

configurations where no floppy drive is

installed, run System Configuration Utility

and make sure the diskette drive

configuration item is set to “None”. 3)

Replace the diskette drive if necessary.

NO INTERRUPTS FROM TIMER 0 The periodic timer interrupt is not

occurring.

RAM PARITY ERROR AT LOCATION xxxx A RAM parity error occurred at the

specified (hexadecimal) location.

ROM AT xxxx (LENGTH YYYY) WITH NON-ZERO

CHECKSUM (zz)

TIME/DATE CORRUPT - RUN SCU The time and date stored in the real time

UNEXPECTED AMOUNT OF MEMORY - RUN SCU The amount of memory detected by

CMOS RAM TEST FAILED A walking built test of CMOS RAM

DMA CONTROLLER FAULTY A sequential read/write of the transfer

FAULTY DMA PAGE REGISTERS A walking bit read/write of the 16 DMA

FAULTY REFRESH CIRCUIT A continuous read/write test of port 61h

INTERRUPT CONTROLLER FAILED A sequential read/write of various

ROM CHECKSUM INCORRECT A checksum of the ROM BIOS does not

An illegal adapter ROM was located at

the specified address. An external

adapter (such as a video card) may be

causing a conflict.

clock have been corrupted, possibly by a

power loss.

POST does not match the amount

specified in CMOS RAM.

locations 0E (Hex) - 3F (Hex) failed.

count and transfer address registers

within the primary and secondary DMA

controllers failed.

controller page registers starting at

location 80 Hex failed.

found that bit 4 (Refresh Detect) failed to

toggle within an allotted amount of time.

Interrupt Controller registers failed.

match the byte value at F000:FFFF.

6

Page 26

OmniBook Diagnostics

The OmniBook diagnostics program provides an effective tool for diagnosing and isolating a

hardware problem. The diagnostics software is intended for use in concert with additional

troubleshooting methods to accurately determine the cause of trouble. The diagnostics program

is not designed for unassisted end customer use.

Diag is a DOS program developed to test the OmniBook 800 computer and docking station. For

the most part Diag is a stand-alone program, testing components and subsystems independently.

Some tests require “loopback” adapters for complete testing, and some tests require other

hardware (e.g. SCSI devices). Basic knowledge of running software is assumed.

Running the diagnostics program

A “clean boot” is the environment from which to run Diag. For a system that normally boots up

to Windows for Workgroups, press F5 at bootup. For a Windows 95 system, press Shift+F5.

Alternatively, the CONFIG.SYS and AUTOEXEC.BAT files may be modified to exclude drivers

and/or launch Diag if desired. Please note that the SCSI tests do require loading some drivers;

those drivers will be addressed in the context of those tests.

The diagnostic program is located in the c:\omnibook\diag directory and is invoked by typing

diag followed by the Enter key.

Main diagnostic screen

The OmniBook diagnostic program is controlled primarily from a single screen. The top two

thirds of the screen reports the tests selected and test results. The bottom third is used to scroll

test results as the tests run. Thirty tests are listed under the Menu heading. See Figure 4 for a

sample of the main diagnostic screen.

Tests selected for looped running show a test level of 1 to 3 to the left of the test name. When a

test ends, the status of the test and the date and time are reported. As a test runs, ongoing

status can be reported either on the same line as the test, or scrolled into the bottom region.

When looping tests are performed, the bottom line reports when the loops begun and which loop

is currently running. If a test ever fails, a red ‘x’ appears to the left of the test name. The

version of Diag is reported near the bottom of the display, as is the version of the BIOS.

External monitor colors can be checked at a glance with the RED GREEN and BLUE colored

text boxes.

7

Page 27

Menu Status Date Time

2 CPU Ok 08/08 14:36:18

2 Cache Ok 08/08 14:35:20

1 RAM, motherboard 16 MB Ok 08/08 14:36:22

1 RAM, plug in 00 MB Ok 08/08 14:36:23

2 BIOS flash ROMS OK C-F=8676? Altera=E56C? Boot=C600? 08/08 14:36:25

2 CMOS Ok 08/08 14:36:26

Upper PC Card

Lower PC Card

2 Timers Ok 08/08 14:36:26

2 Real time clock Ok 08/08 14:36:30

2 IRQ controller Ok 08/08 14:36:31

2 DMA controller Ok 08/08 14:36:32

IR port

Serial port

Printer port

1 Hard disk 813Mb Ok 08/08 14:36:32

Floppy disk

2 Battery Bat=LiIo (OK) Chg=FC B%=60 Vb=8.17 Ta=57.2 08/08 14:36:33

SCSI loopback

1 Keyboard Ok 08/08 14:36:36

1 HP mouse Ok 08/08 14:36:36

2 Audio Ok 08/08 14:36:39

1 Display Ok 08/08 14:36:42

1 Docked device Ok: NOTHING. 08/08 14:36:42

SCSI CD ROM

SCSI Hard disk

Dock slots

Dock keyboard

Dock PS2 mouse

Dock EEPROM

Keyboard Power-On Selftest

Keyboard IRQ Test

Keyboard Interface Test

+3708 +3695

DSP Chip

DMA Channel

Interrupt Lines

Sound Output Test

Version 04 Jan 97, Bios 97/01/29 RED GREEN BLUE

ARROW keys select tests. ENTER or 1, 2, 3 runs test. Or press SPACE to mark

tests then ENTER to run them. F1 or ? gives help. DIAG /? Shows options.

loops=2/20. Last loop begun at 08/08 14:36:18

Figure 4 - Main Diagnostic Screen

Running selected tests

Tests may be initiated individually, or as a group. Some tests may be run at different levels. In

general, tests that can take a long time to be fully checked have levels that permit testing more

quickly while still providing a reasonable level of testing. An unselected test has a <Space>

before the test name. A test at a quick level has a <1> before the test name. A standard level

test has a <2> before the test name. A long test has a <3> before the test name. Every test has

a standard level. Some tests also have a quick level, and some tests also have a long level.

Some have both quick and long.

8

Page 28

The name of the currently selected test is always shown inversed.

To help monitor the progress of testing, the LEDs (near the On button) blink about once per

second from green to off. If a test has failed the LEDs blink from red to off. When Diag finishes

testing, the LEDs blink rapidly. If the system locks up for some reason, the LEDs generally stop

blinking.

Alternative methods for running tests

Individual tests may be run by moving the highlight to the desired test and running it. Move the

highlight and run the tests by the following means:

Keyboard – cursor <Up> and <Down> keys to select, <Enter> to run. Also <Space> to specify a

test level, <Backspace> to cancel a test, <Esc> to exit Diag. Many other features and options

are also available from the keyboard.

Contrast/Brightness buttons – <Down> to select (mimics the Down key), <Up> to run (mimics

the Enter key). This is most useful on production units that have no keyboard. For checking

“Newton rings” during display testing, it is necessary to adjust the contrast. To have the contrast

keys operate normally, press both at once. To have them mimic the Down and Enter keys, press

both again.

Mouse – when the -m command line option is specified, use the top or bottom “bumper” to

select, and left button to run. Also use the right button to specify test level (space), right bumper

to cancel a test (Backspace), and left bumper to exit Diag (Esc).

Serial – same keys as with a keyboard, but from a remote system (HP 100LX, etc) connected

into the RS232 port on the OmniBook. The remote computer’s serial port should be configured

for 9600,N,8,1. The communication program Kermit is well suited to communicate with Diag, in

that it sends cursor and function key codes as PC key codes (e.g. <Up> transmits <NULL> then

<;>). Controlling Diag via the serial port permits the same level of control of modes and toggles

as does direct keyboard control. Please note that the serial test cannot be run when the serial

port is used for control (though the serial port gets a decent workout controlling Diag anyway).

Special test hardware requirements

The following tests require the following hardware to operate:

• The Upper/Lower PC Card tests require a Sycard test card and a modified

extender card.

• The IR port test requires another OmniBook 800 running the fast IR test.

• The Serial port test requires an HP RS-232 serial loop back connector.

• The Printer port test requires an HP parallel port loop back connector.

• The SCSI test requires an HP SCSI port loop back connector.

• The SCSI CD ROM test requires a CD ROM device connected by SCSI cable.

• The SCSI Hard disk test requires a Hard disk connected by SCSI cable.

• The Dock slots test are currently unimplemented.

• The Dock keyboard test requires a docking station and an external keyboard.

• The Dock PS2 mouse test requires a docking station and a PS2 mouse.

• The Dock EEPROM test requires a docking station.

9

Page 29

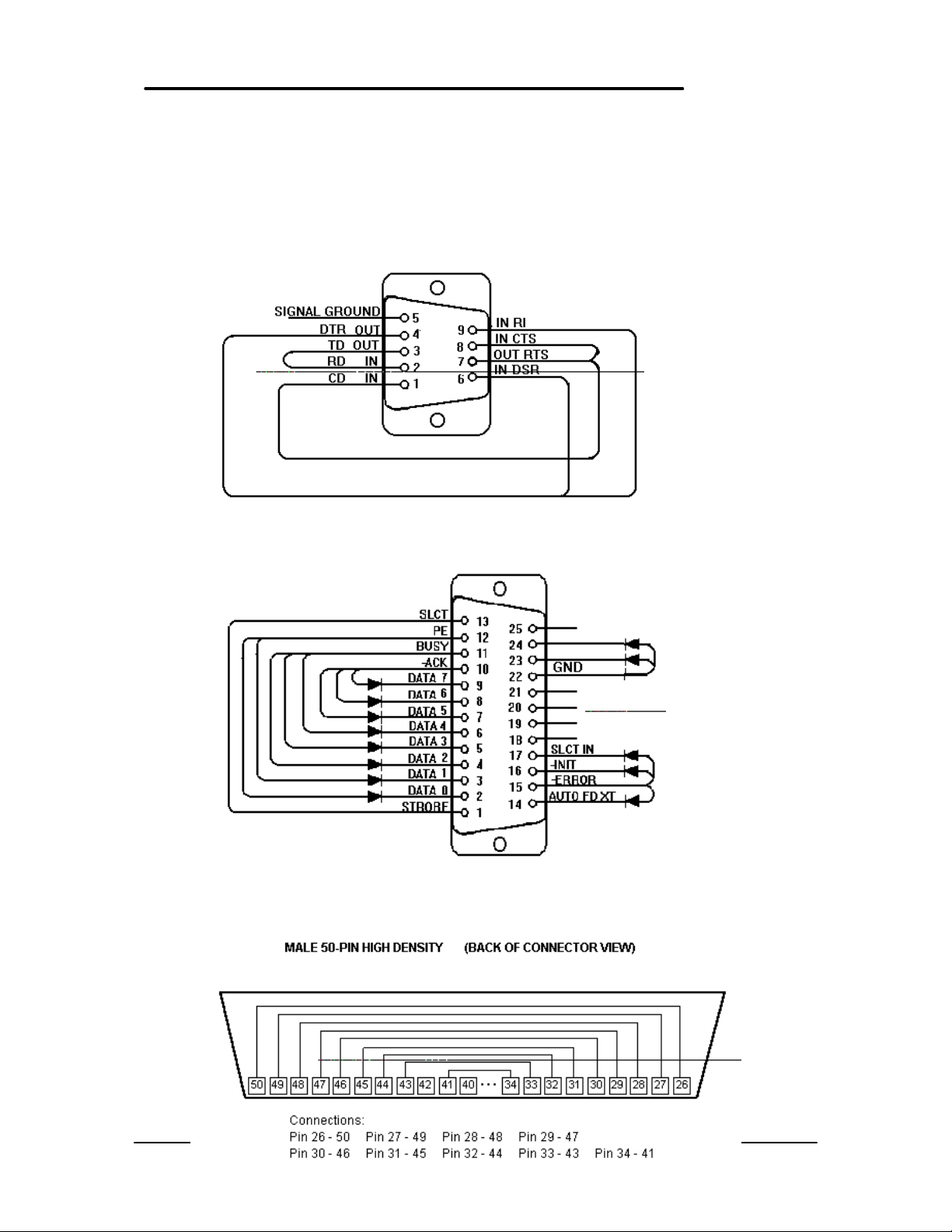

Loop Back Connectors

In order to run the RS232 serial port, parallel port, and SCSI port self-test, a loop back connector

is needed. The loop back may be placed on either the OmniBook port or at the end of the

corresponding cable. This feature is also helpful in diagnosing a defective serial, parallel, or

SCSI cable.

Loop back connectors may be purchased or can easily be constructed. The following illustrations

identify the correct pin-out configurations for the serial, parallel, and scsi loop back connectors.

Figure 5 - Serial Loop Back Connector

10

Figure 6 - Parallel Loop Back Connector

Page 30

PCMCIA Type III extender card

The PCMCIA test that makes use of SyCard Technology’s SyCard also requires an extender

card modified with two jumpers or with solder bridges. In order for the Sycard to be detected,

CD1- and GND must be shorted together, and GND with CD2- must also be shorted together.

These are both pairs of endmost pins on the extender. Once these jumpers or solder bridges are

added, the SyCard will successfully be detected and the SyCard tests can be performed. See

Figure 8.

Solder Bridges

Figure 8 - SyCard Solder Bridges

11

Page 31

Command line options

When Diag is run, either from the command line, or from a batch file, a number of switches (or

options) may be included to “customize” the operation of Diag. Switches must be specified

separately, and must begin with either a - or a / character. Upper or lower case may be used as

desired. Switches may be used in any order. The switches, a brief description, and their use are

described below:

Table 4 - Diagnotic Command Line Options

Switch Description

-? Report the standard command line options available.

-! Report standard and hidden command line and keyboard commands available.

-cNxxxx Specify Nth ROM checksum. The “BIOS flash ROMs” test the flash memory for

correctness. In order for Diag to maintain usefulness in the face of new and

different BIOSes, a way is needed to specify the BIOS ROM values. Though the

test will not fail (as of this writing) if the checksums are not specified, a ‘?’ will show

after a sum to indicate checksum uncertainty. All three checksums must be

specified to fully qualify the ROMs. As an example, to test a build with the

960701.ROM, the user would enter: Diag -c121E9 -c2D631 -c3C600. Batch files

that need to work with both F1175 and F1360 OmniBooks may specify two

checksums after each switch, the first one for the F1175 and the second one for the

F1360. For example, to test the 970121 ROMs for both units, use the following

switches: -c1B7386A45 -c2DC8CDC8C -c316001600.

-d Select Dock tests only. For testers wishing to test docks, this switch restricts the test

shown to those that pertain to the dock only. The set of tests shown in this mode

include the following: Serial port, Printer port, SCSI loopback, Audio, Floppy disk,

Docked device, Dock keyboard, Dock PS2 mouse, Dock EEPROM.

-f Run Fast IR loopback mode on startup. The IR port test needs a computer running

in “passive” mode to send IR data back to the computer being tested. An IR test

station can be automated by having the passive computer run Diag with the -f option

in its AUTOEXEC.BAT file. The key <Alt+F> can also be used to put the computer

into passive mode. Press <Esc> to exit from passive mode.

-k<file> Run a Keyboard macro file. This switch is by far the most powerful and versatile in

that it lets the operator set up different configurations and test sequences and play

them back later just as though they were typing the commands from the keyboard.

For information on creating a keyboard macro file, see the <Alt+R> command.

-m Enable Mouse keyboard control. For units that do not have a keyboard, use this

option to control Diag with a mouse. For more information on this feature, see the

<Alt+M> command

-r<test#> Run nth test and return exit code. For testing from a batch file, this switch can be

used to run a single test and return the test result in the errorlevel. 0=pass, 1=fail,

2=aborted, 3=no loop/can’t run. Tests are specified by ordinal number counting

from 1 at the top. Use the -1, -2, -3 option below to set the test level.

-s Disable control via Serial port. By default, the serial port can be used to control

Diag via a host computer (running Kermit connected at 9600, N, 8, 1) when no

keyboard is available, the unit cannot be easily accessed for entering commands, or

remote automated operation is needed. Serial control is always automatically

disabled during the serial port test, but if the serial port is used for other activities,

use this switch to completely disable control.

-x Test for the eXtra key on foreign keyboards. Foreign keyboards have an extra key

to the left of the space key. To include this key in the internal keyboard test, add a X parameter when running Diag. Because the keyboard test is scancode based (not

ASCII character), the key names are NOT localized to their foreign equivalents.

12

Page 32

Also some key caps have characters that cannot be displayed with the text

characters available. Therefore, when running the keyboard test on a foreign

keyboard, the POSITION of the key within the keyboard should match the

POSITION of the key shown on the display, not necessarily the character printed on

the key (although in nearly all cases, it does match). When -x is specified, the extra

key appears as >< before the SP key.

-1 Mark all tests for quickest test available. This has the same effect as using the <M>

command once and is mainly used with the -r switch.

-2 Mark all tests for standard test available. This has the same effect as using the <M>

command twice and is mainly used with the -r switch

-3 Mark all tests for longest test available. This has the same effect as using the <M>

command thrice and is mainly used with the -r switch.

EDOCK An undocumented/hidden Diag switch: Set the dock serial number. Use this

undocumented switch to set the dock serial number in the dock EEPROM. The date

and time must be valid, and the date must be Jan 1 1996 or later. The serial

number is set to the following code: MDDHHMMS where M is month 1-9 A-C, DD is

day 01-31, HH is hour 00-23, MM is minute 00-59, and S is seconds 0-5 (tens of

seconds only).

User interface commands

The user interface commands of the diagnostics program are divided into three groups:

commands that select tests, commands that toggle test settings, and commands that set test

parameters.

Commands for test selection

The following table describes the various commands used to select test within the diagnostics

program.

Table 5 - Diagnostic Test Selection Commands

Command Description

Down Highlight the next test. At the bottom, wrap to the top test.

Up Highlight previous test. At the top, wrap to the bottom test.

Home Highlight the top test.

End Highlight the bottom test.

Space Mark the highlighted test. Tests that permit multiple levels progress from the

quickest test to the longest test then back to not selected.

M Mark all tests. If no tests are selected, <M> will select all tests to run at the

quickest possible level. Another <M> sets all tests to the standard level.

Another <M> sets the longest possible level. Another <M> unselects all tests. If

any other mixture of tests is selected all tests are unselected.

Enter Run all selected tests. <Enter> is used to begin running a group of selected

tests. If no tests are selected, the highlighted test is run at the standard level.

1 2 3 Run highlighted test ONLY (short, standard, long). If short or long is not

available for the specified test, the standard test is run.

<Backspace> Stop current test. The <Backspace> key is universally used to abort a test that

is running. Some tests may not be able to quickly respond to the keyboard and

it may be necessary to depress the key a few times or hold the key down for it to

be recognized.

Esc Exit Self-test. Upon exit, the Diag display is cleared and the DOS display is

restored. Every attempt is made to restore all settings to their previous state

13

Page 33

upon exit (no reboot necessary in most cases).

Alt+F12 Dump the text screen to a file named DIAG.xxx where xxx begins at 000 and

increases by one each time another screen dump is captured. Screen dumps

from previous runs of Diag are preserved.

? or F1 Display a help screen of keyboard commands.

Commands for toggling test settings

The following table describes the various commands used to toggle test settings within the

diagnostics program.

Table 6 - Diagnostic Commands for Toggling Settings

Command Description

Ctrl+C Toggle battery Charging on/off. This command sends a request to the charging

software in the BIOS to enable charging / disable charging.

Ctrl+E Toggle ignore Errors on/off (continue after error when on). Normally Diag stops

looping when an error occurs, but with this command, Diag will continue to loop

until all requested loops are complete.

Ctrl+L Toggle Logging to disk file (errors, all, all+status, none). This command appends

results to the file DIAG.LOG on the current drive and directory from which Diag

was run. The data logged is either: 1) only tests which fail, 2) all tests results, 3)

all test results, and all messages shown in the lower status window, or 4) none.

For looping tests, the loop count and time is logged at the start of each loop. If a

floppy or hard disk critical error happens when logging results, the normal “Abort,

Retry, Ignore” message may not be visible depending on the display mode. A

special error handler has been incorporated into diag to handle this case. A

flashing message will appear on the top line should an error of this type occur.

Press A, R, or I to continue. If no keyboard is available, press the Contrast Up

button to Retry, or the contrast Down button to Ignore the error.

Ctrl+N Toggle Noise (beep & flash) at test completion. When a test or set of tests

completes, Diag waits for the user to enter more commands. To help notify the

operator of when this happens, use Ctrl+N to cause Diag to invert the display and

sound a noise until the user responds in some way.

Ctrl+P Toggle Power management on/off. Tests that require measuring power levels

may require that Power management be on or off. This can be controlled directly

with this command.

Ctrl+T Toggle between the four types of mouse tests. The HP mouse tests are 1) text

mode mouse test, 2) graphic mode sine wave mouse test, 3) combined text and

sine tests, and 4) graphic draw mode test.

Ctrl+V Toggle Verbose test status reporting. Some tests can report more detailed

information. These tests include: all dock related tests (reports voltages), the HP

and External mouse tests (reports x/y data and button status).

Ctrl+W Toggle printing to Wired serial port (errors, all, all+status, none). Like the

<Ctrl+L> command that logs results to disk, this command similarly logs results to

the com 1 serial port.

Alt+A Toggle cAche on/off. If it is necessary to disable the cache, use this command.

Processor level commands are used to perform this operation.

Alt+K Toggle miKe on & line off, mike off & line on, both off.

Alt+M Toggle program control with Mouse on or off. Like the -m command line option,

Alt+M enables controlling Diag with a mouse. The mouse actions listed below

have the following keyboard equivalents:

Mouse switch Key Action

14

Page 34

Top Bumper <Up> Highlight previous test.

Bottom Bumper <Down> Highlight next test.

Left Button <Enter> Run current or selected tests.

Right Button <Space> Mark highlighted test.

Right Bumper <Backspace> Cancel currently running test.

Left Bumper <Esc> Exit Diag.

Alt+P Toggle ‘Prompt to retry test after a failure.’ Sometimes it is useful to trap failures

and give the operator another opportunity to run a test before logging the test as

failed. When this option is enabled, if a test failed (other than user aborted) the

user is prompted with “Retry test now?”. If <Y> is pressed, the test is immediately

run again and no logging whatsoever of the failure is recorded anywhere. This

option has been useful for running tests manually where test fixtures need to be

installed prior to testing.

Alt+R Record keystrokes in a file for configuring tests. Used to record keystrokes for

later recall, the user is prompted for the name of a file to store the keystroke

names in (note that the extension used with the keyfile is automatically set to

.KEY). Once a unique name has been entered, every key press is recorded to the

file (except keys pressed during the execution of an individual test) until <Alt+R>

is pressed again, or Diag is exited. If Diag is exited, the final <Esc> key is

included in the key file. Please note that macro files run when Diag first starts up,

and that any keys pressed before <Alt+R> is pressed will NOT be included. In

particular, keys that select tests or test settings should be avoided before

recording a keyboard macro file. If you wish to avoid having to wait until AFTER a

set of tests is run to save the keyboard macro file simply enter all the keys you

need UP TO WHERE YOU WOULD PRESS THE ENTER KEY. At this point,

press <Esc> to exit Diag, then use EDIT or another ASCII text editor to add

“<Enter>” to the end of the file.

Alt+S Toggle Suspend hard disk at end of test. The hard disk can either be left spinning

(default) at the end of its test, or spun down and stopped.

Alt+T Toggle 1000Hz Tone on/off. The PC speaker generates a 1000Hz tone when this

option is enabled.

Alt+V Toggle Videos used between both, external, and internal. Diag can drive either or

both displays. When Diag is first run, the currently selected displays continue to

function (whatever the user has specified). The first <Alt+V> enables both

displays, the second enables the external display only, and the third enables the

internal display only.

Alt+W Walk through tests. Sometimes it is useful to advance slowly through a particular

test. By enabling this option, Diag will beep and wait for a keypress each time the

test would normally just check to see if the <Backspace> key was pressed.

The following two-key commands are hidden from general use:

Table 7 - Diagnostic Hidden Commands

Command Description

Alt+E + Alt+C Set the lost mickey Count threshold. Use this command to specify the

minimum number of “lost mickeys” at which a mouse “mickey” error can occur.

The default value is 530 mickeys. See also the Alt+E + Alt+T command, and

the mouse test section.

Alt+E + Alt+D Show dock EEPROM serial number (hidden function). Use this command to

verify the dock serial number is set.

Alt+E + Alt+H Set the Horizontal lost calibration speed thresholds used in the graphic draw

mouse test. The defaults limits are 300 to 500.

15

Page 35

Alt+E + Alt+V Set the Vertical lost calibration speed thresholds used in the graphic draw

mouse test. The defaults limits are 200 to 400.

Alt+E + Alt+M Set mouse bumper failure threshold. The default number of mickeys for this is

1000. The number reflects how much bumper compression is permitted before

a bumper is rejected.

Alt+E + Atl+S Set sine mouse test threshold. For mice that exhibit sine wave patterns along

the left side of the screen, use this key to specify how much will be tolerated.

The default value is 10.

Alt+E + Alt+T Set the lost mickey Time threshold. Use this command to specify the minimum

number of “timer tics” at which a mouse “mickey” error can occur. The default

value is 10 timer tics. See the Alt+E + Alt+C command and the mouse test

section.

Alt+E + Alt+Z Shell out from Diag to a command prompt. This can be used to run small

tasks, (e.g. copy files) without losing any current diagnostic settings. When

ready to return to Diag, type EXIT.

Commands for setting test parameters

The following table describes the various commands used to set test parameters within the

diagnostics program.

Table 8 - Diagnostic Test Parameters

Command Description

# Set loop count limit for looping tests. By default 1 loop is run. If 0 loops are

specified, Diag will loop indefinitely. Other values will loop for the count specified.

Ctrl+A Set wakeup Alarm delay after suspend. The OmniBook can be set to

automatically wake up after a suspend by setting a wakeup alarm of 1 to 59 hours,

minutes, or seconds. By default, no wakeup is scheduled. If an alarm delay has

been set and multiple test loops are set then Diag will automatically suspend at the

completion of each loop.

Ctrl+D Set loop Delay interval. By default, looped testing runs as rapidly as possible with

no delays between loops. This command lets the user specify that each loop of

testing start from 1 to 59 hours, minutes, or seconds after the previous loop

started. No delay will occur if the tests have already run for the specified delay

time (for example, if 2 minutes of delay are specified and the tests selected ran for

2 minutes 10 seconds, then no delay would occur at the end of the loop.

Ctrl+H Report System Hardware found. This test reports on various OmniBook

components. The following are reported: CPU speed (100, 133, 150, etc); Display

technology (TFT, DSTN); Hard disk capacity (814M, 1.4G, etc); Cache size (256,

512, etc) and state (ON,OFF); OS version (varies); system RAM (16M, 24M, …

80M); and disk volume id (varies).

Ctrl+R Set Retries before reporting disk error. By default, 5 retries are permitted before a

disk error is reported. Specifying fewer retries will detect marginal media more

quickly. A related feature of Diag regarding soft read errors (checksum errors), is

that these sectors will be written back to disk to repair the checksum error.

Ctrl+S Enter Suspend state. This command will put the OmniBook into an off state

similar to pressing the Off key. Once suspended, the OmniBook will remain off

indefinitely unless a wakeup alarm has been set with <Ctrl+A>.

Alt+B Set Brightness 0-255. Specify a display brightness from 0 to 255 with this

command. This exceeds the normal range permitted with the brightness buttons

and can result in a blank display. Repeat the command with a less extreme value

to restore the display.

16

Page 36

Alt+C Set Contrast 0-255. Systems with a DSTN display can specify a display contrast

from 0 to 255. This exceeds the normal range permitted with the contrast buttons

and can result in a blank display. Repeat the command with a less extreme value

to restore the display.

Alt+D Set device type that should be found in the dock port. Once specified, the

“Docked device” test will only pass if the correct device is found. The OmniBook

dock port can accept either a SCSI cable for connection to a tower, or a dock

device. Specify N, S, or D when prompted for nothing, SCSI cable, or dock.

Alt+F Set Fast IR loopback mode. The fast I/R test requires two OmniBooks with their

I/R ports directed at each other. One OmniBook must be run in fast IR loopback

mode. To put an OmniBook into this mode either use this command or use the /f

command line option when starting Diag. To exit this mode press the <Esc> key.

Alt+I Enter Idle state. This command puts the OmniBook in a low power state while still

maintaining full readiness to run. Press any key to resume.

Alt+N Enter a Note to log to disk file. When logging to a disk file has been enabled with

<Ctrl+L>, this command can be used to permit entering a line of text, then logging

the text to the log file DIAG.LOG

Details on using the diagnostic tests

Details for the various tests are described below. The levels permitted for each test and a brief

note on hardware or other options are described.

Numerous tests involve pattern testing to determine if the hardware can accept the various data

combinations required. Tests that make use of 18 data patterns use the following pattern set:

0FFFFh, 00000h, 0F0F0h, 0AAAAh, 05555h, 08080h, 04040h, 2020h, 01010h, 00808h, 00404h,

00202h, 00101h, 01111h, 02222h, 04444h, and 08888h. These data patterns are used in place

of “walking bits”, “checkerboards”, and “bit stuck high/low”.

CPU

Level: 2. The CPU test contains numerous subtests as follows. The CPU register test writes the

18 data patterns to the registers and reads them back to verify correctness. The CPU arithmetic

test performs ACD, ADD, DEC, DIV, IDIV, IMUL, INC, MUL, SBB and SUB with 16 and 32 bit

operands. The CPU logical test performs AND, NOT, OR, and XOR with 16 and 32 bit operands.

The CPU string test performs LODS, MOVS, SCAS, and STOS with 16 and 32 bit operands.

The CPU interrupts / exceptions tests software interrupts and real-mode accessible exceptions; if

Diag is running in a DOS box, Windows prevents testing all exceptions but divide by 0. The

coprocessor tests the numeric coprocessor register stack, exception handling, arithmetic,

comparison, and transcendental operations. Failures are reported by register and operation. A

final test of CPU speed is performed to ensure measured speed is within 10% of the expected

value, values below this will fail the test.

Cache

Level: 2. This tests the translation lookaside buffer and the Pentium on-chip cache first with

register addressability, then with the 18 test patterns. No memory managers may be installed for

this test to run.

RAM, motherboard

Levels: 1,2,3. The level 1 test performs an address test only with the 18 data patterns. The

level 2 test performs a pattern test, address test, bus throughput, and code test. The level 3 test

does what level 2 does except the pattern and address tests are repeated 10 times. The

17

Page 37

operation of all tests depend on the presence or absence of XMS or EMS drivers. In general, if

there is no XMS and no EMS driver, then memory will be accessed directly in pseudo-32-bit

mode (i.e. with 4 GB selectors but from real code), if there is an XMS/EMS driver, the XMS

driver will be used to access memory. The recommended environment is real mode without

XMS or EMS drivers (i.e. a clean boot).

Pattern testing and address testing are similar. The pattern test sequentially writes the 18

patterns to memory and reads them back. The address test uses each individual memory

location as the pattern data, but otherwise the test functions just like a pattern test.

Base memory is always pattern/address tested in 16-KB blocks. Extended memory, if no

EMS/XMS drivers are present, will be tested in blocks of up to 1MB. The contents of the

memory is not preserved.

Bus throughput testing is only available for base memory. The test reads memory using a tight

REP LODSD loop, not checking the actual data, but looking out for parity errors (from the

memory, cache, and interface chips).

Code test is only available for extended memory. The test writes a 1-MB program to memory,

switches the CPU to protected mode and runs the program that is in extended memory. This

approach tests not only the data cache and fetch of a CPU, but also the code cache and fetch.

Exceptions and parity errors are also monitored in protected mode.

RAM, plug in

Levels: 1,2,3. These tests are identical to the RAM, motherboard tests except the RAM on the

plug in card is tested.

BIOS

Level: 2 - command line option. This tests the 256k bytes of flash ROM memory. Depending on

whether or not checksums are specified on the command line (with -C1xxxx -C2xxxx and C3xxxx) the test either confirms the checksums specified or just reports the checksums found. If

the checksums are unknown, run this test manually once to determine their value, then use these

values for regular testing by specifying the checksums reported on the command line when Diag

runs. The BIOS is logically divided into three sections named: C-F (BIOS memory C000:0000 to

F000:7FFF), Altera (BIOS memory F000:8000 to F000:BFFF), and Boot (BIOS memory from

F000:C000 to F000:FFFF).

CMOS

Level: 2. This tests CMOS addresses 010h - 03Fh of the nonvolatile real time clock CMOS RAM

with the 18 data patterns, and tests for a correct CMOS checksum.

Upper PC Card

Level: 2. This test uses the Sycard Technology PCMCIA test to check the TI PCI-1130,1131

controller. The controller is checked for I/O signals, VCC and VPP voltages, proper audio signal

generation, INPACK number generation, 3.3 and 5 volt operation and other aspects as detailed

in the following listing of a typical test result. Please note that during the Audio out test a 1KHz

tone should be heard. The Sycard test card is manufactured by Sycard Technology of Santa

Clara, California.

18

Page 38

Sycard Technology PCCtest 27x/37x software v1.50a