HP HCPL-7870, HCPL-7860, HCPL-0870 Datasheet

Isolated 15-bit A/D Converter

Technical Data

Features

• 12-bit Linearity

• 700 ns Conversion Time

(Pre-Trigger Mode 2)

• 5 Conversion Modes for

Resolution/Speed Trade-Off;

12-bit Effective Resolution

with 18 µs Signal Delay

(14-bit with 94 µs)

• Fast 3 µs Over-Range

Detection

• Serial I/O (SPI®, QSPI® and

Microwire® Compatible)

• ±200 mV Input Range with

Single 5 V Supply

• 1% Internal Reference

Voltage Matching

H

HCPL-7860

HCPL-0870, -7870

• Offset Calibration

• -40°C to +85°C Operating

Temperature Range

• 15 kV/µs Isolation Transient

Immunity

• Regulatory Approvals; UL,

CSA, VDE

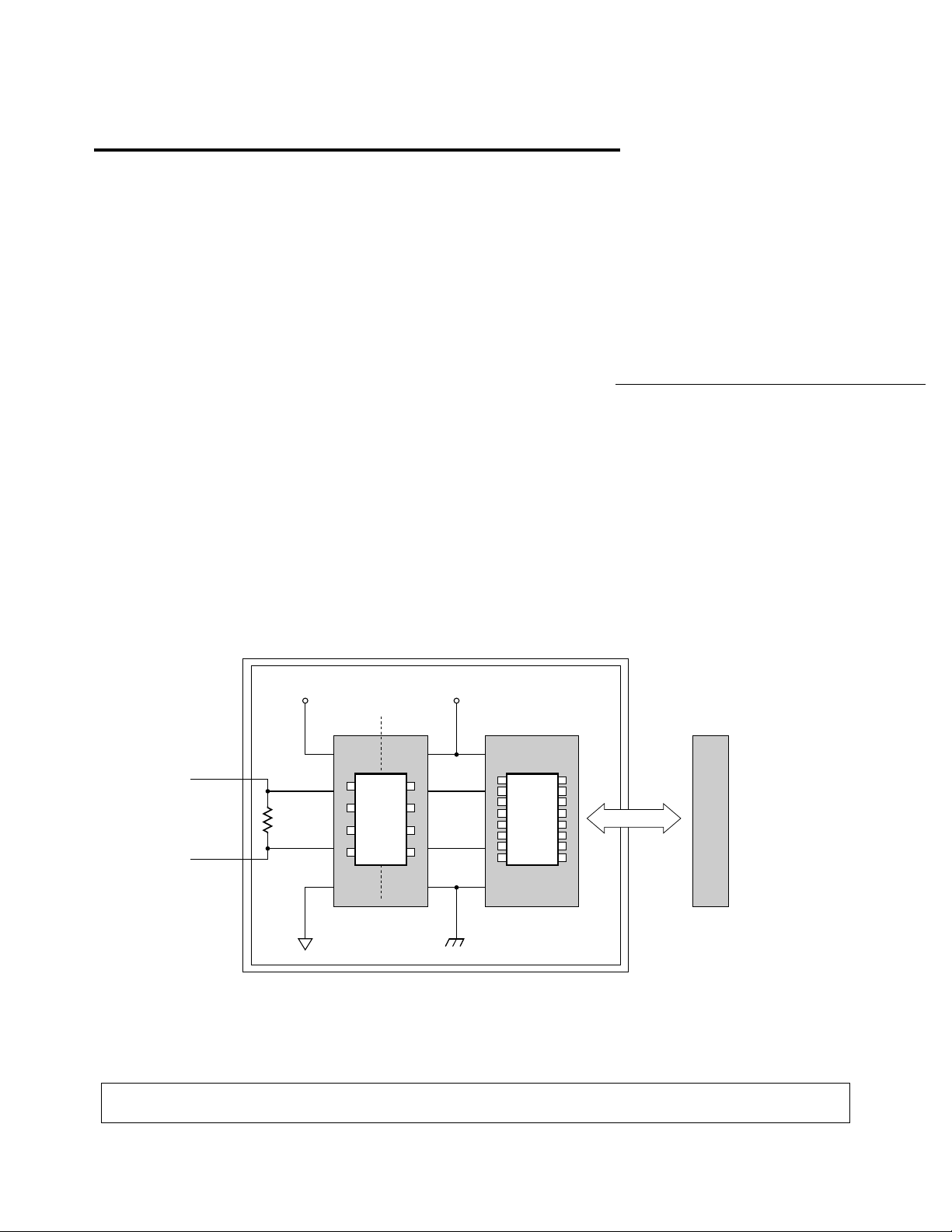

DIGITAL CURRENT SENSOR

++

YYWW

HPx870

DIGITAL

INTERFACE IC

OUTPUT

DATA

MICRO-CONTROLLER

INPUT

CURRENT

ISOLATION

BOUNDARY

YYWW

HP7860

ISOLATED

MODULATOR

Hewlett-Packard’s Isolated A/D Converter delivers the reliability, small size, superior

isolation and over-temperature performance motor drive designers need to accurately

measure current at half the price of traditional solutions.

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to

prevent damage and/or degradation which may be induced by ESD.

SPI and QSPI are trademarks of Motorola Corp.

Microwire is a trademark of National Semiconductor Inc.

1-260

5965-5255E

Digital Current Sensing Circuit

As shown in Figure 1, using the

Isolated 2-chip A/D converter to

sense current can be as simple as

connecting a current-sensing

resistor, or shunt, to the input

and reading output data through

the 3-wire serial output interface.

By choosing the appropriate

shunt resistance, any range of

current can be monitored, from

less than 1 A to more than 100 A.

Even better performance can be

achieved by fully utilizing the

more advanced features of the

Isolated A/D converter, such as

the pre-trigger circuit which can

reduce conversion time to less

NON-ISOLATED

+ 5 V

than 1 µs, the fast over-range

detector for quickly detecting

short circuits, different conversion

modes giving various resolution/

speed trade-offs, offset calibration mode to eliminate initial

offset from measurements, and

an adjustable threshold detector

for detecting non-short circuit

overload conditions.

ISOLATED

+ 5 V

R

SHUNT

0.02

+

C1

0.1 µF

INPUT

CURRENT

Figure 1: Typical Application Circuit.

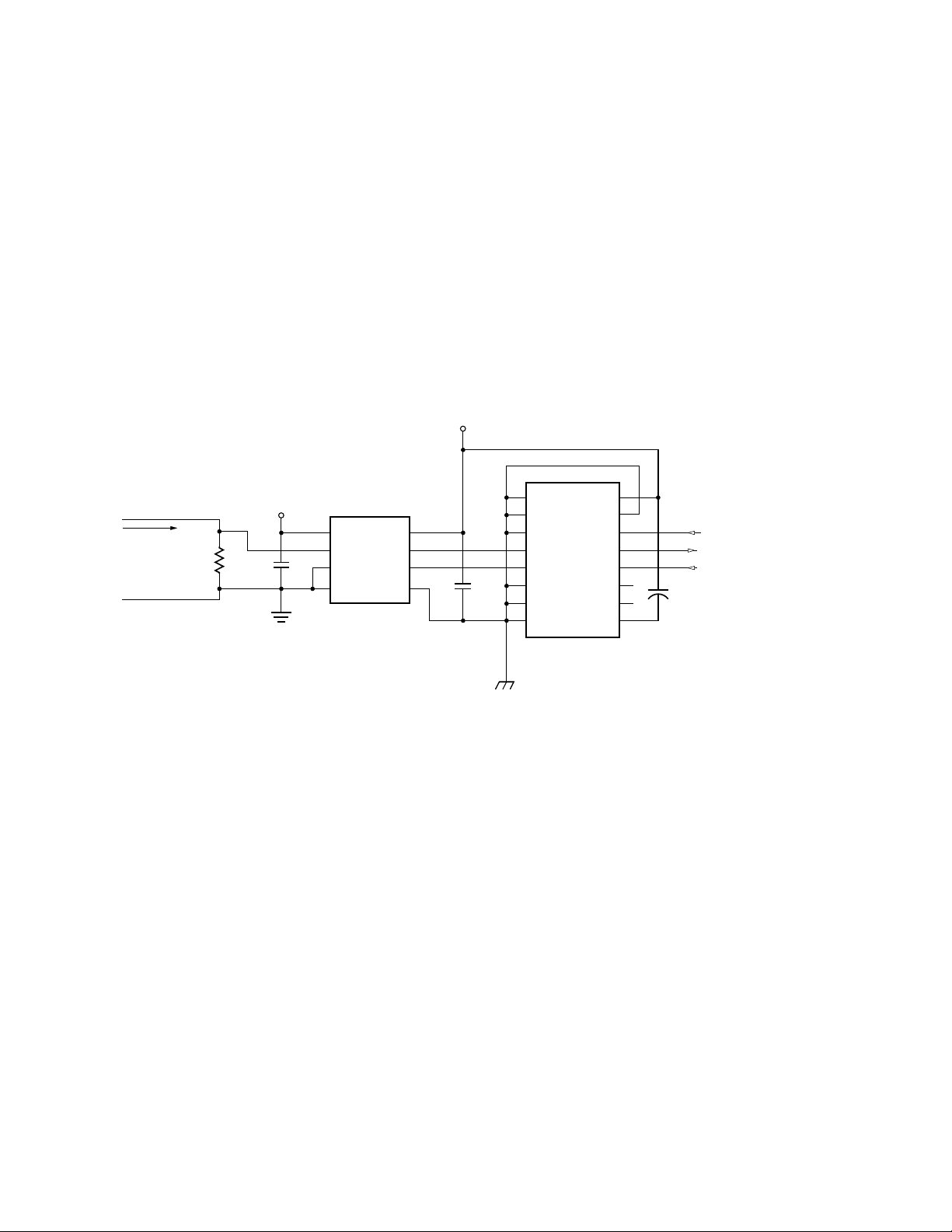

Product Overview

Description

The HCPL-7860 Isolated Modulator and the HCPL-x870 Digital

Interface IC together form an

isolated programmable two-chip

analog-to-digital converter. The

isolated modulator allows direct

measurement of motor phase

currents in power inverters while

the digital interface IC can be

programmed to optimize the

conversion speed and resolution

trade-off.

In operation, the HCPL-7860

Isolated Modulator (optocoupler

with 3750 V

stand voltage rating) converts a

dielectric with-

RMS

V

V

DD1

MCLK

IN+

MDAT

IN-

GND2

HCPL-7860

DD2

C2

0.1 µF

V

V

GND1

low-bandwidth analog input into

a high-speed one-bit data stream

by means of a sigma-delta (∑∆)

oversampling modulator. This

modulation provides for high

noise margins and excellent

immunity against isolation-mode

transients. The modulator data

and on-chip sampling clock are

encoded and transmitted across

the isolation boundary where they

are recovered and decoded into

separate high-speed clock and

data channels.

The Digital Interface IC converts

the single-bit data stream from

the Isolated Modulator into

fifteen-bit output words and

provides a serial output interface

CCLK V

CLAT CHAN

CDAT SCLK

MCLK1 SDAT

MDAT1 CS

MCLK2 THR1

MDAT2 OVR1

GND RESET

HCPL-x870

DD

3-WIRE

SERIAL

INTERFACE

+

C3

10 µF

that is compatible with SPI®,

QSPI®, and Microwire® protocols, allowing direct connection

to a microcontroller. The Digital

Interface IC is available in two

package styles: the HCPL-7870 is

in a 16-pin DIP package and the

HCPL-0870 is in a 300-mil wide

SO-16 surface-mount package.

Features of the Digital Interface

IC include five different conversion modes, three different pretrigger modes, offset calibration,

fast over-range detection, and

adjustable threshold detection.

Programmable features are configured via the Serial Configuration port. A second multiplexed

input is available to allow

measurements with a second

1-261

isolated modulator without

additional hardware. Because the

two inputs are multiplexed, only

one conversion at a time can be

made and not all features are

available for the second channel.

The available features for both

channels are shown in the table

at right.

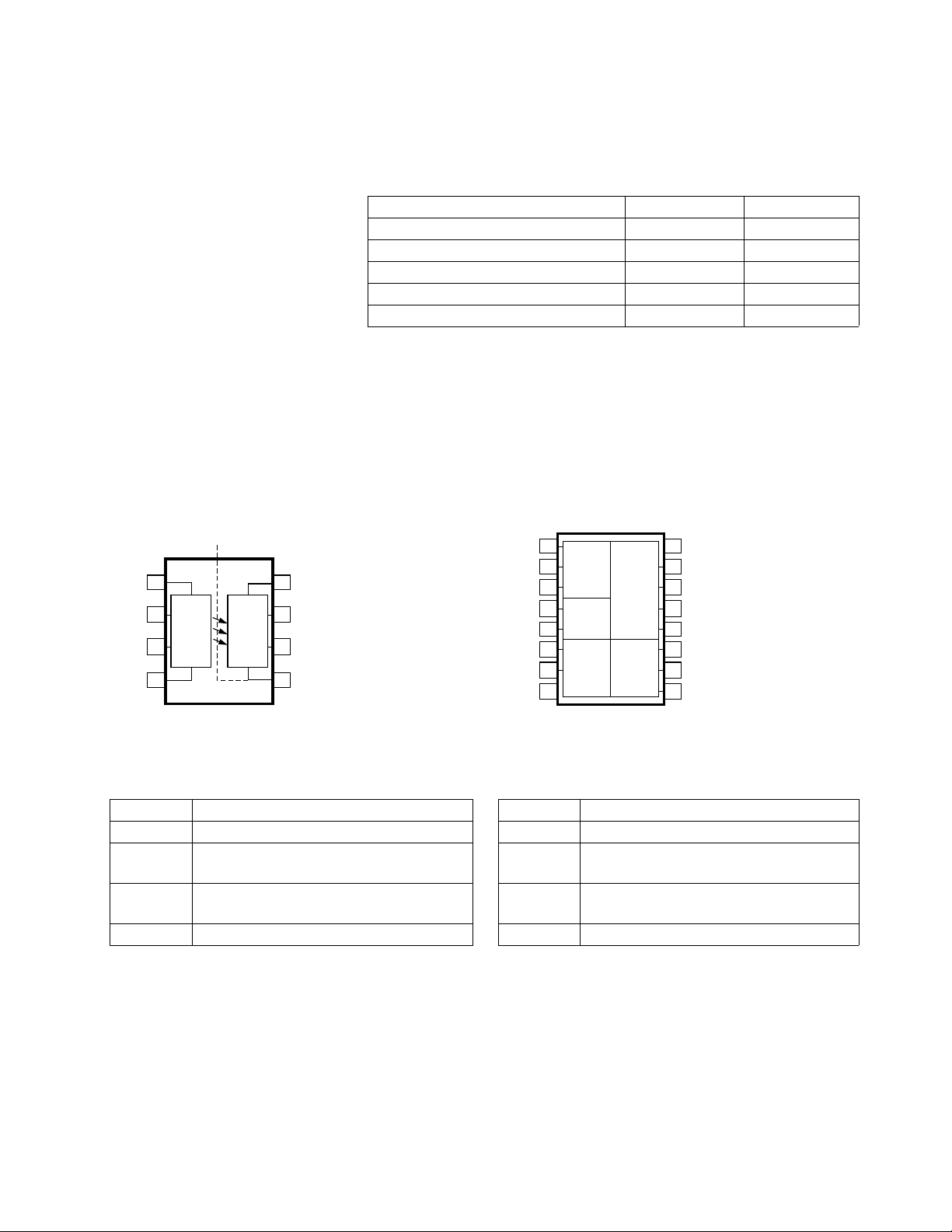

Functional Diagrams

ISOLATION

BOUNDARY

V

DD1

V

IN+

V

IN–

GND1

1

2

3

4

SIGMA-

DELTA

MOD./

ENCODE

DECODE

SHIELD

V

8

DD2

7

MCLK

6

MDAT

GND2

5

HCPL-x870 Digital Interface IC

Feature Channel #1 Channel #2

Conversion Mode ✓✓

Offset Calibration ✓✓

Pre-Trigger Mode ✓

Over-Range Detection ✓

Adjustable Threshold Detection ✓

CCLK

1

2

3

4

5

6

7

8

CONFIG.

INTER-

FACE

CH1

CH2

CON-

VERSION

INTER-

FACE

THRES-

HOLD

DETECT

&

RESET

CLAT

CDAT SCLK

MCLK1 SDAT

MDAT1

MCLK2

MDAT2 OVR1

GND RESET

V

16

DD

15

CHAN

14

13

CS

12

11

THR1

10

9

HCPL-7860 Isolated Modulator

HCPL-x870 Digital Interface IC

Pin Description, Isolated Modulator

Symbol Description Symbol Description

V

DD1

V

IN+

V

IN–

GND1 Input ground GND2 Output ground

Supply voltage input (4.5 V to 5.5 V) V

DD2

Supply voltage input (4.5 V to 5.5 V)

Positive input (± 200 mV MCLK Clock output (10 MHz typical)

recommended)

Negative input MDAT Serial data output

(normally connected to GND1)

1-262

Pin Description, Digital Interface IC

Symbol Description

CCLK Clock input for the Serial Configuration

Interface (SCI). Serial Configuration

data is clocked in on the rising edge

of CCLK.

CLAT Latch input for the Serial Configuration

Interface (SCI). The last 8 data bits

clocked in on CDAT by CCLK are

latched into the appropriate

configuration register on the rising

edge of CLAT.

CDAT Data input for the Serial Configuration

Interface (SCI). Serial configuration

data is clocked in MSB first.

MCLK1 Channel 1 Isolated Modulator clock

input. Input Data on MDAT1 is clocked

in on the rising edge of MCLK1.

MDAT1 Channel 1 Isolated Modulator data

input.

MCLK2 Channel 2 Isolated Modulator clock

input. Input Data on MDAT2 is clocked

in on the rising edge of MCLK2.

MDAT2 Channel 2 Isolated Modulator data

input.

GND Digital ground.

Symbol Description

V

Supply voltage (4.5 V to 5.5 V).

DD

CHAN Channel select input. The input level on

CHAN determines which channel of

data is used during the next conversion

cycle. An input low selects channel 1,

a high selects channel 2.

SCLK Serial clock input. Serial data is clocked

out of SDAT on the falling edge of SCLK.

SDAT Serial data output. SDAT changes from

high impedance to a logic low output

at the start of a conversion cycle.

SDAT then goes high to indicate that

data is ready to be clocked out. SDAT

returns to a high-impedance state after

all data has been clocked out and CS

has been brought high.

CS Conversion start input. Conversion

begins on the falling edge of CS. CS

should remain low during the entire

conversion cycle and then be brought

high to conclude the cycle.

THR1 Continuous, programmable-threshold

detection for channel 1 input data. A

high level output on THR1 indicates

that the magnitude of the channel 1

input signal is beyond a user

programmable threshold level between

160 mV and 310 mV. This signal

continuously monitors channel 1

independent of the channel select

(CHAN) signal.

OVR1 High speed continuous over-range

detection for channel 1 input data. A

high level output on OVR1 indicates

that the magnitude of the channel 1

input is beyond full-scale. This signal

continuously monitors channel 1

independent of the CHAN signal.

RESET Master reset input. A logic high input

for at least 100 ns asynchronously

resets all configuration registers to

their default values and zeroes the

Offset Calibration registers.

1-263

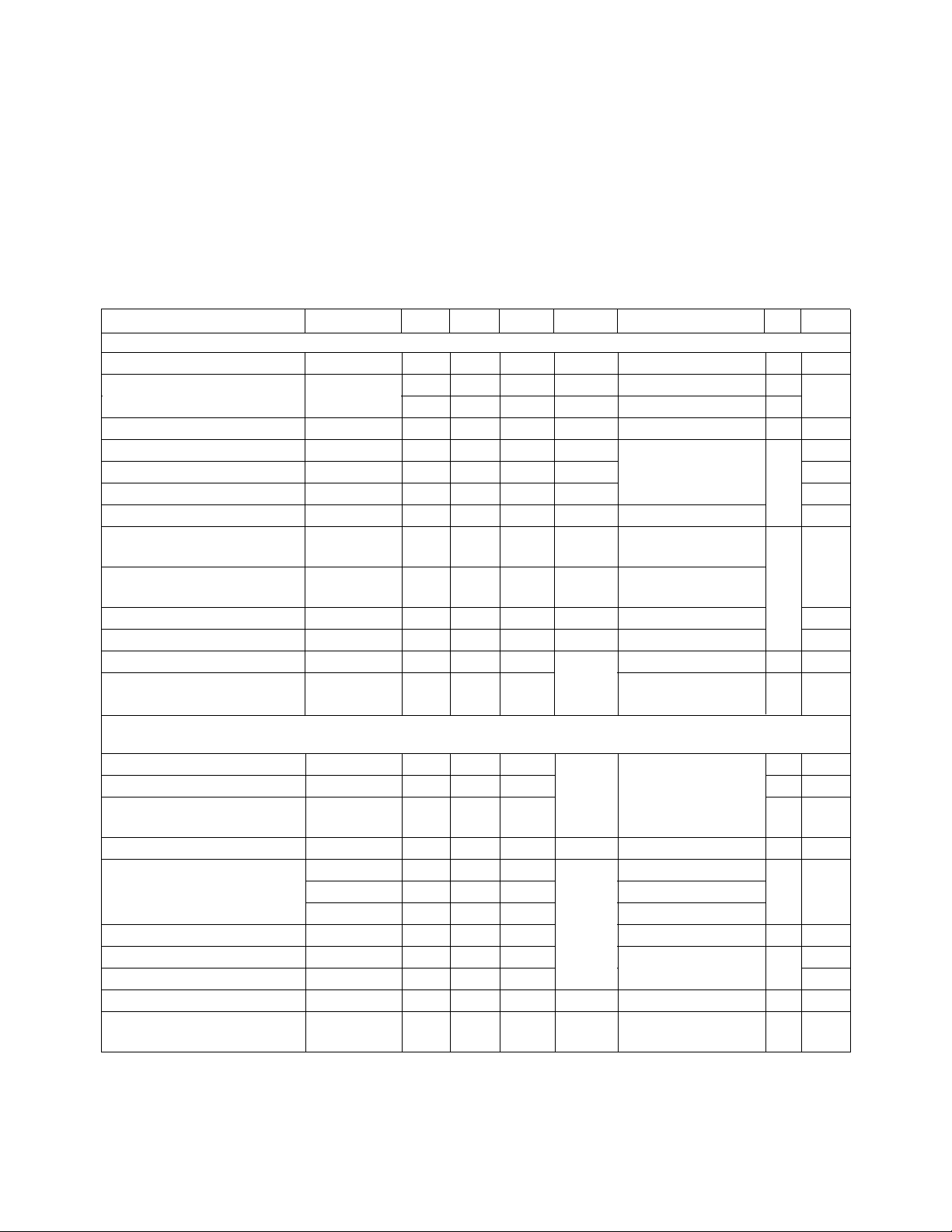

Isolated A/D Converter Performance

Electrical Specifications

Unless otherwise noted, all specifications are at V

specifications are at TA = 25°C and V

TA = -40°C to +85°C, V

DD1

= V

DD2

= V

DD1

DD2

= VDD = 4.5 to 5.5 V.

Parameter Symbol Min. Typ. Max. Units Test Conditions Fig. Note

STATIC CONVERTER CHARACTERISTICS

Resolution 15 bits 1

Integral Nonlinearity INL 6 30 LSB 3 2

Differential Nonlinearity DNL 1 LSB 3

Uncalibrated Input Offset V

OS

Offset Drift vs. Temperature dVOS/dT

Offset drift vs. V

DD1

Internal Reference Voltage V

dVOS/dV

REF

DD1

-1 1 2.5 mV V

A

Absolute Reference Voltage -4 4 % 6 5

Tolerance

Reference Voltage -1 1 % TA = 25°C.

Matching See Note 5

V

Drift vs. Temperature dV

REF

V

Drift vs. V

REF

DD1

dV

Full Scale Input Range -V

REF

REF

/dT

/dV

A

DD1

REF

Recommended Input -200 +200

Voltage Range

DYNAMIC CONVERTER CHARACTERISTICS

(Digital Interface IC is set to Conversion Mode 3.)

Signal-to-Noise Ratio SNR 62 73 dB V

Total Harmonic Distortion THD -67

Signal-to-(Noise SND 66

+ Distortion)

Effective Number of Bits ENOB 10 12 bits 8 7

Conversion Time t

Signal Delay t

Over-Range Detect Time t

Threshold Detect Time t

Signal Bandwidth BW 18 22 kHz 11 12

Isolation Transient CMR 15 20 kV/µsV

Immunity

C2

t

C1

t

C0

DSIG

OVR1

THR1

2.0 2.7 4.2 V

= -200 mV to +200 mV and V

IN+

= 0 V; all Typical

IN-

= VDD = 5 V; all Minimum/Maximum specifications are at

0.025 0.14 % 4

= 0 V 5

IN+

4 µV/°C4

0.7 mV/V

326 mV

190 ppm/°C

0.9 %

+V

REF

mV 6

= 35 Hz, 2,9

IN+

400 mV

(141 mV

pk-pk

rms

) sine

wave.

0.7 1.0 µs Pre-Trigger Mode 2 7, 8

18 22 Pre-Trigger Mode 1

14

37 44 Pre-Trigger Mode 0

18 22 10 9

= 0 to 400 mV 12 10

IN+

10 11

step waveform

= 1 kV 13

ISO

1-264

Notes:

1. Resolution is defined as the total

number of output bits. The useable

accuracy of any A/D converter is a

function of its linearity and signal-tonoise ratio, rather than how many

total bits it has.

2. Integral nonlinearity is defined as

one-half the peak-to-peak deviation

of the best-fit line through the

transfer curve for V

+200 mV, expressed either as the

= -200 mV to

IN+

number of LSBs or as a percent of

measured input range (400 mV).

3. Differential nonlinearity is defined as

the deviation of the actual difference

from the ideal difference between

midpoints of successive output

codes, expressed in LSBs.

4. Data sheet value is the average

magnitude of the difference in offset

voltage from TA=25°C to

TA= -40°C, expressed in microvolts

per °C.

5. All units within each HCPL-7860

standard packaging increment (either

50 per tube or 1000 per reel) have an

Absolute Reference Voltage tolerance

of ±1%. An Absolute Reference

Voltage tolerance of ± 4% is

guaranteed between standard

packaging increments.

6. Beyond the full-scale input range the

output is either all zeroes or all ones.

7. The effective number of bits (or

effective resolution) is defined by the

equation ENOB = (SNR-1.76)/6.02

and represents the resolution of an

ideal, quantization-noise limited A/D

converter with the same SNR.

8. Conversion time is defined as the

time from when the convert start

signal CS is brought low to when

SDAT goes high, indicating that

output data is ready to be clocked

out. This can be as small as a few

cycles of the isolated modulator clock

and is determined by the frequency of

the isolated modulator clock and the

selected Conversion and Pre-Trigger

modes. For determining the true

signal delay characteristics of the A/D

converter for closed-loop phase

margin calculations, the signal delay

specification should be used.

9. Signal delay is defined as the effective delay of the input signal through

the Isolated A/D converter. It can be

measured by applying a -200 mV to

± 200 mV step at the input of modulator and adjusting the relative delay

of the convert start signal CS so that

the output of the converter is at midscale. The signal delay is the elapsed

time from when the step signal is

applied at the input to when output

data is ready at the end of the conversion cycle. The signal delay is the

most important specification for

determining the true signal delay

characteristics of the A/D converter

and should be used for determining

phase margins in closed-loop applications. The signal delay is determined

by the frequency of the modulator

clock and which Conversion Mode is

selected, and is independent of the

selected Pre-Trigger Mode and,

therefore, conversion time.

10. The minimum and maximum overrange detection time is determined by

the frequency of the channel 1 isolated modulator clock.

11. The minimum and maximum threshold detection time is determined by

the user-defined configuration of the

adjustable threshold detection circuit

and the frequency of the channel 1

isolated modulator clock. See the

Applications Information section for

further detail. The specified times

apply for the default configuration.

12. The signal bandwidth is the frequency

at which the magnitude of the output

signal has decreased 3 dB below its

low-frequency value. The signal

bandwidth is determined by the frequency of the modulator clock and

the selected Conversion Mode.

13. The isolation transient immunity (also

known as Common-Mode Rejection)

specifies the minimum rate-of-rise of

an isolation-mode signal applied

across the isolation boundary beyond

which the modulator clock or data

signals are corrupted.

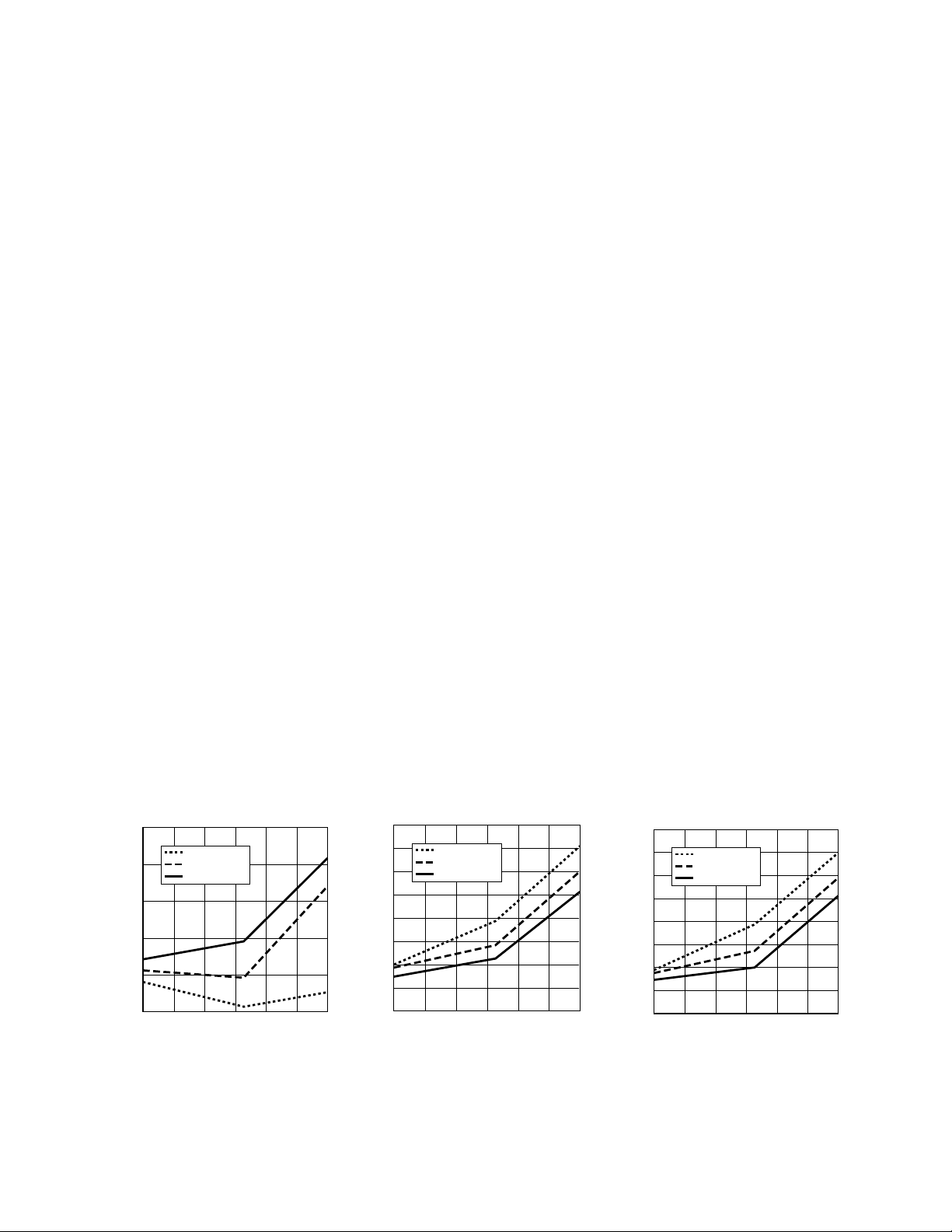

75.0

V

= 4.5 V

DD1

= 5.0 V

74.5

74.0

SNR

73.5

73.0

72.5

-40 85040

V

DD1

V

= 5.5 V

DD1

-20

20 60

TEMPERATURE – °C

Figure 2. SNR vs. Temperature.

16

14

12

10

8

6

INL – LSB

4

2

0

-40 85040

V

= 4.5 V

DD1

= 5.0 V

V

DD1

V

= 5.5 V

DD1

-20

20 60

TEMPERATURE – °C

Figure 3. INL (Bits) vs. Temperature.

0.08

0.07

0.06

0.05

0.04

INL – %

0.03

0.02

0.01

0

-40 85040

V

= 4.5 V

DD1

= 5.0 V

V

DD1

V

= 5.5 V

DD1

-20

20 60

TEMPERATURE – °C

Figure 4. INL (%) vs. Temperature.

1-265

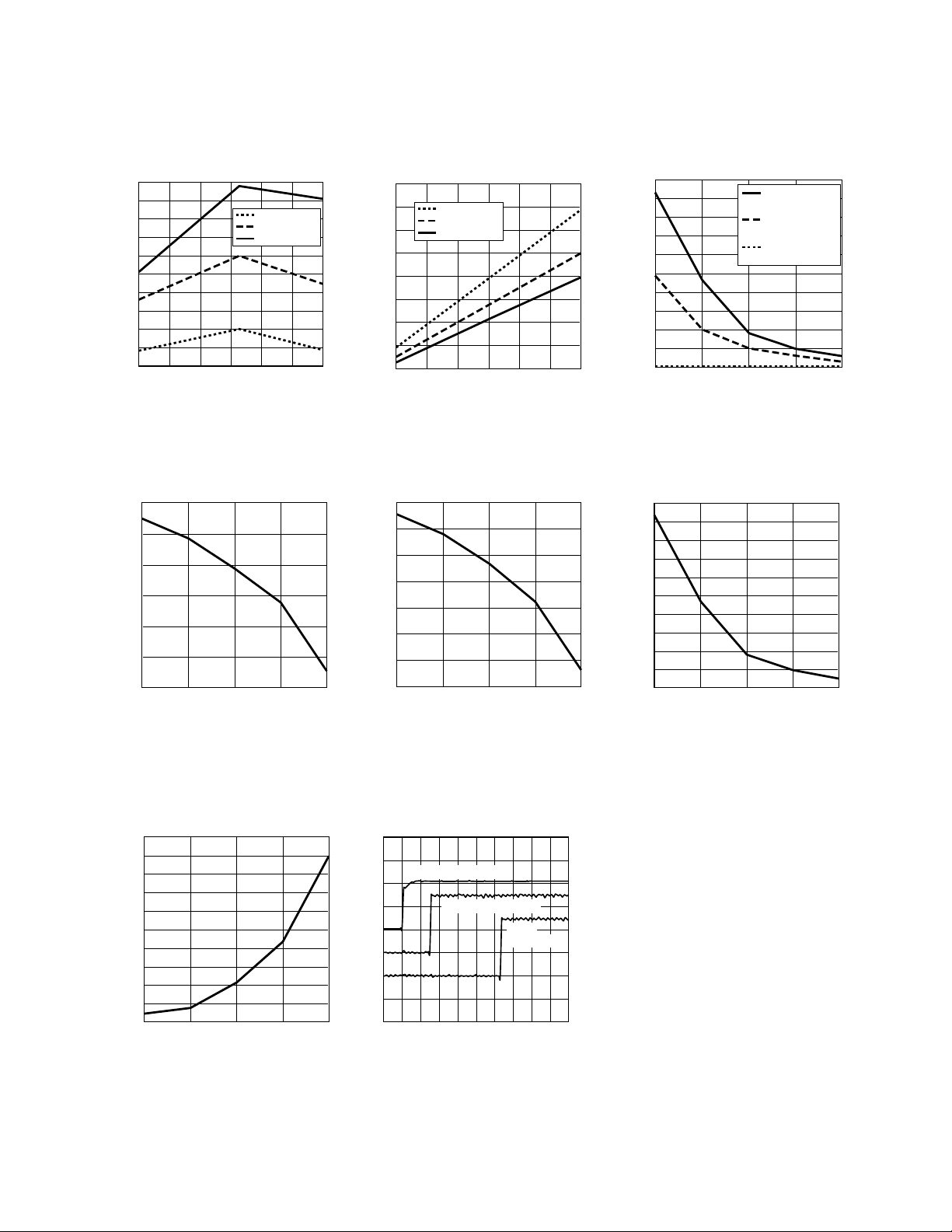

400

300

200

100

0

-100

-200

-300

OFFSET CHANGE – µV

-400

-500

-600

-40 85

040

-20

TEMPERATURE – °C

V

DD1

V

DD1

V

DD1

20 60

= 4.5 V

= 5.0 V

= 5.5 V

2.5

2.0

1.5

1.0

0.5

CHANGE – %

0

REF

V

-0.5

-1.0

-1.5

-40 85040

V

= 4.5 V

DD1

= 5.0 V

V

DD1

V

= 5.5 V

DD1

-20

20 60

TEMPERATURE – °C

200

180

160

140

120

100

80

60

40

CONVERSION TIME – µs

20

0

15

2

CONVERSION MODE #

PRE-TRIGGER

MODE 0

PRE-TRIGGER

MODE 1

PRE-TRIGGER

MODE 2

34

Figure 5. Offset Change vs.

Temperature.

14

13

12

11

10

9

EFFECTIVE RESOLUTION (# BITS)

8

15

2

34

CONVERSION MODE #

Figure 8. Effective Resolution vs.

Conversion Mode.

100

90

80

70

60

50

40

30

20

SIGNAL BANDWIDTH – kHz

10

0

2

15

CONVERSION MODE #

34

Figure 6. V

Temperature.

85

80

75

70

SNR

65

60

55

50

15

Figure 9. SNR vs. Conversion Mode.

V

IN+

Change vs.

REF

2

34

CONVERSION MODE #

(200 mV/DIV.)

OVR1 (200 mV/DIV.)

THR1

(2 V/DIV.)

2

s/DIV.

Figure 7. Conversion Time vs.

Conversion Mode.

100

90

80

70

60

50

40

30

SIGNAL DELAY – µs

20

10

0

2

15

CONVERSION MODE #

34

Figure 10. Signal Delay vs.

Conversion Mode.

Figure 11. Signal Bandwidth vs.

Conversion Mode.

1-266

Figure 12. Over-Range and Threshold

Detect Times.

Isolated Modulator

Ordering Information

Specify Part Number followed by Option Number (if desired).

Example:

HCPL-7860#XXX

No Option = Standard DIP package, 50 per tube.

300 = Gull Wing Surface Mount Option, 50 per tube.

500 = Tape and Reel Packaging Option, 1000 per reel.

Option data sheets available. Contact Hewlett-Packard sales representative or authorized distributor.

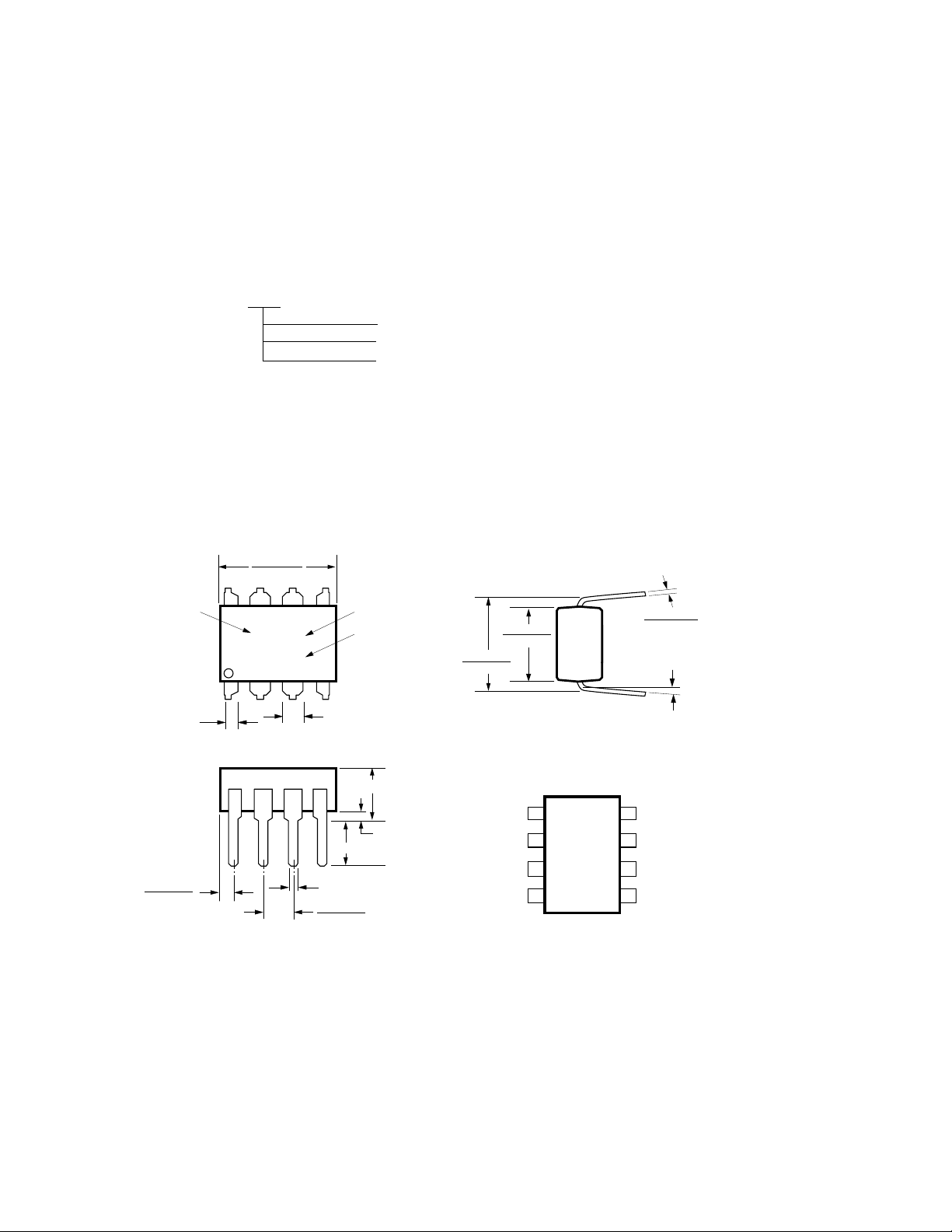

Package Outline Drawings

8-pin DIP Package

9.40 (0.370)

9.90 (0.390)

5678

TYPE NUMBER

PIN ONE

HP 7860X

YYWW

REFERENCE VOLTAGE

MATCHING SUFFIX*

DATE CODE

4321

6.10 (0.240)

6.60 (0.260)

7.36 (0.290)

7.88 (0.310)

0.18 (0.007)

0.33 (0.013)

5° TYP.

1.19 (0.047) MAX.

PIN ONE

0.76 (0.030)

1.24 (0.049)

DIMENSIONS IN MILLIMETERS AND (INCHES).

*ALL UNITS WITHIN EACH HCPL-7860 STANDARD PACKAGING INCREMENT (EITHER 50 PER TUBE OR 1000 PER REEL)

HAVE A COMMON MARKING SUFFIX TO REPRESENT AN ABSOLUTE REFERENCE VOLTAGE TOLERANCE OF ± 1%.

AN ABSOLUTE REFERENCE VOLTAGE TOLERANCE OF ± 4% IS GUARANTEED BETWEEN STANDARD PACKAGING

INCREMENTS.

1.78 (0.070) MAX.

4.70 (0.185) MAX.

0.51 (0.020) MIN.

2.92 (0.115) MIN.

0.65 (0.025) MAX.

2.28 (0.090)

2.80 (0.110)

PIN DIAGRAM

1

V

DD1

2

V

IN+

V

3

IN–

4

GND1

V

DD2

MCLK

MDAT

GND2

8

7

6

5

1-267

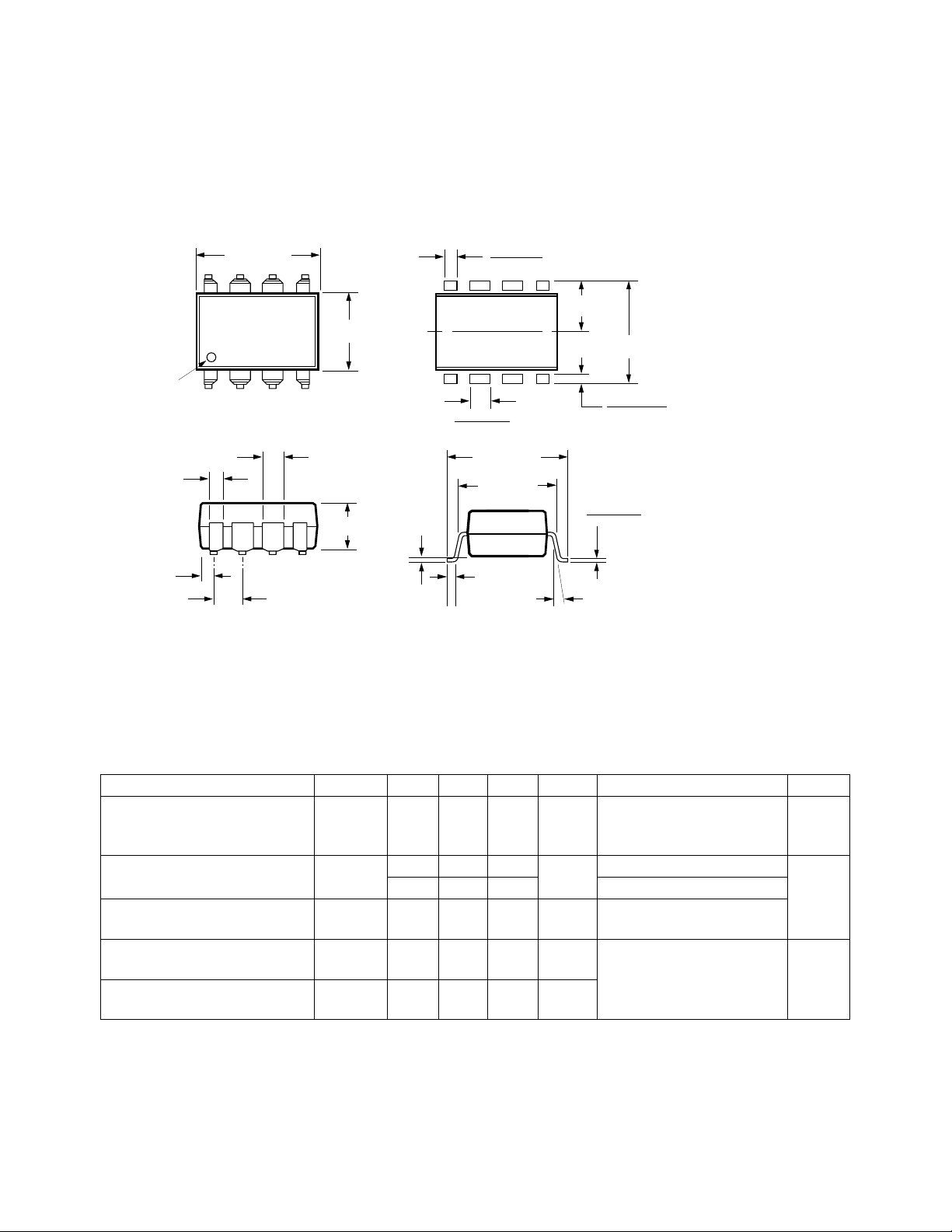

8-pin DIP Gull Wing Surface Mount Option 300

PIN LOCATION (FOR REFERENCE ONLY)

9.65 ± 0.25

(0.380 ± 0.010)

6

5

6.350 ± 0.25

(0.250 ± 0.010)

3

4

1.780

(0.070)

MAX.

4.19

MAX.

(0.165)

MOLDED

1.19

(0.047)

MAX.

7

8

1

2

1.02 (0.040)

1.19 (0.047)

1.19 (0.047)

1.78 (0.070)

9.65 ± 0.25

(0.380 ± 0.010)

7.62 ± 0.25

(0.300 ± 0.010)

4.83

(0.190)

0.255 (0.075)

0.010 (0.003)

TYP.

9.65 ± 0.25

(0.380 ± 0.010)

0.380 (0.015)

0.635 (0.025)

1.080 ± 0.320

(0.043 ± 0.013)

2.540

(0.100)

BSC

DIMENSIONS IN MILLIMETERS (INCHES).

TOLERANCES (UNLESS OTHERWISE SPECIFIED):xx.xx = 0.01

0.51 ± 0.130

(0.020 ± 0.005)

xx.xxx = 0.005

0.635 ± 0.25

(0.025 ± 0.010)

12° NOM.

LEAD COPLANARITY

MAXIMUM: 0.102 (0.004)

Package Characteristics

Unless otherwise noted, all specifications are at TA = +25°C.

Parameter Symbol Min. Typ. Max. Units Test Conditions Note

Input-Output Momentary V

ISO

Withstand Voltage

(See note ** below)

Resistance (Input - Output) R

Capacitance C

(Input - Output)

Input IC Junction-to-Case θ

Thermal Resistance center underside of

Output IC Junction-to-Case θ

jco

Thermal Resistance

3750 V

I-O

I-O

jci

10

10

10

11

0.7 pF f = 1 MHz

96 °C/W Thermocouple located at

12

114 °C/W

13

RH ≤ 50%, t = 1 min. 14,15

rms

Ω V

= 500 Vdc 15

I-O

TA = 100°C

package

** The Input-Output Momentary Withstand Voltage is a dielectric voltage rating that should not be interpreted as an input-output

continuous voltage rating. For the continuous voltage rating refer to your equipment level safety specification or HP Application Note

1074, Optocoupler Input-Output Endurance Voltage.

1-268

Loading...

Loading...