1-385

H

High Bandwidth, Analog/Video

Optocouplers

Technical Data

Features

• Wide Bandwidth

[1]

:

17 MHz (HCPL-4562)

9 MHz (HCNW4562)

• High Voltage Gain

[1]

:

2.0 (HCPL-4562)

3.0 (HCNW4562)

• Low GV Temperature

Coefficient: -0.3%/°C

• Highly Linear at Low Drive

Currents

• High-Speed AlGaAs Emitter

• Safety Approval

UL Recognized - 2500 V rms

for 1 minute (5000 V rms for

1 minute for HCPL4562#020 and HCNW4562)

per UL 1577

CSA Approved

VDE 0884 Approved

-V

IORM

= 1414 V peak for

HCNW4562

BSI Certified (HCNW4562)

• Available in 8-Pin DIP and

Widebody Packages

Applications

• Video Isolation for the

Following Standards/

Formats: NTSC, PAL,

SECAM, S-VHS, ANALOG

RGB

• Low Drive Current Feedback

Element in Switching Power

Supplies, e.g., for ISDN

Networks

• A/D Converter Signal

Isolation

• Analog Signal Ground

Isolation

• High Voltage Insulation

Description

The HCPL-4562 and HCNW4562

optocouplers provide wide bandwidth isolation for analog signals.

They are ideal for video isolation

when combined with their

application circuit (Figure 4).

High linearity and low phase shift

are achieved through an AlGaAs

LED combined with a high speed

detector. These single channel

optocouplers are available in

8-Pin DIP and Widebody package

configurations.

HCPL-4562

HCNW4562

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to

prevent damage and/or degradation which may be induced by ESD.

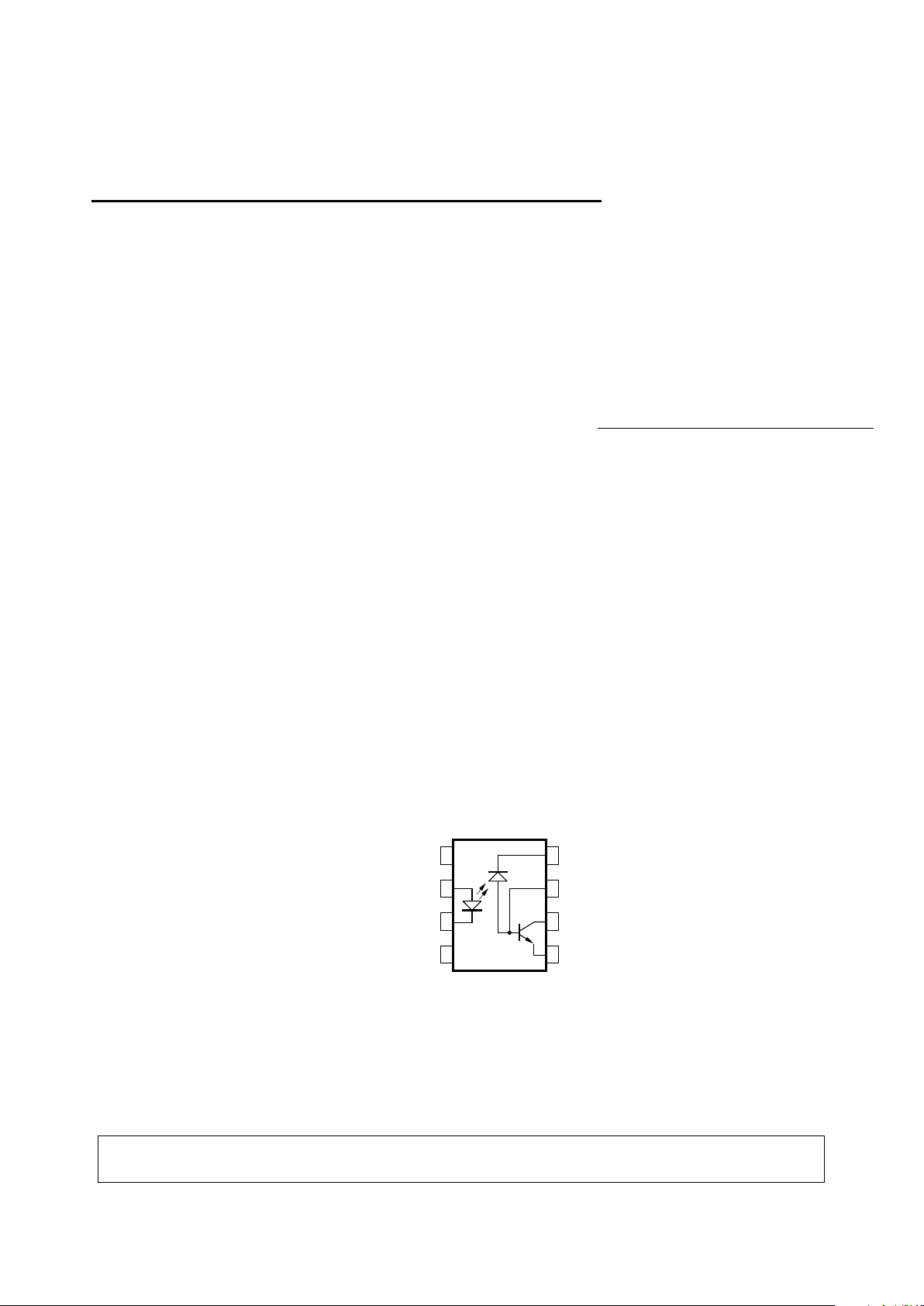

Functional Diagram

7

1

2

3

4

5

6

8

NC

ANODE

CATHODE

NC

V

CC

V

B

V

O

GND

5965-3579E

1-386

Selection Guide

Single Channel Packages

8-Pin DIP Widebody

(300 Mil) (400 Mil)

HCPL-4562 HCNW4562

Ordering Information

Specify Part Number followed by Option Number (if desired).

Example:

HCPL-4562#XXX

020 = UL 5000 V rms/1 Minute Option*

300 = Gull Wing Surface Mount Option†

500 = Tape and Reel Packaging Option

Option data sheets are available. Contact your Hewlett-Packard sales representative or authorized

distributor for information.

*For HCPL-4562 only.

†Gull wing surface mount option applies to through hole parts only.

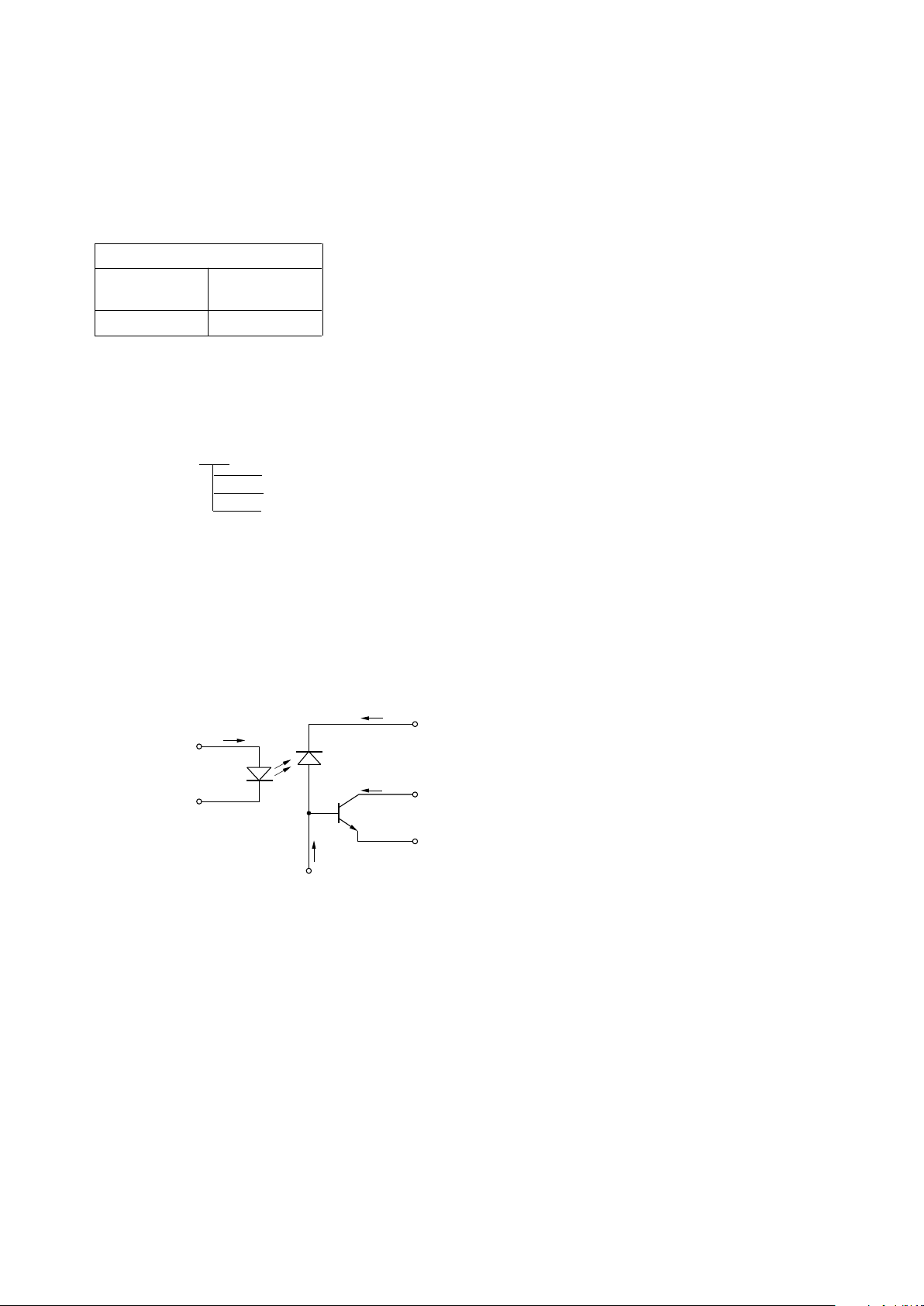

Schematic

I

F

8

6

5

GND

V

CC

2

3

V

O

I

CC

V

F

I

O

ANODE

CATHODE

+

–

7

V

B

I

B

1-387

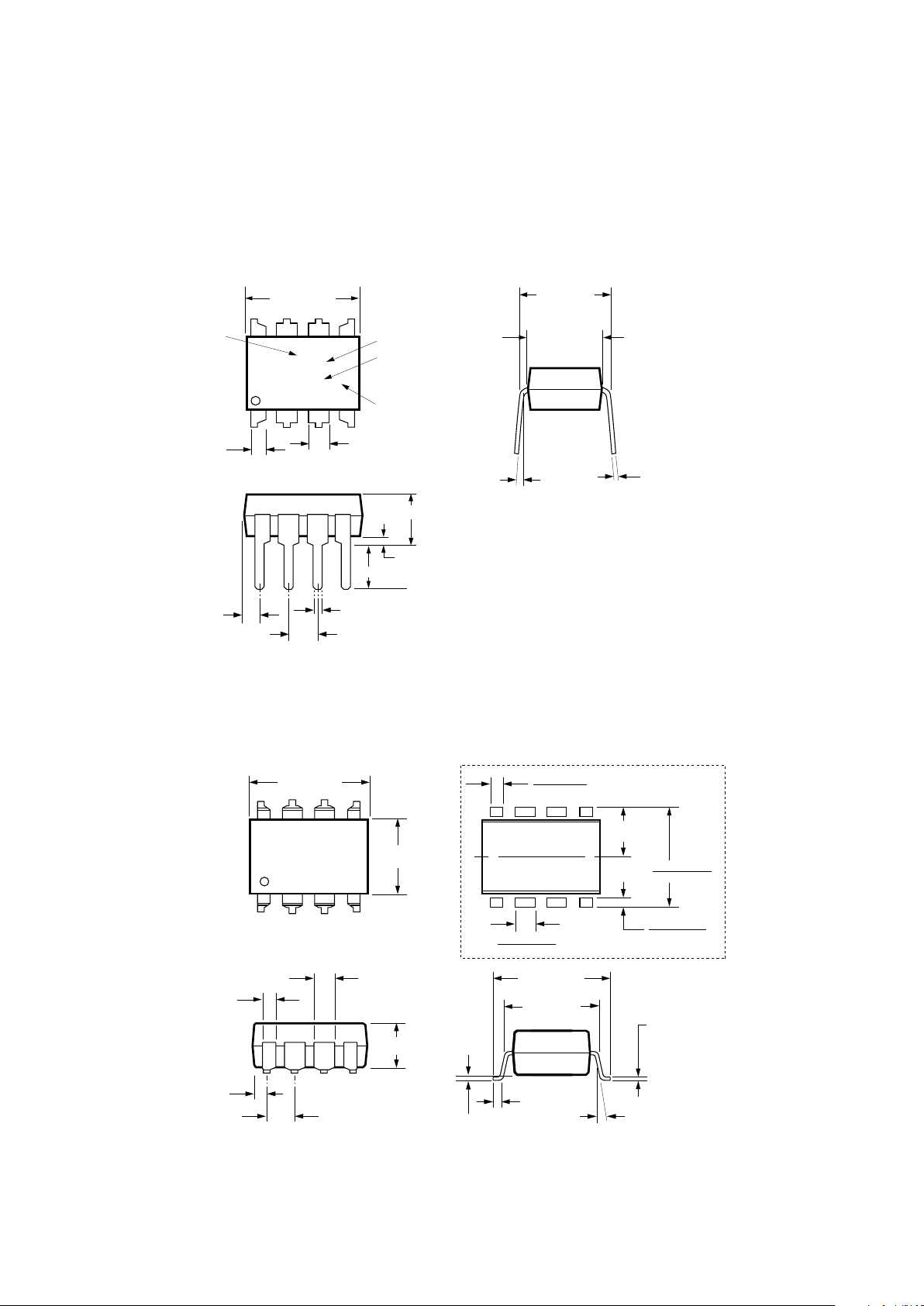

Package Outline Drawings

8-Pin DIP Package (HCPL-4562)

8-Pin DIP Package with Gull Wing Surface Mount Option 300 (HCPL-4562)

0.635 ± 0.25

(0.025 ± 0.010)

12° NOM.

9.65 ± 0.25

(0.380 ± 0.010)

0.635 ± 0.130

(0.025 ± 0.005)

7.62 ± 0.25

(0.300 ± 0.010)

5

6

7

8

4

3

2

1

9.65 ± 0.25

(0.380 ± 0.010)

6.350 ± 0.25

(0.250 ± 0.010)

1.016 (0.040)

1.194 (0.047)

1.194 (0.047)

1.778 (0.070)

9.398 (0.370)

9.906 (0.390)

4.826

(0.190)

TYP.

0.381 (0.015)

0.635 (0.025)

PAD LOCATION (FOR REFERENCE ONLY)

1.080 ± 0.320

(0.043 ± 0.013)

4.19

(0.165)

MAX.

1.780

(0.070)

MAX.

1.19

(0.047)

MAX.

2.54

(0.100)

BSC

DIMENSIONS IN MILLIMETERS (INCHES).

LEAD COPLANARITY = 0.10 mm (0.004 INCHES).

0.254

+ 0.076

- 0.051

(0.010

+ 0.003)

- 0.002)

9.65 ± 0.25

(0.380 ± 0.010)

1.78 (0.070) MAX.

1.19 (0.047) MAX.

HP XXXXZ

YYWW

DATE CODE

1.080 ± 0.320

(0.043 ± 0.013)

2.54 ± 0.25

(0.100 ± 0.010)

0.51 (0.020) MIN.

0.65 (0.025) MAX.

4.70 (0.185) MAX.

2.92 (0.115) MIN.

DIMENSIONS IN MILLIMETERS AND (INCHES).

5678

4321

5° TYP.

OPTION NUMBER*

UL

RECOGNITION

UR

0.254

+ 0.076

- 0.051

(0.010

+ 0.003)

- 0.002)

7.62 ± 0.25

(0.300 ± 0.010)

6.35 ± 0.25

(0.250 ± 0.010)

* MARKING CODE LETTER FOR OPTION NUMBERS.

"L" = OPTION 020

"V" = OPTION 060

OPTION NUMBERS 300 AND 500 NOT MARKED.

TYPE NUMBER

1-388

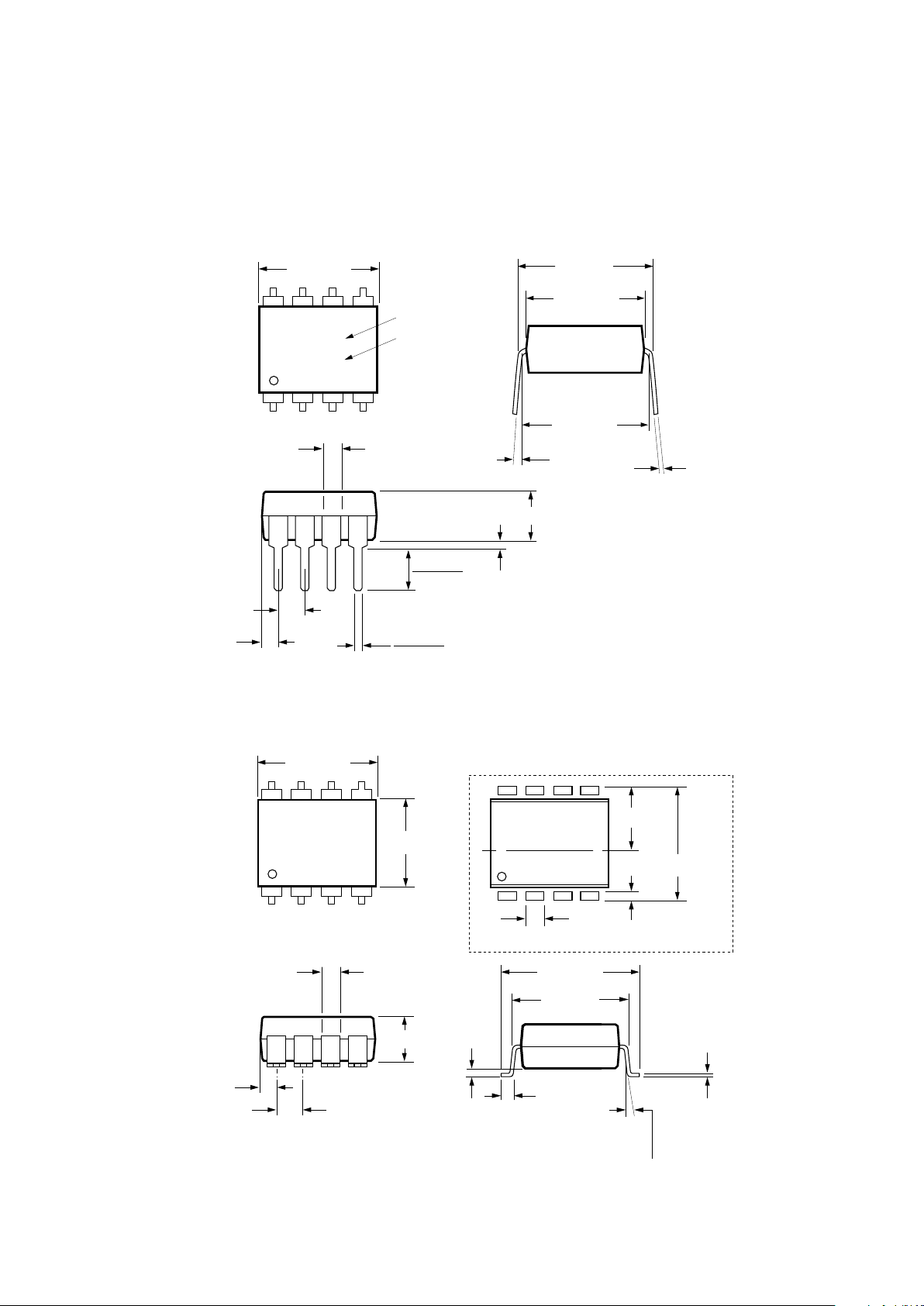

8-Pin Widebody DIP Package (HCNW4562)

8-Pin Widebody DIP Package with Gull Wing Surface Mount Option 300 (HCNW4562)

5

6

7

8

4

3

2

1

11.15 ± 0.15

(0.442 ± 0.006)

1.78 ± 0.15

(0.070 ± 0.006)

5.10

(0.201)

MAX.

1.55

(0.061)

MAX.

2.54 (0.100)

TYP.

DIMENSIONS IN MILLIMETERS (INCHES).

7° TYP.

0.254

+ 0.076

- 0.0051

(0.010

+ 0.003)

- 0.002)

11.00

(0.433)

9.00 ± 0.15

(0.354 ± 0.006)

MAX.

10.16 (0.400)

TYP.

HP

HCNWXXXX

YYWW

DATE CODE

TYPE NUMBER

0.51 (0.021) MIN.

0.40 (0.016)

0.56 (0.022)

3.10 (0.122)

3.90 (0.154)

1.00 ± 0.15

(0.039 ± 0.006)

7° NOM.

12.30 ± 0.30

(0.484 ± 0.012)

0.75 ± 0.25

(0.030 ± 0.010)

11.00

(0.433)

5

6

7

8

4

3

2

1

11.15 ± 0.15

(0.442 ± 0.006)

9.00 ± 0.15

(0.354 ± 0.006)

1.3

(0.051)

12.30 ± 0.30

(0.484 ± 0.012)

6.15

(0.242)

TYP.

0.9

(0.035)

PAD LOCATION (FOR REFERENCE ONLY)

1.78 ± 0.15

(0.070 ± 0.006)

4.00

(0.158)

MAX.

1.55

(0.061)

MAX.

2.54

(0.100)

BSC

DIMENSIONS IN MILLIMETERS (INCHES).

LEAD COPLANARITY = 0.10 mm (0.004 INCHES).

0.254

+ 0.076

- 0.0051

(0.010

+ 0.003)

- 0.002)

MAX.

1-389

Note: Use of nonchlorine activated fluxes is highly recommended.

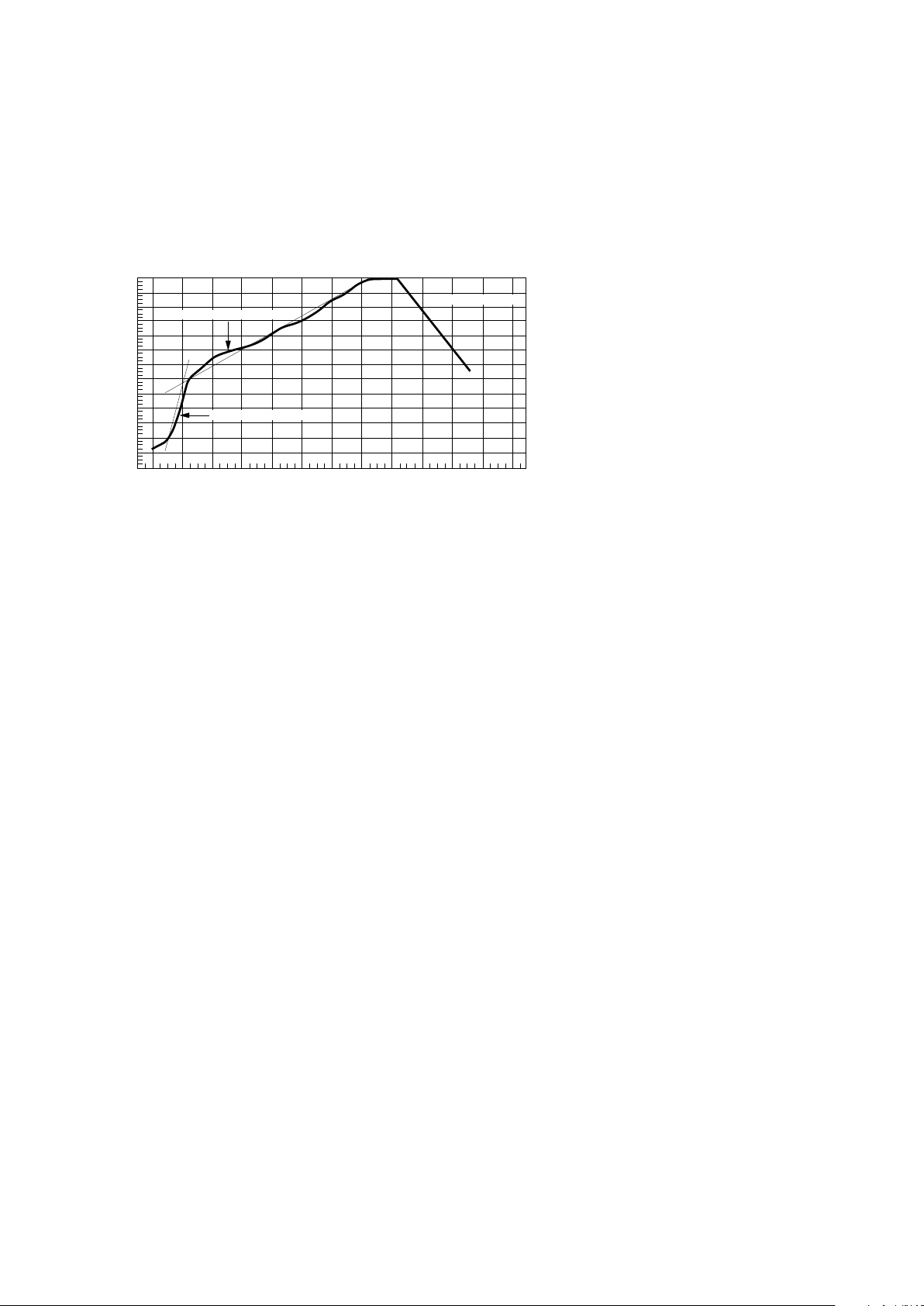

240

∆T = 115°C, 0.3°C/SEC

0

∆T = 100°C, 1.5°C/SEC

∆T = 145°C, 1°C/SEC

TIME – MINUTES

TEMPERATURE – °C

220

200

180

160

140

120

100

80

60

40

20

0

260

123456789101112

Solder Reflow Temperature Profile (Gull Wing Surface Mount Option Parts)

Regulatory Information

The devices contained in this data

sheet have been approved by the

following organizations:

UL

Recognized under UL 1577,

Component Recognition

Program, File E55361.

CSA

Approved under CSA Component

Acceptance Notice #5, File CA

88324.

VDE

Approved according to VDE

0884/06.92 (HCNW4562 only).

BSI

Certification according to

BS415:1994

(BS EN60065:1994);

BS EN60950:1992

(BS7002:1992) and

EN41003:1993 for Class II

applications (HCNW4562 only).

1-390

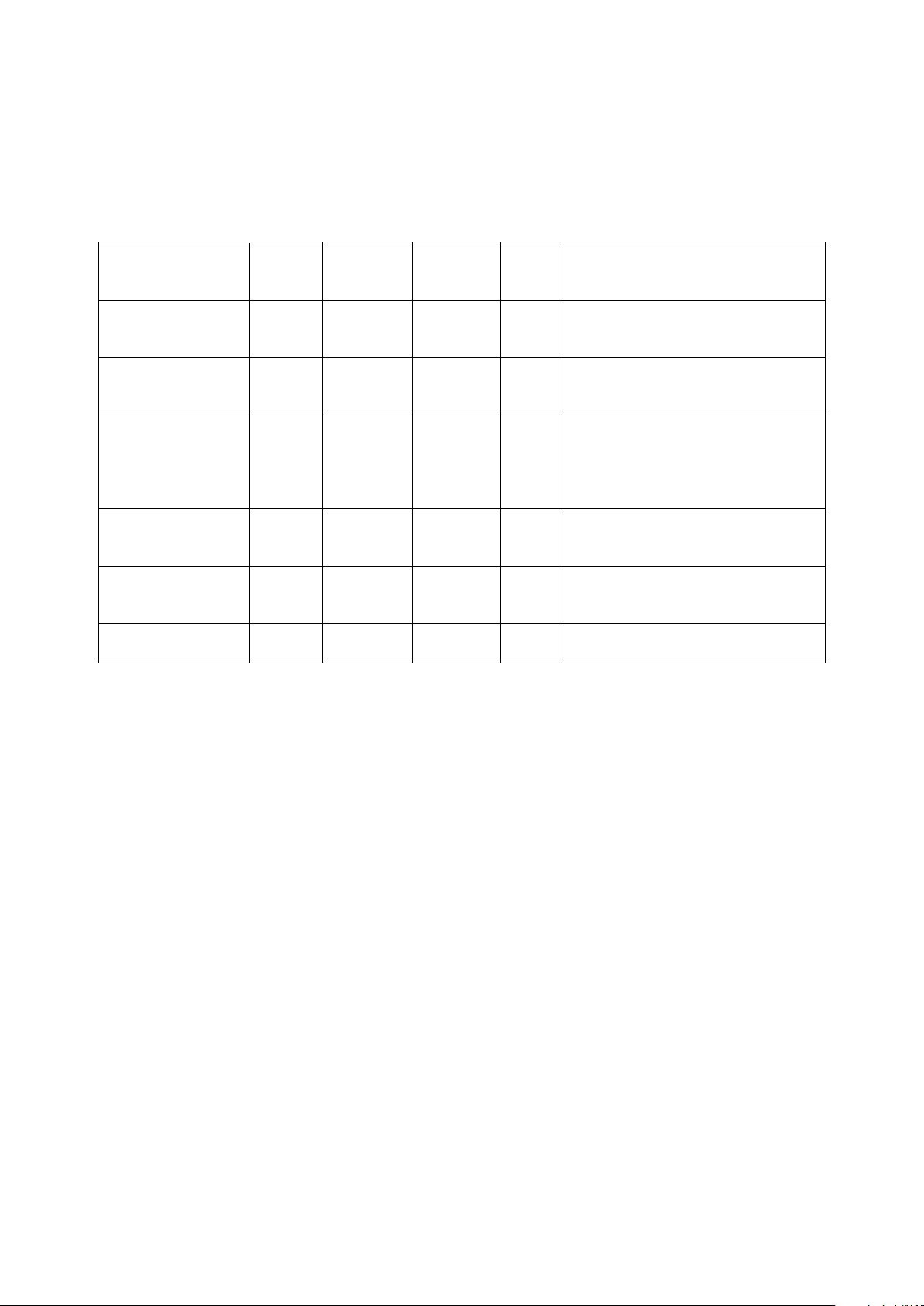

Insulation and Safety Related Specifications

8-Pin DIP Widebody

(300 Mil) (400 Mil)

Parameter Symbol Value Value Units Conditions

Minimum External L(101) 7.1 9.6 mm Measured from input terminals to

Air Gap (External output terminals, shortest distance

Clearance) through air.

Minimum External L(102) 7.4 10.0 mm Measured from input terminals to

Tracking (External output terminals, shortest distance

Creepage) path along body.

Minimum Internal 0.08 1.0 mm Through insulation distance,

Plastic Gap conductor to conductor, usually the

(Internal Clearance) direct distance between the photo-

emitter and photodetector inside the

optocoupler cavity.

Minimum Internal NA 4.0 mm Measured from input terminals to

Tracking (Internal output terminals, along internal cavity.

Creepage)

Tracking Resistance CTI 200 200 Volts DIN IEC 112/VDE 0303 Part 1

(Comparative

Tracking Index)

Isolation Group IIIa IIIa Material Group

(DIN VDE 0110, 1/89, Table 1)

Option 300 - surface mount classification is Class A in accordance with CECC 00802.

Loading...

Loading...