Page 1

Product End-of-Life Disassembly Instructions

Product Category: Personal Computers

Marketing Name / Model

[List multiple models if applicabl e.]

1.0 Items Requiring Selective Treatment

Quantity

in product

Printed Circuit Boards (PCB) or Printed Circuit

Assemblies (PCA)

With a surface greater than 10 sq cm

3

Batteries

All types including standard alkaline and lithium

coin or button style batteries

1

Mercury-containing components

For example, mercury in lamps, display backlights,

scanner lamps, switches, batteries

0

Liquid Crystal Displays (LCD) with a surface

greater than 100 sq cm

Includes background illum inate d dis plays with gas

discharge lamps (14")

1

Cathode Ray Tubes (CRT)

0

Capacitors / condensers (Containing PCB/PCT)

0

Electrolytic Capacitors / Condensers measuring

greater than 2.5 cm in diameter or height

0

External electrical cables and cords

Power cord

1

Gas Discharge Lamps

0

Plastics containing Brominated Flame Retardants

already listed as a separate item above)

0

Components and parts containing toner and ink,

including liquids, semi-liquids (gel/paste) and toner

Include the cartridges, print heads, tubes, vent

chambers, and service stations.

0

Components and waste containing asbestos

0

Components, parts and materials containing

refractory ceramic fibers

0

HP ElitePOS G1 14 inch Touch AiO Retail System Model 141

Purpose: The document is intended for use by end-of-life recyclers or treatment facilities. It provides the basic instructions

for the disassembly of HP products to remove components and materials requiring selective treatment, as defined by EU

directive 2002/96/EC, Waste Electrical and Electronic Equipment (WEEE).

1.1 Items listed below are classified as requiring selective treatment.

1.2 Enter the quantity of items contained within the product which require selective treatment in the right column, as

applicable.

Item Description Notes

weighing > 25 grams (not including PCBs or PCAs

of items

included

EL-MF877-00 Page 1

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 2

Components, parts and materials containing

radioactive substances

0

2.0 Tools Required

List the type and size of the tools that would typically be used to disassemble the product to a point where components

Tool Description

Tool Size (if

applicable)

Electric screwdriver (Cross)

#1, Cross

Electric screwdriver (Cross)

#0, Cross

Electric screwdriver (Trox)

T15

Heating plate

3.0 Product Disassembly Proc ess

and materials requiring selective treatment can be removed.

3.1 List the basic steps that should typically be followed to remove components and materials requiring selective treatment:

1. Follow steps described in Disassembly instruction (file attached)

2. If parts can be removed without using a tool, remove it first

3. Use correct screwdriver and torque value before unlock the screw.

4.

5.

6.

7.

8.

9.

3.2 Optional Graphic. If the disassembly process is complex, insert a graphic illustration below to identify the items

contained in the product that require selective treatment (with descriptions and arrows identifying locations).

EL-MF877-00 Page 2

Template Revision B

PSG instructions for this template are available at EL-MF877-01

Page 3

MANUFACTURING PROCESS INSTRUCTIONS

MECHANICAL ASSEMBLY

MODEL : Nantucket

Auditor : Uen-Tung

Uen-Tung

Tabulator:

Page 4

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

1(1/2)

1.0

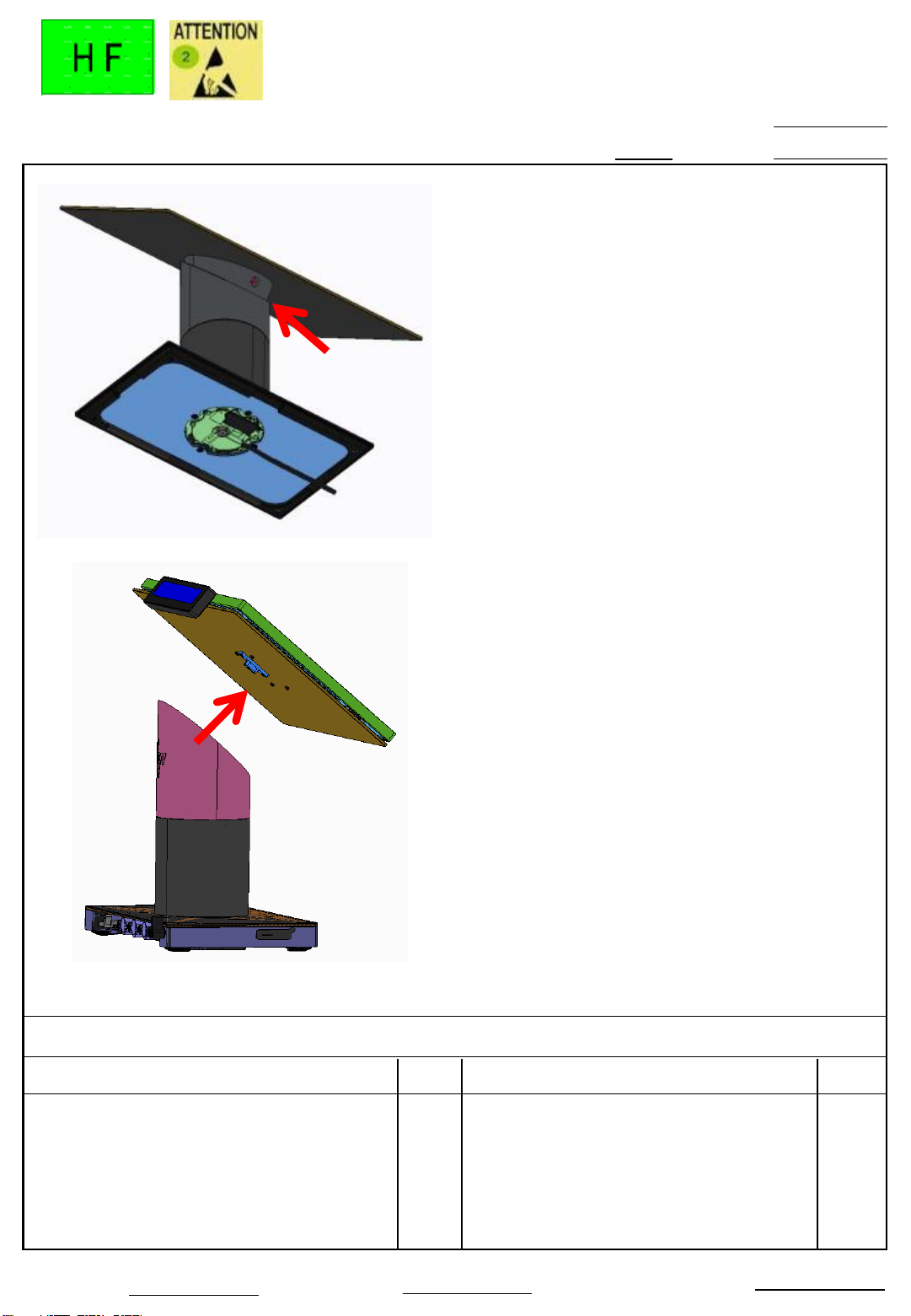

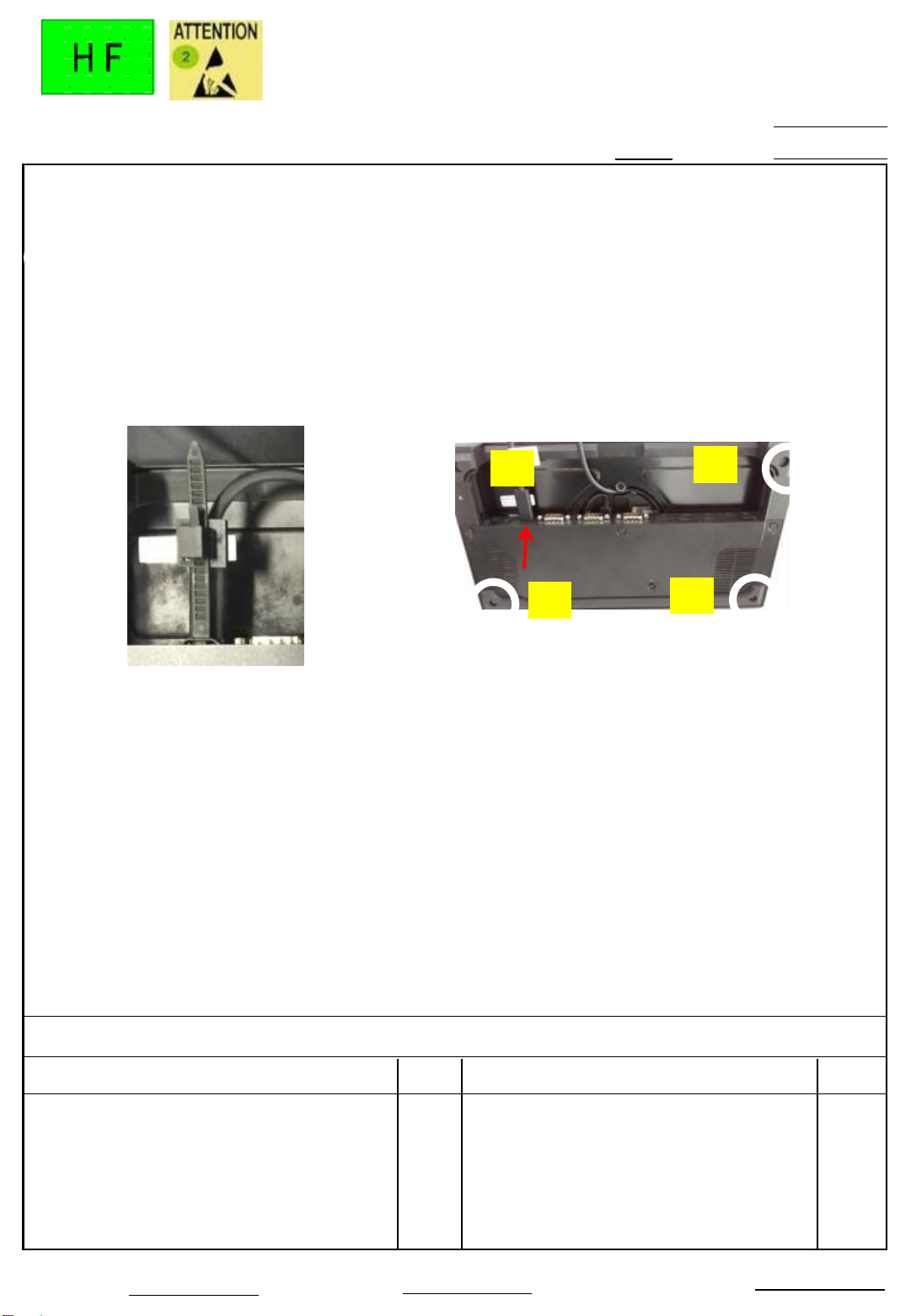

1.Take the Nantucket machine, the tension rises

before Nantucket and peeps out the Stand top

end to put the aperture and put the aperture .

2. Disassemble Nantucket & Stand

Disassemble Nantucket & Stand

2017/6/15

Fig.1

Fig.2

Page 5

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

1(2/2)

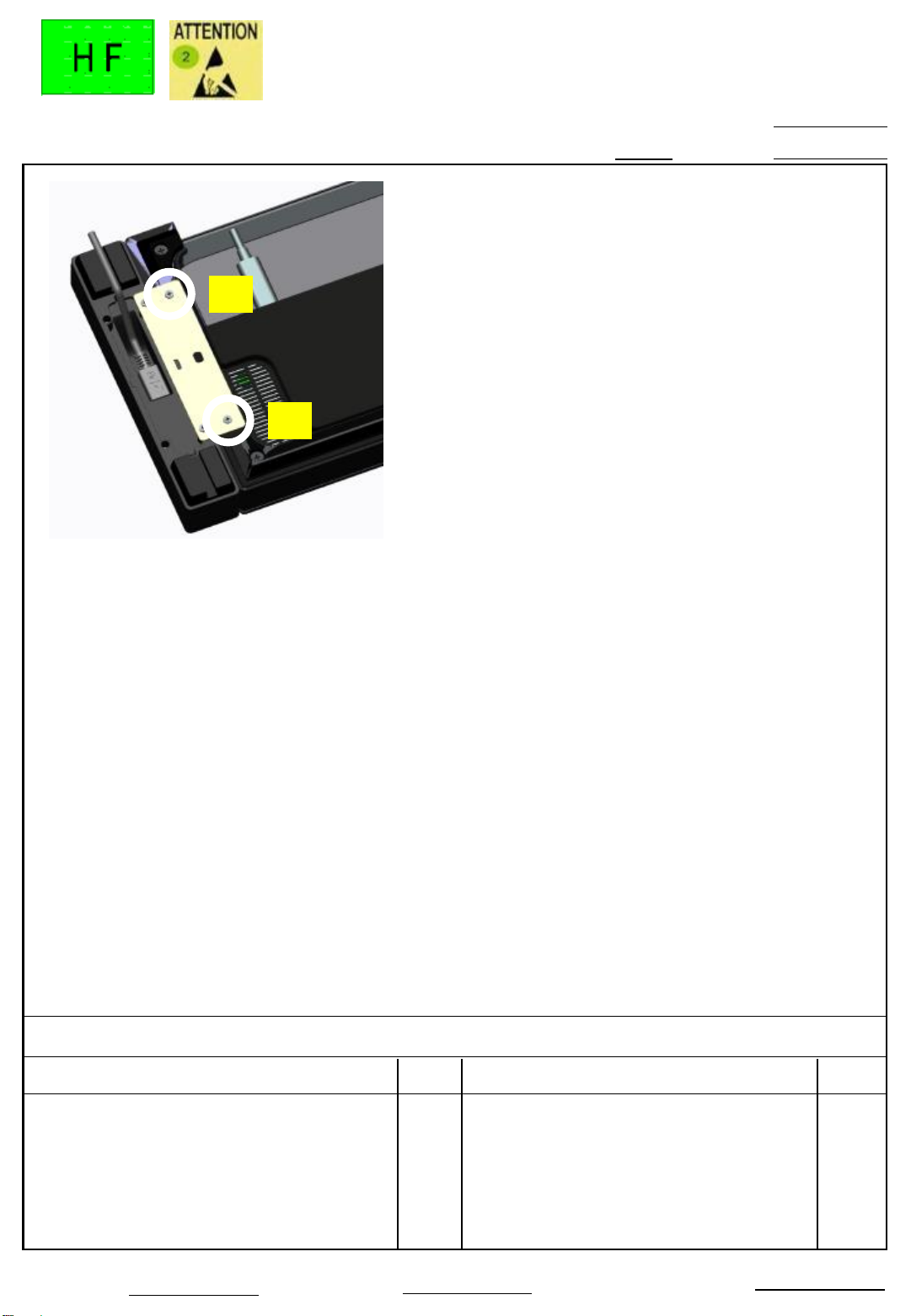

1. Disassemble FPR Cable

2. Loosen BTCB screw ,Disassemble FPR &

BRKT

Disassemble FPR

2

1

1.0

2017/6/13

Fig.1

Electric cross screwdriver #1 1

Support fixture 1

Page 6

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

2(1/2)

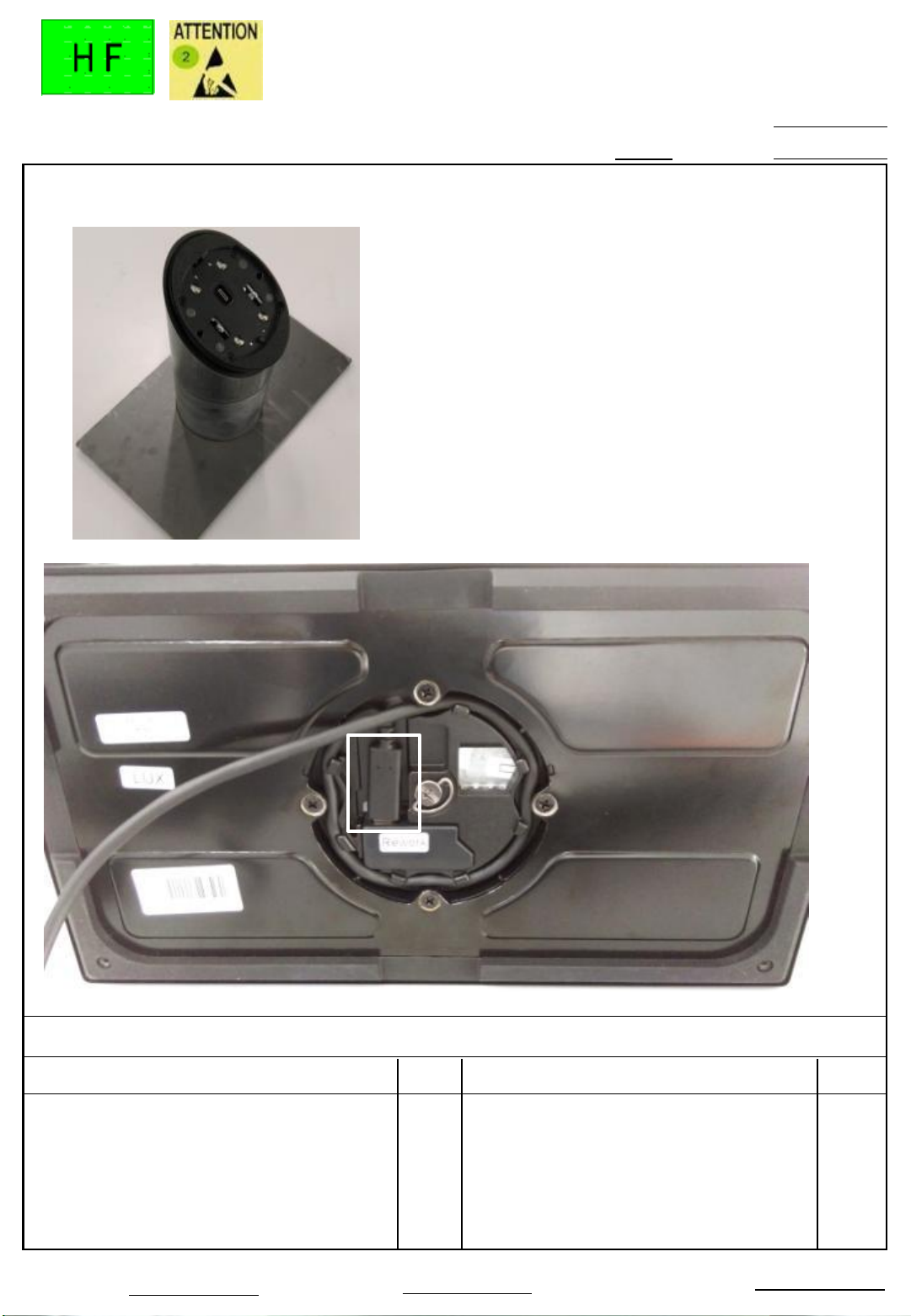

1. Disassemble Type C Cable

2. Loosen screw *4

3. Disassemble Stand(6055B0051101)

Disassemble Stand & Hub

1

2

3

4

1.0

2017/6/13

Fig.1

Fig.2

Electric cross screwdriver #1 1

Support fixture 1

Page 7

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

2(2/2)

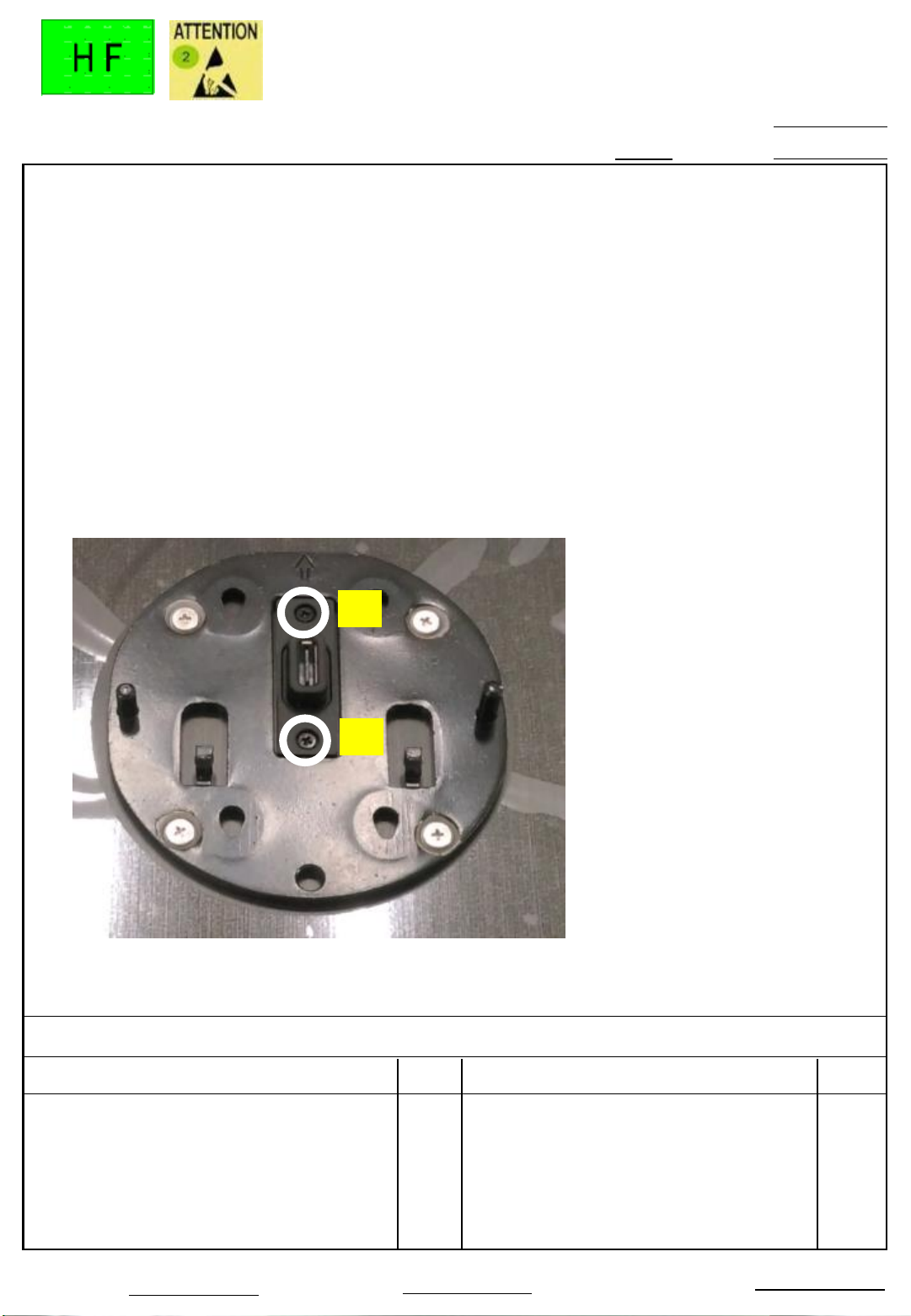

1. Disassemble Stand Type C cable

Disassemble Stand Type C cable

1.0

2017/6/13

Page 8

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

3(1/1)

1.0

2017/6/13

圖一

1

2

3

4

1. Loosen Spacer screw*4

2. Disassemble Spacer

Disassemble Spacer

Electric cross screwdriver #1 1

Page 9

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

4(1/3)

1.0

2017/6/13

圖一

1

2

1. Loosen Type C Cover screw*2

2. Disassemble Type-C Cover

Disassemble Type C Cover

Electric cross screwdriver #1 1

Page 10

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

4(2/3)

1.0

2017/6/13

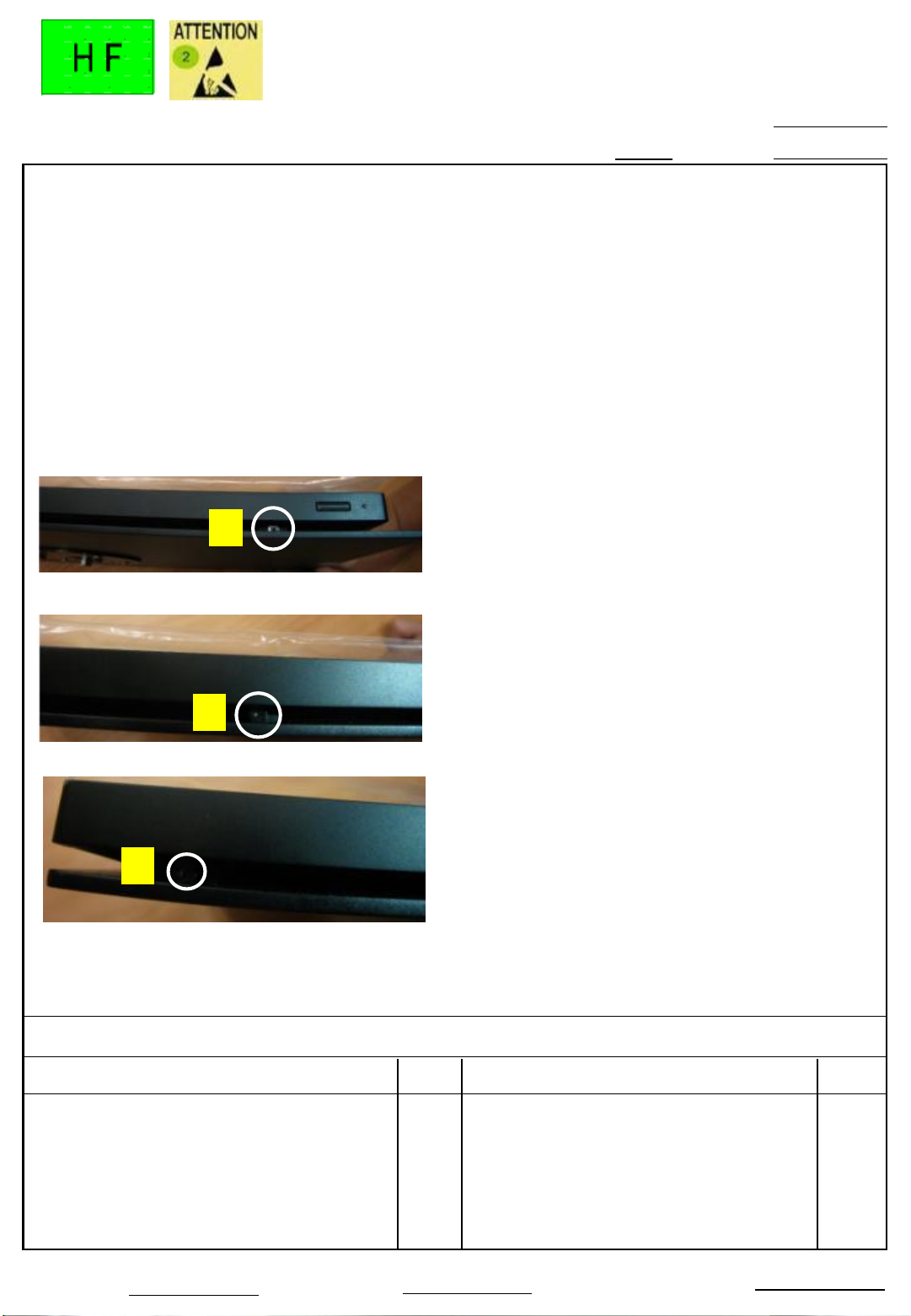

1. Loosen front frame screw *3

1

2

3

Loosen screw

Electric cross screwdriver #0 1

Support fixture 1

Fig.1

Fig .2

Fig .3

Page 11

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

4(3/3)

1.0

2017/6/13

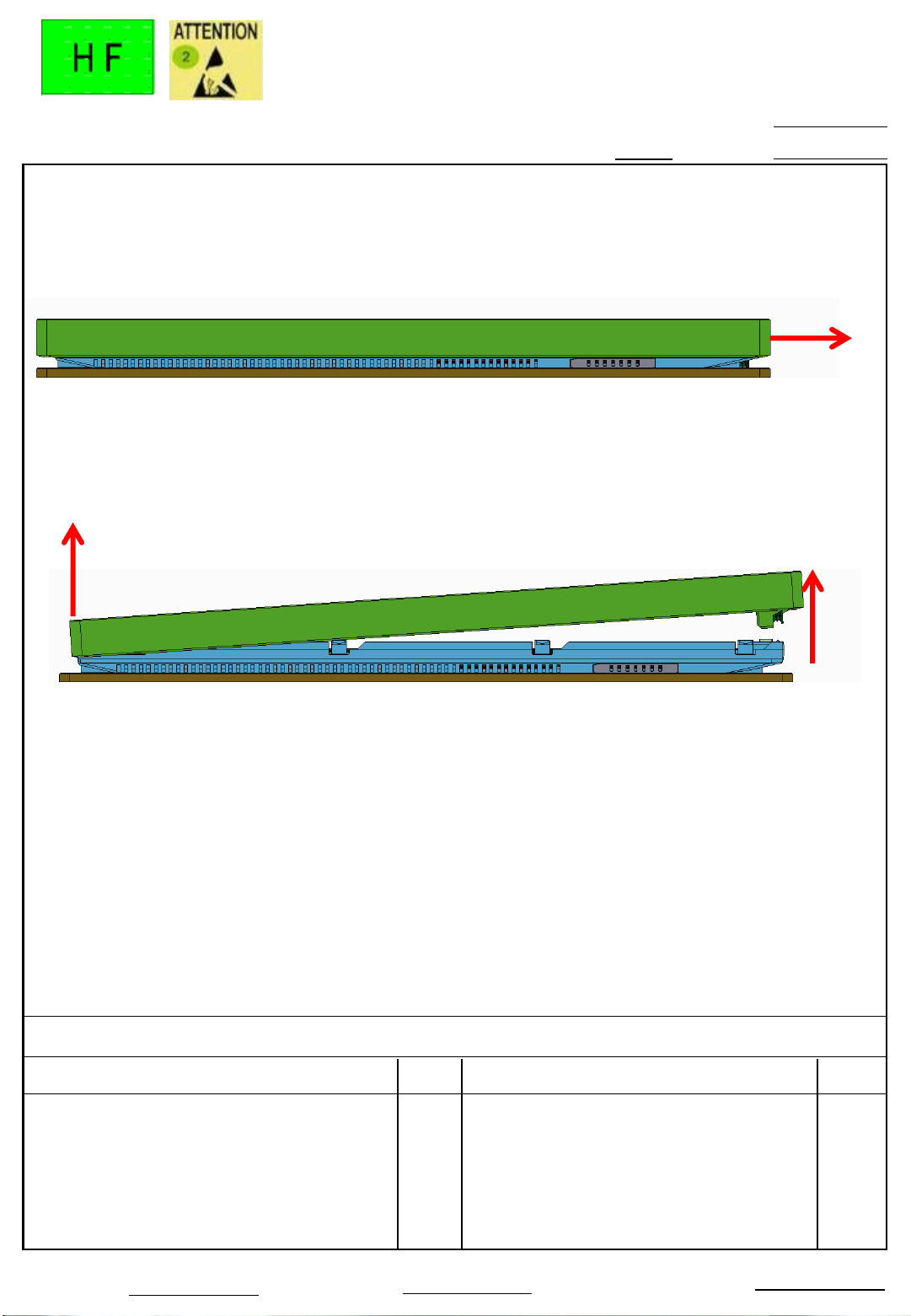

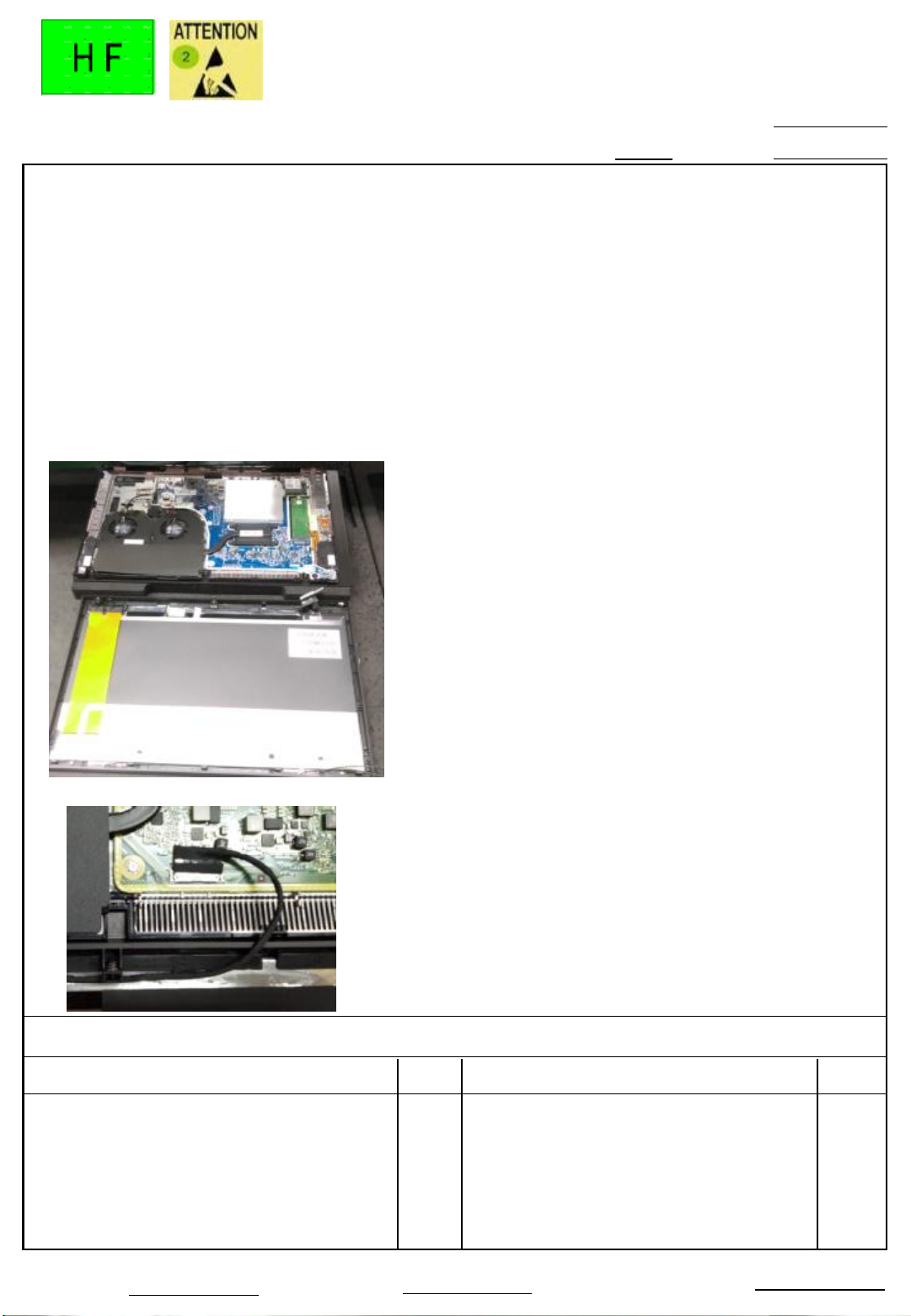

1. Disassemble front frame & LCD

Disassemble front frame & LCD

Fig.1

Fig.2

Page 12

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

5(1/2)

1.0

2017/6/13

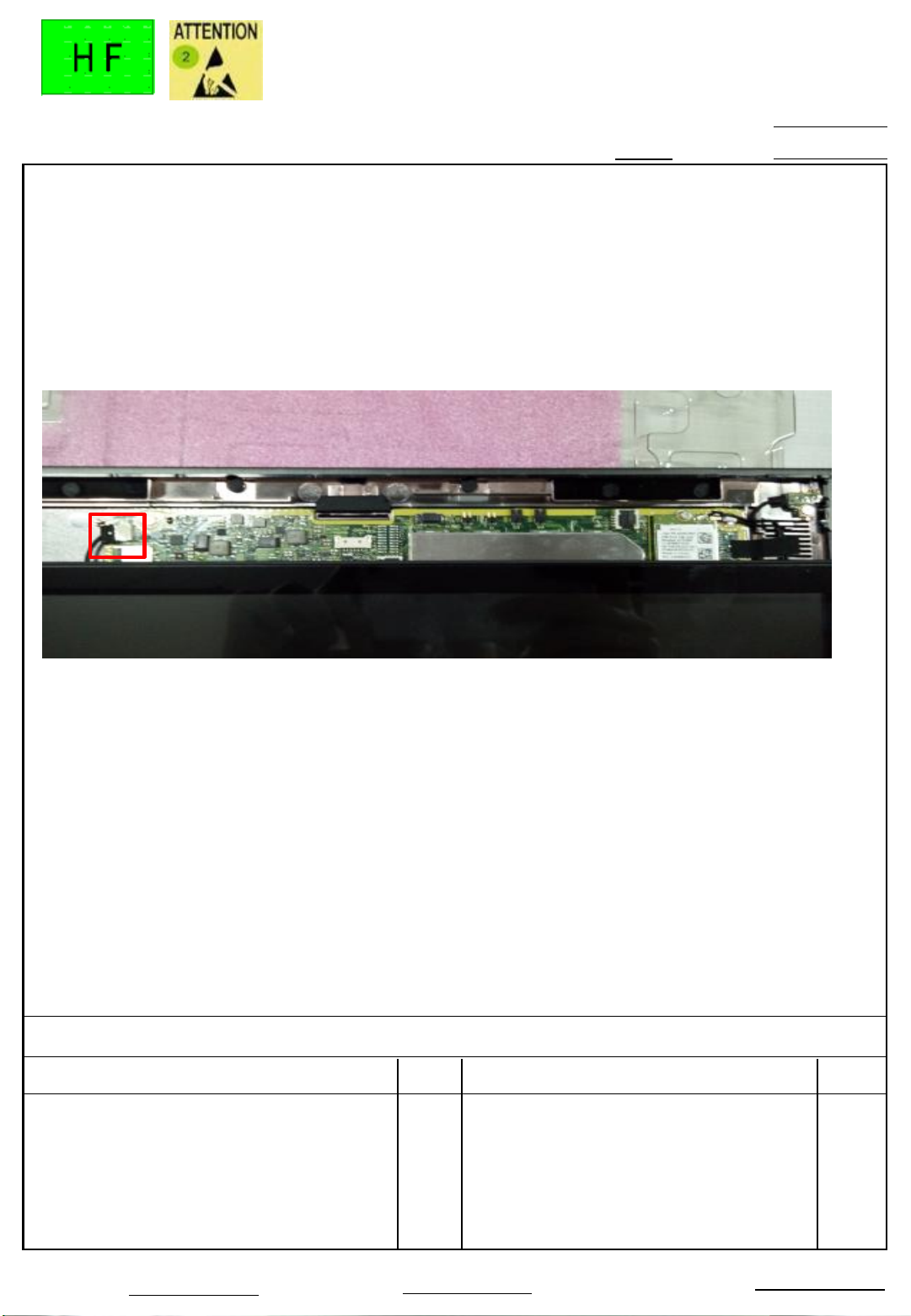

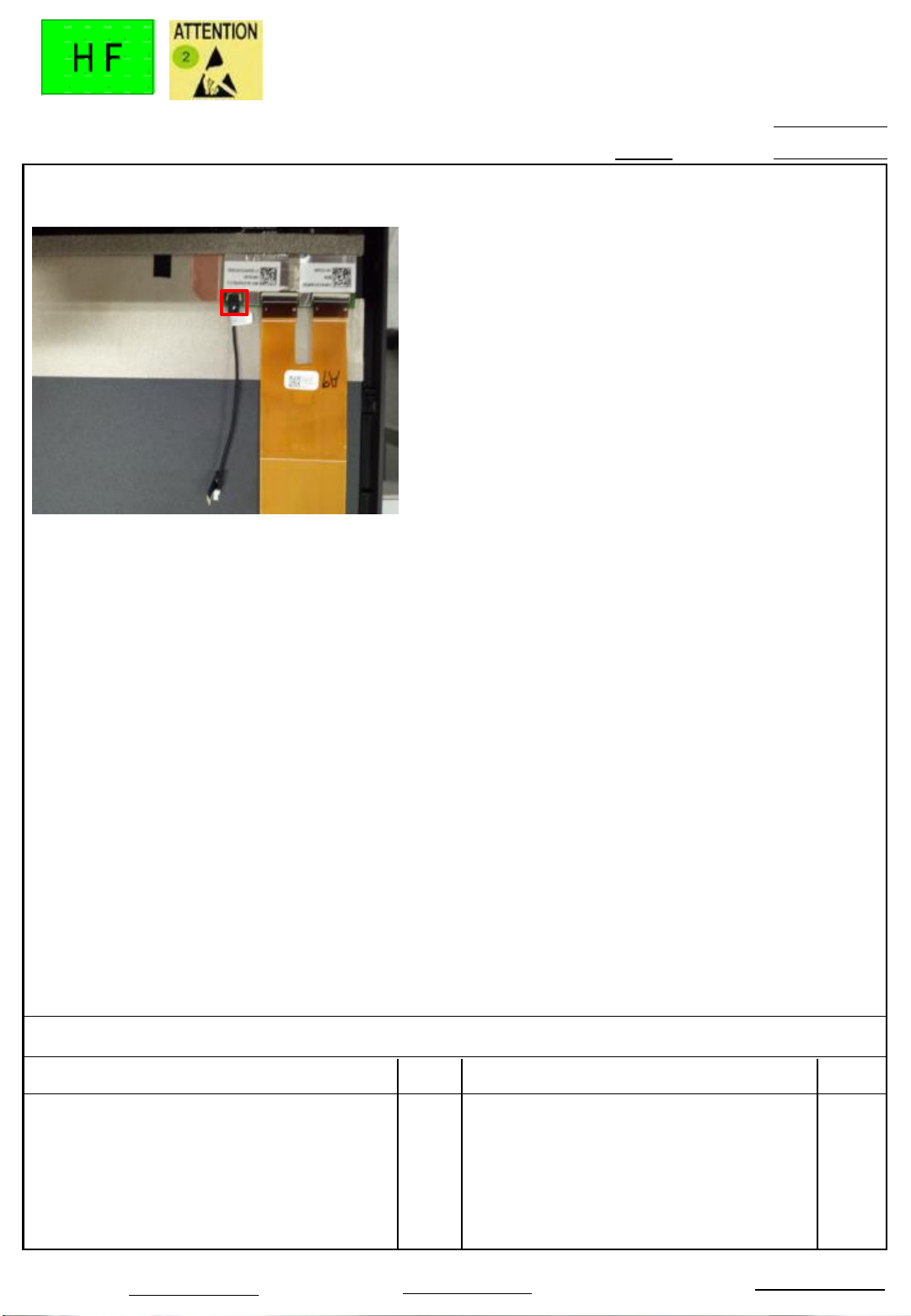

1.Disassemble Touch Ctrl/B CNTR

Disassemble Touch Ctrl/B

Page 13

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

5(2/2)

1.0

2017/6/13

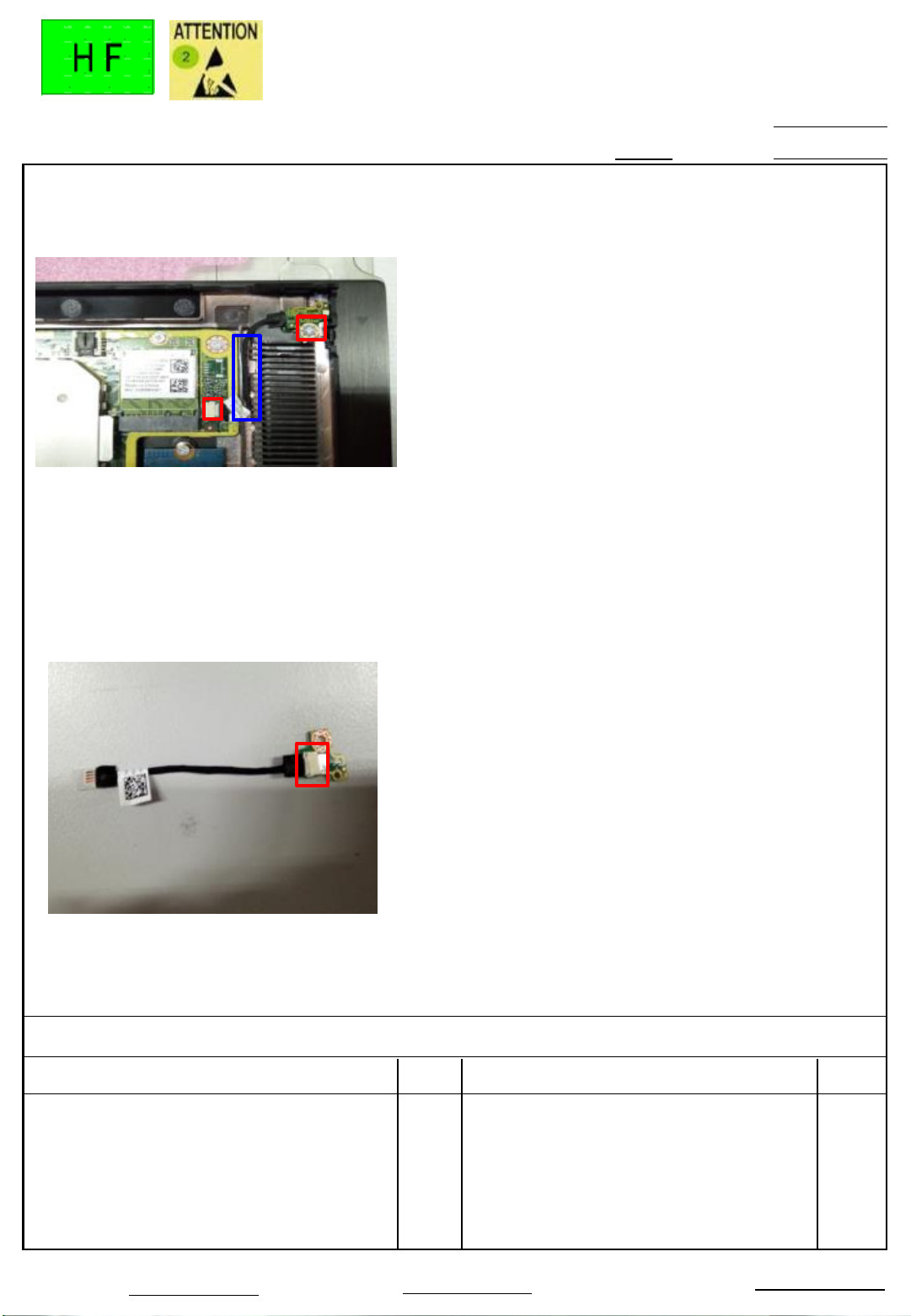

1. Disassemble antenna TAPE.

2. Disassemble antenna.

Disassemble Antenna

Fig .1

Fig .2

Page 14

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

6(1/2)

1.0

2017/6/13

Disassemble EDP

1. Disassemble EDPTAPE.

2. Disassemble EDP.

Fig .2

Fig .1

Page 15

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

6(2/2)

Disassemble touch ctrl/b cable

1.0

2017/6/13

1. Disassemble touch ctrl/b cable

Fig.1

Page 16

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

7(1/1)

1. loosen MSR LED/B screw*1

2. Disassemble MSR Cable

3. Disassemble MSR LED/B

Disassemble MSR LED/B

1.0

2017/6/13

Fig.1

Fig.2

Electric cross screwdriver #1 1

Page 17

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

8(1/1)

1. Loosen screw *2

2. Disassemble CFD Cable

3. Disassemble CFD module

Disassemble CFD

1.0

2017/6/13

Electric cross screwdriver #1 1

Fig.1

Fig.2

Page 18

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

9(1/2)

Disassemble speaker (R)

1. Disassemble speaker Tape

2. Disassemble speaker (R)

1.0

2017/6/13

Fig.1

Page 19

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

9(2/2)

1. Disassemble speaker (L)

1.0

2017/6/13

Disassemble speaker (L)

Fig.1

Page 20

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

10(1/1)

1.Disassemble DDR BRKT

2.Disassemble DDR *2

Disassemble DDR,BRKT

1.0

2017/6/13

Fig.1

Page 21

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

11(1/2)

1. OPEN Latch,Disassemble Power FFC

2. Loosen screw*1

3. Disassemble Power/B

Disassemble Power/B

1.0

2017/6/13

Electric cross screwdriver #1 1

Fig.1

Page 22

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

11(2/2)

1. Loosen screw *1

2. Disassemble SSD

Disassemble SSD

1

1.0

2017/6/13

Fig.1

Electric cross screwdriver #1 1

Page 23

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

12(1/2)

1. Loosen screw*2

2. Disassemble MSR BRKT*2

Disassemble MSR & BRKT

2017/6/13

1.0

Electric cross screwdriver #1 1

Fig.1

Page 24

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

12(2/2)

1. Loosen MSR/B Screw*1

2. Disassemble FPC

3. Disassembel MSR/B

Disassemble MSR

2017/6/13

1.0

Electric cross screwdriver #1 1

Fig.1

Page 25

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

13(1/3)

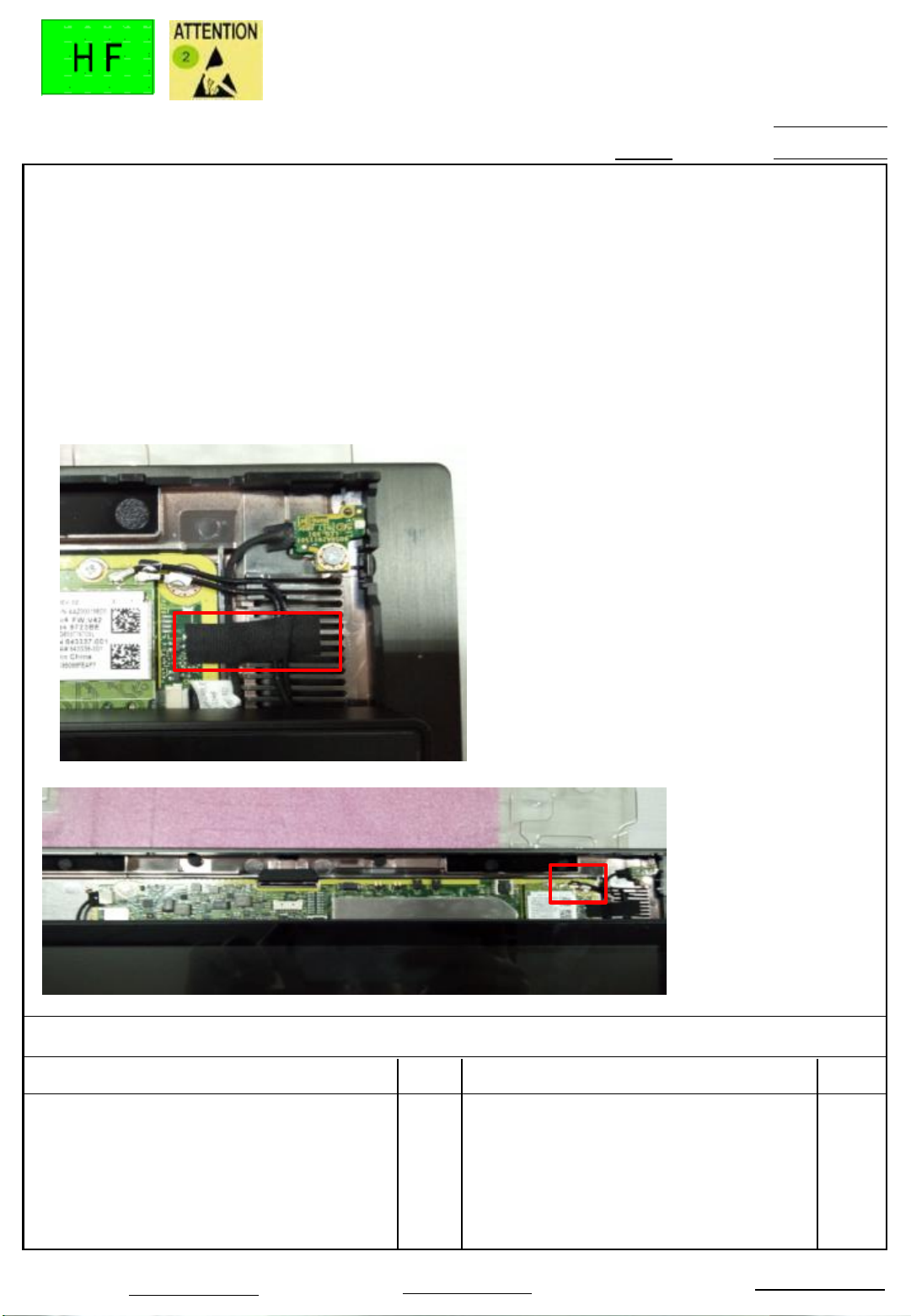

1. Disassemble bios battery

Disassemble BIOS battery

1.0

2017/6/13

Fig.1

Fig.2

Page 26

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

13(2/3)

1. Loosen M/B Screw*6

1

4

6

3

5

2

Loosen M/B Screw

1.0

2017/6/13

Electric cross screwdriver #1 1

Fig.1

Page 27

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

13(3/3)

1. Loosen screw*1

2. Disassemble WLAN

Disassemble WLAN

1

1.0

2017/6/13

Electric cross screwdriver #1 1

Fig.1

Page 28

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

14(1/2)

1. Loosen FAN screw*5

2. Disassemble FAN

Disassemble FAN

1

3

2

4

5

1.0

2017/6/13

Electric cross screwdriver #1 1

Fig.1

Fig.2

Fig.3

Page 29

Standard Operation Procedure

Document No. Nantucket FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

14(2/2)

1.Disassemble M/B

Disassemble M/B

1.0

2017/6/13

Fig.1

Page 30

MANUFACTURING PROCESS INSTRUCTIONS

MECHANICAL ASSEMBLY

MODEL : Aruba

Auditor : Uen-Tung

Uen-Tung

Tabulator:

Page 31

Standard Operation Procedure

Document No. Aruba FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

1(1/1)

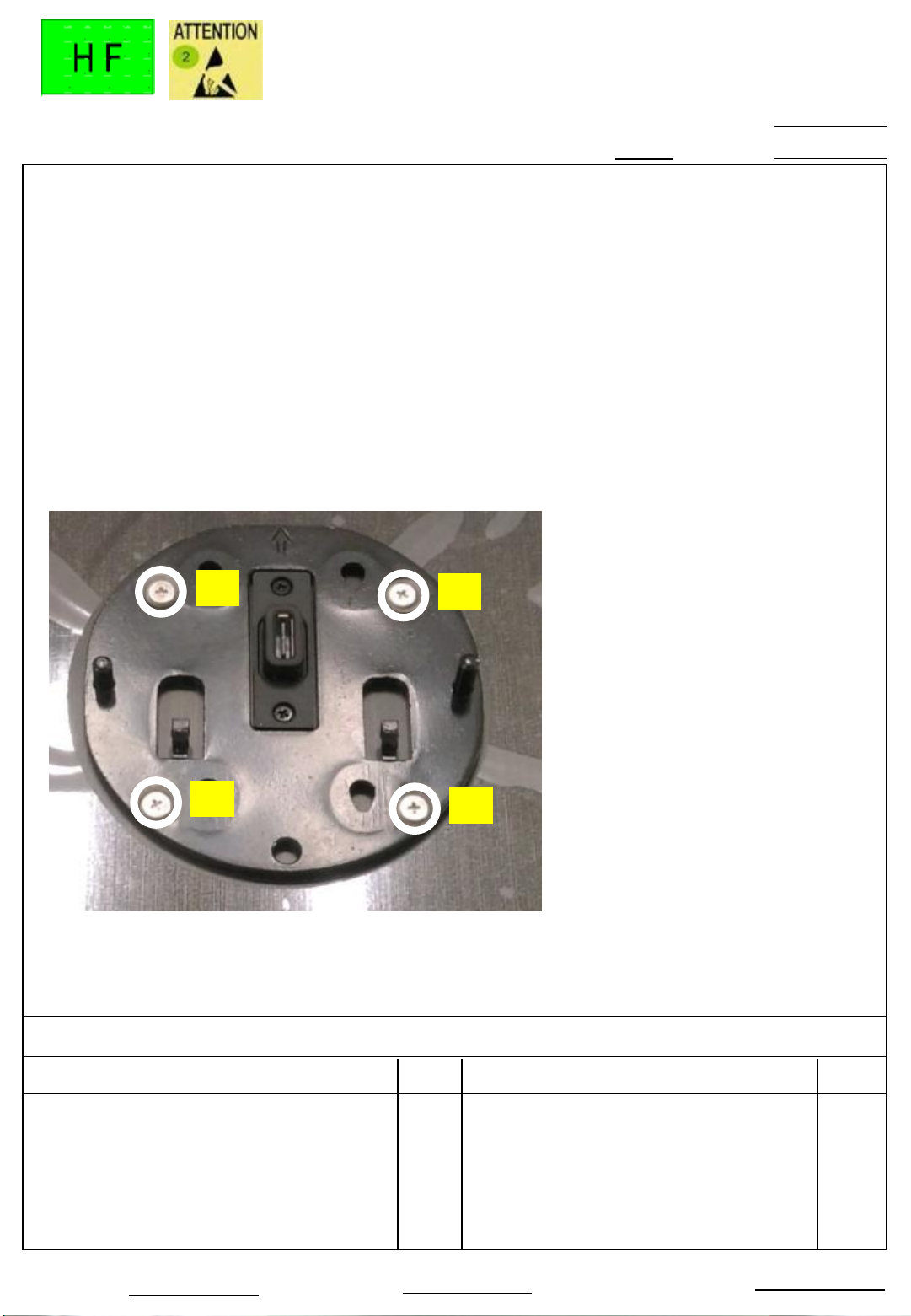

1. Loosen screw*4

Loosen screw *4

1

4

2

3

1.0

2017/6/13

Fig.1

Electric cross screwdriver #1 1

Page 32

Standard Operation Procedure

Document No. Aruba FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

2(1/1)

1. Loosen screw*3

Loosen screw *3

3

1

2

1.0

2017/6/13

Fig.1

Electric cross screwdriver #1 1

Page 33

Standard Operation Procedure

Document No. Aruba FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

3(1/1)

1. Loosen screw *2

2. Disassemble Mylar

3. Disassemble sponge

Loosen screw 、Disassemble Mylar

1

2

1.0

2017/6/13

Electric cross screwdriver #1 1

Fig.1

Fig.2

Page 34

Standard Operation Procedure

Document No. Aruba FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

4(1/1)

1. Disassemble screw*1

Disassemble screw

1.0

2017/6/13

Electric screwdriver 1

Fig.1

Page 35

Standard Operation Procedure

Document No. Aruba FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

5(1/1)

1. Loosen I/O screw*6

Loosen screw *6

1 2 3

4

5

6

0.1

2017/6/13

Fig.1

Electric screwdriver 1

Page 36

Standard Operation Procedure

Document No. Aruba FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

6(1/1)

1. Loosen FAN screw*2

2. Disassemble FAN CNTR

3. Disassemble FAN TAPE*2

4. Disassemble FAN

2

1

Disassemble FAN

0.50

2017/6/13

Fig.1

Fig.2

Fig.3

Electric screwdriver T15 1

Page 37

Standard Operation Procedure

Document No. Aruba FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

7(1/1)

1. Disassemble FAN Cover

Disassemble FAN Cover

1.0

2017/6/13

Fig.1

Page 38

Standard Operation Procedure

Document No. Aruba FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

8(1/1)

1. Disassemble MB screw*5

Disassemble MB screw

1

4

5

3

2

1.0

2017/6/13

Fig.1

Electric screwdriver T15 1

Page 39

Standard Operation Procedure

Document No. Aruba FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

9(1/2)

1.Disassemble MB

1.0

2017/6/13

Disassemble MB

Fig.1

Page 40

Standard Operation Procedure

Document No. Aruba FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

9(2/2)

1.Disassemble DC Rubber

Disassemble DC Rubber

1.0

2017/6/13

Fig.1

Fig.2

Page 41

Standard Operation Procedure

Document No. Aruba FA DIS ASS’Y SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-tung

NPSU-PPE

Auditor :

Uen-tung

10(1/1)

1.0

2017/6/13

Disassemble Button case

Disassemble Button case

Fig.1

Fig.2

Page 42

MANUFACTURING PROCESS INSTRUCTIONS

MECHANICAL ASSEMBLY

MODEL : Nantucket

Auditor :

Tabulator:Uen-Tung

Uen-Tung

Page 43

Standard Operation Procedure

Document No. Nantucket bezel Air bonding DIS SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-Tung

NPSU-PPE

Auditor :

Uen-Tung

1(1/1)

1. Disassemble EDP Cable tape

2. Disassemble EDP Cable

Disassemble EDP Cable

2017/6/5

1.0

Fig.1

Fig.2

Page 44

Standard Operation Procedure

Document No. Nantucket bezel Air bonding DIS SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-Tung

NPSU-PPE

Auditor :

Uen-Tung

2(1/1)

Disassemble RF SPONGE

1. Disassemble RF sponge

2017/6/5

1.0

Page 45

Standard Operation Procedure

Document No. Nantucket bezel Air bonding DIS SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-Tung

NPSU-PPE

Auditor :

Uen-Tung

3(1/1)

1. Disassemble EMI SPONGE

2017/6/5

1.0

Disassemble EMI SPONGE

Page 46

Standard Operation Procedure

Document No. Nantucket bezel Air bonding DIS SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-Tung

NPSU-PPE

Auditor :

Uen-Tung

4(1/1)

1. Disassemble Touch FFC

2. Disassemble Touch/B

Disassemble touch ctrl/B

2017/6/5

1.0

Fig.2

Fig.1

Page 47

Standard Operation Procedure

Document No. Nantucket bezel Air bonding DIS SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-Tung

NPSU-PPE

Auditor :

Uen-Tung

5(1/1)

1. Disassemble Tape*2

Disassemble Tape

2017/6/5

1.0

Fig.1

Fig.2

Page 48

Standard Operation Procedure

Document No. Nantucket bezel Air bonding DIS SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-Tung

NPSU-PPE

Auditor :

Uen-Tung

6(1/1)

1. Disassemble LCM Main antenna

Disassemble Main antenna

2017/6/5

1.0

Fig.1

Fig.2

Page 49

Standard Operation Procedure

Document No. Nantucket bezel Air bonding DIS SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-Tung

NPSU-PPE

Auditor :

Uen-Tung

7(1/1)

Disassemble AUX antenna

2017/6/5

Aux 天線

1. Disassemble LCM AUX antenna

1.0

Fig.1

Fig.2

Page 50

Standard Operation Procedure

Document No. Nantucket bezel Air bonding DIS SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-Tung

NPSU-PPE

Auditor :

Uen-Tung

8(1/1)

1. Disassemble LCM Mylar

Disassemble Mylar

2017/6/5

1.0

Fig.1

Fig.2

Page 51

Standard Operation Procedure

Document No. Nantucket bezel Air bonding DIS SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-Tung

NPSU-PPE

Auditor :

Uen-Tung

9(1/1)

1. LCM module puts into Nantucket to heat to

heat in the disassembly equipment

Heat the disassembly equipment 1

Disassemble Glass

Note:

• Time:5Min

• Heat the temperature:80±5℃

2017/6/5

1.0

Fig.1

Page 52

Standard Operation Procedure

Document No. Nantucket bezel Air bonding DIS SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-Tung

NPSU-PPE

Auditor :

Uen-Tung

10(1/1)

Disassemble Glass 2017/6/5

1.The LCM module after the heating take out,

the employment manage wire bar seriatim glass

with previous the frame split

2.At use to manage the wire bar to take care of

glass and lamp the separation

1.0

Fig.1

Fig.2

Fig.3

Page 53

Standard Operation Procedure

Document No. Nantucket bezel Air bonding DIS SOP Station :

Name : Ver. : Date :

Step:

Notes : If finding anything uncommon, notice foreman or assistant at once.

Holding fixture list (holding fixture standard)

Qty

Holding fixture list (holding fixture standard)

Qty

Tabulator:

Issue department:

Uen-Tung

NPSU-PPE

Auditor :

Uen-Tung

1.0

1. Loosen screw*4

2. Disassemble LCD

Disassemble LCD

2017/6/5

11(1/1)

1

4

2

3

Electric cross screwdriver #1 1

Loading...

Loading...