Page 1

assembly instructions and

routine maintenance procedures

hp designjet 815mfp

s

y

s

t

e

m

r

e

c

o

v

e

r

y

c

d

r

o

1

m

h

p

d

e

s

i

g

n

j

e

t

c

o

p

i

e

r

c

c8

0

0

p

s

20

19

2

screw M6×10 for base and top bar and arm 12

s

18

designjet copier cc800p

hp

3

17

screw M6×30 for base and top bar 8

screw M3x8 for touch screen assembly hub

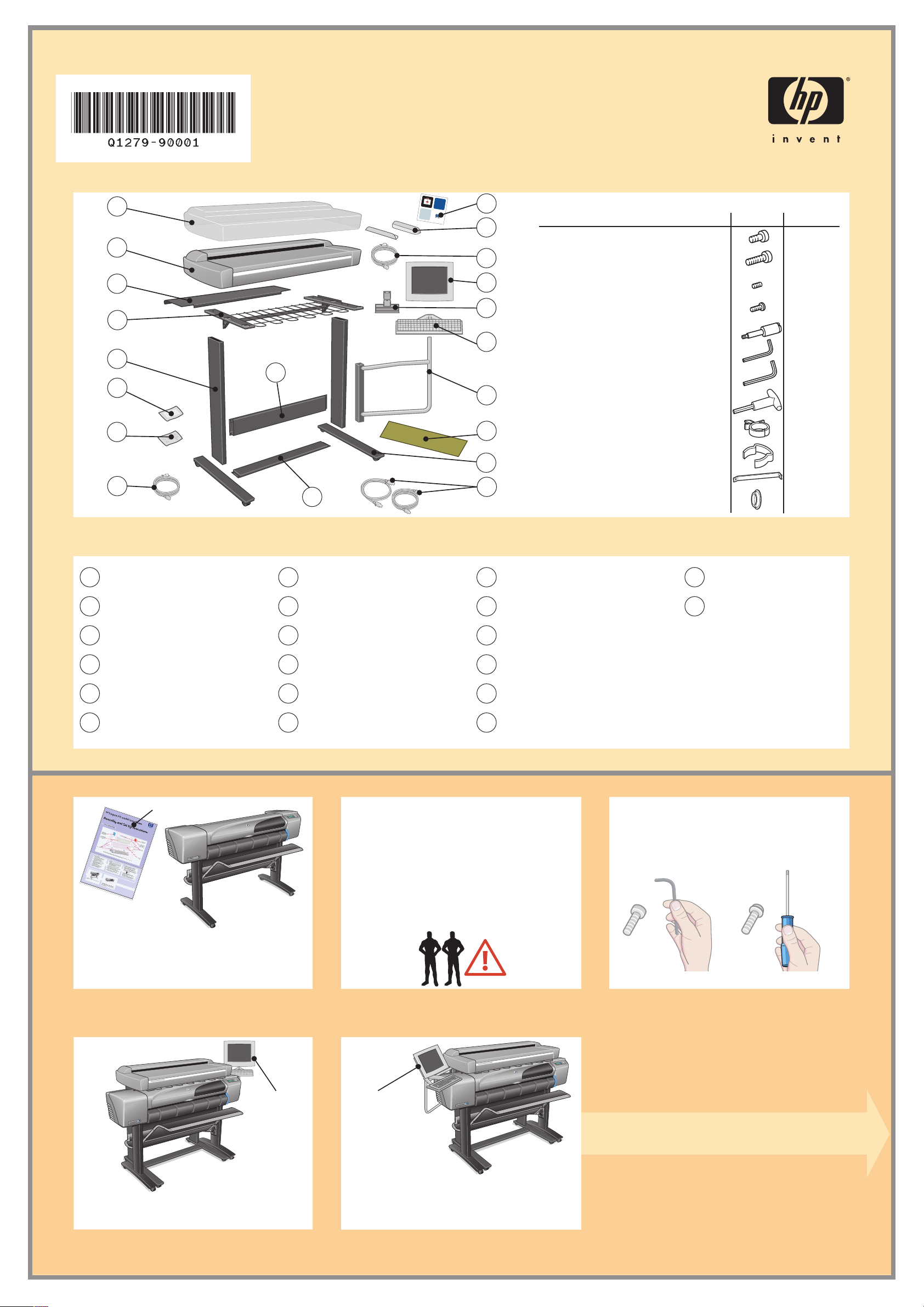

assembly kit contents

description quantity

1

4

5

6

7

8

1

plastic dust cover

2

scanner

16

screw M4×8 for touch screen and key board assembly hub 7

special screw for scanner 4

15

Allen key 2 mm for keyboard assembly 1

9

14

13

Allen key 2.5 mm for touch screen arm brace 1

Allen T key 5 mm for touch screen arm

power cable clips

17

wire routing clips

1

5

12

1

4

10

7

assembly kit

8

power cables

brace

11

13

14

plastic caps

scanner maintenance sheet

touch screen arm

19

media guides (×2)

20

system recovery CD-ROM

3

rear table

4

top bar with guide

5

leg (×2)

6

maintenance kit

assembly poster

Your printer

should already be

assembled and working before starting this

procedure. For instructions on how to

assemble the printer, please refer to the

assembly poster included with the printer.

9

cross bar

10

bottom bar

11

USB and FireWire cable

12

feet (x2)

read these instructions carefully...

and complete each stage before you start the

next.

what you will need to do the job

Because some of the components of your

HP Designjet 815mfp are bulky, you will need

2 or 3 people to lift them. See the

descriptions that follow for details, a symbol

like this is used:

15

keyboard

16

touch screen hub

17

touch screen

18

FireWire cable

a note about fixings

When initially assembling your

HP Designjet 815mfp stand do not fully tighten

the screws; you will be asked to do this later.

touch screen

assembly

please note

The touch screen assembly can be mounted on

either the right or the left side of the stand.

touch screen

assembly

please note

The touch screen assembly can be mounted on

either the right or the left side of the stand.

1

Page 2

1

Attach the two feet

to the left and right

legs using four

M6×30 screws (two

for each foot). Tighten the screws with the Allen

key found in the assembly kit.

2

Secure the

two legs by

fastening the cross

bar with four M6×10 screws (two each side).

3

Lay the two legs

down into the

position shown.

4

Attach the bottom bar to the leg using two

M6×10 screws.

7

M6×30

56

Raise the

legs carefully

Attach the bottom bar to the other leg using two

M6×10 screws.

8

into the

upright position.

9

×10

M6

Fasten the top bar and wire guide to the two

legs using four M6×30 and two M6×10 screws.

At this point you must decide on which

side you are going to fit the touch

screen assembly. This can be fitted on

the left or right side of the stand.

The next steps, 10 to 17, explain how to fit

the touch screen assembly to the right side of the

stand.

To fit the touch screen assembly to the left side

of the stand, using the same parts, just ‘mirror’

the assembly procedure described here.

Connect the rear table. This is fitted by locating

Remove the plastic safety tie and tighten up all

screws firmly.

the four guide pins on the rear of the table into

the rubber-framed holes on the top bar.

10 11

Attach the touch screen arm to the stand legs

using two M6×12 screws.

Attach the brace using two M4×6 screws.

12

Slide the keyboard assembly down as far as it

will go on the touch screen arm.

13 14

Lift the scanner into place, locating the rubber

Lock the keyboard assembly to the touch screen

arm using one M4×8 (headless) screw.

feet in the holes indicated, and fixing with the

four special screws.

2

s

0p

0

cc8

er

i

t cop

nje

g

si

de

hp

Page 3

E

E

X

T

E

N

D

E

D

E

X

I

T

E

X

I

T

N

O

R

M

A

L

E

X

T

E

N

D

E

D

N

O

R

M

A

L

I

n

c

h

e

s

m

m

0

.6

3

0

.

5

5

0

.

4

7

0

.

3

9

0

.

3

1

0

.

2

4

0

.

1

6

0

.0

8

1

6

1

4

1

2

1

0

8

6

4

2

E

X

T

E

N

D

E

D

E

X

I

T

E

X

I

T

N

O

R

M

A

L

E

X

T

E

N

D

E

D

N

O

R

M

A

L

I

nche

s

mm

0

.

6

3

0

.

5

5

0

.

4

7

0

.

3

9

0

.

31

0

.

2

4

0

.

1

6

0

.08

1

6

1

4

1

2

1

0

8

6

4

2

E

X

T

E

N

D

E

D

E

X

I

T

E

X

I

T

N

O

R

M

A

L

E

X

T

E

N

D

E

D

N

O

R

M

A

L

I

n

c

h

e

s

m

m

0.63

0.

55

0.

47

0.3

9

0.3

1

0.

2

4

0.

1

6

0.0

8

1

6

1

4

1

2

1

0

8

6

4

2

E

X

T

E

N

D

E

D

E

X

I

T

E

X

I

T

N

O

R

M

A

L

E

X

T

E

N

D

E

D

N

O

R

M

A

L

I

n

c

h

e

s

m

m

0

.63

0.55

0.47

0.3

9

0.

3

1

0.

2

4

0.1

6

0

.0

8

1

6

1

4

1

2

1

0

8

6

4

2

15

Rest the touch screen face down on a table.

Attach the touch screen bracket to the rear of the

touch screen using two M4×8 screws as shown.

16

Attach with three more M4×8 screws as shown.

17

Slide the hub of the touch screen assembly into

the touch screen arm.

18

Secure the hub of the touch screen bracket using

an M3×8 screw.

cleaning the scan area...

You are now required to clean the scan

area. To do so, you will need the cleaning

tools provided in the maintenance kit and a

cleaning fluid (not included in the

maintenance kit).

19 20

Slide the assembled

printer under the scanner.

The printer’s feet will be positioned outside the

scanner’s feet.

21

E

X

T

E

N

D

E

E

X

I

D

T

6

1

4

1

2

N

1

0

1

O

8

R

6

4

M

2

A

m

L

m

3

6

5

.

5

7

0

.

4

0

.

39

1

0

.

3

4

E

0

.

E

2

6

0

X

.

s

X

1

I

0

T

.

e

08

T

0

.

E

h

0

N

c

D

n

I

E

D

N

O

R

M

A

L

L

A

M

R

O

N

D

m

E

m

D

N

T

2

I

E

4

X

T

6

E

X

8

0

E

1

2

1

4

1

6

1

s

e

h

c

8

L

n

I

0

6

.

A

1

4

0

.

M

2

1

0

.

R

3

9

0

.

3

7

O

0

.

4

5

0

N

.

5

3

0

.

6

T

0

.

I

0

D

X

E

E

D

N

E

T

X

E

Your HP Designjet 815mfp is now assembled

and should appear as in the above illustration.

22

caution: do not use abrasives,

acetone, benzene, or fluids that contain

these chemicals. Do not spray liquids

directly onto the scanner’s glass plate or

anywhere else in the scanner.

23

E

X

T

E

N

D

E

E

X

I

D

T

6

1

4

1

2

N

1

0

1

O

8

R

6

4

M

2

A

m

L

m

5

.63

5

0

.

47

9

0

3

1

0.

.

3

E

4

0

.

2

E

6

X

0

.

X

s

1

I

8

0

T

e

T

0.

.0

E

h

0

N

c

D

n

I

E

D

N

O

R

M

A

L

L

A

M

R

O

N

D

m

E

m

D

N

2

T

I

E

4

X

T

6

E

X

8

0

E

1

2

1

4

1

6

1

s

e

h

c

L

8

n

I

0

6

A

1

4

0.

.

M

2

1

0

R

9

0.

7

O

0.3

4

0.3

N

.

55

0

.

T

0

.63

I

0

D

X

E

E

D

N

E

T

X

E

With the platen pushed down, slide the two locks

inwards until the pins at either end pop up,

locking the platen open and ready to be removed.

Open the scanner cover to expose the scan

area.

24

Raise the two handles, and remove the pressure

platen.

E

X

T

E

N

D

E

E

X

I

D

T

6

1

4

1

2

N

1

0

1

O

8

R

6

4

M

2

A

m

L

m

3

6

5

.

5

7

0

.

4

9

0

.

3

1

0

.

4

E

0

.3

2

E

6

X

0

.

X

s

1

I

8

0

T

.

T

0

.0

E

he

0

N

c

D

n

I

E

D

N

O

R

M

A

L

A

M

R

O

N

D

m

E

m

D

N

2

T

I

E

4

X

T

6

E

X

8

0

E

1

2

1

4

6

1

1

s

e

h

c

L

8

n

I

0

6

.

A

1

4

0

.

M

2

1

0

.

R

3

9

0

.

3

7

O

0

.

4

5

N

0

.

5

3

0

.

6

T

0

.

I

0

D

X

E

E

D

N

E

T

X

E

L

Position your fingers in the four lock slots (two at

each end of the platen indicated by the green

arrows above), and press down (blue arrows).

tion: see note after step 20

Clean the glass with a lint-free cloth and a mild,

streak-free, glass cleaner.

2726

E

X

T

E

N

D

E

E

X

I

D

T

16

4

1

N

12

0

1

O

8

R

6

4

M

2

A

m

L

m

63

5

.

5

7

0

.

4

9

0

.

3

1

0

.

3

4

E

0

.

2

E

6

X

0

.

X

s

I

1

8

0

T

.

e

0

T

0

.

E

h

0

N

c

D

n

I

E

D

N

O

R

M

A

L

L

A

M

R

O

N

D

m

E

m

D

N

T

2

E

I

4

T

X

6

E

X

8

0

E

1

2

1

4

1

6

1

s

e

h

c

L

n

8

I

0

6

.

A

1

0

4

.

M

2

1

0

.

R

3

9

0

.

3

7

O

0

.

4

5

N

0

.

5

0

3

.

6

0

T

.

I

0

D

X

E

E

D

N

E

T

X

E

Dry the glass fully using a separate clean, dry

lint-free cloth like the one provided with the

maintenance kit.

Turn the pressure platen over to expose the white

background plate.

3

Clean the white background plate with a lint-free

cloth and a mild, streak-free, glass cleaner.

Page 4

E

X

T

E

N

D

E

D

E

X

I

T

E

X

I

T

N

O

R

M

A

L

E

X

T

E

N

D

E

D

N

O

R

M

A

L

I

n

c

h

e

s

m

m

0

.6

3

0

.

5

5

0

.

47

0

.3

9

0

.3

1

0

.

2

4

0

.

1

6

0.0

8

1

6

14

12

1

0

8

6

4

2

E

X

T

E

N

D

E

D

E

X

I

T

E

X

I

T

N

O

R

M

A

L

E

X

T

E

N

D

E

D

N

O

R

M

A

L

I

n

c

h

e

s

m

m

0

.

6

3

0

.

5

5

0

.

4

7

0

.

3

9

0

.

3

1

0

.

2

4

0

.

1

6

0

.

0

8

1

6

1

4

1

2

1

0

8

6

4

2

T

Clean the transport rollers and surrounding area.

30

Dry the white background plate, rollers, and

surrounding area fully using a separate clean,

dry lint-free cloth.

31

Replace the pressure platen and lower the two

handles.

32

ba

X

E

L

A

M

R

O

N

D

m

E

m

D

N

2

T

I

E

4

X

T

6

E

X

8

0

E

1

2

1

4

1

6

1

es

ch

L

8

n

I

0

6

A

.

1

4

0

.

M

2

1

0

.

R

3

9

0

.

3

7

O

0

.

4

5

0

N

.

5

3

0

.

6

T

0

.

I

0

D

X

E

E

D

N

E

T

X

E

L

A

M

R

O

N

D

m

E

m

D

N

2

T

I

E

4

X

T

6

E

X

8

0

E

1

2

1

4

1

6

1

s

e

h

c

L

8

n

I

6

A

1

4

0.0

.

M

2

1

0

R

3

9

0.

O

0.

47

0.3

N

55

0.

.

T

0

.63

I

0

D

X

E

E

D

N

E

T

X

E

Pushing downwards on the left side of the

pressure platen, push in the pin (a) and slide in

the lock (b) locking the platen end into place.

keep out dust and reduce maintenance

time...

Cover your scanner with the plastic dust cover

when not in use.

33

a

X

E

b

L

A

M

R

O

N

D

m

E

m

D

N

2

T

I

E

4

X

T

6

E

X

8

0

E

1

2

1

4

1

6

1

s

e

h

c

L

8

n

I

0

6

A

1

4

0.

.

M

2

1

0

R

3

9

0.

O

0.

.3

47

5

0

N

.

5

0

T

0.

.63

I

0

D

X

E

E

D

N

E

T

X

E

E

X

T

E

N

D

E

E

X

I

D

T

6

1

4

1

2

N

1

0

1

O

8

R

6

4

M

A

2

m

L

m

3

6

5

.

5

7

0

.

4

9

0

.

3

1

0

.

3

E

4

0

.

E

6

X

0

.2

X

I

1

8

T

0

.

es

T

0

.0

E

h

0

N

c

D

n

I

E

D

N

O

R

M

A

L

Pushing downwards on the right side of the

pressure platen, push in the pin (a) and slide in

the lock (b) locking the platen end into place.

35

34

E

E

X

X

T

T

E

E

N

N

D

D

E

E

E

E

X

X

I

I

D

D

T

T

6

6

1

1

4

4

1

1

N

N

12

12

0

0

1

1

O

O

8

8

R

R

6

6

4

4

M

M

2

2

A

A

m

m

L

L

m

m

3

3

6

6

5

5

.

.

5

5

7

7

0

0

.

.

4

4

9

9

0

0

.

.

3

3

0

0

.

.

31

31

4

4

E

E

0

0

.

.

E

E

2

2

6

6

0

0

X

X

.

.

s

s

X

X

1

1

I

I

8

8

0

0

T

T

.

.

e

e

0

0

T

T

0

0

.

.

E

E

h

h

0

0

N

N

c

c

D

D

n

n

I

I

E

E

D

D

N

N

O

O

R

R

M

M

A

A

L

L

L

L

A

A

M

M

R

R

O

O

N

N

D

D

m

m

E

E

m

m

D

D

N

N

T

T

2

2

I

I

E

E

4

4

X

X

T

T

6

6

E

E

X

X

8

8

0

0

E

E

1

1

2

2

1

1

4

4

1

1

6

6

1

1

s

s

e

e

h

h

c

c

8

8

L

L

n

n

I

I

0

0

6

6

.

.

A

A

1

1

4

4

0

0

.

.

M

M

2

2

1

1

0

0

.

.

R

R

3

3

9

9

0

0

.

.

3

3

7

7

O

O

0

0

.

.

4

4

5

5

0

0

N

N

.

.

5

5

3

3

0

0

.

.

6

6

T

T

0

0

.

.

I

I

0

0

D

D

X

X

E

E

E

E

D

D

N

N

E

E

T

T

X

X

E

E

s

s

p

p

c800

c800

r c

e

er c

i

pi

p

o

o

c

t

et c

e

j

j

ign

ign

es

es

d

d

p

p

h

h

With the platen firmly locked into place, close

the scanner cover.

36

Caution: make sure the scanner power is

off when using the dust cover.

37

Connect the keyboard to the touch screen.

If you have placed the touch screen assembly on

the right leg you will find that the FireWire cable

is longer than needed. Please keep the cable

bundled and place it in the cable duct. You will

touch screen arm.

have to lift the rear table to access the cable duct.

38 39

Connect the "Y" power cable to the touch screen.

Connect the "Y" power cable to the scanner.

40

Attach the "Y" power cable into the clips on the

touch screen arm.

41 42

Fit the ‘Y’ power cable into the clips. Then attach

the clips to the stand.

on the left leg, the "Y" power cable should only

be attached to the left leg and cross bar.

4

Page 5

43

Connect the "Y" power cable to a power outlet.

44

If you have not done so already, connect the

printer to a power outlet and switch it on.

45

Connect the touch screen to the printer using the

longer USB cable, fastening with the clips on the

touch screen arm. You will have to lift the rear

table to access some of the clips.

46

slack

Adjust the USB cable to leave enough slack to be

able to pull out the printer when changing paper.

48

camera alignment and calibration...

(Height alignment, stitching, basic calibration,

and color calibration)

You are now required to calibrate the scanner.

For this you will need the scanner maintenance

sheet, found in the protective folder shown below.

note: if when switching on the touch screen a

‘not present’ message appears, please press the

‘Rescan’ option on the touch screen.

47

Switch on the scanner and leave it to warm up

for some minutes until the green (ready status)

light appears.

important: make sure that your

HP Designjet 815mfp is turned on for at least

one hour before moving on to the next step

of camera alignment calibration. Slight light

intensity changes and camera shifting can

occur just after turning the scanner on, and

warm-up time will ensure that light conditions

and camera heights have stabilized.

When the green (ready status) light has

appeared, switch on the touch screen.

To start the maintenance procedure:

a) On the touch screen, press the Setup tab.

b) Press the Scan Options button.

c) Press the Scanner Maintenance button

(shown above).

49 50

The maintenance wizard will ask you to insert the

maintenance sheet. The sheet’s printed side must

be face down. Feed the paper in aligning the

two midpoint arrows. Press ‘Next’ to continue.

Now follow the instructions that appear on the

touch screen.

1 hour

51

When the maintenance procedure has

completed, remove the scanner maintenance

sheet and return it to its protective cover. Store

the folder in a dry place away from light.

Your HP Designjet comes equipped with two

magnetic media guides; these can be placed

and moved as required.

5

Insert the plastic caps in the holes on the touch

screen arm.

Page 6

p

d

s

The ruler can be changed between centimeters

and inches by sliding it out, turning it over, and

reinserting it.

92

93

4

9

5

9

96

97

98

90

1

9

92

93

0

Inche

s

4

0

Inches

7

8

8

8

89

E

D

N

T

I

E

X

T

E

X

E

2

1

4

1

6

1

83

4

8

85

86

L

A

M

R

O

N

D

m

m

2

4

6

8

0

1

s

e

h

c

8

L

n

I

0

6

.

A

1

4

0

.

M

1

0

.2

R

3

9

0

.

3

7

O

0

.

4

5

0

N

.

5

3

0

.

T

0

.6

I

0

D

X

E

E

D

N

E

T

X

E

Next, you should check the TCP/IP settings in

your touch screen, and correct them if necessary.

If you intend to scan to the network, you will also

need to create a workgroup. You may want to

share the Images folder in your touch screen so

that it can be accessed from elsewhere on the

network. For more guidance on these steps, see

the online help system.

To connect your HP Designjet to a network, first

connect the network cable to the Ethernet socket

at the back of your touch screen as shown.

To add an HP Designjet printer to the printer list

in your scanner software, follow these steps:

1. On the touch screen, press the

Quit button and then the Exit

button to exit the scanner

software.

2. Press the System Setup button.

3. Press the Install HP Designjet button.

4. Follow the instructions on the screen.

assembly instructions an

routine maintenance procedure

hpdesignjet 815mf

s

y

s

t

e

m

r

e

c

o

v

e

r

y

assembly kit contents

20

c

d

r

o

m

1

h

p

d

e

s

i

g

n

j

e

t

c

o

p

i

e

r

c

c

8

description quantity

0

0

p

s

19

screw M6×10 for base and top bar and arm 12

2

18

screw M6×30 for base and top bar 8

s

p

0

0

8

c

c

r

e

i

p

o

c

t

e

j

n

g

i

s

e

d

p

h

17

3

screw M3x8 for touch screen assembly hub

16

screw M4×8 for touch screen and key board assembly hub 7

4

special screw for scanner 4

15

Allen key 2 mm for keyboard assembly 1

5

9

Allen key 2.5 mm for touch screen arm brace 1

6

14

Allen T key 5 mm for touch screen arm

power cable clips

13

7

wire routing clips

12

brace

8

11

plastic caps

10

1

7

13

assembly kit

plastic dust cover

2

scanner

3

rear table

4

top bar with guide

5

leg (×2)

6

maintenance kit

Your printer

should already be

assembled and working before starting this

procedure. For instructions on how to

assemble the printer, please refer to the

assembly poster included with the printer.

please note

The touch screen assembly can be mounted on

either the right or the left side of the stand.

scanner maintenance sheet

8

14

power cables

touch screen arm

9

15

cross bar

keyboard

10

16

bottom bar

touch screen hub

11

17

USB and FireWire cable

touch screen

12

18

FireWire cable

feet (x2)

assembly poster

read these instructions carefully...

a note about fixings

and complete each stage before you start the

When initially assembling your

next.

HP Designjet 815mfp stand do not fully tighten

the screws; you will be asked to do this later.

what you will need to do the job

Because some of the components of your

HP Designjet 815mfp are bulky, you will need

2 or 3 people to lift them. See the

descriptions that follow for details, a symbol

like this is used:

touch screen

touch screen

assembly

assembly

please note

The touch screen assembly can be mounted on

either the right or the left side of the stand.

1

Your HP Designjet is now ready for use.

Please make sure that the printer is loaded with

media and inks ready for use.

When System Administrators configure your

system in a network domain, they will also need

to set up automatic login. This procedure is

documented in “how do I set up automatic

login” in your online help.

1

1

17

5

1

4

19

media guides (×2)

20

system recovery CD-ROM

keep these instructions

In order to perform routine maintenance (once a month) you will find it

useful to refer again to the following sections:

• cleaning the scan area: steps 21 to 34

• camera alignment and calibration: steps 47 to 51

You can also find these steps described in the online help topic

how do I... maintenance procedures and on the using your scanner CD.

not for resale

©2003 Hewlett-Packard Company

all rights reserved

printed in

Q1279-90001

6

Loading...

Loading...