Page 1

PrinterFAQ.COM

HP DesignJet650C

User Guide

Page 2

SERVICE MANUAL

HP C2858A/C2859A

DRAFTING PLOTTERS

SERIAL NUMBERS

This manual applies directly to HP C2858A and C2859A

plotters with serial numbers prefixed USA.

For additional information about serial numbers, see

SERIAL NUMBER INFORMATION in Chapter 1.

HEWLETT-PACKARD COMPANY 1993

16399 W. BERNARDO DRIVE

SAN DIEGO, CALIFORNIA 92127-1899

C2858-90000 Printed: March 1993

Page 3

Using this Manual

This service manual contains information necessary to test, adjust, and service the

Hewlett-Packard Models C2858A and C2859A DesignJet 650C plotters. It is designed to

help you easily find the cause of a C2858A/C2859A hardware problem and to perform the

necessary repairs and adjustments to get the plotters into proper operating condition.

Service strategy for this manual is to support the products to the field replaceable unit.

For ease of reference, this manual is divided into ten chapters as follows:

Chapter1 Product Information

Chapter2 Site Planning and Requirements

Chapter3 Installation and Configuration

Chapter4 Preventive Maintenance

Chapter5 Functional Overview

Chapter6 Removal and Replacement

Chapter7 Adjustments/Calibrations

Chapter8 Troubleshooting

Chapter9 Product History

Chapter10 Parts and Diagrams

Chapter 1. Product Information

This chapter contains general information regarding the C2858A and

C2859A DesignJet 650C plotters. A description of the plotters features,

options and accessories, performance characteristics, and serial number

information, is included in this chapter.

Chapter 2. Site Planning and Requirements

Included in this chapter is pre-installation information regarding the

physical, environmental and electrical requirements for proper installation

and operation of the plotters.

Chapter 3. Installation and Configuration

In this chapter you will find installation, configuration and plotter

verification procedures. Included is information on ink cartridge and media

loading, accessing the front-panel menu structures for plotter configuration

and instructions on how to perform built-in demonstration plots to verify

proper plotter operation.

Using this Manual iii

Page 4

Chapter 4. Preventive Maintenance

Chapter 4 contains information you will need to keep the plotters in their

best operating condition. Included are procedures that can be performed by

the user.

Chapter 5. Functional Overview

This chapter contains a simplified description of the plotter circuits and

mechanical functions.

Chapter 6. Removal and Replacement

Procedures for the removal and replacement of field replaceable units are

provided in this chapter along with electrostatic discharge information and

recommended tools to perform repairs.

Chapter 7. Adjustments

Here you will find descriptions of any adjustments and calibrations that may

be required to return the plotter to proper operating condition.

Chapter 8. Troubleshooting

Included in Chapter 8 are service tests, error codes and messages, and

diagnostic information to assist you in troubleshooting and solving plotter

symptoms and failures.

Chapter 9. Product History

Chapter 9 provides historical tracking of changes made to the plotters. The

differences between earlier versions of the plotters and the version

described in the main body of this manual are identified.

Chapter 10. Parts and Diagrams

In this chapter you will find drawings for purposes of identifying the various

field replaceable assemblies. Also in this chapter are associated parts lists

for ordering replacement parts shown on the drawings.

Glossary

The glossary contains a listing of terms used throughout the manual.

Index

Use the index to find references and locate subject matter in this manual.

Using this Manualiv

Page 5

Contents

Chapter Page

1 Product Information

Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug-in Memory 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ROM Enhancement Modules 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modular Input/Output (MIO) PCAs 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Characteristics 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number Information 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Site Planning and Requirements

Introduction 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Requirements 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Cord Set 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Specifications 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Specifications 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Restrictions 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232-C Interface 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Centronics Interface 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP-IB Interface 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Installation and Configuration

Introduction 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Instructions 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User-Installable Modules 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connectivity 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Voltage and Fusing 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Configurations 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Information and Operation 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Guidelines 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Type and Print Quality 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Cutting and Stacking 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Usable Media Sizes 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vContents

Page 6

Chapter Page

Loading Roll Media 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading Roll Media 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading Sheet Media 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading Sheet Media 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearing Media Jams 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pen Checking 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Pens 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Pens 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selectable Ink-Drying Times 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Controls 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Menus 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Languages 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Messages 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Verification 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-On Self-Test 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Demonstration Plot 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Preventive Maintenance

Introduction 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Effect on Product Reliability 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance Procedures 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Cleaning 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Roller Cleaning 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Functional Overview

Introduction 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Simplified Description of Circuits 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Overview 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printed Circuit Assembly (PCA) Overview 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main PCA 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carriage PCA 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interconnect PCA 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel PCA 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drop and Bail Sensors 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply PCA 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi Contents

Page 7

Chapter Page

6 Removal and Replacement

Introduction 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Considerations 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ESD Considerations 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Tools 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Procedures 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DRAM SIMM and ROM Module Removal 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . .

MIO Card Removal 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronics Enclosure Cover Removal 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interconnect PCA Removal 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main PCA Removal 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outer Electronics Enclosure Assembly Removal (C2858A Only) 6-11. . . . . . . . . .

Power Supply PCA Removal 6-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Removal 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Window Assembly Removal 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Endcovers (Left and Right) Removal 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Primer Assembly and Sensor Removal 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinch Wheel Sensor Removal 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Window Sensor Removal 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Sensor Removal 6-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trailing Cable Removal 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Back Panel Removal 6-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Removal 6-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carriage Motor Removal 6-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Motor Removal 6-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Encoder Strip Removal 6-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rollfeed Cover Assembly Removal 6-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rollfeed Module Assemblies (Left and Right) Removal 6-31. . . . . . . . . . . . . . . . .

Cutter Assembly Removal 6-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trailing Cable Guide Removal 6-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y-Tensioner and Housing Removal 6-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pen Carriage Assembly and Main Drive Belt Removal 6-38. . . . . . . . . . . . . . . . . .

Drop Detect and Bail Sensors Removal 6-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starguard Assembly Removal 6-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bail Assembly Removal 6-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Station Assembly Removal 6-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overdrive Support Assembly Removal 6-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viiContents

Page 8

Chapter Page

Cutter Enclosure Assembly Removal 6-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entry Platen Assembly Removal 6-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Roller Assembly Removal 6-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Bail Lift Mechanism Removal 6-55. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Diverter Removal 6-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinch Arm and Lift Mechanism Removal 6-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Adjustments/Calibrations

Introduction 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrations 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sheet Length Calibration 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accuracy Calibration 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Sensor Calibration 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drop Detect Calibration 7-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edge Sensor Calibration 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bail Calibration 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Troubleshooting

Introduction 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-On Self Tests 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-On Self Test 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Initialization 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Messages and Codes 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Worded Error Messages 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Error Codes 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Data Plot 8-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servo System Control Failures 8-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Tips 8-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ROM Code Revision Level 8-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Tests 8-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Plot 8-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bar Pattern Analysis 8-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading the EEROM Text Block 8-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analyzing the Pen Nozzle Test Block 8-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii Contents

Page 9

Chapter

Page

9 Product History

Introduction 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

History of Assemblies by Serial Number 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

History of Printed Circuit Assemblies (PCAs) 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Parts and Diagrams

Introduction 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exchange Assemblies 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Parts 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Illustrated Parts Breakdown Drawings 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Labels and Cables 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

ix

Page 10

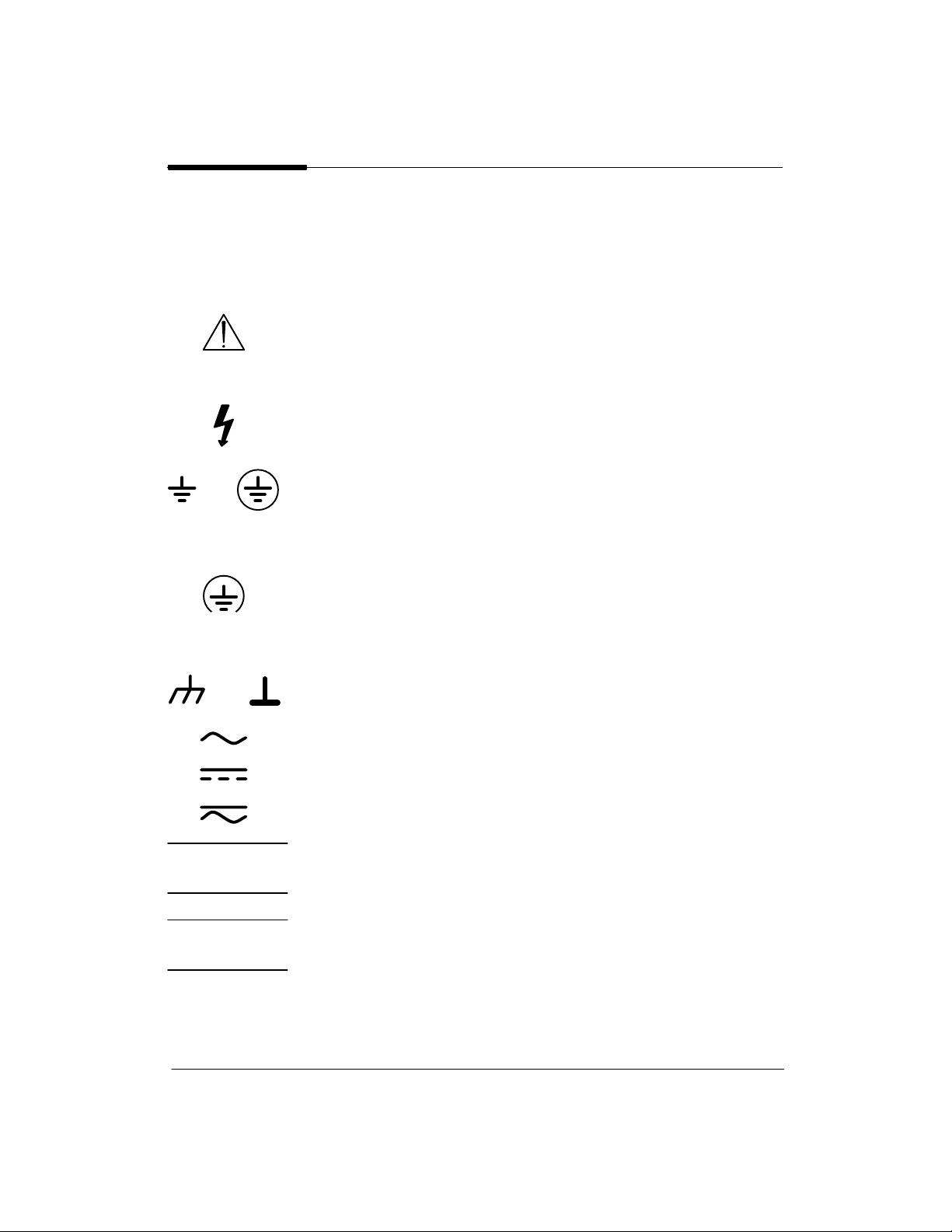

General Definitions of Safety Symbols

International caution symbol (refer to manual): the product will be

marked with this symbol when it is necessary for the user to refer

to the instruction manual in order to protect against damage to the

instrument.

Indicates dangerous voltage (terminals fed from the interior by

voltage exceeding 1000 volts must also be marked).

Protective conductor terminal. For protection against electrical

shock in case of a fault. Used with field wiring terminals to indi–

cate the terminal which must be connected to ground before

operating equipment.

Low–noise or noiseless, clean ground (earth) terminal. Used for a

signal common, as well as providing protection against electrical

shock in case of a fault. A terminal marked with this symbol must

be connected to ground in the manner described in the installation

(operating) manual, and before operating the equipment.

Frame or chassis terminal. A connection to the frame (chassis) of

the equipment which normally includes all exposed metal.

x

Alternating current

Direct current

Alternating or direct current

The WARNING sign denotes a hazard. It calls attention to a pro–

cedure, practice, or the like, which, if not correctly performed or

adhered to, could result in personal injury.

The CAUTION sign denotes a hazard. It calls attention to an op–

erating procedure, practice, or the like, which if not correctly

performed or adhered to, could result in damage to or destruction

of part or all of the product.

Safety

Page 11

Chapter 1 Product Information

INTRODUCTION

This chapter contains a listing of documentation supplied with the HP C2858A and C2859A

DesignJet 650C plotters. Also provided are: descriptions of the plotters, information on the

plotter features, options and accessories, performance characteristics, and plotter serial

number information.

Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug-in Memory 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ROM Enhancement Modules 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modular Input/Output (MIO) PCAs 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Characteristics 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number Information 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1Product Information

Page 12

DESCRIPTION

HP C2858A and C2859A DesignJet 650C plotters provide graphic displays of computer program output data. They operate with a number of computer systems and graphic terminals,

using either RS-232-C or Centronics external controllers. With one of several optional, modular input/output (MIO) cards installed, the plotter can operate: with an HP-IB external controller, within a Novell Ethernet or Token ring network, as a TCP/IP host workstation, with a

LAN Manager, with Ethertalk and with Apple LocalTalk.

The C2858/9A DesignJet 650C plotters will accept drawing data from Computer Aided Design (CAD) software programs supporting the HP-GL (vector), the HP-GL/2 (vector), HP

RTL (raster), and PJL languages. HP-GL/2 is available with Kanji character sets when the

Kanji ROM SIMM is installed. Postscript is also available when the PostScript ROM SIMM

upgrade is installed.

The HP C2858/9A DesignJet 650C plotters (see Figure 1-1) are large-format, color and

monochrome, ink-jet plotters designed to plot monochrome plots on commonly available

opaque bond paper, translucent (Japanese tracing) paper, vellum, or special inkjet-compatible drafting film. Quality color output is only supported when using HP special inkjet paper.

C2858/9A DesignJet 650C plotters can produce plots on single-sheet media or roll-feed media. Large format plots of high resolution and quality are generated for applications such as

computer aided design (CAD), computer aided manufacturing (CAM), mapping, mechanical and architectural drawings, and general drafting.

Five high-capacity ink cartridges are provided with the C2858/9A plotters. Selectable penwidth settings are modified to ISO standard pen widths. The cartridges simultaneously scan

across the media providing 300 dpi resolution in draft and final modes, 300 dpi addressable

resolution for color in enhanced mode and 600 dpi addressable resolution for monochrome in

enhanced mode.

C2858A plotters can plot on media sizes ranging from International Standards Organization

(ISO) sizes A1 through A4, American National Standards (ANSI) sizes A through D, and

architectural media sizes C and D. Model C2859A plotters can plot on media sizes ranging

from International Standards Organization (ISO) sizes A0 through A4, American National

Standards (ANSI) sizes A through E, and architectural media sizes C through E. Roll-feed

capability allows the plotters to perform long-axis plotting in lengths up to 50 feet.

1-2 Product Information

Page 13

Figure 1-1.

The standard HP C2858/9A DesignJet 650C has four megabytes of on-board random access

memory (RAM). Memory expansion upgrades to 20 MB are available as well as various

ROM enhancement and modular I/O options. Other features that are standard include:

Automatic media edge sensing

Automatic pen alignment, testing and servicing

Automatic media stacking with adjustable media bin

An automatic, single-axis cutter

Queueing, nesting and expanded margin capabilities

Easy-to-read 2 row by 20 character vacuum fluorescent display (VFD)

Built-in diagnostic and demonstration plot routines

1-3Product Information

Page 14

OPTIONS

PLUG-IN MEMORY

C2858/9A DesignJet 650C plotters have two memory expansion sockets. Each can hold either a four-megabyte or eight-megabyte, Single In-line Memory Module (SIMM). Therefore, memory can be expanded by 4, 8, 12 or 16 megabytes. The SIMM part numbers are:

Four Mbyte SIMM = P/N C2065A

Eight Mbyte SIMM = P/N C2066A

ROM ENHANCEMENT MODULES

Two ROM expansion sockets are also provided in the C2858/9A DesignJet 650C plotters.

Each will hold a single ROM enhancement SIMM. The ROM SIMMS could include firmware revision upgrades or language enhancements. A Kanji ROM SIMM is available for Japanese users who require the Kanji character sets. A PostScript upgrade is also available in

ROM SIMM. The part numbers for the kits are:

Kanji ROM Kit = P/N C2847-60031

PostScript ROM Kit = P/N C2882A

MODULAR INPUT/OUTPUT (MIO) PCAs

Interface circuitry is provided on the plotters which allows the user to install HP supported

modular I/O (MIO) cards for several interface applications. Although multiple protocols

may reside on an MIO, they are not simultaneously supported, only one protocol at at time

can be used. The MIO card part numbers are:

Multi-protocol Ethernet for Novell, TCP/IP, LAN Manager, Ethertalk

with RJ-45 (twisted pair) and BNC (ThinLAN) connectors) = P/N J2372A

with RJ-45 (twisted pair) connector only = P/N J2371A

Multi-protocol Token Ring for Novell, LAN Manager = P/N J2373A

HP-IB = P/N C1642A

Apple LocalTalk = P/N J2341A

1-4 Product Information

Page 15

ACCESSORIES

The items listed in Table 1-1 are supplied with each plotter. Miscellaneous application notes,

flyers and driver disks are also provided. Depending upon the country of destination, the part

numbers of items listed as English or U.S. will differ. Accessories available for use with the

C2858/9A DesignJet 650C plotters are listed in the Supplies Catalog.

Table 1-1. Accessories Supplied

Description

C2858A/C2859A Manual Kit (English)

includes: Using Your Plotter’s Front Panel

Guide, Setting Up For Plotting Guide, and

Quick Reference Guide

Power Cord (U.S.) 1 8120–1378

Media Sampler Roll (CX Jet Series)

24ºx150’ C2858A

36ºx150’ C2859A

Pens: Black

Cyan

Magenta

Yellow

Hardware Kit 1 C2847–60061

Cable Management Hardware Kit 1 C2847-60030

Front Panel Overlay (English) 1 C2858–60026

Guide/Cutter Holder 1 C1633–40094

Manual Cutter 1 17291C

Supplies Catalog 1 5091–3485EUS

Supplies Catalog Update 1 5091–6787EUS

Unpackaging Instructions 1 C2858–90003

Spindle Assembly: C2858A

C2859A

Spindle Flange 1 07596-40076

Spindle Spacer 1 07596-40077

Qty HP Part Number

1 C2858–90051

1

1

2

1

1

1

1

1

51631D

51631E

51640A

51650C

51650M

51650Y

C2847-60033

07596-60060

1-5Product Information

Page 16

PERFORMANCE CHARACTERISTICS

Table 1-2 lists the performance characteristics of the plotters.

Table 1-2. Performance Characteristics

Accuracy

0.38 mm (0.015 in.) or 0.2% of the specified vector length, whichever is

greater at 23 C (73 F) at 50-60% RH, on HP film (monochrome mode only).

Throughput

D-sized loaded vertically: plain paper special paper special paper

monochrome monochrome color

Draft mode 1.8 min. 1.8 min. 3.4 min.

Final mode 3.2 min. 2.7 min. 4.3 min.

Enhanced mode 6.5 min. 6.5 min. 8.7 min.

Resolution

Draft Mode 300 dpi addressable

Final Mode 300 dpi addressable

Enhanced Mode 300 dpi addressable (color)

600 dpi addressable (monochrome)

Margins

Leading and Trailing 17 mm ( 2mm) (normal plot area),

10 mm (expanded plot area)

Sides 5 mm (normal or expanded plot area)

Media Dimensions

Sheet and Roll

Maximum Widths D (A1)-size 619 mm (24 in.)

E (A0)-size 917 mm (36 in.)

Roll

Maximum Media Length 150 feet (125 ft. for film)

SERIAL NUMBER INFORMATION

If the plotter serial number has a lower revision letter than the one shown on the title page,

information in the Product History chapter, Chapter 9, will adapt this manual to that plotter.

1-6 Product Information

Page 17

Chapter 2 Site Planning and Requirements

INTRODUCTION

This chapter contains information concerning the electrical requirements for the installation

of HP C2858A and C2859A plotters. Also included is information on environmental operating conditions and physical specifications for the plotters.

Introduction 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Requirements 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Cord Set 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Specifications 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Specifications 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Restrictions 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232-C Interface 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Centronics Interface 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP-IB Interface 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1Site Planning and Requirements

Page 18

ELECTRICAL SPECIFICATIONS

POWER REQUIREMENTS

HP C2858A and C2859A DesignJet 650C plotters have self-adjusting power supplies and do

not require voltage selector or switch settings prior to use. Table 2-1 lists the power requirements for the plotters.

Table 2-1. Power Requirements

Voltage Requirements

Voltage Current (max)

100 Vac 1.4 A

120 Vac 1.2 A

220 Vac 650 mA

240 Vac 600 mA

Frequency

Consumption 140 Watts maximum

47-53 Hz and 57-63 Hz

Source

LINE CORD SET

W A R N I N G

The configuration of the ac line cord set required for use with the plotters is determined by the

country of destination for the plotters. Refer to Chapter 3 for a listing of the available ac line

cord connectors.

2-2 Site Planning and Requirements

Page 19

ENVIRONMENTAL SPECIFICATIONS

Table 2-2 lists environmental specifications for the plotters.

Table 2-2. Environmental Specifications

Temperature

Storage

Operating

Optimal Operating

Relative Humidity (Operating) 20 to 80 % RH

–40 to +70 C (–40 to +158 F)

0 to +55 C (+32 to +131 F)

+15 to +30 C (+59 to +86 F)

PHYSICAL SPECIFICATIONS

The plotter physical specifications are listed in Table 2-3.

Table 2-3. Physical Specifications

C2858A C2859A

Length

Depth

Height

Weight

1092 mm (43 in) 1372 mm (54 in)

711 mm (28 in) 711 mm (28 in)

1169 mm (46 in) 1219 mm (48 in)

58 kg (128 lbs) 70 kg (155 lbs)

Packaging:

Plotter Body

Length

Width

Height

Weight

Leg Pack

Length

Width

Height

Weight

1270 mm (50 in) 1574 mm (62 in)

584 mm (23 in) 584 mm (23 in)

635 mm (25 in) 635 mm (25 in)

68 kg (150 lbs) 68 kg (150 lbs)

940 mm (37 in_ 1219 mm (48 in)

711 mm (28 in) 762 mm (30 in)

229 mm (9 in) 229 mm (9 in)

21 kg (45 lbs) 25 kg (55 lbs)

2-3Site Planning and Requirements

Page 20

CABLE RESTRICTIONS

Cable restrictions for the plotter are determined by the type of interface being used. Recommendations for each interface are supplied in the following paragraphs.

RS-232-C INTERFACE

The use of short cables (each less than 15 metres or 50 feet) is recommended for the

RS-232-C Interface. Longer cables are permissible, provided the load capacitance does not

exceed 2500 picofarads.

CENTRONICS INTERFACE

The use of short cables (each less than 2 metres or 6.6 feet) is recommended for the Centronics Interface.

HP-IB INTERFACE

The HP-IB (Hewlett-Packard Interface Bus) allows up to 15 devices to be connected. The

maximum cable length is restricted to 2 metres (6.6 ft.) per device up to a total of 20 metres

(65.8 ft.). The devices may be connected in a star or linear bus network.

2-4 Site Planning and Requirements

Page 21

Chapter 3 Installation and Configuration

INTRODUCTION

This chapter contains the information required to configure and verify proper operation of

the HP C2858A and C2859A DesignJet 650C plotters. Print cartridge and media loading procedures, as well as front panel menu structures, are also provided.

Introduction 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Instructions 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User-Installable Modules 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connectivity 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Voltage and Fusing 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Configurations 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Information and Operation 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Guidelines 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Type and Print Quality 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Media Cutting and Stacking 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Usable Media Sizes 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading Roll Media 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading Roll Media 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading Sheet Media 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unloading Sheet Media 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearing Media Jams 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pen Checking 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Pens 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Pens 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selectable Ink-Drying Times 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Controls 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Menus 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Languages 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Messages 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Verification 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-On Self-Test 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Demonstration Plot 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1Installation and Configuration

Page 22

INSTALLATION INSTRUCTIONS

USER-INSTALLABLE MODULES

Expansion sockets located behind a panel at the rear of the plotter allow the user to install

additional memory modules. These SIMMs (single in–-line memory modules) are available

in 4MB and 8MB sizes. Installation is accomplished by removing the access panel (4

screws), installing the module(s), and reattaching the access panel. ROM sockets are also

provided for use with ROM enhancements as developed. Installation instructions are provided with the modules and also provided in Chapter 6 of this manual. Information on ordering the memory expansion and ROM modules is provided in Chapter 1 of this manual.

An interface port on the back of the plotter allows the user to select one of several available

modular interfaces at a time. The modular I/O cards can be easily changed to match the desired application. Installation instructions are provided with the modules and also provided

in Chapter 6 of this manual. Information on ordering the modular I/Os is provided in Chapter

1 of this manual.

CONNECTIVITY

Depending upon the interface and hardware being used to drive the plotters, different cables

could be required. A listing of cables and other connectivity related issues is provided in the

DesignJet 650C documentation listed in Chapter 1 of this manual.

LINE VOLTAGE AND FUSING

The HP C2858/9A DesignJet 650C plotter ’s power supply automatically adjusts to the input

voltage. The plotter’s autoranging power supply accepts an input of 90 to 264 Vac.

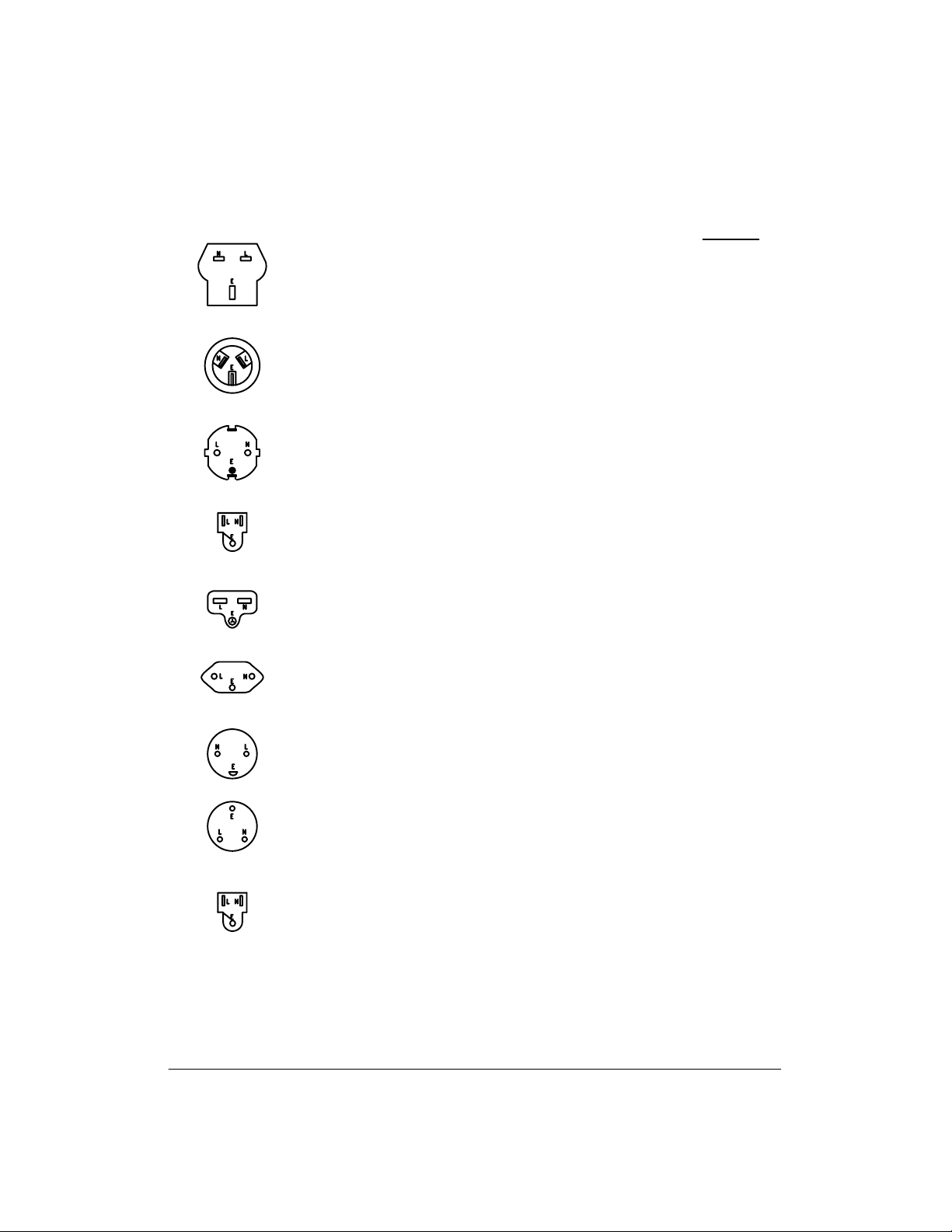

POWER CORD CONFIGURATIONS

Power cord configurations shipped with the plotter depend upon the country of destination

for the plotter. See Figure 3-1 for information on the power cord configurations available for

use with the plotters. When connecting the plotter to the ac source, ensure that the appropriate

power cord is used.

3-2 Installation and Configuration

Page 23

BS 1363A

Option No.

AS C112

CEE 7–VII

NEMA 5–15P

NEMA 6–15P

SEV 1011

250 Vac, 13 A, Single Phase plug rating.

For use in United Kingdom, Cypress,

Nigeria, Zimbabwe, Singapore.

250 Vac, 10 A, Single Phase plug rating.

For use in Australia, New Zealand.

250 Vac, 10/16 A, Single Phase plug rating.

For use in East and West Europe, Egypt.

125 Vac, 15 A, Single Phase plug rating.

For use in Canada, Mexico, Philippines,

Taiwan, Saudi Arabia, UL approved in the

United States

250 Vac, 15 A, Single Phase plug rating.

For use in Canada, UL approved in the

United States.

250 Vac, 10 A, Single Phase plug rating.

For use in Switzerland.

900

901

902

903

904

906

DHCK–107

MITI 41–9692

NOTE:

250 Vac, 10 A, Single Phase plug rating.

For use in Denmark.

250 Vac, 10 A, Single Phase plug rating.

For use in India, Republic of South Africa.

125 Vac, 12 A, Single Phase plug rating.

For use in Japan.

All plugs are viewed from the power outlet connector end.

L = Line or Active Conductor (also called ªliveº or ªhotº)

N = Neutral or Identified Conductor

E = Earth or Safety Ground

Figure 3-1.

912

917

918

3-3Installation and Configuration

Page 24

USER INFORMATION AND OPERATION

MEDIA GUIDELINES

Guidelines on media handling are:

The leading edge must be straight and each side must be loaded evenly. If the

leading edge is jagged, trim it with the media knife (located in the manual holder at

the back of the plotter) using the track on top of the plotter as a guide.

If media is curled, load it with the curl up. The exception to this is film media,

which must always be loaded with the plotting side (matte side) down.

Roll media must be flush with the right edge of the core.

Film should be handled by the edges or when wearing cotton gloves. Load film

with the matte side down (shiny side up).

MEDIA TYPE AND PRINT QUALITY

DesignJet 650C plotters have several combinations of plotting modes. Each mode is dependent upon the color/monochrome setting, media type, and print quality settings input through

the front panel. Interaction between the settings produces the ten modes. Each mode has a

unique combination of print resolution, number of passes and resultant ink-drying time.

Media Type is set through the front panel when media is loaded into the plotter. The front

panel display prompts the user to select for sheet or roll loading and then to scroll through the

menu and select for one of the five media types listed below. The menu selection should be set

to match the media type being used.

Opaque bond (paper)

Film

Special paper

Vellum

Translucent

A front panel button allows you to plot in one of three Plot Quality modes. Continuous pressing of the button toggles through the modes and the associated LEDs are lit indicating the

current print quality mode selection. The Plot Quality modes are:

Draft

Final

Enhanced

3-4 Installation and Configuration

Page 25

Real-time switching between plotting modes is not supported. If the user selects another

mode while plotting, the plotter waits until the current plot is finished and then switches to the

newly selected mode.

MEDIA CUTTING AND STACKING

Automatic and manual cutting of plots is available on the C2858/9A. In roll media operations, the user can choose between continuous plotting or cutting plots off the roll automatically as they are completed.

Automatic cutting When roll media is loaded, whether or not queueing is

ON, the plotter automatically cuts plots and drops them

into the media bin. When queueing and nesting are ON,

the plotter cuts each nest. The automatic cutter can be

programmatically disabled. When cutting is disabled, the

plotter draws tick marks at the plot margins to indicate

the end of a plot or nest. The automatic cutter can be

enabled programmatically or by cycling power.

Manual cutting The front panel Form Feed/Cut button can be used to

feed the media out and cut it after a plot is completed.

Media stacking Unattended stacking of cut sheets is provided by the

adjustable media bin. The user must adjust the movable

shelf of the bin according to the length of the cut sheets.

Bin capacity is 20 sheets.

Manual cutter A manual cutter is provided with the plotter for hand-

cutting of media and is stored in the manual holder on

the back of the plotter.

3-5Installation and Configuration

Page 26

USABLE MEDIA SIZES

Media of different types and sizes can be used on the plotters. Refer to Table 3-1 for the media

sizes usable on each plotter.

Table 3-1. Media Sizes

C2858A

ISO A4 - A1 ISO A4 - A0

ANSI A - D ANSI A - E

ARCH A - D ARCH A - E

JIS B4 - B2 JIS B4 - B1

Oversize A2 Oversize A1

24 in. Wide Roll 24 in. Wide Roll

C2859A

36 in. Wide Roll

LOADING ROLL MEDIA

If the spindle is already loaded into the plotter, remove the spindle by opening the roll cover

and pulling on both ends of the spindle to remove it from the plotter. To load roll media into

the plotter, put a roll of media on the plotter spindle and insert the spindle in the plotter by

performing the following steps:

W A R N I N G

Be sure that the plotter wheels are locked to prevent

the plotter from moving while loading roll media. To

lock the wheels, press the locking levers on the wheels

to the down position.

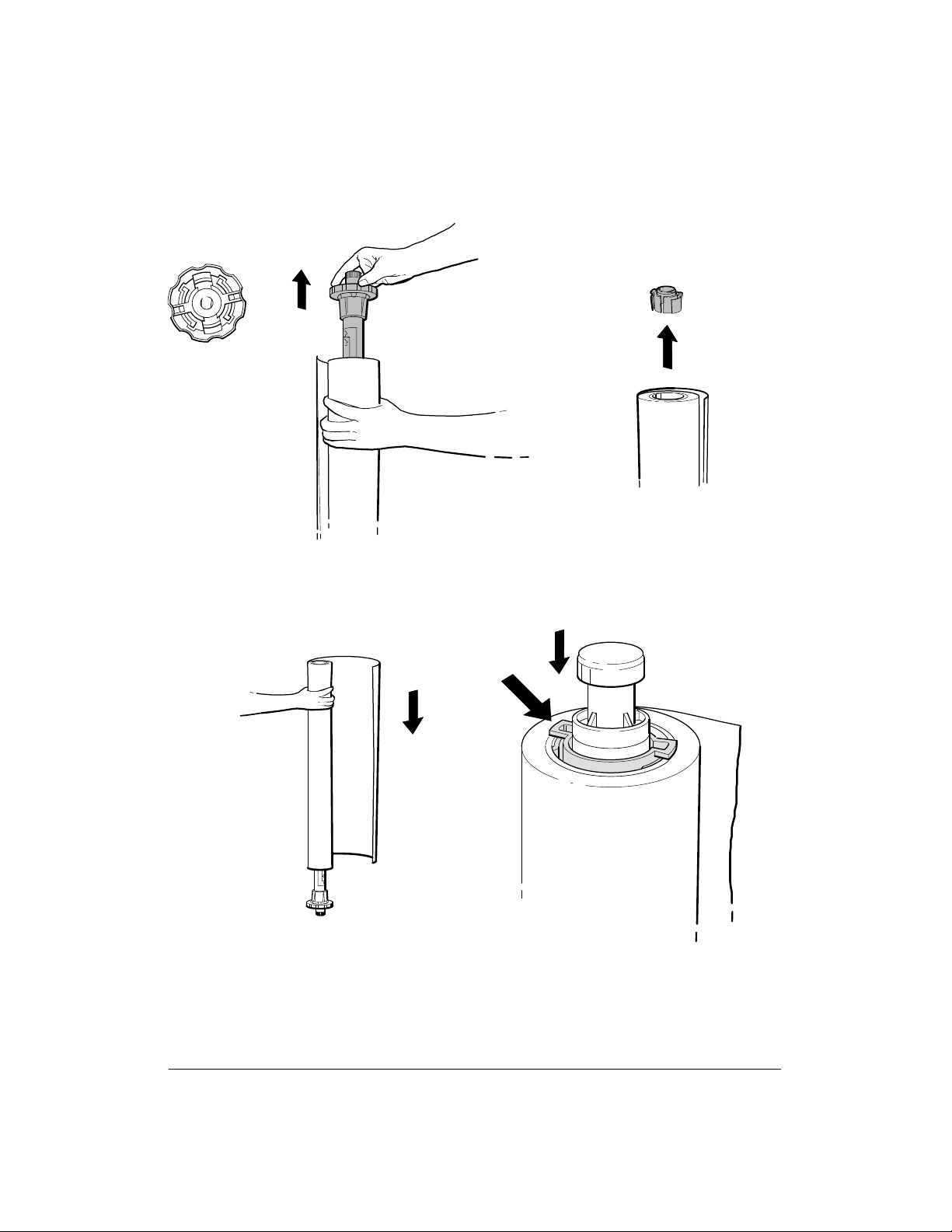

1. Standing the spindle on the end opposite the large, scalloped media stop, pull the

scalloped media stop to release the spindle from the used roll. Set the spindle aside.

Turn the used roll over and slip the endcap out with your finger. See Figure 3-2.

2. Slide the roll onto the spindle with the leading edge winding clockwise. Push the

endcap into the media core, making sure the tabs are flush against the edge of the

roll. See Figure 3-3.

3-6 Installation and Configuration

Page 27

(C) C2847-10(UM)

(C) C2847-16(UM)

Removing the Media Stop and Endcap

Figure 3-2.

Sliding the New Roll onto the Spindle

Figure 3-3.

3-7Installation and Configuration

Page 28

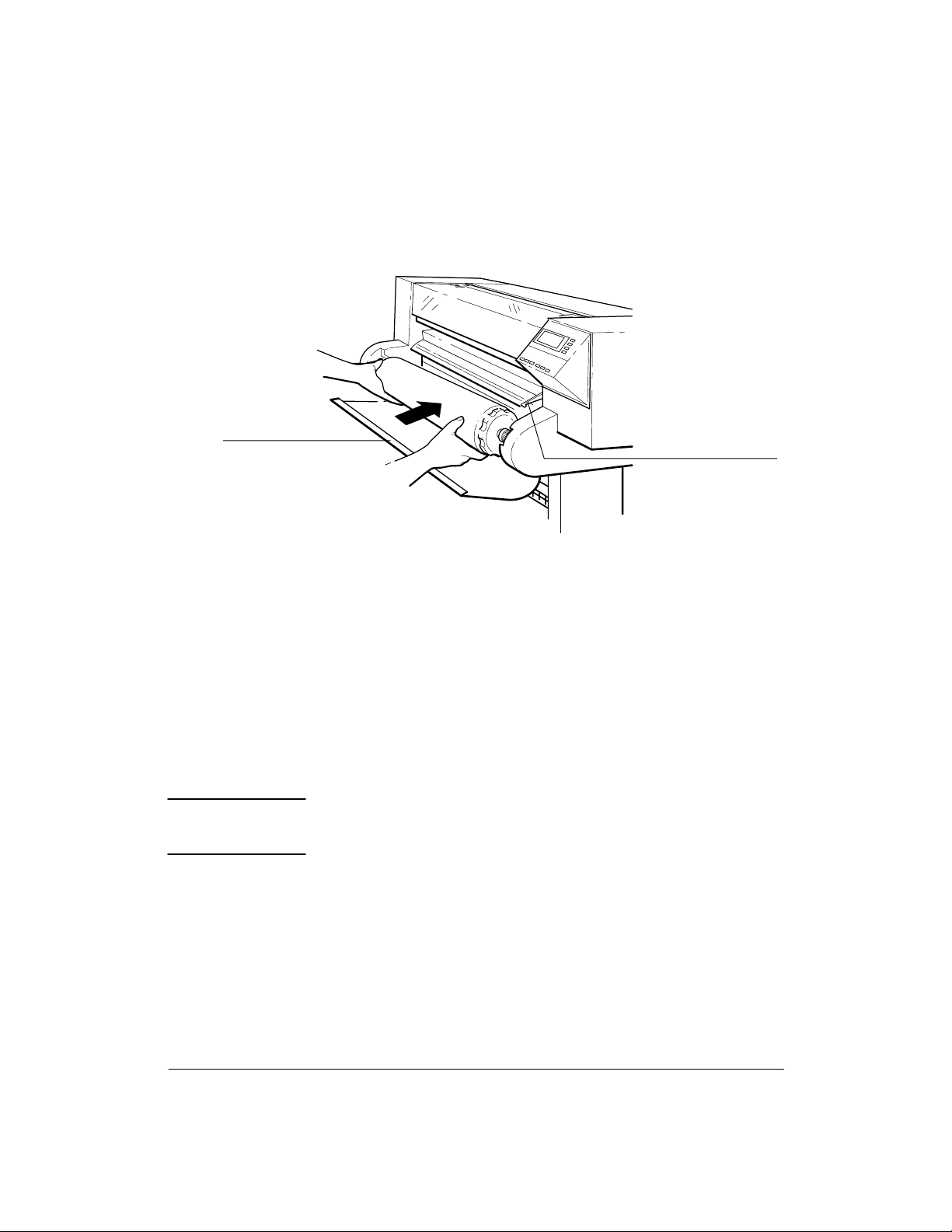

3. Open the roll cover and insert the spindle, with the endcap at the left and the media

stop at the right. Firmly push on both ends. See Figure 3-4.

Roll Cover

Pinchwheel Lever

(C) C2847-31(UM)

Installing the Spindle

Figure 3-4.

4. Once the roll is in place, push the media all the way to the right, so that it’s flush

against the media stop.

5. Ensure that the pinchwheel lever at the right of the plotter is down.

6. Turn the plotter ON, if it is not already ON.

7. Grasp the leading edge of the media and pull about one foot (30 cm) of media out

from the roll. Check the leading edge of the media. If it appears uneven, or to ensure

a straight edge, the edge will need to be trimmed.

W A R N I N G

The cutter blade is very sharp. Use caution when using the

cutter to trim or cut media. Keep hands away from the blade

when cutting. Retract the blade into the cutter after use.

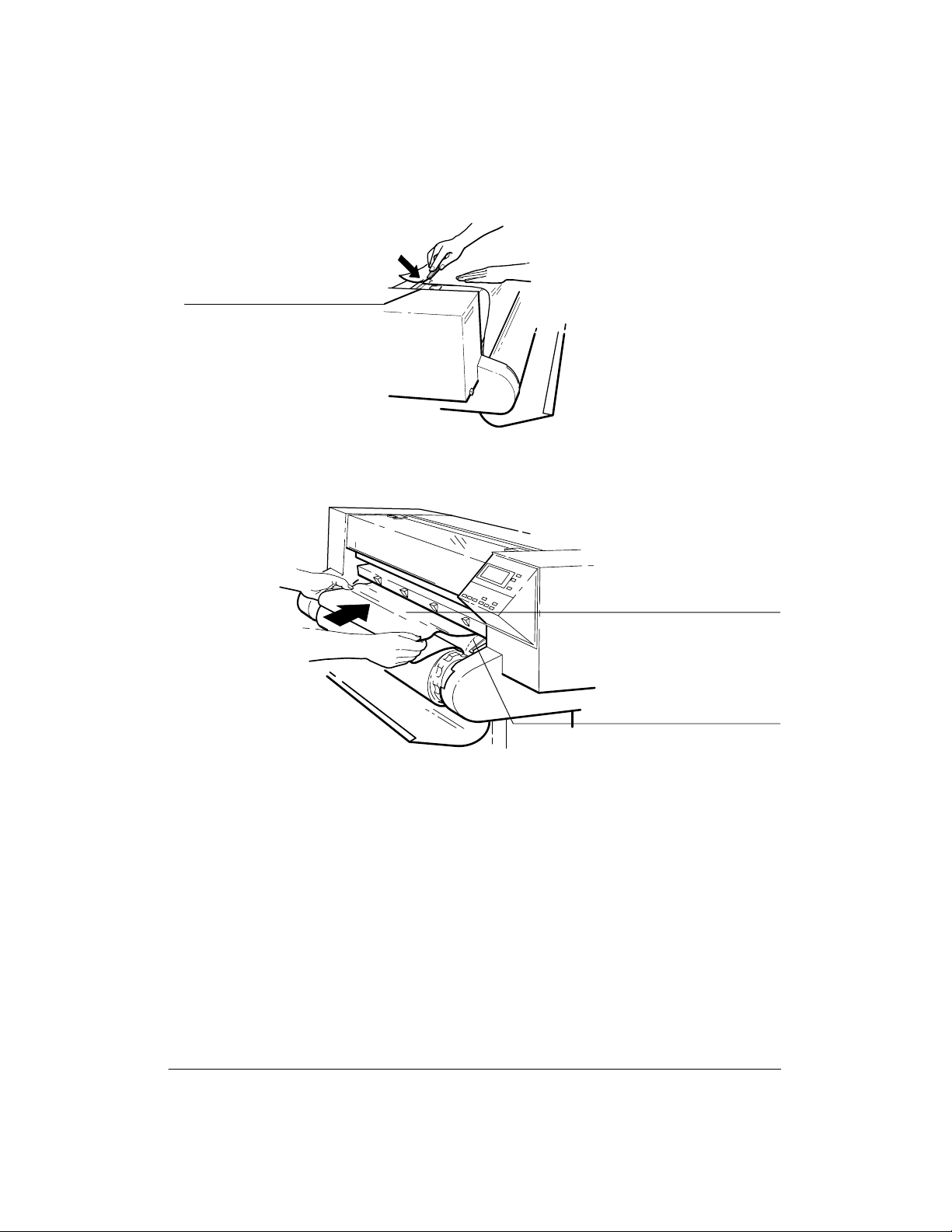

8. Trim the leading edge if it’s uneven. Pull it over the top of the plotter and lay it over

the cutting track. Using the cutter located in the holder at the back of the plotter, cut

off the first few inches of the media. See Figure 3-5. Return the cutter to the holder.

9. Load the leading edge, aligning the right edge with the perforated line on the entry

platen. Push the media in until it buckles slightly as it hits the stops inside the plotter.

Let go when the plotter begins to pull the media in. See Figure 3-6.

3-8 Installation and Configuration

Page 29

Cutting Track

(C) C2847-15(UM)

(C) C2847-7(UM)

Trimming the Leading Edge of the Media

Figure 3-5.

Insert Media Until

it Buckles Evenly

Align Media with

Perforation Line

Loading the Leading Edge of the Media

Figure 3-6.

10. When the front panel displays ªSheet load/Roll load,º press the Down Arrow

button to select ªRoll load.º

11. When the front panel displays ªSELECT MEDIA,º press the Up or Down Arrow

button to scroll through and select the media choice. Press the Enter button to set the

plotter for the media type being used. The plotter will now load the roll of media.

12. When indicated on the front panel, raise the pinchwheel lever to the up position.

13. When ªPull

/ Align edges to rollº is displayed on the front panel, pull the left

and right edges of the roll toward you until taut. Then align the left and right edges of

3-9Installation and Configuration

Page 30

the media so that they are flush with the left and right edges of the roll. See

Figure 3-7.

(C) C2847-97(UM)

(C) C2847-97a(UM)

Aligning the Left and Right Edges of the Media

Figure 3-7.

14. When the front panel instructs you, lower the pinchwheel lever. The plotter checks

to make sure the roll is properly aligned.

15. When ªClose roll cover/Continue

º is displayed, rewind the media stop to take up

any slack in the roll. Make sure the leading edge of the media is outside the roll cover, then close the roll cover. Press the Down Arrow button to continue. The plotter

trims off the first few inches of media. When roll loading is complete, the ªSTATUS

Ready to plotº message is displayed.

UNLOADING ROLL MEDIA

To unload roll media from the platen without removing the spindle from the plotter, do the

following steps:

1. Raise the pinchwheel lever to the up position.

2. Open the roll cover and turn the media stop to wind the media back onto the spindle.

3. Close the roll cover.

4. Lower the pinchwheel lever to the down position.

To remove the spindle with roll media, perform steps 1 and 2 above, then pull on both ends of

the spindle to remove it from the plotter.

3-10 Installation and Configuration

Page 31

LOADING SHEET MEDIA

To load sheet media, perform the following steps:

1. Ensure that the pinchwheel lever is down and the roll cover is closed.

2. Load the leading edge of the sheet making sure to push the sheet in straight (not

skewed) while aligning the right edge of the sheet with the perforated line on the

entry platen. See Figure 3-8.

Insert Media Until

it Buckles Evenly

Align Media with

(C) C2847-15a(UM)

Perforation Line

3. Push the sheet in until it buckles slightly as it hits the stops inside the plotter. (The

buckling should be even across the width of the sheet.) Let go as soon as the plotter

begins to pull the media in.

4. When the front panel displays ªSheet load/Roll load,º press the Up Arrow button to

select ªSheet load.º

5. When the front panel displays ªSELECT MEDIA,º press the Up or Down Arrow

button to scroll through and select the media choice. Press the Enter button to set the

plotter for the media type being used. The plotter will now load the sheet of media.

6. The plotter moves the sheet in and out to check its size and alignment, then advances

it to the start of the page. When sheet loading is complete, the ªSTATUS Ready to

plotº message is displayed.

3-11Installation and Configuration

Page 32

If difficulty in loading sheet media is experienced, an alternate method of loading is possible.

Do the following:

1. Ensure that the pinchwheel lever is down and the roll cover is closed.

2. Raise the window on the plotter.

3. Insert the sheet into the plotter until the leading edge hits the stops inside the platen

area. Align the right side of the sheet with the perforation line on the entry platen.

4. While holding the sheet against the stops and aligned with the perforation line, lower

the window on the plotter. Let go as soon as the plotter begins to pull the media in.

Perform steps 4 through 6 of the sheet loading procedure on the previous page to set the plotter for the media type being used.

UNLOADING SHEET MEDIA

To remove an unplotted sheet, press the Form Feed/Cut button and remove the sheet when

the plotter is finished feeding it out. Another way to remove unplotted sheet media is to raise

the pinchwheel lever at the right, remove the sheet, and lower the lever.

CLEARING MEDIA JAMS

To clear a media jam, first press the Form Feed/Cut button to see if the plotter will cut, and

advance the media out. Should the jam remain, turn the plotter OFF and raise the pinchwheel

lever and window to the up position.

W A R N I N G

If necessary, push the ink-cartridge carriage and the cutter carriage away from the jammed

media. Handle only the solid plastic part of the ink-cartridge carriage and the extension on the

left end of the cutter carriage. Carefully remove the jammed media from the plotter. When

finished, lower the window and pinchwheel lever before turning the plotter back ON.

3-12 Installation and Configuration

The steel encoder strip and automatic cutter blade inside the

plotter are very sharp. Use caution when inserting hands

into the plotter to clear media.

Page 33

PEN CHECKING

Ink usage for cartridges may vary depending upon the ratio of color versus monochrome

plotting and the extent of each color used. Cartridge replacement is necessary only when any

of the following conditions occur:

Pen Checking is ON and you elect to replace the cartridges when the plotter

prompts you.

Poor plot quality indicates an out of ink condition or the cartridges appear clogged.

When Pen Checking is ON (default), the plotter checks the pens both before and after each

plot for proper electrical contact and nozzle function.

If either of the problems exist, the plotter displays the message ªService pens/Continueº,

You may elect to either ignore the message and continue by pressing the Down Arrow or

select ªService pensº by pressing the Up Arrow button. If you select ªService pens,º the

display tells you whether a pen needs to be replaced (nozzles aren’t working) or reseated

(poor electrical contact). The defective pen position is indicated by a flashing icon in the front

panel display.

When Pen-checking is OFF, the plotter does not check the pens for the above problems; the

only way you’ll be able to tell if you need to replace or reseat a pen is if your print quality is

poor. Use the ink level indicators on the cartridges to check ink levels.

Perform the following steps to change the current pen checking selection.

1. Press Enter button and use the arrow buttons to scroll to the Utilities menu.

2. Press Enter button and use the arrow buttons to scroll to ªMenu Modeº. Press

the Enter button.

3. Use the arrow buttons to toggle to ªFullº and press the Enter button.

4. Use the Previous button to return to the Status display.

5. Press Enter button and use the arrow buttons to scroll to the Plotter setup menu.

Press the Enter button.

6. Using the arrow buttons, scroll to ªPen checkº and press the Enter button.

7. Using the arrow buttons to toggle the options, select the option you want (ªOFFº or

ªONº) and press the Enter button.

3-13Installation and Configuration

Page 34

Figure 3-9 shows you how to visually check the ink level in a cartridge.

Checking the Ink Level

Figure 3-9.

ACCESSING PENS

Press the Access Pens button to access the pen carriage when you need to replace, reseat, or

clean pens. The pen carriage will move into the platen area to allow easy access to the pens.

Each time the pen carriage moves out from its service station so that you can access the pens,

the pen nozzles are exposed to the air. If the pen nozzles are exposed to the air (except during

plotting) for more than a few minutes at a time, they are susceptible to clogging and drying.

Each time you remove a pen from its slot and then put it back, the plotter performs the pen

alignment procedure automatically.

REPLACING PENS

The pens should be replaced in response to a Pen Checking prompt or poor plot quality. Four

high-capacity ink cartridges are used in the plotter. Pen life expectancy is dependent on the

type of media and plotting mode used.

To replace the pens, perform the following steps:

Note

The four pens must be loaded in their designated pen slots in the carriage.

Use the color label on the cartridges and color dots on the carriage to match

positions. The plotter should be powered on when changing pens. If you selected ªService pensº from the display, skip step 1.

3-14 Installation and Configuration

Page 35

1. Press the Access Pens button. The pen carriage moves out from the pen service sta-

tion at the left of the plotter and stops in front of the slot in the bail.

2. When the pen carriage stops and the display reads ªOpen window to access pens,º

open the window.

Note

If you don’t open the window within 30 seconds after the message is displayed, the pen carriage returns to the pen service station.

3. Refer to the plotter display. The display indicates, via flashing icon(s), which pen

position(s) is/are detected to be in need of servicing. The four icons represent the

following pen positions: outer left = Y (yellow), inner left = M (magenta), inner

right = C (cyan), outer right = K (black).

Note

In monochrome mode, only the black pen icon will appear solid, while the

remaining icons are outlined. In color mode, all pen icons will appear solid.

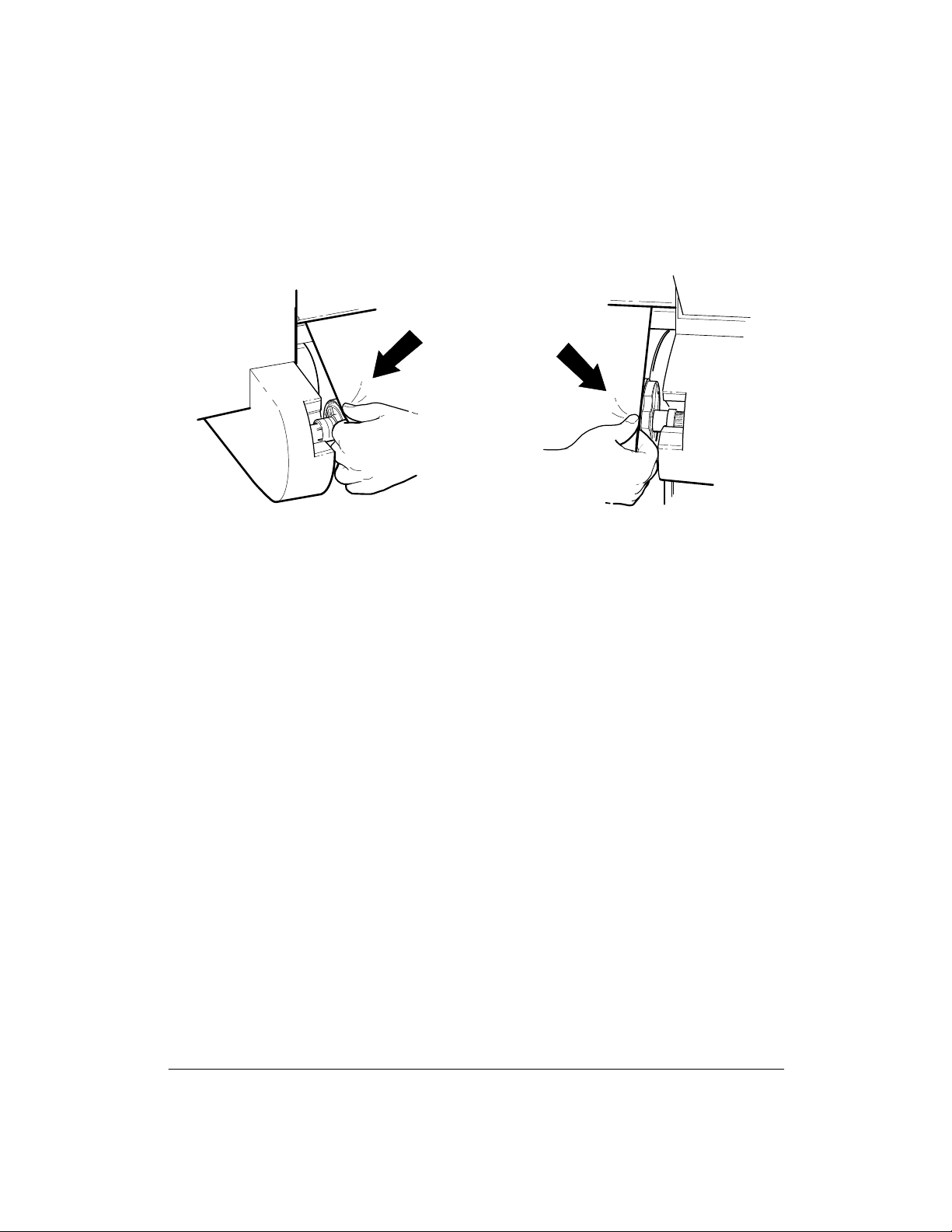

4. Place your hand on top of the pen you are replacing and press down slightly as you

pull the pen toward you. See Figure 3-10.

5. Lift the pen out of its slot.

3-15Installation and Configuration

Page 36

6. Remove the protective tape from the new pen. Insert the pen into the empty pen slot.

7. Press down slightly and push the pen away from you until it snaps into the pen slot.

See Figure 3-11.

Installing a Pen

Figure 3-11.

8. Repeat steps 4 through 7 for each pen being replaced.

9. Close the plotter window. When ªLoad media to align pensº is displayed, load good

quality media into the plotter. Special paper must be used to properly align the color

pens. The pen alignment procedure takes about three minutes to complete.

Note

The plotter tests the pens to ensure proper operation. The test runs approximately one minute and the display indicates the pens being tested. After testing, the pen alignment procedure is automatically performed. Allow the

alignment procedure to complete before resuming normal plotter operation.

SELECTABLE INK-DRYING TIMES

User-selectable ink-drying times are available on the DesignJet 650C plotters through the

front panel menus. Dry time determines how long the plotter waits before cutting the plot.

Users should be cautioned that insufficient dry time can result in plot smearing as plots are

stacked in the media bin. Dry time choices are accessible through the Plotter setup menu.

3-16 Installation and Configuration

Page 37

CONFIGURATION

FRONT PANEL CONTROLS

Plotter set-up and plot management functions are input through the front panel. The front

panel contains a 2-row by 20-character vacuum fluorescent display. Menu scrolling and implementation are accomplished through 4 menu buttons. Plotting modes are initiated through

the color/monochrome select buttons and print quality buttons. User interaction is available

through 3 pen/media action buttons. LEDs associated with various buttons are used to indicate whether the function is enabled or disabled. The front panel is shown in Figure 3-12.

message display

Cancel Form Feed/Cut Access Pens

action buttons

(L)C2858-1

Pause

Previous

Enter

Color

Mono

menu buttons

Busy

Enhanced

Final

Draft

plot mode buttons

The front panel display is used for plotter set-up and management messages including menu

selections and operator interaction messages. It also provides various plotter status messages

and error messages. The Busy LED is lit whenever the plotter is processing information.

3-17Installation and Configuration

Page 38

Front panel controls and LEDs are described below.

Menu buttons:

Previous

Use the Previous button to move to the

next highest level and to return to the

ªStatusº display.

Use the up-arrow and down-arrow buttons

to scroll through menu options or respond

to action or error messages.

Enter

Use the Enter button to activate the

current menu option, access additional

submenus as indicated and to enter

(L) C2847-1a

the first level of the menu structure

from the ªStatusº display.

Plot Mode (Color/Mono and print quality) buttons:

Plotter set to plot in Enhanced, Final or Draft

modes. LED will be lit for mode selected. Sets the

resolution quality parameter for the media type

being used.

Select Color mode or Mono (black and white) mode.

Color

Mono

Enhanced

Final

Draft

Plot Type Media Type Print Quality Resolution (dpi) #Passes Pass Density

Mono Paper Draft

Final

Enhanced

Mono Trans/Vel Draft

Final

Enhanced

Mono Film Draft

Final

Enhanced

Color Special Draft

Final

Enhanced

300 addressable

300 addressable

600 addressable

300 addressable

300 addressable

600 addressable

300 addressable

300 addressable

600 addressable

300 addressable

300 addressable

600 addressable

1 50%

1 100%

2 50%

1 50%

2 50%

4 25%

2 50%

2 50%

4 25%

1 50%

1 100%

2 50%

3-18 Installation and Configuration

Page 39

Action buttons:

Cancel stops current

operation (plotting,

accuracy calibration,

pen alignment and

media loading).

Form Feed/Cut advances the page and,

if roll media, cuts it.

Cancel Form Feed/Cut Access Pens

Pause

Access Pens brings the pen carriage out to the

plotting area for pen access. (Plotter window

must be closed).

Pause stops plotter after

plotting current drawing.

Press again to continue.

To select and confirm a menu option, do the following:

1. Press the Enter button to move from the ªStatusº display to the menu structure.

2. Press either the up ( = ) or down ( Ο) arrow button to review the options at the current

menu level.

3. When the menu or option you want is displayed, press the Enter button.

4. Repeat from step 2 to reach the next level or sublevel of options you want to set.

Note

Many menus contain subgroups of plotter options. Pressing Enter then dis-

plays the next level of options. When you have reached the final level of

your option, pressing Enter confirms your menu selection or value. In many

instances, your choice is saved in the plotter’s continuous memory. This

means it is not erased or reset when you turn OFF the plotter.

To exit to a previous menu, press the Previous button. Continuous pressing of the Previous

button will move you to higher levels of the menu structure until you reach the ªStatus’ display. If you are in a menu that has variables, pressing Previous returns you to the previous

menu without changing any values or without saving any menu changes. You can confirm

menu changes only by pressing Enter.

3-19Installation and Configuration

Page 40

FRONT PANEL MENUS

There are seven main menus, each with an option or series of submenus. Pressing the Enter

button from the ªStatusº display will access the menu structure. Both a short menu and a full

menu are available in the plotter display. The short menu is the default menu and displays the

more commonly used menus. Changing to the short or full menu (Menu mode submenu) is

accessed through the ªUtilitiesº main menu.

A brief description of the main menus is given below.

Plot Management Controls plot file management in the queue including queueing,

nesting and number of copy specifications.

Page Format Specifies the size, orientation and margins for the plots.

Pen Settings Defines the pen attributes including the palette which contains

individual pen width and shading/color settings. Two custom

palettes of 16 pens each can be defined and stored by the user.

Plotter Setup Defines basic operating setup including graphics language, dry

time, pen checking and media bypass conditions.

I/O Setup Controls plotter I/O configuration and interaction with the

controller. For configuring the RS-232 and MIO interfaces and

parameters. Two user customized RS-232 configurations can be

stored in memory.

Demo Plot Accesses the internal demonstration plot routine.

Utilities Accesses accuracy calibration procedures. Also contains front

panel menu configuration information, plotter statistic information

(plot size, memory size, firmware revision level, ROM SIMMs

present) and default menu options.

Complete information on using the various menu and submenu options is contained in the HP

C2858A and C2859A DesignJet 650C Using Your Plotter’s Front Panel Guide. Additional

setup information is available in the DesignJet 650C Setting Up For Plotting Guide. Refer to

Chapter 1 in this manual for more information regarding these guides.

Figure 3-12, located at the end of this chapter, provides a diagram of the menu tree showing

the various menus and submenus of the DesignJet 650C plotters. Both the short and full menu

structures are presented on the diagram.

3-20 Installation and Configuration

Page 41

FRONT PANEL LANGUAGES

DesignJet 650C plotter menus and messages can be configured to display in English, French

(ªFrancaisº), German (ªDeutschº), Spanish (ªCastell.º), Italian (ªItalianoº), Portuguese

(ªPortugueseº) and Japanese (Katakana) characters.

To change the display language, or if the display is in a language you cannot understand, use

the following procedure to get to a language you do understand.

1. Turn the plotter OFF.

2. Press and hold down the Enter button while turning the plotter ON. Release the

Enter button.

3. Using the arrow buttons, scroll to the desired language to be displayed and press the

Enter button.

3-21Installation and Configuration

Page 42

FRONT PANEL MESSAGES

In addition to the menus that appear in the front panel display, three types of messages may

also appear in the display. They are state messages, action messages, and error messages.

State messages do not require any action and serve to notify the user of any current plotter

actions occurring. State messages are listed in Table 3-2. Action messages do require user

interaction. Typically the user is prompted to press a button, move a lever or load pens or

media. Action messages are listed in Table 3-3. Error messages indicate that either a user error or internal plotter error has occurred. Some error messages require user action to clear and

others are only displayed until the next operation is performed by the plotter. Error messages

and their recommended actions are a part of the troubleshooting information presented in

Chapter 8 of this manual.

Table 3-2. State Messages

Message

Accessing pens You have pressed the Access Pens button. The pen carriage is moving out

Aligning pens Machine is aligning pens.

Cancelling You have pressed the Cancel button and the plotter is in the process of

Checking media Machine is checking to see if media is properly positioned with respect

Creating

calibration plot

Ink drying

(xxx seconds)

Loading roll Machine is loading roll media.

Loading sheet Machine is loading sheet media.

Measuring plot Machine is measuring the accuracy calibration plot you just loaded.

Pen palette

loaded

State

so you can access it.

cancelling the procedure. You may continue when this message is no

longer displayed.

to the perforated line of the entry platen.

Machine is performing accuracy calibration.

The ink on your plot is drying. Wait the indicated number of seconds before removing the plot. If you need to remove it before the indicated time

has passed, use caution to avoid smearing the ink.

The pen palette you just entered (Palette A, Palette B, or Factory) has

been loaded.

3-22 Installation and Configuration

Page 43

Message State

Table 3-2. State Messages (Continued)

Pen palette

saved

The pen source, pen number widths, and pen number shades you just entered have been saved as either Palette A or Palette B (whichever you

specified).

Returning pens The pen carriage is returning to its station at the left of the plotter.

Roll feed

Machine is trimming the edge of roll media.

Edge trim

RS-232 config

loaded

RS-232 config

saved

The RS-232-C configuration you just entered (Config A, Config B, or

Factory) has been loaded.

The baud, handshake, and parity settings you just entered for your

RS-232-C configuration have been saved as either Config A or Config B

(whichever you specified).

STATUS

Machine is doing internal checking upon power-up.

Initializing

STATUS

Out of media

STATUS

The plotter has detected that the roll is empty (you must be in Roll mode

for this to happen). If desired, remove the old roll and insert a new one.

Machine is plotting.

Plotting

STATUS

Machine is ready for you to load media.

Ready for media

STATUS

Machine is ready to plot.

Ready to plot

STATUS

Machine has received plot data.

Receiving

Testing pens The machine is testing the pens for problems, i.e., clogged pen or bad

electrical connection (improper seating).

3-23Installation and Configuration

Page 44

Message Action

Special Media

Mono Media

Calibrate done

Press Up Arrow for Color plotting on Special (CX) paper.

Press Down Arrow for Monochrome plotting.

Accuracy calibration is complete. Press Down Arrow to continue.

Continue

Can’t replot

Resend plot

Close roll cover

Continue

Create plot

Measure plot

Replot buffer doesn’t have enough memory to hold the entire plot. Resend the plot.

Rewind the media to take up any slack in the roll, close the roll cover,

then press Down Arrow to continue.

Press Up Arrow to create a calibration plot.

Press Down Arrow to measure a calibration plot.

Lift lever Lift the media lever at the right of the plotter.

Load arrow edge

print side down

Load cancelled

Remove media

Load media

Remove accuracy calibration plot, turn it so that the edge with arrows

printed on it is print side down, then load that edge into the plotter.

You pressed the Cancel button while media loading was in progress.

Remove media.

Load media to proceed with pen alignment.

to align pens

Lower lever

after aligning

Lower window

to continue

Open window to

When you’ve finished aligning the roll media as instructed, lower the

media lever at the right of the plotter.

You have lifted the window while the processor is busy. Close the win-

dow to continue.

Lift the window to access the pens.

access pens

Pen alignment

Close the window to proceed with pen alignment.

Close window

Power OFF

Y-Axis servo shutdown. Troubleshoot and repair.

Check Pen Path

Power OFF

X-Axis servo shutdown. Troubleshoot and repair.

Check Paper Path

3-24 Installation and Configuration

Page 45

Message Action

Pull / Align

edges to roll

Remove media

Continue

Replace

Y, C, M, K pen

Reseat

Y, C, M, K pen

Sheet load

Roll load

Sheet / Roll?

Reload media

Grasp the left and right free edges of the roll media and pull toward

you until the media is taut. At the same time, align the left and right

edges of the media so that they are flush with the left and right edges of

the roll.

Ink is dry; you can remove the accuracy calibration plot the plotter just

produced. Press Down Arrow to continue with accuracy calibration.

Y, C, M, or K pen has a clogged nozzle. You must replace the defective

pen to continue. Defective pen position is indicated by a flashing icon

in the display.

Y, C, M, or K pen has not made proper contact in the pen slot. Remove

the appropriate pen and reseat it in the slot. Defective pen position is

indicated by a flashing icon in the display.

Press Up Arrow to load sheet media.

Press Down Arrow to load roll media.

You have chosen Sheet mode while loading roll media. Reload media.

You have loaded a sheet more than 51 inches (130 cm) long. Trim

sheet and reload.

3-25Installation and Configuration

Page 46

OPERATIONAL VERIFICATION

DesignJet 650C plotters contain several types of internal operational checks and tests to ensure that the plotter is properly functioning and to help identify problems if any are detected.

POWER-ON SELF-TEST

Whenever the plotter is switched ON, it automatically performs a series of internal self-tests

and initialization sequences which check the basic electrical and mechanical functions of the

plotter. Among the items checked are the processors, motors and sensors. If an error is detected, a message or system error code will be visible in the front panel display. Error codes

and messages are presented in Chapter 8 of this manual. Self tests are listed in Chapter 8.

DEMONSTRATION PLOT

Two demonstration plot samples are resident in the HP DesignJet 650C plotters. Proper plotter operation can be checked through use of the demo plots. The demo plots show different

plotter capabilities including pen line widths and shading. The demo plot can be set to plot in

any of the available front panel languages.

To plot a demo plot, perform the following steps:

1. Turn the plotter ON and load a sheet of media.

2. From the ªStatusº display, press the Enter button.

3. Using the arrow buttons, scroll to the ªDemo plotº main menu display.

4. Press the Enter button.

5. Using the arrow buttons, scroll to select either the Sample or Palette demo plot.

6. Press the Enter button.

7. The ªBusyº LED will light indicating that the demo plot is being accessed.

8. The demonstration plot will be plotted.

3-26 Installation and Configuration

Page 47

Chapter 4 Preventive Maintenance

INTRODUCTION

This chapter contains information on keeping the HP C2858A and C2859A DesignJet 650C

plotters in good operating condition. Included are general cleaning procedures to be performed by the user.