Page 1

Introduction

This User’s Reference Guide explains how to use your D/A1 size or A0+/E+ size HP Designjet 500 Plus Printer.

The Introduction Tab contains these topics:

• Introducing the Documentation

Introduces your printer’s documentation.

• Introducing Your

Contains a brief overview of the printer. It contains information about the printer’s features and what is

included with the printer.

• Front View of Printer

Contains a view of the front of the printer showing the location of the printer’s consumable items.

• Printer Connections

Shows all the connections to the printer: power, parallel interface, USB and optional network interface.

HP Designjet 500 Plus Printer

Page 2

Introducing the Documentation

You have the following resources to help you in using your HP Designjet 500 Plus printer.

•The Assembly and Set-up Poster comes with your printer and shows step-by-step information on how to

prepare your printer for use.

•This User’s Reference Guide explains the

details of using your printer. For more day-to-day

guidance you can refer to the Pocket Guide.

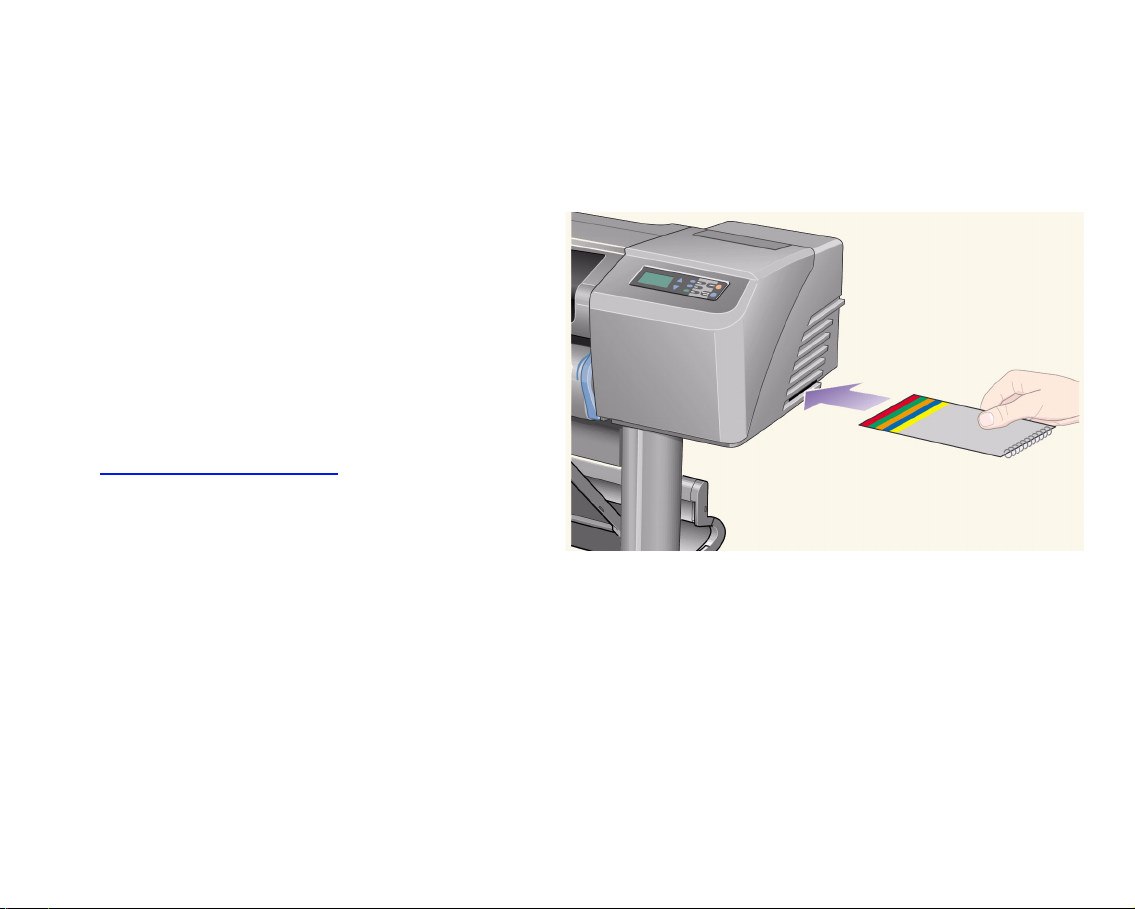

•The Pocket Guide can be found in a slot on the

right-hand side of the printer (as shown). It gives

information that you are most likely to need for

printer operation on a daily basis, such as

loading paper or replacing ink supplies.

• You can also visit us on our Web page:

www.hp.com/go/designjet

.

Pocket Guide location

Page 3

Introducing Your HP Designjet 500 Plus Printer

• Your Printer’s Main Features

A general overview of the major features of your printer.

• HP Ink Supplies

A description of the HP Ink Supplies required for your printer.

• Print Resolution

Specifications of the print resolution for your printer.

• Media

A description of the different types of media available for your printer.

• User Interface

A description of the printer’s user interface.

• Memory

Details of internal memory and memory options available with your printer.

• Drivers

Details of the drivers delivered with your printer.

Page 4

Your Printer’s Main Features

The HP Designjet 500 Plus printing system is specially designed for individuals or small work-groups in

Architecture, Engineering and Construction (AEC) and mechanical CAD design.

For the complete printing solution, HP also offers a wide range of media including HP Heavyweight Coated Paper

with fade-resistant photo-quality output and HP High-Gloss Photo Paper for high-quality long-lasting prints that

produce a professional look and feel. And with the HP Complementary Media Program, HP provides users with a

wide spectrum of choice and flexibility in their media selection.

The HP Designjet 500 Plus printer comes in two sizes: A0+/E+ size (42 inches/1066.8 mm) and D/A1 size

(24 inches/609.6 mm) models. Both models have roll-feed capabilities and come with an HP-GL/2

Card. The A0+/E+ size model also includes legs and a media bin.

• Ultimate Photo Image Quality and Excellent Line Quality: The HP Designjet 500 Plus printer delivers ultimate

line quality with a true resolution of 1200×600-dpi, using HP’s color layering technology, which layers multiple

color ink drops on a single drop, on coated paper. This excellent line quality is achieved due to the fact that

each one-half inch/12.7mm printhead contains 304 nozzles, producing miniscule 18-picoliter black pigmented

ink drops and four picoliter color dye-based drops, that are idea for engineering and architectural applications.

In addition, the HP Designjet 500 Plus printer delivers excellent photo quality for renders and photographs,

providing continuous tones and smooth transitions.

• Unattendedness: The HP Designjet 500 Plus printing system includes a modular ink delivery system, with

69-cc cartridge capacity, and long life printheads which last, on average, through ten black ink cartridges and

six color ink cartridges, depending on use. This modular system allows users to replace individual ink supplies

separately, as needed and also provide automatic alignment and cutting and stacking of finished prints in the

media bin, enabling continuous and unattended printing. In addition, the HP Designjet 500 Plus printer

includes smart chips that are embedded into each individual printhead and ink cartridge that alert the user if it

time to replace the printhead and continuously monitor ink levels.

• Ease-of-use: The HP Designjet 500 Plus printing system is a true out-of the box solution and provides the

user with everything he or she needs to install and use the printer. The HP Designjet 500 Plus printer

includes a control-display panel for simple navigation, straightforward media loading and easy-to-install

drivers.

More…

Accessory

Page 5

• HP Premium Printing Material: The HP Designjet 500 Plus A0+/E+ size and D/A1 size printing systems

accept a wide range of roll and sheet media from 24 inches/609.6 mm (D/A1 size) to 42 inches/1066.8 mm

(A0+/E+ size) wide including HP Satin Poster Paper, HP High-Gloss Photo Paper and HP Heavyweight

Coated Paper. In addition, the HP Designjet 500 Plus printer accepts a wide range of media for technical

applications.

• Complementary Media Program (CMP

): The CMP helps HP customers grow their businesses by referencing

third-party printing material choices to ensure maximum HP Designjet printer flexibility and printing solutions.

Page 6

HP Ink Supplies

HP Ink Supplies for your printer contain two components: printheads and ink cartridges. Your HP Designjet 500

Plus printer uses the following HP Ink Supplies:

• Black Ink Cartridges are HP No 10 Supplies.

• Cyan, Magenta and Yellow Cartridges are HP No 82 Supplies.

• All Printheads are HP No 11 Supplies.

Each 600-dpi thermal inkjet printhead applies thousands of ink droplets onto the paper. The printer automatically

refills the printhead as it prints, enabling continuous uninterrupted printing. The ink is supplied to each printhead

from a separate large capacity ink cartridge.

There is more information available in a pamphlet which comes with the printheads and in Print Times for a

Selected Print Quality.

Page 7

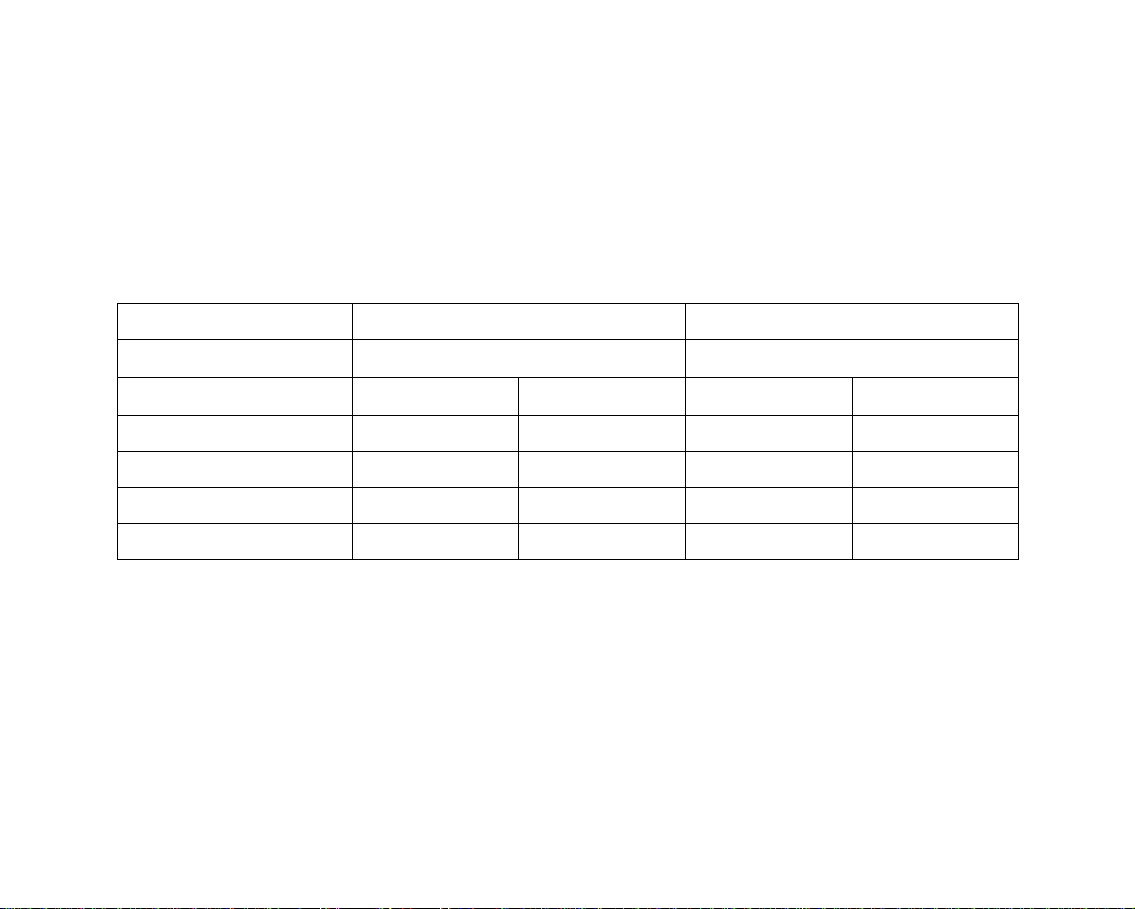

Print Resolution

Your HP Designjet 500 Plus printer provides two different print modes that change the print resolutions of each of

the print quality modes. These different print modes are optimized for: Line Drawings/Text or Images.

You can then choose between three levels of print quality for each of the print modes: Best, Normal or Fast from

your software or from the printer's front panel.

With the best mode selected you have an additional selection available to provide maximum detail for your printed

image by increasing the resolution of your job above the default resolution.

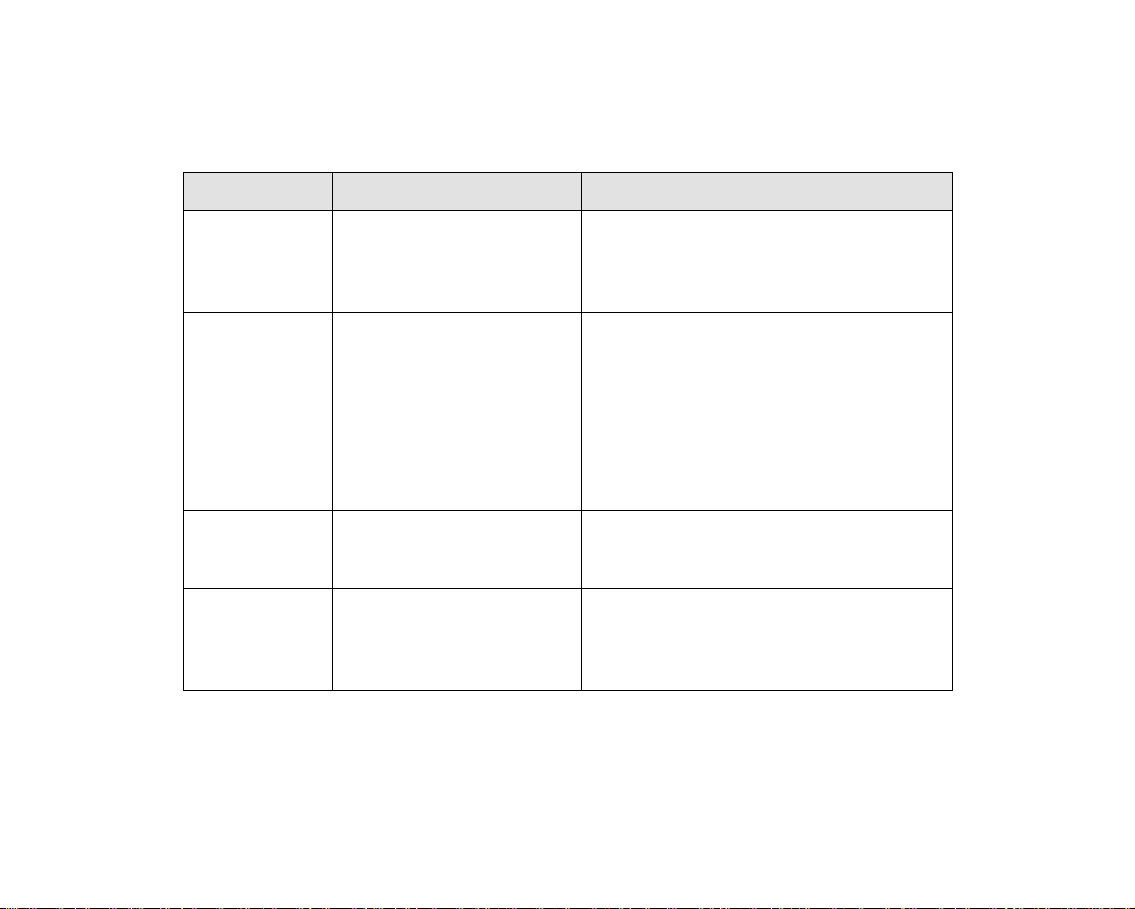

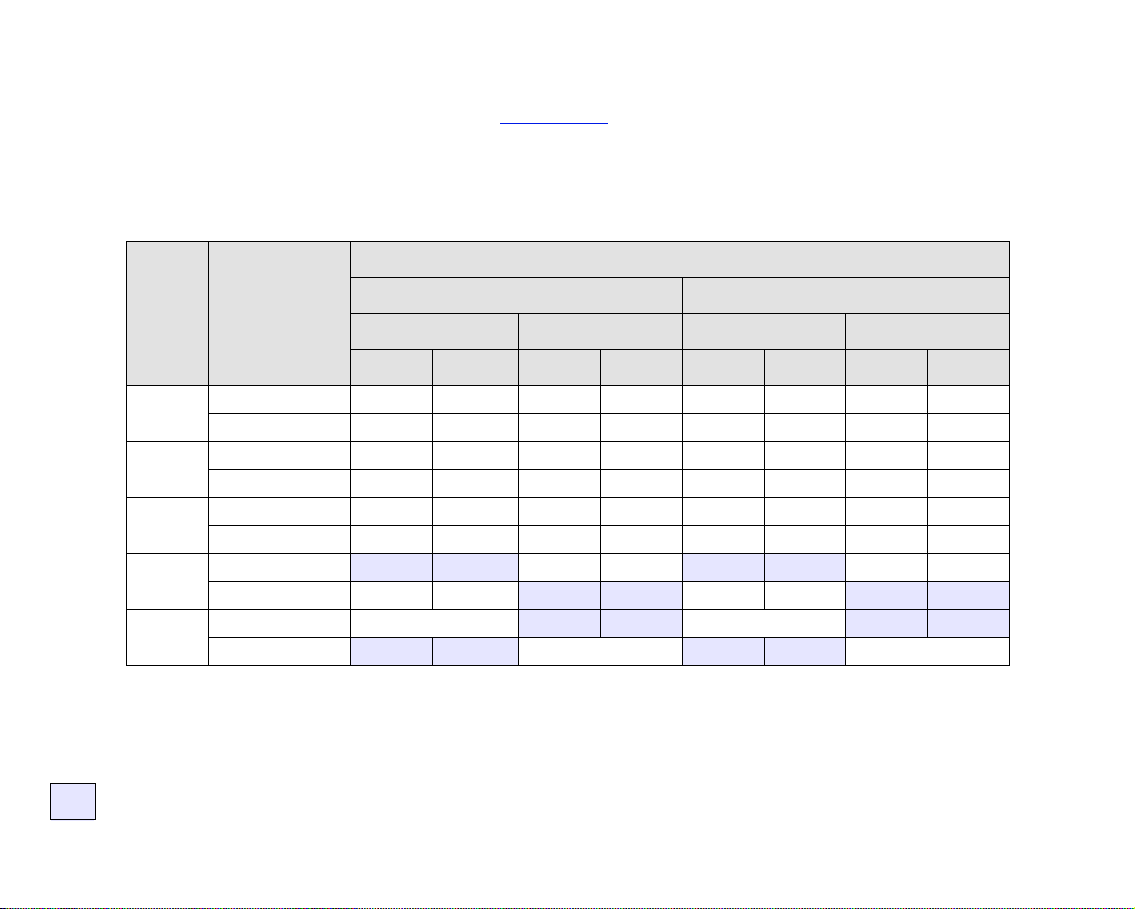

Print Quality Setting Optimized for Line Drawing/Text Optimized for Images

Resolution in dpi Resolution in dpi

Re0×nder Halftone Render Halftone

Fast 300×300 600×300 150×150 600×300

Normal 600×600 600×600 300×300 600×600

Best (default) 600×600 600×600 600×600 600×600

Best (maximum detail) 600×600 1200×600 600×600 1200×600

Use Fast to get draft copies of your prints at maximum throughput. Normal is optimized so that you get the best

line quality with the fastest throughput. Select Best if you want to get the best quality for images and renderings.

Page 8

Media

You can print on roll media or sheet media up to 42 inches (1066.8 mm) wide with the A0+/E+ size HP Designjet

500 Plus printer and up to 24 inches (609.6 mm) with the D/A1 size model.

The following media types are supported on the HP Designjet 500 Plus printer:

• HP Bright White Inkjet Paper (Bond) • HP Paper-Based Semi-Gloss

• HP Vellum • HP Clear film

• HP Natural Tracing Paper • HP Translucent bond

• HP Coated Paper • HP Studio Canvas

• HP Heavyweight Coated Paper • HP Satin Poster Paper

• HP Matte film • HP Banners with Tyvek®

• HP High-Gloss Photo Paper • HP Colorfast Adhesive Vinyl

• HP Semi-Gloss Photo Paper

Page 9

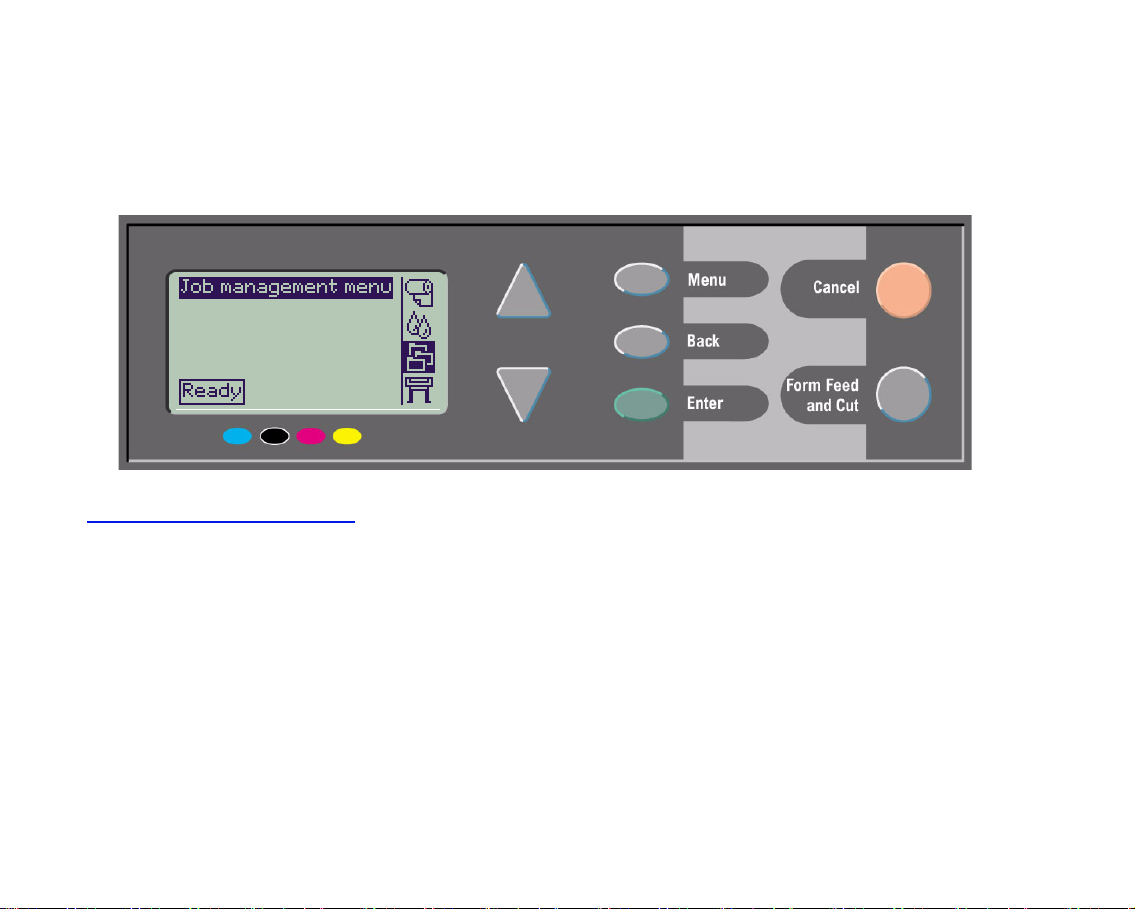

User Interface

The printer’s front panel includes an easy-to-use interface with a display, giving you access to a comprehensive

set of printer functions.

See Navigating the Menu System

description of internal prints.

, for a short tutorial to teach you how to navigate through the menus and a

Page 10

Memory

The D/A1 size and A0+/E+ size HP Designjet 500 Plus printers come with 32 MB of internal Random Access

Memory (RAM). Additional memory can be added to the HP-GL/2

can add 64 MB (part number C2387A) or 128 MB (part number C2388A) of memory for large file processing and

improved printing.

Accessory card that came with your printer. You

Page 11

Drivers

Always use the right driver (configured correctly) for the combination of your application software and your printer

to ensure that your printer prints exactly what you were expecting in terms of: size, position, orientation, color and

quality.

NOTE: Many software applications include their own drivers.

Your HP Designjet 500 Plus printer comes supplied with:

• Windows drivers

• Mac OS X drivers

• AutoCAD drivers for Windows

NOTE: If AutoCAD drivers are available for the specific AutoCAD release you are using, it is strongly

recommended that you install them to print from AutoCAD.

Page 12

Front View of Printer

Ink Cartridge

Power

Switch/Indicator

Printhead

Front Panel

Page 13

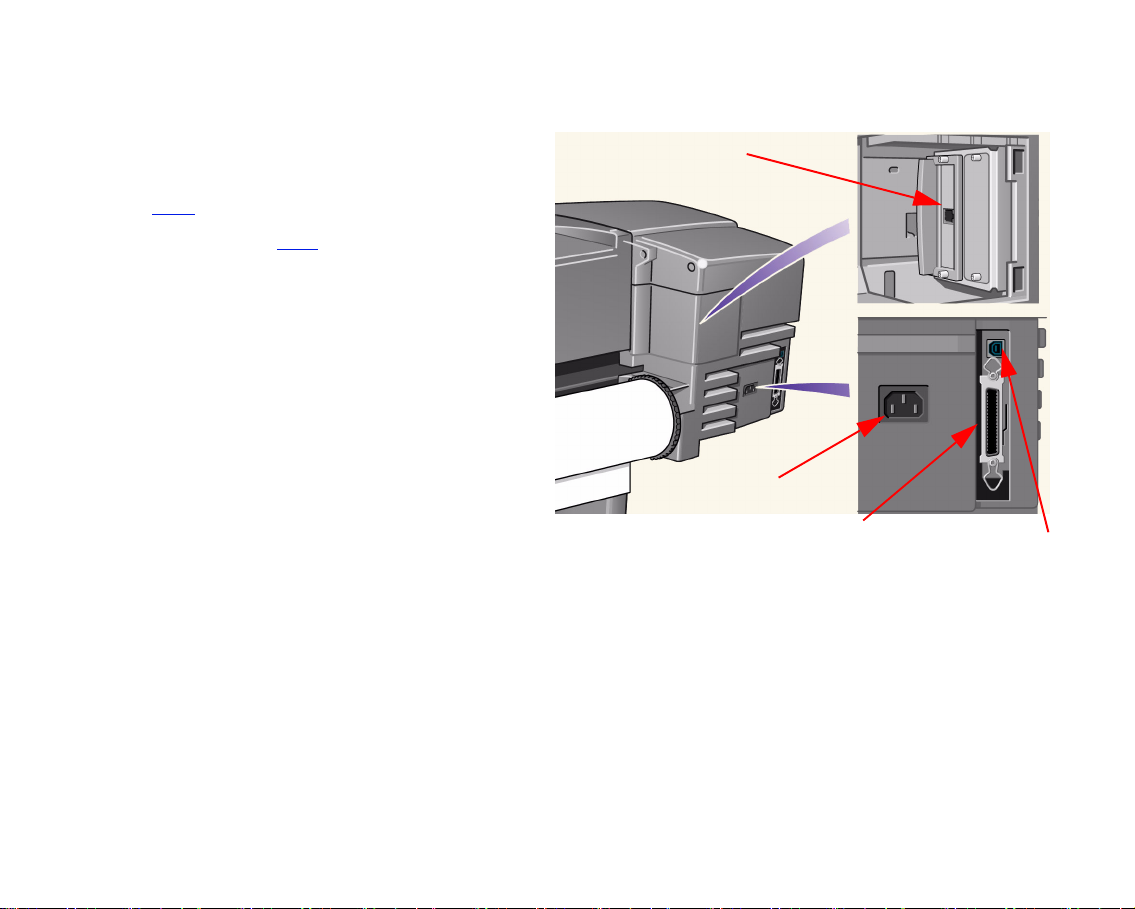

Printer Connections

Your HP Designjet 500 Plus printer can be

connected directly to your computer via the

traditional parallel interface or through the Universal

Serial Bus (USB

For Local Area Network (LAN

printer can be fitted with an optional HP JetDirect

Print Server Fast Ethernet 10/100 base TX network

interface card.

See the Assembly and Set-up Poster for information

on connecting your printer to a computer or network.

) port.

) connection your

Connection

Power socket

Parallel Port

USB Connection

Page 14

Media & Ink

The D/A1 size and A0+/E+ size format HP Designjet 500 Plus Printers use a variety of media. The

recommended media are engineered to use with your printer and your printer’s ink system to give you the best

results.

The Media & Ink Tab contains these topics:

• Media Choice

needs is an essential step in ensuring good image quality.

• Roll Media

• Sheet Media

• Ink System

optimum use.

• Ink Cartridges

replacing ink cartridges.

• Printheads

and aligning printheads.

explains how to choose the correct media type. Choosing the correct paper type for your

details the procedures used for loading and unloading your roll media.

details the procedures used for loading and unloading your sheet media.

gives you an overview of the printer’s ink system, with some warnings and precautions for its

details the procedures used for: obtaining information, interpreting errors, checking levels and

details the procedures used for: obtaining information, interpreting errors, replacing printheads

Page 15

Media Choice

• Choosing Paper or Other Media

Your printer supports several types of paper. Choosing the best paper type for your needs is an essential

step in ensuring good image quality. These topics help you to select the best media for your particular

printing task.

• Paper Types

Detailed information concerning the different types of media available for your printer. This includes

information on: the types of paper supported, their physical characteristics, quality selection, handling and

how to obtain information.

• Print Times for a Selected Print Quality

Typical Printing Times for color and black lines and images on different types of paper.

• Printable Area

The dimensions for all the printable areas for all paper and other types of media formats.

Page 16

Choosing Paper or Other Media

For best printing results, use only genuine Hewlett-Packard paper or other type of media, whose reliability and

performance have been developed and thoroughly tested. All Hewlett-Packard printing components (printer, ink

system, and paper/other media) have been designed to work together to give trouble-free performance and optimal

image quality. For detailed information on Hewlett-Packard paper, see Paper Types

You should also take note of some important points about paper and other types of media:

• This printer supports many types of paper. However, the quality of some images may be reduced if you do not

use the correct paper for your application. For example, images with large regions of intense color, where

many ink drops are needed to fully saturate the color, will not print well on HP Bright White InkJet Paper. On

HP Coated paper

printheads, smearing your print and risking damage to the printhead. See Combinations of Media Type and

Print Quality Selection.

• Whenever you load a roll or a sheet, the printer’s front-panel display prompts you to specify the paper type

you are loading. It is absolutely essential to specify this correctly for good image quality. The Physical Charac-

teristics of Paper Types table gives you all the information you need. If paper is already loaded and you are

unsure which paper type was specified, go to the Paper Menu and press Enter; see Obtaining Roll or Sheet

Paper Information.

• Make sure the appropriate print-quality setting (Best, Normal or Fast) is selected. You can set the print qual-

ity either from your software or from the printer’s front panel (software driver settings override any print-quality

settings made on the front panel). The combination of paper type and print-quality settings tells the printer

how to place the ink on the paper—for example, the ink density, dithering method, and number of passes of

the printheads. For more details, see Combinations of Media Type and Print Quality Selection

• Included with this printer is the Hewlett-Packard Printing Materials catalog which gives ordering details for

Hewlett-Packard paper supplies. To get the latest version of this document, contact your local Hewlett-Packard Sales and Support office.

, the same images might cause the paper to wrinkle and then come into contact with the

.

.

Page 17

Paper Types

The following topics address the various types of media available, their particular use and how to obtain

information about them.

• Physical Characteristics of Paper Types

Details the physical characteristics of each of the supported paper types.

• Combinations of Media Type and Print Quality Selection

Gives guidelines for selecting the correct Print Quality selection for the type of paper or other type of media

you are using.

• Handling Your Paper or Type of Media

Explains the precautions to take when handling paper or other type of media.

• Obtaining Roll or Sheet Paper Information

Page 18

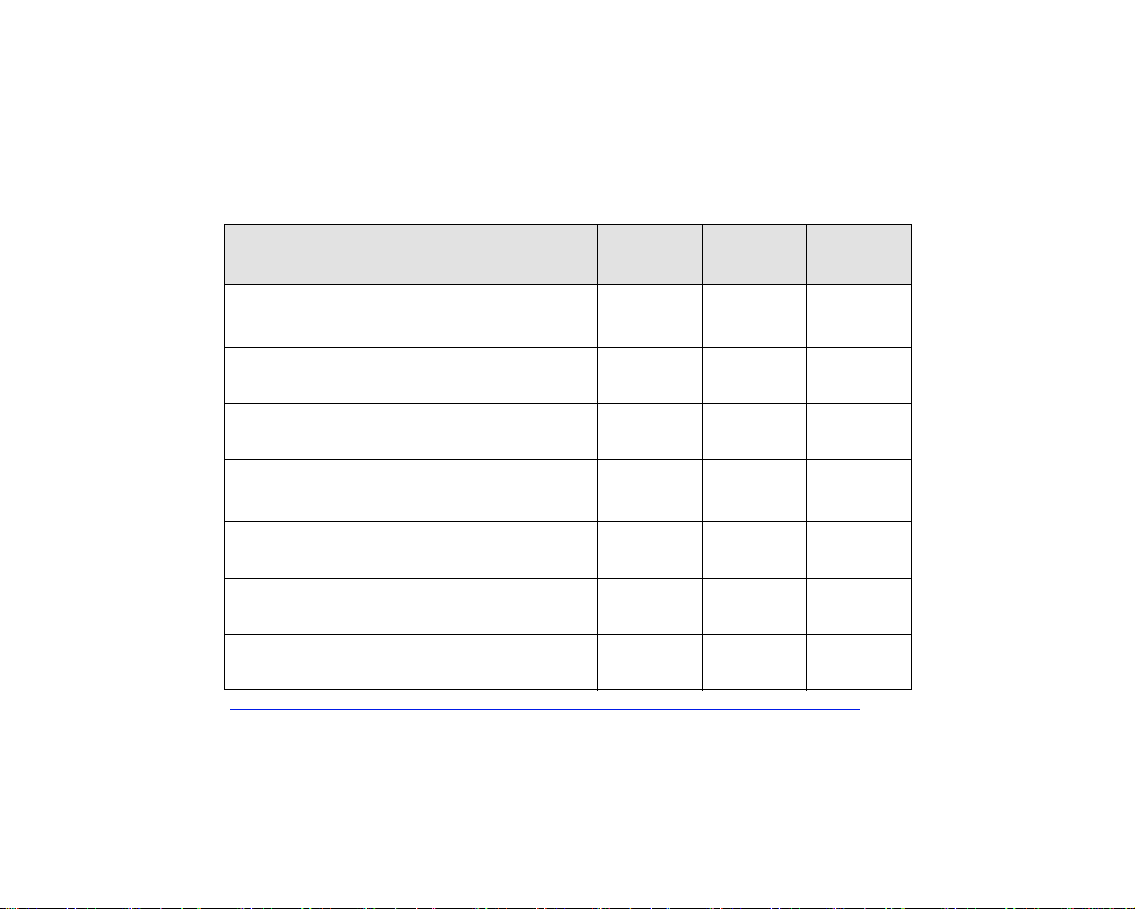

Physical Characteristics of Paper Types

The following table lists the physical characteristics and selection numbers of supported HP Premium Printing

Material. Always print on the image side with the special coating. Image side faces outward on roll products from

Hewlett-Packard.

Physical Characteristics of Paper and Other Media

HP Premium Printing Material

HP Bright White Inkjet Paper (Bond)

24 lb. (90g/m2) - 150 ft. (45m)

24 inch

610 mm

C1860A

C6035A

a

b

36 inch

914 mm

C1861A

C6036A

42 inch

1067 mm

a

b

HP Vellum C3862A C3861A

3 mil (75g/m2) - 150 ft. (45m)

HP Natural Tracing Paper C3869A C3868A

3 mil (90g/m2) - 150 ft. (45m)

HP Coated Paper C6019B C6020B

26 lb. (98g/m2) - 150 ft. (45m)

C6559B

C6567B

HP Heavyweight Coated Paper C6029C C6030C C6569C

35 lb. (130g/m2) - 100 ft. (30m)

HP Matte film 51642A 51642B

5 mil (198g/m2) - 120 ft. (36m)

HP High-Gloss Photo Paper C6813A C6814A

8 mil (207g/m2) - 100 ft. (30m)

Click on the Next Page Icon to see more Paper and Other Media Types

a

b

Page 19

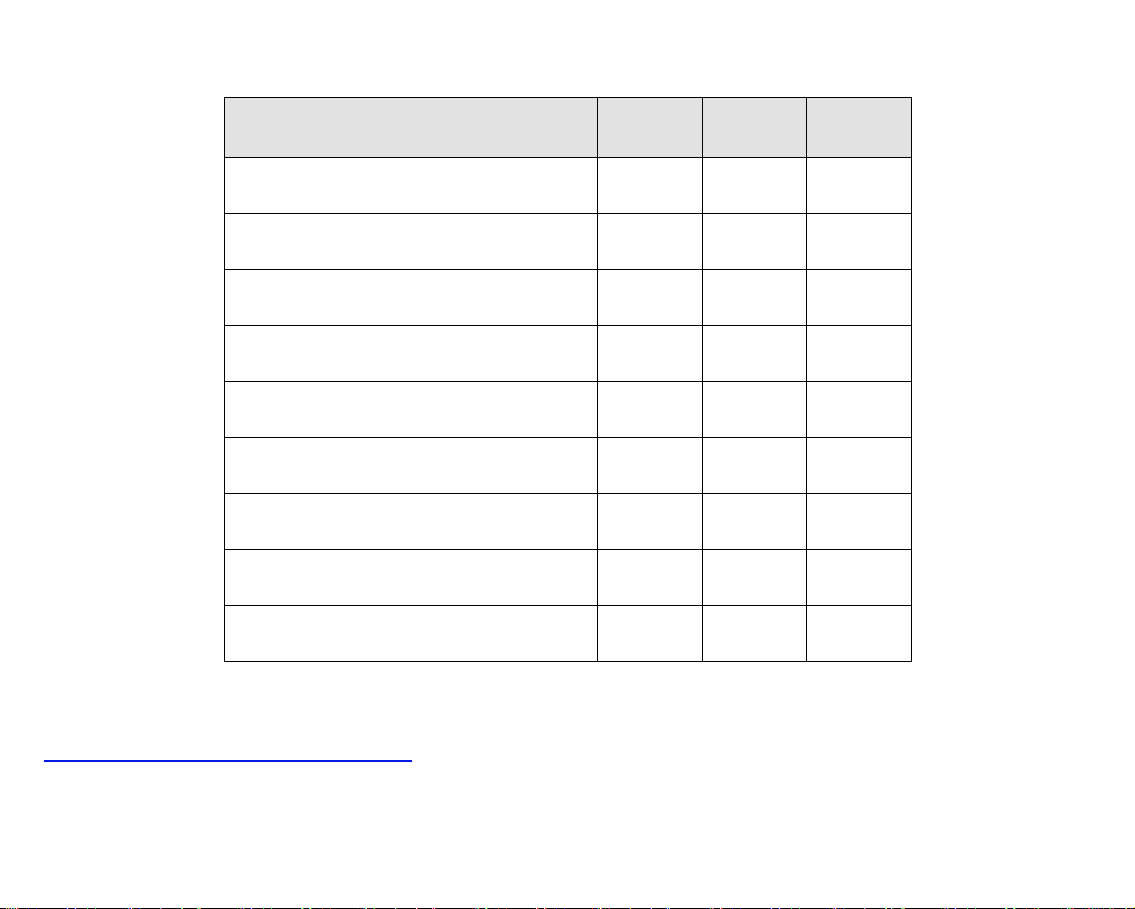

Physical Characteristics of Paper and Other Media (Continued)

HP Premium Printing Material

HP High-Gloss Photo Paper C3882A C3881A

6 mil (158g/m2) - 100 ft. (30m)

HP Semi-Gloss Photo Paper C3884A C3883A

6 mil (158g/m2) - 100 ft. (30m)

HP Paper-Based Semi-Gloss C6782A C6783A

6 mil (158g/m2) - 100 ft. (30m)

HP Clear film C3876A C3875A

4 mil (174g/m2) - 75 ft. (22m)

HP Translucent bond C3860A C3859A

3 mil (67g/m2) - 75 ft. (45m)

HP Studio Canvas C6771A

20 mil (368g/m2) - 35 ft. (10m)

HP Satin Poster Paper C7011A

5.5 mil (162g/m2) - 100 ft. (30m)

HP Banners with Tyvek® C6786A C6787A

10 mil (140g/m2) - 50 ft. (15m)

HP Colorfast Adhesive Vinyl C6775A

10 mil (140g/m2) - 50 ft. (15m)

a. Available in United States, Canada and Latin America

b. Available in Europe, Asia and Japan

24 inch

610 mm

36 inch

914 mm

42 inch

1067 mm

Additional Information About Paper Types

Page 20

Additional Information About Paper Types

The following HP Premium Printing Material can be used to perform the printhead alignment, see Printhead

Alignment.

• HP Bright White Inkjet Paper (Bond)

• HP Coated Paper

• HP Heavyweight Coated Paper

• HP High-Gloss Photo Paper

• HP Satin Poster Paper

You can also use Plain Paper in addition to the above.

To order any of the HP Premium Printing Material, see the pamphlet Hewlett-Packard Printing Materials.

From time to time, new paper types may become available. For up-to-date information, please contact your

Hewlett-Packard dealer, local Hewlett-Packard Sales and Support Office or the Designjet Online

Web site.

Page 21

Combinations of Media Type and Print Quality Selection

Use the following tables, given by application, to guide you when choosing your paper and selecting the print

quality setting (Fast, Normal, Best).

• CAD Drawings—Mono

• CAD Drawings and GIS—Color (Lines and low density)

• CAD Rendering, GIS and Images—Color and CAD (high ink density).

As a general guide:

• Fast is best for draft copies of your prints at maximum throughput

• Normal is optimized so that you get the best line quality with the fastest throughput

• Best is for when you want to get the best quality for images and renderings.

Page 22

CAD Drawings—Mono

The following table lists the recommended print quality settings for specific usage with typical media.

Supported Paper Types—Mono

Usage Typical Media Selection Recommended Print Quality Setting

Drafts Plain Paper

Bright Inkjet Paper

Natural Tracing Paper

Translucent Bond

Final Versions Plain Paper

Bright Inkjet Paper

Natural Tracing Paper

Translucent Bond

Coated paper

Heavy Coated Paper

Matte Film

Clear film

Archives Vellum

Matte Film

Clear Film

Diazo Translucent Bond

Natural Tracing Paper

Vellum

Matte Film

Fast or normal

Normal or Best

Best

Normal or Best

Page 23

CAD Drawings and GIS—Color (Lines and low density)

The following table lists the recommended print quality settings for specific usage with typical media.

Supported Paper Types—Color

Usage Typical Media Selection Recommended Print Quality Setting

Drafts Plain Paper

Bright Inkjet Paper

Natural Tracing Paper

Translucent Bond

Final Versions Plain Paper

Bright Inkjet Paper

Coated paper

Heavy Coated Paper

Matte Film

Clear film

Archives Matte Film

Clear Film

Transparencies Clear Film Normal or Best

Fast or Normal

Normal or Best

Best

Page 24

CAD Rendering, GIS and Images—Color and CAD (high ink density)

The following table lists the recommended print quality settings for specific usage with typical media.

Supported Paper Types—Color and CAD

Usage Typical Media Selection Recommended Print Quality Setting

Matte Paper Heavy Coated Paper Normal or Best

Glossy High Gloss Photo Paper Normal or Best

Transparencies Clear Film Best

Page 25

Handling Your Paper or Type of Media

Take the following precautions when handling paper or other type of media:

• Handle film and glossy paper by the edges or wear cotton gloves. Skin oils can interact with the ink and cause

it to smear.

• Although the ink systems supplied with this printer have good light fastness, colors will eventually fade or

change if exposed to sunlight over a long period of time.

• Rewrap partially used rolls if they are not being used and do not stack rolls.

• Always keep unused rolls in their plastic wrappings to prevent discoloration.

Page 26

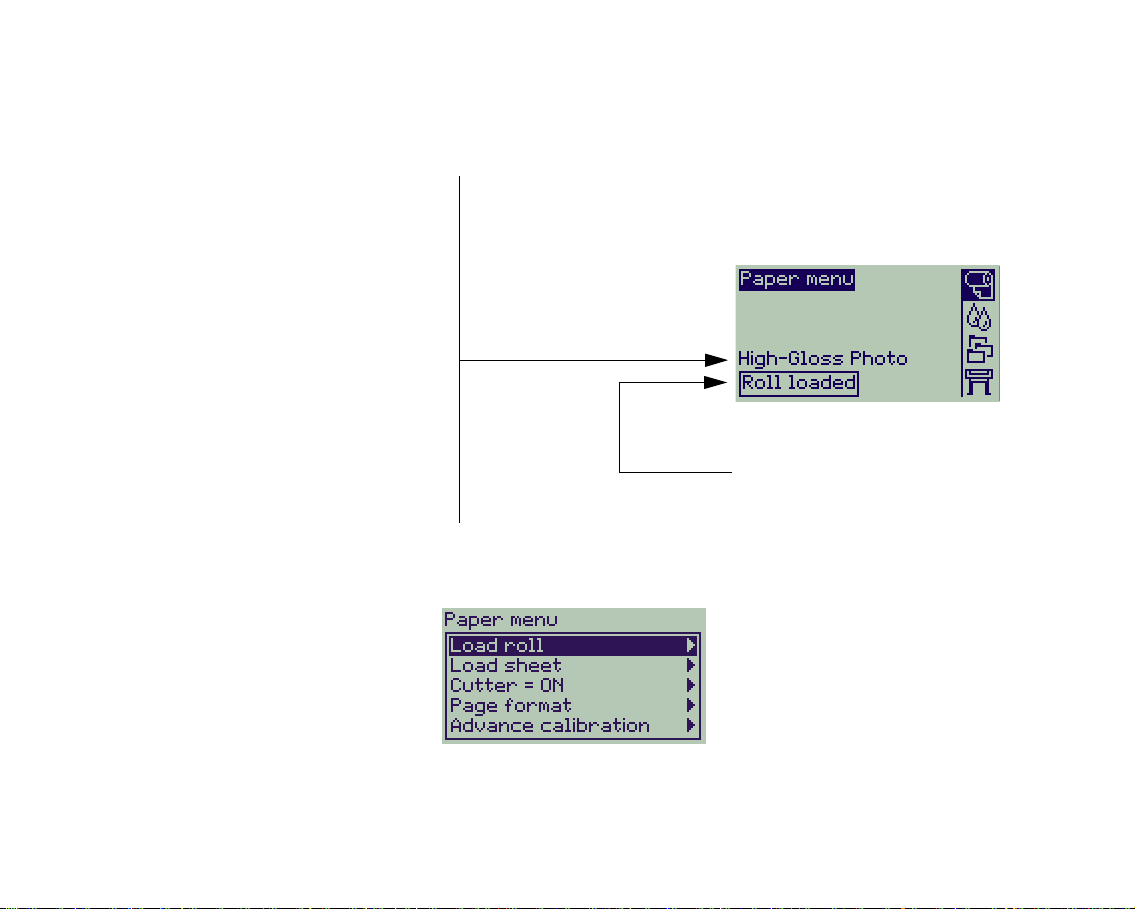

Obtaining Roll or Sheet Paper Information

If roll media or sheet media is loaded, the type of media is displayed when you select the Paper menu on the front

panel.

Bright White Inkjet Paper

Plain Paper

Vellum

Natural Tracing Paper

Translucent Bond

Clear Film

Matte Film

Coated Paper

Heavy Coated Paper

High-Gloss Photo

Canvas

Poster Paper

If there is no paper loaded the front panel display shows the following message and you will need to load roll or

sheet media.

Roll or Sheet

Page 27

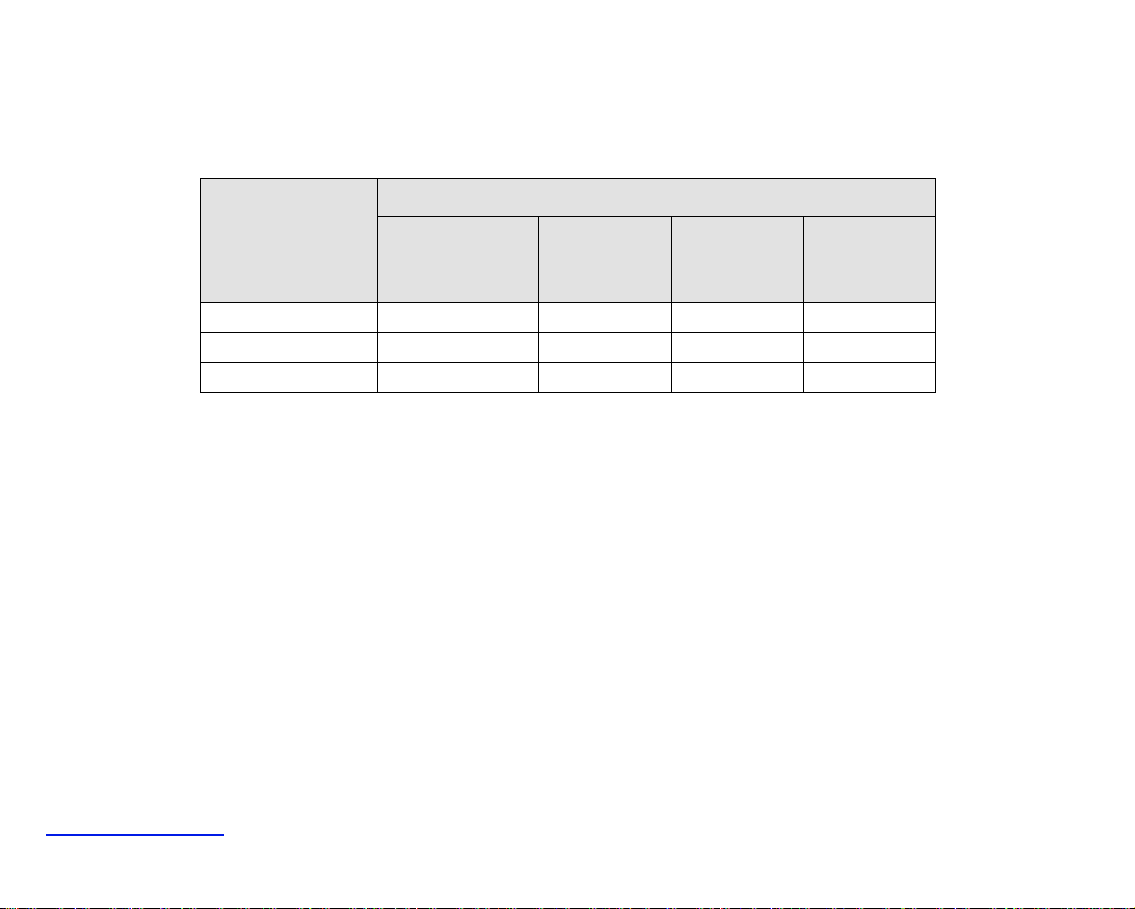

Print Times for a Selected Print Quality

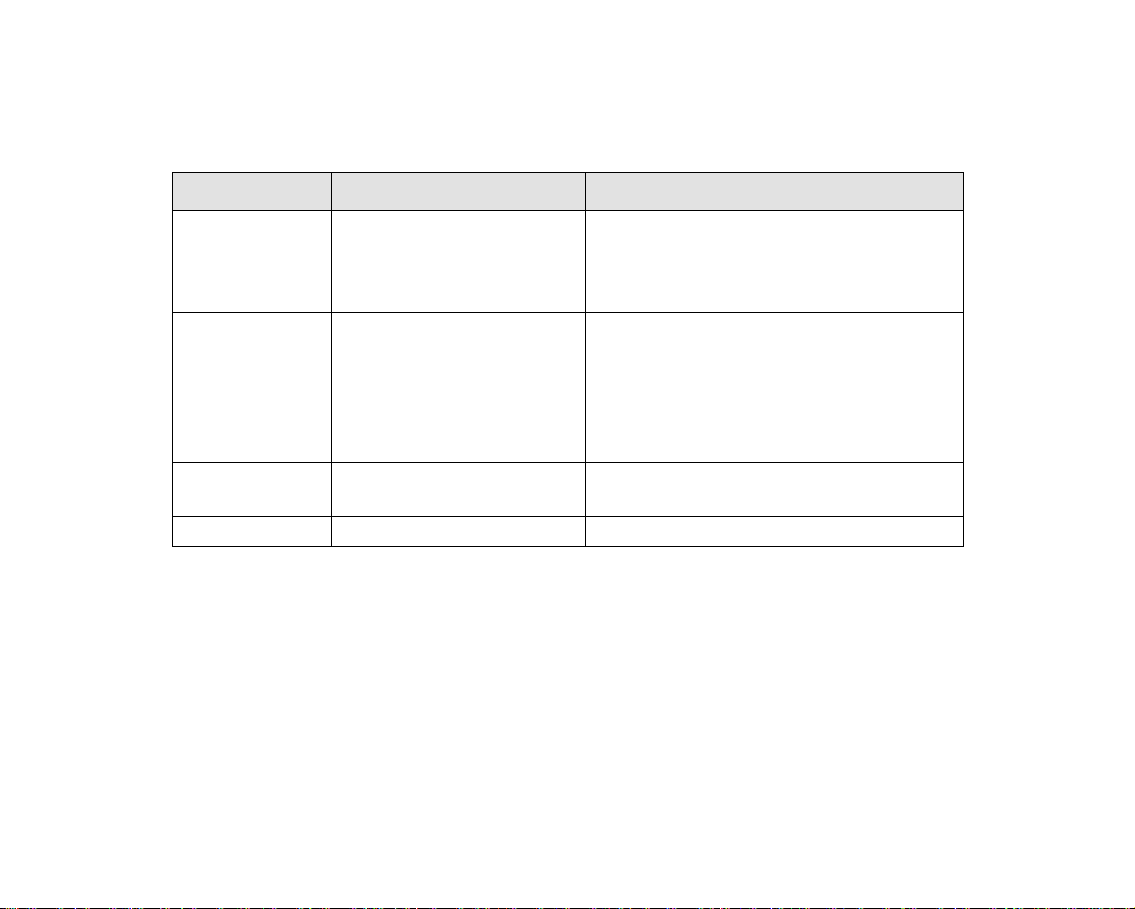

The following table lists some typical printing times for D/A1 size paper.

Typical Printing Times

Print Quality Time (in seconds)

Mono Lines

on Bond

Fast 96 96 234 480

Normal 216 216 550 690

Best 360 285 940 990

Color Lines

on Coated

Paper

Images

on Coated

Paper

Images

on Glossy

Paper

More Printing Times

Page 28

Printable Area

The following topics detail the printable areas for each of the different paper size systems:

• ANSI Paper

The American National Standards Institute imperial paper sizing system.

• Architectural Paper

The Architectural paper sizing system.

• ISO Paper

The International Standards Organization metric paper sizing system, which is the size system commonly

used in Europe.

Page 29

ANSI Paper

The following table lists the printable area for the ANSI paper size system. The left and right margins are

0.2 inches (5 mm) and the leading and trailing edge margins are 0.7 inches (17 mm).

Where

:

Printable area Paper Size Margins–=

Printable Areas for ANSI paper

Printable area (width × height) by Image Orientation

Paper

size

A Portrait 9.7 8.1 8.1 9.7 245 206 206 245

B Portrait 15.7 10.6 10.6 15.7 398 269 269 398

C Portrait 20.7 16.6 16.6 20.7 525 422 422 525

D Portrait

E Portrait N/A

Orientation of

paper in

printer

Landscape 7.2 10.6 10.6 7.2 182 269 269 182

Landscape 9.7 16.6 16.6 9.7 245 422 422 245

Landscape 15.7 21.6 21.6 15.7 398 549 549 398

Landscape 20.7 33.6

Landscape

Landscape Portrait Landscape Portrait

Width Height Width Height Width Height Width Height

32.7 21.6 21.6 32.7 830 549 549 830

32.7 43.6 N/A 830 1108 N/A

Inches Millimeters

33.6 20.7 525 854 854 525

33.6 42.7 N/A 854 1084

Indicates this printable area is only available if you are using the A0+/E+ size format

HP Designjet 500 Plus printer

Page 30

Architectural Paper

The following table lists the printable area for the Architectural paper size system.

The left and right margins are 0.2 inches (5 mm) and the leading and trailing edge margins are 0.7 inches

(17 mm).

Where:

.

Printable area Paper Size Margins–=

Printable Areas for Architectural paper

Printable area (width × height) by Image Orientation

Paper

size

C Portrait 22.7 17.6 17.6 22.7 576 447 447 576

D Portrait

E1 Portrait

E Portrait N/A

Orientation of

paper in

printer

Landscape 16.7 23.6 23.6 16.7 423 600 600 423

Landscape 22.7 35.6

Landscape

Landscape

Landscape Portrait Landscape Portrait

Width Height Width Height Width Height Width Height

34.7 23.6 23.6 34.7 880 600 600 880

40.7 29.6 29.6 40.7 1033 752 752 1033

28.7 41.6 41.6 28.7 728 1057 1057 728

34.7 47.6 N/A 880 1209 N/A

Inches Millimeters

35.6 22.7 576 904 904 576

35.6 46.7 N/A 904 1185

Indicates this printable area is only available if you are using the A0+/E+ size format

HP Designjet 500 Plus printer

Page 31

ISO Paper

The following table lists the printable area for the ISO paper size system.

The left and right margins are 0.2 inches (5 mm) and the leading and trailing edge margins are 0.7 inches

(17 mm).

Where:

Printable area Paper Size Margins–=

Printable Areas for ISO paper

Printable area (width × height) by Image Orientation

Paper

size

A4 Portrait 10.4 7.9 7.9 10.4 263 200 200 263

A3 Portrait 15.2 11.3 11.3 15.2 386 287 287 386

A2 Portrait 22.0 16.1 16.1 22.0 560 410 410 560

A1 Portrait

A0 Portrait N/A

Orientation of

paper in

printer

Landscape 6.9 11.3 11.3 6.9 176 287 287 176

Landscape 10.4 16.1 16.1 10.4 263 410 410 263

Landscape 15.2 23.0 23.0 15.2 386 584 584 386

Landscape 22.0 32.7

Landscape Portrait Landscape Portrait

Width Height Width Height Width Height Width Height

31.7 23.0 23.0 31.7 806 584 584 806

Inches Millimeters

32.7 22.0 560 830 830 560

32.7 45.4 N/A 830 1154

Indicates this printable area is only available if you are using the A0+/E+ size format

HP Designjet 500 Plus printer

Page 32

Roll Media

The following procedures are described in detail, with animations where appropriate:

• Installing a New Roll on the Printer

• Loading Roll Media

• Unloading Roll Media

• Removing Roll Media from the Spindle

• Cutter Replacement

Page 33

Installing a New Roll on the Printer

The animation sequence shows how to install a new roll

of paper on the printer.

CAUTION: Make sure the printer wheels are locked

(the brake lever on each wheel is

pressed Down) to prevent the printer

from moving.

If you are a regular user of different types of roll paper,

you can change the paper quicker if you have more

than one spindle. This allows you to do the following:

1. Pre-load the different types of paper onto the spindles.

2. Remove and replace the spindle with the new type

of paper.

NOTE: Additional spindles are available from

Hewlett Packard as accessories.

Click on this icon to run the animation sequence. A printable version

that you can take the key illustrations to the printer, if it is remote from your computer.

of the sequence is also available so

Page 34

Loading Roll Media

The animation sequence shows how to lo ad a new r oll

of paper on the printer.

NOTE: You must have installed

paper on the printer before you can load

it.

The front-panel menu items are:

Select (using the keys)

1. Paper Enter

2. Load Roll Enter

3. Select Roll Type Enter

Click on the icon to run the animation

sequence. A printable version

available so that you can take the key illustrations to the printer, if it is remote from your computer.

of the sequence is also

a new roll of

Then Press:

Page 35

Unloading Roll Media

The animation sequence shows how to unload a roll of

paper from the printer.

Click on the icon to run the animation

sequence. A printable version

available so that you can take the key illustrations to the

printer, if it is remote from your computer.

of the sequence is also

Page 36

Removing Roll Media from the Printer

The animation sequence shows how to remove a roll of

paper from the printer.

NOTE: You must have unloaded

paper from the printer before you can

remove it.

Click on the icon to run the animation

sequence. A printable version

available so that you can take the key illustrations to the

printer, if it's remote from your computer.

of the sequence is also

the roll of

Page 37

Removing Roll Media from the Spindle

The animation sequence shows how to remove a roll of

paper from the roll spindle

.

NOTE: Y ou must have removed

from the printer before you can remove it

from the spindle.

Click on the icon to run the animation

sequence. A printable version

available so that you can take the key illustrations to the

printer, if it is remote from your computer.

of the sequence is also

the roll of paper

Page 38

Cutter Replacement

The animation sequence shows the complete

procedure for the replacement of the paper cutter in

your printer.

Prerequisites

Before attempting to replace the cutter you must

contact your local HP Customer Care

• Order the replacement cutter.

• Receive instructions on how to access the Front

Panel Service Menu.

Important Information

• The cutter unit is attached to the printer by a black

cutter holder that runs along the metal guide rail,

and is hooked onto the edge of the platen

front of the printer.

• The cutting wheel is inside the cutter unit.

• Do not remove the cutter holder.

• When inserting the new cutter, with the cutter holder raised to about 45 degrees, partially insert the cutter so it

rests in the cutter holder, but do NOT clip it in at this stage.

CAUTION: Be very careful when replacing the cutter because you can easily break the cutter holder if you

apply too much force.

center to:

at the

Click on the icon to run the animation sequence. A printable version

that you can take the key illustrations to the printer, if it is remote from your computer.

of the sequence is also available so

Page 39

Sheet Media

• Which Side Up?

Instructs you how to identify which side of the sheet media should be printed on.

• Which Edge First?

Explains which edge of the sheet should be loaded first (short edge or long edge).

• Loading Sheet Media

Details the sheet media loading procedure.

• Unloading Sheet Media

Details the sheet media unloading procedure.

Page 40

Which Side Up?

The printer prints on the side of the paper that faces up. It may be important to load the sheet with the correct side

facing up. See the table below.

Print Side for Media Types

Media Type Matte or Glossy

HP Bright White Inkjet Paper (Bond) Both sides are the same. If sheet

HP Vellum

Natural Tracing Paper

Coated Paper Load with the coated side up.

Heavy Coated Paper

Matte Film Load with the matte side up.

High-Gloss Photo Load with the glossy side up.

Clear Film

Translucent Bond Both sides are the same. If sheet

Canvas

Poster Paper

Plain Paper Both sides are the same. If sheet

is curled, load with curl down.

is curled, load with curl down.

is curled, load with curl down.

Page 41

Which Edge First?

You can load sheet paper in either portrait or landscape orientation. Unless you are using the Rotate option,

always load the sheet in the same orientation as you have specified in your software.

Landscape (long edge first)

Portrait (short edge first)

Page 42

Loading Sheet Media

The animation sequence shows how to load a new

sheet of paper on the printer.

Important

• If you have a roll of paper loaded on the printer you

must first unload

• Make sure the correct side of the sheet is facing up

when you load it.

The front panel menu selections are:

it from the printer.

Select (using the keys)

1. Paper Enter

2. Load sheet Enter

3. Select Sheet T ype Enter

Click on the icon to run the animation sequence. A printable version

that you can take the key illustrations to the printer, if it's remote from your computer.

Then Press:

of the sequence is also available so

Page 43

Unloading Sheet Media

The animation sequence shows how to unload a sheet

of paper from the printer.

Important

• To give the ink time to dry the printer holds the

paper for some time.

Click on the icon to run the animation

sequence. A printable version

available so that you can take the key illustrations to the

printer, if it is remote from your computer.

of the sequence is also

Page 44

Ink System

These topics cover the various elements of the Ink System.

• What are HP Ink Supplies?

Details the elements of the HP Ink Supplies supplies.

• Component identification

Shows you where to find the various elements of the Ink System.

• Ink Supply Guidelines

Explains how to obtain the best results from your Ink System.

• Precautions

Details the specific precautions you must take to avoid damaging the components of your Ink System.

• Color Calibration

Explains how to calibrate the ink system for the type of media loaded

• Drying Time

Explains drying time function and details how to use it to ensure you obtain the highest quality print under all

conditions.

Page 45

What are HP Ink Supplies?

For each of the four ink colors used in the printer, there are two separate components, the printhead and the

ink cartridge

selection number to help you reorder the correct replacement. Your HP Designjet 500 Plus printer uses the

following HP Ink Supplies:

• Black Ink Cartridges are HP No 10 Supplies.

• Cyan, Magenta and Yellow Cartridges are HP No 82 Supplies.

• All Printheads are HP No 11 Supplies.

Ink Cartridges

The Hewlett-Packard ink cartridges for your printer require no maintenance or cleaning. As long as each ink

cartridge is inserted correctly into its slot, the ink will flow to the printheads. Because the printheads control the

amount of ink transferred to the page, you will continue to see high-quality printing results, even when the ink

levels are getting low.

The front panel notifies you when an ink cartridge’s ink level is low. You can also check the ink levels of all the ink

cartridges to determine if an ink cartridge needs to be replaced, see Ink Cartridge Information

. These components are called the HP Ink Supplies and are coded with a Hewlett-Packard No.

.

If the ink cartridge is empty, the printer stops printing. See Ink Cartridge Replacement

.

Printheads

The Hewlett-Packard printheads are extremely durable and do not need to be replaced every time an ink cartridge

is replaced. They are independent of the ink cartridges and will continue giving excellent image quality results

even if the ink cartridges are low in ink.

If you notice a decline in print quality such as lines or dots missing from text or graphics, see Stepped Lines

.

Page 46

Component identification

The following illustration will help you identify the components of the HP Ink Supplies.

Printheads

Ink Cartridges

The Hewlett-Packard selection number on the ink cartridges and printheads makes it easy for you to find the

correct HP Ink Supplies for your printer. Determine the color of the printhead or ink cartridge you need, then make

sure you purchase or order the correct Hewlett-Packard printhead or ink cartridge. Each ink cartridge and

printhead can be purchased separately from your usual Hewlett-Packard retailer. See Ordering Accessories

.

Page 47

Ink Supply Guidelines

For optimum results from your printer and the ink system, always follow these guidelines when handling HP Ink

Supplies:

• Always install the ink cartridges and printheads before the expiry date, which is on the packaging.

• Install ink cartridges and printheads in their color-coded slots.

• Follow the instructions on the front panel during installation.

• Avoid unnecessary removal of the ink cartridges and printheads.

• When turning off your printer, always use the power-off button on the front panel. The printheads are then

parked correctly which prevents them from drying out.

• The ink cartridges should never be removed while the printer is printing. They should only be removed when

the printer is ready for you to replace them. The front panel will guide you through the removal and installation

procedure. See When to Replace

CAUTION: When you first received your printer it was supplied with a set of four setup printheads installed

in the printhead carriage. These setup printheads are used for the priming of the tubes in the

modular ink delivery system. Do not remove the setup printheads from the carriage without

following the procedures in the Assembly and Set-up Poster.

HP Ink Supplies.

Page 48

Precautions

Handle HP Ink Supplies with care. In particular, the printhead, which is a high-precision device, must be handled

carefully.

CAUTION: Do not touch, wipe or attempt to clean the printhead nozzles. This can damage the printhead.

• Do not put the printhead down on the nozzles.

• Do not be rough when handling the printheads.

Always set them down gently.

• Do not drop the printheads. Proper handling will

assure optimum performance throughout the printhead life.

• Do not touch the end of the ink cartridge which is

inserted into the printer as there may be a small

amount of ink on the connection.

• Avoid storing partly used ink cartridges on their

ends.

Page 49

Color Calibration

You can calibrate the ink system for the specific media loaded in your printer. Doing this ensures the printed

output matches the colors of the original image as closely as possible. The printer stores the calibration data for

each type of media you have calibrated it for since it was powered up. Once the printer has been powered down,

the next time you use it only the last calibration made will be available and it will print using this calibration data.

To color calibrate your printer, first make sure you have the correct type of media loaded and then make the

following front-panel selections:

Select (using the keys)

1. Ink Enter

2. Color calibration Enter

3. Calibrate Paper Enter

Then Press:

The printer prints a calibration pattern and scans it to create the calibration data for the type of media loaded.

If you want to check the color calibration status of your printer, make the following front-panel selections:

Select (using the keys)

1. Ink Enter

2. Color calibration Enter

3. Status Enter

Then Press:

The front panel display shows what types of media the ink system is currently calibrated for.

To remove all the calibrations and reset the printer to its factory values choose

Color calibration > Reset from the Ink menu.

Page 50

Drying Time

The following topics detail the drying time function and how to use it to ensure you obtain the highest quality print

under all conditions.

• Drying Time Settings

Describes how to set the required drying times from the front panel.

• Typical Drying Times

Lists typical drying times for Hewlett-Packard tested paper at approximately 25°C with 50% relative humidity.

• Drying Procedure

Details how the drying procedure operates.

Page 51

Drying Time Settings

With some paper types and environmental conditions the ink needs time to dry before the paper is unloaded. The

printer has three settings which you can choose through the front panel. See Navigation Example

Manual

The printer holds in place paper which has a specific drying time, and displays a “drying time to go” countdown on

the front panel. You can change this time from one minute to 99 minutes in one minute increments.

Automatic

The printer automatically determines the appropriate drying time, based on the type of paper you have selected

and the current temperature. If there is any drying time the printer displays a “drying time to go” countdown on the

front panel.

None

With this setting, when the printer has finished printing an image, the paper will fall into the paper bin under the

printer.

CAUTION: Changing the drying time to speed up the printer could result in damage to your printed image

or reduce the quality of your print.

for more help.

Page 52

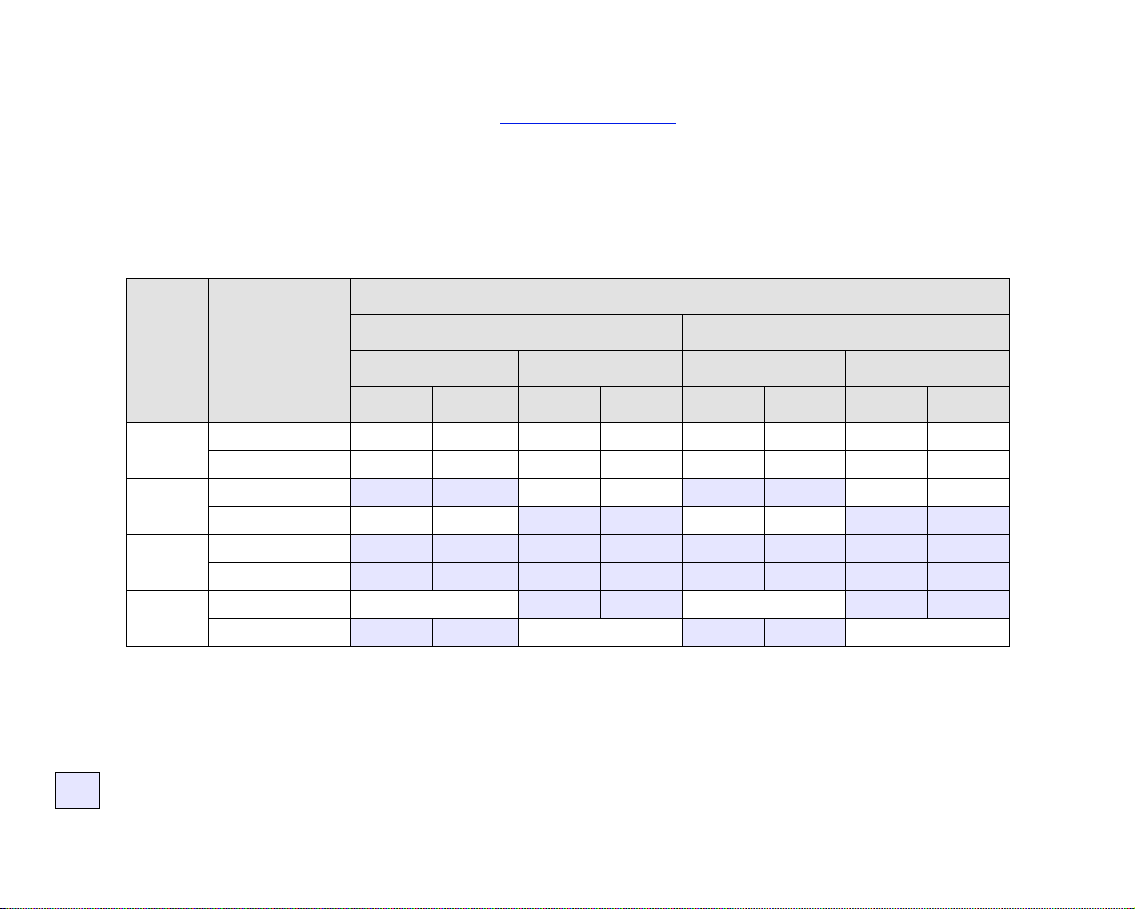

Typical Drying Times

The following table shows the typical drying times for Hewlett-Packard tested paper at approximately 25°C with

50% relative humidity.

Drying Times by Paper Types

Hewlett Packard Tested Paper

Type

HP Bright White Inkjet Paper (Bond) 0 25

HP Vellum

HP Natural Tracing Paper

HP Coated Paper 0 60

HP Heavyweight Coated Paper 0 60

HP Matte film 60

HP High-Gloss Photo Paper 120

HP Semi-Gloss Photo Paper

HP Paper-Based Semi-Gloss

HP Clear film 60

HP Translucent bond 60 120 180

HP Studio Canvas 6000

HP Satin Poster Paper 60

HP Banners with Tyvek®

HP Colorfast Adhesive Vinyl

Fast Normal Best

Drying Time (seconds)

60 120 180

180

Page 53

Drying Procedure

The drying procedure operates as follows:

1. The printed image emerges from beneath the printer window and a vacuum holds it on the platen

of the

printer.

2. The front panel displays:

The countdown

timer indicates

how much

drying time

remains

3. You can press the Cancel or the Form Feed & Cut key to cancel the drying time and release the paper.

4. After the drying time has elapsed:

For roll media the printer cuts the media and turns off the vacuum so the printed image can drop into the

printer bin.

For sheet media the vacuum is turned off and the printed image drops into the printer bin.

Page 54

Ink Cartridges

• Ink Cartridge Errors

Details the error messages that could be displayed on the front panel for the Ink Cartridges.

• Ink Cartridge Levels

Details the information about levels that can be displayed on the front panel for the Ink Cartridges.

• Ink Cartridge Information

Shows you how to display the current status of the Ink Cartridges on the front-panel display.

• Ink Cartridge Replacement

Details the Ink Cartridge replacement procedure.

Page 55

Ink Cartridge Errors

The Front Panel can display the following error messages for the ink cartridges:

Cartridge

Missing

Faulty

Cartridge

NOTE: If a cartridge has actually passed its expiry date, it will be shown as a faulty cartridge and will

have to be replaced.

Cartridge

Nearly

Reached

End of Life

Cartridge

Empty

The printer will also display the Ink Cartridge Levels

.

Page 56

Ink Cartridge Levels

The Front Panel will tell you when your ink supply is low, very low or empty. This means you know current status

of your HP Ink Supplies all the time:

Cartridge

Full

Cartridge

Empty

NOTE: Depending on type of print jobs, a cartridge with a Low Ink Warning may in fact last quite a long

time (for example, with line drawings).

NOTE: The Ink Cartridges levels information can also be selected with

Ink menu > Information > Ink Cartridges > Ink Levels if it is not automatically shown in the Ink

menu.

Low Ink

Warning

Page 57

Ink Cartridge Information

Use the following procedure to display the Ink Cartridge Information screen on the front panel.

The front-panel menu items are:

Select (using the keys)

1. Ink Enter

2. Information Enter

3. Ink Cartridges Enter

4. Cyan, Magenta, Yellow or Black

Ink cartridge

Then Press:

Enter

The front panel displays the following information for the selected ink cartridge:

• Color: Cyan, Magenta, Yellow or Black.

• Model: Hewlett-Packard No 82 (Cyan, Magenta and Yellow) or Hewlett-Packard No 10 (Black).

• Status: inserted, low on ink, out of ink, missing, expired and faulty.

• Expiration date.

• Serial Number.

• Ink Level: in cc and % used.

Page 58

Ink Cartridge Replacement

The animation sequence opposite shows how to

replace an Ink Cartridge.

WARNING: Make sure the printer wheels are locked

(the brake lever is pressed down) to

prevent the printer from moving.

CAUTION: Only remove an ink cartridge if you are

replacing it.

CAUTION: Do not replace cartridges while the

printer is printing because doing this will

cancel the current print job.

Y ou would need to change cartridges either if prompted

to do so on the Front Panel because the printer has

detected a cartridge is out of ink or the cartridge is low

and you want to replace it before it runs out.

Click on the icon to run the animation

sequence.

A printable version

remote from your computer.

of the sequence is also available so that you can take the key illustrations to the printer, if it is

Page 59

Printheads

• Printhead Errors

Details the different error messages that could be displayed on the front panel for the Printheads.

• Printhead Information

Shows you how to display the current status of the Printheads on the front panel display.

• Printhead Replacement

Details the Printhead Replacement procedure.

• Printhead Alignment

Details the Printhead Alignment procedure.

Page 60

Printhead Errors

The Front Panel can display the following error messages for the printheads:

Printhead

Missing

Faulty

Printhead

NOTE: An unknown error is displayed when one of the printheads is causing a problem but the system

cannot detect which one it is. Refer to Unknown Printhead Error

Printhead

Worn Out

Unknown

Error

to solve this problem.

Page 61

Printhead Information

Use the following procedure to display the Printheads Information screen on the front panel.

The front panel menu selections are:

Select (using the keys)

1. Ink Enter

2. Information Enter

3. Printhead Enter

4. Cyan, Magenta, Yellow or Black

printhead

Then Press:

Enter

The front panel displays the following information for the selected printhead:

• Color: Cyan, Magenta, Yellow or Black

• Model: Hewlett-Packard No 11 and Warranty (In warranty or Out of warranty)

• Status: inserted, missing, faulty worn-out and unknown.

If there is a problem the system displays an action: missing -> insert, unknown -> troubleshoot,

faulty, worn out -> replace.

• Expiration date.

• Serial Number.

• Ink Used: in cc and % used.

• Paper Jams.

• If the printheads are aligned and color calibrated.

Page 62

Printhead Replacement

The animation sequence shows how to replace a

printhead in the printer.

The front-panel menu selections are:

Select (using the keys)

1. Ink Enter

2. Replace Printheads Enter

Click on the icon to run the animation

sequence. A printable version

available.

Once you have replaced the printhead, if you have

media loaded, the printer prompts you to start the

Printhead Alignment

the printer prompts you to load paper and then automatically starts the alignment. The alignment takes several

minutes to complete and then printer will then prompts you to run the Color Calibration

procedure. If no media is loaded

of the sequence is also

Then Press:

procedure.

Page 63

Printhead Alignment

You should have one of the following types of paper loaded before attempting to align the printheads: HP Bright

White Inkjet Paper (Bond), HP Coated Paper, HP Heavyweight Coated Paper, HP High-Gloss Photo Paper, HP

Satin Poster Paper or Plain Paper. If you try to do this with any other type of paper loaded, the printer will prompt

you to load a different type of paper before letting you align the printheads.

From time to time you may be required to align the printheads to ensure maximum print quality. To select

Printhead Alignment manually, make sure you have the correct type of roll or sheet media loaded.

There are two types of alignment: Standard which will take about 4½ minutes; and Special which takes about

11 minutes. Standard alignment is recommended for normal use and requires paper of at least A4/Letter-size,

loaded in landscape mode. Special alignment should be used to correct pen to paper spacing variations which

would be show by variations in vertical line quality, particularly in wide plots and fast print modes. Special

alignment requires paper of at least A3/B-size, loaded in landscape mode. Two separate prints are made.

Then use the following front panel menu selections to start the alignment:

Select (using the keys)

1. Ink Enter

2. Align Printheads Enter

3. Standard (4.5 minutes)

Special (11 minutes)

Once you have made this selection the printer starts the alignment process which then takes several minutes.

The printer will also automatically use the standard alignment process to align its printheads after

Printhead Replacement

prompts you to ask if you want to run the Color Calibration

. When the alignment procedure completes after a printhead replacement, the printer

procedure.

Then Press:

Enter

Page 64

Solutions

These topics guide you through the different procedures required to troubleshoot and find the solutions to various

problems you could encounter while using your printer.

The Solutions Tab contains these topics:

• Solving Problems

where you can get further information.

• Image Quality Problems

you through the troubleshooting procedure step-by-step.

• Ink Supply Problems

cartridges and printheads.

• Media Problems

also what to do if you have a media jam.

• Image Error

you expected.

• Other Problems

• Getting Help

of the steps to take to contact the Hewlett-Packard Customer Care Center.

helps you to quickly troubleshoot your specific problem; it also contains instructions on

helps you to solve any image quality problems you may be experiencing. It takes

guides you when you have problems installing the consumable ink items: the ink

contains information on what to do if you have image smears or marks on your media, and

contains information on what to do if the image that your printer printed is incorrect, or not what

covers miscellaneous problems you could face.

explains what to do if you cannot solve the problem you are having. It also provides full details

Page 65

Solving Problems

• To find the meaning of front-panel messages, see Message Descriptions.

• If you know the problem is related to a certain task, first check the relevant section in this manual, for step-bystep procedures. Use this manual’s index or table of contents to find the section. For example, if you are having difficulty with page formatting, refer to Page Format

• If the problem is directly related to the quality of your printed images, refer first to Image Quality Problems

• Refer to the appropriate topic:

– Ink Supply Problems

– Media Problems

– Communication Problems

– Image Error

– Other Problems

• If the problem could be related to your software driver, and you are using an HP driver, refer to the driver’s

troubleshooting documentation and the on-line help in your application software.

• If the problem has no obvious cause, refer to Finding the Source of Your Problem

• If you still cannot solve the problem, see Getting Help

.

.

.

.

Page 66

Finding the Source of Your Problem

1. Look at the front-panel display for messages. See Message Descriptions for a full explanation of front-panel

messages.

2. Test the printer.

– Switch the printer off on the front of the printer. Make sure that the power cord is firmly inserted in the

printer and plugged in to an outlet that you know works.

– Switch the printer on and make sure the front-panel display shows the HP welcome screen followed by

Main Menu after a short initialization period.

3. Test your computer hardware and interface.

– Make sure that you have the correct interface cable between the computer and the printer and that it is

firmly connected to the correct ports (see the Assembly and Set-up Poster).

Page 67

Image Quality Problems

Your HP Designjet 500 Plus printer provides a full troubleshooting utility to ensure you can always quickly

overcome any image problems you encounter. You should use this utility whenever you (and not the printer)

perceive a problem with print quality.

Often what you believe to be a print quality problem is in fact caused by incorrect configuration of the printer for

the type of image you are trying to print. Always check Configuration Correction

the cause of your problem.

If a message, such as “PRINTHEADS not functional” appears on the front-panel of your printer, follow the

instructions given for the particular message (see Message Descriptions

The types of problems you could possibly encounter are:

• Stepped Lines

• Incomplete Lines

• Color Accuracy

• Horizontal Banding

• Color Alignment

Whenever you see any of these problems work through the Troubleshooting Procedure replying to the questions

displayed on the front panel. This will lead you to correct remedial action required to solve your image quality

problem.

as your first diagnostic task to find

).

Page 68

Configuration Correction

Before attempting the image quality diagnostic procedures contained in this section, you should first check that

the printer is correctly configured to print what you want. Many problems concerned with image quality can be

solved by correcting the way the printer is configured.

1. To achieve the best performance from your printer, only use genuine HP accessories and supplies, whose

reliability and performance have been thoroughly tested to give trouble-free performance and best-quality

prints. For details of HP media, see Paper Types

2. Make sure that the Type of paper selected in the front panel is the same type of paper loaded into the printer.

To check this go to the Roll or Sheet menu in the front panel and press Enter.

3. To ensure the maximum print quality use HP certified media only. For details of HP media see Physical

Characteristics of Paper Types. You can also look at the Web page http://www.hp.com/go/designJet for the

most up-to-date information.

4. Make sure that the Print quality (Fast, Normal, Best) used for your printer is correct. This is set in the Print

Setup dialog box of the printer driver or in the front panel from the Set-up menu. The printer driver setting

overrides the front panel setting.

5. Select Best print mode for maximum print quality.

6. For Non-HP drivers, set front panel media settings to match the media type loaded in the printer. The

documentation that came with your software should provide information about media type/print quality

settings.

.

7. If your image quality problem is color accuracy related, go to Color Accuracy

for further configuration help.

Page 69

Troubleshooting Procedure

Working through the Troubleshooting procedure should always be your first action when you encounter image

quality problems. Refer to the Troubleshooting Flow Chart

complete troubleshooting procedure.

It is important that the paper loaded for this procedure is exactly that used when you encountered image quality

problems, type (for example, glossy paper) and size. If you use a different kind of paper or a different size, you

stand less likelihood of resolving the problem.

Running the Troubleshooting Utility

1. From the main front-panel menu, select the Ink menu ( ) and press Enter.

2. Select Troubleshooting and press Enter.

3. The printer first checks to see whether the

printheads are aligned. Misalignment of the

printheads is a common cause of image quality

problems. If they are not aligned, you are prompted

to accept Printhead Alignment

requires a few centimeters of paper loaded and takes several minutes to perform.

NOTE: Note that you do not have to interpret the patterns printed by the Printhead Alignment routine.

4. If the printheads do not seem to require alignment, the printer prints Diagnostic Print A. See Diagnostic Print

A Interpretation for full details of how to use this diagnostic print.

. This procedure

for a description of the sequence of processes used to

Page 70

Diagnostic Print A Interpretation

Diagnostic Print A

Diagnostic Print A contains several blocks of color and a block of thin black

broken lines (the lines are actually very much closer than those represented

here).

1. Examine the broken lines in Diagnostic Print A carefully and indicate whether

there are problems with them. The sorts of problems to look for here are:

• Jaggedness or serrations in the thin lines, like this:

; the thin lines should be straight,

though not necessarily perfectly aligned. The irregularities that are significant

extend along the whole of the length of the lines. Shorter irregularities,

arranged in columns, can be ignored at this stage.

Ignore this

black bar

2. Examine the blocks of color in Diagnostic Print A carefully and indicate whether

there are problems with them. The sorts of problems to look for here are:

• White streaks or bands in the solid blocks.

3. If you indicate that there is a problem with the dashed lines in Diagnostic Print A,

you are prompted to use the Advance Calibration

routine; your printer will be at step 3 of the routine (if you don’t

want to continue with calibration, press the Cancel key).

4. If there are problems in the blocks of color in Diagnostic Print A, for example white streaks or bands, the printer will

try to clean the printheads that have the problem. A printhead can be cleaned up to three times this way; after that

it cannot be cleaned and you will be told; the Troubleshooting routine will finish. In that case we recommend that

you try to reprint your print, and then, if necessary, start the Troubleshooting routine again.

After cleaning the printheads, the printer reprints the blocks of color (but not the black lines) in Diagnostic Print A,

and asks you to examine it again (as in step 1).

5. If there are no problems the first time you print Diagnostic Print A, the printer prints Diagnostic Print B. See

Diagnostic Print B Interpretation

for full details of how to use this diagnostic print.

Page 71

Diagnostic Print B Interpretation

1. For each color in the pattern in Diagnostic Print B, you are asked about the

Diagnostic Print B

quality—look for missing lines. If you answer that a color is defective, the

printer tries to clean that printhead.

If the printhead cleaning process completes, Diagnostic Print B is printed

again and you are asked the same questions again.

2. Afterwards, if problems with images remain, use the Troubleshooting

procedure again.

Ignore these

solid bars

If none of the patterns or blocks in the two Diagnostic Prints shows any problem, it could be that your image

quality problem is caused by a wrong setting in your software, or perhaps the job should have been printed with

the Print quality set to Best instead of Normal or Draft.

If the Troubleshooting routine didn’t indicate that printhead alignment was necessary, you can select Align

printheads in the Ink menu to try to solve any further image quality problems.

Page 72

Troubleshooting Flow Chart

The following diagram shows the flow of the troubleshooting procedure.

Star t

Printer checks

whether Printhead

Alignment is required

No

Printer prints

Diagnostic Print A

including black lines

Ye s

Printer recommends

Printhead Alignment

(Standard or Special)

Printer prints

Diagnostic Print A

without black lines

Wrong paper advance.

Printer recommends

Advance Calibration

Indicates that

troubleshooting has

completed but further

procedures are required

to solve the problem

Indicates that

troubleshooting has

completed successfully

and there no problems

Troubleshooting

completed successfully

Printer asks questions

about Diagnostic

Printheads are OK

Yes

after first printing of

Diagnostic Print A

Printer prints

Diagnostic Print B

without black lines

Printer asks if Cyan,

Magenta, Yellow and

Diagnostic Print B are

No problems detected

Print A

No

Black Patterns in

OK

Yes

Diagnostic Print B

No

If possible printer tries

to clean printheads

Printer prints

Printheads need

cleaning. If possible

printer tries to clean

printheads

If printheads have

been cleaned three

time Troubleshooting

finishes

Page 73

Advance Calibration

It is important that the paper loaded for this calibration is exactly that used for normal printing, both in quality (for

example, glossy paper) and in width (for example, A0 or 36-inch). Either roll or sheet paper can be used.

The routine prints a pattern and then cuts the roll (the cutter must be set to On—see Controlling the Cutter

ejects the sheet; it requires paper that is at least 65 cm/25.5 inches long and at least 50 cm/19.7 inches wide. You

must then reload that piece of paper as a sheet, so that the printer can accurately measure the pattern, and make

whatever adjustments are appropriate to the amount it advances between printing swaths of data. (See Loading

Sheet Media)

The pattern printed is solely for the use of the printer; you are not expected to relate any of its characteristics to the

quality of your images.

1. From the main front-panel menu, with the correct paper loaded, select the Paper menu ( ) and press Enter.

2. Select Advance calibration and press Enter.

3. Select Create pattern and press Enter.

The printer prints its calibration pattern (as represented here) and

cuts or ejects the paper.

4. Load the sheet printed side up with the dotted line at the top (that is,

rotated 90º).

5. Now select Measure pattern and press Enter.

The printer reads the calibration pattern and makes the appropriate

Direction of paper while

printing (creating pattern)

internal adjustments.

) or

These Advance Calibration Values

are used whenever you print on the

same type of media until you have used the Advance calibration twice

more with different types of media.

Direction of paper when

loading (measuring pattern)

Page 74

Advance Calibration Values

The printer stores the advance calibration values of the last two

different types of media used for the calibration. When you print the

printer ties to match the media you have selected to the stored

values. If there is a match the printer applies the stored Advance

calibration values.

If the type of media you are using has not been used for either of the

last two Advance calibrations the printer uses a set default values for

your media.

The Restore factory option of the Advance calibration menu erases any stored advance calibration values from

the printer memory. This means that until you run the advance calibration again the printer will use the factory

default values for all types of media.

Page 75

Stepped Lines

When you look at the image you have printed there are ‘stepped lines’ in the borders of arrows and diagonal

lines. The lines should be straight with no stepping.

The following is an example of what you might see if you have problems with stepped lines.

To solve this problem:

1. Increase the dpi setting by changing the print quality to Best in the front panel and driver software.

2. The problems may be inherent in the image you are trying to print. Try to improve the image with the

application that generated the file.

Page 76

Incomplete Lines

TEST

When you look at the image you have printed there are:

• Missing or faint lines.

• Printed characters having missing parts to them.

The following is an example of what you might see if you have problems with incomplete lines.

Missing parts of text; this

should say TEST

See the Troubleshooting Procedure

for instructions on how to solve this problem.

Page 77

Color Alignment

When you look at the image you have printed:

The colored lines are printed

double and they are the wrong

colors

The borders of colored blocks

are overlapped and the

overlapping areas have

different colors in them.

See the Troubleshooting Procedure

Vertical lines are misaligned or

fuzzy (not smooth)

for instructions on how to solve this problem.

Page 78

Horizontal Banding

When you look at the image you have printed there are light or dark lines on the image, these are particularly

highlighted in high density ink areas. This problem is known as banding.

IMPORTANT Banding can occur to a certain degree in Fast and Normal mode when printing high

density prints. To obtain the best image always print in Best Mode.

The following is an example of what you might see if you have problems with banding.

80

Expanding Possibilities

80

Ironk

Pojfdjop ernk aure

Pojfdjop ernk Chorme

Pojfdjop ernk aure

See the Troubleshooting Procedure

80

Expanding Possibilities

80

Ink erov

Caps

Ink cartridge

kheuhg sfrfefg

kheuhg sfrfefg

80

for instructions on how to solve this problem.

Page 79

Color Accuracy

These are the areas you should review when troubleshooting a color accuracy problem:

Media

Ensure the media loaded is genuine HP media and the correct media type selected on the front panel and in the

driver.

Related Topics

• Color Consistency problems

• Long Term Color Bleeding (Glossy Papers)

• Color Accuracy Configuration

• Additional Color Accuracy Information

Page 80

Color Consistency problems

• Some media may discolor or change with age. Check that your media is fresh and has been stored correctly.

• If the environmental conditions you are printing in change rapidly, you may see changes in the color consis-

tency. By reducing the time the print stays in extreme environmental conditions after being printed (especially

very high humidity) you can reduce the color consistency problems.

• There may be color changes between images printed on your HP Designjet 500 Plus and other types HP

Designjet printers. This is quite normal because the other printers use different ink.

Long Term Color Bleeding (Glossy Papers)

High ambient humidity at your location could cause the colors to bleed into the paper making the lines fuzzy and

bleary.

• Change the paper that you are printing with or remove the printer from the high humidity conditions.

Page 81

Color Accuracy Configuration

The configurations of the printer defines how ink is applied to each type of media. Use the information in the

following table to configure your printer and software for best color accuracy.

Location of

Setting

Ink Menu Color Calibration > Calibrate

Setting Description Selection

Paper

Set to match the media type loaded in the printer.

See Paper Types

.

Page 82

Additional Color Accuracy Information

The means of accurately managing the colors printed by your printer vary with the software application and driver

being used. Refer to the following documentation:

• On-line documentation in the drivers shipped with your printer.

• If you cannot find any reason for the discrepancy, before getting help, find out for which CMYK printer inks the

colors have been specified.

Page 83

Ink Supply Problems

Most of the problems that you could encounter when working with HP Ink Supplies are solved with guidance from

the front panel. The only exception to this is the Unknown Printhead Error

supplied in Message Descriptions

.

Printhead Problems after Replacement

If, after replacing the printheads, the printer complains about wrong or missing printheads, perform the following

steps:

• Check that you have removed the protective tape from the printhead.

• Insert the printhead into the carriage assembly, but this time close the cover using the latch.

• Replace the printhead with a new one, see Printhead Replacement

Problems Inserting the Ink Cartridge

1. Make sure that you have the correct HP Ink Supplies ink cartridge.

2. Make sure that the cartridge is the correct color for that slot.

3. Make sure the cartridge is in the correct orientation, with the color coded label at the top.

CAUTION: Never clean inside the ink cartridge slots.

Problems Inserting the Printhead

1. Make sure that you have the correct HP Ink Supplies printhead.

2. Make sure that the printhead is the correct color for that slot.

. A full list of front messages are

.

3. Make sure that the printhead is the correct orientation.

See Printhead Replacement

for further details.

Page 84

Unknown Printhead Error

An unknown printhead error occurs when the one of the printheads is causing a

problem but the system cannot detect which one it is. Whenever this happens the

front panel displays this error message. The number of printheads with unknown

errors will either be all the color printheads or all the printheads.

Use the following procedure to isolate the faulty printhead.

1. Select Replace Printheads from the front panel.

2. Open the carriage cover and remove ALL the printheads.

3. Reinsert the Cyan printhead only and close the carriage cover and the window.

4. Check the front panel—if the status of the Cyan printhead is X or ?, the conclusion is that the Cyan printhead

is faulty and must be replaced. If the status of the Cyan printhead is OK, the conclusion is that the Cyan

printhead is working correctly. Repeat the process from step 1 for the other color printheads to identify which

one is failing.

Page 85

Media Problems

• Media

Details the general rules to follow to avoid media problems.

• Clearing a Media Jam

Describes how to clear a media jam.

• Ink Marks on the Media

Details the way to solve ink mark problems: warped lines, blurred lines, marks or scratches on glossy paper.

• Media Loading Problems

Explains what to do when the front panel keeps indicating that media is misaligned or incorrectly positioned.

• Media Output Problems

Explains what to do when the prints fall on the floor or do not stack correctly in the media bin.

Page 86

Media

Always make sure that you are using the appropriate media for your image and that it is consistent with your

software application. To ensure color accuracy and print-quality performance of the printer, use only media types

that have been certified for your printer.

Use of non-HP media or HP media not certified for your printer may significantly reduce the color and print quality

of your images. For details of HP media, see Paper Types

.

Page 87

Clearing a Media Jam

If the front panel displays this message:

There is probably paper jammed in the printer. Paper jams can have

various causes:

• The paper is too thick or too thin for the printer, or is otherwise not

supported.

• The paper is creased or misaligned or is bubbled.

• Too much ink is being placed on the paper causing it to cockle or bubble.

• The end of the roll of paper is glued to the core and won’t advance further.

• Pieces of paper or paper powder are clogging up the cutter guide or other moving parts.

See Removing Jammed Paper

for full instructions on how to clear jammed paper.

Page 88

Removing Jammed Paper

1. Open the window.

2. Switch the printer off at the front.

3. If necessary, carefully move the printhead carriage out of the way—if possible all the way to the enclosed area

on the left or the right. Which way you are able to move it depends on where the paper is jammed.

CAUTION: When moving the printhead carriage, touch only the black plastic parts.

4. If necessary, carefully move the paper cutter out of the way to the left,

or to the right depending on where the paper is jammed (though if

moved right it may block the paper path).

CAUTION: The cutter is easily moved by holding it as close as

possible to the guide running across the width of the

printer. Be careful not to touch the metal slider bar that

runs across the printer.

5. If necessary, lift the blue paper lever, to release any trapped paper.

Remember to lower it again when you have finished.

6. Carefully remove any of the jammed paper which you can easily lift up and out from the top of the printer.

7. Carefully pull the rest of the roll or sheet down and out of the printer. You may need to cut the edge of the roll

with scissors.

8. Check that the printing zone, including the cutter guide, the paper path, and the area where the printhead

carriage is parked, is clear and clean; remove any paper powder by brushing it away or with a vacuum

cleaner.

Slider bar

Guide

More …

Page 89

Removing Jammed Paper (continued)

CAUTION: The area where the printhead carriage is parked can get quite dirty; be careful not to get ink on

your hands.

9. Close the window and switch on the printer.

10. Wait for the printer to finish initializing.

11. Press the Form Feed and Cut key on the front panel to eject any small pieces of paper that are still in the

paper path.

12. Reload the paper as normal (see Loading Roll Media

may need to trim the edge first, to ensure that it is straight.

NOTE: If there is still paper left in the paper path, try loading a sheet of stiff or rigid paper into the

printer, such as heavy coated or matte film; this will help to force out any paper jammed in the

paper path.

13. If the cutter seems to be causing the problem, check in Paper Types

printer. Try disabling the cutter from the front panel; use → Cutter → Off.

You are strongly recommended to align the printheads (see Printhead Alignment

the problem may have caused the printheads to be misaligned.

Back …

or Loading Sheet Media). If you are using roll paper you

that the type of paper is supported by the

) after clearing a paper jam, as

Page 90

Ink Marks on the Media

• Warped Lines

• Blurred Lines (Ink “Bleeds” from Lines)

• Marks or Scratches on Glossy Paper after Printing

• Smears or Scratching on Your Printed Media