Page 1

HP COLOR LASERJET CP5220

SERIES PRINTER

Service Manual

Page 2

Page 3

HP Color LaserJet CP5220 Series Printer

Service Manual

Page 4

Copyright and License

© 2009 Copyright Hewlett-Packard

Development Company, L.P.

Trademark Credits

®

, Acrobat®, and PostScript® are

Adobe

trademarks of Adobe Systems Incorporated.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CE710-90910

Edition 1, 9/2009

Corel® is a trademark or registered

trademark of Corel Corporation or Corel

Corporation Limited.

Microsoft®, Windows®, Windows® XP, and

Windows Vista® are U.S. registered

trademarks of Microsoft Corporation.

®

is a registered trademark of The Open

UNIX

Group.

ENERGY STAR and the ENERGY STAR

mark are registered U.S. marks.

Page 5

Table of contents

1 Theory of operation

Basic operation ..................................................................................................................................... 2

Major product systems ......................................................................................................... 2

Product block diagram ......................................................................................................... 2

Sequence of operation ......................................................................................................... 3

Normal sequence of operation ............................................................................ 3

Formatter-control system ..................................................................................................................... 5

Sleep mode .......................................................................................................................... 5

Input/output .......................................................................................................................... 5

CPU ..................................................................................................................................... 6

Memory ................................................................................................................................ 6

Firmware ............................................................................................................. 6

Nonvolatile memory ............................................................................................ 6

PJL overview ....................................................................................................................... 6

PML ..................................................................................................................................... 6

Control panel ....................................................................................................................... 6

Engine-control system .......................................................................................................................... 7

DC controller ........................................................................................................................ 8

Motors ............................................................................................................... 11

Fans .................................................................................................................. 13

Fuser-control circuit ........................................................................................... 14

Fuser temperature control ................................................................ 15

Fuser protective function .................................................................. 16

Fuser failure detection ...................................................................... 17

Low-voltage power supply ................................................................................. 18

Overcurrent/overvoltage protection .................................................. 20

High-voltage power supply ................................................................................ 21

Laser scanner system ........................................................................................................ 23

Laser failure detection ....................................................................................... 24

Image-formation system ..................................................................................................................... 25

Electrophotographic process ............................................................................................. 25

Image formation process ................................................................................................... 27

Latent-image formation block ............................................................................ 28

Pre-exposure .................................................................................... 28

ENWW iii

Page 6

Primary charging .............................................................................. 28

Laser beam exposure ....................................................................... 29

Developing block ............................................................................................... 30

Transfer block ................................................................................................... 31

Primary transfer ................................................................................ 31

Secondary transfer ........................................................................... 31

Separation ........................................................................................ 32

Fusing block ...................................................................................................... 32

ITB cleaning block ............................................................................................. 33

Drum cleaning block .......................................................................................... 33

Print cartridges ................................................................................................................... 34

Memory tag ....................................................................................................... 35

Cartridge presence detection ............................................................................ 35

Toner level detection ......................................................................................... 35

Cartridge life detection ...................................................................................... 35

Developing unit engagement and disengagement control ................................ 35

ITB unit .............................................................................................................................. 37

Primary transfer roller engagement and disengagement control ...................... 38

ITB unit presence detection .............................................................................. 39

ITB cleaning mechanism ................................................................................... 39

Calibration .......................................................................................................................... 40

Color-misregistration control ............................................................................. 40

Environment change control ............................................................................. 41

Image stabilization control ................................................................................. 41

Image density control (DMAX) .......................................................... 42

Image halftone control (DHALF) ....................................................... 42

Pickup, feed, and delivery system ...................................................................................................... 43

Photo sensors .................................................................................................................... 44

Motors and solenoids ......................................................................................................... 45

Pickup and feed block ........................................................................................................ 45

Cassette pickup ................................................................................................. 45

Cassette multiple-feed prevention ..................................................................... 46

Tray 1 (MP tray) paper pickup ........................................................................................... 47

Tray 1 (MP tray) last-paper detection ................................................................................ 48

Paper feed ......................................................................................................................... 49

Skew-feed prevention ....................................................................................... 50

Feed-speed control ........................................................................................... 51

Fusing and delivery block .................................................................................................. 52

Loop control ...................................................................................................... 52

Pressure roller pressurization and depressurization control ............................. 53

Output bin full detection .................................................................................... 55

Duplex block (duplex models only) .................................................................................... 56

Jam detection .................................................................................................................... 57

Paper feeder ....................................................................................................................................... 59

iv ENWW

Page 7

Paper-feeder motors .......................................................................................................... 60

Paper-feeder paper pickup and feed ................................................................................. 61

Paper-feeder cassette lift operation ................................................................................... 61

Paper-feeder jam detection ............................................................................................... 62

2 Removal and replacement

Introduction ......................................................................................................................................... 64

Removal and replacement strategy ................................................................................................... 65

Electrostatic discharge ....................................................................................................................... 66

Required tools ................................................................................................................................... 67

Service approach ............................................................................................................................... 68

Before performing service .................................................................................................. 68

After performing service ..................................................................................................... 68

Post-service test ................................................................................................................ 68

Removal and replacement procedures .............................................................................................. 69

Customer self repair (CSR) components ........................................................................... 69

External panels, covers, and doors ................................................................................... 89

Print-quality test ................................................................................................ 68

Print cartridges .................................................................................................. 69

Toner-collection unit .......................................................................................... 72

Memory DIMM ................................................................................................... 74

Product memory ............................................................................... 74

Install memory and font DIMMs ........................................................ 74

Enable memory ................................................................................ 78

Check DIMM installation ................................................................... 78

Fuser ................................................................................................................ 79

Pickup roller (Tray 1) ......................................................................................... 80

Separation pad (Tray 1) .................................................................................... 81

Separation roller assembly (Tray 2) .................................................................. 82

Pickup roller (Tray 2) ......................................................................................... 84

Pickup roller, separation roller, and feed roller (Tray 3) .................................... 85

Secondary transfer roller ................................................................................... 86

Intermediate transfer belt (ITB) ......................................................................... 87

Identification and location .................................................................................. 89

Right-front cover and control-panel assembly ................................................... 90

Left cover .......................................................................................................... 92

Rear cover ......................................................................................................... 93

Remove the rear cover ..................................................................... 93

Toner collection unit access door ...................................................................... 93

Right-rear cover ................................................................................................ 95

Top cover .......................................................................................................... 96

Remove the top cover ...................................................................... 96

Front-door assembly ......................................................................................... 98

ENWW v

Page 8

Right-door assembly ....................................................................................... 102

Internal assemblies .......................................................................................................... 104

Laser scanner assembly ................................................................................. 105

Remove the laser scanner assembly ............................................. 105

Cassette pickup drive assembly ...................................................................... 108

Remove the cassette pickup drive assembly ................................. 108

Registration sensor assembly ......................................................................... 112

Remove the registration sensor assembly ..................................... 112

Lifter-drive assembly ....................................................................................... 115

Remove the lifter-drive assembly ................................................... 115

ITB front guide assembly ................................................................................ 117

ITB rear guide assembly ................................................................................. 119

Residual toner full sensor ............................................................................... 120

Remove the residual toner full sensor ............................................ 121

Formatter case ................................................................................................ 123

Delivery assembly ........................................................................................... 124

Remove the delivery assembly ....................................................... 124

Duplex drive assembly (duplex models) ......................................................... 127

Remove the duplex-drive assembly ............................................... 127

Delivery drive assembly (simplex models) ...................................................... 129

Remove the delivery drive assembly .............................................. 129

Residual-toner-feed assembly ........................................................................ 130

Remove the residual-toner-feed assembly ..................................... 130

ITB motor ........................................................................................................ 132

Remove the ITB motor ................................................................... 132

Drum motor ..................................................................................................... 134

Remove the drum motor ................................................................. 134

Developing motor ............................................................................................ 135

Remove the developing motor ........................................................ 135

Fuser motor ..................................................................................................... 136

Remove the fuser motor ................................................................. 136

Developing-disengagement motor .................................................................. 137

Remove the developing-disengagement motor .............................. 137

Power-supply fan ............................................................................................ 139

Remove the power-supply fan ........................................................ 139

Fuser fan ......................................................................................................... 142

Remove the fuser fan ..................................................................... 142

Formatter PCA ................................................................................................ 144

Formatter resets ............................................................................. 144

DC controller PCA ........................................................................................... 146

Remove the DC controller PCA ...................................................... 146

Low-voltage power supply ............................................................................... 148

Remove the low-voltage power supply ........................................... 148

Imaging (developing) high-voltage power supply ............................................ 152

vi ENWW

Page 9

Remove the imaging (developing) high-voltage power supply ....... 152

First transfer high-voltage power supply ......................................................... 153

Remove the first transfer high-voltage power supply .................... 153

Second transfer high-voltage power supply .................................................... 155

Remove the second transfer high-voltage power supply ................ 155

Driver PCA ...................................................................................................... 157

Remove the driver PCA .................................................................. 157

Power switch PCA ........................................................................................... 159

Remove the power switch PCA ...................................................... 159

Environmental sensor ..................................................................................... 160

Remove the environmental sensor ................................................. 160

Optional paper feeder assembly (Tray 3) ........................................................................ 161

Tray 3 rear cover ............................................................................................. 161

Tray 3 left cover .............................................................................................. 161

Tray 3 right-front cover .................................................................................... 163

Tray 3 front-upper cover .................................................................................. 164

Tray 3 right door .............................................................................................. 164

Tray 3 right-lower cover .................................................................................. 166

Tray 3 pickup assembly .................................................................................. 167

Tray 3 lifter drive assembly ............................................................................. 168

Tray 3 pickup motor ........................................................................................ 169

Tray 3 driver PCA ............................................................................................ 170

3 Solve problems

Solve problems checklist .................................................................................................................. 172

Menu map ........................................................................................................................................ 173

Troubleshooting process .................................................................................................................. 174

Tools for troubleshooting .................................................................................................................. 177

Pretroubleshooting checklist ........................................................................................... 174

Power-on checks ............................................................................................................. 176

Diagrams ......................................................................................................................... 177

Block diagrams ................................................................................................ 177

Plug/jack locations .......................................................................................... 179

Location of connectors .................................................................................... 180

DC controller connections .............................................................. 180

Product connections ....................................................................... 182

Locations of major components ...................................................................... 189

General timing charts ...................................................................................... 196

General circuit diagram ................................................................................... 197

HP ToolboxFX ................................................................................................................. 200

Open HP ToolboxFX ....................................................................................... 200

Status .............................................................................................................. 201

Event log ......................................................................................... 201

ENWW vii

Page 10

Alerts ............................................................................................................... 202

Set up Status Alerts ........................................................................ 202

Set up E-mail Alerts ........................................................................ 202

Product information ......................................................................................... 202

Set password .................................................................................................. 202

Help ................................................................................................................. 203

System Settings .............................................................................................. 204

Device Information .......................................................................... 204

Paper Setup .................................................................................... 205

Print Quality .................................................................................... 206

Print Density ................................................................................... 206

Paper Types ................................................................................... 206

Extended Print Modes .................................................................... 206

System Setup ................................................................................. 206

Save/Restore Settings .................................................................... 206

Product Security ............................................................................. 207

Print Settings ................................................................................................... 207

Printing ........................................................................................... 207

PCL5 ............................................................................................... 207

PostScript ....................................................................................... 207

Network Settings ............................................................................................. 207

Shop for Supplies ............................................................................................ 207

Other Links ...................................................................................................... 207

Internal print quality test pages ........................................................................................ 208

Use HP ToolboxFX to troubleshoot print-quality problems ............................ 208

Configuration page .......................................................................................... 209

Print quality troubleshooting tools .................................................................................... 209

Repetitive image-defect ruler .......................................................................... 209

Calibrate the product ....................................................................................... 210

Control-panel menus ....................................................................................................... 211

Use the menus ................................................................................................ 211

Reports menu .................................................................................................. 211

System Setup menu ........................................................................................ 213

Service menu .................................................................................................. 216

Network Configuration menu ........................................................................... 217

Interpret control-panel and status-alert messages .......................................................... 218

Event-log messages ........................................................................................................ 229

Print an event log ............................................................................................ 229

Event-log messages ........................................................................................ 229

Clear jams ........................................................................................................................................ 230

Common causes of jams ................................................................................................. 230

Jam locations ................................................................................................................... 231

Change Jam Recovery setting ......................................................................................... 231

Clear jams in the right door .............................................................................................. 232

viii ENWW

Page 11

Clear jams in the output bin area ..................................................................................... 235

Clear jams in Tray 1 ......................................................................................................... 235

Clear jams in Tray 2 ......................................................................................................... 237

Clear jams in the optional 500-sheet paper and heavy media tray (Tray 3) .................... 238

Clear jams in the lower right door (Tray 3) ...................................................................... 239

Solve image-quality problems .......................................................................................................... 240

Image defects table ......................................................................................................... 240

Clean the product ............................................................................................................................. 246

Solve performance problems ........................................................................................................... 247

Solve connectivity problems ............................................................................................................. 248

Solve direct-connect problems ........................................................................................ 248

Solve network problems .................................................................................................. 248

Service mode functions .................................................................................................................... 249

Secondary service menu ................................................................................................. 249

Open the secondary service menu ................................................................. 249

Secondary service menu structure .................................................................. 249

Product resets .................................................................................................................. 250

Restore the factory-set defaults ...................................................................... 250

Engine test page ............................................................................................. 250

Cold reset ........................................................................................................ 250

NVRAM initialization ........................................................................................ 251

Super NVRAM initialization ............................................................................. 251

Product updates ............................................................................................................................... 252

4 Parts and diagrams

Order parts by authorized service providers .................................................................................... 254

Order parts, accessories, and supplies ........................................................................... 254

Related documentation and software .............................................................................. 254

Supplies part numbers ..................................................................................................... 255

Customer self repair parts ............................................................................................... 255

Accessories part numbers ............................................................................................... 257

How to use the parts lists and diagrams .......................................................................................... 258

Assembly locations ........................................................................................................................... 259

External covers, panels, and doors .................................................................................................. 260

Right door assembly ......................................................................................................................... 262

Internal components (1 of 6) ............................................................................................................ 264

Internal components (2 of 6) ............................................................................................................ 266

Internal components (3 of 6) ............................................................................................................ 268

Internal components (4 of 6) ............................................................................................................ 270

Internal components (5 of 6) ............................................................................................................ 272

Internal components (6 of 6) ............................................................................................................ 274

Cassette ........................................................................................................................................... 276

Paper pickup assembly .................................................................................................................... 278

ENWW ix

Page 12

Paper delivery assembly .................................................................................................................. 280

Printed circuit assemblies ................................................................................................................. 282

Paper feeder external components .................................................................................................. 284

Paper feeder internal components ................................................................................................... 286

Paper feeder PCA ............................................................................................................................ 288

Alphabetical parts list ....................................................................................................................... 290

Numerical parts list ........................................................................................................................... 297

Appendix A Service and support

Hewlett-Packard limited warranty statement .................................................................................... 306

HP's Premium Protection Warranty: LaserJet print cartridge limited warranty statement ................ 307

HP Color LaserJet Fuser Kit Limited Warranty Statement ............................................................... 308

End User License Agreement .......................................................................................................... 309

Customer self-repair warranty service .............................................................................................. 311

Customer support ............................................................................................................................. 312

Appendix B Product specifications

Physical specifications ..................................................................................................................... 314

Performance specifications .............................................................................................................. 314

Electrical specifications .................................................................................................................... 314

Acoustic specifications ..................................................................................................................... 314

Environmental specifications ............................................................................................................ 315

Skew specifications .......................................................................................................................... 316

Appendix C Regulatory information

FCC regulations ............................................................................................................................... 318

Declaration of conformity .................................................................................................................. 319

Safety statements ............................................................................................................................. 320

Laser safety ..................................................................................................................... 320

Canadian DOC regulations .............................................................................................. 320

VCCI statement (Japan) .................................................................................................. 320

Power cord statement (Japan) ......................................................................................... 320

EMC statement (Korea) ................................................................................................... 320

Laser statement for Finland ............................................................................................. 320

Substances Table (China) ............................................................................................... 321

Index ................................................................................................................................................................. 323

x ENWW

Page 13

1 Theory of operation

Basic operation

●

Formatter-control system

●

Engine-control system

●

Image-formation system

●

Pickup, feed, and delivery system

●

Paper feeder

●

ENWW 1

Page 14

Basic operation

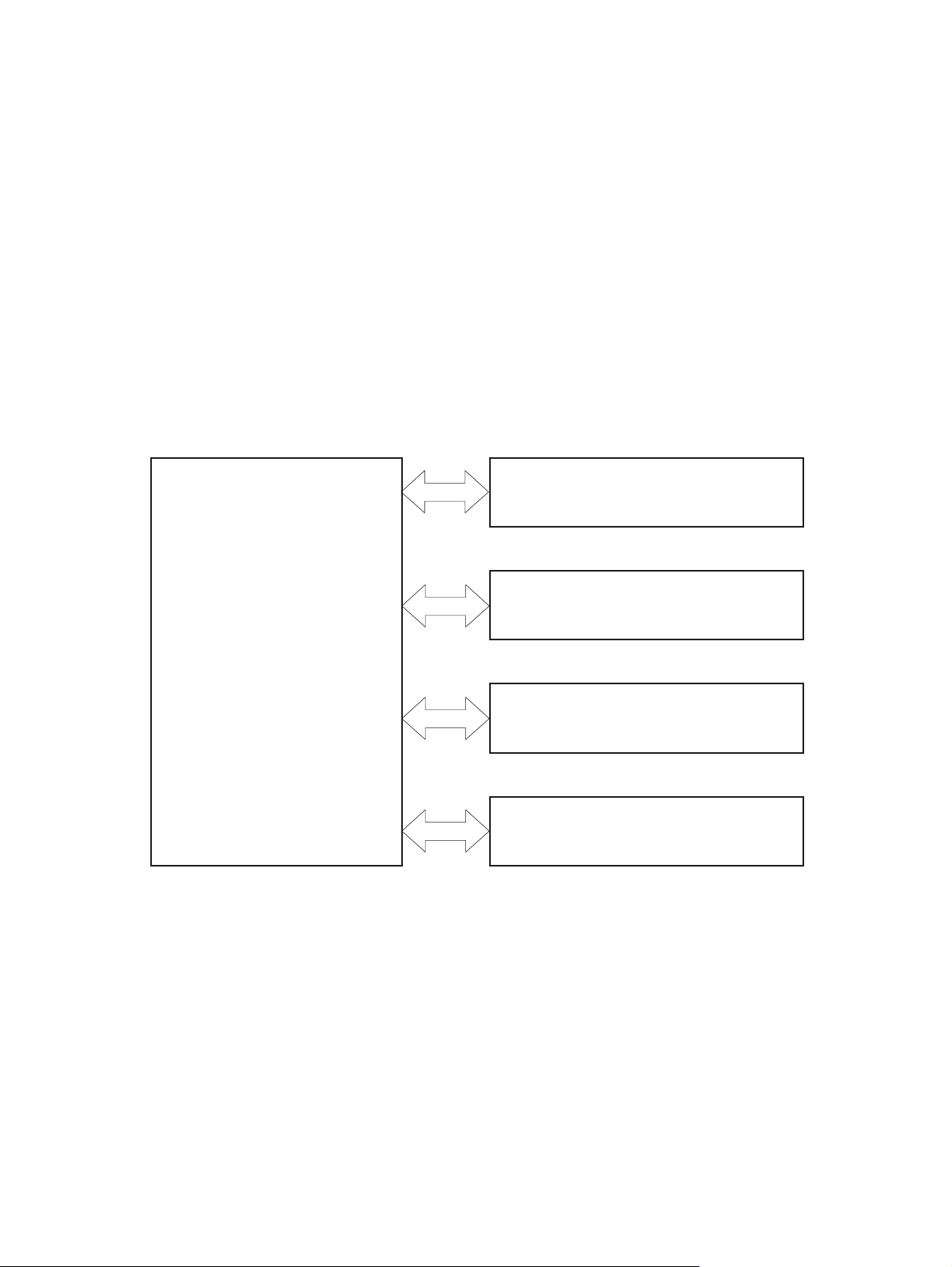

Major product systems

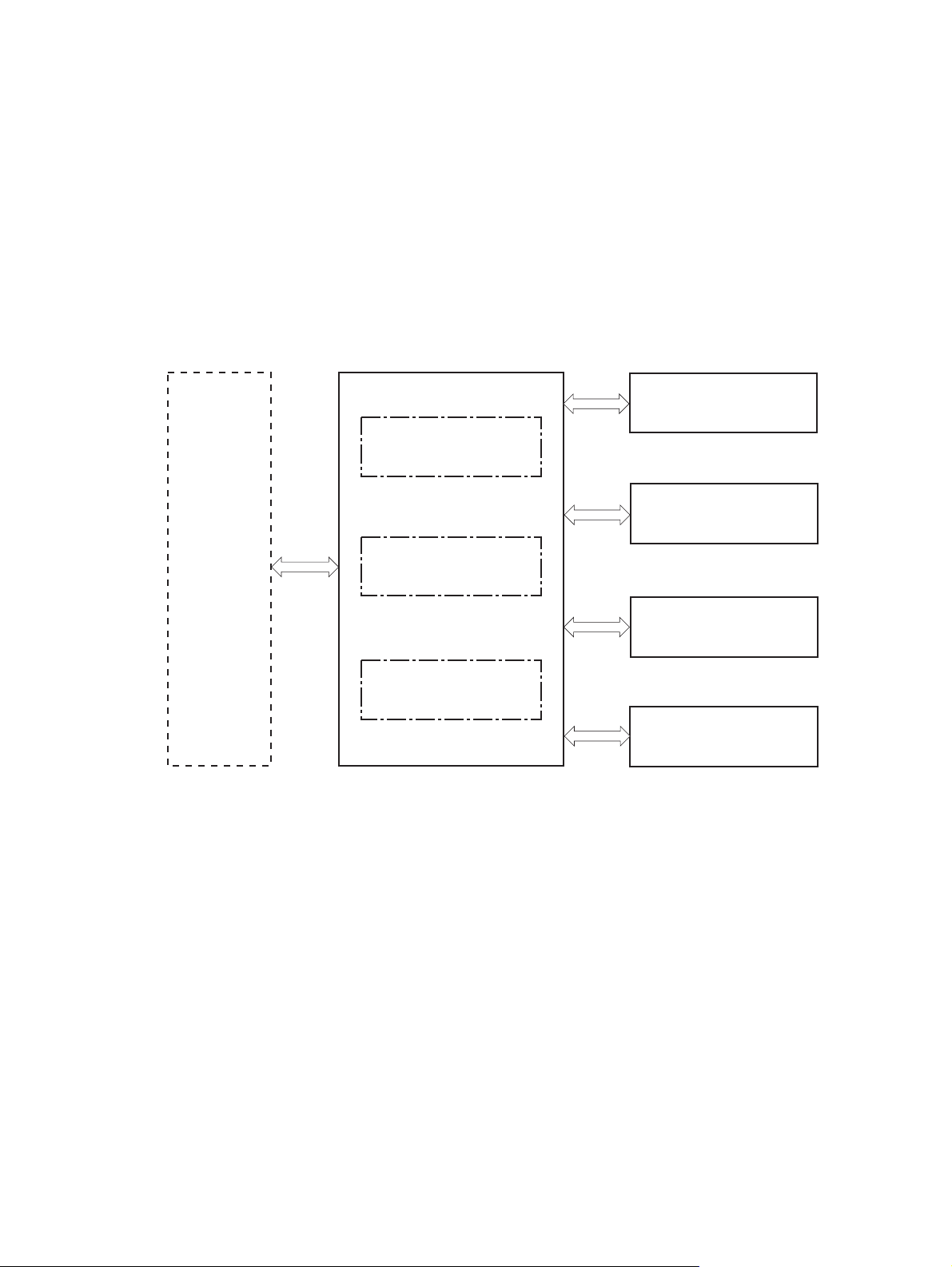

The product contains the following five systems:

Engine-control system

●

Laser scanner system

●

Image-formation system

●

Media feed system

●

Optional paper feeder system

●

Product block diagram

Figure 1-1 Product block diagram

LASER SCANNER SYSTEM

ENGINE CONTROL SYSTEM

IMAGE-FORMATION SYSTEM

MEDIA FEED SYSTEM

OPTION

2 Chapter 1 Theory of operation ENWW

Page 15

Sequence of operation

The DC controller in the engine-control system controls the operational sequences of the product. The

following table describes durations and operations for each period of a print operation from when the

product is turned on until the motor stops rotating.

Normal sequence of operation

Table 1-1 Sequence of operation

Name Timing Purpose

WAIT From the time the power switch is turned on, the door

STBY (standby) From the end of the WAIT or LSTR period until either

INTR (initial

rotation)

is closed, or the product exits Sleep mode until the

product is ready for a print operation.

a print command is sent or the power switch is turned

off.

From the time the print command is received until the

product picks up a piece of paper.

Brings the product to printable condition:

Detects and heats the fuser

●

Detects the print cartridge and any cartridge

●

changes

Detects the ITB, and moves the ITB and the

●

developing unit to the home position

Cleans residual toner from the ITB and the

●

secondary transfer roller

Maintains the product in printable condition:

Enters Sleep mode if the sleep command is

●

received

Performs a calibration if the calibration

●

command is received

Prepares for the print job

Activates the high-voltage power supply

●

Activates the laser scanner

●

Opens the laser shutter

●

Cleans the protective laser glass

●

Engages the print cartridges

●

Warms the fuser

●

ENWW Basic operation 3

Page 16

Table 1-1 Sequence of operation (continued)

Name Timing Purpose

PRINT From the end of the INTR period until the last sheet

completes the fusing operation.

LSTR (last

rotation)

From the end of the PRINT period until the main motor

stops rotating.

Prints

Forms the image on the photosensitive drum

●

Transfers the toner image to the paper

●

Fuses the toner image to the paper

●

Moves the last printed sheet to the output bin.

Stops the high-voltage power supply

●

Stops the laser scanner

●

Closes the laser shutter

●

Cleans the protective laser glass

●

Disengages the print cartridges

●

Stops the fuser

●

The product enters the INTR period as the LSTR

period is completed, if the formatter sends another

print command.

4 Chapter 1 Theory of operation ENWW

Page 17

Formatter-control system

The formatter is responsible for the following procedures:

Controlling sleep mode

●

Receiving and processing print data from the various product interfaces

●

Monitoring control-panel functions and relaying product-status information (through the control

●

panel and the network or bidirectional interface)

Developing and coordinating data placement and timing with the DC controller PCA

●

Storing font information

●

Communicating with the host computer through the network or the bidirectional interface

●

The formatter receives a print job from the network or bidirectional interface and separates it into image

information and instructions that control the printing process. The DC controller PCA synchronizes the

image-formation system with the paper-input and -output systems, and then signals the formatter to

send the print-image data.

The formatter also provides the electrical interface and mounting locations for an additional DIMM.

Sleep mode

NOTE: In the System Setup menu, this item is termed Sleep Delay.

This feature conserves power after the product has been idle for an adjustable period of time. When the

product is in Sleep Delay, the control-panel backlight is turned off, but the product retains all settings,

downloaded fonts, and macros. The default setting is for Sleep Delay to be enabled, and the product

enters Sleep Delay after a 30-minute idle time.

The product exits Sleep Delay and enters the warm-up cycle when any of the following events occur:

A print job, valid data, or a PML or PJL command is received

●

A control-panel button is pressed

●

A cover is opened

●

A paper tray is opened

●

The engine-test switch is pressed

●

NOTE: Product error messages override the Sleep message. The product enters Sleep Delay at the

appropriate time, but the error message continues to appear.

Input/output

The product has two I/O interfaces:

A USB 2.0 port for connecting directly to a computer

●

An internal 10/100Base-T network port.

●

ENWW Formatter-control system 5

Page 18

CPU

The formatter incorporates a 540 MHz Coldfire processor.

Memory

The random access memory (RAM) on the formatter PCA contains the page, I/O buffers, and the font

storage area. It stores printing and font information received from the host system, and can also serve

to temporarily store a full page of print-image data before the data is sent to the print engine. Memory

capacity can be increased by adding a DIMM to the formatter. Note that adding memory might also

increase the print speed for complex graphics.

NOTE: If the product encounters a problem when managing available memory, a clearable warning

message appears on the control-panel display.

Firmware

The firmware is contained on NAND flash memory soldered on the formatter board. A remote firmware

upgrade process is available, which overwrites the firmware in the NAND flash.

Nonvolatile memory

The product uses nonvolatile memory (NVRAM) to store device and user configuration settings. The

contents of NVRAM are retained when the product is turned off or disconnected.

PJL overview

The printer job language (PJL) is an integral part of configuration, in addition to the standard printer

command language (PCL). With standard cabling, the product can use PJL to perform a variety of

functions such as these:

Two-way communication with the host computer through a network connection or a USB

●

connection. The product can inform the host about such things as the control-panel settings, and

the control-panel settings can be changed from the host.

Dynamic I/O switching. The product uses this switching to be configured with a host on each I/O.

●

The product can receive data from more than one I/O simultaneously, until the I/O buffer is full.

This can occur even when the product is offline.

Context-sensitive switching. The product can automatically recognize the personality (PS or PCL)

●

of each job and configure itself to serve that personality.

Isolation of print environment settings from one print job to the next. For example, if a print job is

●

sent to the product in landscape mode, the subsequent print jobs print in landscape mode only if

they are formatted for landscape printing.

PML

The printer management language (PML) allows remote configuration and status read-back through the

I/O ports.

Control panel

The formatter sends and receives product status and command data to and from the control-panel PCA.

6 Chapter 1 Theory of operation ENWW

Page 19

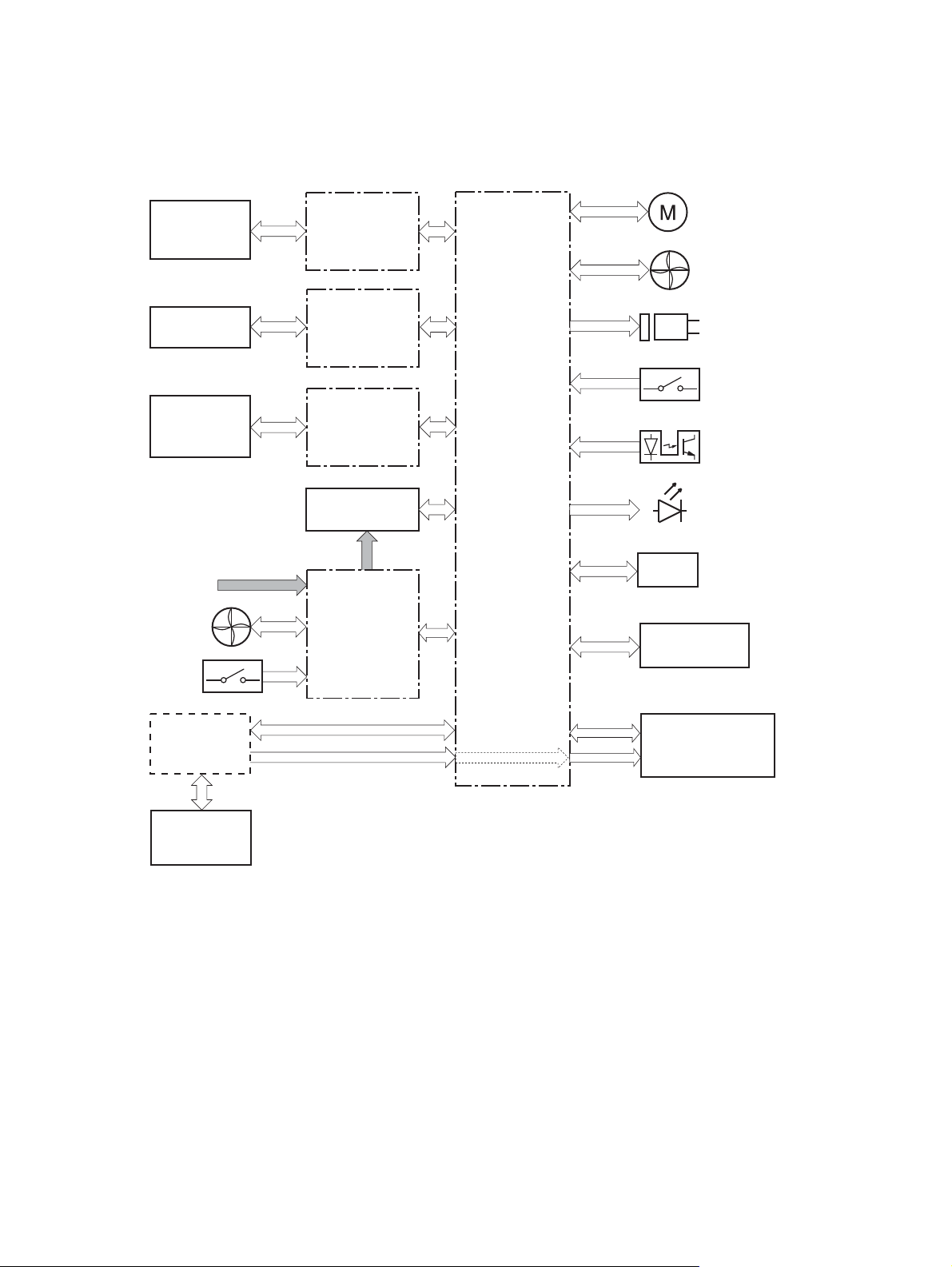

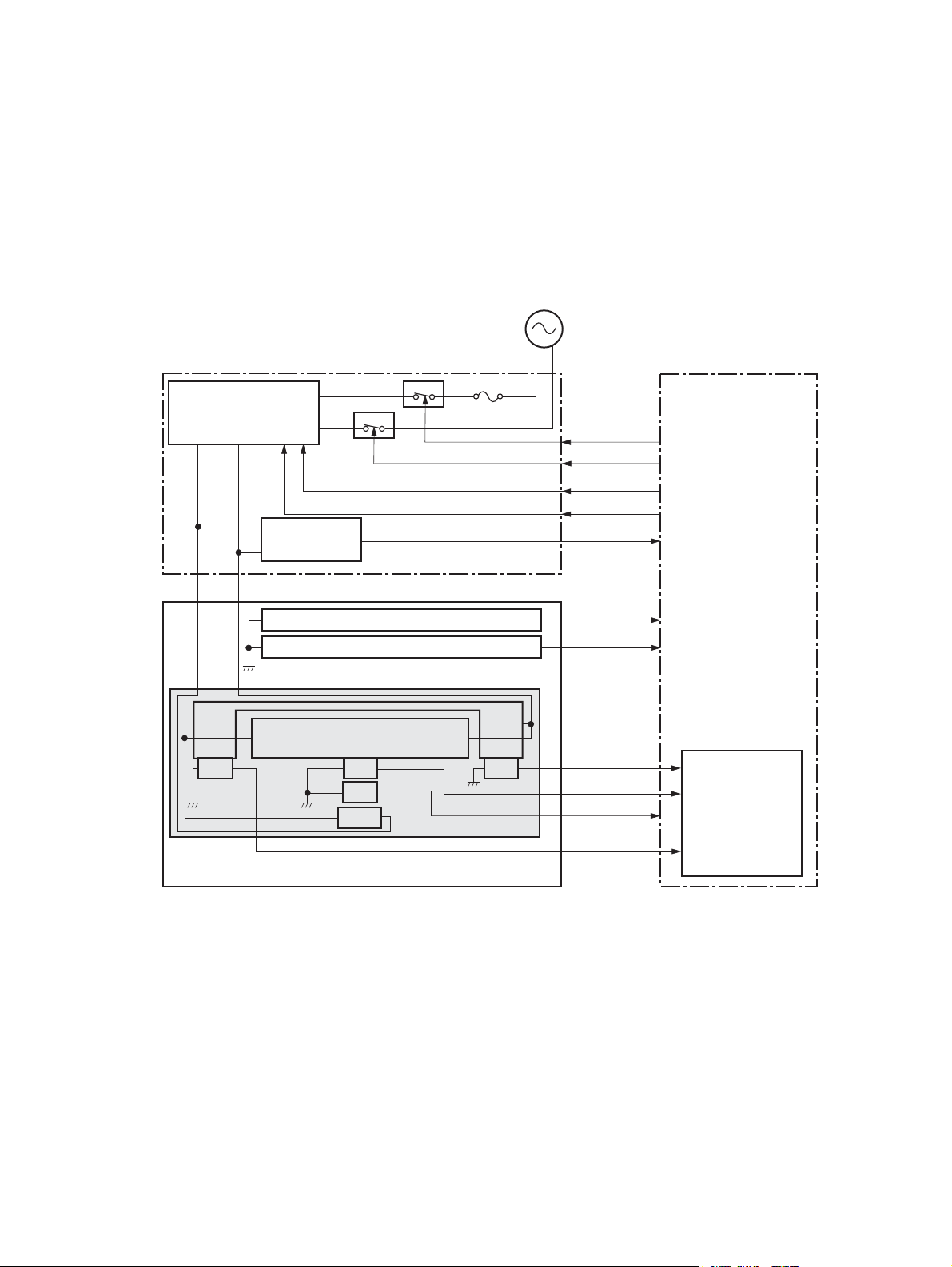

Engine-control system

The engine-control system coordinates all product functions, according to commands that the formatter

sends. The engine-control system drives the laser/scanner system, the image formation system, and

the pickup/feed/delivery system.

The engine control system contains the following major components:

DC controller

●

Low-voltage power supply

●

High-voltage power supply

●

Figure 1-2 Engine-control system

Formatter

ENGINE CONTROL SYSTEM

LASER SCANNER SYSTEM

DC controller

IMAGE-FORMATION SYSTEM

Low-voltage power supply

MEDIA FEED SYSTEM

High-voltage power supply

OPTION

ENWW Engine-control system 7

Page 20

DC controller

The DC controller controls the operational sequence of the product.

Figure 1-3 DC controller diagram

Cartridge

(x4)

ITB unit

Secondary

transfer roller

AC input

Fan

DEV high-voltage

power supply

TR1 high-voltage

power supply

TR2 high-voltage

power supply

Fuser

Low-voltage

power supply

Motor

Fan

Solenoid

Switch

Photointerrupter

DC controller

LED

Sensor

Option

Switch

Formatter

Control

panel

Laser scanner unit

The DC controller controls the product's electrical components, listed in the following table.

8 Chapter 1 Theory of operation ENWW

Page 21

Table 1-2 Electrical components

Component type Abbreviation Name

Switch SW1 Power switch

SW2 24V interlock switch

SW3 5V interlock switch 1

SW4 5V interlock switch 2

SW5 Primary transfer disengagement switch

SW6 Toner collection unit switch

SW7 Cassette media end guide position switch

SW8 Cassette media width guide position switch

Solenoid SL1 Cassette pickup solenoid

SL2 Tray 1 pickup solenoid

SL3 Duplex reverse solenoid 1 (duplex models only)

SL5 Primary transfer disengagement solenoid

SL7 Duplex reverse solenoid 2 (duplex models only)

Fan FM1 Power supply fan

FM2 Fuser fan

Photointerrupter (sensor) PS1 Cassette paper-presence sensor

PS2 Tray 1 paper-presence sensor

PS3 Last-paper sensor

PS4 Cassette paper-stack surface sensor

PS5 Top-of-page (TOP) sensor

PS6 Fuser delivery sensor

PS7 Loop sensor 1

PS8 Loop sensor 2

PS9 Fuser pressure-release sensor

PS10 Output bin full sensor

PS11 Developing disengagement sensor

PS12 Black drum home-position sensor

PS13 YMC drum home-position sensor

PS14 Front door sensor

PS15 Right door sensor

ENWW Engine-control system 9

Page 22

Table 1-2 Electrical components (continued)

Component type Abbreviation Name

Motor M1 ITB Motor

M2 Drum motor

M3 Developing motor

M4 Fuser motor

M5 Pickup motor

M6 Developing disengagement motor

M9 Cassette lifter motor

M10 Scanner motor

10 Chapter 1 Theory of operation ENWW

Page 23

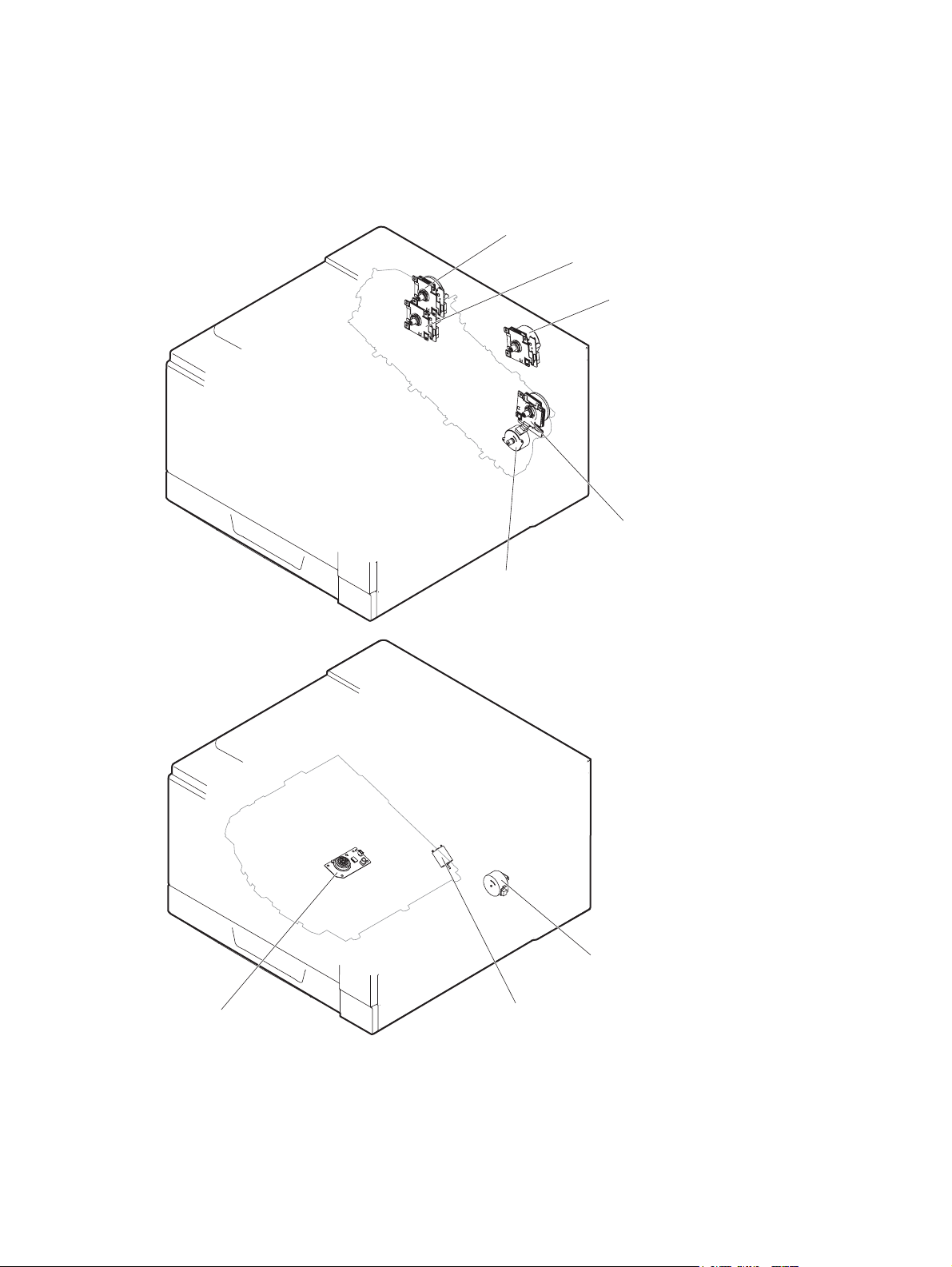

Motors

The product has eight motors for paper feed and image formation. The DC controller determines a motor

failure if a motor does not reach a specified speed within a specified period after motor startup or if the

rotational speed is outside a specified range for a specified period.`

Figure 1-4 Motors

Drum motor (M2)

Developing motor (M3)

Fuser motor (M4)

ITB motor (M1)

Scanner motor (M10)

Developing disengagement motor (M6)

Pickup motor (M5)

Cassette lifter motor (M9)

ENWW Engine-control system 11

Page 24

Table 1-3 Motors

Description Components driven Failure

ITB motor (M1) ITB

Black photosensitive drum

Developing roller

Drum motor (M2) Yellow, magenta, and cyan photosensitive drums Yes

Developing motor (M3) Yellow, magenta, and cyan developing rollers Yes

Fuser motor (M4) Fuser pressure and delivery rollers

Pressurizes and depressurizes the pressure roller

Engages and disengages the primary transfer roller

Pickup motor (M5) Tray 1 pickup roller

Cassette pickup roller

Feed roller

Duplex feed roller (duplex models only)

Developing

disengagement motor

(M6)

Engages and disengages the developing unit No

detection

Yes

Yes

No

Cassette lifter motor

(M9)

Scanner motor (M10) Scanner mirror No

Lifter for the cassette No

12 Chapter 1 Theory of operation ENWW

Page 25

Fans

The product uses to fans to maintain the correct internal temperature. The DC controller determines a

fan failure when a fan locks for a specified period after it starts driving.

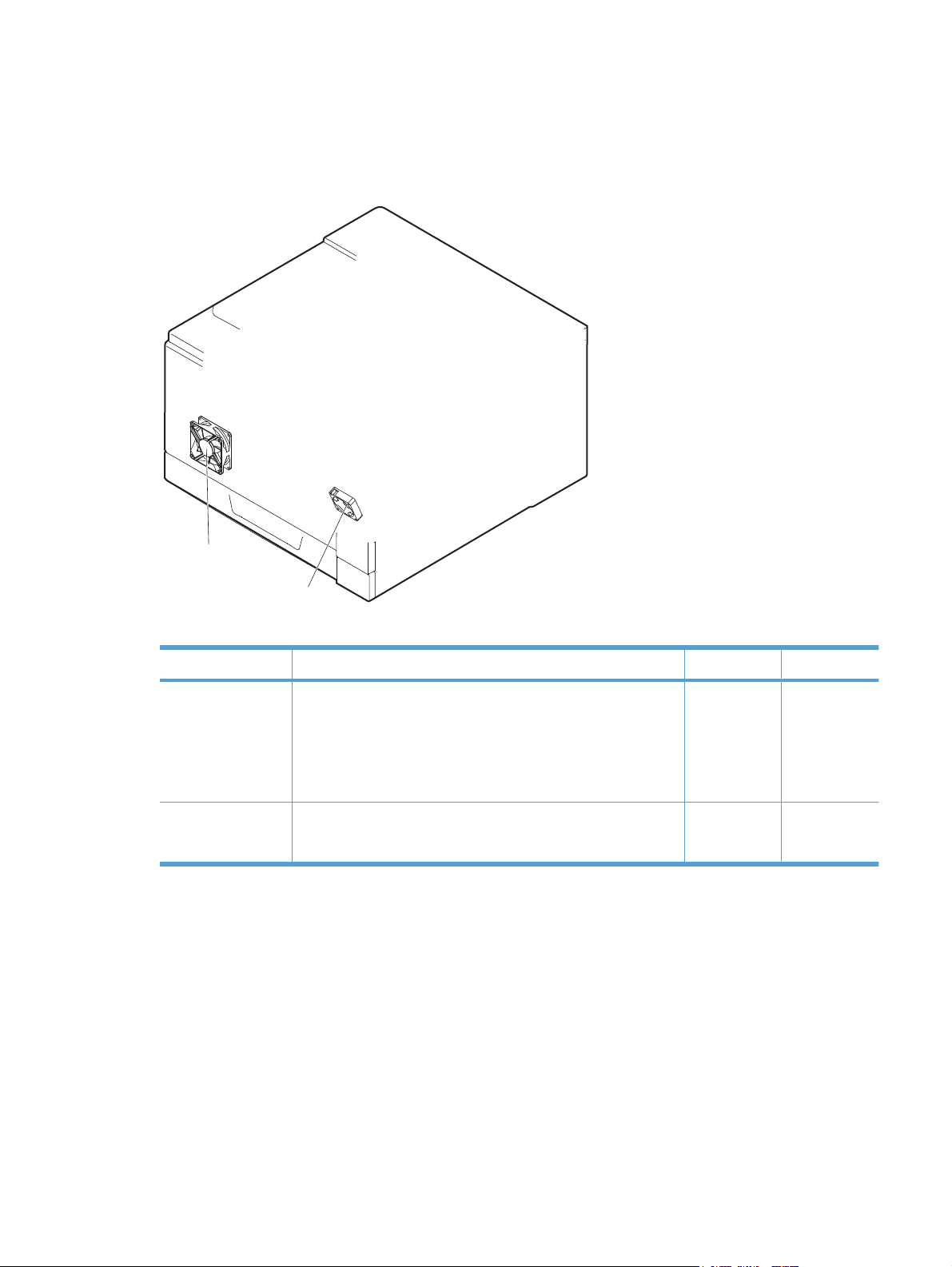

Figure 1-5 Fans

Power supply fan

(FM1)

Fuser fan

(FM2)

Table 1-4 Fans

Description Area cooled Type Speed

Power supply fan

(FM1)

Fuser (FM2) Duplex feed unit

Low-voltage power supply

Output bin

Delivery unit

Laser scanner unit

ITB area

Intake Full/Half

Intake Full

ENWW Engine-control system 13

Page 26

Fuser-control circuit

The fuser-control circuit monitors and controls the temperature in the fuser. The product uses ondemand fusing. The fuser-control circuit consists of the following major components:

Fuser main heater (H1): heats the center of the fuser sleeve

●

Fuser sub heater (H2): heats the ends of the fuser sleeve

●

Thermistors; detects the fuser temperature (contact type)

●

Sleeve thermistor (TH1): Detects the temperature at the center of the fuser sleeve

◦

Main thermistor (TH2): Detects the temperature at the center of the fuser heater

◦

Sub thermistor 1 (TH3): Detects the temperature at the end of the fuser heater nearest the

◦

front of the product

Sub thermistor 2 (TH4): Detects the temperature at the end of the fuser heater nearest the

◦

rear of the product

Thermal fuse (FU1): prevents abnormal temperature rise in the fuser heater (non-contact type)

●

Figure 1-6 Fuser-control circuit

TH3

Pressure roller

Front of engine

H2

TH4

Fuser sleeve

H1

TH2

FU1

TH1

FUSER TEMPERATURE signal

FUSER HEATER

CONTROL signal

Low-voltage power supply

Fuser heater

control circuit

DC controller

Fuser heater

safety circuit

14 Chapter 1 Theory of operation ENWW

Page 27

Fuser temperature control

The fuser temperature control maintains the fuser heater at its targeted temperature.

The fuser main heater and sub heater control the temperature of the fuser sleeve.

The DC controller monitors the main thermistor and the sleeve thermistor. The DC controller controls

the FUSER MAIN HEATER CONTROL (FSRD1) and the FUSER SUB-HEATER CONTROL (FSRD2)

signals according to the detected temperature. The fuser-heater control circuit controls the fuser heater

depending on the signal so that the heater remains at the targeted temperature.

Figure 1-7 Fuser-heater control circuit

AC input

Low-voltage power supply

Noise filter

Fuser heater

control circuit

Zerocross

circuit

Improper fuser installation prevention circuit

H2

TH3 TH4

RL102

FU102

RL103

Fuser

Fuser presence circuit

Fuser sleeve

H1

TH2

TH1

FU1

RLD1

RLD2

FSRD1

FSRD2

ZEROX

FUSEROPEN

FUHL

THERM4

THERM2

THERM1

THERM3

DC controller

Fuser heater

safety circuit

ENWW Engine-control system 15

Page 28

Fuser protective function

The protective function detects an abnormal temperature rise of the fuser unit and interrupts power

supply to the fuser heater.

The following three protective components prevent an abnormal temperature rise of the fuser heater:

DC controller

●

The DC controller interrupts power supply to the fuser heater when it detects an abnormal

◦

temperature of the fuser heater.

Fuser-heater safety circuit

●

The fuser heater safety circuit interrupts power supply to the fuser heater when the detected

◦

temperature of the main and sub thermistors is abnormal.

Thermal fuse

●

The thermal fuse is broken to interrupt power supply to the fuser heater when the thermoswitch

◦

detects an abnormal temperature of the fuser heater.

16 Chapter 1 Theory of operation ENWW

Page 29

Fuser failure detection

The DC controller determines a fuser unit failure, deactivates the FUSER HEATER CONTROL signal,

releases the relay to interrupt power supply to the fuser heater and notifies the formatter of a failure

state when it encounters the following conditions:

Abnormal temperature rise: The sleeve thermistor does not rise at a specified temperature within

●

a specified period after the fuser heater control starts.

Abnormally low temperature: The thermistors are at a specified temperature or lower during a print

●

operation or other fuser heating cycle.

Abnormally high temperature: The thermistors are at a specified temperature or higher, regardless

●

of the fuser control status.

Drive circuit abnormality: The frequency in the zerocross circuit is out of a specified range when

●

the product is turned on or is in the standby period.

ENWW Engine-control system 17

Page 30

Low-voltage power supply

The low-voltage power supply (LVPS) converts AC input voltage to DC voltage.

Figure 1-8 Low-voltage power supply

Low-voltage power supply

Power switch

SW1

Formatter

FU101

FU102

RL102

RL103

Noise filter

Fuser heater

control circuit

Fuser

Noise filter

Rectifying circuit

RL101

RLD1

RLD2

REMOTEON

Zerocross

circuit

ZEROX

+3.3V generation

circuit

Protection

circuit

+24V generation

circuit

+24V

Remote switch

control circuit

+5V generation

circuit

+5V

+3.3V

PWRON

+3.3V

SWON/OFF

DC controller

SW2

+24R

+24V

Interlock switch

SW4

SW3

+5V

Interlock switch

+5R

The product uses three DC voltages: 24V, 5V, and 3.3V. The voltages are subdivided as follows:

+24V Supplied constantly

Stopped during Sleep mode

+24R Interrupted when the front or right door is opened

18 Chapter 1 Theory of operation ENWW

Page 31

+5V Supplied constantly

Stopped during Sleep mode

+5R Interrupted when the front or right door is opened

+3.3V Supplied constantly

ENWW Engine-control system 19

Page 32

Overcurrent/overvoltage protection

The low-voltage power supply has a protective circuit against overcurrent and overvoltage to prevent

failures in the power supply circuit. The low-voltage power supply automatically stops supplying the DC

voltage whenever excessive current flows or voltage abnormally increases.

If the dc voltage is not being supplied from the low-voltage power supply, the protective function may

be running. In this case, turn off the power switch and unplug the power cord. Do not turn the power

switch on until the root cause is found.

The LVPS has two fuses on the PCA. The LVPS 24V output is interrupted to the fuser and the highvoltage power supply if the either of the interlock switches (SW3 and SW4) is in the off position (door

open).

WARNING! The product power switch only interrupts dc voltage from the LVPS. The AC voltage is

present in the product when the power cord is plugged into a power receptacle and the power switch is

in the off position. You must unplug the product power cord before servicing the product.

WARNING! If you believe the overcurrent or overvoltage protection circuits have been activated, do

not plug in the product power cord or turn on the product power until the cause of the failure is found

and corrected.

In addition, fuses in the low-voltage power supply protect against overcurrent. If overcurrent flows into

the AC line, the fuses melt and cut off the power distribution.

20 Chapter 1 Theory of operation ENWW

Page 33

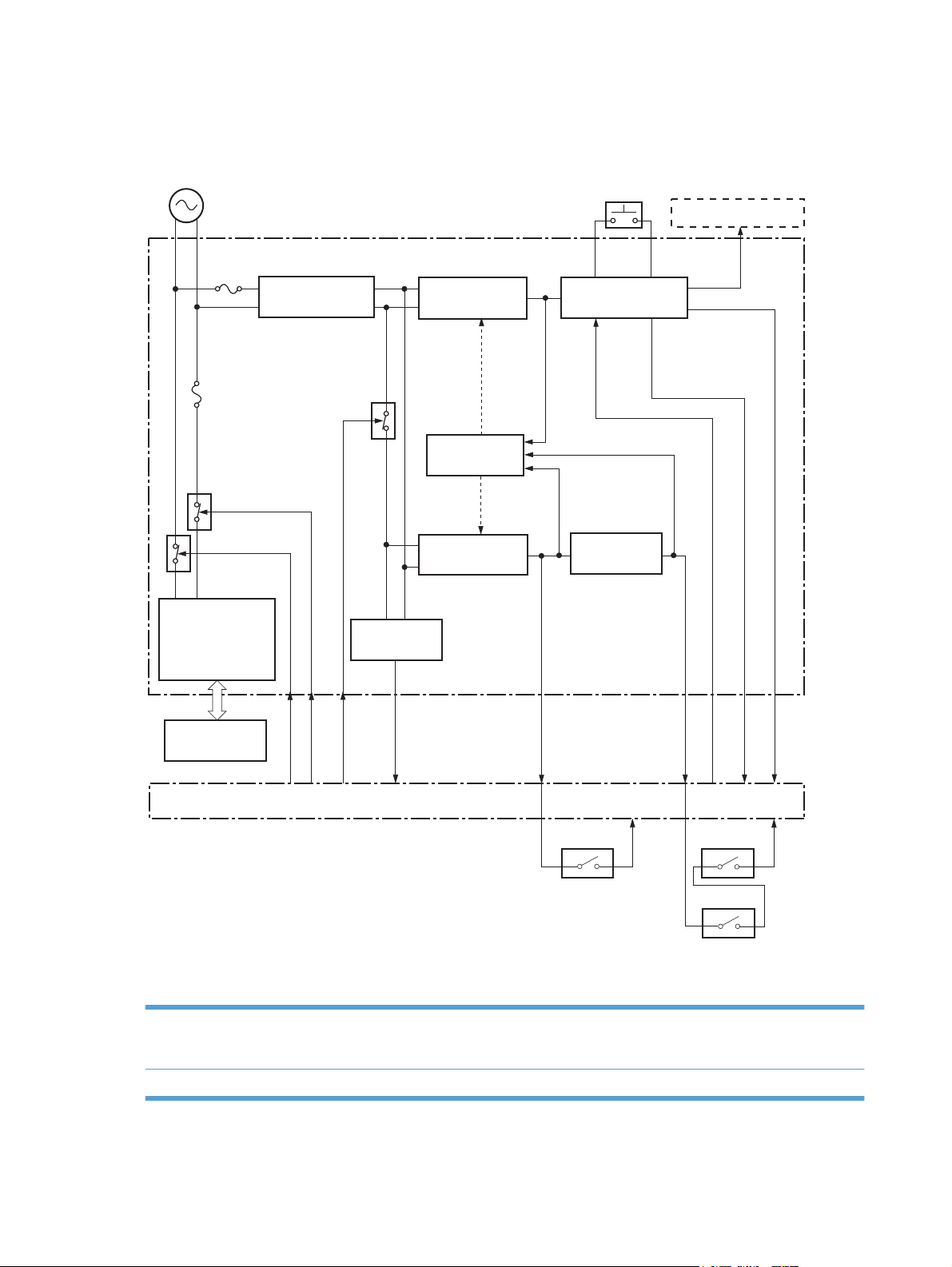

High-voltage power supply

The DC controller controls the high-voltage power supply to generate biases.

Figure 1-9 High-voltage power supply

TR1 high-voltage power supply

Primary transfer bias circuit

TRI-1

PRI-1

DEV-4

DEV-2

DEV-3

DEV-1

Developing bias circuit

TRI-2

PRI-2

PRI-4

Primary charging bias circuit

PRI-3

TRI-3

TRI-4

FG

Secondary transfer bias circuit

TRS2

DEV high-voltage power supply

DC controller

TR2 high-voltage power supply

The high-voltage power supply (HVPS) applies biases to the following components:

Primary charging roller: The primary charging bias is applied to the surface of the photosensitive

●

drum to charge it uniformly negative as a preparation for the image formation.

Developing roller: The developing bias is used to adhere toner to an electrostatic latent image

●

formed on the photosensitive drum.

ENWW Engine-control system 21

Page 34

Primary transfer roller: The primary transfer bias is used to transfer the toner from each

●

photosensitive drum onto the ITB.

Secondary transfer roller: The secondary transfer bias is used to transfer the toner image from the

●

ITB onto the paper. The reversed bias is applied to transfer residual toner on the secondary transfer

roller back to the ITB. The residual toner on the ITB is deposited in the toner collection unit.

22 Chapter 1 Theory of operation ENWW

Page 35

Laser scanner system

The laser scanner system forms latent images on the photosensitive drums according to the VIDEO

signals sent from the formatter.

The main components of the laser/scanner are the laser unit and the scanner motor unit. The DC

controller sends signals to the laser/scanner to control the functions of these components.

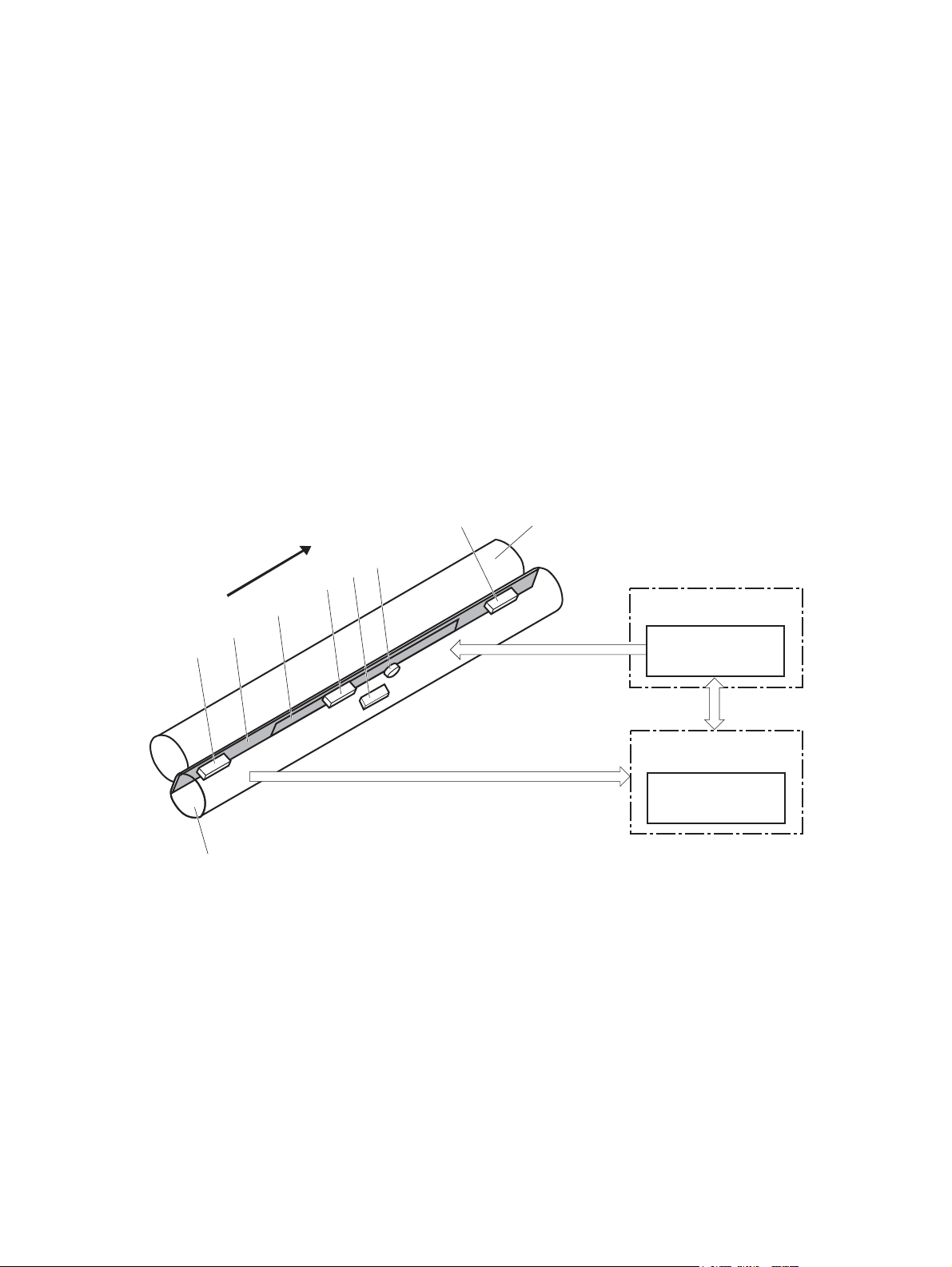

Figure 1-10 Laser/scanner system

Photosensitive drum

Scanner motor unit

Connecting board

SCANNER MOTOR CONTROL signal

VIDEO signal

LASER CONTROL signal

BDI signal

Laser unit (C/Bk)

Laser unit (Y/M)

Scanner mirror

DC controller

Formatter

ENWW Engine-control system 23

Page 36

Laser failure detection

The DC controller determines an optical unit failure and notifies the formatter, if the laser/scanner

encounters the following conditions:

The scanner motor does not reach a specified rotation frequency within a specified period of the

●

scanner motor start up.

The beam detect (BD) interval is out of a specified value during a print operation.

●

24 Chapter 1 Theory of operation ENWW

Page 37

Image-formation system

Electrophotographic process

The electrophotographic process forms an image on the paper. Following are the major components

used in the process:

Print cartridges

●

Intermediate transfer belt (ITB)

●

Secondary transfer roller

●

Fuser

●

Laser scanner

●

The DC controller uses the laser scanner and HVPS to form the toner image on the photosensitive drum.

The image is transferred to the print media and then fused onto the paper.

Figure 1-11 Electrophotographic process block diagram

TR1 high-voltage

Cartridge

power supply

Laser scanner

ITB

DEV high-voltage

power supply

Fuser

Secondary transfer

roller

TR2 high-voltage

power supply

DC controller

ENWW Image-formation system 25

Page 38

Figure 1-12 Electrophotographic process drive system

Drum motor

M2

Developing roller

Developing roller

Developing roller

Fuser motor

M4

Developing roller

Developing motor

M3

M1

ITB motor

26 Chapter 1 Theory of operation ENWW

Page 39

Image formation process

Each of the following processes functions independently and must be coordinated with the other product

processes. Image formation consists of the following processes:

Latent-image formation block Step 1: pre-exposure

Developing block Step 4: developing

Transfer block Step 5: primary transfer

Fusing block Step 8: fusing

ITB cleaning block Step 9: ITB cleaning

Drum cleaning block Step 10: Drum cleaning

Figure 1-13 Image formation process

: Media path

: Direction of drum rotation

: Block

Step 2: primary charging

Step 3: laser-beam exposure

Step 6: secondary transfer

Step 7: separation

Delivery

ITB cleaning

9. ITB cleaning

: Step

4. Developing

Developing

5. Primary transfer

10. Drum cleaning

1. Pre-exposure

2. Primary charging

3. Laser beam exposure

Latent image formation

8. Fuser

Fuser

Transfer

7. Separation

6. Secondary transfer

Drum cleaning

Registration

Pickup

ENWW Image-formation system 27

Page 40

Latent-image formation block

During the latent-image formation stage, the laser scanner forms invisible images on the photosensitive

drums in the print cartridges.

Pre-exposure

Step 1: Light from the pre-exposure LED strikes the photosensitive drum surface. This eliminates the

residual electrical charges on the drum surface.

Figure 1-14 Pre-exposure

LED

Photosensitive drum

Primary charging

Step 2: DC and AC biases are applied to the primary charging roller, which transfers a uniform negative

potential to the photosensitive drum.

Figure 1-15 Primary charging

Primary charging roller

Photosensitive drum

Primary charging bias

28 Chapter 1 Theory of operation ENWW

Page 41

Laser beam exposure

Step 3: The laser beam scans the photosensitive drum to neutralize negative charges on parts of the

drum surface. An electrostatic latent image is formed on the drum where negative charges were

neutralized.

Figure 1-16 Laser beam exposure

Laser beam

ENWW Image-formation system 29

Page 42

Developing block

Step 4: In the print cartridge, toner acquires a negative charge from the friction that occurs when the

developing roller rotates against the developing blade. The developing bias is applied to the developing

roller to create a difference in the electric potential of the drum. When the negatively charged toner

comes in contact with the photosensitive drum, it adheres to the latent image because the drum surface

has a higher potential.

Figure 1-17 Developing

Developing blade

Developing roller

Developing bias

Photosensitive drum

30 Chapter 1 Theory of operation ENWW

Page 43

Transfer block

Primary transfer

Step 5: The toner on the photosensitive drum is transferred to the intermediate transfer belt (ITB). The

ITB is given a positive charge by the bias of the primary transfer roller. The negatively charged toner on

the drum surface is transferred onto the ITB. All four color planes are transferred onto the ITB in this

step.

Figure 1-18 Primary transfer

Primary transfer roller

ITB

Primary transfer bias

Photosensitive

drum

Secondary transfer

Step 6: The toner image on the ITB is transferred to the paper. The secondary transfer bias is applied

to the secondary transfer roller to charge the paper positive. As the paper passes between the secondary

transfer roller and the ITB, the complete toner image on the ITB is transferred onto the paper.

Figure 1-19 Secondary transfer

Secondary transfer roller

Secondary transfer

opposed roller

ITB

Paper

Secondary transfer bias

ENWW Image-formation system 31

Page 44

Separation

Step 7: The elasticity of the paper and the curvature of the secondary transfer opposed roller cause the

paper to separate from the ITB. The static charge eliminator reduces back side static charge of the paper

and controls excess discharge after the transfer process for stable media feed and image quality.

Figure 1-20 Separation

Secondary transfer

opposed roller

ITB

Paper

Static charge eliminator

Secondary transfer roller

Fusing block

Step 8: The product uses an on-demand fuser. The toner image is permanently affixed to the printing

paper by heat and pressure.

Figure 1-21 Fusing

Fuser sleeve

Fuser heater

Toner

Paper

Pressure roller

32 Chapter 1 Theory of operation ENWW

Page 45

ITB cleaning block

Step 9: The cleaning blade scrapes the residual toner off the surface of the ITB. The residual toner feed

screw deposits residual toner in the toner collection unit.

Figure 1-22 ITB cleaning

Residual toner feed screw

Drum cleaning block

Step 10: The cleaning blade scrapes the residual toner off the surface of the photosensitive drum, and

toner is deposited in the waste section inside the print cartridge.

Figure 1-23 Drum cleaning

Cleaning blade

ITB

Cleaning blade

Toner waste

Photosensitive

drum

ENWW Image-formation system 33

Page 46

Print cartridges

The product has four print cartridges, one for each color: yellow, magenta, cyan, and black. Each of

them has the same structure. The cartridges are filled with toner and consist of the following

components:

Photosensitive drum

●

Developing unit

●

Primary charging roller

●

The DC controller rotates the motors to drive the photosensitive drum, developing unit, and primary

charging roller.

Figure 1-24 Print cartridge block diagram

DC controller

PS13:

YMC drum home

position sensor

Memory tag

Developing

M6

disengagement

motor

Photosensitive drum

Primary charging roller

Developing unit

PS11:

Developing disengagement

sensor

M2

Drum motor

M3

Developing motor

34 Chapter 1 Theory of operation ENWW

Page 47

Memory tag

The memory tag is a non-volatile memory chip in the cartridge that stores information about usage for

the cartridge. The product reads and writes the data in the memory tag. The DC controller determines

a memory tag error and notifies the formatter when it fails to either read from or write to the memory

tag.

Cartridge presence detection

The DC controller detects the presence of the cartridges by monitoring the RD sensor. When the DC

controller determines a cartridge absence, it notifies the formatter.

Toner level detection

The DC controller detects the remaining toner level in a cartridge by the optical detection method. The

DC controller notifies the formatter of the remaining toner level.

Cartridge life detection

The DC controller detects the cartridge life by monitoring the total operational wear limit or remaining

toner level of the cartridge. The DC controller determines a cartridge end of life and notifies the formatter

when the operational wear limit of the cartridge reaches a specified amount or the cartridge runs out of

toner.

Developing unit engagement and disengagement control

The developing unit engagement and disengagement control engages the developing unit with the

photosensitive drum or disengages the developing unit from the drum depending on the print mode: fullcolor mode or black-only mode. The developing unit is engaged only when required, preventing a

deterioration of the drums and maximizing their life.

The developing disengagement motor rotates the developing disengagement cam. As the cam rotates,

the developing unit engages with or separates from the photosensitive drum.

When the product is turned on and when each print job is completed, all four of the developing units

disengage from the photosensitive drums. When the print mode is in full-color mode, all of the developing

units engage with the drums. When the print mode is in black-only mode, only black developing unit

engages with the drum.

ENWW Image-formation system 35

Page 48

The DC controller determines a developing disengagement motor abnormality and notifies the formatter

when it does not detect a specified signal from the developing disengagement sensor during the

developing roller engagement and disengagement operation.

Figure 1-25 Developing unit engagement and disengagement control

Developing unit is disengaged

Photosensitive drum

Developing unit

PS11:

Developing

disengagement

sensor

Developing disengagement cam

Developing unit is engaged

Developing disengagement motor

M6

DC controller

36 Chapter 1 Theory of operation ENWW

Page 49

ITB unit

The ITB unit receives the toner image from the photosensitive drums and transfers the complete toner

image to the print media. The ITB unit consists of the following components:

ITB

●

ITB drive roller

●

Primary transfer rollers

●

ITB cleaner

●

The ITB motor drives the ITB drive roller which rotates the ITB. The rotation of the ITB causes the primary

transfer rollers to rotate. The ITB cleaner cleans the ITB surface.

Figure 1-26 ITB unit block diagram

DC controller

ITB

ITB cleaner

Primary transfer roller

ITB drive roller

M1

ITB motor

ENWW Image-formation system 37

Page 50

Primary transfer roller engagement and disengagement control

Figure 1-27 Primary transfer roller engagement and disengagement control

DC controller

M4

Fuser motor

<All colors are disengaged>

YMC slide plate

<All colors are engaged>

Primary transfer

disengagement solenoid

ITB

Primary transfer roller

SL5

SW5

Bk slide plate

Primary transfer

disengagement switch

Primary transfer

disengagement cam

<Only black is engaged>

Photosensitive drum

38 Chapter 1 Theory of operation ENWW

Page 51

The primary transfer roller engagement and disengagement control engages the ITB with the

photosensitive drum or disengages the ITB from the drum depending on the requirements of the print

job. There are three states of the primary transfer rollers.

All rollers disengaged: The ITB disengages from all the four photosensitive drums. This is the

●

state during a standby period, and it is the home position for the primary transfer rollers.

All rollers engaged: The ITB engages with all the four photosensitive drums. This is the state for

●

full-color jobs.

Only black roller engaged: The ITB engages with only the black photosensitive drum. This is the

●

state for the black-only jobs.

The operational sequence of the primary transfer roller engagement and disengagement control is as

follows:

1. The fuser motor drives the primary transfer disengagement solenoid to rotate the primary transfer

disengagement cam.

2. As the cam rotates, the YMC slide plate or the Bk slide plate moves to right or left. This causes the

primary transfer roller to move up or down.

3. The ITB engages with or disengages from the photosensitive drum depending on the movement

of the primary transfer rollers.

The DC controller determines an abnormal primary transfer roller disengagement mechanism and

notifies the formatter when it does not detect a specified signal from the primary transfer disengagement

switch even though the primary transfer disengagement solenoid is driven.

ITB unit presence detection

The DC controller detects the ITB unit presence by monitoring the primary transfer disengagement

switch. The DC controller drives the primary transfer disengagement solenoid for specified times during

the initial rotation period of the following:

The product is turned on

●

The product exits Sleep mode

●

The door is closed

●

The DC controller determines an ITB unit absence and notifies the formatter when it does not detect a

specified signal from the primary transfer disengagement switch.

ITB cleaning mechanism