Honda CBR 954 RR 2002 Service manual

HOW TO

USE

THIS

MANUAL

This service manual describes the service procedures for the

Follow the Maintenance Schedule (Section

that

the

vehicle is in peak operatlng condition.

Performing the first scheduled maintenance is very important. It compensates for the initial wear that occurs during the break

Sections

dures for removaI/instailation of components that may be required to per

form service described in the following sections.

Section 4 through

location.

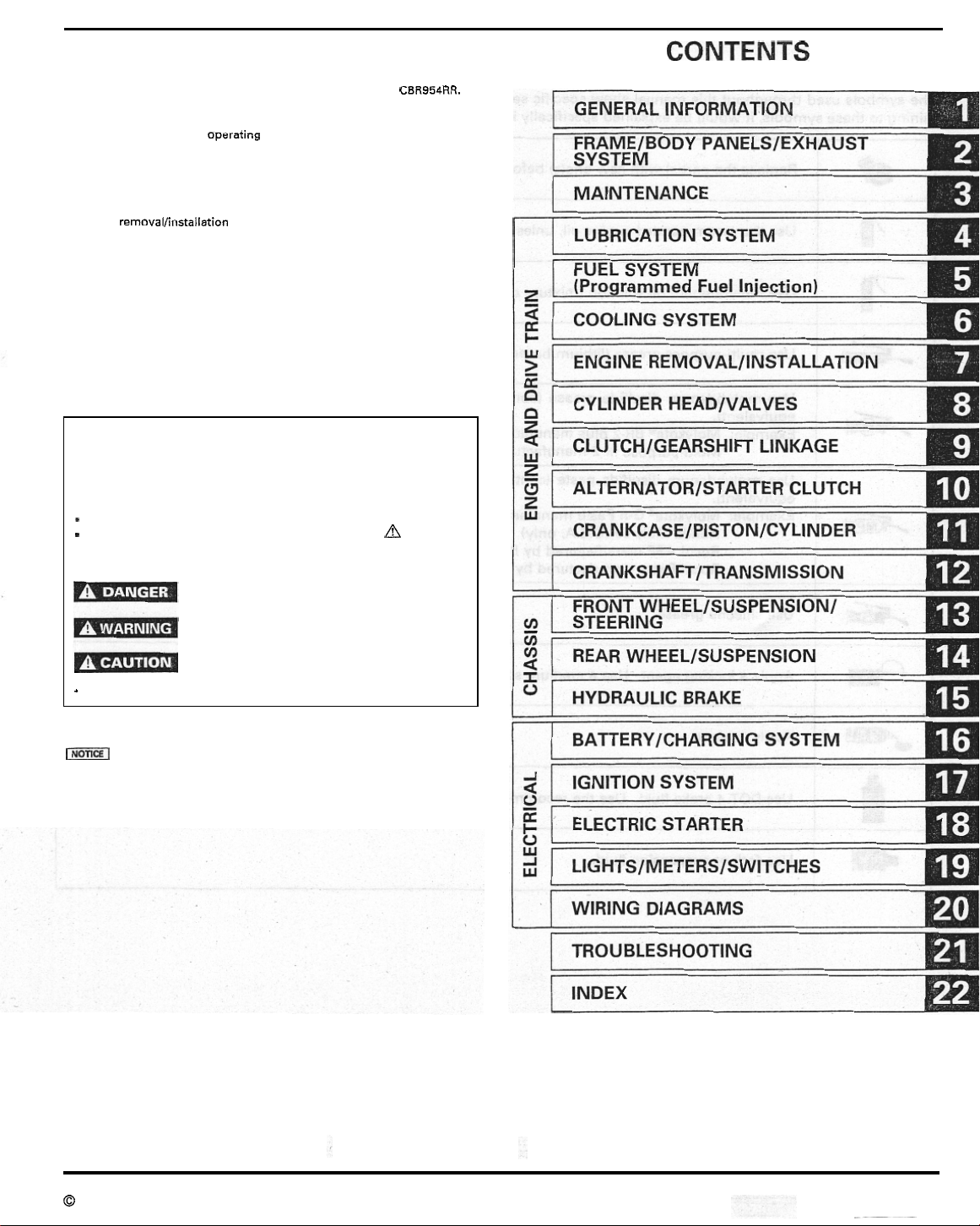

Find the section you want on this page, then turn to the table of contents on

the first page of the section.

Most sections start with an assembly or system illustration, service informa

tion and troubleshooting for the section. The subsequent pages give

detailed procedure.

If you don't know the source of

1

and 3 apply to the whole motorcycle. Section 2 illustrates proce

19

describe parts of the motorcycle, grouped according to

the

trouble,

Your

safety, and the safety of others, is very important. To help you make

informed decisions we have provided safety messages and other infor

mation throughout this manual. Of course,

to warn you about all the hazards associated with servicing this vehicle.

You

must

use

You

will find important safety information in a variety of forms including:

*

Safety Labels - on the vehicle

-

Safety Messages - preceded by a safety alert symbol d and one of

three signal words,

These signal words mean:

*

Instructions - how to service this vehicle correctly and safely.

your own good judgement.

DANGER, WARNING,

You

WILL

be

you don't follow instructions.

You CAN

you don't follow instructions.

You CAN

instructions.

KILLED

be

KILLED

be HURT

3)

recommendations to ensure

go

to section

it

is not practical or possible

or

CAUTION.

or

SERIOUSLY HURT

or

SERIOUSLY

if

you don't follow

CBR954RR.

-

in period.

21,

Troubleshooting.

HURT if

-

if

-

-

-

As

you

read this manual, you will find information that is preceded by a

1-

your

Date

0

symbol. The purpose of this message is to help prevent damage to

vehicle, other property,

of

Issue:

January,

Honda

Motor

Co.,

or

the environment.

2002

Ltd.

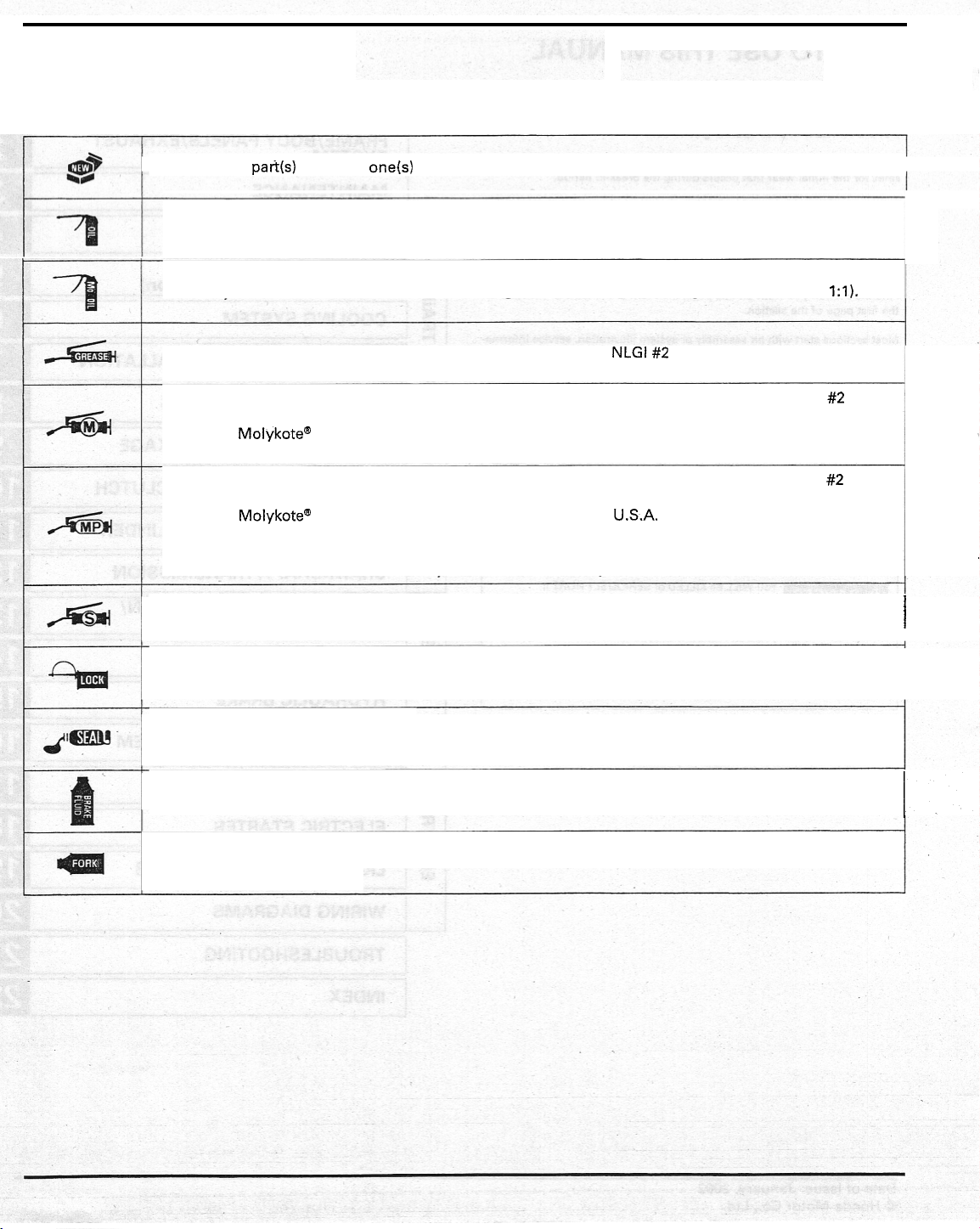

SYMBOLS

The symbols used throughout this manual show specific service procedures. If supplementary information is required per

taining to these symbols,

it

would be explained specifically

Replace the

Use the recommended engine oil, unless otherwise specified.

Use molybdenum oil solution (mixture of the engine

Use multi-purpose grease (lithium based multi-purpose grease NLGl#2

Use molybdenum disulfide grease (containing more than

equivalent).

Example:

Use molybdenum disulfide paste (containing more than

equivalent).

Example:

part(s) with new one(s) before assembly.

Molykote" BR-2 plus manufactured by Dow Corning, U.S.A.

Multi-purpose M-2 manufactured

Molykote" G-n Paste manufactured by

Honda

Moly

60

(U.S.A. only)

Rocol ASP manufactured by Rocol Limited, U.K.

Rocol Paste manufactured by Sumico Lubricant, Japan

in

the text without the use of the symbols.

oil

and molybdenum grease in a ratio of

3%

molybdenum disulfide, NLGl #2 or

by

Mitsubishi Oil, Japan

40% molybdenum disulfide, NLGl #2 or

Dow

Corning, USA.

or

equivalent).

1:l).

-

I

\4

v

Use silicone grease.

Apply a locking agent. Use a medium strength locking agent unless otherwise specified.

Apply sealant.

Use

DOT

Use fork

4

brake fluid.

or

suspension fluid.

Use the recommended brake fluid unless otherwise specified.

I

I

l-

I

I

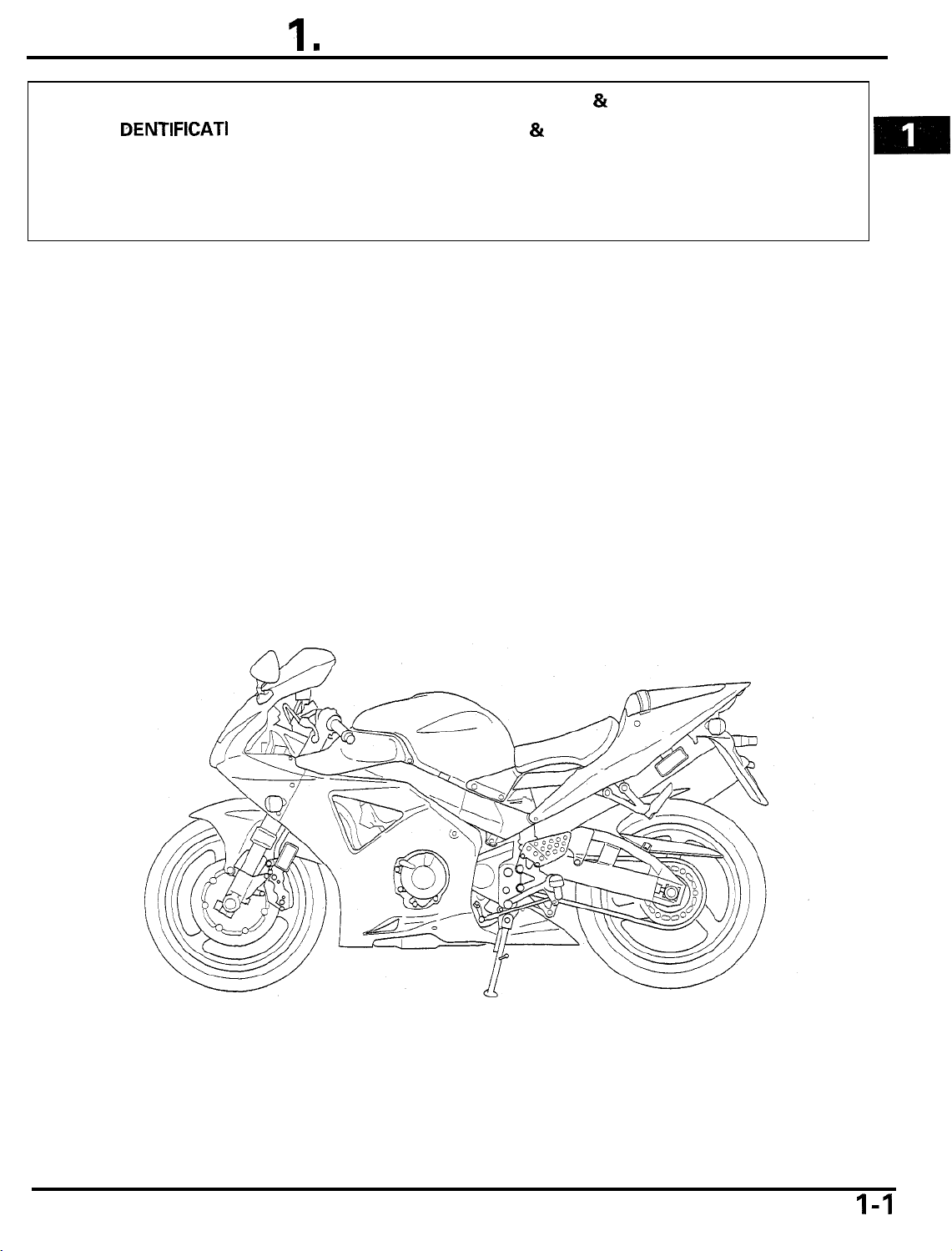

GENERAL INFORMATION

SERVICE RULES 1-1 LUBRICATION & SEAL POINTS 1-19

I

MODEL

DENT1 FlCATl ON 1-1 CABLE & HARNESS ROUTING 1-23

SPECIFICATIONS 1

TORQUE VALUES

TOOLS

-

3 EMISSION CONTROL SYSTEMS 1-37

1

-

12 EMISSION CONTROL INFORMATION

1

-

17

LABELS 1

-

40

SERVICE RULES

1.

Use genuine Honda or Honda-recommended parts and lubricants or their equivalents. Parts that

design specifications may cause damage to the motorcycle.

2.

Use the special tools designed for this product to avoid damage and incorrect assembly.

3.

Use only metric tools when servicing the motorcycle. Metric bolts, nuts and screws are not interchangeable with English

fasteners.

4.

Install new gaskets, O-rings, cotter

5.

When tightening bolts or nuts, begin with the larger diameter or inner bolt first. Then tighten to the specified torque

diagonally in incremental steps unless a particular sequence is specified.

6.

Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces before reassembly.

7.

After reassembly, check all parts for proper installation and operation.

8.

Route all electrical wires as shown on pages

pins,

and lock plates when reassembling.

1-23

through

1-36,

Cable and Harness Routing.

do

not meet Honda's

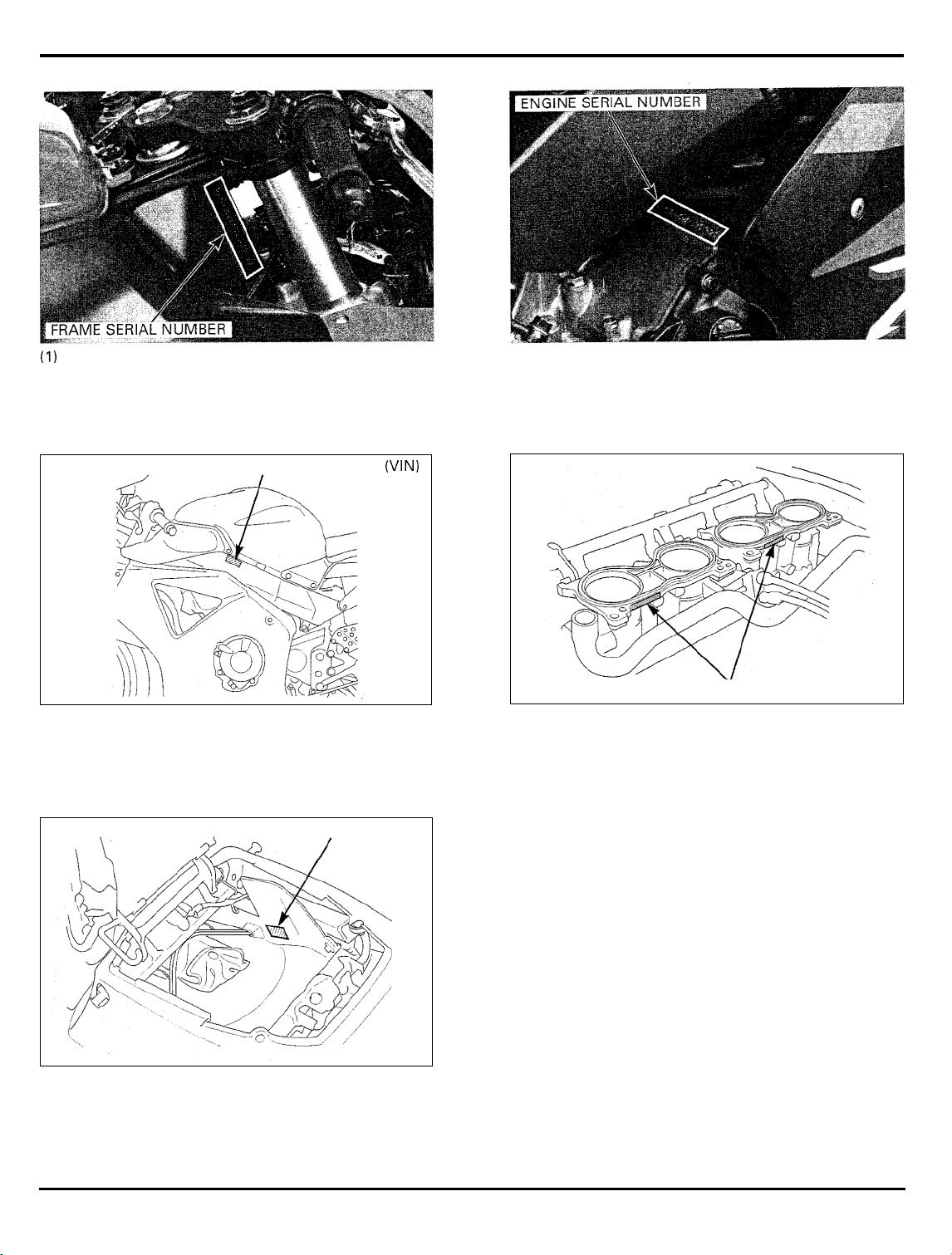

MODEL IDENTIFICATION

1-1

GENERAL INFORMATION

(1)

The frame serial number is stamped on the right side

of the steering head.

(2)

The engine serial number is stamped on the right

side of the upper crankcase.

VEHICLE IDENTIFICATION NUMBER

(3)

The Vehicle Identification Number (VIN) is located on

left side

Labels.

of

the main frame

on

the Safety Certification

COLOR LABEL

(VIN)

THROTTLE

(4)

The throttle body identification number is stamped

on the intake side of the throttle body as shown.

BODY

ID~NTIFICATION

NUMBER

(5)

The color label is attached as shown. When ordering

-

coded parts, always specify the designated

color

color code.

1-2

SPECIFICATIONS

GENERAL INFORMATION

GENERAL

DIMENSIONS

FRAME

ENGINE

ITEM

Overall length

Overail

Overal

Wheelbase

Seat height

Footpeg

Ground clearance

Dry weight

Curb weight

Maximum weight capacity

Frame type

Front suspension

Front wheel travel

Rear suspension

Rear wheel travel

Rear damper

Front tire size

Rear tire

Tire brand

Front brake

Rear brake

Caster angle

Trail length

Fuel tank capacity

Cylinder arrangement

Bore and stroke

Displacement

Compression ratio

Valve train

Intake valve opens

Exhaust valve opens

Lubrication system

Oil pump type

Cooling system

Air filtration

Engine dry weight

Firing order

width

I

height

height

49 states, Canada type:

California type:

49 states, Canada type:

California type:

49 states, California type:

Canada type:

size

Bridgestone

Michelin

closes

closes

at 1

mm

(0.04 in) lift

SPECIFICATIONS

2,025

mm

(79.7 in)

mm

(26.8

680

1,135 mm (44.7 in)

1,395

mm

820

mm

mm

383

130

mm

kg (370 Ibs)

168

170 kg (375

195 kg (430 Ibs)

197 kg (434 Ibs)

160 kg (353 Ibs)

164 kg (362 Ibs)

Diamond

Inverted telescopic fork

110

mm

Swingarm

135

mm

Nitrogen gas filled damper

120170 ZR17 M/C (58W)

190/50 ZR17 M/C (73W)

Front: BT012F RADIAL G /Rear:

Front: Pilot SPORT E /Rear: Pilot SPORT E

Hydraulic double disc brake with 4 pots caliper

Hydraulic single disc brake with 1 pots caliper

23

"

45'

97

mm

18.0 liter (4.76

4 cylinders in

75.0

x

54.0

954 cm3 (58.2 cu-in)

11.5:

1

Chain driven, DOHC

25' BTDC

38

"

ABDC

41" BBDC

22O ATDC

Forced pressure and wet sump

Trochoid

Liquid cooled

Paper element

61.2

kg (134.9 Ibs)

1-2-4-3

in)

(54.9 in)

(32.3 in)

(15.1

in)

(5.1 in)

Ibs)

(4.3

in)

(5.3 in)

(3.8 in)

US

gal, 3.96 Imp gal)

-

line, inclined 30" from vertical

mm

(2.95 x 2.13

in)

BT012R

RADIAL G

1-3

GENERAL INFORMATION

,--

GENERAL

DRIVE

TRAIN

I

(Cont’d)

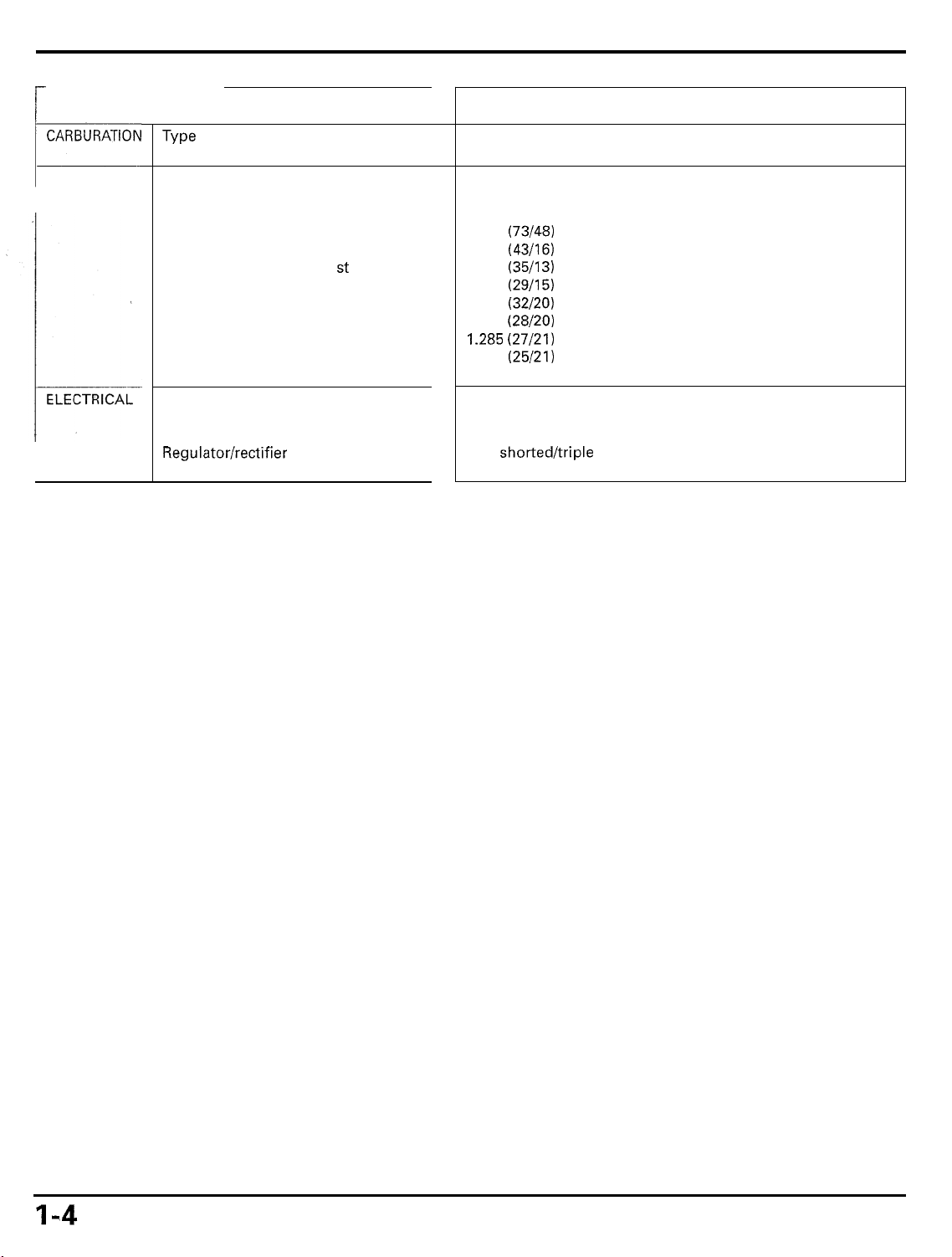

ITEM

Type

Throttle bore

Clutch system

Clutch operation system

Transmission

Primary reduction

Final reduction

Gear ratio 1

Gearshift pattern

Ignition system

Starting system

Charging system

Regulator/rectifier

Lighting system

st

2nd

3rd

4th

5th

6th

SPECIFICATIONS

PGM-FI

42

Multi

Cable operating

Constant mesh, 6

1.520

2.687 (43/16)

2.692 (35/13)

1.933 (29/15)

1.600 (32/20)

1.400 (28/20)

1.285 (27/21)

1.190

Left

Computer

Electric starter motor

Triple phase output alternator

SCR

Battery

(Programmed Fuel Injection)

mm

(1.7 in)

-

plate, wet

-

speeds

(73/48)

(25/21)

foot operated return system,

-

controlled digital transistorized with electric advance

shorted/triple phase,

full

1

-

N

- 2 -

3

-

wave rectification

4

- 5 -

6

GENERAL INFORMATION

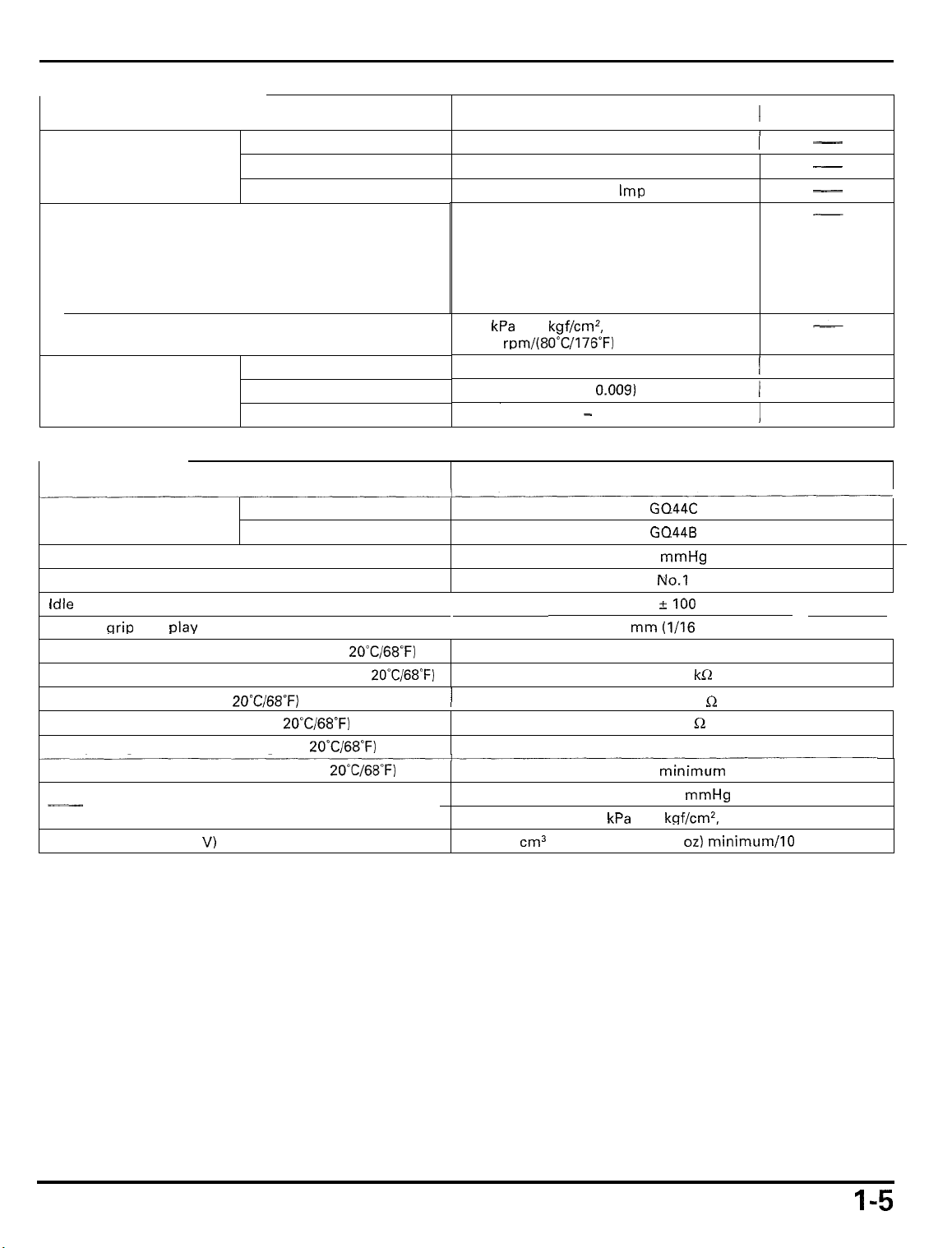

Unit:

mm

(in)

Engine oil capacity

Oil pump rotor

Throttle body identification

number

Starter valve vacuum difference

Base throttle valve for synchronization

Idle speed

Throttle

Intake air temperature sensor resistance (at

Enqine coolant temperature sensor resistance (at 20°C/68"F)

Fuel injector resistance (at 2OoC/68"F)

PAIR solenoid valve resistance (at

Cam pulse generator peak voltage (at 20"C/68"F)

Ignition pulse generator peak voltage (at

Manifold absolute pressure at idle

___

Fuel pressure at idle

Fuel pump flow (at 12

nrip

free play

At draining

At oil filter change

At disassembly

Tip

clearance

Body clearance

Side clearance

ITEM

Except California type GQ44C

California type GQ44B

20°C/68"F)

20"C/68"F)

20"C/68"F)

V)

STANDARD

3.5 liter (3.7 US

3.7 liter (3.9

4.0 liter (4.2

Pro Honda GN4 or HP4 (without molybde

num additives) 4-stroke

motor oil

API service classification: SG or higher

JASO T 903 standard: MA

Viscositv: SAE 1 OW

kPa

490

5,400

0.15

0.1

~~

0.02 - 0.07

(5.0

rr~m/(80"C/176"F)

(0.006)

5

-

0.22

I

188 cm3 (6.4

qt,

3.1 Imp qt)

US

qt,

3.3

Imp

qt)

US

qt,

3.5 Imp

-

kgf/cm2,

(0.006 - 0.009)

(0.001

-

0.003)

2

343 kPa (3.5 kqf/cm2, 50 psi)

US

qt)

oil

or equivalent

40

71

psi) at

SPECIFICATIONS

20 mmHg

No.1

1,200

f

100 rpm

-

6

mm

(1/16 - 1/4

1-4kR

2.3

-

2.6 kL2

10.5

-

14.5

20

-

24

0.7 V minimum

0.7 V minimum

150 - 250 mmHg

oz,

6.6

Imp

R

52

oz) minimum/lO seconds

I

SERVICE LIMIT

I

-

I

0.20 (0.008)

1

0.35

1

0.10 (0.004)

in)

-

__

-

(0.014)

I

1-5

GENERAL INFORMATION

ITEM

Coolant capacity

Radiator cap relief pressure

Thermostat

Recommended antifreeze

Standard coolant concentration

1

Radiator and engine

1

Reserve tank

Begin to open

Fully

1

Valve

CYLINDER HEADNALVES

ITEM STANDARD

Cylinder compression

Valve clearance

Cam shaft Cam lobe height

Runout

I

oil

clearance

Valve lifter Valve lifter

Valve lifter bore

Valve,

valve guide

Valve spring free length

Cylinder head warpaqe

Valve stem

Valve guide

Stem-to-guide clearance

Valve guide projection above

cylinder head

Valve seat width

O.D.

O.D.

I.D.

IN

open

lift

I.D.

SPECIFICATIONS

I

i

I

Pro Honda HP Coolant or an equivalent high quality ethylene

glycol

I

I

1,196

at

1

IN

EX 0.27

IN

EX 36.45

I

IN/EX 1 25.978 - 25.993 (1.0228 - 1.0233)

i

IN/EX 1 26.010 - 26.026 (1.0240 - 1.0246)

I

IN

1

EX

1

IN/EX 4.500 - 4.512 (0.1722 - 0.1776) 4.540 (0.1787)

IN

EX

IN 14.3 - 14.6 (0.56 - 0.57)

EX 12.4 - 12.7 (0.49 - 0.50)

lN/EX

1

Inner

i

Outer

0.16 f 0.03 (0.006 f 0.001)

36.74 - 36.98 (1.446 - 1.456)

1

0.020 - 0.062 (0.0008 - 0.0024)

1

4.475 - 4.490 (0.1762 - 0.1768)

1

4.465 - 4.480 (0.1758 - 0.1764)

0.010 - 0.037 (0.0004 - 0.0015)

0.020 - 0.047 (0.0008 - 0.0019)

1

0.90

I

34.80 (1.370)

1

37.97 (1.495)

1

39.60 (1.559)

I

108 - 137

antifreeze containing corrosion protection inhibitors

1:l

kPa

(12.2

350

rpm

-c

0.03 (0.01 1

-

36.69 (1.435 - 1.444)

-

1.10 (0.035 - 0.043) 1.5 (0.06)

liter

(3.3

US

qt,

2.7

at,

0.4

kgf/cm2,

minimum

Imp

Imp

3.1

0.4

liter

(0.4

US

kPa

(1.1 - 1.4

80.5 - 83.5"C (177 - 182°F)

95°C (203°F)

8

rnm

(0.3

in)

mixture of antifreeze and

kgf/cm2,

-r-

0.001)

-

174

psi)

qt)

qt)

16 - 20

soft

psi)

water

I

I

SERVICE LIMIT

36.72 (1.446)

36.43 (1.434)

0.04 (0.002)

1

0.10 (0.004)

i

25.97 (1.022)

I

26.04 (1.025)

I

4.465 (0.1758)

1

4.455 (0.1754)

I

33.1 (1.30)

I

36.1 (1.42)

I

37.6 (1.48)

1

0.10 (0.004)

Unit:

-

-

-

-

-

-

-

mm

i

(in)

1-6

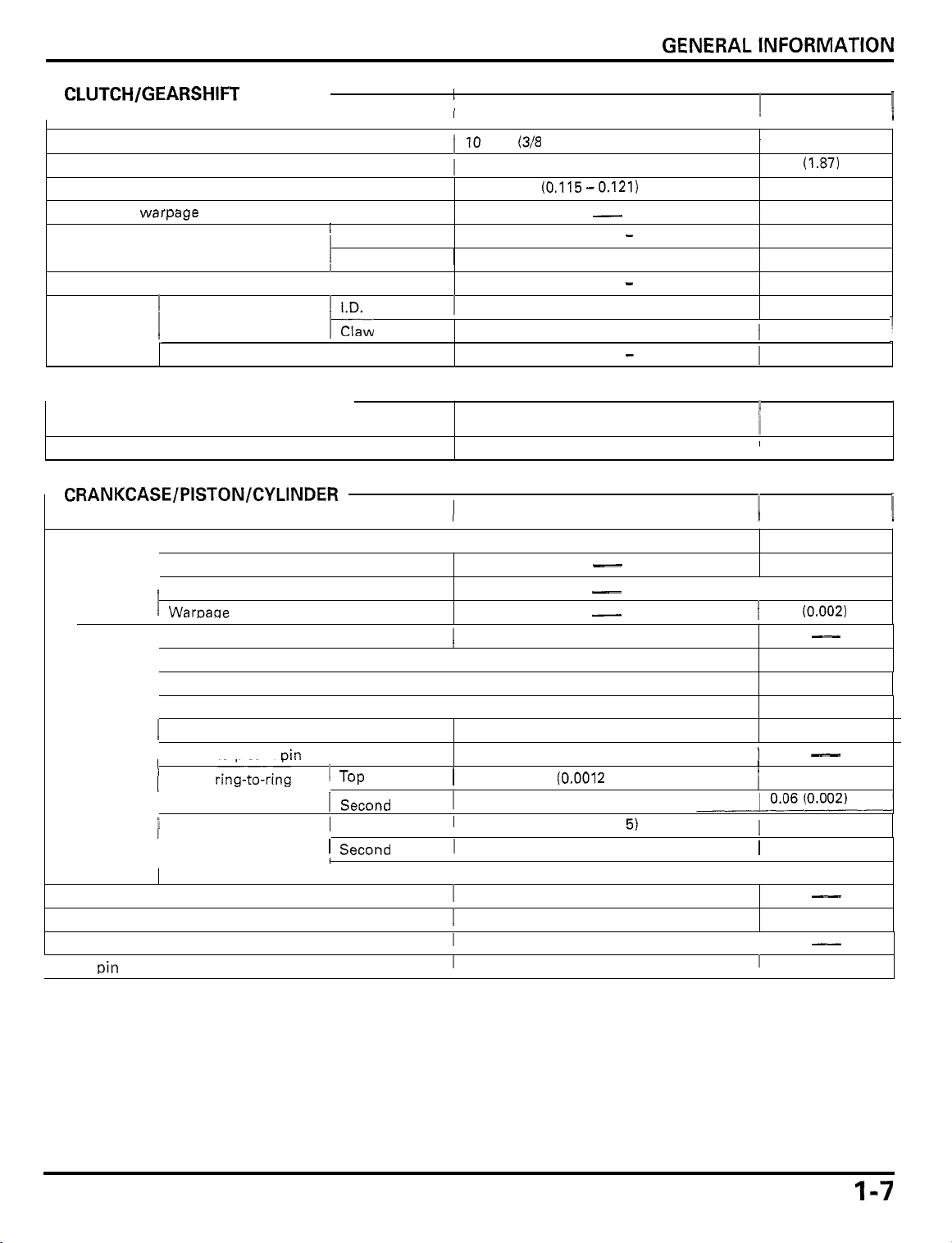

CLUTCH/GEARSHIFT LINKAGE

I

-

Clutch lever free play

Clutch spring free length

Clutch disc thickness 2.92

Clutch plate warpage

Clutch outer guide

Mainshaft

Shift fork,

forkshaft ~

O.D.

at clutch outer guide

I

Fork

Fork shaft

ITEM

O.D.

'

I.D.

~

O.D.

~

Ew

thickness

1

I

1

1

1

1

,

Unit: mm (in)

STANDARD

I0

-

20 (3/8 - 13/16)

48.8 (1.92) 47.4 (1.87)

-

3.08 (0.115-0.121) 2.6 (0.10)

-

25.000 - 25.021 (0.9843 - 0.9851) 25.03 (0.985)

34.975 - 34.991 (1.3770 - 1.3776)

24.980

-

24.993 (0.9835 - 0.9840)

12.000 - 12.018 (0.4724 - 0.4731) 12.03 (0.474)

5.93 - 6.00 (0.233 - 0.236)

11.957 - 11.968 (0.4707 - 0.4712)

1

SERVICE LIMIT

1

1

1

-

0.30 (0.012)

34.97 (1.377)

24.96 (0.983)

5.9 (0.23)

11.95 (0.470)

I

1

ITEM STANDARD

Starter driven sear boss

CRANKCASE/PISTON/CYLINDER

I

Taper

1

WarDase

Piston,

piston rings

Piston mark direction

1

Piston pin

i

Piston-to-oiston Din clearance

j

Piston rin$-to-rin'g

groove clearance

i

Piston ring end gap

i

Cylinder-to-piston clearance

Connecting rod small end

Connecting rod-to-piston pin clearance

Crank Din oil clearance

O.D.

ITEM

O

I.D.

.D.

I

I

I

1

1

TOP

Second

Top

Second

51.699 - 51.718 (2.0354 - 2.0361)

I

STANDARD

-

-

-

1

"0"

mark facing toward the intake side

16.994 - 17.000 (0.6691 - 0.6693)

0.002 - 0.014

i

0.030 - 0.065 (0.001 2 - 0.0026)

I

0.015 - 0.045 (0.0006 - 0.0018)

1

0.28 - 0.38 (0.01 1 - 0.01 5)

I

0.40 - 0.55 (0.016 - 0.022)

1

0.020 - 0.055 (0.0008 - 0.0022)

I

17.016 - 17.034 (0.6699 - 0.6706)

1

0.016 - 0.040 (0.0006 - 0.0016)

1

0.030 - 0.052 (0.0012 - 0.0020)

(0.0001

-

0.0006)

I

i

SERVICE LIMIT

i

51.684 (2.0348)

Unit: mm (in)

I

SERVICE LIMIT

0.10 (0.004)

,

,

0.10 (0.004)

~ 0.05

(0.002)

-

16.98 (0.669)

I

I

i

1

1

-

0.08 (0.003)

0.06 (0.002)

0.5 (0.02)

0.7

(0.03)

-

17.04 (0.671)

I

'

-

0.062 (0.0024)

I

GENERAL INFORMATION

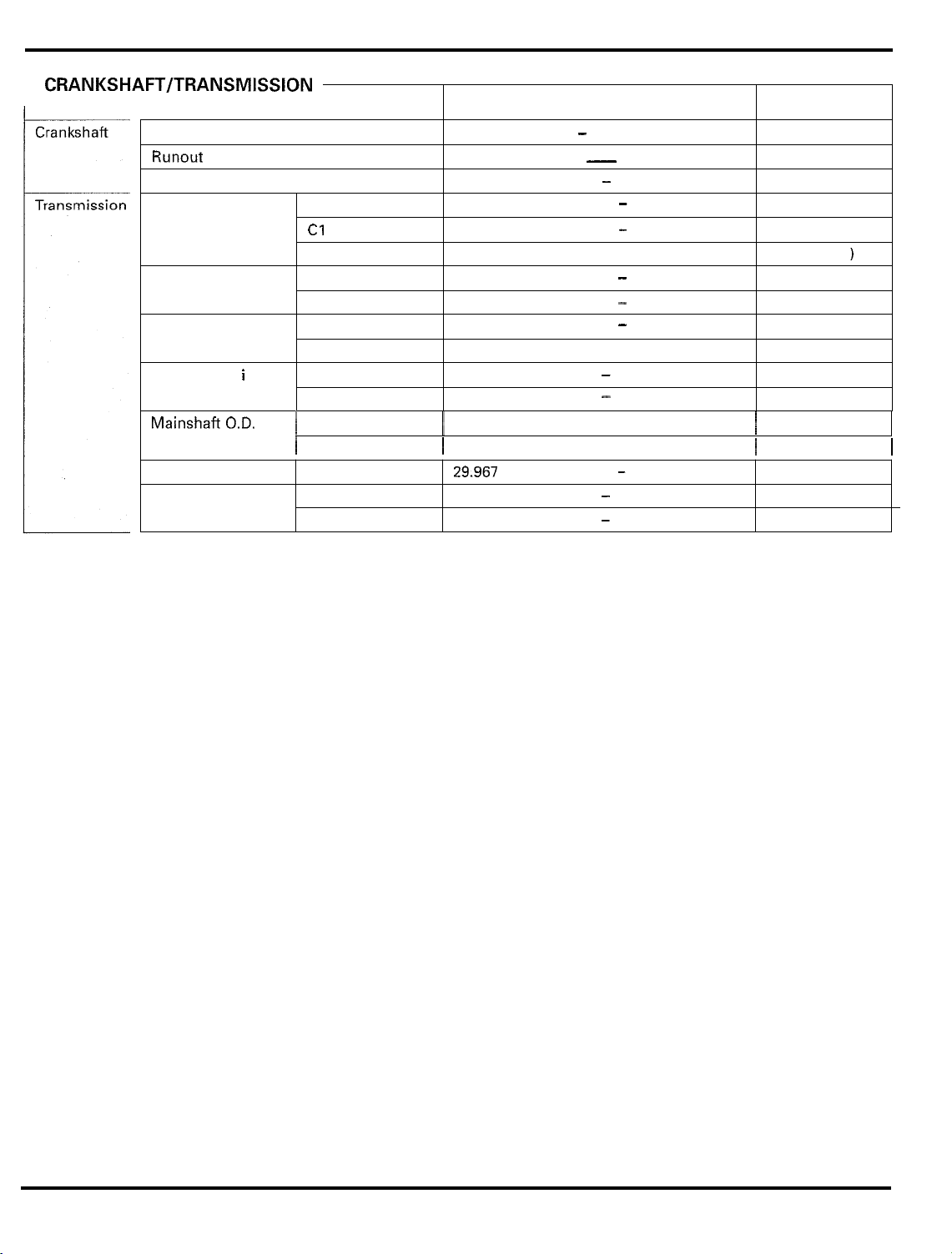

CRANKSHAFT/TRANSMISSlON

r

Side clearance

Runout

Main journal oil clearance

Gear I.D. M5, M6 31.000

Bushing O.D. M5, M6 30.950

Bushing

Gea r

clearance c3, c4 0.025

Mainshaft0.D.

Countershaft O.D.

Bushing

clearance

-to-

ITEM

I.D.

bus

-to-

h i ng

s haft

STANDARD

-

0.20 (0.002 - 0.008)

0.05

-

-

0.017

c1

c2, c3, c4

c3, c4

M5 27.985 - 28.006 (1.1018 - 1.1026)

c2

M5, M6

1

M5

1

Clutch outer guide I 24.980 - 24.993 (0.9835 - 0.9840)

C2 29.967 - 29.980 (1.1798 - 1.1803) 29.96 (1.180)

M5 0.005

c2 0.005 - 0.039 (0.0002 - 0.0015)

26.000

33.000

32.950

29.985

0.025

I

27.967 - 27.980 (1.1011 - 1.1016)

0.035 (0.0007 - 0.0014)

-

31.025 (1.2205 - 1.2215)

-

26.021 (1.0236 - 1.0244)

-

33.025 (1.2992 - 1.3002)

-

30.975 (1.2185 - 1.2195)

-

32.975 (1.2972 - 1.2982)

-

30.006 (1.1805- 1.1813)

-

0.075 (0.0010 - 0.0030)

-

0.075 (0.0010 - 0.0030)

-

0.039 (0.0002 - 0.0015)

SERVICE LIMIT

0.30 (0.012)

0.03 (0.001)

0.045 (0.0018)

31.04 (1.222)

26.04 (1.025)

33.04 (1.301

30.93 (1.218)

32.93 (1.296)

28.02 (1.103)

30.02 (1.182)

0.11 (0.004)

0.11 (0.004)

1

27.957 (1.1007)

1

24.96 (0.983)

0.08

(0.003)

0.08

(0.003)

)

I

1-8

Minimum tire tread depth

Cold tire pressure

Axle runout

Wheel rim runout Radial

Wheel balance weigh

Fork

Up to 90

Up to maximum weight capacity

Axial

Spring free length

Spring direction

Fork pipe runout

Recommended fork oil

Fluid level

Fluid

-

load adjuster initial setting

Pre

Rebound adjuster initial setting

Compression adjuster initial setting

kg

(200

capacity

Ib)

load

-

kPa (2.50 kgf/cm2, 36 psi)

250

kPa (2.50 kgf/cm2, 36 psi)

250

-

-

-

255.8

(10.07)

With the tapered end facing up

-

Pro Honda Suspension Fluid

73

(2.9)

513

k

2.5 cm3

18.1 2 0.09

7

turns from

2

turns from

2

turns from full hard

(17.3 * 0.08

Imp

02)

full

soft

full

hard

SS-8

US

02,

1.5 (0.06)

_____

-

-

0.20

(0.008)

2.0

(0.08)

2.0 (0.08)

250.8 (9.87)

-

0.20

(0.008)

-

-

-

-

-

-

Cold tire pressure

Axle runout

rim

Wheel

Wheel balance weight

Drive chain

Shock absorber

runout Radial

ITEM

Up to 90

Up

Axial

Size/l i n k DID

Slack

Spring adjuster standard position

Rebound adjuster initial setting

Compression adjuster initial setting

kg (200

to

maximum weight capacity 290 kPa (2.90 kgf/cm2, 42 psi)

Ib)

load

RK

kPa (2.90 kgf/cmz, 42 psi)

290

50VA8

50

(1.6 - 2.0)

C1/108

full

full

DID

RK

GB50HFOZ5/108

40

-

4th groove

2

turns from

2

turns from

STANDARD

-

-

-

-

-

hard

hard

SERVICE LIMIT

2.0 (0.08)

-

-

0.20

(0.008)

2.0

(0.08)

2.0

(0.08)

60 g (2.1

50

-

-

(2.0)

-

02)

max.

-

-

1-9

GENERAL INFORMATION

r

Front

Rear

ITEM STANDARD

1

Specified brake fluid

Brake disc thickness

Brake disc runout

1

Master cylinder I.D.

1

Master piston

Caliper cylinder I.D. ~ Upper

Caliper piston

Specified brake fluid

Brake disc thickness

Brake disc runout

Master cylinder I.D.

1

Master t7iston O.D.

Caliper cylinder I.D.

Caliper cylinder O.D.

O.D.

O.D.

Lower

Upper

I

Lower

SERVICE LIMIT

1

Honda

I

4.5 (0.18)

I

I

I

17.460 - 17.503 (0.6874 - 0.6891)

I

1

17.321 - 17.367 (0.6819 - 0.6837)

1

32.025 - 32.035 (1.2608 - 1.2612)

30.250 - 30.280 (1.1909 - 1.1921)

~

31,965 - 31.998 (1.2585 - 1.2598)

I

j

30.082 - 30.115 (1.1843 - 1.1856)

1

Honda

I

i

5.0 (0.20) 4.0 (0.16)

I

,

15.870 - 15.913 (0.6248 - 0.6265)

1

15.827 - 15.854 (0.6231 - 0.6242)

38.180 - 38.230 (1.5031 - 1.5051)

38.098

DOT 4

Brake Fluid

-

DOT

4

Brake Fluid

-

-

38.148 (1.4999 - 1.5019)

1

1

3.5 (0.14)

~

0.30 (0.012)

1

17.515 (0.6896)

I

I

17.309 (0.6815)

,

32.05 (1.262)

1

30.29 (1.193)

I

31.953 (1.2580)

i

30.074 (1.1840)

0.30 (0.012)

15.925 (0.6270)

1

15.815 (0.6226)

38.24 (1.506)

38.090 (1.4996)

-

-

I

1

1

I

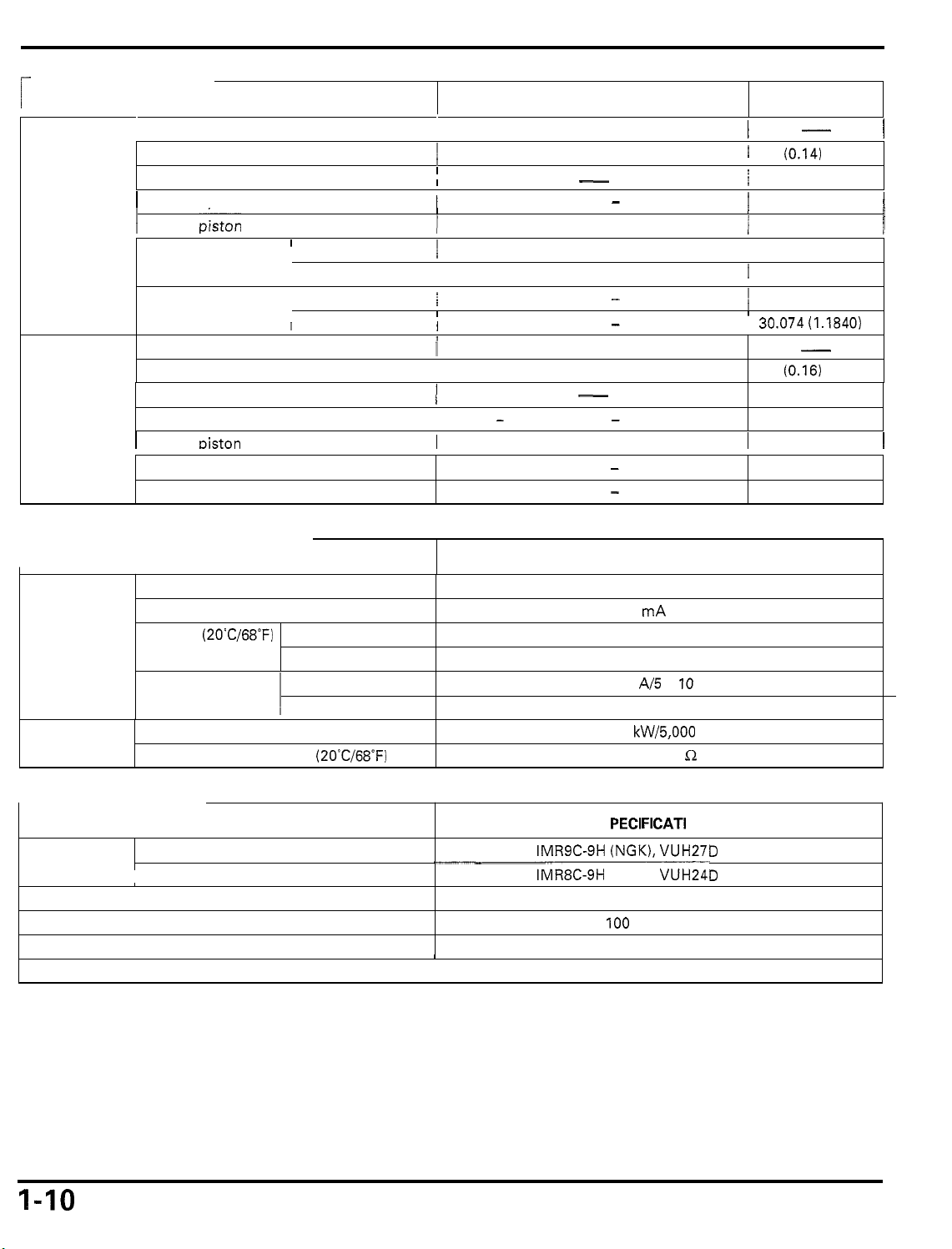

Battery

Alternator

-

IGNITION SYSTEM

Spark plug Standard

Spark plug gap

Ignition coil peak voltage

Ignition pulse generator peak voltage

Ignition timing (

Capacity

Current leakage

Voltage

Charging current Normal

Capacity

Charging coil resistance

~

Optional

"F"

(2O"C/68'F)

ITEM

mark)

12V - 8.6

0.2

0.421

-

0.90

S

13.0 - 13.2

0.9

4.0

PECl

(NGK),

mm

100 V

0.7 V

13

"

Fully charged

Needs charging Below

1

Quick

(2O"C/68"F) 0.1 - 1.0

IMR9C-9H (NGK),

I

1

IMR8C-9H

0.80

Ah

mA max.

V

12.3 V

A/5

-

10

h

A10.5

h

kW/5,000

Fl

minimum

minimum

BTDC at idle

rpm

R

CAT1 ONS

VUH27D (DENSO)

VUH24D (DENSO)

(0.031 - 0.035

in)

7-70

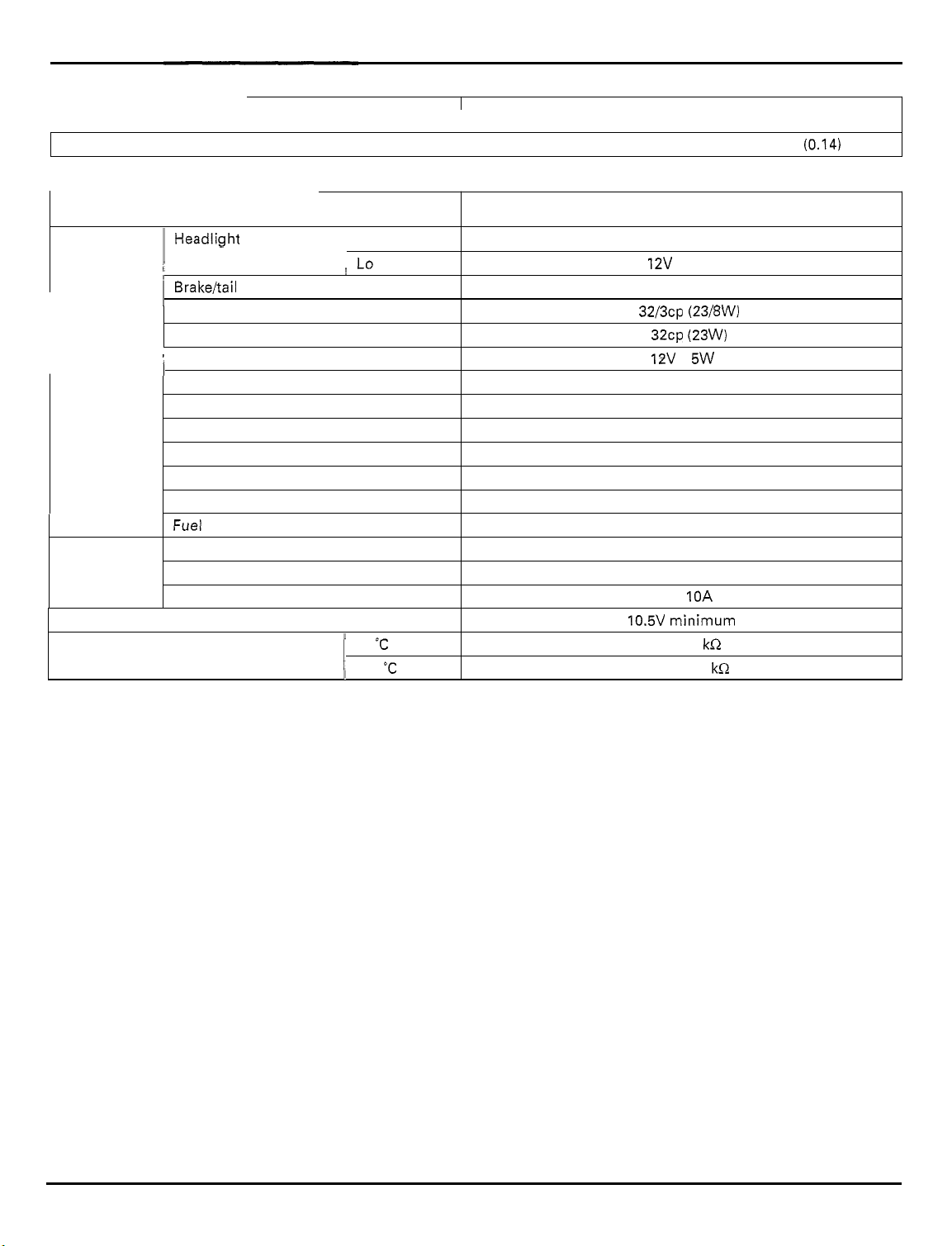

GENERAL INFORMATION

Starter motor brush length

Bulbs

1

1

Brakehail light

Front turn signal light

Rear turn

i

License light

Instrument light

Turn signal indicator

High beam indicator

Neutral indicator

Oil pressure indicator

PGM

-

FI warning indicator

Fuel reserve indicator

Fuse Main fuse

-

FI fuse

PGM

Sub fuse

Tachometer peak voltage

Thermo sensor resistance

ITEM

signal

light

Hi

!

Lo

80

"C

1

120

(176°F)

'C

(248°F)

1

10.0 - 10.5

(0.39

-

0.41) 3.5

SPECIFICATIONS

12v - 55w

12V - 55W

LED

12V - 32/3~p (23/8W)

12V - 32cp (23W) X 2

12V - 5W

LED

X

LED

LED

LED

LED

LED

LED

30 A

20

A

X

2, 10A X 3

20A

10.5V minimum

2.1 - 2.6

0.65 - 0.73 kQ

2

kQ

x

(0.14)

2

X

2

1-11

GENERAL INFORMATION

TORQUE

5

mm hex bolt and nut

10

mm hex bolt and nut

12

mm hex bolt and nut

-

Torque specifications listed below are for important fasteners.

Others should be tightened

NOTES:

3.

4.

5.

6.

7.

8.

9.

10.

11.

VALUES

I

FASTENER TYPE

to

standard torque values listed above.

1.

Apply sealant to the threads.

2.

Apply a locking agent to the threads.

Apply grease to the threads.

Stake.

Apply oil to the threads and flange surface.

Apply clean engine oil to the O-ring.

U-nut

ALOC bolt: replace with a new one.

CT bolt

Apply molybdenum disulfide oil to the threads and seating surface (after removing anti-rust oil additive).

One-way bolt

TORQUE

N-m (kgf-m, Ibf-ft)

5 (0.5, 3.6)

34 (3.5, 25)

54 (5.5,

40)

I

5

mm

screw

small flange)

6

mm

flange bolt

large flange)

FASTENER TYPE

(8

mm head,

TORQUE

~

N-m (kgf-m, Ibfbft)

4 (0.4, 2.9)

I

12 (1.2, 9)

r

ENGINE

ITEM

MAINTENANCE:

Spark plug

Timing

Oil drain bolt

Oil filter cartridge

LUBRICATION SYSTEM:

Oil cooler mounting bolt

Oil pump assembly flange bolt

Oil pump driven sprocket bolt

Oil pressure switch

Oil pressure switch wire terminal screw

Lower crankcase

FUEL SYSTEM (Programmed Fuel Injection):

ECT (Engine Coolant

Throttle body insulator band screw

Throttle cable bracket mounting bolt

Fuel pipe mounting bolt

Pressure regulator mounting bolt

Starter valve synchronization plate screw

Fast idle wax unit link plate screw

Fast idle wax unit mounting screw

Starter valve lock nut

COOLING SYSTEM:

Water pump cover flange bolt

Thermostat cover flange bolt

ENGINE MOUNTING:

Drive sprocket special bolt

hole cap

20

rnm

sealing bolt

Temperature)/thermo sensor

,

O'TY

1

;;RE:)

10

45

12

20

20

6

6

PT

118

4

20

12

5

5

6

6

3

3

6

10

2

2

1

6

6

10

I

TORQUE

~

N-m (kgf-m, IbfW

12 (1.2, 9)

18 (1.8, 13)

29 (3.0, 22)

26 (2.7, 20)

74 (7.5,

8

15 (1.5, 11)

2 (0.2, 1.4)

29 (3.0, 22)

23 (2.3,

See page

3 (0.35, 2.5)

1 (0.09,

1 (0.09, 0.7)

5 (0.5, 3.6)

2 (0.18, 1.3)

54 (5.5, 40)

54)

(0.8, 5.8)

12 (1.2,

10

10

12 (1.2,

12 (1.2, 9)

9)

17)

1-14

(1.0,

7)

(1.0, 7)

0.7)

9)

I

1

REMARKS

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

I

3

6

9

2

1

2

9

9

1-12

r

ENGINE

CYLINDER

Cylinder head cover bolt

PAIR

Breather plate flange bolt

Camshaft holder flange bolt

Cylinder head sealing bolt

Cylinder head mounting bolt

Cylinder head mounting

Cam sprocket bolt

Cam pulse generator rotor bolt

Cam chain tensioner pivot socket bolt

Cam chain guide mounting socket bolt

Cylinder head stud bolt (exhaust pipe stud bolt)

CLUTCH/GEARSHIFT LINKAGE:

Clutch center lock nut

Clutch spring

Shift drum center socket bolt

Shift drum stopper arm pivot bolt

Gearshift return spring pin

S

h ift d ru m bea ri n g/s h ift fork retaining bolt/was h er

ALTERNATORETARTER CLUTCH:

Alternator wire clamp bolt

Flywheel flange bolt

Stator mounting socket bolt

Starter one

CRANKCASE/PISTON/CY LINDER:

Mainshaft bearing set plate bolt

Crankcase bolt,

Connecting rod nut

Upper crankcase

Lower crankcase

Lower crankcase

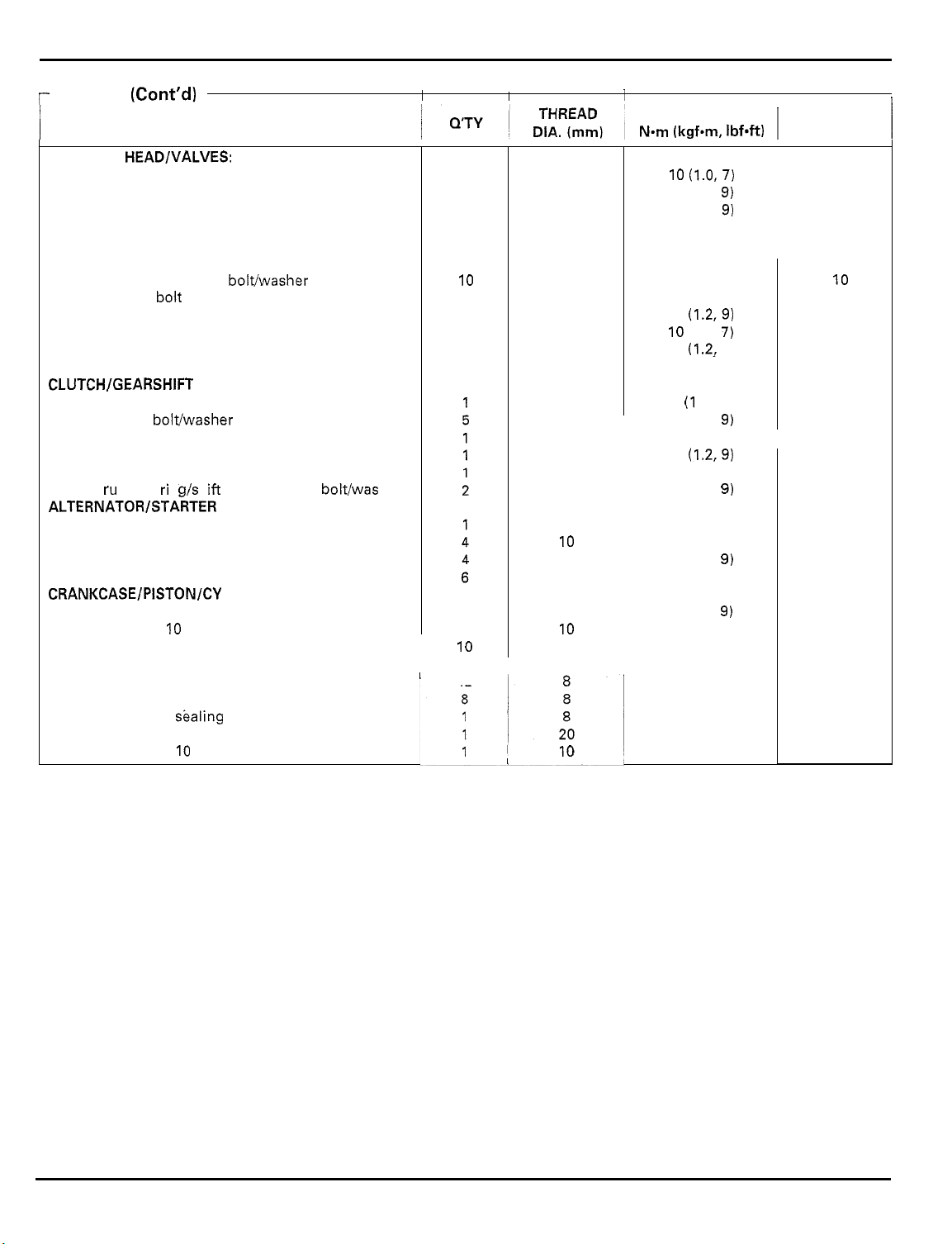

(Cont’d)

ITEM

HEADNALVES:

reed valve cover flange bolt

bolt/washer

boltiwasher

-

way clutch torx bolt

10

mm

9

mm

(main journal bolt)

8

mm

skaling bolt

20

mm sealing bolt

10

mm socket bolt

GENERAL

I

20

10

‘

12

4

4

3

1

2

10

4

2

1

1

8

3

1

I

6

6

6

6

18

8

9

7

6

6

6

8

22

6

8

6

8

6

6

10

6

6

6

10

9

I

10

1

N.m

10 (1.0,7)

12 (1.2, 9)

12 (1.2, 9)

12 (1.2, 9)

27 (2.8, 20)

25 (2.5, 18)

51 (5.2, 38)

20 (2.0, 14)

12

10 (1.0, 7)

12 (1.2! 9)

See page

127

12 (1.2,

23 (2.3, 17)

12

23 (2.3, 17)

12 (1.2,

14 (1.4, 10)

103 (10.5, 76)

12 (1.2,

16

12 (1.2, 9)

39 (4.0, 29)

(2.0,

20

25 (2.5, 18)

35

22 (2.2, 16)

29 (3.0, 22)

12 (1.2, 6.5)

TORQUE

(kgf-m,

(1.2,9)

(1 3.0, 94)

(1.2,9)

(1.6,

14) + 150”

(3.6,

INFORMATION

I

IbfW

1-14

9)

9)

9)

12)

26)

REMARKS

NOTE 2

NOTE

NOTE

NOTE 2

NOTE 5

NOTE

NOTE 2

NOTE 2

NOTE 2

NOTE 2

NOTE 4,5

NOTE 2

NOTE 2

NOTE 9

NOTE 5

NOTE 2

NOTE 2

See

NOTE 5

NOTE 5

NOTE 2

NOTE 2

NOTE 2

2

5

10

page

1

11-12

1-13

GENERAL INFORMATION

r

ENGINE

IG

N

IT10 N SYSTEM

Ignition pulse generator rotor mounting bolt

ELECTRIC STARTER:

Starter motor terminal nut

LIGHTS/METERS/SWITCHES:

Neutral switch

(Cont'd)

ITEM

:

Q'TY

I

Nm

DIA.

(rnrn)

(kgfm,

IbfW

I

REMARKS

4

NOTE

5

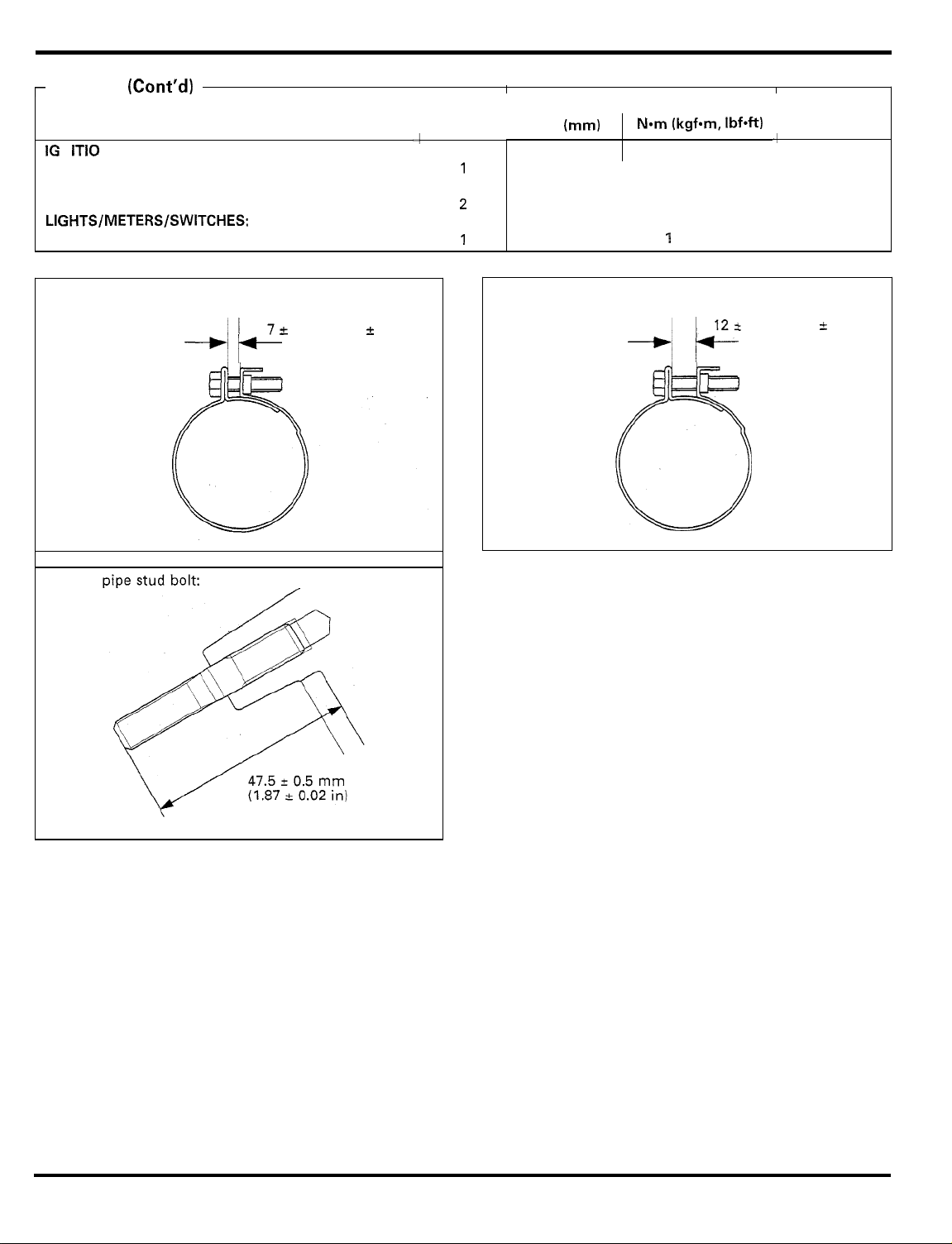

Insulator clamp (Throttle body side):

7

-4

Exhaust

't

1

mm

(0.3

i

0.04

in)

insulator clamp (Cylinder head

-4

side):

12

it

2

1

mm (0.5

i:

0.04 in)

1-14

-

FRAME

ITEM

~

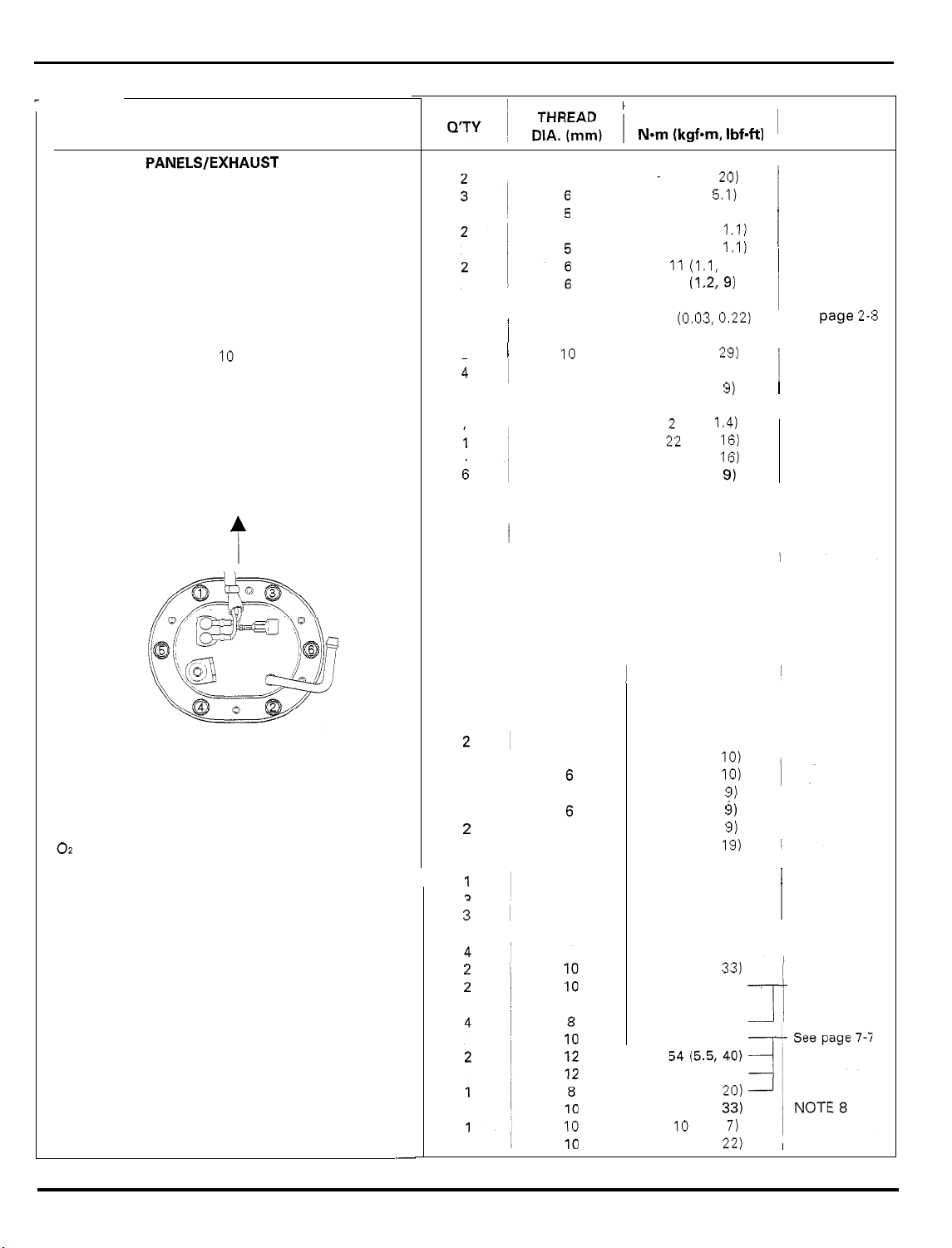

FRAME BODY PANELWEXHAUST SYSTEM:

Upper cowl stay mounting bolt

Upper cowl stay mounting

Upper cowl pan screw

Lower cowl pan screw

Rear cowl truss screw

Pillion seat mounting nut

Pillion seat hinge special screw

Duct cover pan screw

Windscreen mounting screw

Seat rail mounting bolt,

Seat rail mounting nut,

Pillion step mounting socket bolt

Exhaust

FUEL SYSTEM (Programmed Fuel Injection):

Fuel filler cap bolt

Fuel hose banjo bolt (fuel tank side)

Fuel hose sealing nut (throttle body side)

Fuel pump mounting nut

pipe

joint nut

(see tightening sequence below)

8

10

SH

mm

mm

bolt

8

4

5

2

2

41

7

2

1

41

8'

7' 4

1

6i

5

8

10

8

7

12

12

6

GENERAL INFORMATION

I

TORQUE

I

N-m (kgf-m,

-

26 (2.7, 20)

7 (0.7, 5.1)

1.5 (0.15,

1.5 (0.15, 1.1)

1.5 (0.15,

11

(1.1,

12 (1,2,9)

1.5 (0.15,

0.3 (0.03, 0.22)

39 (4.0, 29)

39

(4.0, 29)

39 (4.0, 29)

12 (1.2,

2 (0.2, 1.4)

22 (2.2,

22 (2.2,

12 (1.2,

Ibf-ft)

1.1)

1.1)

8)

1.1)

9)

16)

16)

9)

1

REMARKS

1

'

1

NOTE7

See page

I

2-8

FRONT

f

Bank angle sensor mounting screw

Exhaust valve mounting bolt (front)

(rear)

Exhaust valve cover mounting bolt

Exhaust valve pulley nut

Exhaust valve pulley cover mounting bolt

02

sensor (California type only)

COOLING SYSTEM:

Cooling fan nut

Fan motor nut

Fan motor shroud mounting bolt

ENGINE MOUNTING:

Main footpeg bracket mounting socket bolt

Main footpeg mounting bolt

Lower bracket mounting nut

Lower bracket mounting pinch bolt

Engine hanger bolt (front)

Engine hanger bolt (middle)

Engine hanger nut (rear)

Rear engine hanger pinch bolt

Side stand bracket bolt

Side stand pivot bolt

Side stand pivot lock nut

21

4'

4~

3

11

1

i

3

I/

31

2

1

2

1

6

6

6

6

12

5

5

6

8

10

14

14 (1.4,

25 (2.6, 19)

3 (0.3, 2.2)

5 (0.5, 3.6)

8

39 (4.0, 29)

44

42 (4.3, 31)

26 (2.7, 20)

39 (4.0,

54 (5.5,

26 (2.7, 20)

44 (4.5,

29 (3.0, 22)

11

(1.1,

8)

(1.4,

10)

10)

12 (1.2, 9)

12 (1.2,

12 (1.2,

10

9)

9)

(0.8,

5.8)

(4.5, 33)

29)

40)

33)

(1.0,

7)

4

NOTE

8

See

page

7-12

NOTE

7

i

NOTE

7

1-15

GENERAL

INFORMATION

FRAME

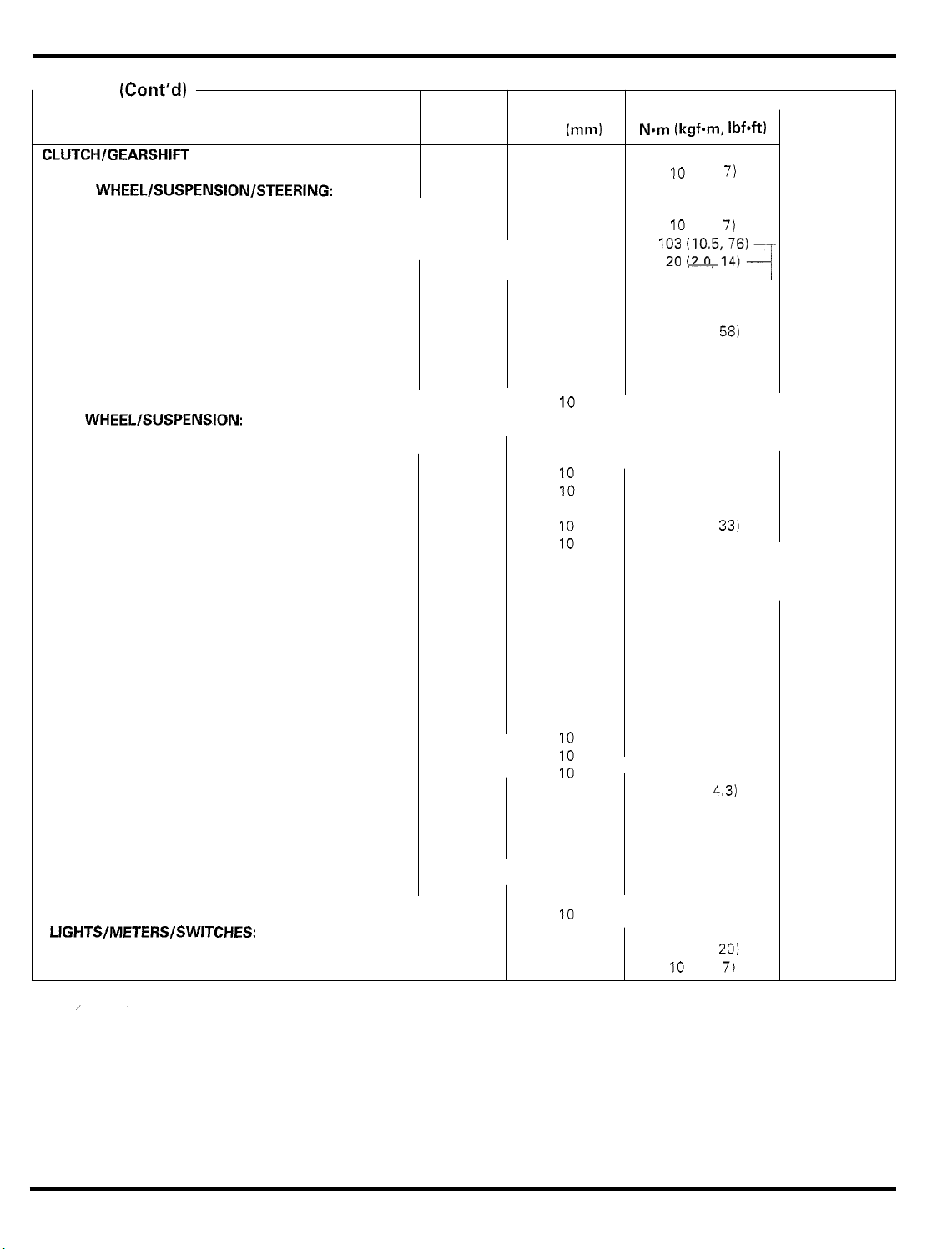

CLUTCH/GEARSHIFT LINKAGE:

Gearshift pedal link pinch bolt

FRONT

Handlebar pinch bolt

Handlebar weight mountign screw

Steering stem nut

Steering stem adjusting nut

Steering stem lock nut

Fork top bridge pinch bolt

Fork bottom bridge pinch bolt

Front axle bolt

Front axle holder pinch bolt

Front brake disc mounting bolt

Fork bolt

Fork center bolt

REAR WHEEL/SUSPENSION:

Rear axle nut

Rear brake disc mounting bolt

Driven sprocket nut

Rear shock absorber upper mounting nut

Rear shock absorber upper bracket mounting nut

Shock arm plate nut

Shock link nut (frame side)

Swingarm pivot nut

Swingarm pivot pinch bolt

Drive chain slider bolt

HYDRAULIC BRAKE:

Front brake master cylinder cup mounting nut

Brake lever pivot bolt

Brake lever pivot nut

Front brake light switch screw

Front brake caliper mounting bolt

Caliper body assembly torx bolt

Front caliper pad pin

Rear caliper pad pin

Rear caliper pad pin plug

Brake caliper bleeder

Rear brake hose clamp screw

Brake pedal joint nut

Rear master cylinder push rod lock nut

Rear master cylinder hose joint screw

Rear brake caliper pin bolt

Rear brake caliper

Brake hose oil bolt

LIGHTS/METERS/SWITCHES:

Ignition switch mounting one-way bolt

Side stand switch mountinq bolt

(Cont'd)

ITEM

WHEEL/SUSPENSION/STEERING:

bolt

Q'TY

1

2

2

1

1

1

2

4

1

4

12

2

2

1

4

6

1

1

3

1

1

2

3

1

1

1

1

4

8

4

1

1

3

1

1

1

1

1

1

5

2

1

THREAD

DIA.

(mm)

6

8

6

24

26

26

8

8

18

8

6

42

10

22

8

10

10

16

10

10

24

8

6

6

6

6

4

8

8

10

10

10

8

5

8

8

4

12

8

10

8

6

TORQUE

N-m (kgf-m, Ibf*ft)

10 (1.0, 7)

26 (2.7, 20)

10

(1.0, 7)

I;:

;;005\;q

-

23 (2.3, 17)

26 (2.7, 20)

78 (8.0,

58)

22 (2.2, 16)

20 (2.0, 14)

23 (2.3, 17)

34 (3.5, 25)

113 (11.5,

83)

42 (4.3, 31)

64 (6.5, 47)

(9.5,

33)

69)

33)

33)

44 (4.5,

93

44 (4.5,

44 (4.5,

118 (12.0, 87)

26 (2.7, 20)

9 (0.9, 6.5)

6 (0.6, 4.3)

1 (0.1, 0.7)

6 (0.6, 4.3)

1 (0.1, 0.7)

30 (3.1, 22)

23 (2.3, 17)

18 (1.8, 13)

18 (1.8, 13)

3

(0.3, 2.2)

4.3)

6 (0.6,

4 (0.4, 2.9)

18 (1.8, 13)

18 (1.8, 13)

1 (0.15, 1.1)

27 (2.8,

20)

23 (2.3, 17)

34 (3.5, 25)

26 (2.7,

20)

10 (1.0, 7)

REMARKS

NOTE

8

NOTE

8

See page

NOTE

8

NOTE

7

NOTE

8

NOTE

7

NOTE

7

NOTE

7

NOTE

7

NOTE

7

NOTE

7

NOTE

8

NOTE

7

NOTE

8

NOTE

2

NOTE

8

NOTE

2

NOTE

2

NOTE

2

NOTE

11

13-30

1-16

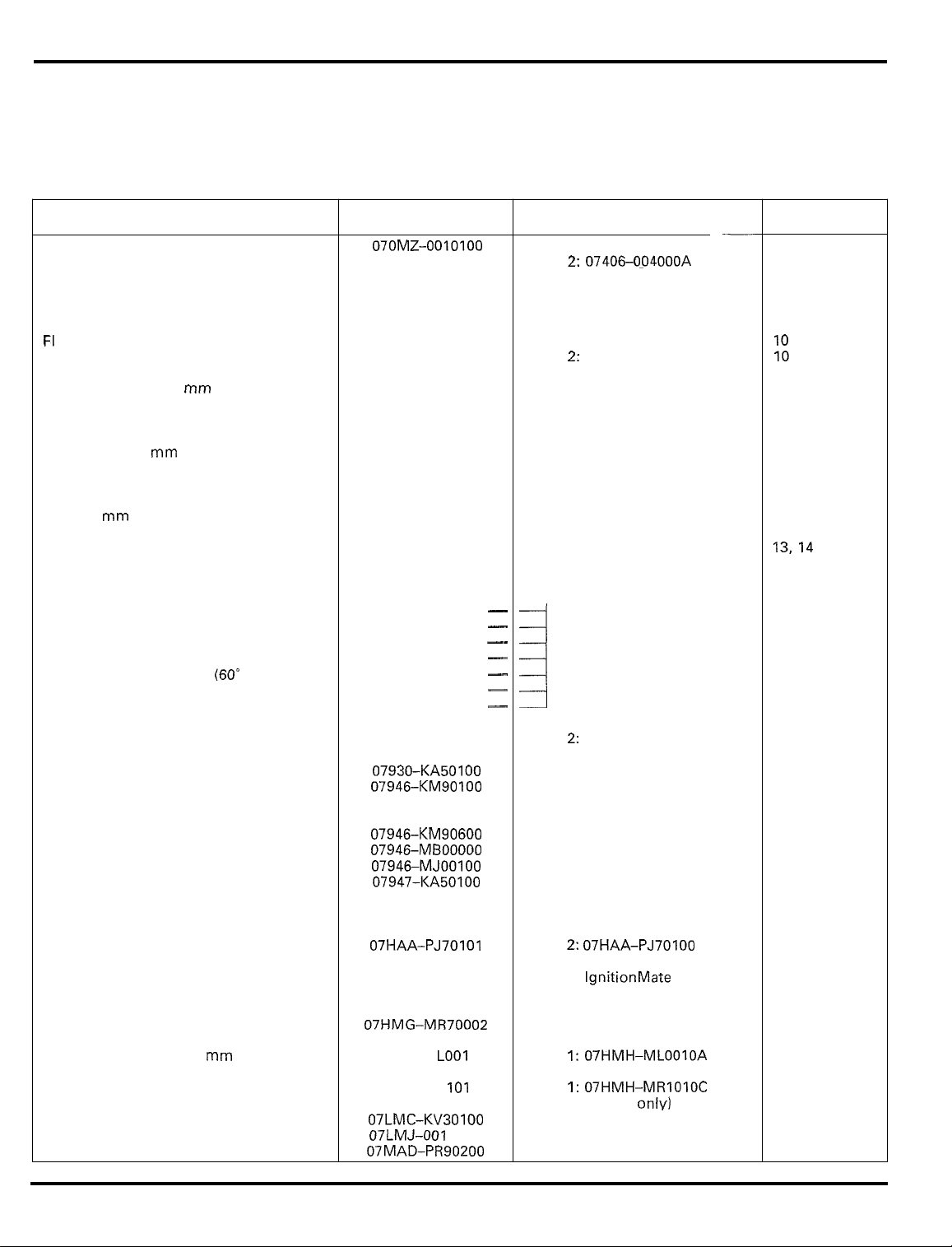

TOOLS

GENERAL INFORMATION

NOTES:

Valve spring compressor

Valve seat cutter

Assembly

Steering stem driver

Fork seal driver

Driver

Valve spring compressor attachment

Driver shaft

Oil filter wrench

Peak voltage adaptor

Tappet hole protector

Valve guide driver,

Valve guide reamer,

Drive chain tool set

Needle bearing remover

Vacuum gauge set

Pilot,

1.

Equivalent commercially available

2.

Alternative

3.

Newly designed tool.

4.

Not available in

ECM

test harness,

Fuel pressure gauge

Oil pressure gauge set

Oil pressure gauge attachment

Clutch center holder

FI

yw heel holder

Rotor puller

17

42 x 47

52 x 55

22 x 24

40 x 42

40

25

mm

mm

mm

28

30

24 x 27

base

Attachment,

Attachment,

Attachment,

Attachment,

inner driver,

Attachment,

Pilot,

Pilot,

25

Pilot,

35

Bearing remover shaft

Bearing remover head,

Driver

Seat cutter,

Seat cutter,

Flat cutter,

Flat cutter,

interior cutter,

Interior cutter,

Cutter holder,

Snap ring pliers

Steering stem socket

Rod holder,

Driver attachment,

Driver shaft assembly

Bearing remover,

Driver shaft

tool.

U.S.A.

DESCRIPTION

26P

mm

mm

mm

mm

mm

I.D.

mm

I.D.

25

mm

24.5

mm

mm

mm

mm

26

30

4.5

A

A

(45

(32

(32

mm

mm

mm

mm

(45

"

"

"

(60"

(60

IN)

EX)

IN)

29

"

EX)

EX)

"

IN)

body

4.5

mm

4.5

mm

32 x 50

mm

in

U.S.A.

TOOL NUMBER

070MZ-0010100

07406-0040003

-

07506

0751 0

07724

07725

07733

07746

07746

07746

07746

07746

07746

07746

07746

07746

07746

07746

07749

07757

07780-0010100

07780-0010300

07780-0012100

07780-0012200

07780-001 4500

07780-0014000

07781-0010600

0791 4-SA50001

07916

07930-KA50100

07946-KM90 100

07946-KM90300

07946

07946-KM90600

07946-MB00000

07946-MJ00100

07947-KA50100

07949-3710001

07959

07964

07HAA-PJ70101

07HGJ-0020100

07HMG-MR70002

07H M

07HMH

07 HMH

07LMC-KV30100

07iMJ-001 OOOA

07MAD-PR90200

3000001

-

MA70000

-

0050002

-

0040000

-

0020001

-

0010300

-

001 0400

-

0010800

-

0010900

-

0030100

-

0030200

-

0040400

-

0040600

-

0040800

-

0050100

-

0050800

-

0010000

-

001

-

3710101

-

KM90401

-

KM30101

-

MB00200

D-M

LOO 1 0 1

-

M LOO1 01

-

MR 101 03

0000

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

-

-

-

-

-

-

1

-

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

NOTE

REMARKS

2: 07406-OO4000A

(U.S.A.

1

1

1

2: 07933-3950000

(U.S.A.

1

2: 07916-3710100

(U.S.A.

4

4

4

4

2: 07HAA-PJ70100

4

1:

IgnitionMate peak

voltage tester

(U.S.A.

4

1:

07HMH-MLOOIOA

(U.S.A.

1: 07HMH-MR1010C

(U.S.A.

only)

only)

only)

only)

only)

only)

REF. SEC.

5

5

4

4

9

10

10

9, 13, 14

14

14

14

12

12

14

13, 14

9

13, 14

13,14

9, 13, 14

8

8

15

13

7, 14

13

13

13

13

13

14

13

14

8

12

3, 4

5,

17, 19

8

8

8

3

14

5

14

1-17

GENERAL INFORMATION

DESCRIPTION

Race remover

Driver attachment

Compression gauge attachment

Fork damper holder handle

Installer attachment, A

Installer attachment,

Remover attachment, A

Remover attachment,

Fork damper holder

Oil seal driver

Driver attachment, 25

Installer shaft guide

Installer shaft

installer shaft, 14

Remover, 14

Cam chain tensioner holder

Batterv tester

x

B

x

30 mm

16 mm

B

x

38.5 mm

TOOL NUMBER

07NMF-MT70110

07NMF-MT70120

07RMJ-MY50100

07TMB-00101 OA

07VMF-MAT0100

07VMF-MAT0200

-

BM

MAT0300

-

MAT0400

-

210-AH

00

00

00

07VMF

07VMF

07YMB-MCF0101

07YMD-MCFOI

07Y M D-MCJOI

07YMF-MCJOI

07YMF-MCJ0200

07Y M F-M CJ 0300

07YMF-MCJ0400

07ZM G-MCAA400

REMARKS

NOTE 4

NOTE 4

U.S.A. only

U.S.A. only

U.S.A. only

U.S.A. only

1: 07NMD-KZ301OA

NOTE

NOTE

NOTE 2: 07YMF-MCJA200

NOTE 2: 07YMF-MCJA300

NOTE 2: 07YMF-MCJA400

U.S.A. only

NOTE 2: BM

(U.S.A. only)

2: 07YMF-MCJA100

(U.S.A. only)

(U.S.A. only)

(U.S.A. only)

(U.S.A. only)

-

210 (U.S.A. only)

13

,I

8

13

13

13

13

13

13

13

14

5

5

5

5

3,

16

REF.

3

8

SEC.

1-18

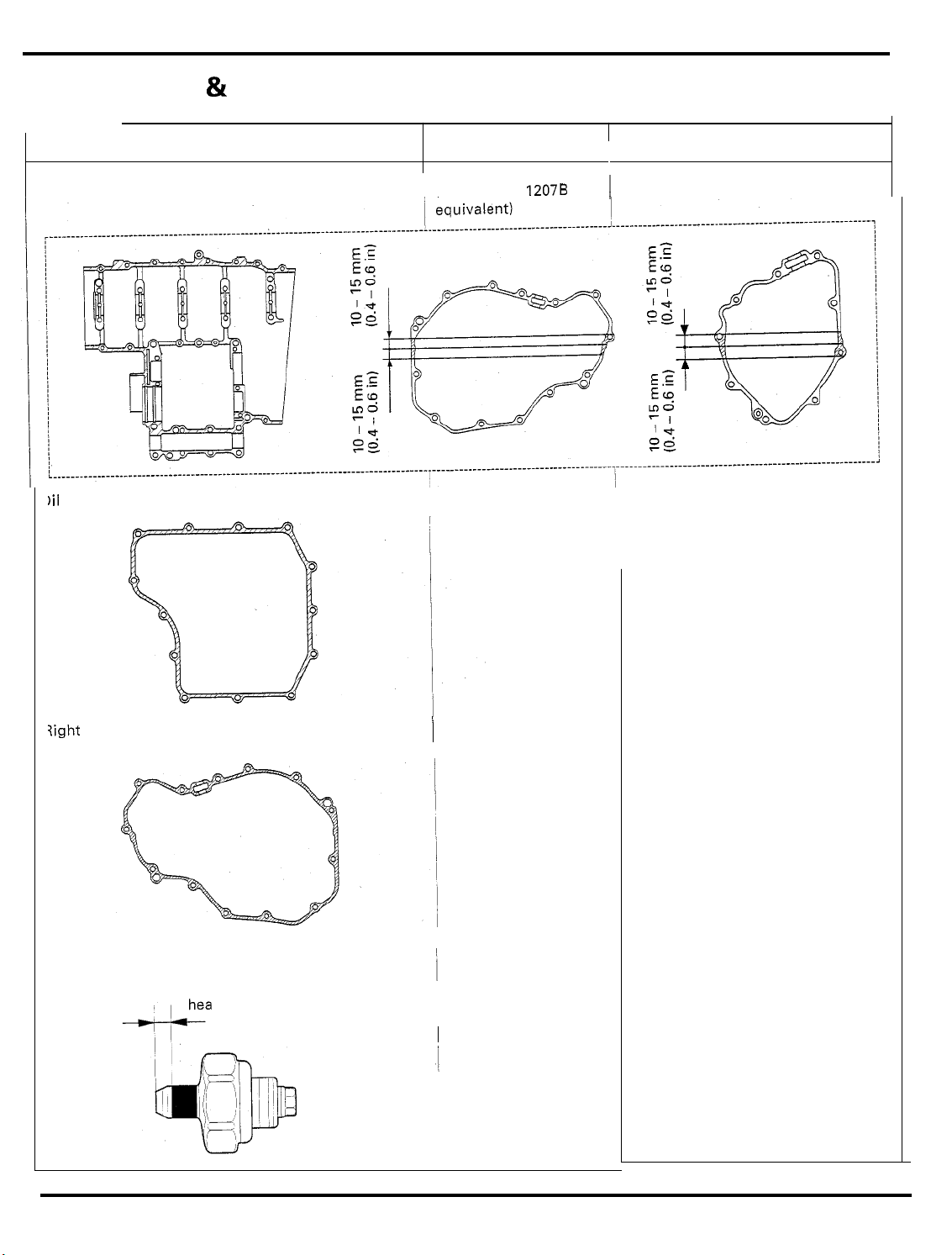

LUBRICATION & SEAL POINTS

GENERAL INFORMATION

LOCATION

Crankcase mating surface

)iI pan mating surface

MATERIAL

Liquid sealant

1

(Three Bond

I

I

1207B

or

~

1

REMARKS

3ight crankcase cover mating surface

Oil

pressure switch threads

Do

not apply sealant

d

3

-

4

mm

to

(0.1 - 0.2

the thread

in)

I

1

I

I

I

1-19

GENERAL INFORMATION

ENGINE

Cylinder head semi-circular cut-out

Main journal bearing surface

Piston pin sliding surface

Connecting rod bearing surface

Connecting rod small end inner surface

Crankshaft thrust surface

Camshaft

Valve stem (valve guide sliding surface)

Valve lifter outer sliding surface

Clutch

Clutch outer guide sliding surface

M314,

Starter reduction gear shaft outer surface

Cylinder head special bolt (after removing anti

oil

additive)

Primary

(Cont'd)

LOCATION

lobes/journals and thrust surface

outeriprimary driven gear sliding surface

C5, C6 shifter gear (shift fork grooves)

sub-gear friction spring sliding surface

-

rust

MATERIAL

Sealant

Molybdenum disulfide

oil (a mixture of

engine oil and

mo I ybdenum d isulfide

grease

1/2

1/2

REMARKS

I

APPLICATION

Piston ring sliding area

Oil strainer packing

Clutch disc surface

Starter one

Connecting rod nut threads

Flywheel bolt threads and seating surface

Main journal

surface (after removing anti

Clutch center lock nut threads

Oil

filter cartridge threads

Camshaft holder bolt threads and seating surface

Oil

cooler center

Each gear teeth and rotating surface

Each bearing rotating area

Each O

-

ring

Other rotating area and sliding surface

AREA

-

way clutch sliding surface

9

mm bolt threads and seating

-

and

bolt

threads

rust

O-ring

oil

/c7f-===$

additive)

1-20

Engine oil

GENERAL INFORMATION

LOCATION

Timing hole cap threads

Each oil seal lip

Upper crankcase sealing bolt threads

Lower crankcase sealing bolt threads

Cam chain guide

Cam pulse generator rotor bolt threads

Cylinder head sealing bolt threads

Cylinder head cover breather joint threads

Starter one

Oil

pump driven sprocket bolt threads

Shift drum bearing set plate bolt threads

Mainshaft bearing set plate bolt threads

Cam sprocket bolt threads

Cylinder head cover breather plate bolt threads

Shift drum center bolt threads

Cam chain tensioner pivot bolt threads

Cam chain guide pivot bolt threads

Gearshift return spring pin

A

mounting bolt threads

-

way clutch outer bolt threads

j

1

MATERIAL

Multi-purpose grease

I

~

Locking agent

Coating width:

REMARKS

6.5

2

1

mm

4

-

21

GENERAL INFORMATION

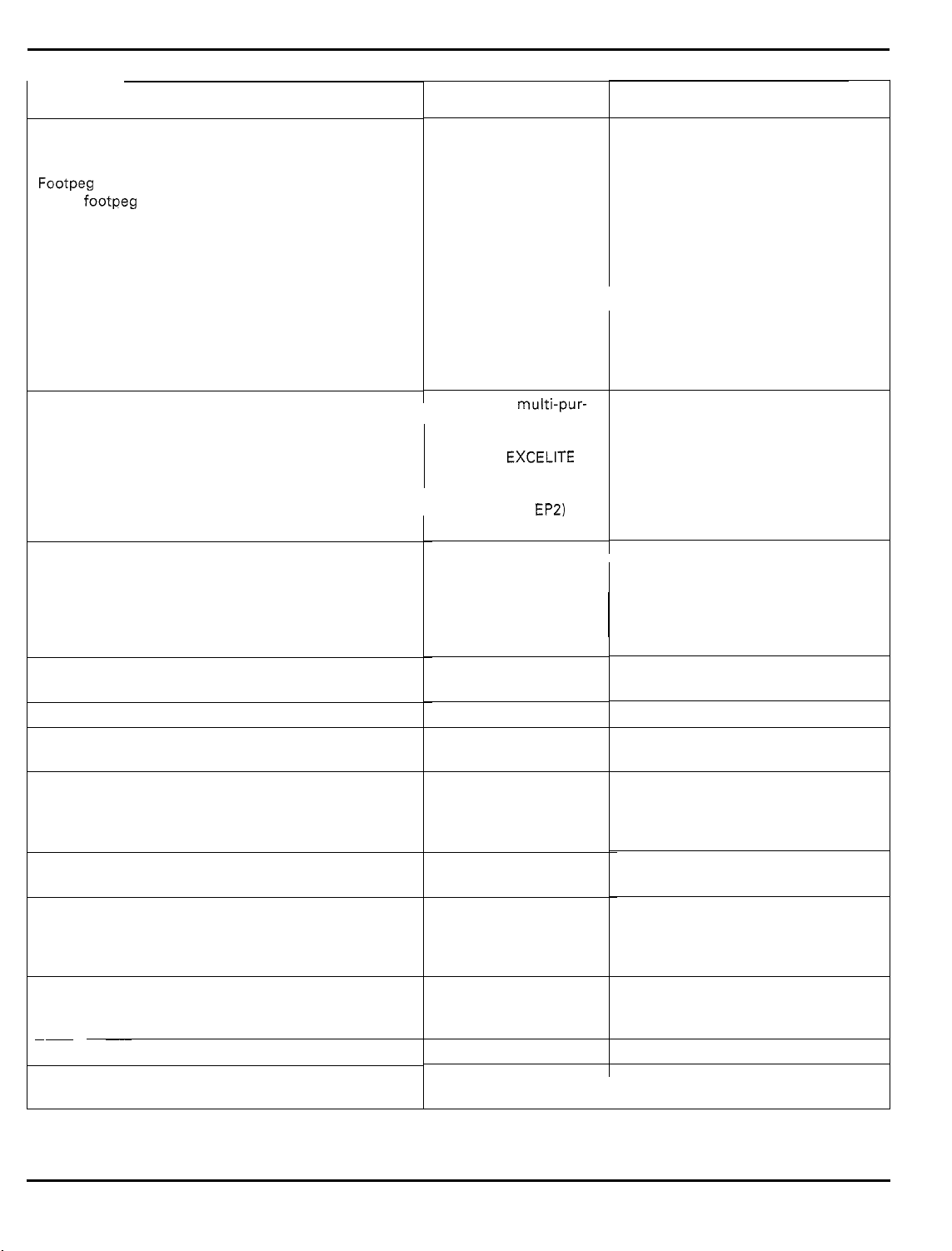

FRAME

LOCATION

Front wheel dust seal lips

Rear wheel dust seal lips

-

Rear wheel hub O

Footpeg sliding area

footpeg sliding area

Pillion

Rear brake pedal pivot sliding area

Gearshift pedal pivot sliding area

Gearshift pedal tie

Clutch lever pivot bolt sliding area

Throttle pipe sliding area

Pillion seat pivot sliding area

Pillion seat catch hook

Pillion seat spring sliding area

Side stand pivot surface

Throttle pipe cable sliding surface

Steering head bearing sliding surface

Steering head dust seal lips

Swingarm pivot bearings

Swingarm pivot bearings

Swingarm pivot dust seal lips

Shock arm and link dust seal lips

Shock arm and link needle bearings

Shock absorber needle bearing

Shock absorber dust seal lips

Side stand pivot surface

Throttle pipe cable sliding surface

Shock absorber spring adjuster cam surface

Steering stem top thread

Brake pipe joint threads

Throttle cable

Clutch cable casing inner

Variable air intake valve cable inner

Exhaust gas control valve cable

Brake master cylinder cups

Brake caliper piston seals

Brake caliper dust seals

Front brake lever pivot and piston tips

Rear master cylinder boot inside and push rod tips

Rear brake caliper slide pin surface

Rear brake caliper slide pin threads

Rear master cylinder hose joint screw threads

Driven sprocket stud bolt threads

____

Handlebar grip rubber inside

Fork cap O

Fork oil seal lips

~~~

-

ring

ring

-

rod ball joint

A,

B casing inner

A,

B casing inner

MATERIAL

Multi-purpose grease

Urea based

pose grease for

extreme pressure

(example:

EP2 manufactured by

KYODO YUSHI, Japan,

Shell Stamina

equivalent

Multi

(Shell Alvania EP2 or

equivalent)

Molybdenum disulfide

grease

Molybdenum paste

Engine oil

Cable lubricant

DOT

Silicone grease

Locking agent

Honda Bond

Fork fluid

multi-pur-

EXCELITE

EP2) or

-

purpose grease

4

brake fluid

A

REMARKS

1-22

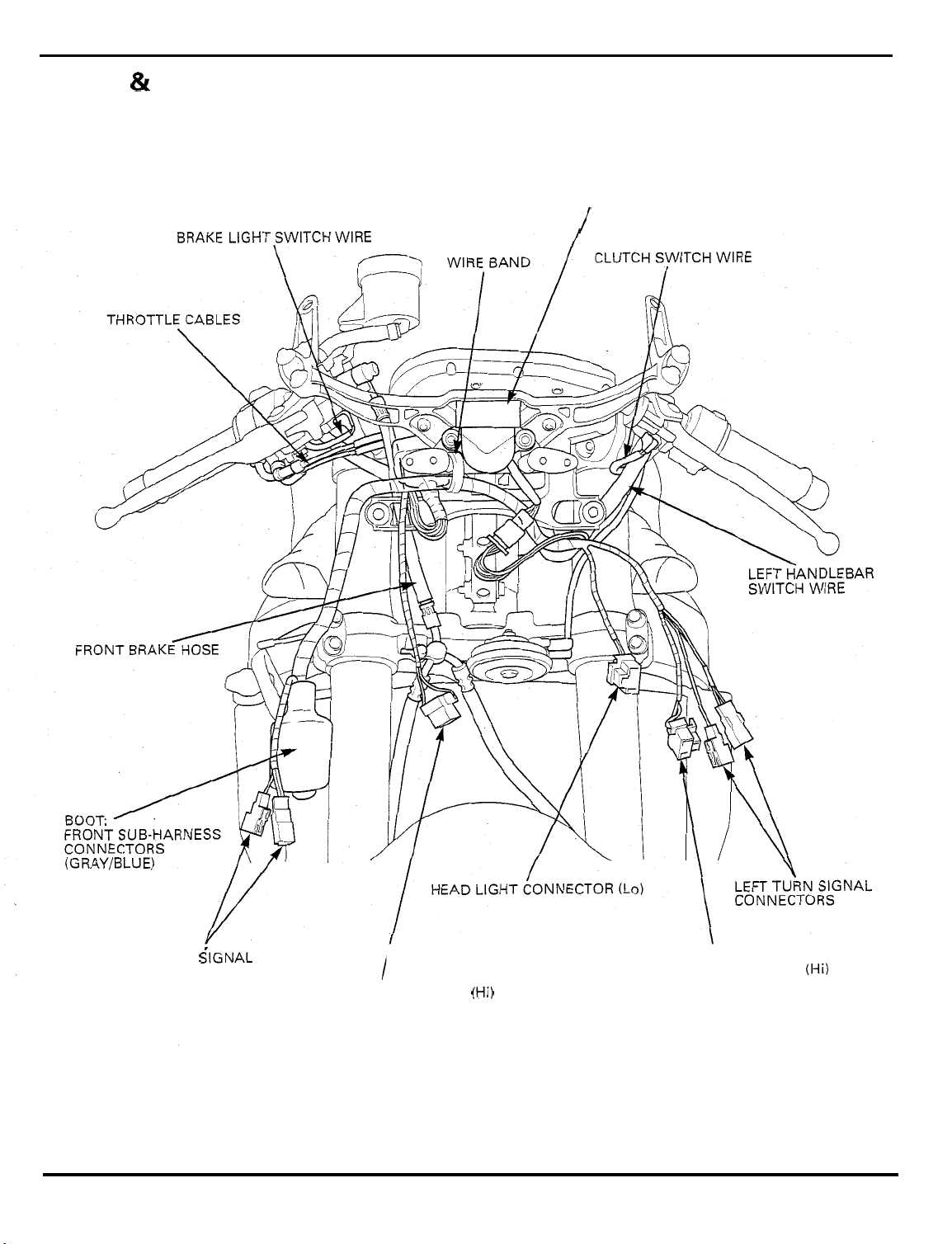

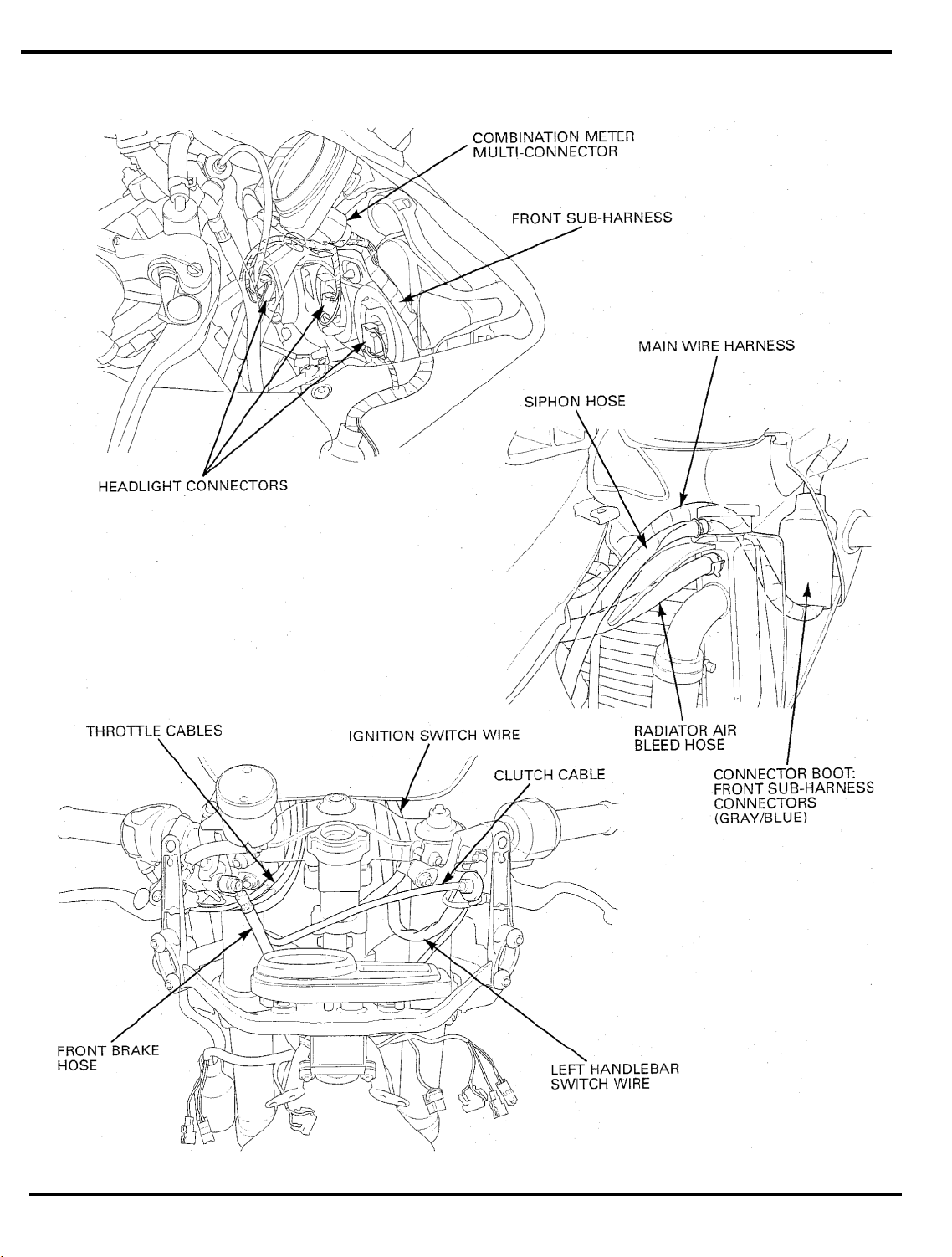

CABLE & HARNESS ROUTING

GENERAL INFORMATION

BANK ANGLE SENSOR

/

RIGHT

TURN

CON N ECTORS

~IGNAL

HEAD LIGHT CONNECTOR

(Hi)

HEAD LIGHT CONNECTOR (Hi)

\

1-23

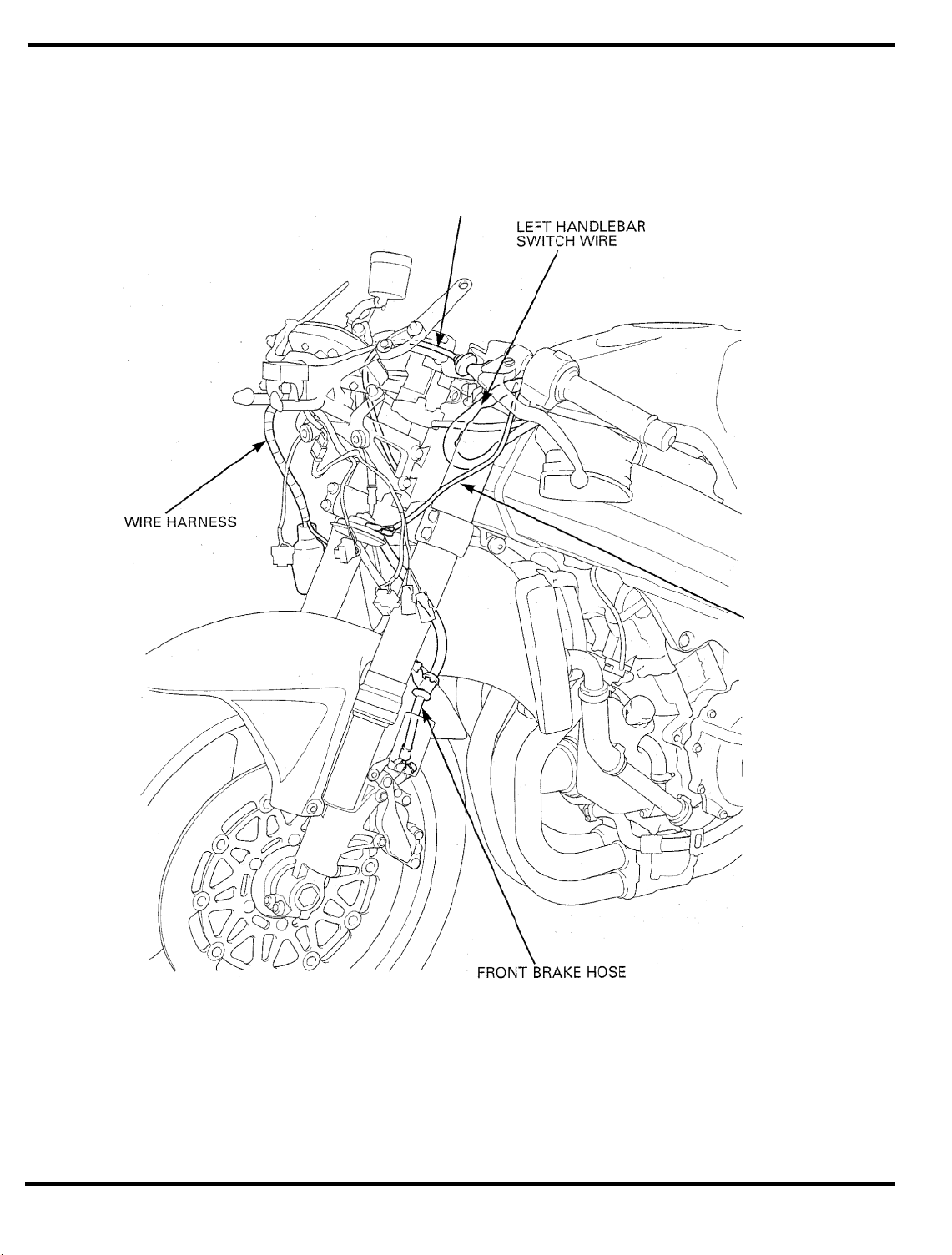

GENERAL INFORMATION

CLUTCH CABLE

I

MAIN

\

HORN WIRE

1-24

GENERAL INFORMATION

FRONT

BdAKE

HOSE

1-25

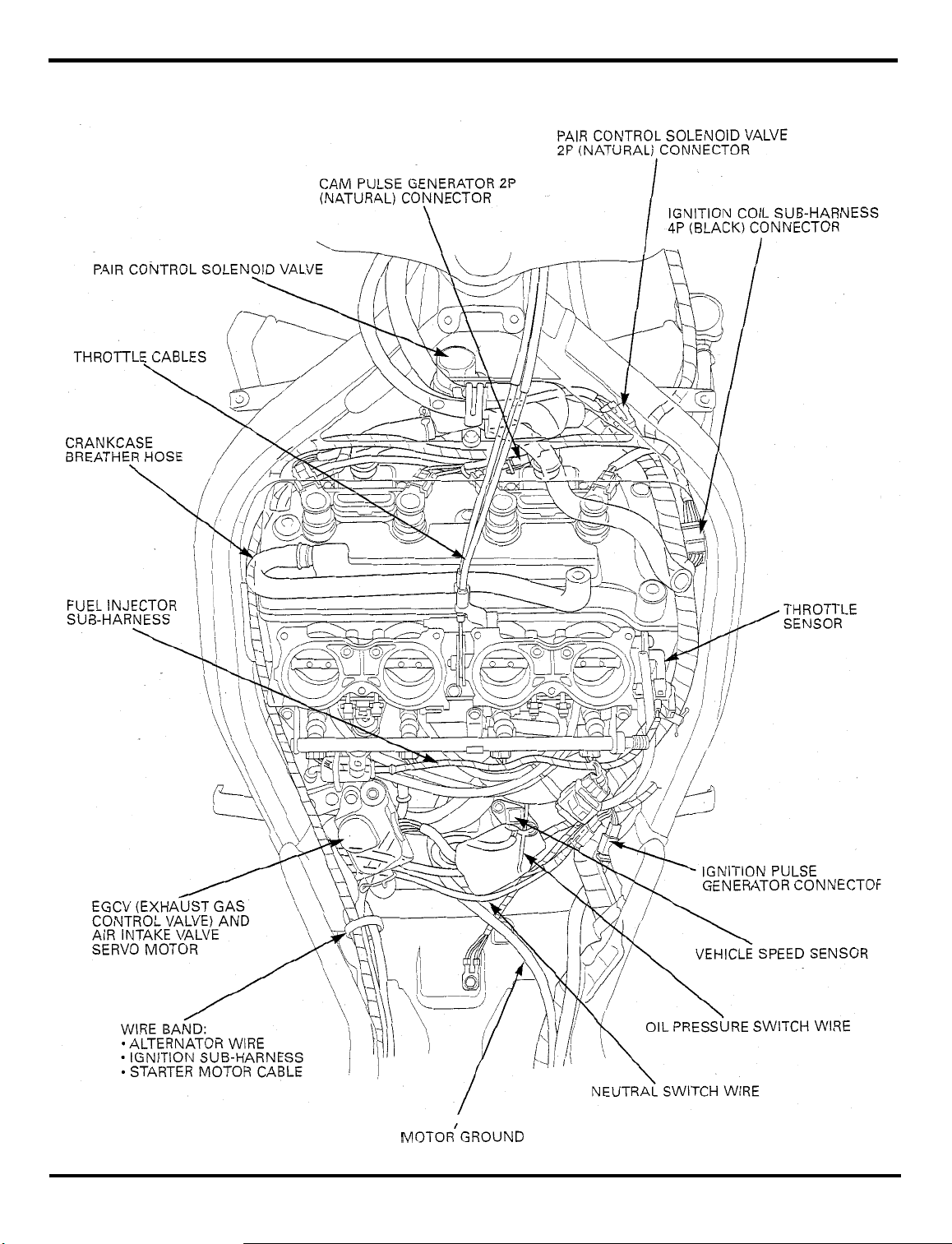

GENERAL INFORMATION

'I

-

26

GENERAL INFORMATION

EXCEPT CALIFORNIA

TYPE:

STARTER

MOTOR'GROUND

CABLE

1-27

Loading...

Loading...