Honda CBR 954RR Service Manual 04 lubrication

LUBRICATIQN

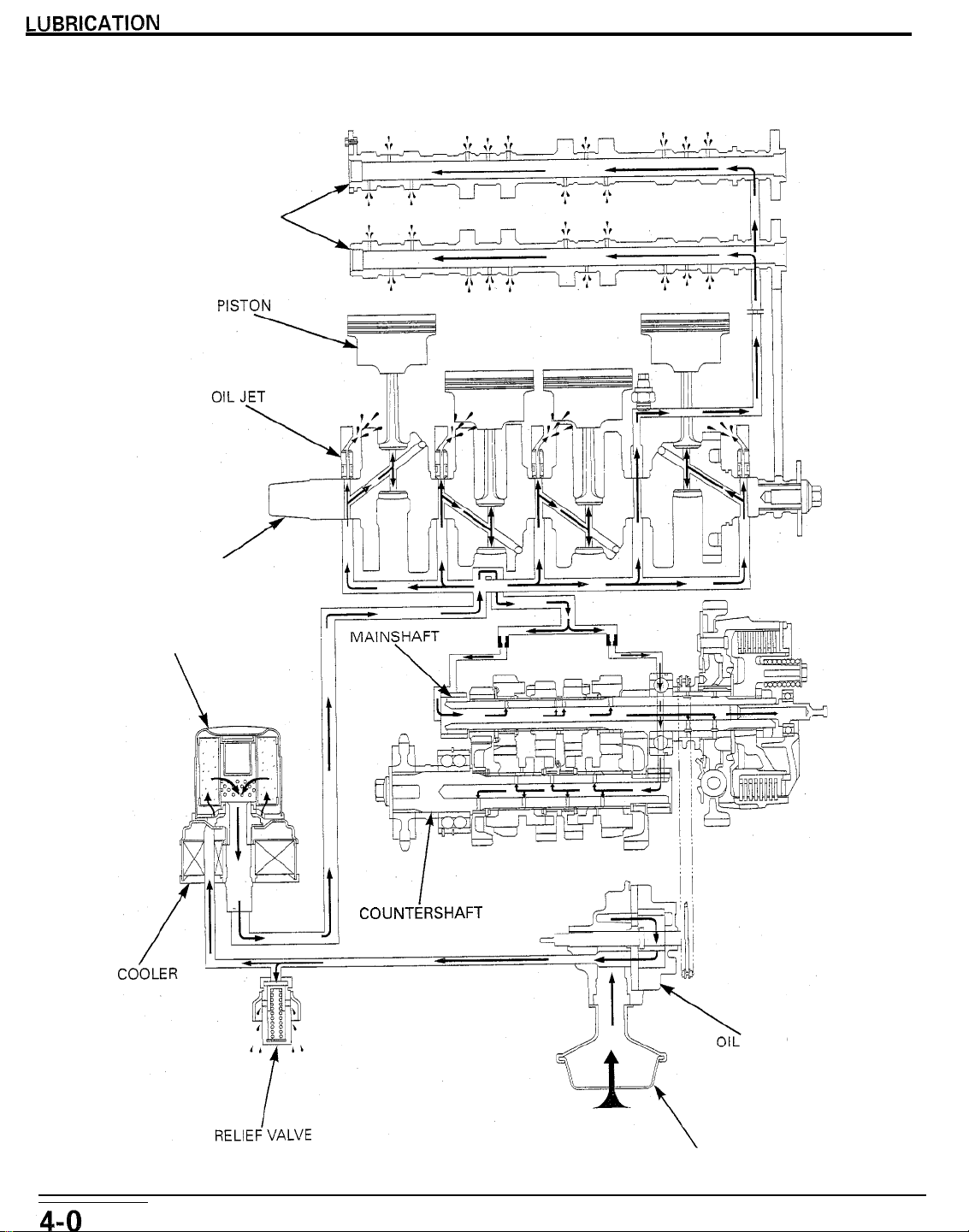

SYSTEM

LUBRICATION

CAMSHAFTS

SYSTEM

DIAGRAM

CRANKSHAFT

OIL

FILTER CARTRIDGE

1

OIL

cou

NTERSHAFT

1

i

PUMP

OIL STRAINER

n

T

LUBRICATION SYSTEM DIAGRAM

SERVICE INFORMATION

TROUBLESHOOTING

OIL PRESSURE INSPECTION

SERVICE

INFORMATION

4-0

4

-

1

4-2

4-3

OIL STRAINERPRESSURE RELIEF

VALVE

OIL

PUMP

OIL COOLER

GENERAL

Repeated, prolonged exposure to used motor oil may cause skin cancer.

Wash your hands thoroughly with strong soap as soon as possible after handling used oil.

The oil pump can be serviced with the engine installed in the frame.

The service procedures in this section must be performed with the engine oil drained.

When removing and installing the oil pump, use care not to allow dust or dirt to enter the engine.

If

any portion of the oil pump is worn beyond the specified service limits, replace the oil pump as an assembly.

-

After the oil pump has been installed, check that there are no oil leaks and that oil pressure is correct.

SPECIFICATIONS

4-3

4-5

4-9

Unit:

mm

(

Engine

Recommended engine oil

I

Oil pressure at oil pressure switch

Oil pump rotor

oil

capacity

At draining

At oil filter change

1

At disassembly

Tip clearance

Body clearance

Side clearance

STANDARD

3.5 liter (3.7 US qt, 3.1

3.7 liter (3.9

4.0 liter (4.2 US

Pro Honda GN4 or

num additives) 4-stroke oil or equivalent

motor oil

API service classification:

JASO

Viscositv: SAE IOW-40

490 kPa (5.0 kgf/cm2,

5,400

0.15

(0.006)

-

0.15

0.02

-

US

T

903 standard:

rpm/(80"C/176"F)

max.

0.22 (0.006

0.07

(0.001 - 0.003)

qt, 3.3

qt,

3.5

HP4

-

0.009)

Imp

qt)

Imp

qt)

Imp

qt)

(without molybde

SG

or higher

MA

71

psi) at

-

SERVICE

0.20

0.35 (0.014)

0.10

LIMI-

__

(0.008)

(0.004)

LUBRICATION

SYSTEM

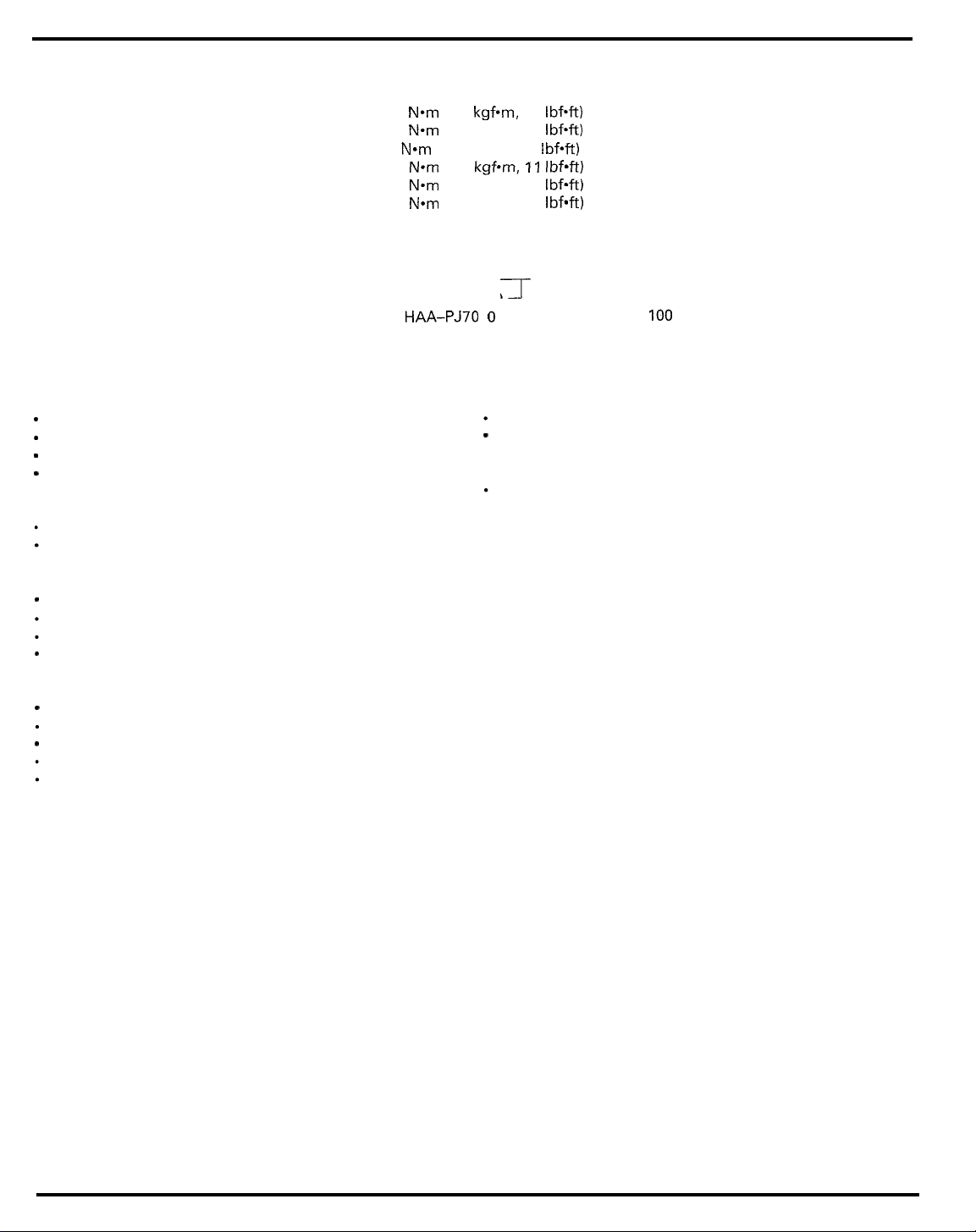

TORQUE VALUES

Oil drain bolt

Oil cooler mounting bolt

Oil pump assembly flange bolt

Oil pump driven sprocket bolt

Oil filter cartridge

20

mm

Lower crankcase

sealing bolt

TOOLS

Oil pressure gauge set

Oil pressure gauge attachment

Oil filter wrench

TROUBLESHOOTING

Engine

-

-

-

Low

No

-

oil

level too

Oil consumption

External oil leak

Worn piston ring or incorrect piston ring installation

Worn valve guide or seal

or no oil pressure

Clogged oil orifice

Incorrect oil being used

oil pressure

Oil level too low

Oil pump drive sprocket broken

Oil pump damaged (pump shaft)

Internal

oil

low

leak

29

N*m

(3.0

kgf-m,

74

N-m

(7.5

kgf-m,

8

N*m

(0.8

kgf-m,

15

N-m

(1.5

kgfom,

26

N-m

(2.7

kgf-m,

29

N*m

(3.0

kgf-m,

07506-3000001

-

MA70000

0751 0

HAA-PJ70

07

1 0 1

High

-

Oil

22

Ibfeft)

54

lbf-ft)

5.8

Ibf*ft)

11

Ibf-ft)

20

Ibf-ft)

22

Ibfoft)

Equivalent commercially available

CT bolt

Apply a locking agent to the threads.

Apply clean engine oil to the O

Apply a locking agent to the threads.

_I

07 HAA-PJ7O

or

oil pressure

Plugged

Incorrect oil being used

contamination

From coolant mixing with oil

-

-

-

-

oil

filter, gallery, or metering orifice

Faulty water pump mechanical seal

Faulty cylinder head gasket

Water leak

Faulty oil cooler

in

100

crankcase

in

U.S.A.

-

ring.

Low

oil

pressure

-

Clogged oil strainer screen

Oil pump worn or damaged

*

Internal oil leak

Incorrect oil being used

Low oil level

4-2

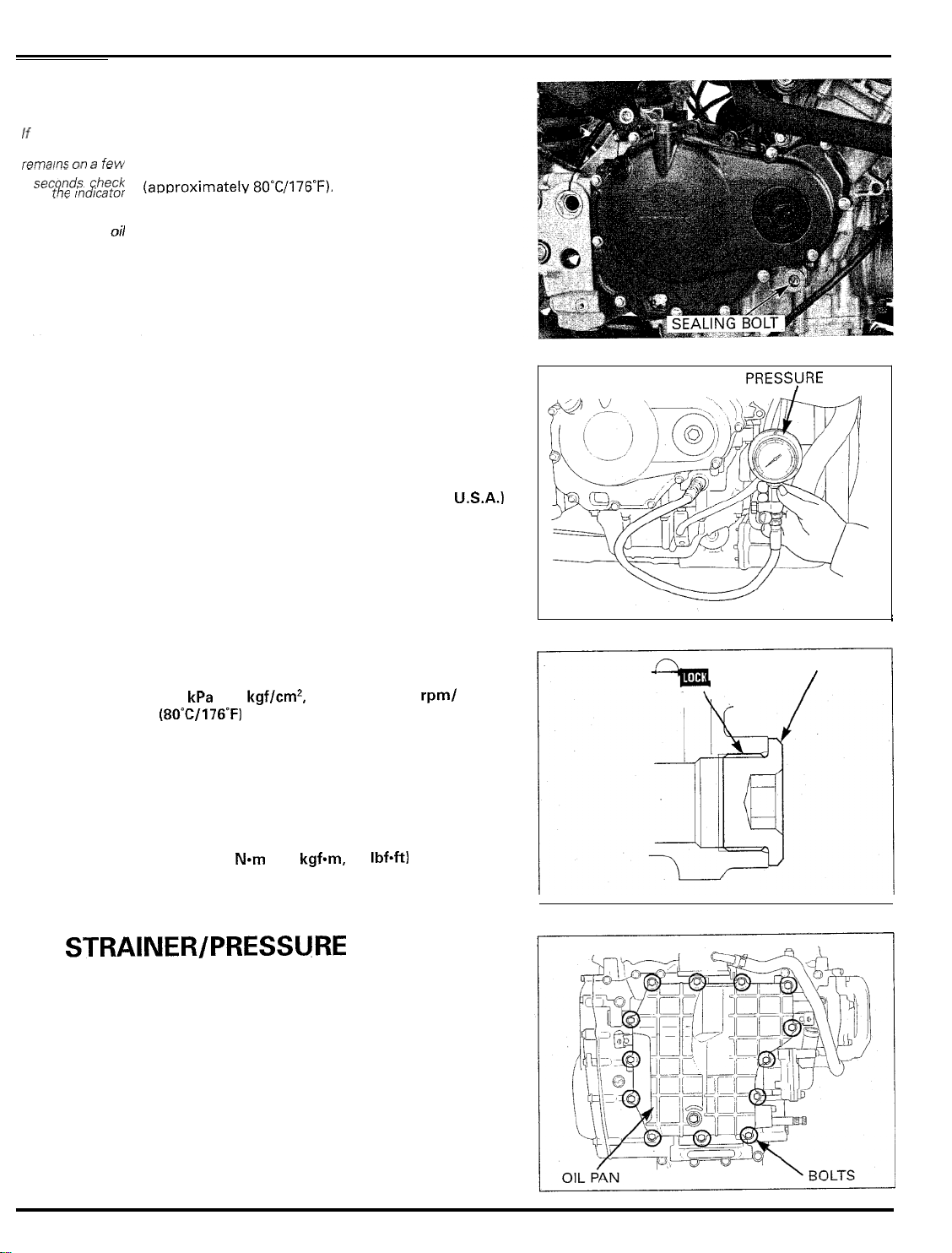

OIL PRESSURE INSPECTION

LUBRICATION SYSTEM

If the oil pressure

indicator light

remains

on

a

few

seconds,

system before

checking the

Ihe

indicator

pressure.

check

oii

Check the oil level (page 3-15).

Warm up the engine to normal operating temperature

(aeeroximately 80°C/176"F).

Sto'p the engine and remove the crankcase sealing

bolt.

Connect an

crankcase.

TOOLS:

Oil

pressure gauge set 07506-3000001

Oil

pressure gauge attachment

Start the engine and increase the rpm to 5,400 rpm

and read the oil pressure.

OIL PRESSURE:

490

(80"C/176"F)

oil

pressure gauge and attachment

kPa (5.0 kgf/cm*, 71 psi) at

(Equivalent

commercially

-

MA70000

rpm/

U.S.A.)

U.S.A.)

available in

0751 0

(Equivalent

commercially

available in

5,400

to

the

OIL

PRESSlJRE

I

SEALING

GAUGE

I

BOLT

/

Stop the engine and remove the tools.

Apply a locking agent to the sealing bolt threads.

Install and tighten the sealing bolt to the specified

torque.

TORQUE:

29

N-m

(3.0

kgf-m,

22

Ibf-ftl

OIL STRAINER/PRESSURE RELIEF

VALVE

REMOVAL

Drain the engine oil (page

Remove the exhaust pipe (page 2-13)

Remove the

oil

pan flange bolts and

3-15).

oil

pan.

I

I

4-3

Loading...

Loading...