Honda CBR 954RR Service Manual 15 brakes

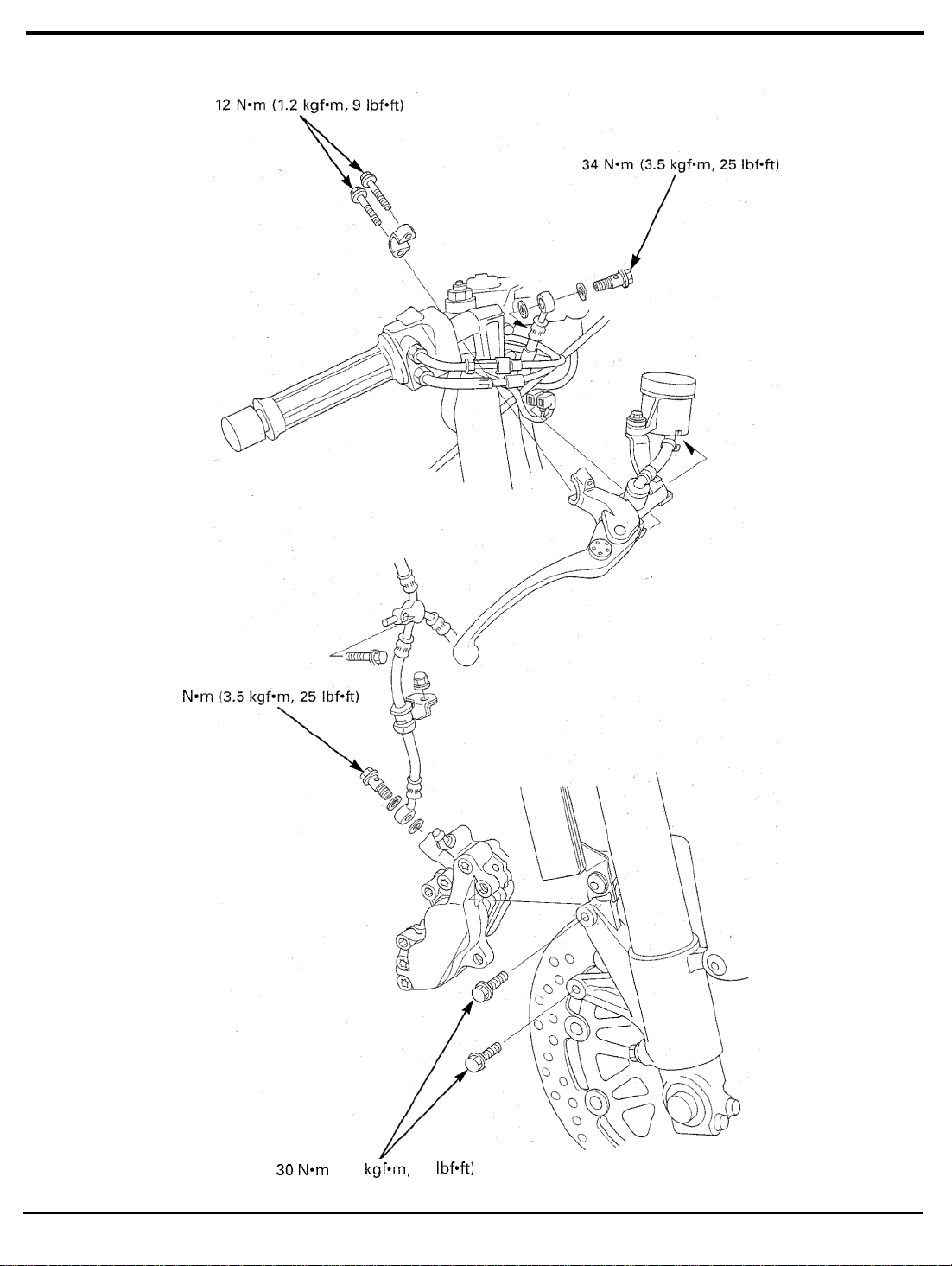

HYDRAULIC BRAKE

FRONT:

34

N-m

30

N*m

(3.1

kgf-m,

22

Ibf-ft)

15-0

15.

HYDRAULIC BRAKE

SERVICE INFORMATION 15

TROUBLESHOOTING

BRAKE FLUID REPLACEMENT/

AIR BLEEDING 15

BRAKE

FRONT MASTER CYLINDER 15

PAD/DISC 15-8

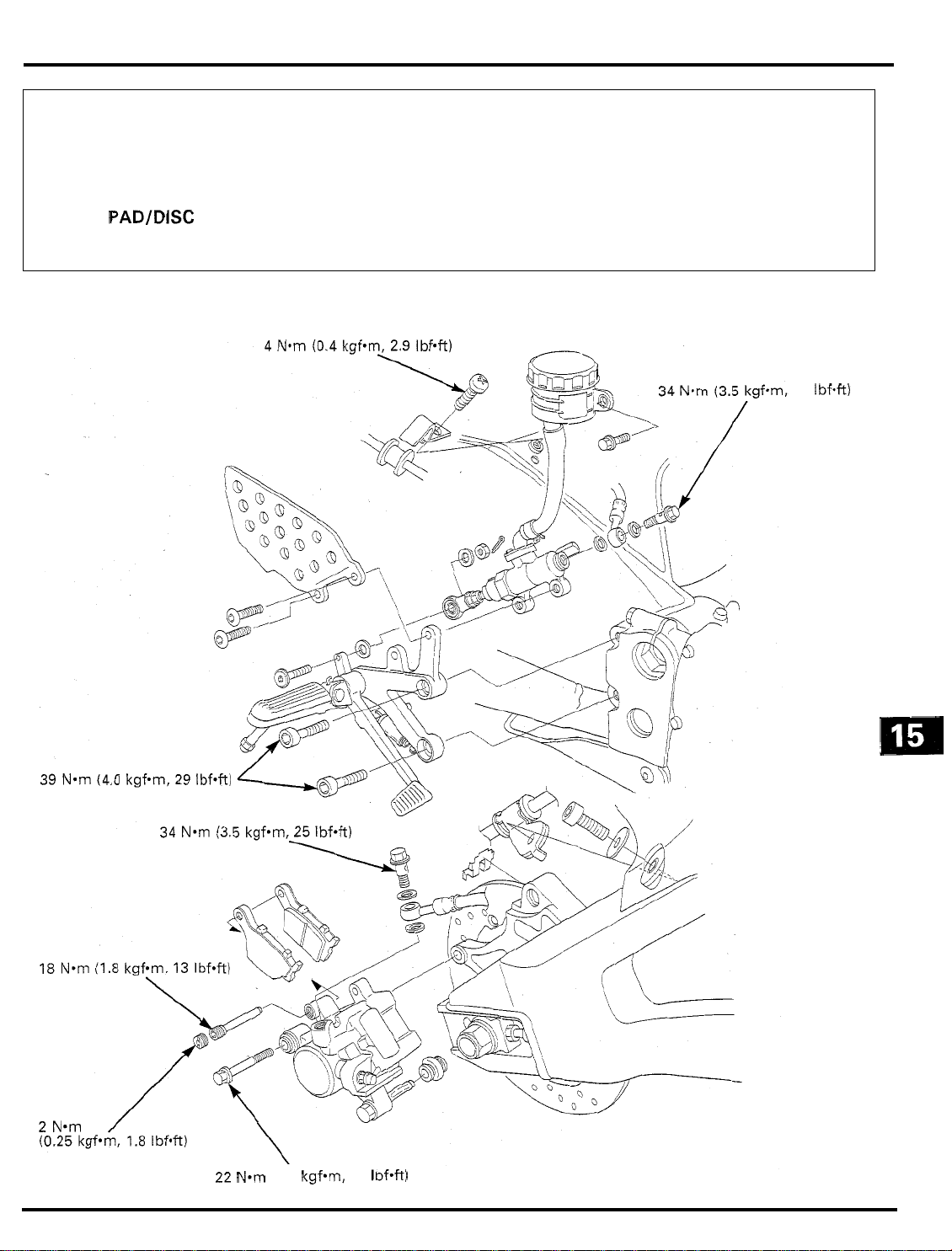

REAR:

-

2 REAR MASTER CYLINDER

-

3 FRONT BRAKE CALIPER 15-21

15

REAR BRAKE CALIPER 15

-

4 BRAKE PEDAL 15-28

-

12

15-17

25

Ibf-ft)

-

25

22

N*m

(2.2

kgf-m,

16

Ibf-ft)

15-1

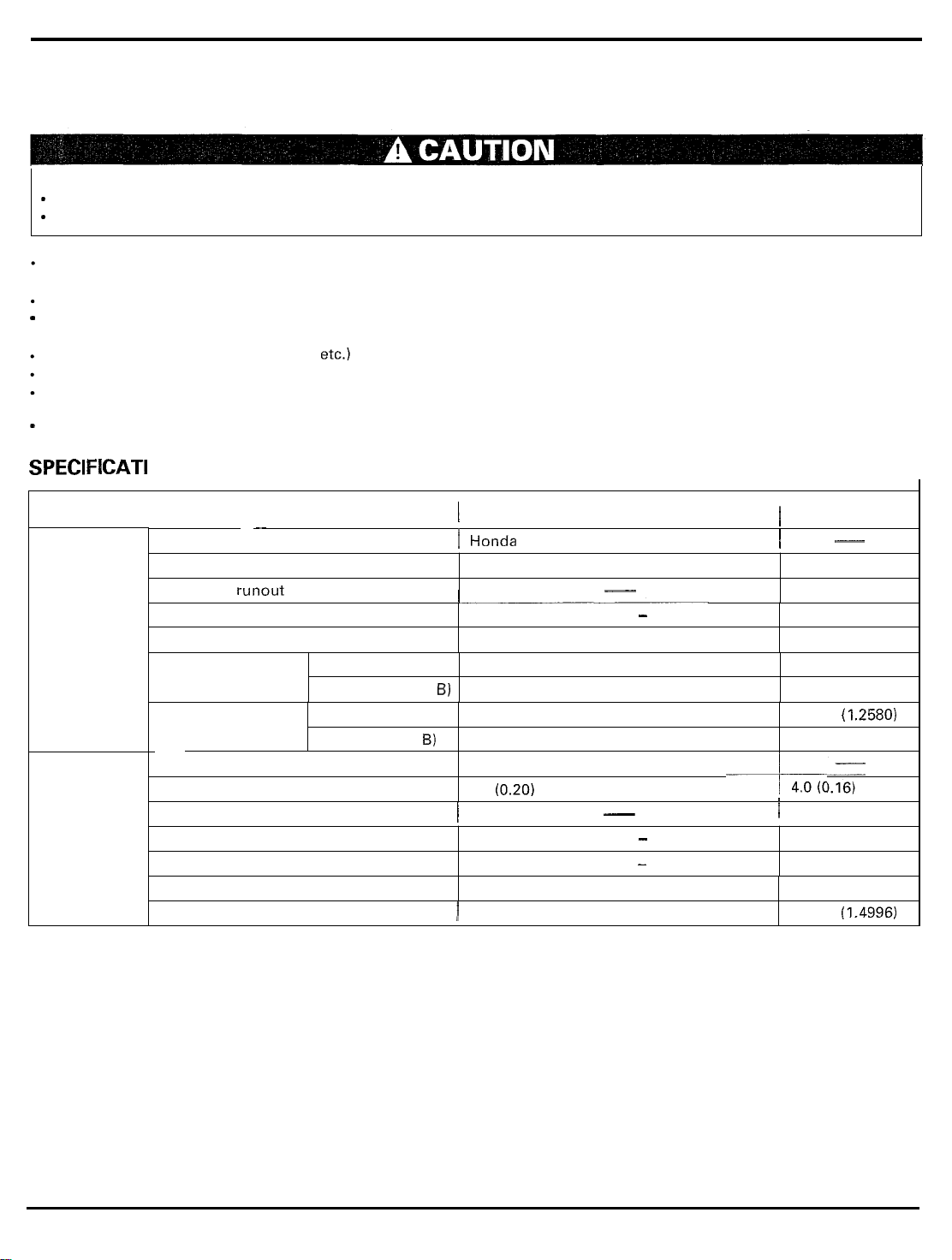

HYDRAULIC BRAKE

SERVICE

INFORMATION

GENERAL

Frequent inhalation of brake pad dust, regardless of material composition could be hazardous to your health.

Avoid breathing dust particles.

-

Never use an air hose or brush to clean brake assemblies. Use an OSHA

A contaminated brake disc or pad reduces stopping power.

a high quality brake degreasing agent.

Check the brake system by applying the brake lever or pedal after the air bleeding.

Spilled brake fluid

careful whenever you remove the reservoir cap; make sure the front reservoir is horizontal first.

Never allow contaminates

Once the hydraulic system has been opened, or

Always use fresh DOT 4 brake fluid from a sealed container when servicing the system. Do not mix different types of fluid

they may not be compatible.

-

Always check brake operation before riding the motorcycle.

SPEC1

Front

Rear

Fl

CAT1

will

severely damage instrument lenses and painted surfaces.

(dirt,

water, etc.) to get into an open reservoir.

ONS

ITEM

Specified brake fluid

Brake disc thickness

Brake disc runout

Master cylinder I.D.

Master piston

Caliper cylinder I.D.

Caliper piston O.D.

Specified brake fluid

Brake disc thickness

Brake disc runout

Master cylinder I.D.

Master piston O.D.

Caliper cylinder I.D.

Caliper cylinder O.D.

~ ~~

O.D.

if

the brake feels spongy, the system must be bled.

Upper (Cylinder A)

Lower (Cylinder

Upper (Piston A)

Lower (Piston

Discard contaminated pads and clean a contaminated disc with

1

1

Honda DOT 4 Brake Fluid

4.5 (0.18) 3.5 (0.14)

17.460 - 17.503 (0.6874 - 0.6891)

-

17.321

32.025 - 32.035 (1.2608 - 1.2612)

6)

B)

-

30.250

31.965 - 31.998 (1.2585 - 1.2598)

30.082

-

Honda DOT 4 Brake Fluid

5.0

(0.20)

I

15.870 - 15.913 (0.6248 - 0.6265)

-

15.827

38.180 - 38.230 (1.5031 - 1.5051)

1

38.098 -38.148 (1.4999 - 1.5019)

approved vacuum cleaner.

It

is also harmful to some rubber parts. Be

STANDARD

17.367 (0.6819 - 0.6837)

30.280 (1.1909 - 1.1921)

30.1 15 (1.1843 - 1.1856)

-

15.854 (0.6231 - 0.6242)

Unit:

1

SERVICE

I

+-

1

-

0.30 (0.012)

17.515 (0.6896)

17.309 (0.6815)

32.05 (1.262)

30.29 (1.193)

31.953

(1 2580)

30.074 (1.1840)

4.0 (0.16)

0.30 (0.012)

15.925 (0.6270)

15.815 (0.6226)

38.24 (1.506)

38.090 (1.4996)

mm

LIMIT

(in

15-2

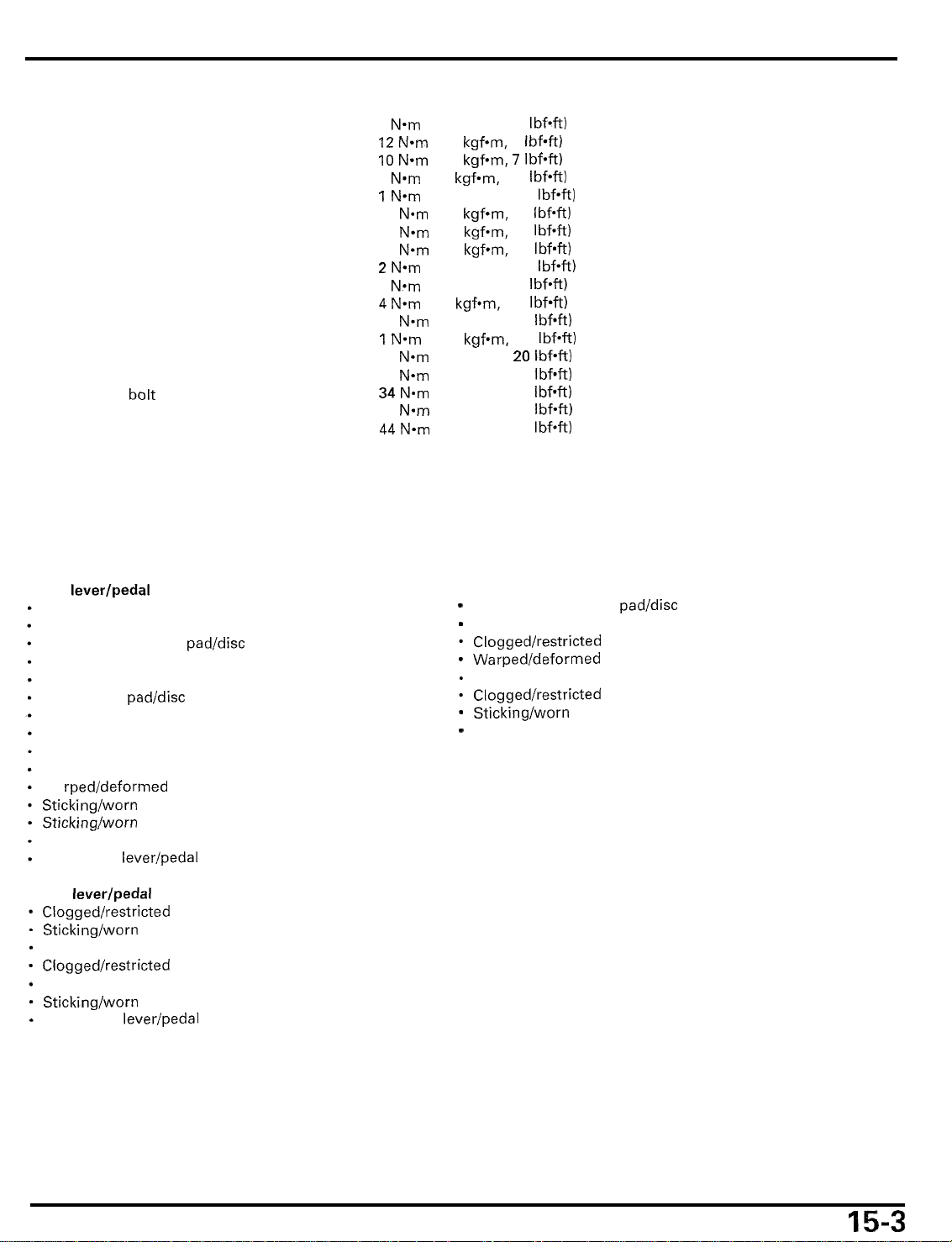

TORQUE VALUES

Front brake master cylinder cup mounting nut

Front master cylinder bracket bolt

Brake lever pivot bolt

Brake lever pivot nut

Front brake light switch screw

Front brake caliper mounting bolt

Caliper body assembly torx bolt

Pad pin

Pad pin plug

Brake caliper bleed valve

Rear brake hose clamp screw

Rear master cylinder push rod nut

Rear master cylinder hose joint screw

Rear brake caliper mounting bolt

Rear brake caliper slide pin bolt

Brake hose oil

Main footpeg bracket socket bolt

Main footpeg mounting bolt

bolt

TOOL

6

N-m

(0.6

kgf-m, 4.3 Ibf-ft)

12 N*m (1.2 kgfom, 9 Ibf-ftt)

10 N*m

6

1 N*m (0.12 kgf-m, 0.9 Ibfmft)

30 N*m (3.1 kgf-m, 22 Ibf-ft)

23 N*m (2.3 kgfmm, 17 Ibf-ft)

18 N-m (1.8 kgf-m, 13 Ibf-ft)

2 N-m (0.25 kgf-m, 1.8 Ibf-ft)

6

4

18 N-m (1.8 kgf-m, 13

1 N-m (0.15 kgfmm, 1.1

27 N*m (2.8 kgf-m, 20 Ibf*ft)

22 N-m (2.2 kgf-m, 16

34 N-m (3.5 kgf-m, 25 IbfW

39 N-m (4.0 kgf-m, 29 Ibf-ft)

44 N-m (4.5 kgf-m, 33

(1.0

kgf*m,

7

N-m

(0.6

kgf-m, 4.3 IbfW

N*m

(0.6

kgf-m, 4.3

N*m (0.4 kgf-m, 2.9

Ibf-ft)

Ibf-ft)

Ibf-ftt)

IbfW

Ibf-ft)

Ibf-ft)

Ibf-ft)

HYDRAULIC BRAKE

-

nut

U

ALOC bolt

ALOC bolt

ALOC bolt

Apply a locking agent to the threads.

Apply a locking agent to the threads.

Apply a locking agent to the threads.

ALOC bolt

Snap ring pliers

TROUBLESHOOTING

Brake lever/pedal

Air in hydraulic system

Leaking hydraulic system

Contaminated brake

Worn caliper piston seal

Worn master cylinder piston cups

Worn brake

Contaminated caliper

Caliper not sliding properly (rear)

Low brake fluid level

Clogged fluid passage

rped/deformed brake disc

Wa

Sticking/worn caliper piston

Sticking/worn master cylinder piston

Contaminated master cylinder

Bent brake

Brake lever/pedal hard

Clogged/restricted brake system

Sticking/worn caliper piston

Caliper not sliding properly (rear)

Clogged/restricted fluid passage

Worn caliper piston seal

Sticking/worn master cylinder piston

Bent brake

soft

or

pad/disc

pad/disc

lever/pedal

leveripedal

spongy

07914-SA50001

Brake drags

-

Contaminated brake padidisc

-

Misaligned wheel

Clogged/restricted brake hose joint

-

Warped/deformed brake disc

Caliper not sliding properly (rear)

Clogged/restricted brake hydraulic system

Sticking/worn caliper piston

-

Clogged master cylinder port

HYDRAULIC BRAKE

BRAKE

BLEED1

FLUID

NG

REPLACEMENT/AIR

Do not allow foreign material to enter the system

when filling the reservoir,

Avoid spilling fluid on painted, plastic, or rubber

parts. Place a rag over these parts whenever the

system

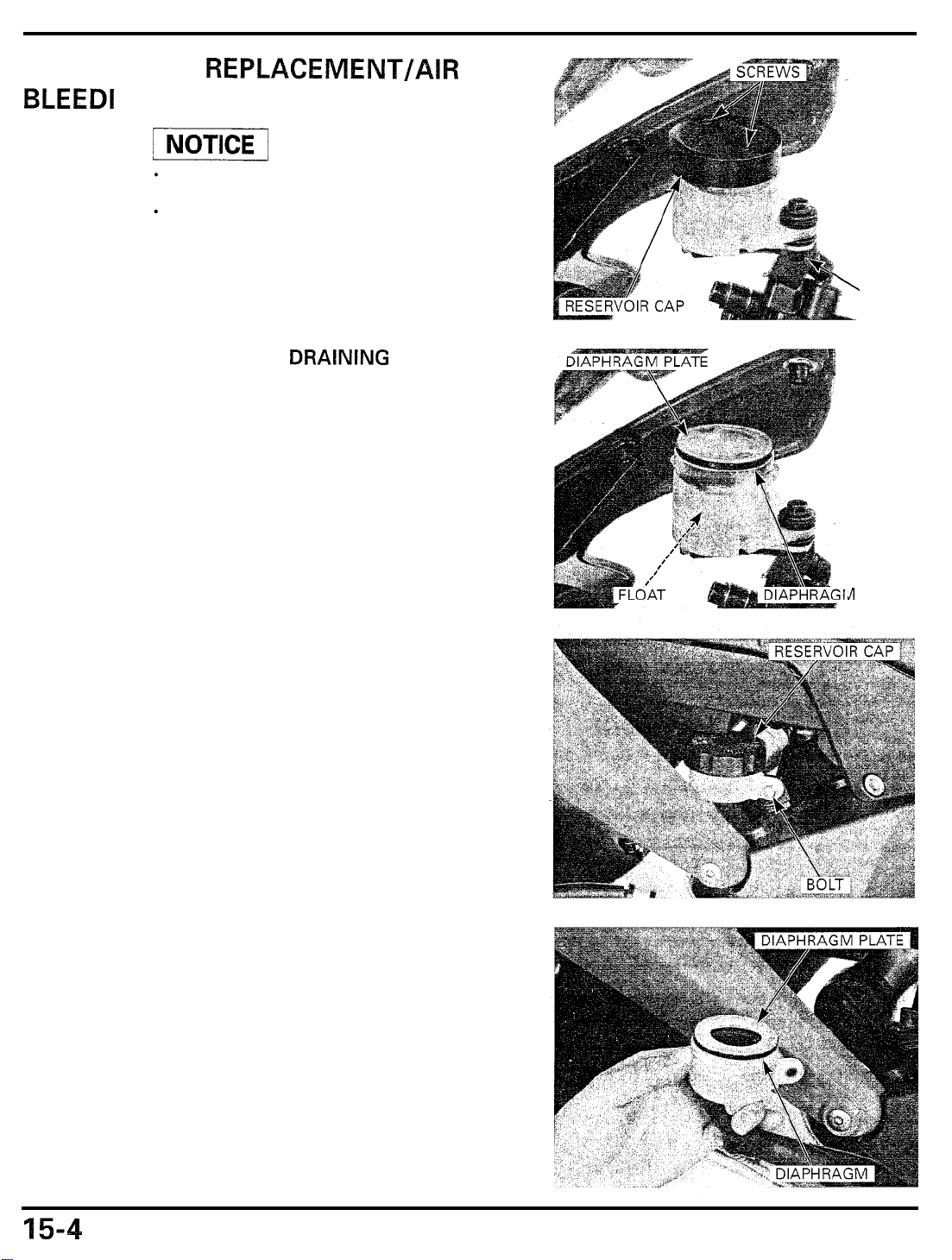

BRAKE FLUID DRAiNlNG

For the front brake, turn the handlebar until the reser

voir is parallel to the ground, before removing the

reservoir cap.

Loosen the master cylinder reservoir mounting nut.

Remove the screws and reservoir cap.

Remove the diaphragm plate, diaphragm and float.

is

serviced.

\

NUT

-

For the rear brake, remove the rear brake reservoir

mounting bolt.

Remove the reservoir cap.

Remove the diaphragm plate and diaphragm.

n

15-4

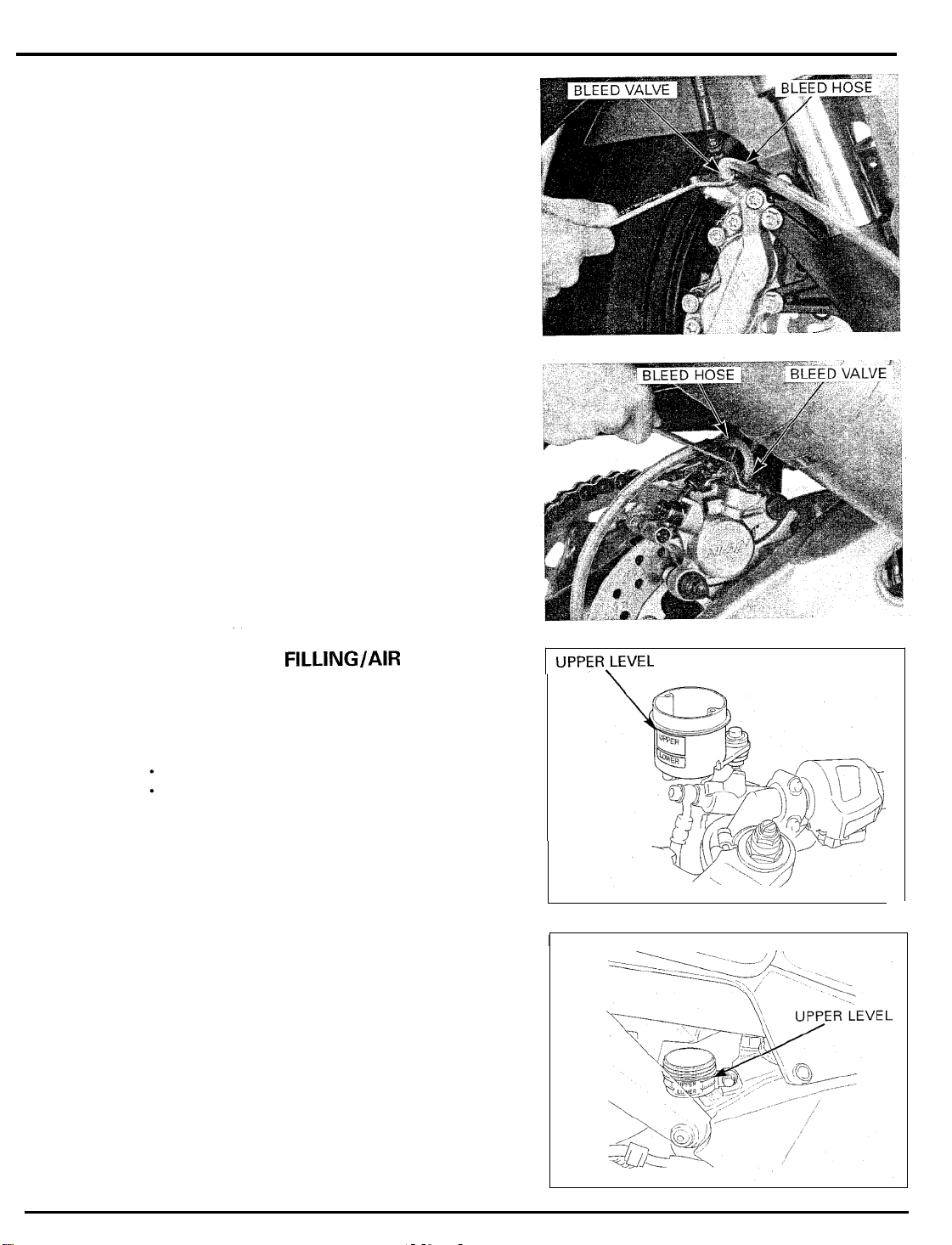

Connect a bleed hose to the caliper bleed valve.

Loosen the bleed valve and pump the brake lever or

pedal.

Stop pumping the lever or pedal when

flows out of the bleed valve.

no

more fluid

HYDRAULIC BRAKE

BRAKE FLUID FILLING/AIR BLEEDING

Fill

the reservoir with DOT 4 brake fluid from a sealed

container.

NOTE:

Use only DOT 4 brake fluid from a sealed container.

Do not mix different types of fluid. They are not

compatible.

UPPER,LEVEL

4

5-5

HYDRAULIC BRAKE

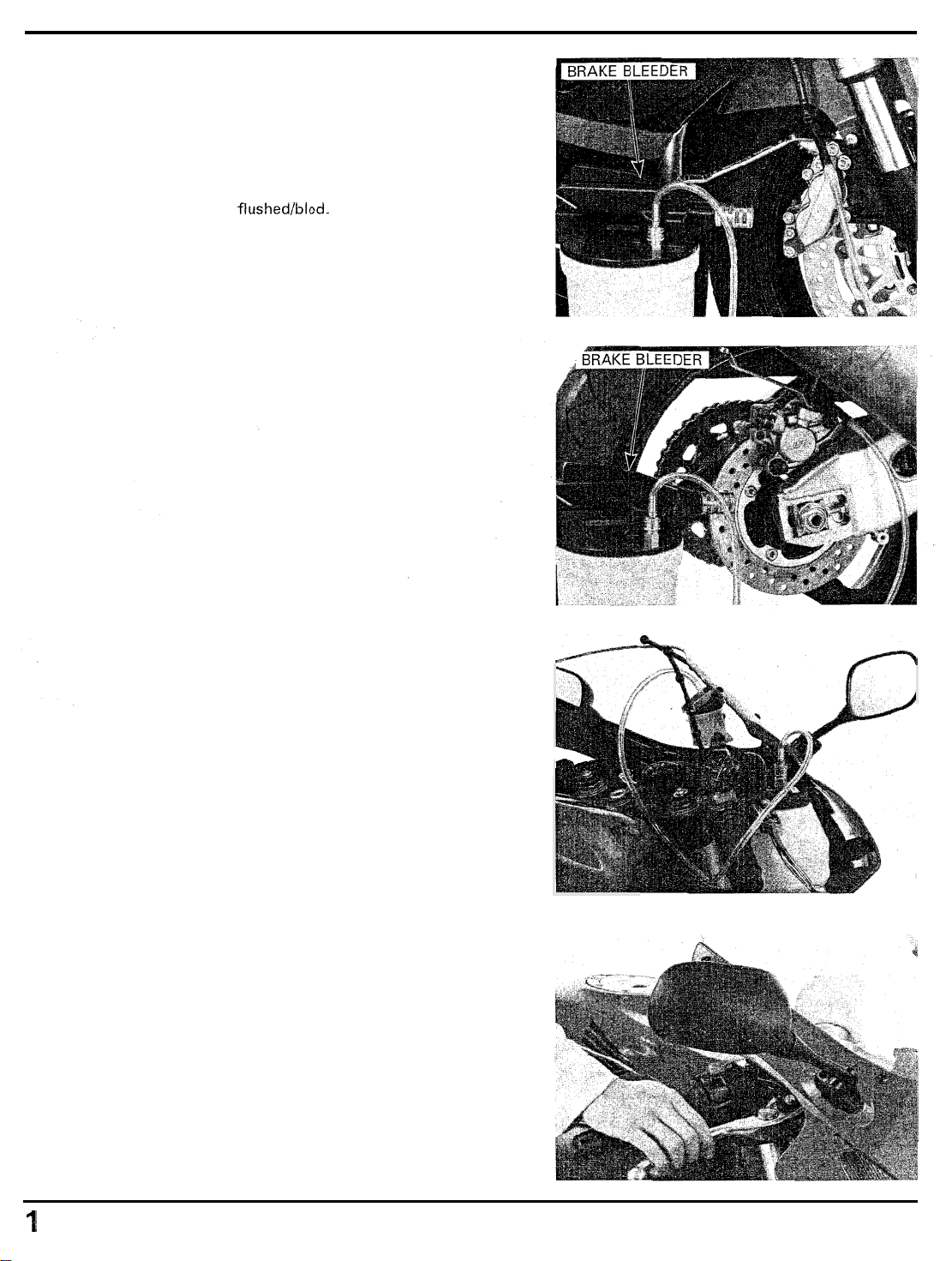

Connect a commercially available brake bleeder to the

bleed valve.

Operate the brake bleeder and loosen the bleed valve.

If

an automatic refill system is not used, add fluid

when the fluid level in the reservoir is low.

Perform the bleeding procedure

completely

Close the bleed valve and operate the brake lever or

pedal.

If

until

the system is

flushed/bled.

it

still feels spongy, bleed the system again.

7

5-6

If

the brake bleeder is not available, perform the fol

lowing procedure.

Pressurize the system with the lever or pedal until

there are no air bubbles in the fluid flowing out of the

reservoir small hole and lever resistance is felt.

-

HYDRAULIC

BRAKE

Donotreiease

the brake /ever

pedai

untii

Meed vaive has

been

1.Squeeze the brake lever or push the brake pedal,

or

the

open the bleed valve

valve.

2.Release the brake lever or pedal until the bleed

valve has been closed.

Repeat steps 1 and

the fluid coming out of the bleed valve.

Tighten the bleed valve.

TORQUE: 6

Fill the fluid reservoir to the upper level.

N-m

(0.6

112 turn and then close the

2

until bubbles cease to appear in

kgf-m,

4.3

Ibf-ft)

UPPER

LEVEL

\

Reinstall the diaphragm and diaphragm plate.

15-7

HYDRAULIC BRAKE

On the front brake, install the reservoir cap, and tight

en the screws.

Tighten the master cylinder reservoir mounting nut

securely.

On the rear brake, install the reservoir cap securely,

then install the reservoir onto the frame and tighten

the mounting bolt.

-

\

IR

CAP

NUT

KE

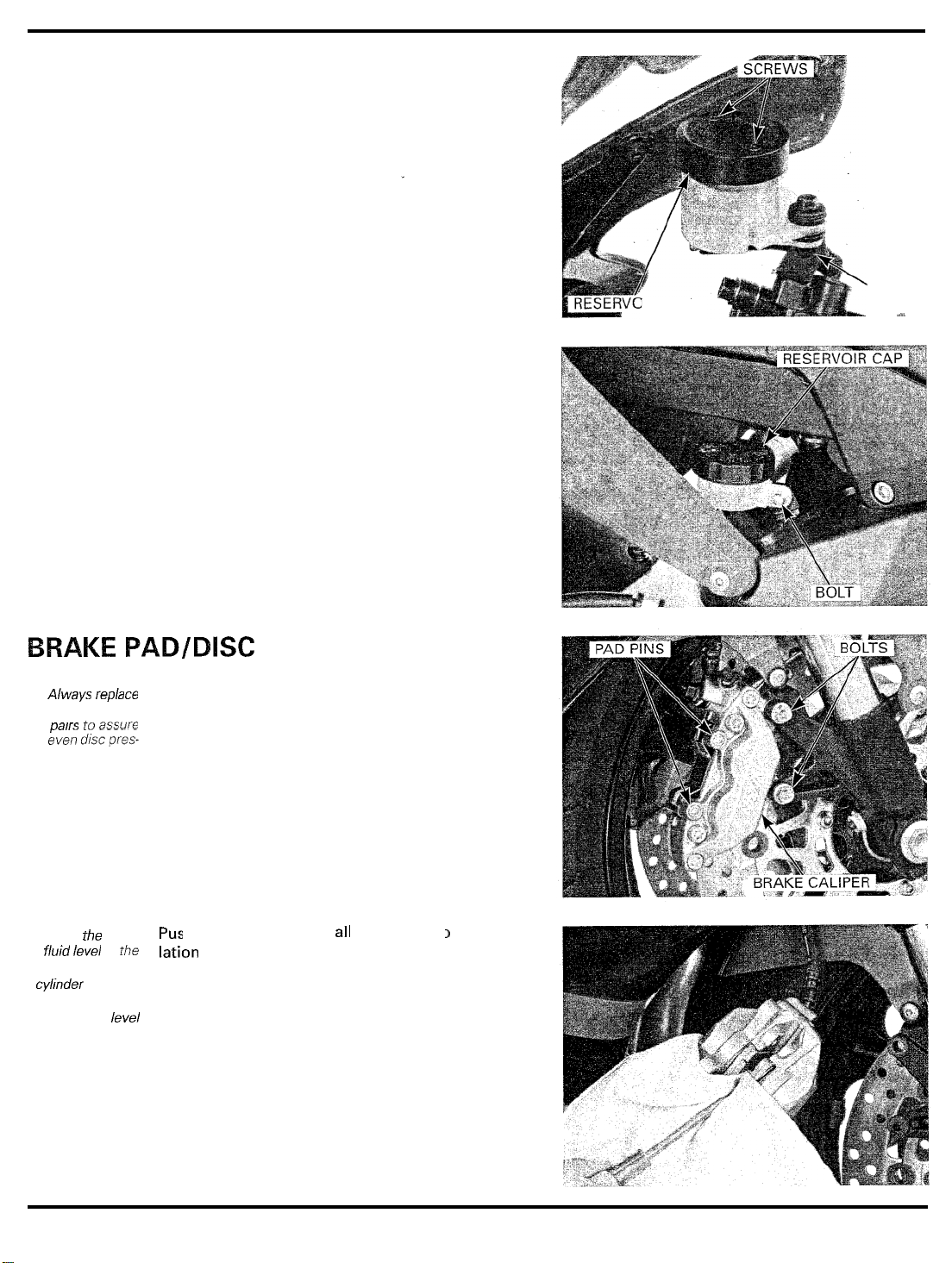

PAD/DISC

Aiways repiace

the brake pads in

Pairs to assure

even

discpres-

sure

Check t!Je biake

fluid /eve/ in The

brake master

cyiinder reservoir

as this opeiation

causes the

/eve/

to rise

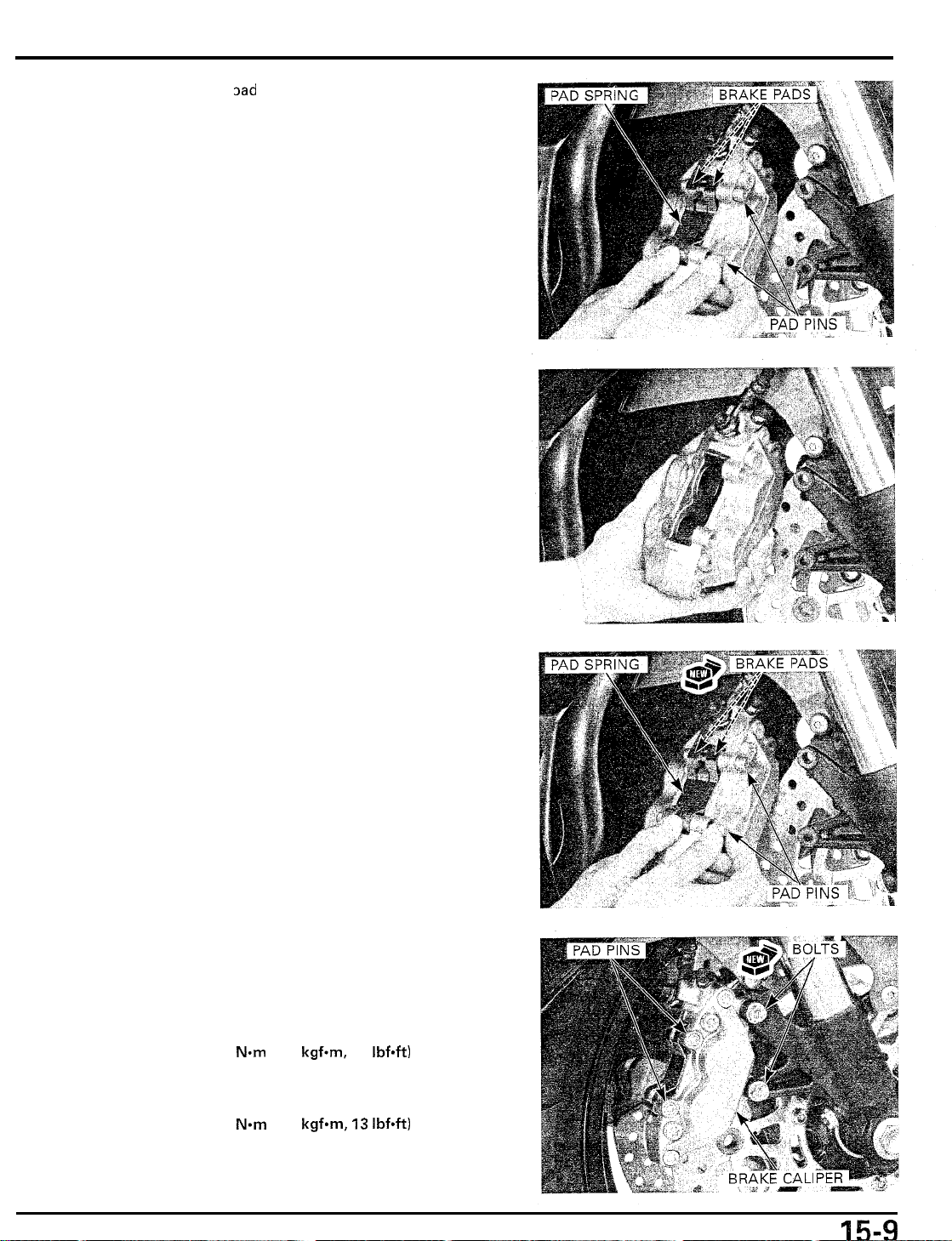

FRONT BRAKE PAD REPLACEMENT

Loosen the pad pins.

Remove the bolts and brake caliper.

I

the caliper pistons

Pus

lation of new brake pads.

all the way in

allow instal

-

'I

5-8

HYDRAULIC

BRAKE

Remove the

I

3ad pins, pad spring and brake pads.

Clean the inside

caliper pistons.

of

the caliper especially around the

Be

careful

not

damage the pads.

to

Install the new brake pads.

Install the pad spring with its arrow mark facing up

(page

15-23).

Push the pad spring, then install the pad pin.

Install the brake caliper to the fork leg

so

the disc is

positioned between the pads.

Install and tighten the new brake caliper mounting

bolts.

TORQUE:

30

N-m

(3.1

kgf-m,

22

Ibf-ft)

Tighten the pad pins.

TORQUE:

18

N-m

(1.8

kgf-m,

13

Ibf-ft)

Loading...

Loading...