Honda CBR 954RR Service Manual 08 cylinder head

CYLINDER

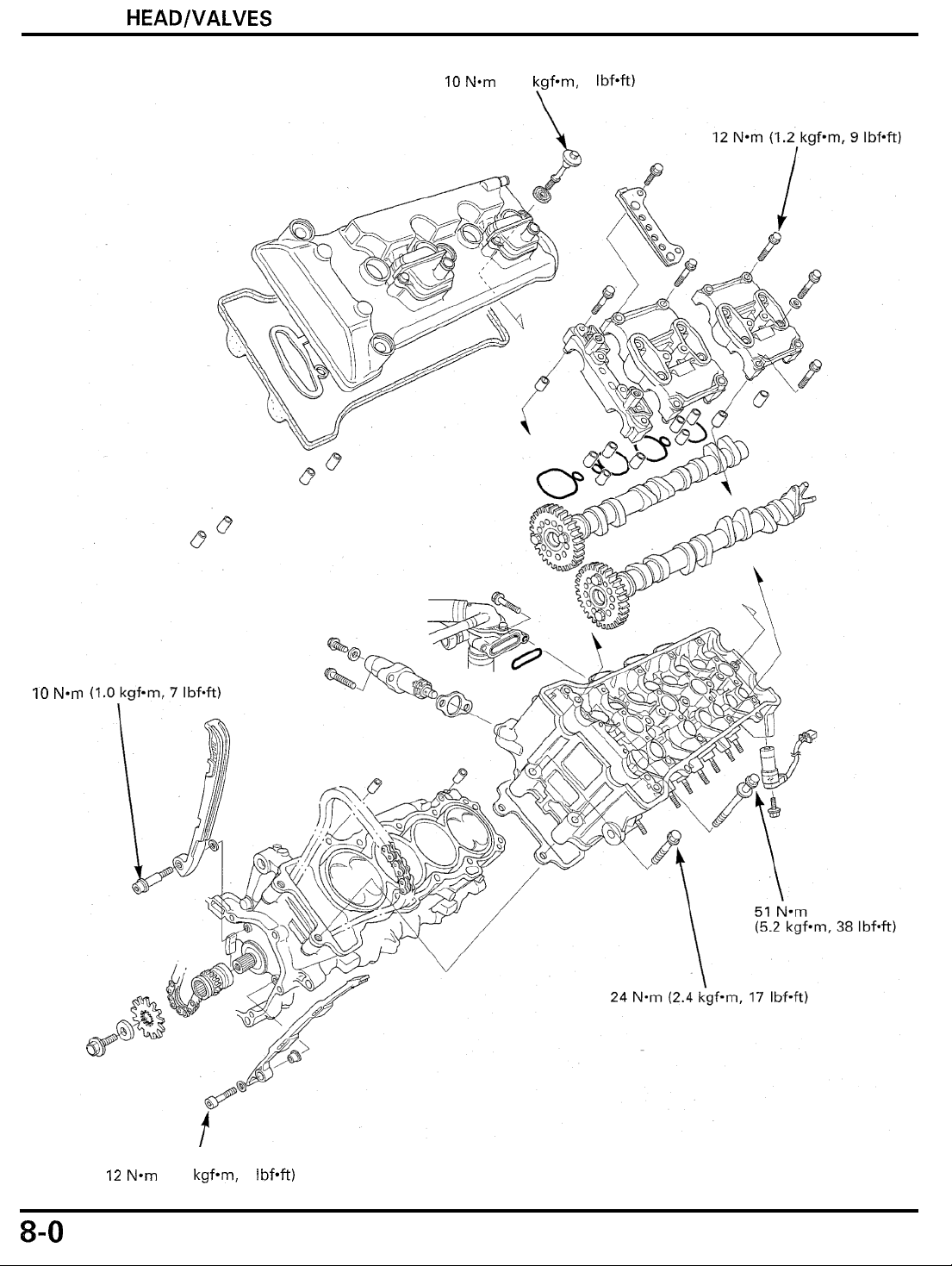

HEAD/VALVES

10

N*m

(1.0

kgf-m, 7 Ibf*ft)

10

N-n

12

N*m

I

(1.2

kgf*m, 9 Ibf*ft)

8-0

8.

CYLINDER

HEAD/VALVES

SERVICE INFORMATION 8-1

TROUBLESHOOTING 8

CYLINDER COMPRESSION TEST 8

CYLINDER HEAD COVER REMOVAL 8

CYLINDER HEAD COVER

DISASSEMBLY 8

CAMSHAFT REMOVAL 8

CYLINDER HEAD REMOVAL 8

CYLINDER HEAD DISASSEMBLY 8

CYLINDER HEAD INSPECTION 8

SERVICE

INFORMATION

-

-

-

-

-

7

-

12

-

13

-

14

3

4

5

6

VALVE GUIDE REPLACEMENT

VALVE SEAT INSPECTION/

REFACING 8-18

CYLINDER HEAD ASSEMBLY 8

CYLINDER HEAD INSTALLATION 8

IN

CAMS HAFT

CYLINDER HEAD COVER ASSEMBLY 8

CYLINDER HEAD COVER

INSTALLATION 8

CAM CHAIN

STALLATI 0 N

TENSIONER LIFTER 8-32

8-17

-

20

-

22

8-24

-

29

-

30

GENERAL

-

This section covers service of the cylinder head, valves and camshaft.

The camshaft services can be done with the engine installed

removal.

-

When disassembling, mark and store the disassembled parts to ensure that they are reinstalled in their original locations.

-

Clean all disassembled parts with cleaning solvent and dry them

tion.

Camshaft lubricating oil

cylinder head.

Be careful not to damage the mating surfaces when removing the cylinder head cover and cylinder head.

is

fed through oil passages

in

the cylinder head. Clean the oil passages before assembling the

in

the frame.

by

blowing them off with compressed air before inspec

The cylinder head service required engine

-

8-1

CYLINDER HEADNALVES

SPECIFICATIONS

Cylinder compression

Valve clearance

Cam shaft

I

Valve lifter

Valve,

valve guide

Valve spring free length

Cylinder head warpage

1

Cam lobe height

~

Runout

'

Oil clearance

~

Valve lifter

Valve lifter bore

1

Valve stem

Valve guide

Stem-to-guide clearance

Valve guide projection above IN

cylinder head

Valve seat width

ITEM

O.D.

O

.D.

I.D.

,

IN

I

EX

I.D.

i

I

j

1,196

kPa

at

350

rpm

1

IN

~~ ~~

EX

IN

1

IN/EX

lN/EX

1

:",

lN/EX 1 4.500 - 4.512 (0.1722 - 0.1776)

IN

'

EX

EX

"/EX I 0.90 - 1.10 (0.035 - 0.043)

I

Inner

j

Outer

0.16 i 0.03 (0.006 i 0.001)

1

0.27 2 0.03 (0.011 i 0.001)

I

36.74 - 36.98 (1.446 - 1.456)

I

1

0.020 - 0.062

25.978 - 25.993 (1.0228 - 1.0233)

26.01

0

-

4.475 - 4.490 (0.1762 - 0.1768)

1

4.465 - 4.480 (0.1758 - 0.1764)

0,010 - 0.037 (0.0004 - 0.0015)

-

0.020

14.3 - 14.6 (0.56 - 0.57)

~

12.4 - 12.7 (0.49 - 0.50)

34.80 (1.370)

37.97 (1.495)

I

39.60 (1.559)

1

0.047

STANDARD

(12.2

kgf/cm2,

174

-

(0.0008 - 0.0024)

26.026 (1.0240 - 1.0246)

(0.0008 - 0.0019)

-

psi)

Unit: mm (in)

I

I

1

1

1

~

1

~

1

--1

36.72 (1.446)

36.43 (1.434)

0.04 (0.002)

0.10

(0.004)

25.97 (1.022)

26.04 (1.025)

4.465 (0.1758)

4.455 (0.1754)

4.540 (0.1787)

-

-

-

I

1

1

'

-

1.5 (0.06)

33.1 (1.30)

36.1 (1.42)

37.6 (1.48)

0.10 (0.004)

1

1

TORQUE VALUES

Cylinder head cover bolt

PAIR reed valve cover flange bolt

Breather plate flange bolt

Camshaft holder flange bolt

Cylinder head sealing bolt

Cylinder head mounting bolt

Cylinder head mounting bolt, 8 rnm

Cam sprocket bolt

Cam pulse generator rotor dowel bolt

Cam chain tensioner pivot socket bolt

Cam chain guide mounting socket bolt

Cylinder head stud bolt (exhaust pipe stud bolt)

Throttle cable guide bracket mounting bolt

10

N*m

(1.0

12

N*m

(1.2

12

N-m

(1.2

12

N-m

(1.2

27

N-rn

(2.8

51

N-m

(5.2

24

N-m

(2.4

20

N-m

(2.0

12

N-m

(1.2

10

N*m

(1.0

12

N-rn

(7.2

See page 1-

N-m

(0.3

3

kgf-m, 7 IbfW

kgfsm, 9 Ibf-ft)

kgf-m, 9 IbfW

kgf-m, 9 Ibf-ft)

kgf-m,

20

IbfW

kgf-m,

38

Ibf-ft)

kgf-m,

17

Ibf-ft)

kgf-m,

14

Ibf-ft)

kgfom, 9 Ibf-ft)

kgf-m, 7 Ibf*ft)

kgf-m, 9 Ibf-ft)

14

kgf-m,

2.2

Ibf-ft)

Apply a locking agent to the threads

Apply

a

locking agent to the threads

Apply oil to the threads

Apply

a

locking agent to the threads

Apply molybdenum disulfide oil to the

threads and seating surface (after removing

anti

-

rust oil additive)

Apply oil to the threads

Apply a locking agent to the threads

Apply

a

locking agent to the threads

Apply

a

locking agent to the threads

Apply a locking agent to the threads

8-2

TOOLS

CYLINDER

HEADNALVES

Compression gauge attachment

Valve spring compressor

Valve spring compressor attachment

Tappet hole protector

Valve guide driver,

Valve guide reamer,

Valve seat cutters

Seat cutter,

Seat cutter,

Flat cutter,

Flat cutter,

Interior cutter,

Interior cutter,

Cutter holder,

Cam chain tensioner holder

24.5

29

28

30

4.5

rnm

mm

mm

26

30

mm

4.5

4.5

mm

(32

(32

mm

mm

mm

(45

mm

(45

"

"

"

(60

(60

"

EX)

IN)

EX)

IN)

"

"

EX)

IN)

07RMJ-MY50100

07757--

0010000

07959

-

KM30101

07HMG-MR70002

07 H M D-M LOO 1 0 1

H-ML001

07H M

07780-0010100

07780-0010300

-

0012100

07780

-

0012200

07780

07780

-

0014500

07780

-

0014000

-

0010600

07781

07ZMG-MCAA400

0

1

or equivalent commercially available in

not available

or refer to page

or

07H MH-ML001 OA

1

equivalent commercially available in U.S.A.

(U.S.A. only)

in

U.S.A.

8-13

for alternative tool (U.S.A. only)

(U S.A. only)

U.S.A.

TROUBLESHOOTING

Engine top-end problems usually affect engine performance. These problems can be diagnosed by a compression test or

by

tracing engine noises to the top-end with a sounding rod or stethoscope.

-

If

the performance is poor at

for a seized piston ring (Section

Compression too

low

speed

-

Valves:

-

Incorrect valve adjustment

-

Burned or bent valve

-

Incorrect valve timing

-

Broken valve spring

-

Uneven valve seating

-

Cylinder head:

-

Leaking or damaged head gasket

-

Warped or cracked cylinder head

Worn cylinder, piston or piston rings (section

Compression too high, overheating or knocking

Excessive carbon build-up on piston crown or on combus

tion chamber

low,

hard starting or poor performance at

low

speeds, check for white smoke

11).

11)

in

the crankcase breather hose.

Excessive noise

Cylinder head:

-

Incorrect valve adjustment

-

Sticking valve or broken valve spring

-

Damaged or worn camshaft

-

Loose

or worn cam chain

-

Worn or damaged cam chain

-

Worn or damaged cam chain tensioner

-

Worn cam sprocket teeth

-

Worn cylinder, piston or piston rings (section

Rough

-

-

idle

Low

cylinder compression

If

the hose is smoky, check

11

Excessive smoke

Cylinder head:

-

Worn valve stem or valve guide

-

Damaged stem seal

-

Worn cylinder, piston or piston rings (section

11)

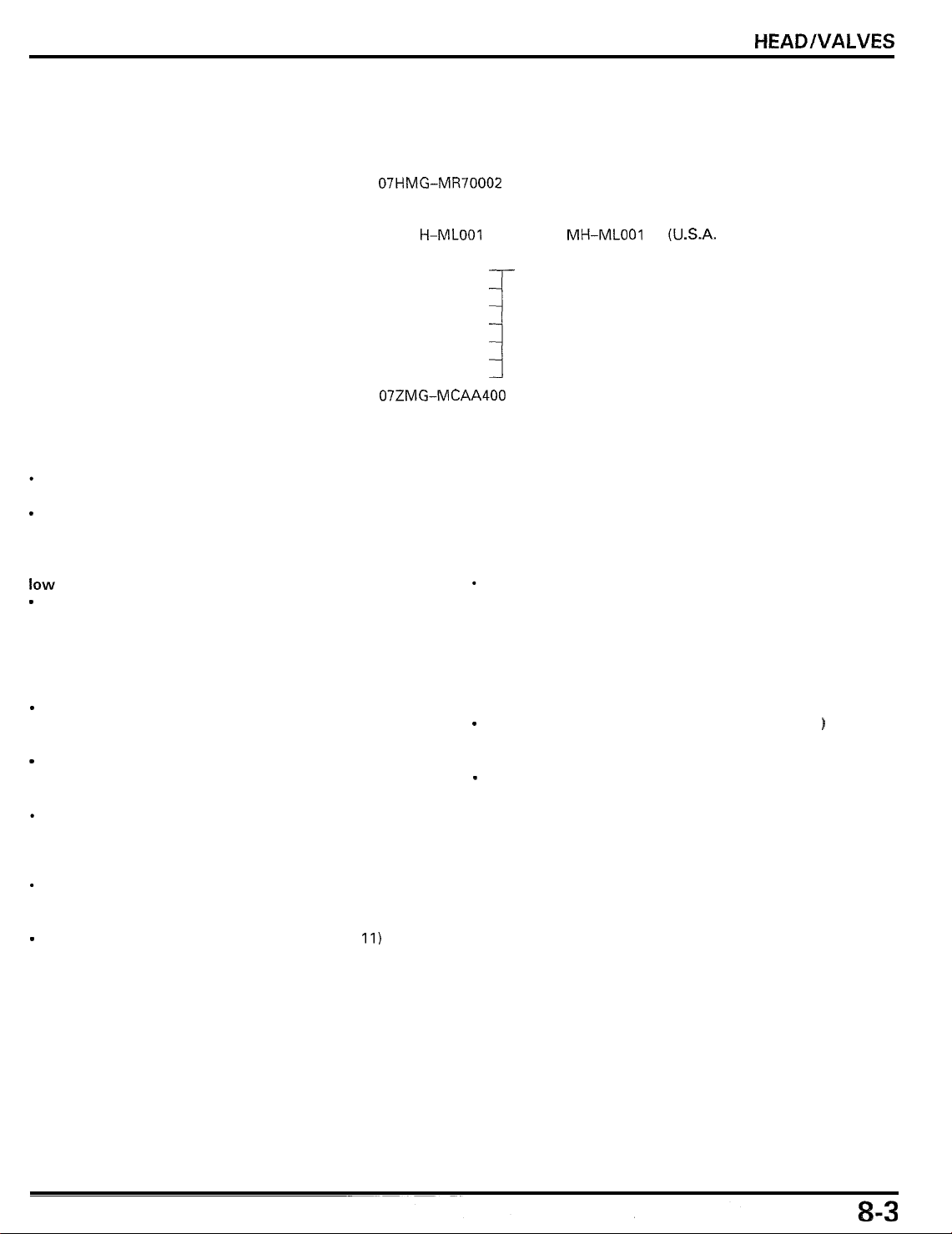

CYLINDER HEADNALVES

CYLINDER COMPRESSION TEST

Warm up the engine to normal operating tempera

ture.

Stop the engine and remove all the direct ignition

coilispark plug caps and spark plugs (page

Open and support the front end of the fuel tank (page

3-41.

Disconnect the fuel pumpireserve sensor

connector.

Install a compression gauge into the spark plug hole.

TOOL:

Compression gauge attachment

07RMJ-MY50100

(Equivalent cornrner-

cially available in

USA.)

Open the throttle all the way and crank the engine

with the starter motor until the gauge reading stops

rising.

To

avoiddischarg

ing the battery,

not operate the

Starter motor

for

more

7

seconds

The maximum reading is usually reached within

-

do

seconds.

Compression pressure:

than

1,196

kPa

(12.2

kgf/crn2,

Low compression can be caused by:

-

Blown cylinder head gasket

-

Improper valve adjustment

-

Valve leakage

-

Worn piston ring or cylinder

High compression can be caused by:

-

Carbon deposits in combustion chamber or on pis

ton head

174

psi) at

350

3-61,

3P

rpm

(Black)

4

-

7

1

3P (BLACK) CONNECTOR

-

I

-

COMPRESSION

GAUGE

CYLINDER HEAD CQVER REMOVAL

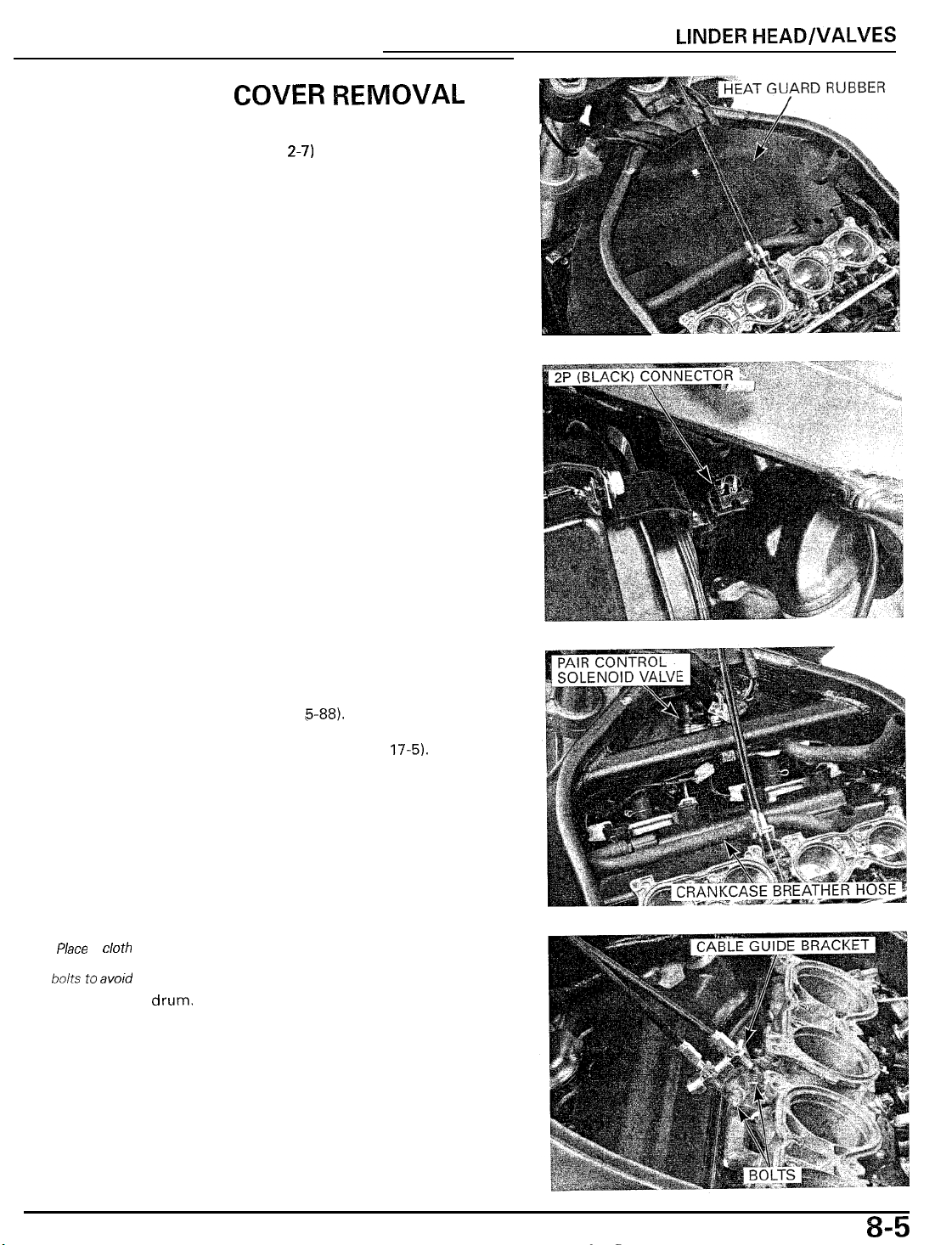

Remove the following:

-

Lower cowl (page 2-71

-

Air cleaner housing (page

Remove the heat guard rubber.

Disconnect the fan motor 2P (Black) connector.

5-64)

CY

LlNDER

HEAD/VALVES

Piace a cioth

underneath the

bdts

to

dropping them

into the engine

avoid

area

Disconnect the cam pulse generator 2P (natural) con

nector (page

Remove the mounting bolt and PAIR control solenoid

valve assembly (page

Disconnect the ignition coil sub-harness

connector and sub

Disconnect the crankcase breather hose.

Remove the throttle cable guide bracket mounting

bolts.

Disconnect the throttle cable ends from the throttle

drum,

5-83).

-

harness (page

5-88].

17-51.

4P

(Black)

-

8-5

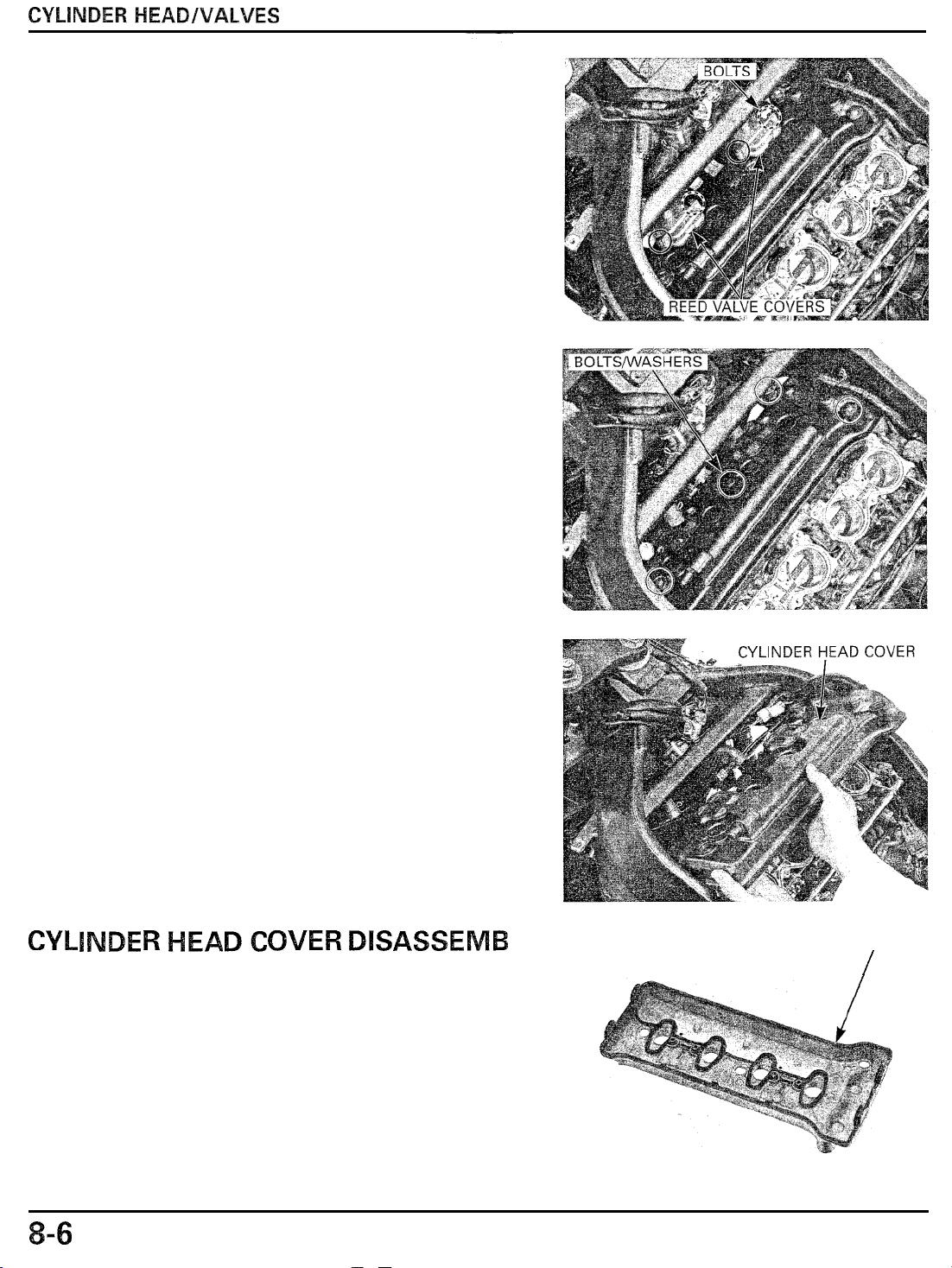

Remove the

the cylinder head.

Remove the cylinder head cover bolts and washers.

SH

bolts

and PAIR reed valve covers from

CVL

Remove the cylinder head cover rearward.

R

Remove the cylinder head cover (page

Remove the cylinder head cover packing.

OVER

DIS

8-5).

LY

PACKING

/

Remove the bolts and breather separator and gasket.

BOLTS

c

Check the PAIR

replace

if

check valves for wear or damage,

necessary.

FT

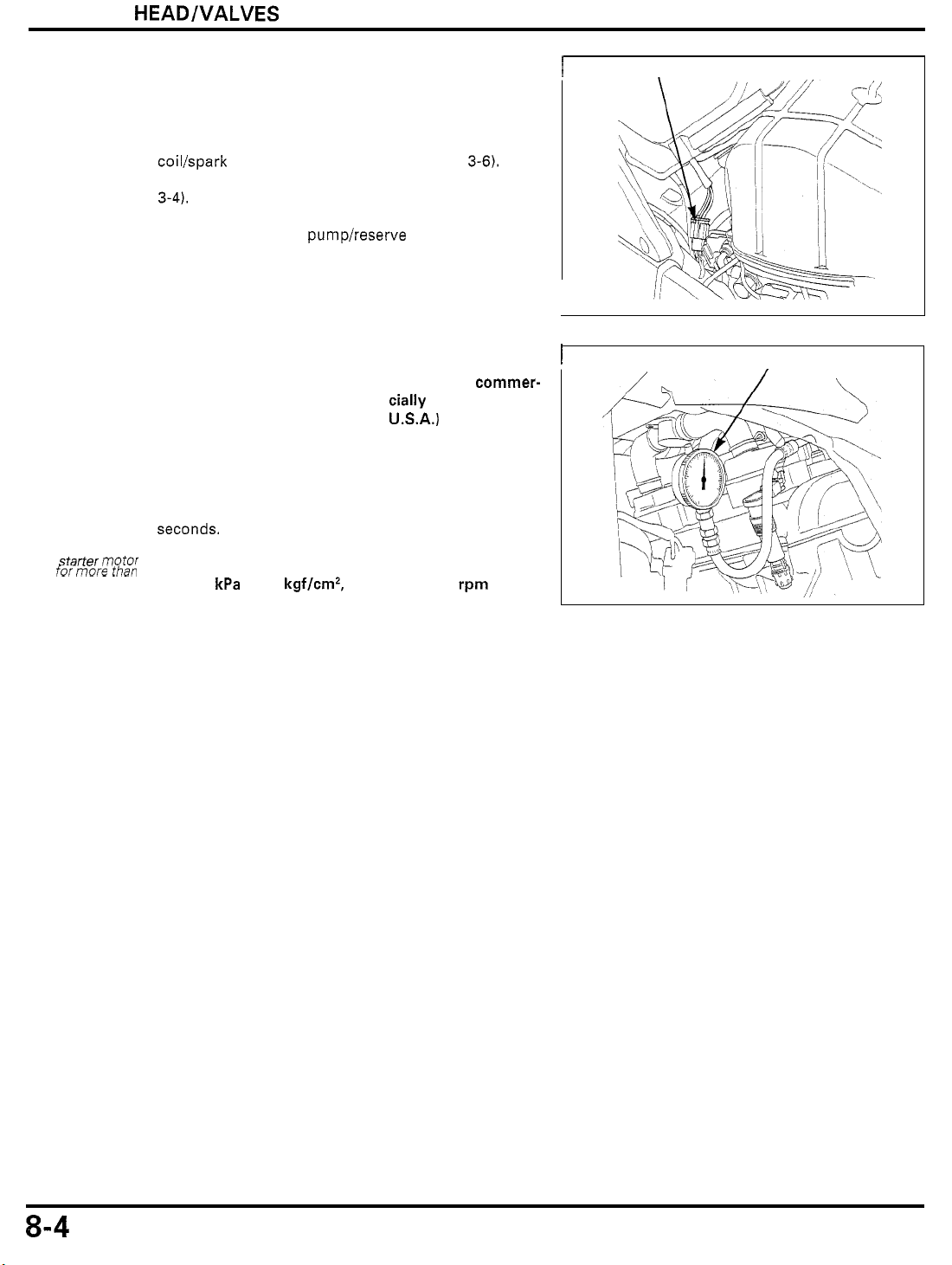

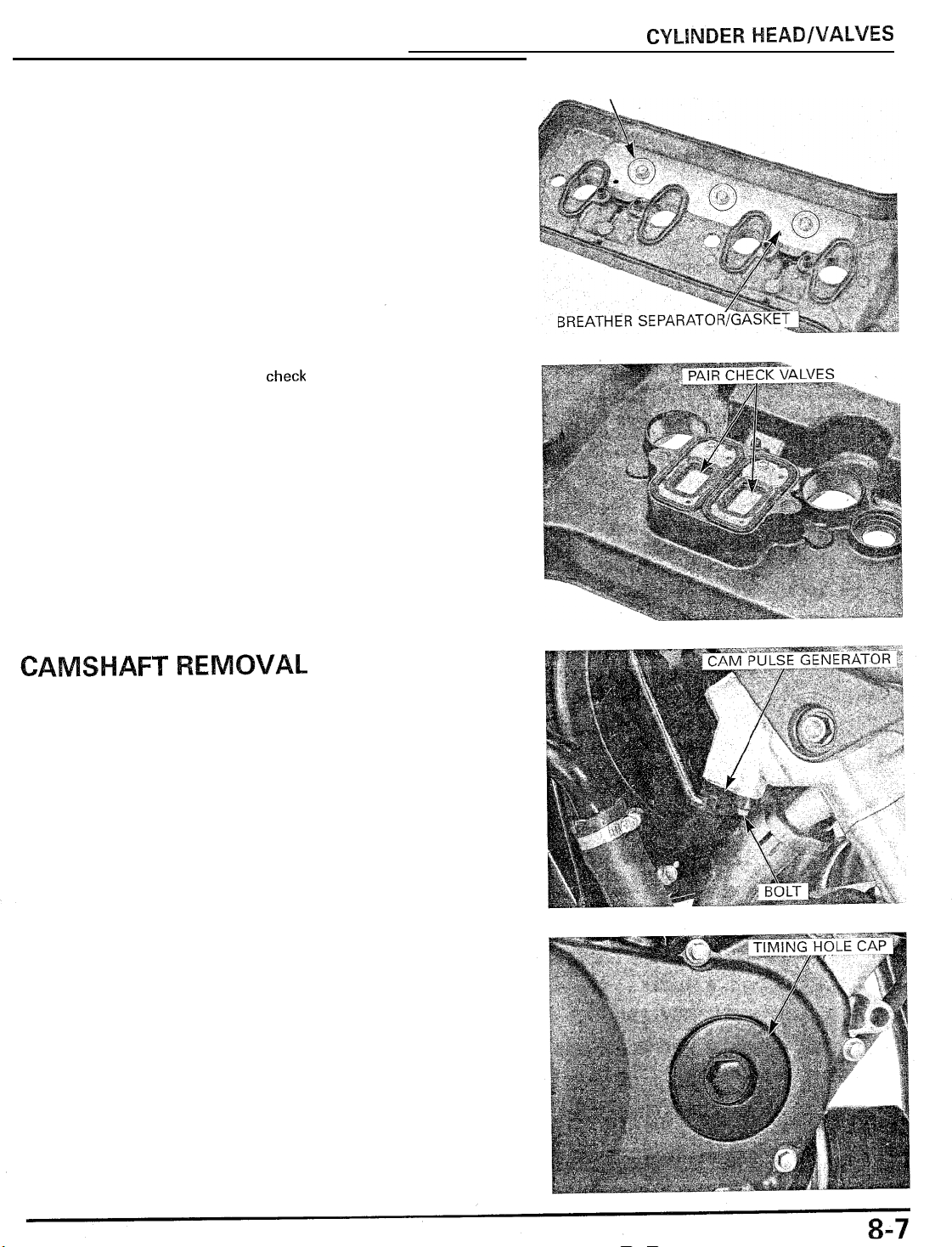

Remove the cylinder head cover (page 8Avoid damaging the cam pulse generator while

removing the camshafts, remove the bolt and cam

pulse generator from the cylinder head.

5).

Remove the timing hole cap and O

-

ring.

CY

LlNDER HEAD/VALVES

Turn the crankshaft clockwise, align the

the ignition pulse generator rotor with the index mark

on the right crankcase cover.

Make sure the

on the compression stroke.

Remove the cam chain tensioner lifter sealing bolt

and sealing washer.

No.1 piston

is

at TDC

"T"

(Top

Dead Center)

mark on

CAM CHAIN TENSIONER LIFTER BOLT

Turn the tensioner lifter shaft

secure

TOOL:

Cam chain tensioner holder 07ZMG-MCAA400

it

using the cam chain tensioner holder.

Remove the bolts and cam chain guide

fully

in (clockwise) and

(U.S.A. only)

B.

CHAIN TENSIONER HOLDER

I

CAM

\

SEALING WASHER

-

8

CYLINDER HEAD/VALVES

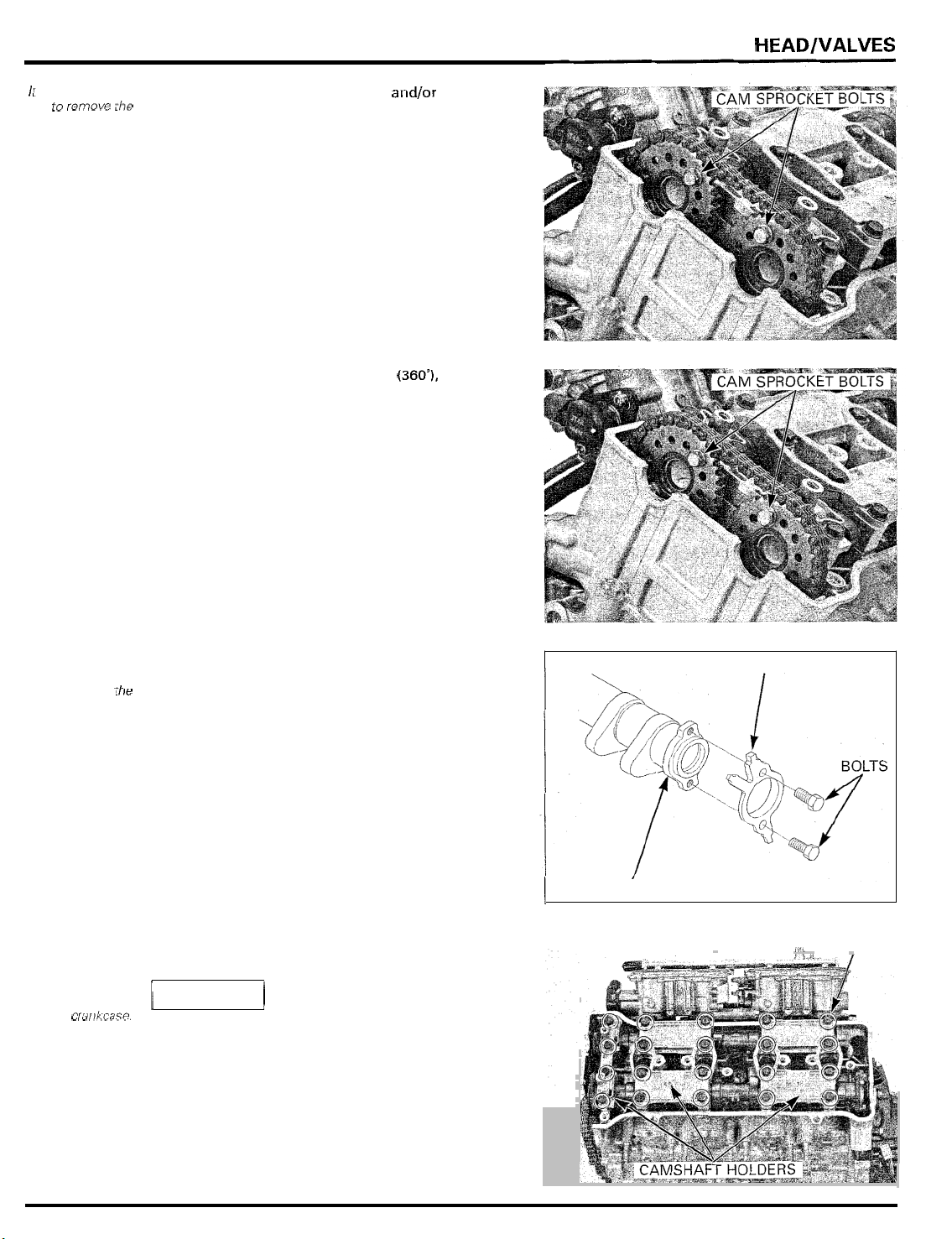

it is not necessary

to

~mOve the

cam sprocket

from the

camshaft except

when replacing

the camshaft

and/or cam

sprocket

Be careful not to

drop the cam

sprocket bolts

into the

crankcase

If

you plan to replace the camshaft and/or cam sprock

et, loosen the cam sprocket bolts as follows:

-

Remove the cam sprocket bolts from intake and

exhaust camshafts.

-

Turn the crankshaft

other cam sprocket bolts from the camshafts.

-

Remove the cam sprocket from the camshaft.

one

full turn

(360"),

remove the

-

Be

careful not to

drop the rotor

bolts into the

Suspend the cam

chain with a piece

of

wire to prevent

the chain from

falling into the

or

crankcase

crankcase.

-

Remove the bolts and cam pulse generator rotor

from the exhaust camshaft.

Loosen and remove the camshaft holder bolts, then

remove the camshaft holders and camshafts.

1

NOTICE

From outside to inside, loosen the bolts in a crisscross

or

pattern in several steps

break.

the camshaft holder

might

CAM

I

EXHAUST'CAMSHAFT

PULSE

GENERATOR ROTOR

,~~

BOLTS

8-9

CYhS

EAD/VALVES

Remove the valve lifters and shims.

Be carefui not to damage the valve lifter bore.

-

Shims may stick to the inside

not allow the shims

*

Mark all valve lifters and shims to ensure correct

reassembly in their original locations.

The valve lifter can be easily removed with a valve

lapping tool or magnet.

The shims can be easily removed with tweezers or

a magnet.

to

of

the valve lifters. Do

fall into the crankcase.

INSPECTION

CAMSHAFT HOLDER

Inspect the bearing surface of each camshaft holder

for scoring, scratches, or evidence of insufficient

Iu

brication.

CAMSHAFT

Support both ends

check the camshaft

SERVICE LIMIT: 0.04

RUNOUT

of

runout with a dial gauge.

the cam$haft with V-blocks and

rnm

(0.002

in)

CAMSHAFT CAMSHAFT HOLDER C

HOLDER A

I

CAMSHA~T

MEASURE POINT

HOLD HOLD

HOLDER

B

CAM LOBE HEIGHT

Using a micrometer, measure each cam lobe height.

SERVICE LIMITS:

IN:

36.72

mm

(1.446 in)

EX: 36.43

mm

(1.434

in)

Loading...

Loading...