Honda CBR 954RR Service Manual 06 cooling

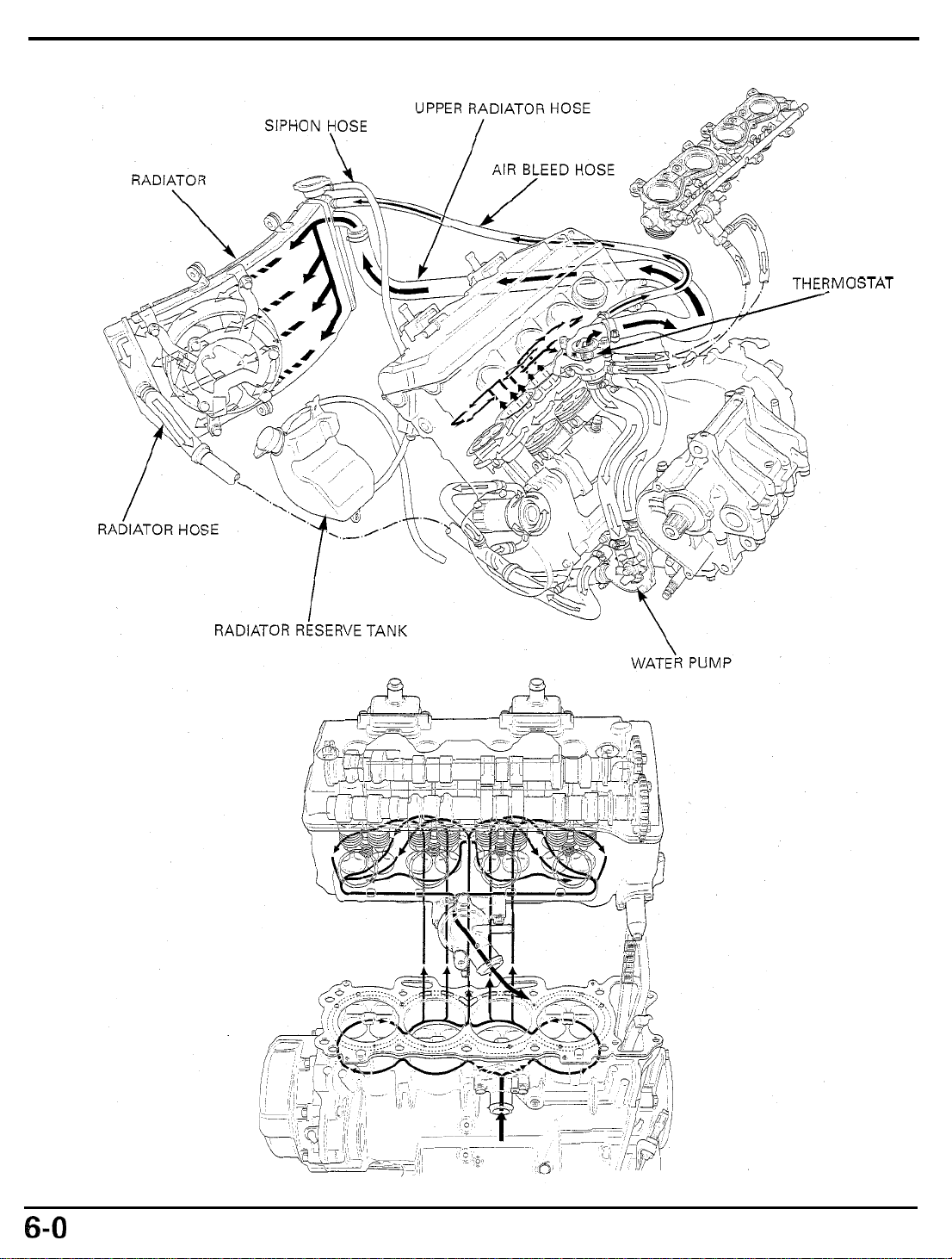

COOLING

SYSTEM

SYSTEM

LOWER

FLOW

PATTERN

ISTAT

6.

COOLING

SYSTEM

SYSTEM

SERVICE INFORMATION

TROUBLESHOOTING

SYSTEM TESTING

COOLANT REPLACEMENT 6

SERVICE

FLOW

PATTERN 6-0 THERMOSTAT 6-6

INFORM

AT1

0

N

-

1

6

6-2

6

-

3 RADIATOR RESERVE TANK 6-16

-

4 FAN CONTROL RELAY 6-1

RADIATOR 6-8

WATER PUMP 6-13

GENERAL

Removing the radiator cap while the engine is hot can cause the coolant to spray out, seriously scalding you.

Always let the engine and radiator cool down before removing the radiator cap.

Using coolant

Using tap water may cause engine damage.

Add cooling system at the reserve tank.

All cooling system services can

Avoid spilling coolant on painted surfaces.

After servicing

Refer

to

section

with

silicate inhibitors may cause premature

Do

be

done with the engine in the frame.

the

system, check for leaks with a cooling system tester.

19

for coolant temperature sensor inspection.

not remove the radiator cap except to refill or drain the system.

wear of

water

pump

seals

or

blockage

of radiator

7

passages.

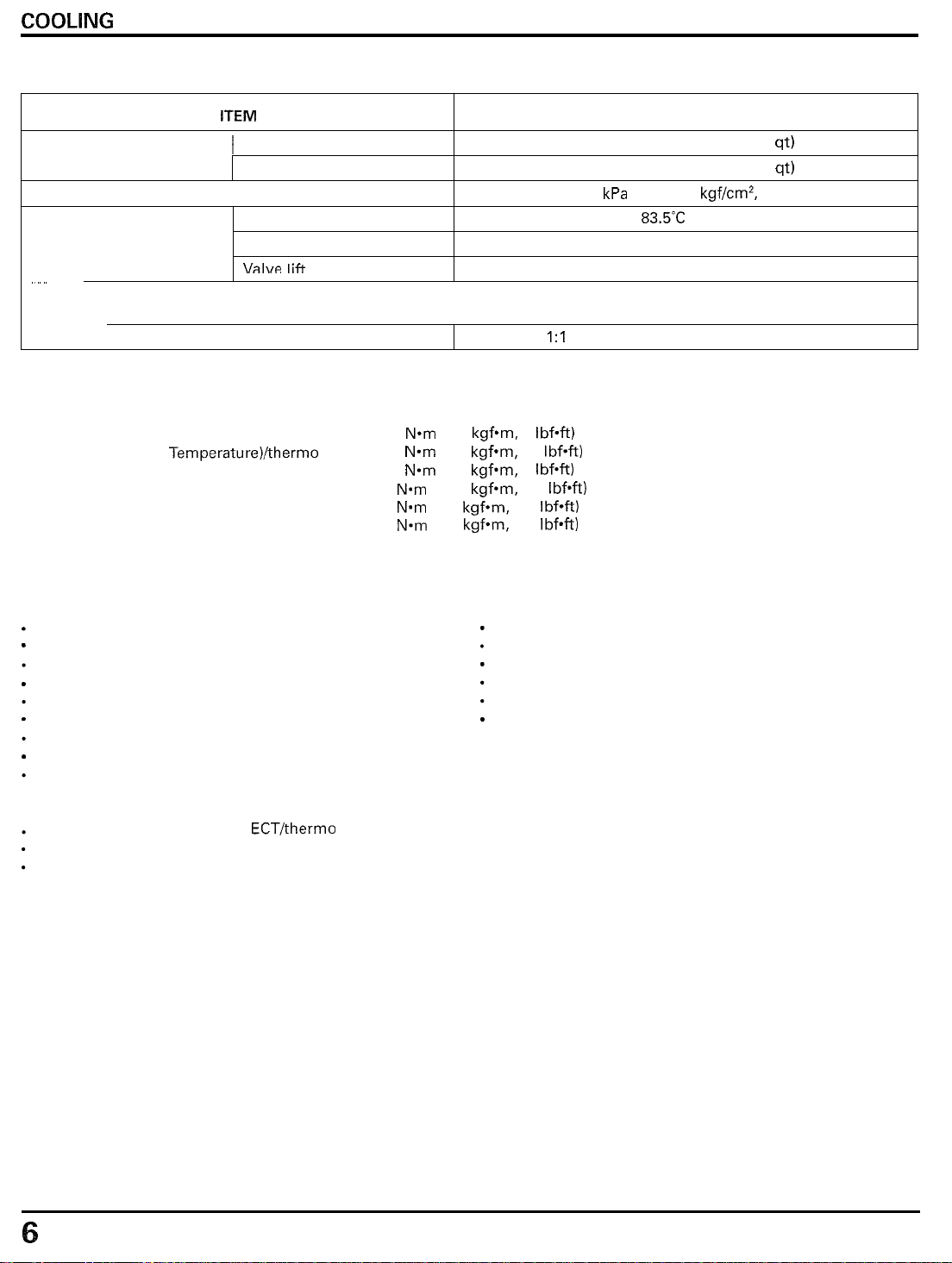

COOLING

SYSTEM

SPECIFICATIONS

ITEM

1

Coolant capacity

Radiator cap relief pressure

Thermostat Begin to open

~

Recommended antifreeze

~

Standard coolant concentration

Radiator and engine

Reserve tank

Fully open

\/al\w

lift

108 - 137 kPa

Pro Honda HP Coolant or an equivalent high quality ethylene

glycol antifreeze containing corrosion protection inhibitors

1:l mixture of antifreeze and

SPECIFICATIONS

3.1 liter (3.3

0.4 liter (0.4

(1.1

80.5

-

83.5-C (177 - 182°F)

95°C (203°F)

8

mm

(0.3 in) minimum

US

US

-

TORQUE VALUES

Water pump cover bolt

ECT (Engine Coolant

Thermostat cover flange bolt

Cooling fan nut

Fan motor nut

Fan motor shroud mounting bolt

Temperature)/thermo sensor

12

N*m (1.2 kgf-m, 9

23 N-m (2.3 kgf-m,

12 N-m (1.2 kgf-m, 9

3

N-m (0.27 kgf-m,

5 N-m

(0.5

kgfom, 3.6

8 N.m (0.8 kgf-m, 5.8 Ibf-ft)

Ibf-ft)

17

Ibf*ft)

2.0

IbfW

Ibf-ft)

Ibf-ft)

CT bolt

Apply sealant to the threads.

CT bolt

Apply a locking agent to the threads.

TROUBLESHOOTING

Engine temperature too high

Faulty radiator cap

-

Insufficient coolant Deteriorated O-rings

Passages blocked in radiator, hoses or water jacket

Air in system

Faulty water pump Damaged or deteriorated hose

-

Thermostat stuck closed

Faulty temperature gauge or coolant temperature sensor

-

Faulty cooling fan motor

Faulty fan control relay

Coolant leak

-

Faulty water pump mechanical seal

-

Damaged or deteriorated gasket

Loose hose connection or clamp

-

Faulty radiator cap

qt, 2.7

Imp

qt)

qt, 0.4

Imp

qt)

1.4 kgf/cm2, 16 - 20 psi)

soft

water

Engine temperature too

Faulty temperature gauge or ECT/thermo sensor

Thermostat stuck open

Faulty fan control relay

-

2

low

COOLING

SYSTEM

SYSTEM

TESTING

COOLANT

Remove the right duct cover (page

Remove the radiator cap.

Test the coolant specific gravity using a hydrometer

(see below for

For maximum corrosion protection, a

ethylene glycol and distilled water is recommended

(page

6-41.

Look

for contamination and replace the coolant if nec

essary.

(HYDROMETER TEST)

2-4).

"

Coolant gravity chart").

1:l

solution of

-

COOLANT GRAVITY CHART

Coolant temperature "C

Coolant ratio

%

60

("F)

'\

~

0

5

(32)

(41)

1

1,100 1 1.098

I0

15

(50)

(59)

1

1.095 1 1.092

25

30 35

(86)

20

(68) (77)

11.089 I 1.086 1 1.083

i

40

(104) (113) (122)

(95)

1

,080

!

1.077 1 1.074 i 1.071

45

50

1

-

3

COOLING SYSTEM

Before insrailing

rhe cap

tesrec wet the

seaiing

in

surfaces

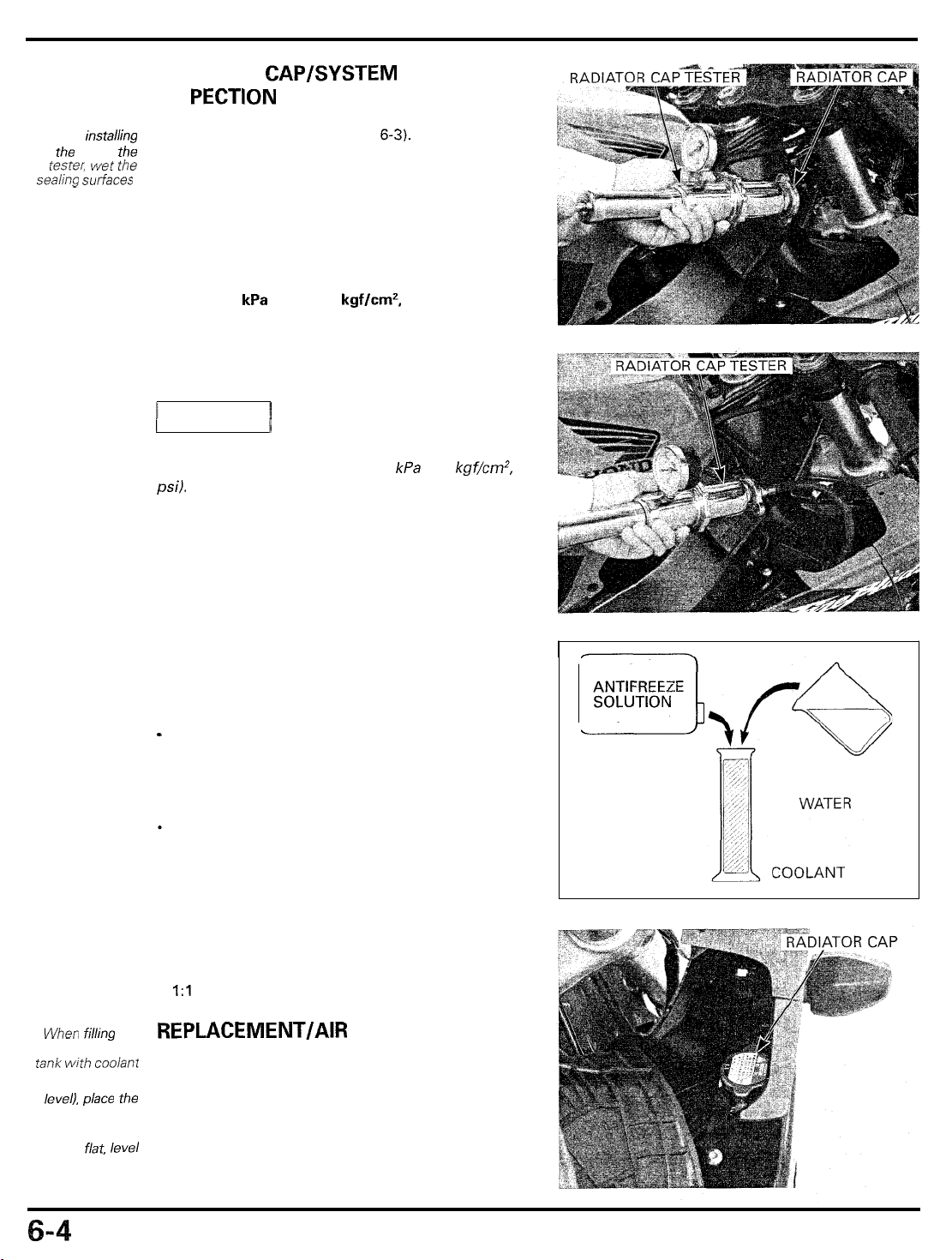

RADIATOR

I

NS PECTION

Remove the radiator cap (page

rhe

Pressure test the radiator cap.

Replace the radiator cap if

or if relief pressure is too high or too low.

It

must hold the specified pressure for at least

seconds.

RADIATOR CAP RELIEF PRESSURE:

108 - 137

Pressurize the radiator, engine and hoses, and check

for leaks.

1

NOTICE

Excessive pressure can damage the cooling system

components.

psi).

Repair or replace components

hold the specified pressure for at least

GAPISYSTEM PRESSURE

6-31.

it

does not hold pressure,

kPa

(1.1

-

1.4

kgf/cmz,

16

-

20

1

Do

not exceed

137

kPa

if

the system

(1.4

6

seconds.

psi)

kgf/cm2,

will

6

20

not

COOLANT REPLACEMENT

PREPARATION

-

The effectiveness of coolant decreases

if

there is a change

When filling the

system or reserve

tank

with

(checking cooiant

codanr

/eve/), piace rhe

rnotorcycie

verticai position

on

in

a fiat, /eve/

surface

accumulation of rust or

mixing proportion during usage. Therefore, for

best performance change the coolant regularly as

specified in the maintenance schedule.

Mix only distilled, low mineral water with the anti

freeze.

RECOMMENDED ANTIFREEZE:

Pro Honda HP Coolant or an equivalent high quali

ty ethylene glycol antifreeze containing corrosion

protection inhibitors

RECOMMENDED MIXTURE:

1:l

(Distilled water and antifreeze)

REPLACEMENT/AIR BLEEDING

Remove the radiator cap.

a

with

in

the

the

-

ANTIFREEZE

SOLUTION

i

(ETHYLENE

GLYCOL BASE

SOLUTION)

-

LOW MINERAL

OR DISTILLED

COOLING SYSTEM

Remove the lower cowl (page

Remove the drain bolt on the water pump cover and

drain the system coolant.

Remove the cylinder drain bolt and drain the coolant

from the cylinder.

Reinstall the drain bolt

Disconnect the siphon hose from the radiator.

Drain the reserve tank coolant.

Empty the coolant and rinse the inside of the reserve

tank with water.

Reinstall the radiator siphon hose.

with

2-7)

a new sealing washer.

Fill

the system with the recommended coolant

up

to

through the filler opening

Remove the radiator reserve tank cap and fill the

reserve tank to the upper level line.

Bleed air from the system as follow:

1.

Shift the transmission into neutral. Start the engine

it

and let

2.Snap the throttle three to four times to bleed air

from the system.

3.Stop the engine and add coolant up to the proper

level

4. Check the level of coolant

to the upper level

idle for

if

necessary. Reinstall the radiator cap.

2

-

3 minutes.

if

it

is low.

the filler neck.

in

the reserve tank and

fill

6-5

Loading...

Loading...