Honda CBR 954RR Service Manual 12 crankshaft trans

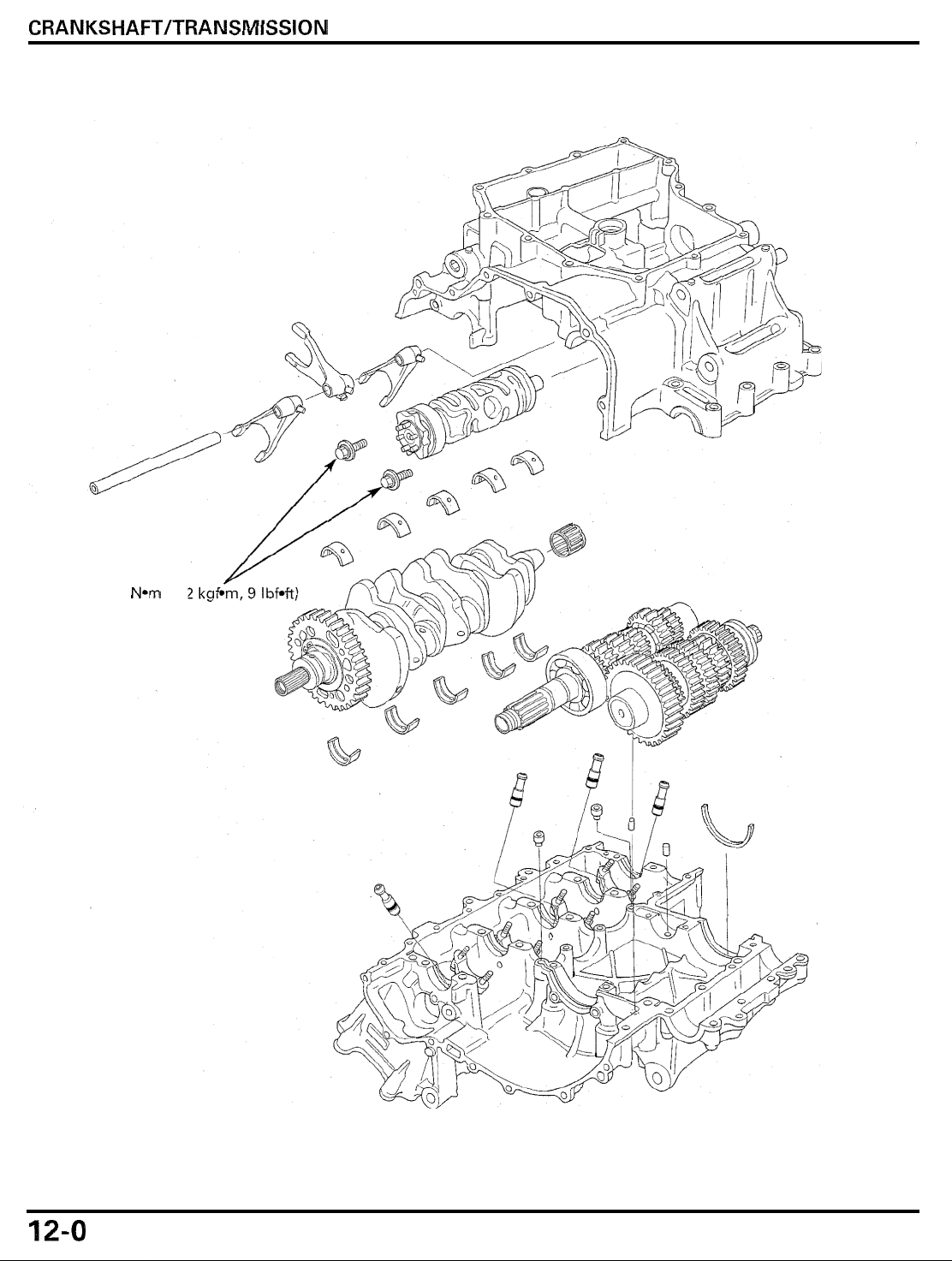

CRANKSHAFT/TRANSMISSION

12

N*m

(1.2

m

SERVICE INFORMATION

TROUBLESHOOTING

-

1 CRANKSHAFT 12-3

12

12

-

2 TRANSMISSION

10

12-9

SERVICE

INFORMATION

GENERAL

The crankcase must be separated to service the crankshaft and transmission. Refer to section

ti

on/assem bly.

Be careful not to damage the crankshaft main journal and journal bearing while removing or installing the crankshaft.

Mark and store the disassembled parts to ensure that they are installed in their original locations.

Mark and store the bearing inserts to ensure that the parts are in their correct locations during reassembly.

are improperly installed, they

The main journal bearing inserts are a select

code tables. After installing new bearings, recheck them with a plastigauge to verify clearance. Apply molybdenum

fide oil to the main journal during assembly.

S

P

ECI FI

CAT1

0

N

S

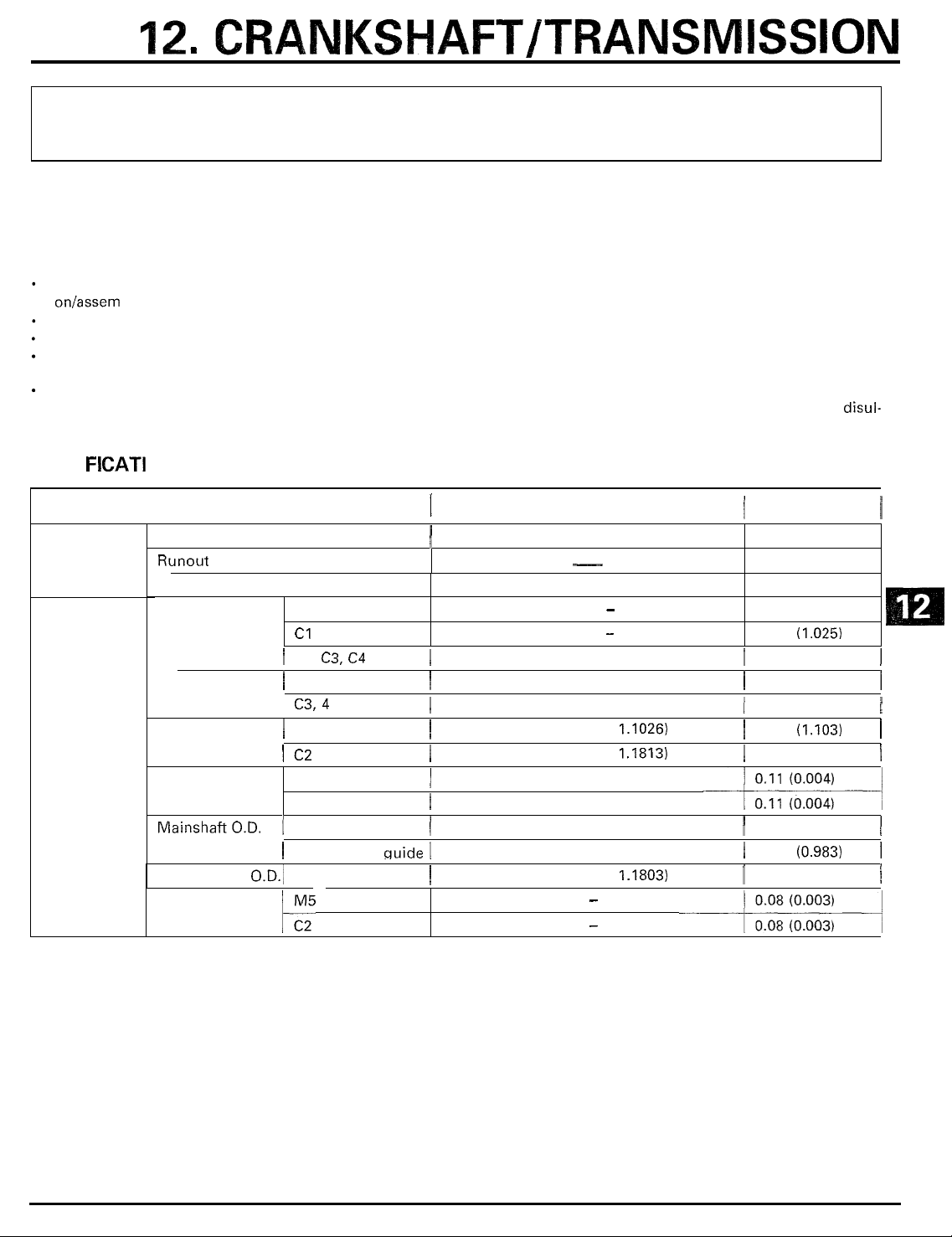

Crankshaft

Transmission

Side clearance

Runout

Main journal oil clearance

I.D.

Gear

Bushing

Bushing

Gear-to-bushing

clearance

Mainshaft0.D. 1 M5

Countershaft

Bushing

clearance

ITEM

O.D.

I.D.

-to-

will

block the oil holes, causing insufficient lubrication and eventual engine seizure.

fit

and are identified

I

1

0.05 - 0.20 (0.002 - 0.008)

by

color codes. Select replacement bearings from the

STANDARD

-

0.017 - 0.035 (0.0007 - 0.0014)

M5,

O.D.1

shaft

M6

c1

I

c2, c3,c4

1

M5,

M6

I

c3,4

1

M5

I

c2

M5, M6

c3,

c4

I

Clutch outer quide I 24.980 - 24.993 (0.9835 - 0.9840)

C2

31.000 - 31.025 (1.2205 - 1.2215)

26.000

-

26.021 (1.0236 - 1.0244)

1

33.000 - 33.025 (1.2992 - '1.3002)

1

30.950 - 30.975 (1.2185 - 1.2195)

1

32.950 - 32.975 (1.2972 - 1.2982)

1

27.985 - 28.006 (1.1018 - 1.1026)

1

29.985 - 30.006 (1.1805 - 1.1813)

]

0.025 - 0.075 (0.0010 - 0.0030)

1

0.025 - 0.075 (0.0010 - 0.0030)

1

27.967 -27.980 (1.1011 - 1.1016)

1

29.967 - 29.980 (1.1798 - 1.1803)

0.005 - 0.039 (0.0002 - 0.0015)

-

0.005

0.039 (0.0002 - 0.0015)

11

for crankcase separa

If

the inserts

Unit:

1

SERVICE LIMIT

0.30 (0.012)

0.30 (0.012)

0.045 (0.0018)

31.04 (1.222)

(1.025)

26.04

1

33.04 (1.301)

1

30.93 (1.218)

1

32.93 (1.296)

I

28.02 (1.103)

1

30.02 (1.182)

1

27.957 (1.1007)

1

24.96 (0.983)

I

29.96 (1.180)

mm

-

disul-

(in)

1

I

1

1

I

1

I

I

1

12-1

CRANKSHAFT/TRANSMISSION

TORQUE VALUES

Connecting rod bearing cap nut

9

Crankcase

mm bolt (main journal bolt)

TOOLS

Inner driver, 40 mm

Attachment,

Driver shaft

25

I.D.

mm

TROUBLESHOOTING

Excessive noise

Worn connecting rod big end bearing

Bent connecting rod

Worn crankshaft main journal bearing

Worn transmission bearing

Hard

to

shift

Improper clutch operation

Incorrect transmission oil weight

Incorrect clutch adjustment

Bent shift fork

Bent fork shaft

Bent fork claw

Damaged shift drum cam groove

Bent shift spindle

35

N*m (3.6 kgf-m, 26 Ibf-ft)

See page 12-7

07746

-

0030100

07746

-

0030200

07964

-

MB00200

Transmission jumps

Worn gear dogs and slots

Bent fork shaft

Broken shift drum stopper

Worn or bent shift forks

Broken shift linkage return spring

Engine vibration

Excessive crankshaft runout

Apply oil to the threads and seating surface

out

of

gear

12-2

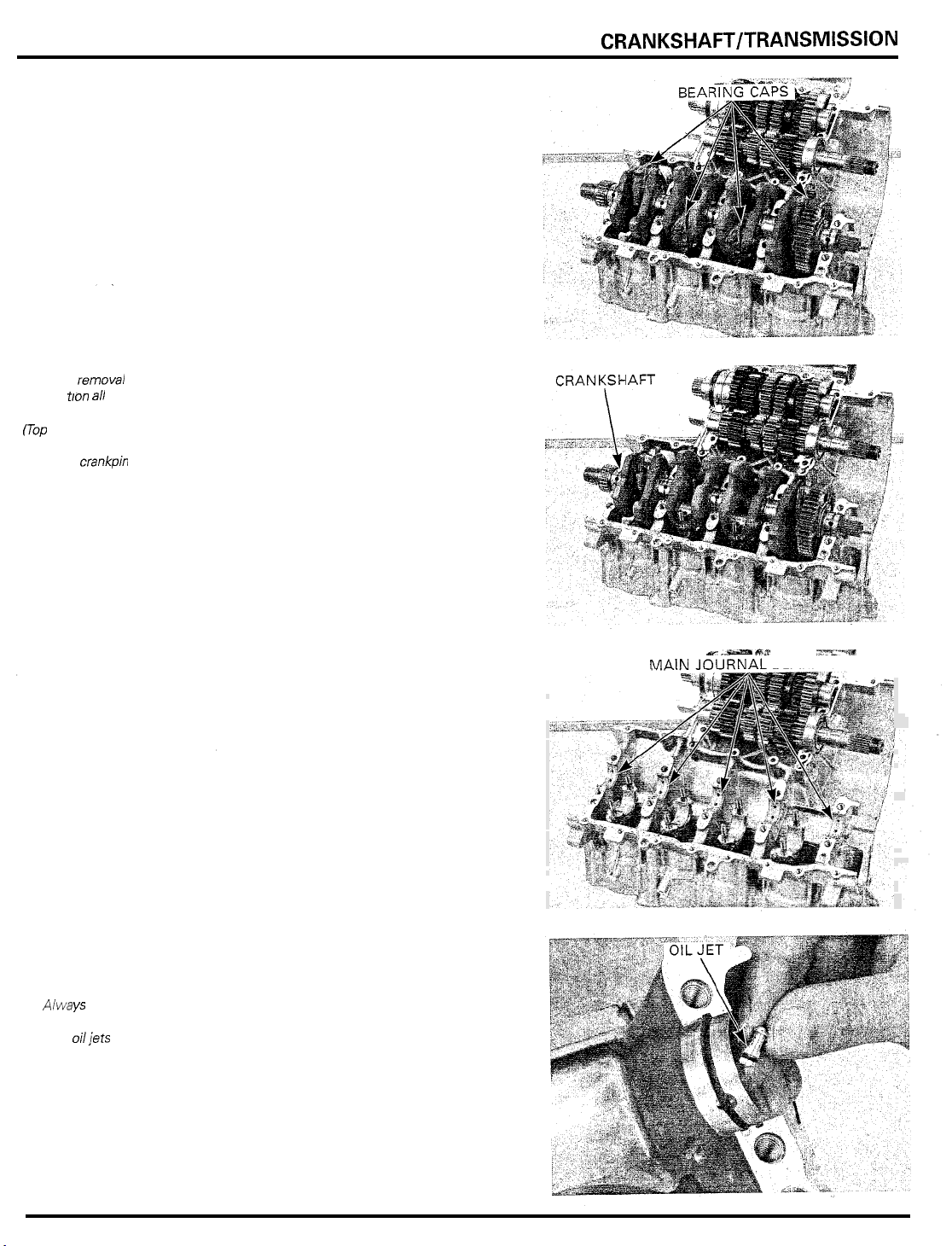

CRANKSHAFT

REMOVAL

CRANKSHAFT/TRANSMISSION

Before removai

pos tion a// the

at

pistons

(Top Dead Center)

to prevent damag

ing the crankpin

with the connect

TDC

ing rod bolt

threads

Separate the crankcase halves (page

11-3).

Remove the connecting rod bearing cap nuts and

bearing caps.

Remove the crankshaft.

-

-

Remove the

main journal bearings from both the

crankcases.

MAIN

I

.-

IOlJRNAL

bR0

--9ie-*w

BEARINGS

Aha

the O

the

ys

replace

-

ring when

oiijets are

removed.

Remove the crankshaft oil jets from the upper

crankcase.

Inspect the oil jets for clogs, and replace if necessary.

12-3

PRIMARY

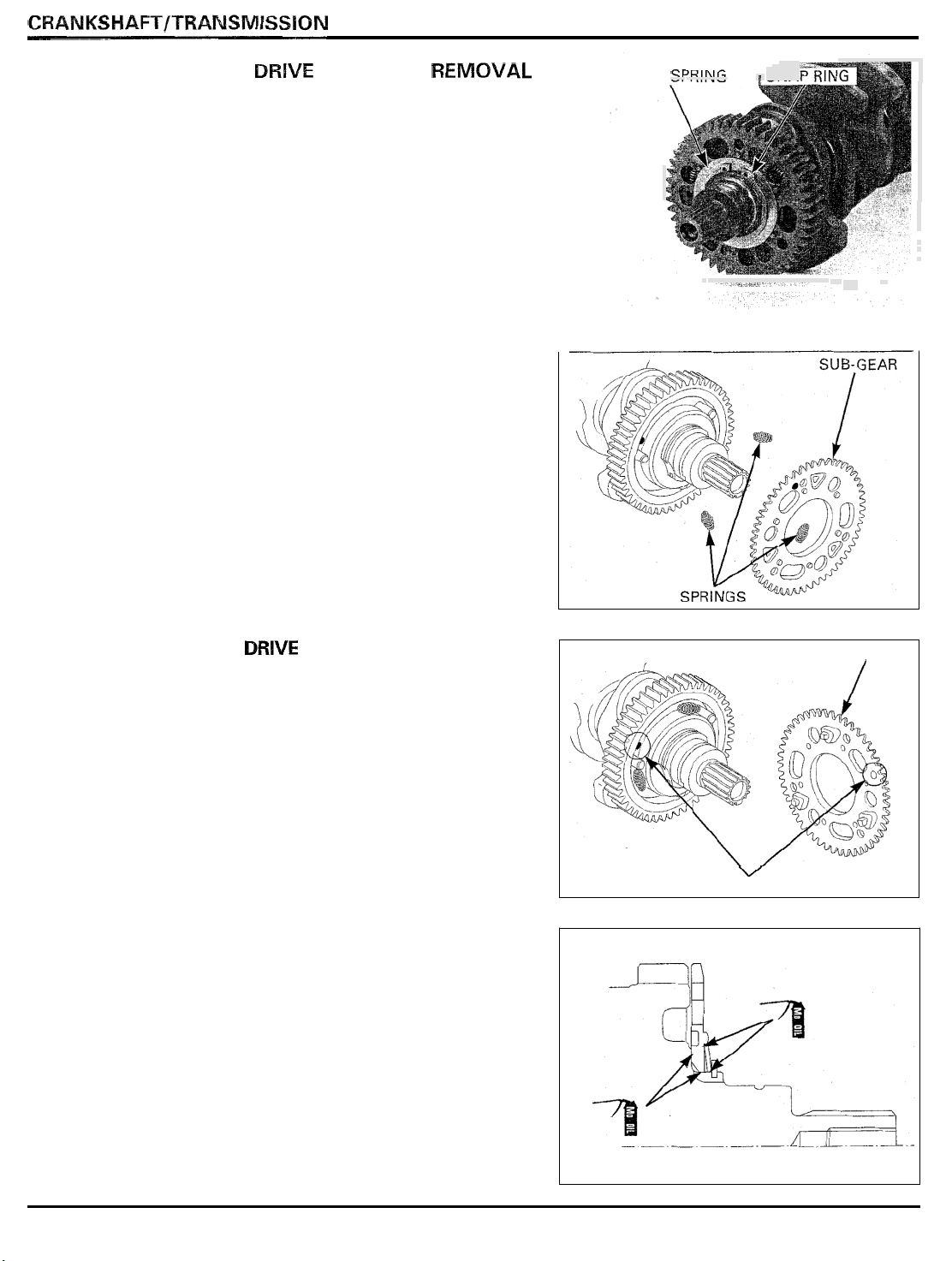

Remove the special snap ring and friction spring.

DRWE

SUB-GEAR

REMOVAL

FRICTION

SPRING

3

SNA

Remove the primary drive sub

PRIMARY

Install the springs into the primary drive gear as

shown.

Install the primary drive sub

drive gear, aligning the holes between the gear.

DRIVE

SUB-GEAR INSTALLATION

-

gear and springs.

-

gear onto the primary

SU

B-GEAR

12-4

Apply molybdenum disulfide oil to the area shown in

the illustration.

v

ALIGN

Loading...

Loading...