UW50 UTENSIL WASHER

MODEL

UW50 ML-27838

(Electric

machines only)

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 18241 Rev. J (July 2013)

TABLE OF CONTENTS

GENERAL ..............................................................................................................................................................3

INSTALLATION ......................................................................................................................................................3

Unpacking ........................................................................................................................................................3

Installation Codes ............................................................................................................................................3

Location ...........................................................................................................................................................3

Installation Diagrams .......................................................................................................................................4

Plumbing Connections .....................................................................................................................................7

Gas Connection (When Specied) ...................................................................................................................7

Steam Connection (When Specied) ...............................................................................................................7

Venting Required With Gas Heat (Optional With Steam or Electric Heat) .......................................................8

Rate Of Exhaust Flow Calculations .................................................................................................................9

Detergent Feeder (Optional By Others) .........................................................................................................10

Rinse Agent Feeder (Optional By Others) .....................................................................................................10

Vent Exit .........................................................................................................................................................10

Vent Fan Control (Optional); Power Vent (Optional) ......................................................................................10

Electrical Connection .....................................................................................................................................10

OPERATION ......................................................................................................................................................... 11

Controls (Fig. 3) .............................................................................................................................................11

General Operating Instructions ......................................................................................................................12

Cleaning the Utensil Washer ..........................................................................................................................12

Dos and Don'ts For Your New Hobart Utensil Washer ...................................................................................13

MAINTENANCE ...................................................................................................................................................14

Motor ..............................................................................................................................................................14

Wash and Rinse Arms ....................................................................................................................................14

Deliming .........................................................................................................................................................14

TROUBLESHOOTING .........................................................................................................................................15

Service ...........................................................................................................................................................16

Model UW50 Utensil

Washer With Booster

©HOBART, 2012

– 2 –

INSTALLATION, OPERATION AND CARE OF

MODEL UW50 UTENSIL WASHER

SAVE THESE INSTRUCTIONS

GENERAL

The UW50 Utensil Washer is the answer to volume utensil washing problems in your kitchen, bakery or

supermarket operation. The UW50 occupies a minimum amount of oor space (under 48" x 43" with door

open) and does not require separate dishtables. The upper portion of the door raises, while the lower portion

swings out to provide a drain platform. The rack can then be pulled out for easy loading and unloading.

The program selector lets you select a 2-, 4- or 6-minute cycle; each wash cycle is followed by a dwell

and a 15-second rinse. The two upper and two lower wash arms provide thorough cleaning. Four rinse

arms provide a sanitizing rinse at the end of each cycle. The 5-horsepower pump produces 343 gallons

per minute.

The UW50 may be ordered with steam coil, electric or gas tank heat. A top-mounted electric booster is

also available. When equipped with a top-mounted electric booster, a spray hose and nozzle is provided

on the left side of the machine. On models without top-mounted electric booster, the spray hose and

nozzle can be installed in the eld as an accessory. All machines are equipped with a pressure reducing

valve to be adjusted during installation.

Features include: sloping strainer system, self-closing drain with overow, timed ll, wash and rinse

thermometers and rack with inserts for trays. The at rack can accommodate a 140-quart Hobart mixer

bowl.

INSTALLATION

UNPACKING

Immediately after unpacking the UW50, check for possible shipping damage. If the UW50 is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

If the Utensil Washer is lifted with a lift truck, place the forks so the drain assembly under the tank is not

damaged.

Prior to installation, test the electrical service to ensure that it agrees with the specications on the data

plate located below the controls (lower right front).

INSTALLATION CODES

Installation must be in accordance with state and local codes, with the national Fuel Code, ANSIZ223.1

(latest edition), if applicable, and the National Electrical Code ANSI/NFPA70 (latest edition). In Canada,

the installation codes are: CAN/CGA B149.1, CAN/CGA B149.2 and CSA 22.1 (latest edition).

LOCATION

Set the machine in place after the nal oor covering is installed. Make sure the machine is level before

making any plumbing connections. Machines equipped with gas heat require a minimum 3" clearance

from the rear of the ue to any combustible construction. Allow at least 3" at the rear and 18" at the sides

of the machine as a suggested minimum for service access. Allow 13" in front of the machine for the door

to lower and sufcient additional space for the operator to work.

– 3 –

Drain lever located inside of tank.

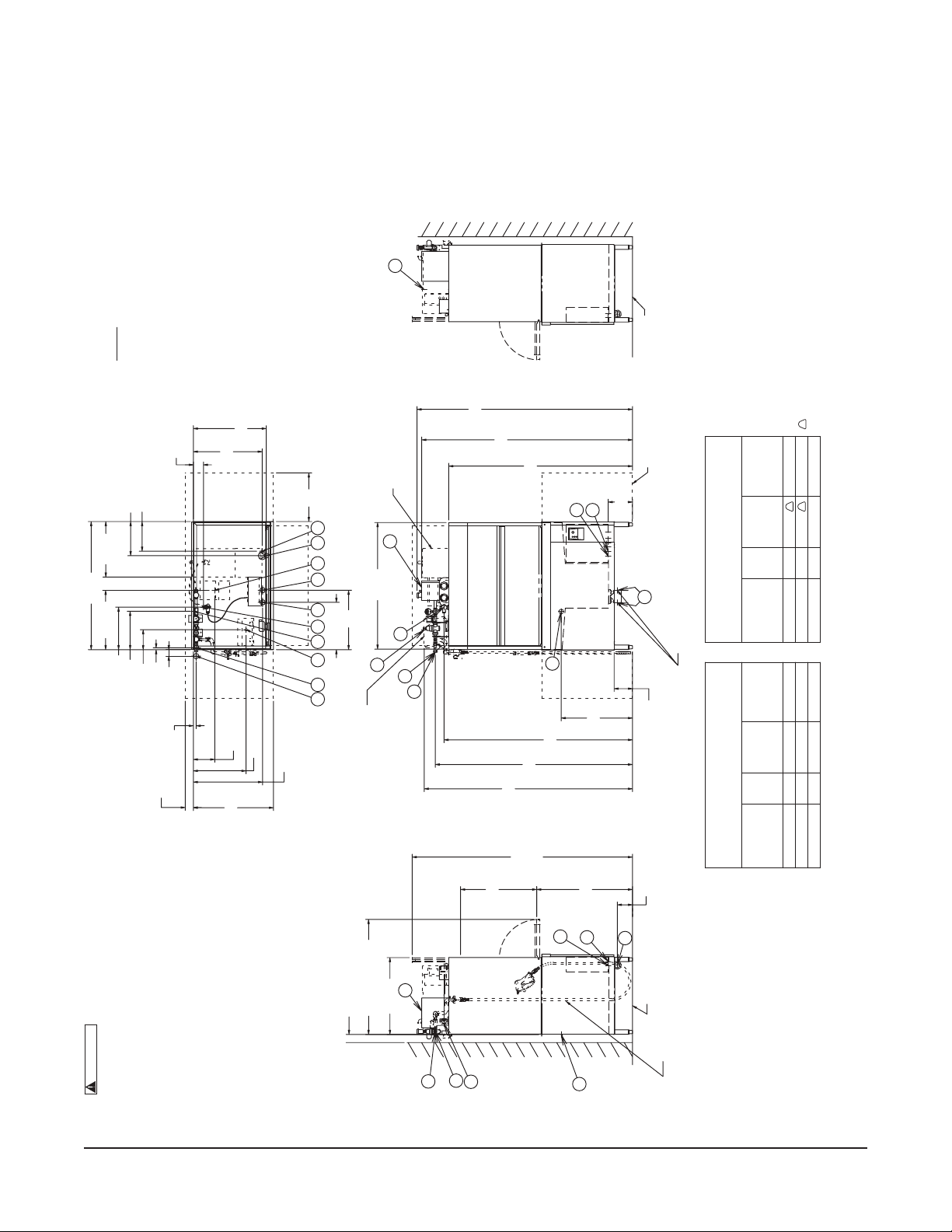

CONNECTION INFORMATION

T)

MODEL: UW-50

Electrical and grounding connections

must comply with the applicable portions

of the National Electrical Code and/or

other local electrical codes.

Plumbing connections must comply with

a

WARNING

ELECTRIC

00-812969

REV E

WALL

(*AFF - ABOVE FINISHED FLOOR)

LEGEND

E1 ELECTRICAL CONNECTION (INCLUDING ELECTRIC HEA

1-1/4" CONDUIT HOLE, 9" AFF.

(WHEN ORDERED); 3/4" CONDUIT HOLE; 77-1/16" AFF

P1 COMMON WATER CONNECTION: 180°F WATER MIN.

1/2" FPT, 73" AFF.

E3 ELECTRIC CONNECTION-VENT FAN CONTROL

3 3/4"

2 3/8"

1"

SUPPLIED BY 3/4" LINE FITTED WITH 3/4" TO 1/2"

ADAPTER (SUPPLIED BY OTHERS).

25 1/2"

RA

H

H

20 1/2"

47 3/8"

21 15/16"

12 5/8"

15 3/4"

14 3/16"

E2 ELECTRIC CONNECTION-DETERGENT/RINSE AGENT

FEEDERS: 1/2" CONDUIT HOLE; 9" AFF

10 15/16"

7 3/8"

11/16"

3"

SUPPLIED BY 3/4" LINE FITTED WITH 3/4" TO 1/2"

P2 DRAIN: 2" FPT, 5-5/8" AFF TWO CONNECTIONS.

P3 COMMON WATER CONNECTION WITH BOOSTER

(WHEN ORDERED); 110°F MIN., 1/2" FPT, 73" AFF.

27"

D

D

7 15/16"

19 1/2"

29 11/16"

ADAPTER (SUPPLIED BY OTHERS).

E1

25 5/8"

PIPE PLUG TO ACCESS TAPPED HOLE; 69-3/4" AFF.

18"

ACCESS (BOTH ENDS)

SUGGESTED MINUMUM

CLEARANCE FOR SERVICE

E1P1P3 E2E3 P4 P2P5 V1

P2

22"

17 1/2"

EXPANSION OF AIR. (NEED NOT BE CONNECTED TO

EXTERNAL VENT); IF REQUIRED,VENT HOOD TO

V1 VENT EXIT: 7" X 11" X 10" HIGH TO ALLOW FOR

P4 DETERGENT PROBE SENSOR: REMOVE CAP AND STUD

ASSEMBLY TO ACCESS 7/8" HOLE, 26-3/8" AFF

P5 RINSE AGENT FEEDER: 1/8" NPT, REMOVE 1/8" NPT

e

.

d

PROVIDE 400 CFM EXHAUST.

BROKEN LINES INDICATE

V1

46 7/8"

E3

(WHEN ORDERED)

BROKEN LINES INDICATE

VENT FAN CONTROL

E3

BOOSTER OUTLINE

(WHEN ORDERED)

P5

P1

P3

79 3/4"

78"

28 1/8"

FLOOR LINE

FOR SUPPLY CONNECTION USE

WIRES SUITABLE FOR AT LEAST

90°C OR EQUIVALENT.

1

FLOOR LINE

68 1/16"

9"

E1

E2

AND 15KW ELECTRIC BOOSTER

P2

P4

26 3/8"

69 3/4"

73"

77 1/16"

81 9/16"

WITH

DOOR UP

35 1/2"

E2

E1

6 13/16"

5 5/8"

P2

UW-50 WITH 10KW ELECTRIC HEAT

SINGLE POINT ELECTRIC CONNECTION

OF VALV E, PLUG OPPOSITE SIDE.

MAY BE DRAINED TO EITHER SIDE

UW-50 WITH 10KW ELECTRIC HEAT

SINGLE POINT ELECTRIC CONNECTION

(CONTROLS AND 5HP PUMP MOTOR)

(CONTROLS AND 5HP PUMP MOTOR)

DEVICE

MAXIMUM

PROTECTIVE

OVERCURRENT

SUPPLY

CIRCUIT

MINIMUM

AMPACITY

CONDUCTOR

AMPS

RATED

ELEC.

SPECS.

DEVICE

MAXIMUM

PROTECTIVE

OVERCURRENT

SUPPLY

CIRCUIT

MINIMUM

AMPACITY

CONDUCTOR

AMPS

RATED

ELEC.

SPECS.

100100

1

1

100100

93.9

86.3

240/60/3

208/60/3

7070

60 60

50.3

46.2

240/60/3

208/60/3

50 50

43.8

480/60/3

30 30

23.5

480/60/3

eeting ASSE-1010 STANDARD

m

(

r

o

t

s

e

r

r

pplicable sanitary, safety and plumbingcodes. Drain and fill line configurationsvary, some methods are shown on this drawing.

ater hammer a

ressure regulator furnished.

or best results.

42 9/16"

WITH DOOR OPEN

3" MINIMUM

V1

28 7/16"

P3

P1

WALL

P5

P4

FLOOR LINE

BROKEN LINES INDICATE

PRE-WASH SPRAY HOSE

(WHEN ORDERED WITH BOOSTER)

MISCELLANEOUS NOTES:

All dimensions taken from floor line may be increased

by up to 1-1/8" with leg adjustment.

Net weight of machine: 640 lbs. w/o booster

Domestic shipping weight: 782 lbs. w/o booster

Net weight of machine: 691 lbs. w/booster

Domestic shipping weight: 833 lbs. w/booster

Shipping dimensions:

60" X 38" X 85" high.

Size of racks:

40-7/8" X 22-7/8" X 4-1/8"

UW50 with 10KW Electric Tank Heat with or without 15KW Electric Booster – Installation Diagram: D-812969 sheet 1

– 4 –

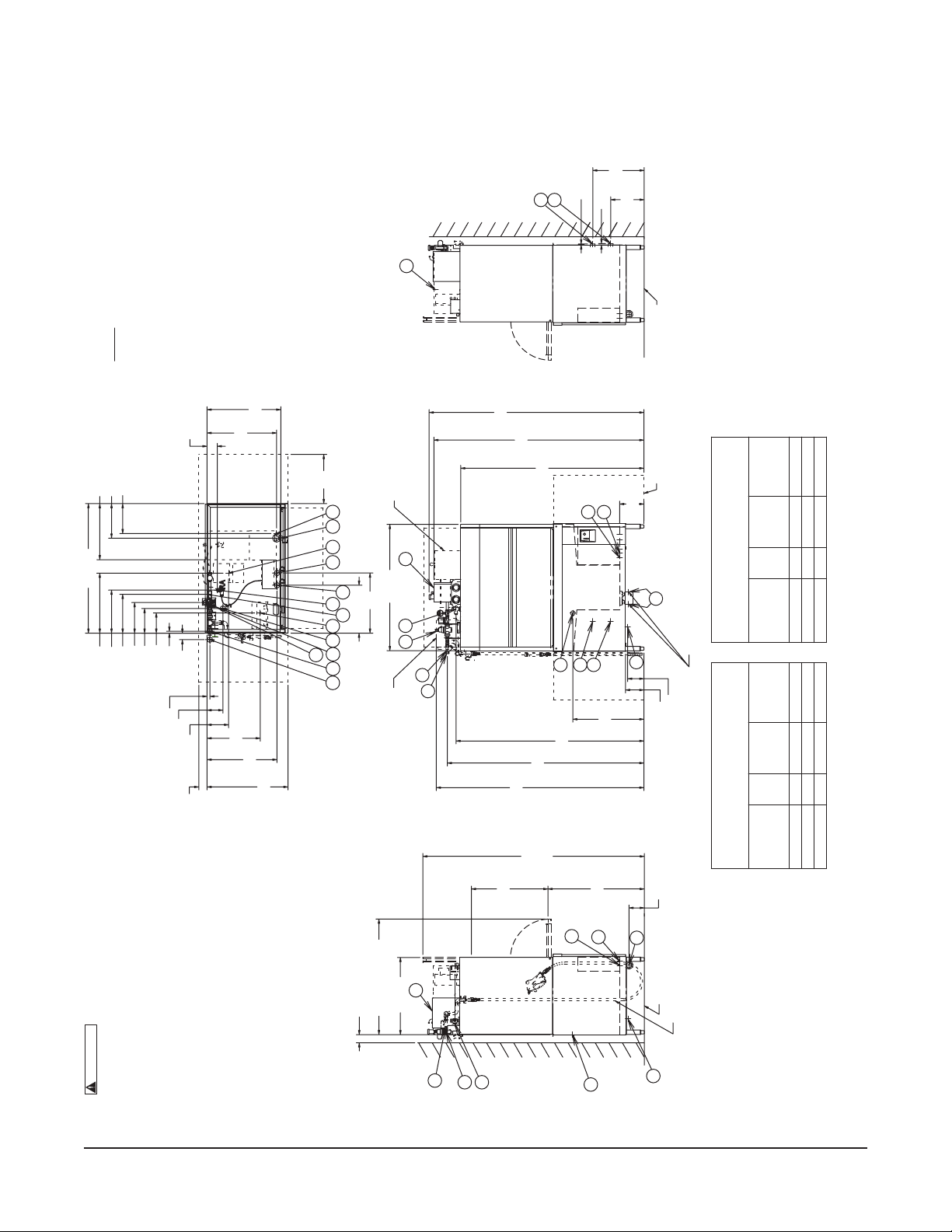

Drain lever located inside of tank.

CONNECTION INFORMATION

PLUMBING NOTES:

or equivalent) to be supplied (by others) in

common water supply line at service connection

Recommended water hardness to be 3 grains or less

Recommended building flowing water pressure to th

dishwasher is a minimum of 25 PSI.

P

For convenience when cleaning, water tap should be

installed near machine with heavy duty hose an

squeeze valve.

19"

47 3/8"

Electrical and grounding connections

must comply with the applicable portions

of the National Electrical Code and/or

other local electrical codes.

Plumbing connections must comply with

a

WARNING

5/16"

P7

P8

1/2"

WALL

E3

12 3/8"

MODEL: UW-50

STEAM

00-812969

REV E

1-1/4" CONDUIT HOLE, 9" AFF.

(*AFF - ABOVE FINISHED FLOOR)

LEGEND

E1 ELECTRICAL CONNECTION (MOTORS & CONTROLS);

E2 ELECTRIC CONNECTION-DETERGENT/RINSE AGENT

FEEDERS: 1/2" CONDUIT HOLE; 9" AFF

12 5/8"

20 1/2"

10 15/16"

9"

15 3/4"

11 3/16"

14 3/16"

21 15/16"

E3 ELECTRIC CONNECTION-VENT FAN CONTROL

7 3/8"

(WHEN ORDERED); 3/4" CONDUIT HOLE; 77-1/16" AFF

11/16"

1"

P1 COMMON WATER CONNECTION: 180°F WATER MIN.

1/2" FPT, 73" AFF.

SUPPLIED BY 3/4" LINE FITTED WITH 3/4" TO 1/2"

3 3/4"

2 3/8"

5 13/16"

7 15/16"

3"

P2 DRAIN: 2" FPT, 5-5/8" AFF TWO CONNECTIONS.

P3 STEAM INJECTOR: 10 TO 25 PSI FLOWING,

50 PSI MAX.; 3/4" FPT; 6" AFF.

P4 DETERGENT PROBE SENSOR: REMOVE CAP AND STUD

ASSEMBLY TO ACCESS 7/8" HOLE, 26-3/8" AFF

P5 RINSE AGENT FEEDER: 1/8" NPT, REMOVE 1/8" NPT

ADAPTER (SUPPLIED BY OTHERS).

CR

SC

H

H

PIPE PLUG TO ACCESS TAPPED HOLE; 69-3/4" AFF.

27"

25 1/2"

RA

S

19 1/2"

25 5/8"

29 11/16"

e

.

9"

P3

FLOOR LINE

FLOOR LINE

P2

6"

6 13/16"

5 5/8"

UW-50 WITH STEAM HEAT

AND 15KW ELECTRIC BOOSTER

(CONTROLS AND 5HP PUMP MOTOR)

SINGLE POINT ELECTRIC CONNECTION

OF VALVE, PLUG OPPOSITE SIDE.

MAY BE DRAINED TO EITHER SIDE

UW-50 WITH 10KW STEAM HEAT

(CONTROLS AND 5HP PUMP MOTOR)

SINGLE POINT ELECTRIC CONNECTION

DEVICE

MAXIMUM

PROTECTIVE

OVERCURRENT

SUPPLY

CIRCUIT

MINIMUM

AMPACITY

CONDUCTOR

AMPS

RATED

ELEC.

SPECS.

DEVICE

MAXIMUM

PROTECTIVE

OVERCURRENT

SUPPLY

CIRCUIT

MINIMUM

AMPACITY

CONDUCTOR

AMPS

RATED

ELEC.

SPECS.

8080

70 70

64.7

59.4

240/60/3

208/60/3

2525

25 25

17.6

20.3

240/60/3

208/60/3

35 35

29.9

480/60/3

15 15

9.2

480/60/3

EXPANSION OF AIR. (NEED NOT BE CONNECTED TO

EXTERNAL VENT); IF REQUIRED, VENT HOOD TO

PROVIDE 400 CFM EXHAUST.

P6 COMMON WATER CONNECTION WITH ELECTRIC BOOSTER

SUPPLIED BY 3/4" LINE FITTED WITH 3/4" TO 1/2"

ADAPTER (SUPPLIED BY OTHERS).

(WHEN ORDERED); 110°F MIN.,1/2" FPT, 73" AFF.

E1

D

D

V1 VENT EXIT: 7" X 11" X 10" HIGH TO ALLOW FOR

P7 STEAM COIL: 10 TO 25 PSI FLOWING, 50 PSI MAX.,

3/4" FPT, 19" AFF.

P8 CONDENSATE RETURN: 10 TO 50 PSI FLOWING, 3/4"

FPT. 12-3/8" AFF, (BUCKET T YPE TRAP FURNISHED).

18"

ACCESS (BOTH ENDS)

SUGGESTED MINUMUM

CLEARANCE FOR SERVICE

E1 E2V1

P2

P2

22"

P5P6

P4

17 1/2"

P8

P7

P1 P3 E3

BROKEN LINES INDICATE

BOOSTER OUTLINE

(WHEN ORDERED)

V1

46 7/8"

P5

E3

P1

P6

(WHEN ORDERED)

BROKEN LINES INDICATE

VENT FAN CONTROL

79 3/4"

28 1/8"

78"

68 1/16"

E1

E2

P8

P4

P7

26 3/8"

69 3/4"

73"

77 1/16"

81 9/16"

WITH

DOOR UP

35 1/2"

d

E2

E1

P2

eeting ASSE-1010 STANDARD

m

(

r

o

t

s

e

r

r

pplicable sanitary, safety and plumbingcodes. Drain and fill line configurationsvary, some methods are shown on this drawing.

ater hammer a

ressure regulator furnished.

or best results.

42 9/16"

28 7/16"

WITH DOOR OPEN

3" MINIMUM

V1

P6

P1

WALL

P5

P4

FLOOR LINE

BROKEN LINES INDICATE

PRE-WASH SPRAY HOSE

(WHEN ORDERED WITH BOOSTER)

P3

MISCELLANEOUS NOTES:

All dimensions taken from floor line may be increased

by up to 1-1/8" with leg adjustment.

Net weight of machine: 640 lbs. w/o booster

Domestic shipping weight: 782 lbs. w/o booster

Net weight of machine: 691 lbs. w/booster

Domestic shipping weight: 833 lbs. w/booster

Shipping dimensions:

60" X 38" X 85" high.

Size of racks:

40-7/8" X 22-7/8" X 4-1/8"

UW50 with Steam Coil Tank Heat with or without 15KW Electric Booster – Installation Diagram: D-812969 sheet 2

– 5 –

CONNECTION INFORMATION

R

squeeze valve.

WALL

20"

MODEL: UW-50

GAS

00-812969

REV E

5 7/8"

9"

P6

P7

17 3/8"

FLOOR LINE

FLOOR LINE

THIS AREA MUST BE KEPT CLEAR

GAS SHROUD AND FLUE

OF ALL PIPING.

16 5/8"

P2

6 13/16"

11 5/8"

UW-50 WITH GAS HEAT

SINGLE POINT ELECTRIC CONNECTION

SINGLE POINT ELECTRIC CONNECTION

MAY BE DRAINED TO EITHER SIDE

OF VALVE, PLUG OPPOSITE SIDE.

AND 15KW ELECTRIC BOOSTER

(CONTROLS AND 5HP PUMP MOTOR)

UW-50 WITH GAS HEAT

MAXIMUM

OVERCURRENT

SUPPLY

MINIMUM

RATED

(CONTROLS AND 5HP PUMP MOTOR)

ELEC.

MAXIMUM

OVERCURRENT

SUPPLY

MINIMUM

RATED

ELEC.

DEVICE

8080

PROTECTIVE

CIRCUIT

AMPACITY

CONDUCTOR

AMPS

64.7

SPECS.

208/60/3

DEVICE

3030

PROTECTIVE

CIRCUIT

AMPACITY

CONDUCTOR

AMPS

21.4

SPECS.

208/60/3

35 35

70 70

59.4

29.9

480/60/3

240/60/3

15 15

25 25

9.6

18.6

480/60/3

240/60/3

E3

6"

SUPPLIED BY 3/4" LINE FITTED WITH 3/4" TO 1/2"

ADAPTER (SUPPLIED BY OTHERS).

P2 DRAIN: 2" FPT, 5-5/8" AFF TWO CONNECTIONS.

1/2" FPT, 73" AFF.

(WHEN ORDERED); 3/4" CONDUIT HOLE; 77-1/16" AFF

P1 COMMON WATER CONNECTION: 180°F WATER MIN.

(*AFF - ABOVE FINISHED FLOOR)

E3 ELECTRIC CONNECTION-VENT FAN CONTROL

LEGEND

E1 ELECTRICAL CONNECTION (MOTORS & CONTROLS);

1-1/4" CONDUIT HOLE, 9" AFF.

E2 ELECTRIC CONNECTION-DETERGENT/RINSE AGENT

FEEDERS: 1/2" CONDUIT HOLE; 9" AFF

P3 COMMON WATER CONNECTION WITH ELECTRIC BOOSTE

SUPPLIED BY 3/4" LINE FITTED WITH 3/4" TO 1/2"

(WHEN ORDERED); 110°F MIN., 1/2" FPT, 73" AFF.

ASSEMBLY TO ACCESS 7/8" HOLE, 26-3/8" AFF

P5 RINSE AGENT FEEDER: 1/8" NPT, REMOVE 1/8" NPT

ADAPTER (SUPPLIED BY OTHERS).

P4 DETERGENT PROBE SENSOR: REMOVE CAP AND STUD

P6 GAS CONNECTION - NAT. :

1/2" FPT, 11-5/8" AFF.

P7 GAS CONNECTION - L.P.:

1/2" FPT, 11-5/8" AFF.

V1 VENT EXIT: 7" X 11 " X 10" HIGH TO ALLOW FOR

EXPANSION OF AIR. (NEED NOT BE CONNECTED TO

PIPE PLUG TO ACCESS TAPPED HOLE; 69-3/4" AFF.

EXTERNAL VENT); IF REQUIRED, VENT HOOD TO

PROVIDE 400 CFM EXHAUST.

REF

3" MINIMUM FLUE

CLEARANCE REQUIRED

FOR GAS HEAT

79 3/4"

78"

27"

3 3/4"

12 5/8"

20 1/2"

10 15/16"

47 3/8"

25 1/2"

BROKEN LINES INDICATE

BOOSTER OUTLINE

(WHEN ORDERED)

18"

ACCESS (BOTH ENDS)

SUGGESTED MINUMUM

CLEARANCE FOR SERVICE

E1 E2V1

E1

P2P2

D

RA

V1

46 7/8"

77 11/16"

68 1/16"

E1

E2

22"

17 1/2"

E3 P4 P5

P1

P6

E3

P5

P1

P3

P4

P7

P6

26 3/8"

69 3/4"

73"

(WHEN ORDERED)

BROKEN LINES INDICATE

VENT FAN CONTROL

77 1/16"

15 3/4"

21 15/16"

14 3/16"

1 13/16"

7 3/8"

11/16"

2 3/8"

1 1/2"

1"

6"

GDG

H

H

7 15/16"

P7

P3

19 1/2"

25 5/8"

29 11/16"

Propane not factory built. Field conversion kit required.

WARNING

Electrical and grounding connections

must comply with the applicable portions

of the National Electrical Code and/or

other local electrical codes.

Plumbing connections must comply with

applicable sanitary, safety and plumbing

codes. Drain and fill line configurations

vary, some methods are shown on this drawing.

GAS HEATED DISHWASHERS

For natural gas, pressure to the burner (customer

connection) should not exceed 7" W.C.

For liquified petroleum gas, pressure to the burner

(customer connection) should not exceed 11" W. C.

If gas pressure is higher than 7" or 11" W. C.,

a pressure requlating valve must be installed

(by others) in the gas line to the dishwasher.

Gas heat BTU input - 47,000 Natural

47,000 Propane

When gas tank heat is specified, gas exhaust venting

must be installled according to local code. Do not

connect flue to power vent.

V1

42 9/16"

28 7/16"

WITH DOOR OPEN

P3

P1

– 6 –

MISCELLANEOUS NOTES:

All dimensions taken from floor line may be increased

by up to 1-1/8" with leg adjustment.

Net weight of machine: 640 lbs. w/o booster

Domestic shipping weight: 782 lbs. w/o booster

Net weight of machine: 691 lbs. w/booster

Domestic shipping weight: 833 lbs. w/booster

Shipping dimensions:

60" X 38" X 85" high.

Size of racks:

40-7/8" X 22-7/8" X 4-1/8"

81 9/16"

WITH

DOOR UP

28 1/8"

WALL

P5

35 1/2"

E2

E1

P4

P2

5 5/8"

FLOOR LINE

BROKEN LINES INDICATE

eeting ASSE-1010 STANDARD

m

(

r

o

t

s

e

r

r

(WHEN ORDERED WITH BOOSTER)

PRE-WASH SPRAY HOSE

PLUMBING NOTES:

Water hammer a

or equivalent) to be supplied (by others) in

common water supply line at service connection.

Recommended water hardness to be 3 grains or less

for best results.

Drain lever located inside of tank.

UW50 with Gas Tank Heat with or without 15KW Electric Booster – Installation Diagram: D-812969 sheet 3

Recommended building flowing water pressure to the

dishwasher is a minimum of 25 PSI.

Pressure regulator furnished.

For convenience when cleaning, water tap should be

installed near machine with heavy duty hose and

PLUMBING CONNECTIONS

Plumbing connections must comply with applicable sanitary, safety and plumbing

codes.

Water Supply Connection

Water must be proper hardness. Recommended water hardness is 3 grain or less. Higher hardness may

cause excessive formation of lime scale. Chlorides must not exceed 50 ppm.

A water hammer arrestor (meeting ASSE-1010 Standard) should be provided (by others) in the water

supply line ahead of its connection to the line strainer. The water supply line should be a 3/4" pipe tted

with a 3/4" to 1/2" NPT reducer (supplied by others).

A owing pressure of 15 to 25 psig is required at the pressure gauge, provided. The pressure gauge may

be connected to a petcock, if equipped, and should remain closed, except when the owing pressure is

being checked. A pressure-reducing valve with relief bypass is furnished with all machines.

The water-pressure regulator must have a relief bypass. Failure to use the proper type of

pressure regulator may result in damage to the unit.

The minimum water supply

temperature per cycle time

required to maintain 180°F nal

rinse temperature is shown at

the right:

Cycle

2 Minute 110°F 180°F

4 Minute 110°F 180°F

6 Minute 80°F 180°F

With Optional Booster Heater Without Booster Heater

Minimum Water Supply Temperatures

Drain Connection

A proper drain should be connected to the 2" internal threads at the "T" tting underneath the machine.

The drain can be connected on either the left or right side of the "T" tting. The right side of the "T" tting

is plugged at the factory, allowing the drain to be connected on the left side. If it is more convenient to

connect the drain on the right side, remove the plug from the right side of the "T" tting, reinstall it on the

left side and connect the drain to the right side.

GAS CONNECTION (WHEN SPECIFIED)

Check the gas data plate attached to the dishwasher or tag attached to the gas burner tubing for type of

gas to be used.

Connect the gas supply to the machine. Field conversion required for propane gas.

The burner is not adjustable. If line pressure is above 7" W.C. (natural gas) or 11" W.C. (propane gas), an

additional regulator valve (not supplied) must be installed in the supply line.

The burner is ignited by solid state electronic circuitry; there is no pilot light. Gas ow is regulated by the

temperature control circuit via a blower and centrifugal switch system.

STEAM CONNECTION (WHEN SPECIFIED)

Machines equipped with steam coil tank heat have the steam supply connection (3/4" female pipe thread)

located at the rear of the wash tank, 19" above the oor, and a condensate return connection (3/4" female

pipe thread), located at the rear of the wash tank, 123/8" above the oor (a bucket-type trap is furnished).

Flowing steam pressure should be 15 to 25 psig (50 psig maximum). A manually operated steam

control valve (supplied by others) should be installed at a convenient location ahead of the steam supply

connection.

– 7 –

VENTING REQUIRED WITH GAS HEAT (OPTIONAL WITH STEAM OR ELECTRIC HEAT)

6" MINIMUM OVERHANG

18" MINIMUM OVERHANG

The Hobart UW50 Utensil Washer, equipped for gas tank heat, is not provided with a ue collar and is not

intended to have the ue directly connected to a ventilation system. However, the products of combustion

must be vented to the outside air. A vent hood over the entire utensil washer (Fig. 1) can be employed to

vent both the moist air from the wash chamber and the ue gases from the gas tank heat. The volume of

ue exhaust required for venting moist air and ue gases using a single vent hood over the entire utensil

washer must be calculated using the formulas on the next page.

If a powered means of exhaust is used, an electrical interlock must be provided to allow the ow of gas

to the utensil washer burner only when the exhaust system is in operation.

For additional information, refer to the National Fuel Gas Code, ANSI Z223.1, NFPA 54 (latest editions).

In all cases, local codes will prevail.

EXHAUST DUCT SHOULD

BE CENTERED IN HOOD

Type I or Type II canopy hoods are recommended. A factory-built commercial exhaust hood may be listed

as conforming to Underwriters Laboratory's standard 710, titled Exhaust Hoods for Commercial Cooking

Equipment. Hoods must be installed according to the manufacturer's instructions. Make-up air must be

provided so that the exhaust ow rate results in a positive building pressure in the room where the unit

is located (more outside air than exhaust air). Factory-built hoods not tested to UL standard 710 and

custom-built hoods must comply with the following specications: Stainless steel should have a minimum

thickness of 0.037 in. (0.94 mm) [No. 20 Gauge] or copper sheet weighing at least 24 ounces per square

foot (7 Kg/m2); the hood must be secured in place by noncombustible supports and must meet the RATE

OF EXHAUST FLOW CALCULATIONS on the next page.

1' TO 4'

CLEARANCE

AT FRONT OPENING

ON ALL SIDES

Fig. 1

– 8 –

RATE OF EXHAUST FLOW CALCULATIONS (FIG. 2)

CLEARANCE

Based on the International Mechanical Code (latest edition).

HEIGHT

LENGTH

Fig. 2

WIDTH

Canopy size and location

The inside lower edge of canopy-type Type I and II commercial hoods shall overhang or extend a horizontal

distance of not less than 6 inches (152 mm) beyond the edge of the top horizontal surface of the appliance

on all open sides. The vertical distance between the front lower lip of the hood and such surface shall not

exceed 4 feet (1219 mm).

The RATE of air ow required for a vent hood is a minimum of 100 CFM per linear foot of hood length.

– 9 –

DETERGENT FEEDER (OPTIONAL BY OTHERS)

If installing a detergent feeder (by others), remove cap to expose 7/8" diameter hole at rear of machine.

RINSE AGENT FEEDER (OPTIONAL BY OTHERS)

If a rinse agent feeder (by others) is being installed, remove the 1/8" NPT pipe plug to access the tapped

hole in the incoming water line below the vacuum breaker on top of the machine.

VENT EXIT

A vent exit (7" x 11" x 10") is provided in the top of the machine to allow for expansion of air. It should not

be directly connected to an external vent.

VENT FAN CONTROL (OPTIONAL); POWER VENT (OPTIONAL)

The Vent Fan Control option (factory- or eld-installed) provides switching for a vent fan (by others). The

vent hood comes on when the UW50 is on and goes off when the UW50 is off. This is appropriate for

a hood over a UW50 with gas tank heat. The Vent Fan Control can be rewired by your Hobart service

technician to control the Power Vent option (not available on UW50 with gas tank heat). Power Vent is

used on UW50 with steam or electric tank heat to exhaust moist air from the chamber after the rinse cycle

is nished. Power Vent operates for 45 seconds. Power Vent (eld installed only) extends upward 131/8"

above the Vent Exit (227/8" above the top of the wash chamber) and terminates in a round duct connection

for a 101/4" O.D. duct.

ELECTRICAL CONNECTION

Electrical and grounding connection must comply with the applicable portions of

the National Electrical Code and/or other local electrical codes.

Disconnect electrical power supply and follow lockout / tagout procedures.

Connect incoming power to the control box in accordance with the wiring diagram located inside the control

box and the electrical data chart. The front trim rail and the front panel must be removed to access the

control box.

ELECTRICAL DATA

10KW Electric Heat

(Single Point

Connections)

Rated

Volts/Hz/Ph

208/60/3 50.3 70 93.9 **100 20.3 25 64.7 80 21.4 30 64.7 80

240/60/3 46.2 60 86.3 **100 17.6 25 59.4 70 18.6 25 59.4 70

480/60/3 23.5 30 43.8 50 9.2 15 29.9 35 9.6 15 29.9 35

* Minimum Circuit Size / Maximum Protective Device (Amps) compiled in accordance with the National Electrical Code (NFPA 70), latest edition.

** For supply connection, use wires suitable for at least 90°F or equivalent.

Amps

Circuit Size*

(Amps)

10KW Electric Heat

With 15KW Electric

Booster (Single Point

Connections)

Rated

Circuit Size*

Amps

(Amps)

Steam Coil Tank Heat

(Single Point

Connections)

Rated

Circuit Size*

Amps

(Amps)

Steam Coil Tank Heat

With 15KW Electric

Booster (Single Point

Connections)

Rated

Circuit Size*

Amps

(Amps)

Gas Tank Heat

(Single Point

Connections)

Rated

Circuit Size*

Amps

(Amps)

Gas Tank Heat

With 15KW Electric

Booster (Single Point

Connections)

Rated

Circuit Size*

Amps

(Amps)

Rotation of Pump Motor

Before using the machine, check the pump motor rotation to be sure it is rotating in the right direction. From

the front of the machine, the motor should rotate counterclockwise. Looking from the rear of the machine,

the correct rotation is clockwise. Inspection is easiest from the right side using a ashlight and mirror to

check the motor fan in front. Be aware that the mirror will reverse the perceived direction.

If the pump motor is rotating in the wrong direction, follow this procedure.

Disconnect electrical power supply and follow lockout / tagout procedures.

Reverse any two of the three incoming line wires (not the ground wire). Reconnect and recheck rotation

of pump motor.

– 10 –

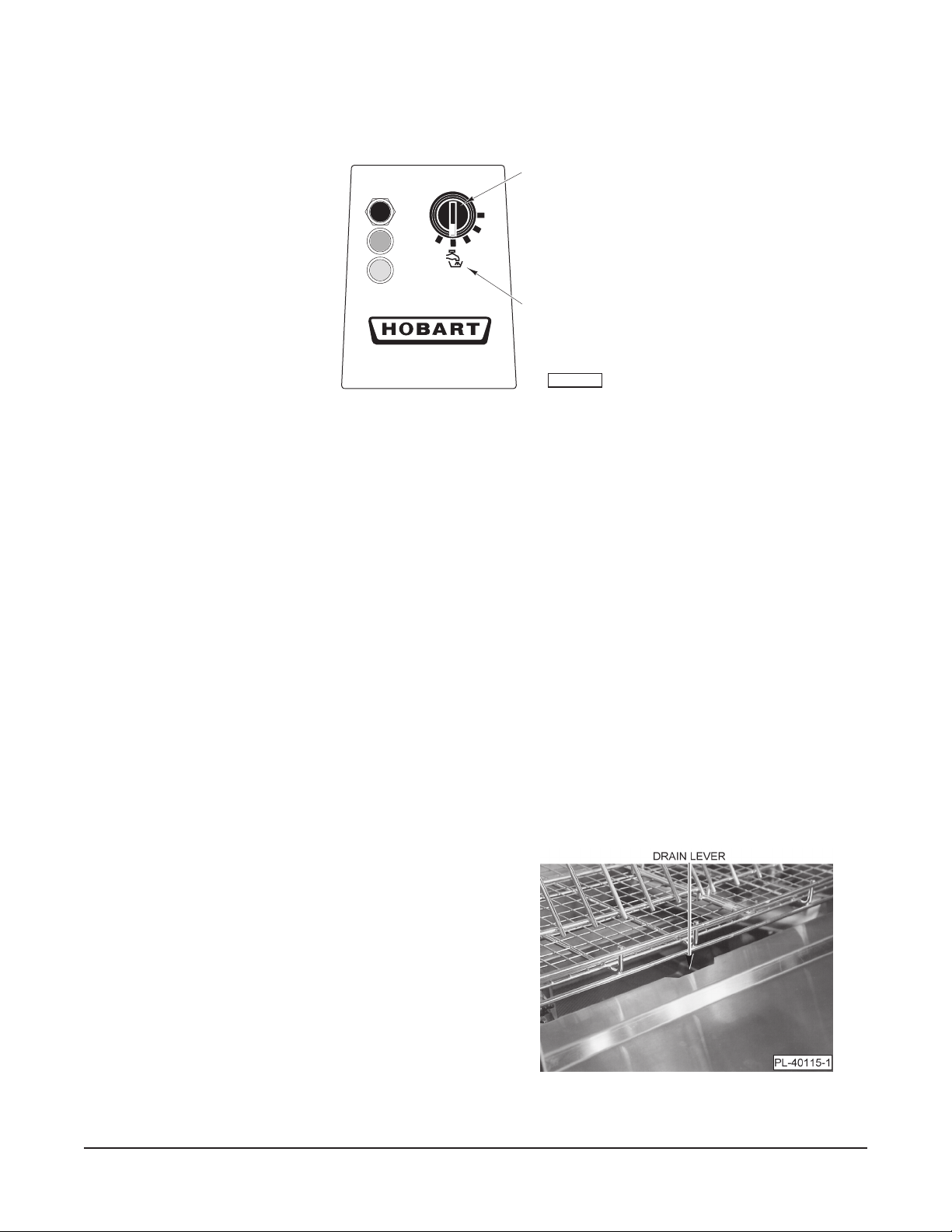

CONTROLS (FIG. 3)

SELECTOR

OPERATION

START

POWER

CYCLE

OFF

2

Fig. 3

SWITCH

6

4

FILL

PL-56351

SELECTOR SWITCH

OFF Electric power to machine is off. POWER and CYCLE lights are off.

FILL Timed ll requires about 3 minutes. Be sure Drain Lever (Fig. 4) is closed. Press

the START button to begin a timed ll.

SELECT WASH CYCLE and press START.

2 A 2-minute wash cycle is followed by a 15-second low water rinse.

4 A 4-minute wash cycle is followed by a 15-second low water rinse.

6 A 6-minute wash cycle is followed by a 15-second low water rinse.

All rinse cycles are followed by a 10 second pause, the white cycle light extinguishes after the pause indicating clean ware is ready for removal.

START button Begins a timed ll or starts a wash cycle.

POWER light (green) Indicates the machine has power, and the Selector Switch is not off.

CYCLE light (white) Indicates a timed ll or wash cycle is in process.

NOTE: Opening the door during cycles will cause cycle to start over at the beginning.

DRAIN LEVER (Fig. 4)

Drain lever is located inside the wash chamber

(middle front with door open). Lower the lever to

close the drain before beginning a timed ll. Rotate

lever upward to open the drain after turning the

machine off at the end of the day.

DIAL THERMOMETERS (not shown)

Thermometers indicate the Wash Tank Temperature

and the Rinse Temperature. Thermometers are

located on top of the wash chamber and are clearly

visible when the doors are shut. Minimum Wash Tank

Temperature is 150°F. Minimum Rinse Temperature

Fig. 4

is 180°F.

– 11 –

GENERAL OPERATING INSTRUCTIONS

Keep the utensil washer clean to provide best results. Do not allow foreign objects to enter the unit,

especially metallic contaminants.

Do not wash aluminum utensils in the utensil washer. The caustic detergent and high water temperature

will cause aluminum oxide formation (black). Copper utensils may require polishing to remove oxide

formation after exposure to utensil washer cleaning for a period of time. Stainless steel utensils should

clean quickly and easily if the food soil is not baked on.

It may be necessary to scrub or prewash some hard-to-remove substances which may not come clean

in the utensil washer with even a 6-minute washing. For stubborn food soil, a plastic scraper, plastic

abrasive pad, nylon bristle brush or sponge with abrasive surface (Scotch Brite) may be used before

washing in the utensil washer. Never use steel wool on ware to be loaded into the utensil washer. Use

only products formulated to be safe on stainless steel. Rinse items thoroughly after scrubbing to remove

metallic debris.

CLEANING THE UTENSIL WASHER

Disconnect electrical power supply and follow lockout / tagout procedures.

The utensil washer must be thoroughly cleaned at the end of each working shift or at least daily. Never

use steel wool to clean utensil washer surfaces.

Turn the Selector Switch OFF.

Open the doors and lift up on the drain lever to drain the

tank.

Remove the strainer pan and strainer basket (Fig. 5), and

empty into a waste disposer or garbage container. Wash and

rinse strainer pan and strainer basket thoroughly. Do not bang

strainer pan or basket on tables to remove food soil.

After the tank has drained completely, lower the overow

tube to close the drain. Reconnect the electrical power to

the machine.

Fig. 5

Turn the Selector Switch to FILL and press the Start button. The machine will ll and rinse any debris into

the tank.

After Fill is complete, turn the Selector Switch OFF, open the doors and lift up on the drain lever to drain

the machine.

Disconnect electrical power supply and follow lockout / tagout procedures.

Remove the overow cover and the overow tube. Wash and rinse the overow tube inside and out.

Thoroughly cleanse and ush the interior of the machine. Remove remaining soil with a soft cloth or brush

and a mild cleanser. Rinse again. Do not allow food soil to accumulate in the tank bottom.

Reinstall the overow tube.

Carefully reinstall the strainer pan, strainer basket and drain cover. The opening at the corner of the strainer

pan allows the capillary tube to go into the tank.

On machines with the capillary tube in the tank, use care when assembling strainer pan so the

capillary tube is not damaged during assembly.

Make sure that the wash and rinse arms rotate freely and are free of any obstructions. If any obstructions

are present, remove the wash and rinse arms. Clean the wash and rinse arms under running water in a

sink.

– 12 –

The wash and rinse arms are easily removed for

cleaning.

To remove upper, low water rinse arm and wash arm

(Fig. 6):

• Unscrew the rinse arm by loosening the

knurled ring at top of rinse arm.

• Remove both Rinse and Wash arms at the

same time, being careful not to drop these

arms.

• Reverse the process to replace.

To remove lower, low water rinse arm and wash arm

(Fig.7):

(Low water rinse, upper assembly)

Fig. 6

• Unscrew the rinse arm by loosening the

knurled ring at top of rinse arm.

• Remove both Rinse and Wash arms at the

same time, being careful not to drop these

arms.

• Reverse the process to replace.

Leave the doors open to allow the interior to dry and

air out.

Fig. 7

(Low water rinse, lower assembly)

DOS AND DON'TS FOR YOUR NEW HOBART UTENSIL WASHER

DO ensure proper water hardness (3 grain or less). Total Dissolved Solids (TDS) must be 50 ppm or

greater. Chlorides must not exceed 50 ppm.

DO pre-scrap dishes thoroughly.

DO use only detergents recommended by your chemical professional.

DO thoroughly cleanse, rinse and dry (leave door open) the machine at the end of the day.

DO closely follow your chemical professional's prescribed deliming schedule.

DO use only products formulated to be safe on stainless steel.

DO NOT use detergents formulated for residential dishwashers.

DO NOT allow food soil to accumulate on the tank bottom.

DO NOT exceed chemical manufacturer's recommended concentrations for detergent, sanitizer, rinse aid

or lime scale remover.

DO NOT use steel wool to clean ware or warewasher surface.

DO NOT allow foreign objects to enter the unit, especially metallic contaminants.

NOTE: Failure to follow use, care and maintenance instructions may void your Hobart warewasher

warranty.

– 13 –

MAINTENANCE

Disconnect electrical power supply and follow lockout / tagout procedures.

MOTOR

The motor has permanently sealed bearings and requires no lubrication.

WASH AND RINSE ARMS

All wash arms and rinse arms should turn freely and continue turning for a few seconds after being whirled by

hand. To check, DISCONNECT ELECTRICAL POWER SUPPLY, rotate arms and remove any obstructions

causing improper operation. Refer to CLEANING THE UTENSIL WASHER on pages 12 and 13.

If the slanted strainer pan and strainer basket are not properly in place, obstructions (such as food particles

or toothpicks) may clog the wash arm nozzles.

DELIMING

Deliming solution must not come in contact with bleach or rinse solution containing

bleach. Mixing may cause hazardous gas to form. This entire procedure must be followed stepby-step for safe and satisfactory results.

The dishwasher should be delimed on a regular basis as required. How often depends on the mineral

content of the water. Deliming should be done when you can see clear signs of lime deposits (a white

chalky substance) on the inside walls and on the wash and rinse arms.

Inspect the machine interior for lime deposits. If deliming is necessary, a deliming agent (available from

your detergent representative) should be used for best results.

Delime as follows:

1. Lift drain lever and drain tank.

2. Remove rack from machine.

3. Close door.

4. Fill machine.

5. Open door and add deliming agent (carefully follow supplier's instructions).

NOTE: The sump holds 27 gallons of water.

6. Close door and allow machine to complete a 6-minute cycle.

7. Open door and lift drain lever to drain tank.

8. Inspect interior of machine for lime deposits. Repeat Steps 3 through 7 if necessary.

Do not allow deliming agent to remain in the machine longer than recommended by the deliming

agent manufacturer. After deliming, run the machine through two 6-minute cycles with no utensils in order

to rinse and ush machine interior.

– 14 –

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE

Utensils spotted or

not clean

Overloaded rack.

Low water level.

Water conditions:

— Incorrect rinse water temperature. Refer to WATER SUPPLY CONNECTION,

page 7.

— Excessive water hardness may indicate that a water softener is needed.

— Incorrect detergent type or concentration for water conditions.

— Incorrect rinse additive for water conditions.

Inadequate rinse.

— Dirty line strainer causing reduced water ow. Turn off water supply. Remove

strainer cap. Withdraw and clean screen. Reassemble.

— Low water pressure (supply line).

— Excessive mineral deposits throughout wash and rinse system. Deliming may

be necessary.

Check water level in tank. The machine won't clean well if there isn't enough water

for the pump to maintain adequate wash pressure.

— Drain overow tube may not be seated.

— Worn or torn O-Ring may cause overow tube not to seat.

Loss of water pressure due to pump obstruction.

— DISCONNECT ELECTRIC POWER SUPPLY. Drain tank and check for

obstruction at the strainer, basket and pump intake.

Insufcient detergent dispensing.

— Check supply or detergent supplier.

Excessive mineral deposits throughout wash and rinse system.

— Deliming may be necessary.

— Excessive water hardness may indicate that a water softener is needed.

Utensil washer was not cleaned properly. Refer to CLEANING THE UTENSIL

WASHER, pages 12 and 13.

Wash arm blocked with debris. Refer to WASH AND RINSE ARMS, page 14.

– 15 –

SYMPTOM POSSIBLE CAUSE

Machine won't

operate.

Fuse blown or circuit breaker tripped.

Selector Switch is turned OFF.

Check water level in tank.

— Drain overow tube may not be seated.

— Worn or torn O-Ring may cause overow tube not to seat.

Leaking valves. Solenoid valves.

— Contact Service.

Vacuum breaker.

— Foreign material preventing proper valve operation. A critical period is soon

after installation when pipe compound or metal shavings may lodge at the

valve seat. DISCONNECT ELECTRICAL POWER SUPPLY. Shut off water

supply line. Unscrew and lift bonnet from valve body. Clean valve and

reassemble.

No wash tank heat. The low water detector will shut off heat if water level is too low.

— Check water level. The overow tube may not be seated.

Fuse blown or circuit breaker tripped (if equipped with electric heat).

Manual steam valve not open completely (if equipped with steam heat).

Overtemperature protector tripped (gas or electric tank heat only).

— Contact Service.

No ll or slow ll. Dirty line strainer causing reduced water ow.

— Turn off water supply. Remove strainer cap. Withdraw and clean screen.

Reassemble.

SERVICE

In the event a gas orice tting shall be adjusted or replaced, have it serviced by qualied personnel.

Contact your Hobart service ofce for any repairs or adjustments needed on this equipment. Long-term

service contracts are available on this and other Hobart products.

FORM 18241 Rev J (July 2013) PRINTED IN U.S.A.

– 16 –

Loading...

Loading...