Page 1

Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

ULTIMA 2000 PLU PREPACK

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

THE HOBART ULTIMA 2000 PLU

PREPACK WEIGHING SYSTEM

PROVIDES MERCHANDISING

FLEXIBILITY, NUTRITIONAL AND TEXT

PRINTING AND IS VERY SIMPLE TO USE

The Hobart Ultima 2000 PLU Prepack Weighing

System offers supreme flexibility in a variety of

installations.

The Ultima 2000 is a PLU Prepack System that

gives you merchandising capabilities with multiple

fonts, graphics and label types. It allows for

flexibility in label design and helps you sell more

product. Provides flexible text printing to meet

labeling requirements.

The easy to use control panel allows for an

extremely productive operation.

CONFIGURATIONS

The modular design may be used in a variety of

wrapping systems:

WEIGHING SYSTEM

MODEL

❏ Ultima 2000 PLU Prepack Weighing System

Specifications, Details and Dimensions on Inside and Back.

Stand-Alone

Hand Wrap Station HWS

ULTIMA 2000 PLU PREPACK WEIGHING SYSTEM

❏ STAND-ALONE

System can be free-standing for hand weighing

and labeling.

❏ HAND WRAP STATION

Using the HWS Wrap Stand, the Ultima is a

productive system for lower volume operations,

as well as complimenting higher volume

operations.

❏ SEMI-AUTOMATIC

Using the ILA or CLA Indexers, packages are

wrapped manually. Weighing and labeling occurs

automatically. Using the NWS FastPak, wrapping

and weighing occurs automatically, and the label

is applied manually.

These systems provide flexibility in medium

volume operations.

❏ FULLY AUTOMATIC

Using the ESW Film Mizer or the NSW FastPak,

wrapping, weighing and labeling occur automatically to provide an extremely productive

and efficient system for a high volume operation.

Semi-Automatic NSW

Semi-Automatic ILA

F-7634 – Ultima 2000 PLU Prepack Weighing System Page 1 of 8

Page 2

ULTIMA 2000 PLU PREPACK

WEIGHING SYSTEM

ULTIMA 2000 FEATURES:

OPERATOR’S CONTROL PANEL

■ Remote and dual keyboard capabilities.

■ Large, High Resolution Display: Presents clear,

crisp images in an easy to read format. Maximizes

productivity, reduces operator training, and

minimizes errors due to a visual confirmation of

the product data. All necessary operator data

appears on the screen: Totals type, product

number, description, unit price, tare, shelf life,

_sell-by date, UPC number, weight and total price

for verification.

■ Security can be assigned to any field in the item

record on the operator display (configured by user)

denying access to that field.

■ 8 function keys (F1-F8) correspond to menu

selections on the screen. This simplifies option

selection since the system is menu driven and

options are easy to find. Accelerates system

operation because all PLU information is

immediately accessible. Reduces operator error

since the number of keys required on the operator

control panel are reduced. Reduces complexity

since keys with dual meanings are eliminated.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

■ Total types

– Total types allow the operator to track totals for

production as well as 7 other user defined

totals, such as rewraps, markdowns, discards,

specials, new items and cutting tests. Also

available are class totals to track product

categories, hourly totals to assist scheduling

and operator totals to track productivity. Total

types provide greater control and productivity

measurements.

MEMORY CAPACITY

■ 2MB of memory standard on automatic systems

(approximately 16,000 PLU’s with basic item

information).

■ 5MB standard on manual systems (approximately

4,000 PLU’s with basic item information).

■ All units expandable up to 6MB in 2MB increments,

which provides plenty of future data storage

(approximately 48,000 PLU’s with basic item

information).

■ Battery backup for memory retention up to

100 hours.

SPECIAL OPERATOR FUNCTIONS

■ Help key:

– Allows access to the one screen PLU library.

■ Speed Keys:

One-keystroke memory for the most frequently

used PLU’s. Faster operations and reduced error

probability is the result of fewer keystrokes needed

to enter product information.

■ Weigh type:

– Automatic, semi-automatic and manual weigh-

ing methods meet all needs.

– Repeat allows the operator to print multiple

labels with the same data.

– Countdown provides the ability to easily

produce a specific quantity of an item by

weight, value or number of packages with a

totals label for each run and carton.

OPTIONS FOR PROGRAMMING MEMORY

■ Manually through the supervisor’s control panel or

with optional computer type keyboard plugged into

the bottom of the control panel.

■ Cassette or disk load with optional data recorders.

– Mini-network to other Ultimas or to SP Series

Systems.

■ Computer controlled Scalemaster networking

system. Scalemaster provides uninterrupted scale

operations even during communications, provides

extra flexibility and efficiencies when transmitting

and receiving data.

CHANGE FILE

Any changes to the item file through the Ultima

keyboard are flagged resulting in only the changes

being transmitted during mini-net or writing to a disk

or cassette. Reduces time since “changes” only are

sent rather than the entire item file.

Page 2 of 8 F-7634 – Ultima 2000 PLU Prepack Weighing System

Page 3

ULTIMA 2000 PLU PREPACK

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

ITEM FILE INFORMATION STORED IN MEMORY

PLU number – 1 to 6 digits

UPC numbering systems – 0, 2, 4, 6 & 7

UPC number – 1 to 10 digits

Description – up to 200 characters

Special message – up to 2000 characters

Expanded text – up to 2000 characters

Nutrifacts – 2 line header, 8 line body & 2 line footer

Tare – maximum of 9.99 lbs.

Shelf life – maximum of 997 days

Product life – up to 999 days

Class number – 1 to 6 digits

Graphic – 1 graphic per Product Number

Label type – assigned by product for primary and

secondary printer

Label rotation – assigned by product (for CLA only) for

primary and secondary printer. Rotate label 90, 180,

270 or 360 degrees prior to applying the label to the

package to meet your merchandising needs.

WEIGHING SYSTEM

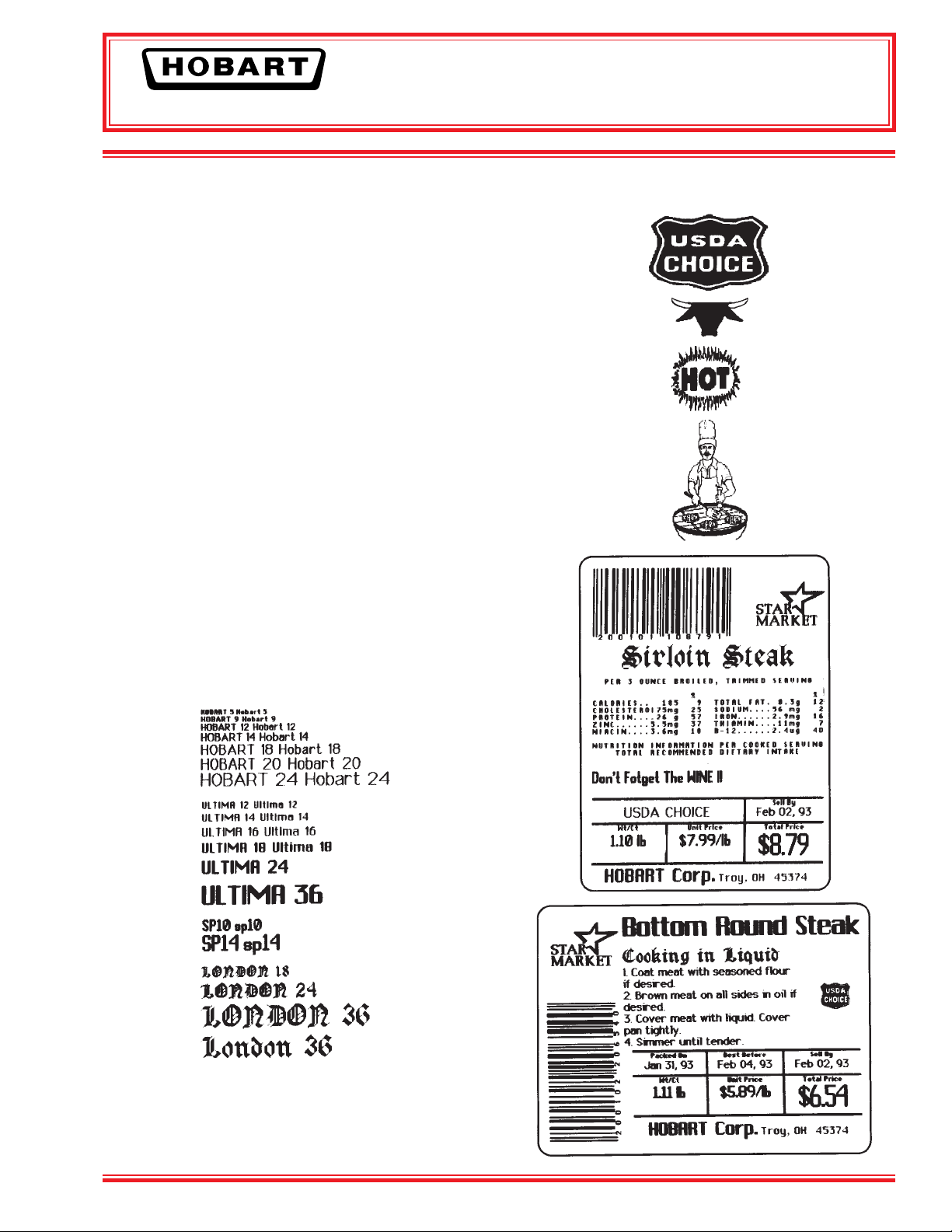

■ Graphics

(Examples)

PRINTING

■ Fonts

F-7634 – Ultima 2000 PLU Prepack Weighing System Page 3 of 8

Page 4

ULTIMA 2000 PLU PREPACK

WEIGHING SYSTEM

LABELS

■ Cartridge label loading system provides fast and

efficient change of label stock or easy label size

change for merchandising

flexibility.

■ 7 label sizes (3 wide widths - 2.25",

4 narrow widths - 1.5")

1.5" Wide ×

1.0

1.5

2.0

3.0

2.25" Wide ×

1.75

2.375

3.0

■ Multiple label types to meet merchandising

requirements. Each item can be assigned a

different label type. The fields that can be printed

on a label are:

Bar code

Store logo

Description – Up to 4 lines

Nutri-template – 2 lines

Header and footer - 8 lines

Body

Expanded text - Up to 37 lines

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Special message – Up to 37 lines

Graphic

Packed on

Sell by

Product life

Store name and address – 2 lines

Weight/count

Unit price

Total price

Tare

Operator ID

Store ID

Any of the fields can be printed on the label

depending on the amount of space available.

The bar code must be printed in the same direction

that the label is issued to insure scanning accuracy.

The Logo can be preprinted or printed by the

system. The label type must be in a legal format.

■ Blank or Customized (preprinted) label stock. Blank

label stock reduces costs with a system-generated

label, including a store logo. Customized labels

enhance eye appeal with

preprinted color logo and lines.

■ Standard or high speed label stock. Increase

productivity 14-20% with high speed printing label

stock depending on label size.

■ Large label roll - 2800 to 4500 labels per roll for

wide labels and 2500 to 6400 for the narrow label.

TOTALS

■ Production totals stored in memory.

– Number of packages up to 9999.

– Number of pounds up to 999999.99.

– Number of dollars up to 999999.99.

– Number of runs up to 9999.

■ Totals grouped and stored by

– Production totals

– Class totals

– Price change totals

– Grand totals

– 7 additional totals types assigned by user

Page 4 of 8 F-7634 – Ultima 2000 PLU Prepack Weighing System

Page 5

ULTIMA 2000 PLU PREPACK

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

SUPERVISOR FUNCTIONS

■ Change product

– Change unit price

– Delete product

– Change tare

– Change shelf life

– Change product life

– Change class

– Change class structure

– Change all price fields

(Price, tare, by-count and fixed weight)

– Change all fields

(Description, UPC numbering system, UPC

number, price, tare, shelf life, product life,

class, graphic, label type and rotation for

primary and secondary printer, special

message, expanded text and nutrifacts)

■ Totals

– View product totals

– View operator totals

– View hourly totals

– Clear all product totals

– Clear one products totals

– Clear one total type for all products

– Clear all operator totals

– Clear all hourly totals

– Clear all totals

– Void product totals

– Void operator totals

– Void hourly totals

– Configure totals type – Up to 7 user defined

total types

– Collect totals via MiniNet II from other Ultima

systems.

■ Reports

– Print product totals for all PLU’s

– Print product totals range

– Print all operator totals

– Print all hourly totals

– Print hourly totals range

– Print all totals reports

– Print product list for all PLU’s

WEIGHING SYSTEM

– Print product list range

– Print product review for all products

– Print product review range

– Print speedkey overlay

– Print operator ID list

– Print all special messages

– Print special message range

– Print all expanded text

– Print expanded text range

– Print all nutrifacts

– Print nutrifacts range

– Print cutting test

■ Backup or Restore

– Backup to cassette or disk

– Backup changes to cassette or disk

– Restore from cassette or disk

– Add changes from cassette or disk

– Update scale via mininet

– Update changes via mininet

– Unmark changed items

– Select data to transfer

– Bad record scan

■ Scale Setup

– Assign operator ID’s

– Assign speedkeys

– Select special fields to print on a label:

Sell by date

Julian sell by

Packed-on date

Julian packed-on

Product life date

Julian product life

Unit price

By count

Weight on by count

UPC number/bar code

2nd UPC check digit

Preprint text names

– Label text names

– Label information:

Default primary label

Default secondary label

Default supervisor label size on continuous

paper

F-7634 – Ultima 2000 PLU Prepack Weighing System Page 5 of 8

Page 6

ULTIMA 2000 PLU PREPACK

WEIGHING SYSTEM

– Set what the operator can modify:

Date and time

Price

By count

Tare

Shelf life

Label type

Fixed weight

Provides security in the operations mode.

– Set date and time

– Set normal scale operation

Collect product totals

Collect hourly totals

Collect operator totals

Sound a beep at stable weight

Countdown mode by packages, weight or value

By count calculation method

Auto-lookup of a product

Number of digits to begin auto-lookup

– Set store and scale ID’s and store name

– Select cassette or disk interface

– Select mininet or ScaleMaster network option

OPTIONS

■ Label cartridge: Additional label cartridges available to allow quick reload of label stock or to ease

the changing of label sizes.

■ XT-Type Keyboard: Optional keyboard that plugs

into the front of the operator display.

Ease in programming large amounts of data.

■ Second remote control panel allows operation of

the system from two convenient locations.

■ Enhanced Memory: Memory can be increased

with 512K or 2MB memory boards. Up to 3

memory boards per system.

■ Control panel posts: Posts are available for the

HWS & W32 wrap stands, ILA index label applier,

NSW & ESW automatic wrappers.

■ Scale Platters: Small or Large heavy gauge

stainless steel platters.

■ Disk Player/Recorder: 3.5" low density disk

player/recorder for efficient file transfer.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

SPECIFICATIONS

Listed by Underwriters Laboratories, Inc.

DESIGN:

Three component modular system consisting of a

scale, controller/printer and operator’s control panel.

Connected by electronic cables, the components

operate as a system to automatically weigh, compute, print and issue labels and collect production

totals data for prepackaged product.

SCALE:

Gray enamel metal construction. Stainless steel

platter.

Configurable for 30 lbs. or 50 lbs. capacity.

CONTROLLER/PRINTER:

Compact, solid-state microprocessor designed with

expandable item capacity. Incorporates a back-up

battery for memory retention up to 100 hours in the

event of an external power failure. Label printer

receives signals from controller to print a thermal,

pressure sensitive label. Cartridge label loading

makes label changing easy.

OPERATOR’S CONTROL PANEL:

Control panel acts as an input device for the Ultima

system.

Alphanumeric LCD display provides operator and

supervisor data for ease of operation. Sealed, flush,

touchtone keyboard is human engineered for operator

efficiency. Audible tone signals positive contact with

keys. Up to two control panels may be used with the

system, mounted in remote locations.

NOTICE: Fluorescent lamp in display panel contains

a small amount of mercury. Please dispose of

according to local, state or federal laws.

ELECTRICAL:

115 V, 60 cycle, single phase. Power for the

system is supplied through a cord and plug on the

controller/printer.

WEIGHT:

Net Shipping

Scale 5.4 6.7

Controller/Printer 24.5 29.7

Operator’s Control Panel

(30 Speedkeys) 3.9 5.4

(102 Speedkeys) 4.9 6.6

Page 6 of 8 F-7634 – Ultima 2000 PLU Prepack Weighing System

Page 7

ULTIMA 2000 PLU PREPACK

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

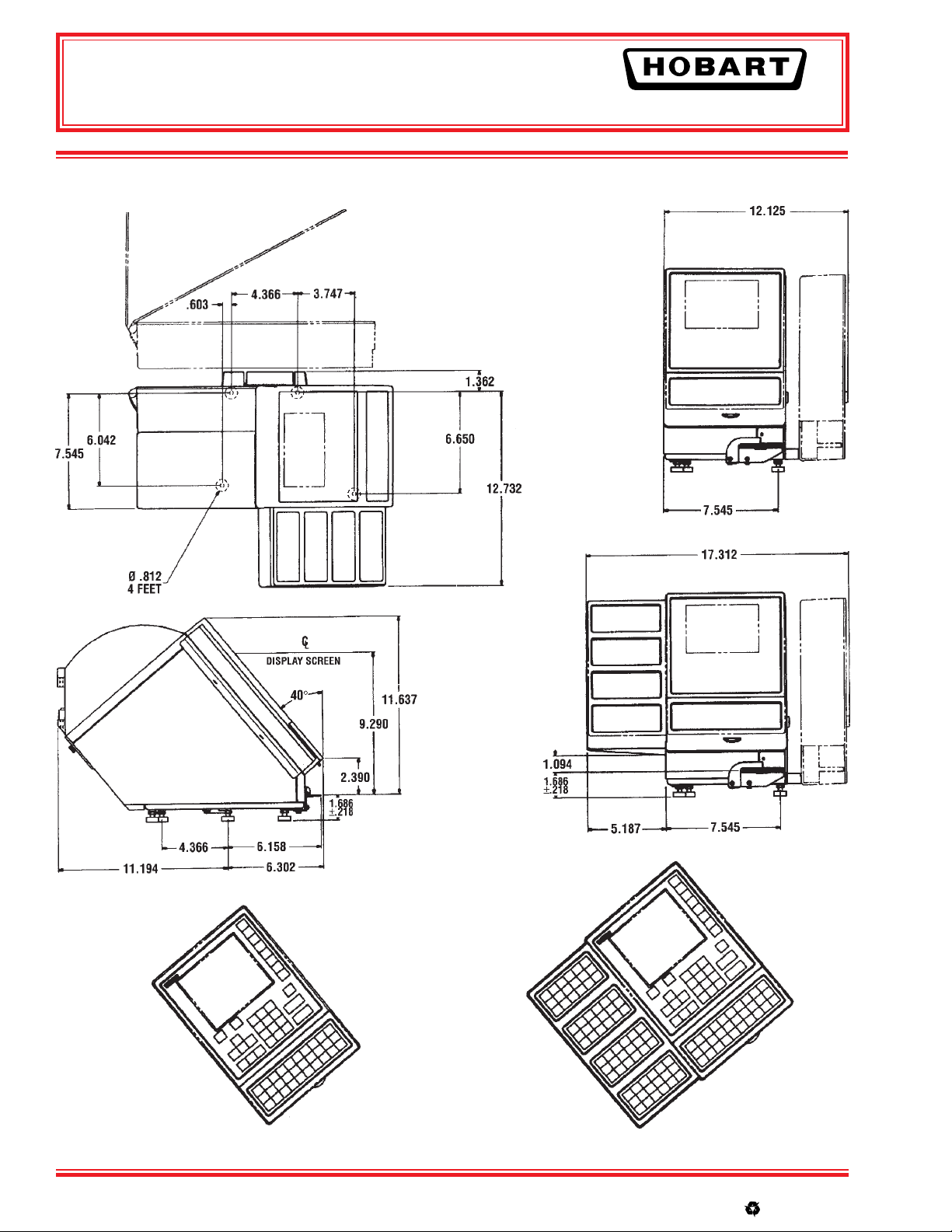

DETAILS AND DIMENSIONS

WEIGHING SYSTEM

F-7634 – Ultima 2000 PLU Prepack Weighing System Page 7 of 8

Page 8

Printed On Recycled Paper

ULTIMA 2000 PLU PREPACK

WEIGHING SYSTEM

DETAILS AND DIMENSIONS

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

As continued product improvement is a policy of Hobart, specifications are subject to change without notice.

Page 8 of 8 F-7634 – Ultima 2000 PLU Prepack Weighing System

F-7634 (REV. 7/06) LITHO IN U.S.A. (H-01)

Loading...

Loading...