Page 1

Ultima System

Operator Manual

COP GMO Product Service

Device # Models

Ultimc4-1 U2000CP1 Control Panel (30) ML – 28811

Ultimc2-1 U2000CP2 Control Panel (30) ML – 28821

Ultimc3-1 U2000CP3 Control Panel (102) ML – 28810

Ultimc1-1 U2000CP4 Control Panel (102) ML – 28820

Ultimp1-1 U2000P1 Printer ML – 28812

Ultimp2-2 U2000P2 Printer ML – 28819

Ultimsp-1 U2000P3 2

Ultimsa-1 U2000S1 Stand Alone Scale ML – 28808

Ultimsn-1 U2000S2 NSW Scale ML – 28816

Ultimsc-2 U2000S3 Scale Conveyor ML – 28859

Description Reference #

nd

Printer ML – 28813

701 S. RIDGE AVENUE

TROY, OHIO 45374

www.hobartcorp.com

F-34319 (10-99)

Page 2

Page 3

Ultima System

Table of Contents

INTRODUCTION...........................................................................................................................1-2

FCC Note............................................................................................................................................1-3

Verify Correctness of Weight & Price...........................................................................................1-3

Operator Manual Overview...........................................................................................................1-3

UNDERSTANDING THE SYSTEM...........................................................................................2-2

Electrical Connections .....................................................................................................................2-2

Communication Connections.........................................................................................................2-3

Using the Console.............................................................................................................................2-3

The Keypad ..................................................................................................................................2-4

User Display.................................................................................................................................2-6

Loading Labels..................................................................................................................................2-7

Removing and Replacing the Label Cassette............................................................................2-11

START-UP PROCEDURES...........................................................................................................3-2

Powering Up the System.................................................................................................................3-2

Setting the Date & Time ..................................................................................................................3-2

Understanding the Start a Run Screen .........................................................................................3-3

Verifying Zero Weight................................................................................................................3-4

Rezeroing the Scale .....................................................................................................................3-4

Weigh Types.................................................................................................................................3-4

Totals Types..................................................................................................................................3-5

Selecting Weigh and Totals Types ...........................................................................................3-5

Entering Operator IDs................................................................................................................3-5

HELP Key Functions........................................................................................................................3-6

Help on "F" Keys..........................................................................................................................3-6

About the Keyboard ...................................................................................................................3-6

Basic Help.....................................................................................................................................3-6

Moving Through the System.....................................................................................................3-7

Accessing the On Screen Library...................................................................................................3-7

USING THE ULTIMA SYSTEM..................................................................................................4-2

Weighing, Printing and Applying (Auto Weigh).......................................................................4-2

Auto Repeat.......................................................................................................................................4-3

Weighing, Printing and Applying (Semi Auto Weigh)............................................................4-4

Semi Auto Repeat.............................................................................................................................4-5

Weighing and Printing (Manual Weigh) .....................................................................................4-5

Manual Repeat..................................................................................................................................4-6

Copyright Hobart Corporation 1999

Page 4

Ultima System

Printing Totals and Subtotals.........................................................................................................4-6

Setting the Countdown ...................................................................................................................4-8

Entering the Sell By or Best Before Dates ..................................................................................4-10

Changing Product Information (Temporarily).........................................................................4-12

Using Forced Price.........................................................................................................................4-13

Using Forced Tare..........................................................................................................................4-14

Using Platter Tare...........................................................................................................................4-15

CLEANING AND MAINTAINING YOUR SYSTEM............................................................5-2

Hygiene Requirements for Cleaning and Sanitizing.................................................................5-2

Cleaning the Printhead....................................................................................................................5-3

TROUBLESHOOTING..................................................................................................................6-2

Reviewing System Errors................................................................................................................6-2

INDEX................................................................................................................................................7-2

ii

Page 5

Chapter One: Introduction

♦ Introduction

♦ FCC Note

♦ Verify Correctness of Weight & Price

♦ Operator Manual Overview

Ultima System

1 - 1 Introduction

Page 6

Ultima System

PL-41341-1

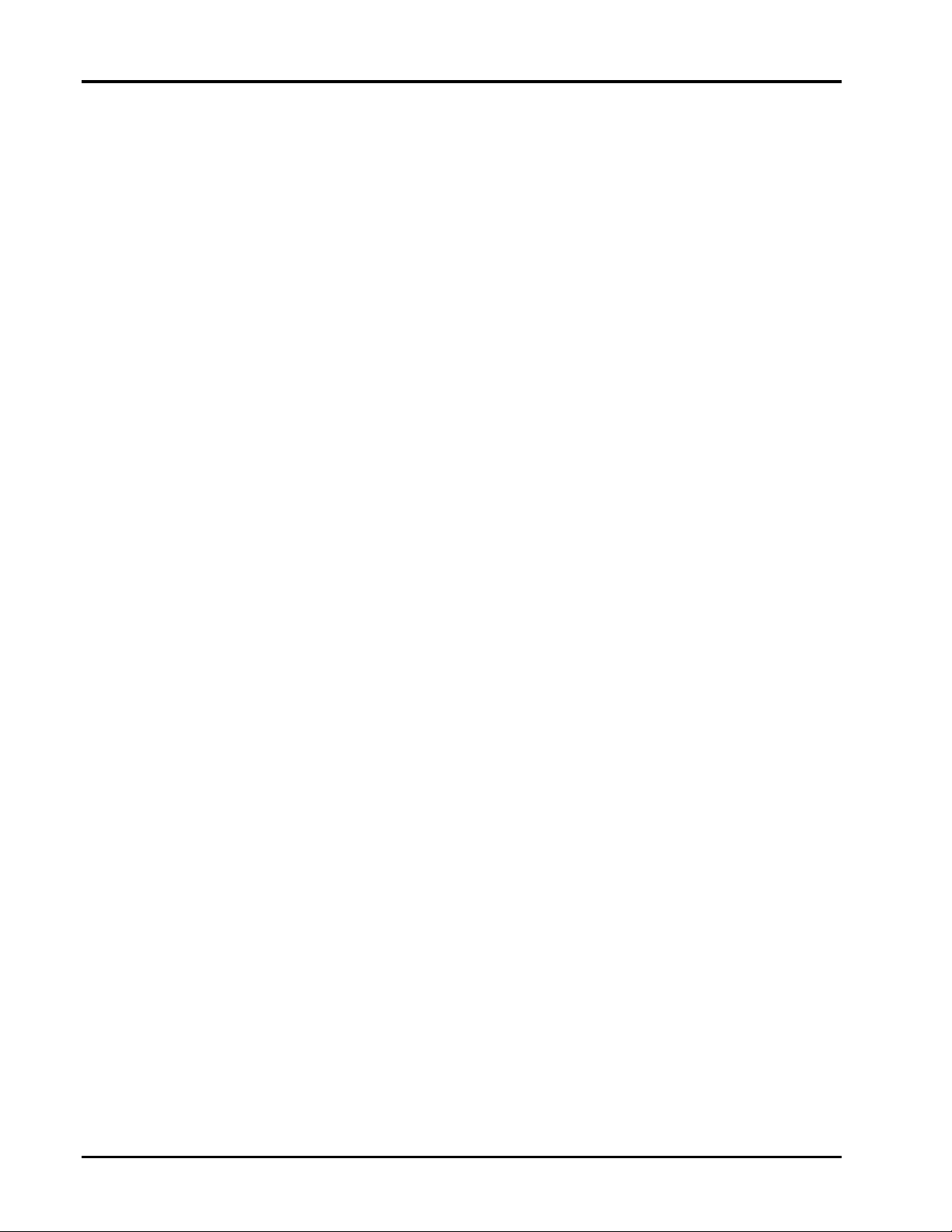

FUNCTION KEYS

SPEED KEYS

Introduction

The Ultima Scale Printer System can handle a broad variety

of products for meat, produce, fish, cheese, or bakery

departments. It functions as a prepack system with Hobart

wrapping and labeling equipment. It gives you

merchandising capabilities with multiple fonts, graphics,

and label types and allows for flexibility in label design.

Ultima 2000

The easy to use control panel allows for productive

operation. All necessary operator data appears on the screen

and Function Keys (F1-F8) provide easy access to PLU

information. Speed Keys can be used for the most frequently

used PLUs. An optional panel is available with 72 additional

Speed Keys.

This Operator Manual describes product weighing and label

printing. The companion Supervisor Manual covers

programming and setup.

Introduction 1 - 2

Page 7

Ultima System

FCC Note

Verify Correctness of

Weight & Price

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference; in

which case, the user will be required to correct the

interference at his own expense.

Verification of information on labels should be made

routinely. Check the multiplication of price-per-pound times

weight, and check the indicated weight against printed

weight. Weigh the same package several times to verify

consistency. Keep in mind that some packages which weigh

near the middle of the .01 lb. increment will normally vary

up or down by .01 lb. Greater variation than .01 lb. indicates

a need for adjustment of the system. In such cases, or

whenever necessary, contact your authorized Hobart service

representative.

Operator Manual

Overview

This manual will use the following methods to explain

keystrokes and data entry procedures:

♦ The word PRESS means to press a key on the Control

Panel.

♦ The word TYPE means to press a series of keys on the

Control Panel followed by the [ENTER] key.

♦ The word SELECT means to choose an item from the

display.

♦ The word ENTER means to press the [ENTER] key on

the Control Panel. Be aware that, in normal operation,

the [ENTER] key and [DOWN ARROW] key perform

the same function.

♦ Words in uppercase enclosed in brackets (for example

[ENTER]) represent specific keys.

1 - 3 Introduction

Page 8

Ultima System

The following special instructions are used in the manual:

☛ Note

A note is information that you need to know, but it is not an

actual step in the procedures.

✎ Tip

A tip is additional information that may be useful when you

are using the system.

Look At This

Look At This is information to alert you that you may be

doing something that will permanently alter your system.

Introduction 1 - 4

Page 9

Chapter Two: Understanding the System

♦ Electrical Connections

♦ Communication Connections

♦ Using the Console

• The Keypad

• User Display

♦ Loading Labels

♦ Removing and Replacing the Label Cassette

Ultima System

2 - 1 General Information

Page 10

Ultima System

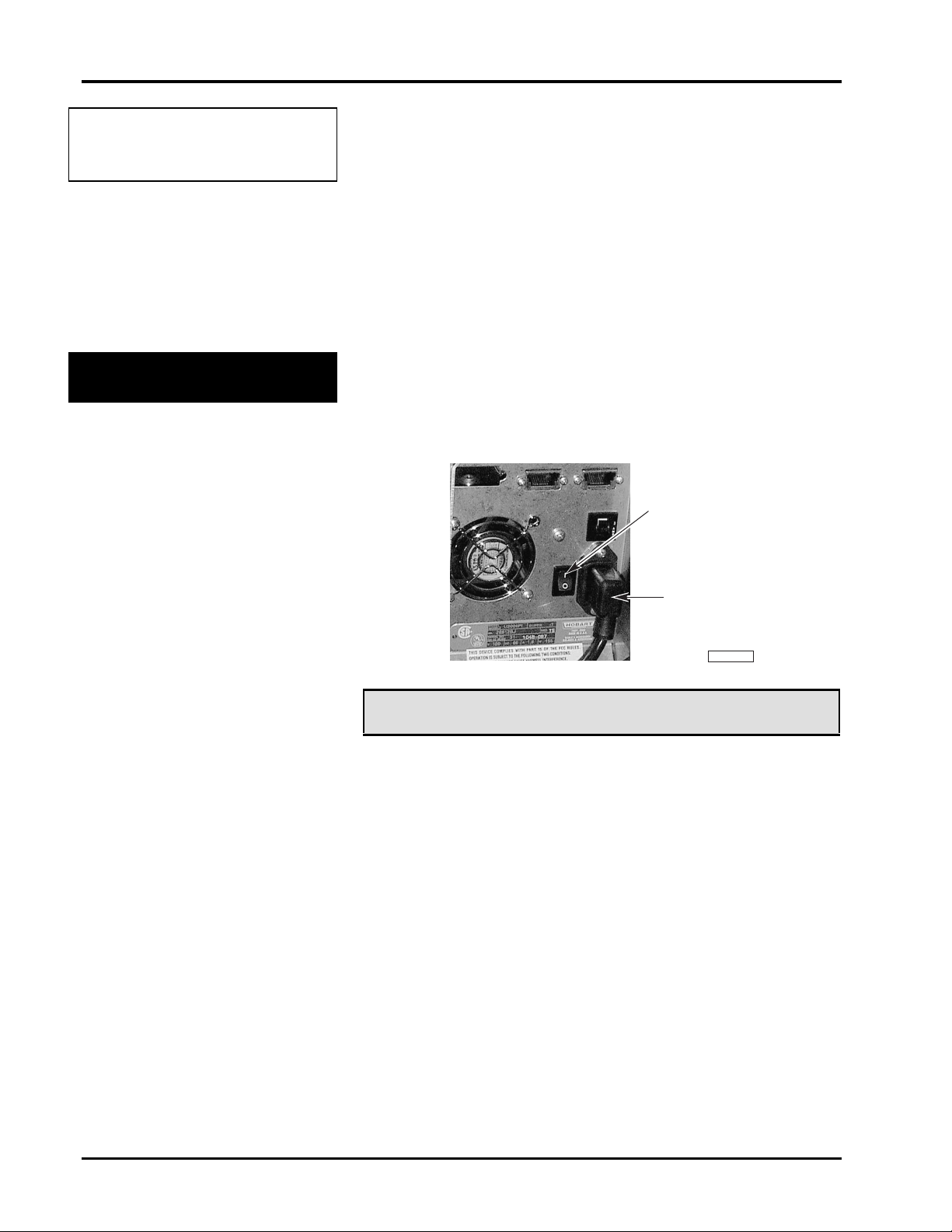

PL-41340-1

POWER CORD

POWER SWITCH

Understanding the

System

Electrical Connections

Utilizing memory from 1 MB expandable to 6 MB, the

system can store information on thousands of products. This

information includes NutriFacts and Safe Handling

instructions (which enable you to meet labeling law

requirements), Expanded Text (which is used for

Ingredients), Health Tips, Meal Planners, Recipes and

Cooking Instructions, as well as, Merchandising Graphics.

The Ultima System should be installed or moved only by

qualified Hobart Service Technicians. It can operate in a

temperature range from 32˚F to 104˚F (0˚C to 40˚C).

A Power Cord and Main Power Switch are located at the

back of the printer. An electric power of 120 volts, 60Hz,

Phase 1 (3-wire plus ground) is required. The Main Power

Switch turns the system ON (I) and OFF (O).

☛ Note

The POWER key on the console is used to turn the User

Display on or off only. This does not impact the system

power. The Power key should be used at the end of the day,

not the Main Power Switch.

General Information 2 - 2

Page 11

Ultima System

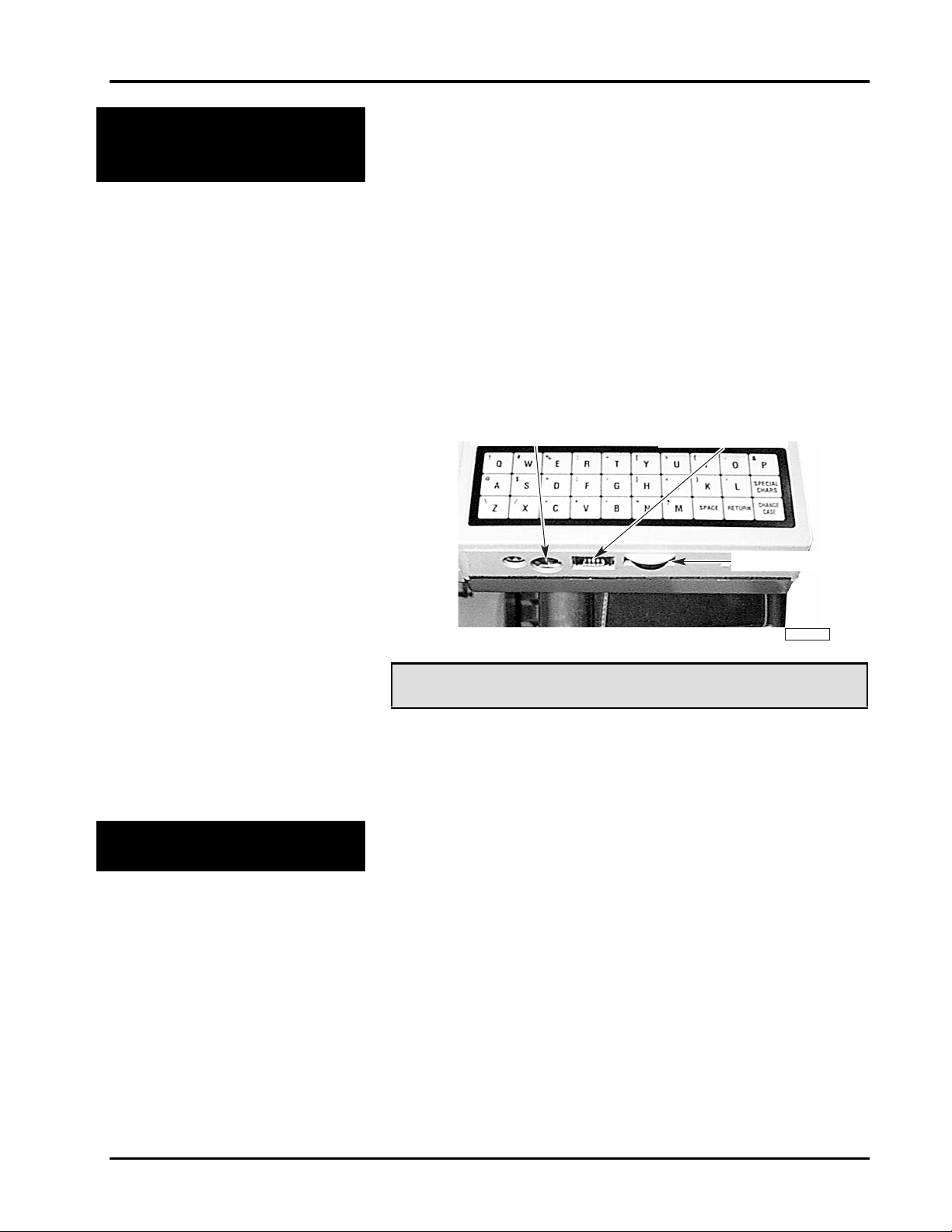

PL-41347-1

EXTERNAL DISK DRIVE

CONTRAST KNOB

IBM–AT/PS KEYBOARD

yp

Communication

Connections

In addition to the electrical connections, there are up to four

(4) additional communication connections. There are several

ports which can be configured for peripherals.

At the rear of the printer:

♦ Disk Player/Recorder & Cassette Player/Recorder

(RS232)

♦ Parallel Port for Printer (80 column Dot Matrix) –

Optional

♦ RJ-11 Jack for RS-485 Communications (ScaleMaster)

♦ RJ-45 Jack for Ethernet 10BaseT Connector (TCP/IP)

(Wireless TCP/IP – Symbol wireless Ethernet card)

At the front of the printer:

♦ External Disk Drive or Secondary Printer (MODNET)

♦ IBM-AT/PS keyboard

Using the Console

☛ Note

You can use an IBM-AT/PS keyboard in place of the

keypad. To purchase the keyboard kit or the interface cable,

contact your local Hobart Representative.

The console consists of:

♦ User Display - displays all information to the user.

♦ Ke

♦ Speedkey Panel (Optional) - adds 72 additional

ad - enables you to enter information into any field.

Speedkeys.

2 - 3 General Information

Page 12

Ultima System

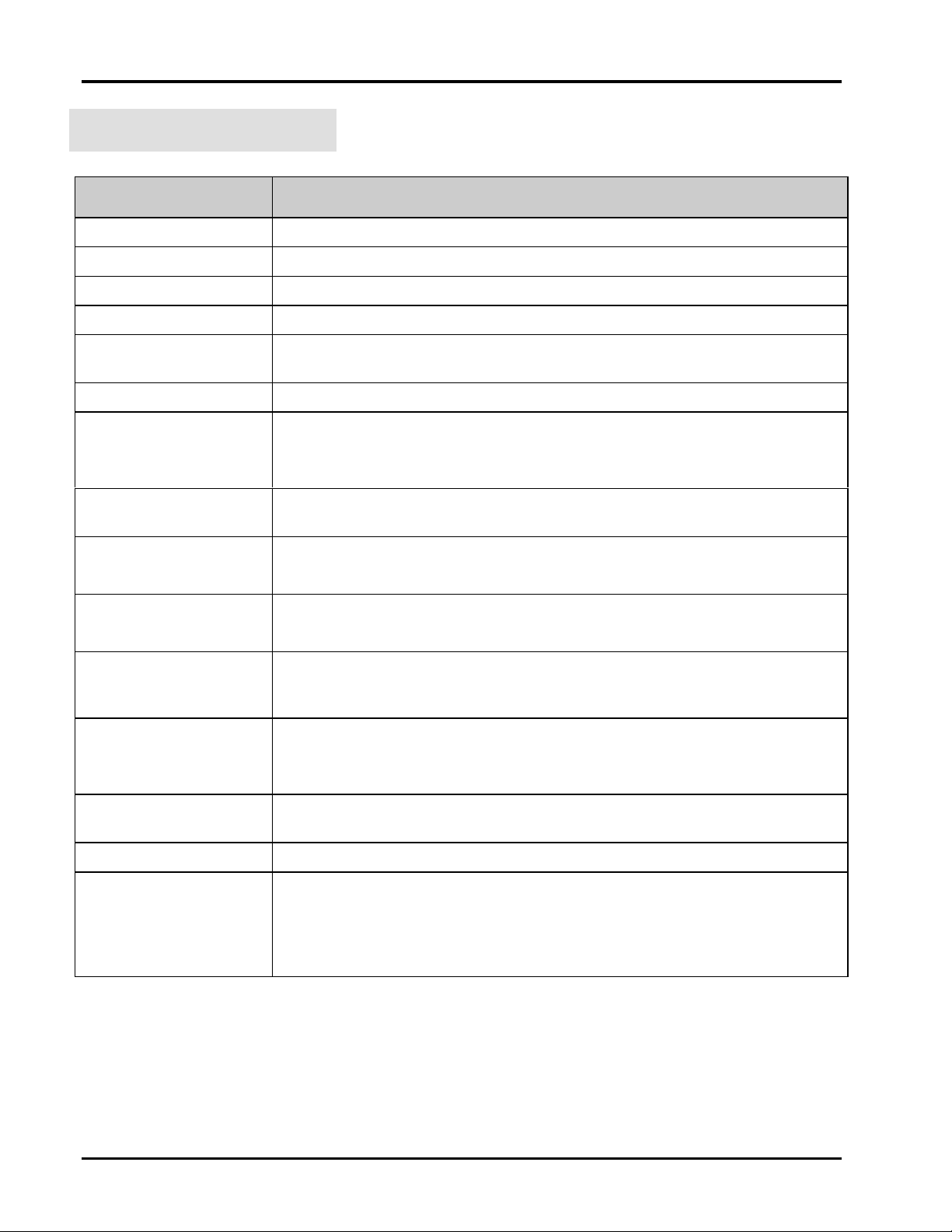

The Keypad

Refer to the following table for specific key descriptions.

Key/Highlight Function

POWER Turns the screen and the keyboard ON/OFF.

Function Keys (F1-F8) Enables you to make selections from the menu screens.

Numeric Keypad Enables you to enter numeric data.

BACKSPACE Enables you to remove the character to the left of the cursor.

CLEAR

Enables you to reset a numeric field to zero. This key is not active in a text

field.

ESCAPE Enables you to return to the previous screen.

PRINT Enables you to print a label or report.

NOTE: This is only available in specific modes; Manual Weigh,

Manual Repeat and Supervisor.

ENTER

Enables you to accept the selected data and advance to the next field or

screen.

PREV (Previous) Moves you back one page.

NOTE: This can also be used to print Subtotals.

NEXT Moves you to the next page.

NOTE: This can also be used to print Totals.

ARROW KEYS UP and DOWN Arrow Keys enable you to move the cursor from field-to-

field or LEFT and RIGHT Arrow Keys enable you to move the cursor

from character-to-character within a field.

SAVE/RECALL

Press this key to have the system remember a series of keystrokes which

can be recalled later by entering a reference number (Macro ID).

NOTE: This key should be used in Supervisor mode only.

SUPER MENU

Enables you to access the Supervisor Menu.

ON/OFF

REZERO Enables you to set the scale to 0.00 pounds/0.000 grams.

HELP

Enables you to access the Help Screens. The system is equipped with

context sensitive Help Screens to assist you in quick, efficient operation.

From the Run Screen in the Operate mode, it enables you to access the On

Screen Library and select a PLU. Refer to the Glossary for a complete

description of the On Screen Library.

General Information 2 - 4

Page 13

Key/Highlight Function

Ultima System

ALPHA

CHARACTERS

SPECIAL CHARS. Press this key to type a special character (found in the upper left corner of

CHANGE CASE

RETURN

SPACE Enables you to type (add) a space between words and characters.

Enables you to enter upper case or lower case alpha characters while in a

text field.

each alpha-key). You must press Special Chars. For each special character

you type.

Enables you to switch between Upper or Lower case. You must press

Change Case each time you want to change the case in the text field.

Advances the cursor to the next field or inserts the End-of-Line in a text

field.

✎ Tip

The optional keyboard interface cable is REQUIRED for

programming on a remote keyboard.

The optional IBM AT/PS keyboard is helpful when entering

large amounts of data at one time.

2 - 5 General Information

Page 14

Ultima System

User Display

The Ultima System’s User Display has several common

screen highlights that assist you in interacting with the

system. The highlights act the same regardless of your

screen location.

Highlight Description

Active Field A box surrounding text or numeric fields

indicates that the field is active. If you

begin typing from the keyboard or

control panel, data is entered into this

field.

Bar Cursor

Block Cursor

Changeable Fields If a field has a dotted line (.............)

Grayed Fields

A bar cursor (❚) indicates that the field is

a text field.

A block cursor (■) indicates that the field

is a numeric field.

under it, the field can be changed or

edited.

If a field or selection is grayed, it is not

available for that particular screen or

transaction.

Prompt Line The Prompt Line is white text, reversed

out of a black box. It is typically located

at the bottom portion of the screen. It

prompts you on what your next step

should be. (Depending on your

configuration, it may be black text

reversed out of a white box.)

Screen Title The Screen Title identifies the screen

name and function that you are

attempting to complete. It is typically

located at the top left corner of the

screen.

General Information 2 - 6

Page 15

Ultima System

PL-41338

PL-41339

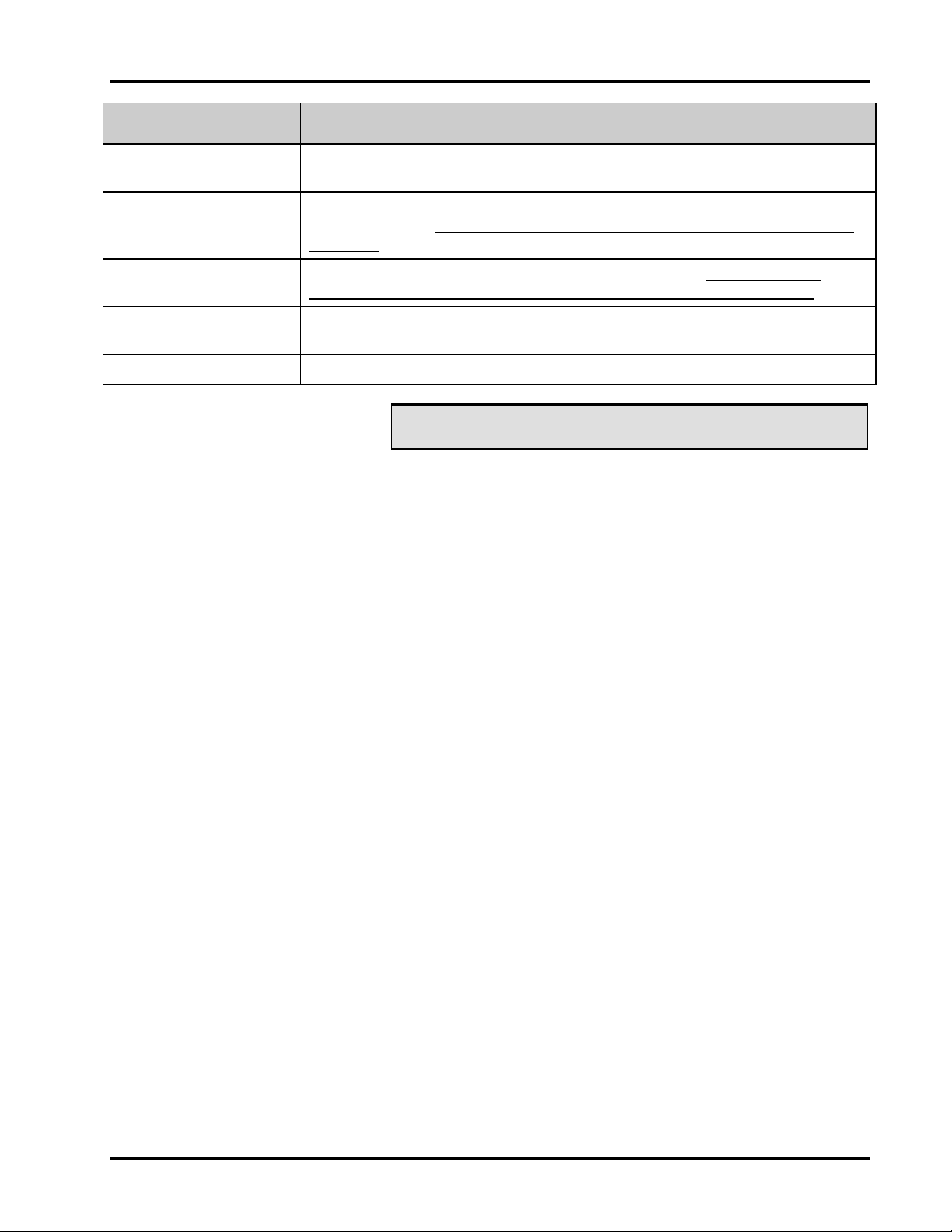

Loading Labels

In order to accommodate different label stock widths the

system uses different label cassettes.

The Ultima 2000 uses a cassette for standard label stock and

another cassette for narrow label stock.

☛ Note

If you want to change label stock, contact your local Hobart

Service Office to make the necessary adjustments.

Your Hobart Representative can create custom labels to

accommodate your unique merchandising needs.

The Ultima 2000 uses:

• A Standard Label Cassette for standard (2.25”) wide

label stock.

• A Narrow Label Cassette for narrow (1.5”) wide label

stock.

2 - 7 General Information

Page 16

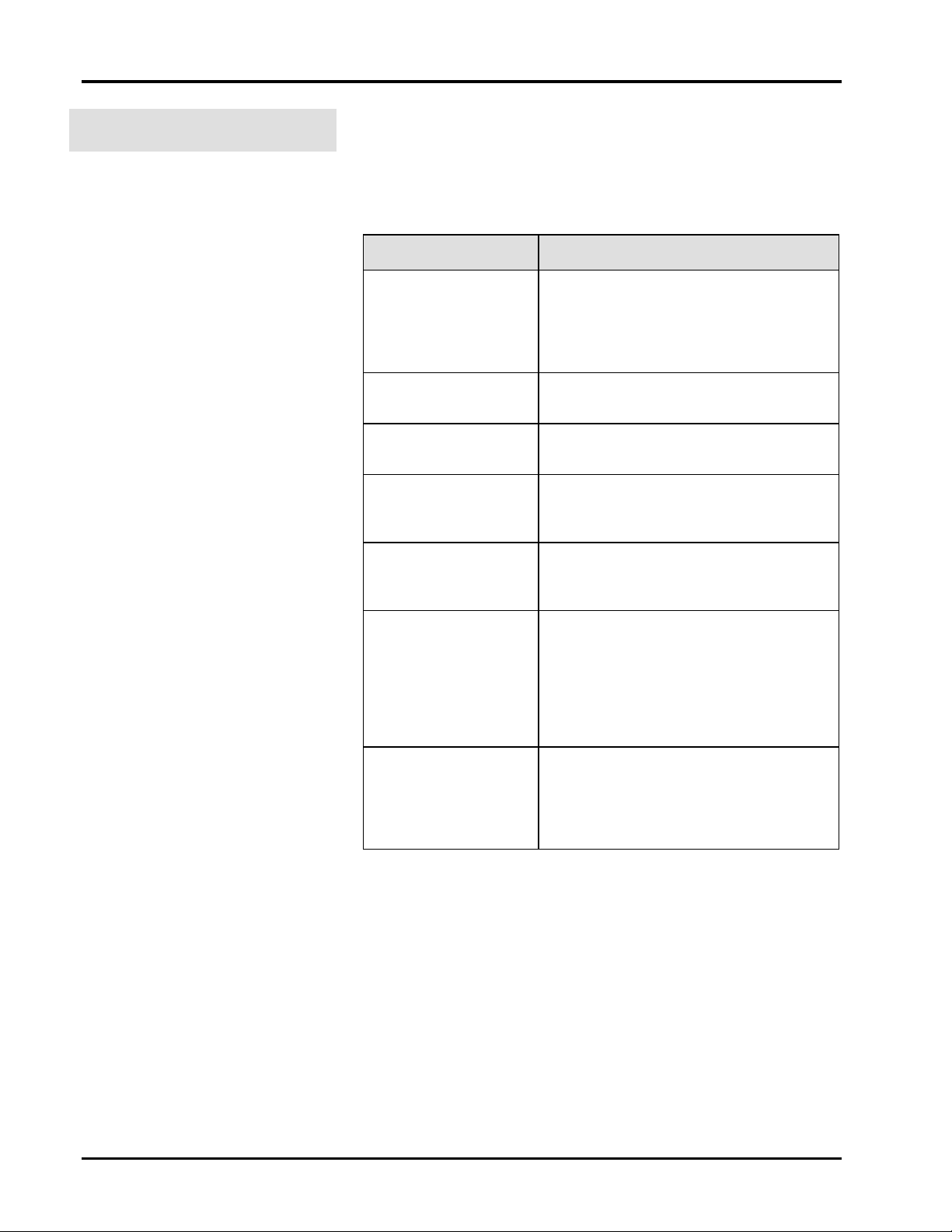

Ultima System

PL-41342-1

DOOR LATCH

PRINTHEAD LEVER

(UNLOCKED POSITION)

✎ Tip

To promote cleanliness and sanitation, Hobart recommends

you do not remove the label cassette to load labels.

☛ Note

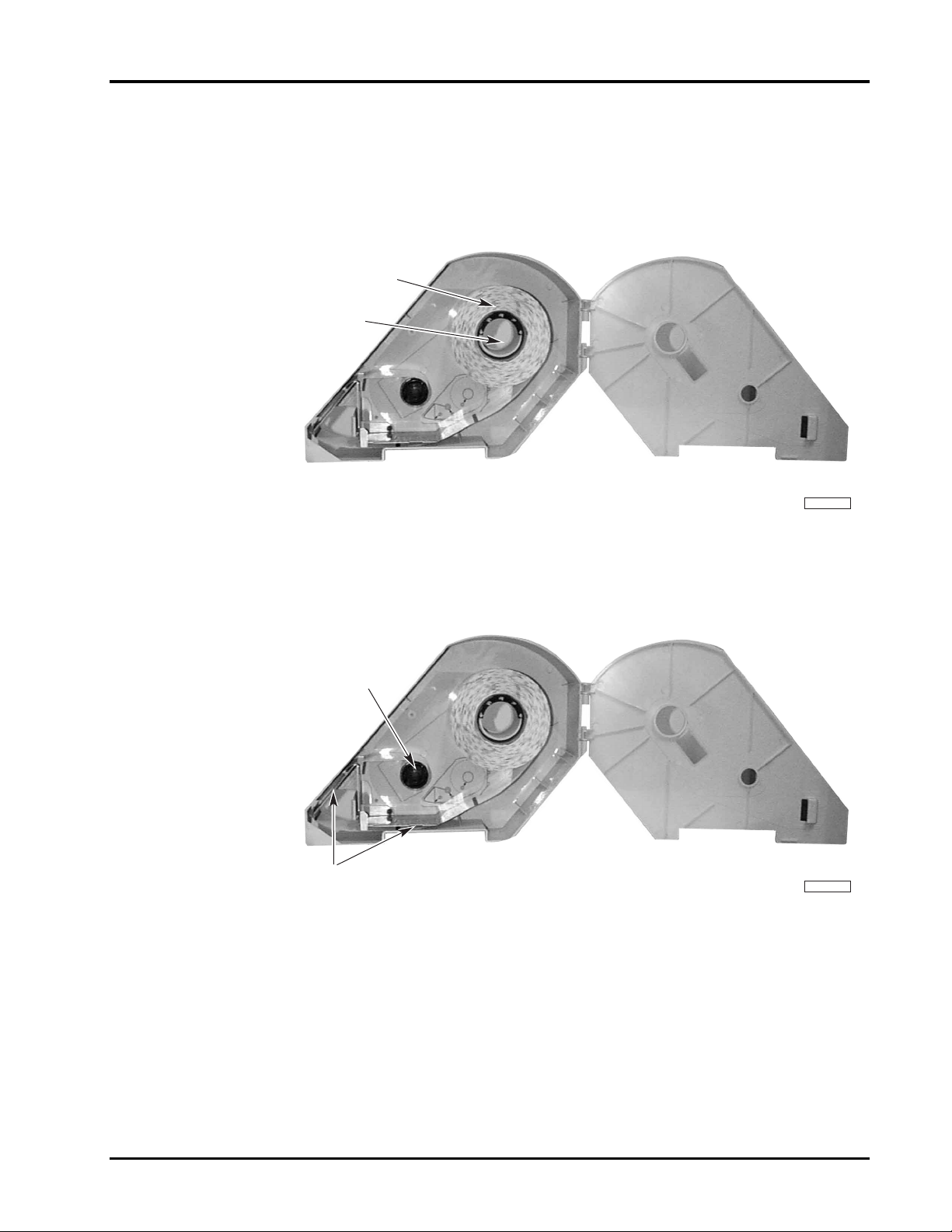

Labels load the same for a narrow cassette and standard

cassette. The following are photos of the standard cassette.

To load labels:

1. Open the label cassette door.

2. Rotate the printhead lever clockwise to the unlocked

position.

3. Push the door latch in while opening the cassette door

from the bottom.

General Information 2 - 8

Page 17

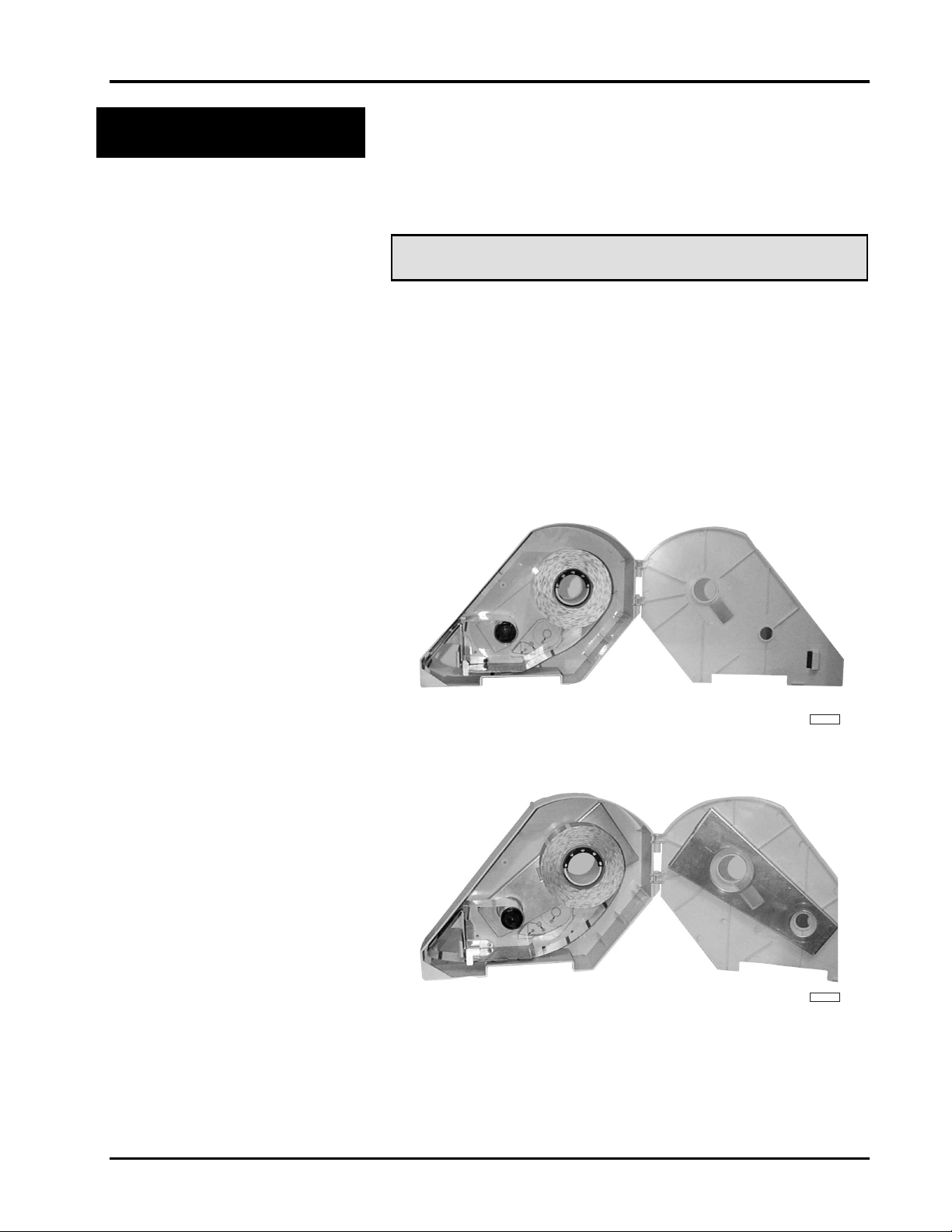

Ultima System

PL-41338-1

LABEL ROLL

HUB

PL-41338-2

TAKE-UP

REEL KNOB

PAPER GUIDES

4. Remove labels from the first eighteen (18) inches of the

label roll. This creates a leader which attaches to the

take-up reel.

5. Place the label roll on the hub in the cassette. (The leader

feeds from the bottom of the roll in a clockwise

direction.)

6. Thread the leader around the paper guides, as shown on

the label instructions on the inside of the cassette.

7. Pull out the take-up reel knob.

2 - 9 General Information

Page 18

Ultima System

PL-41338-3

TAKE-UP REEL

LEADER

CASSETTE

HOUSING

PL-41344-1

PRINTHEAD

LEVER

(LOCKED POSITION)

8. Fold about 1/2” of the leader and insert the leader into

the slot on the take-up reel.

9. Align the leader until it is straight.

10. Push in the take-up reel knob.

11. Wind the remaining leader without labels onto the

take-up reel.

12. Tighten the take-up reel by turning the knob clockwise.

Be sure the leader is flush against the cassette housing.

13. Close the cassette door.

14. Rotate the printhead lever counterclockwise to the

locked position. One or two blank labels are issued as

the system determines the size of the labels.

Note

☛

You should clean the printhead and pressure roller when

refilling the label supply. Refer to Cleaning the Printhead for

detailed procedures.

General Information 2 - 10

Page 19

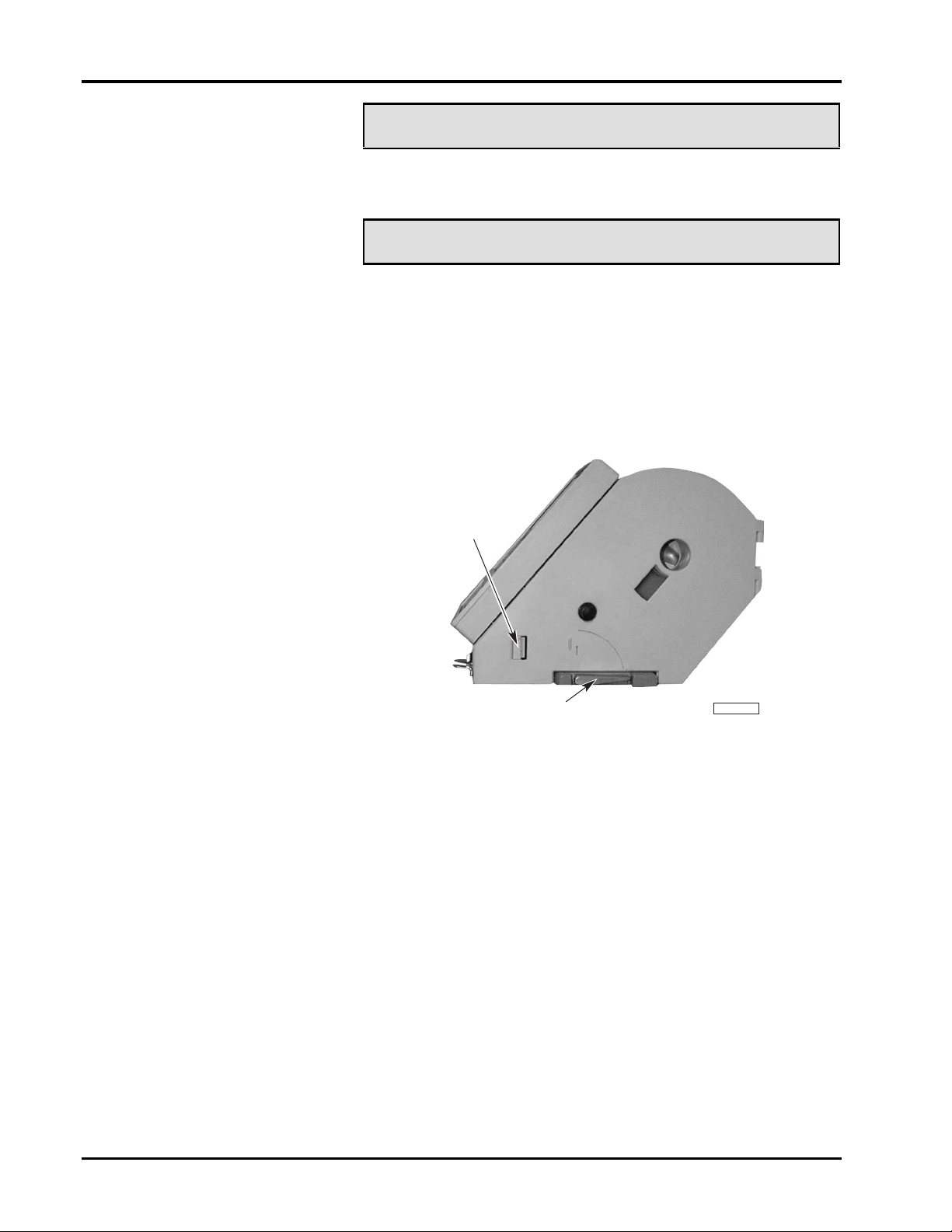

Ultima System

PL-41343-1

ROLLER

CASSETTE

SUPPORT

TAKE–UP SHAFT

CASSETTE

GUIDE

PRINTHEAD

Removing and

Replacing the Label

Cassette

To remove label cassette:

1. Rotate the printhead lever clockwise to the down

position.

2. Push the label cassette up while pulling it towards you.

To replace label cassette:

1. Align the cassette guide with the open base at the

bottom of the cassette.

2. Carefully slide the cassette into place making sure the

cassette is aligned with the cassette support and take-up

shaft. Also, the label leader should be in between the

roller and printhead.

3. Rotate the printhead lever counterclockwise to the

locked position. One or two blank labels are issued as

the system determines the size of the labels.

2 - 11 General Information

Page 20

Page 21

Chapter Three: Start-Up Procedures

♦ Powering Up the System

♦ Setting the Date & Time

♦ Understanding the Start a Run Screen

• Verifying Zero Weight

• Rezeroing the Scale

• Weigh Types

• Totals Types

• Selecting Weigh and Totals Types

• Entering Operator IDs

♦ HELP Key Functions

• Help on “F” Keys

• About the Keyboard

• Basic Help

• Moving Through the System

♦ Accessing the On Screen Library

Ultima System

3 - 1 Start-Up Procedures

Page 22

Ultima System

Start-up Procedures

Powering Up the

System

In this section, you will learn how to:

♦ Power up the System

♦ Set the Date and Time (on Initial Setup)

♦ Check the Date and Time

♦ Understanding & Using the Start a Run Screen

To power up the system:

1. Verify that Power Cord is connected and Power Switch

is turned on.

2. Remove any objects from the scale platter/weigher.

3. At the console, PRESS [POWER] to begin the Power-up

Sequence. The System Screen displays Power-up test in

progress. The Start a Run Screen displays when the scale

is ready. There may be a slight delay (depending on

room temperature) until the Zero weight appears on the

screen.

☛ Note

Power Key on console should be used to turn console on

and off at the beginning and at the end of each day, not the

Main Power Switch.

Setting the Date &

Time

QUICK STEPS

From the Start a Run Screen:

1. PRESS [F1]

2. TYPE the Current Date

3. PRESS [ENTER] or [▼]

4. TYPE the Current Time

and PRESS [F1] - If Needed

5. PRESS [ESC]

To set the Date and Time:

1. From the Start a Run Screen, PRESS [F1].

2. With the cursor in the Date field, TYPE the current Date.

Enter the Date as a six-digit number (MM/DD/YY).

Start-Up Procedures 3 - 2

Page 23

Ultima System

3. PRESS [ENTER] or [DOWN ARROW (▼)] to move the

cursor to the Time field.

4. Enter the Time as a four-digit number (HH:MM). If you

need to change AM or PM, PRESS [F1] to select the

correct time of day.

5. PRESS [ESC] to save the changes and return to the Start a

Run Screen.

Understanding the

Start a Run Screen

☛ Note

If designated during Scale Setup, any operator may be

permitted to change the Date/Time.

The Start a Run Screen is the initial Operator location. All

operations begin and end from this screen. The following

lists the keystrokes you can use to move around on the Start

a Run Screen:

♦ To move the cursor use the UP ARROW (▲) and DOWN

ARROW (▼) Keys.

♦ To move the cursor between Weigh type and Total type,

use the LEFT ARROW (

Keys.

♦ The “active” column is shown in Reverse Video (White

letters on a Black field).

♦ PRESS [ENTER] to select the task.

) and RIGHT ARROW ( )

☛ Note

If your system requires an Operator ID, the Operator ID

block displays at the bottom right corner of the Start a Run

Screen.

3 - 3 Start-Up Procedures

Page 24

Ultima System

Verifying Zero Weight

Rezeroing the Scale

Weigh Types

Verify zero weight before you begin operation. To verify

zero weight, from the Start a Run Screen, check the top, left

side of the screen to see if Zero Weight: 0.00 lb displays. Zero

Weight: 0.00 lb must display before you enter a PLU.

If Zero Weight: 0.00 lb doesn’t display on the screen, you must

REZERO the scale.

To rezero the scale:

1. Remove any item(s) from the weighing mechanism.

2. PRESS [REZERO].

The following list gives you a brief overview of how each

Weigh Type selection functions within an operation. Use the

UP ARROW (▲) and DOWN ARROW (▼) keys to move the

cursor to the Weigh Type you require.

Weigh Type Description

Auto Weigh Enables you to weigh, print

and apply a label. If used

with a fully automatic

system, the package is also

wrapped.

Auto Repeat Enables you to print

duplicate labels

automatically while a fully

automatic system is running.

Semi-Auto Weigh

Semi-Auto Repeat

Manual Weigh Enables you to control label

Manual Repeat

Countdown Enables you to specify the

Enables you to weigh, print

and apply a label on prepackaged products.

Enables you to print

duplicate labels

automatically.

generation. You must PRESS

[PRINT] for the system to

issue a label.

Enables you to continually

duplicate labels.

amount to be labeled by

weight, value, or packages

and the number of cartons.

Start-Up Procedures 3 - 4

Page 25

Ultima System

Totals Types

Selecting Weigh and Totals

Types

All Totals Types, except Production, are created by the

Supervisor and enable reporting of totals information. For

example, you could keep track of items on sale this week.

The list below provides you a list of additional examples for

Totals Types you may want to track.

♦ Production

♦ Ad Items *

♦ Manager’s Specials *

♦ Coupon Items *

Use the ARROW Keys to move the cursor to the Totals Type.

☛ Note

* Totals Types marked with an asterisk are examples only.

To select the weigh and totals type:

1. PRESS the [UP ARROW (▲)] or [DOWN ARROW (▼)]

key to select your choice of Weigh Types.

2. PRESS the [RIGHT ARROW (

to the Totals Type column. Pressing the [LEFT ARROW

(

)] key will move you back to the Weigh Type column.

3. PRESS the [UP ARROW (▲)] or [DOWN ARROW (▼)]

key to select your choice of Totals Types.

4. PRESS [ENTER] to select the Weigh and Totals Type

required for your operation. The Run Screen displays.

)] key to move the cursor

Entering Operator IDs

QUICK STEPS

From the Start a Run Screen:

1. TYPE your Operator ID

2. PRESS [ENTER]

Although you selected a Weigh Type and Totals Type, you

may also be required to enter your identification number

prior to beginning a task.

To enter the Operator ID:

1. From the Start a Run Screen, type your Operator ID

number.

2. PRESS [ENTER].

3 - 5 Start-Up Procedures

Page 26

Ultima System

HELP Key Functions

Help on “F” Keys

The system is equipped with context sensitive Help Screens

to assist you in quick, efficient scale operation. The HELP

Function has four (4) levels of assistance.

♦ Help of “F” Keys

♦ About the Keyboard

♦ Basic Help

♦ Moving Through the System

☛ Note

In addition to assisting you with scale operation, you can

also press HELP to access the On Screen Library.

To access Help Screens from the Start a Run Screen:

1. PRESS [HELP].

2. PRESS desired function key [F1 - F4].

3. PRESS [ESCAPE] to exit Help Screen.

By pressing [F1] on the Help Screen, you get an explanation

of the functions that can be performed when you select the

various “F” Keys available for the current function (i.e., the

function for which you pressed HELP). An explanation of

Date/Time is the only “F” Key available on that screen.

About the Keyboard

Basic Help

By pressing [F2] to select “About the Keyboard,” you get a

detailed explanation of the following keys:

♦ ENTER

♦ ESCAPE

♦ ARROW KEYS

♦ BACKSPACE

♦ CLEAR

♦ POWER

When you press [HELP], the default automatically sends

you to the Basic Help Screen(s) for the selected function or

field. As you might suspect, Basic Help gives you a brief

description of the function or selected field, including notes

to help you process the transaction better. From any other

HELP selection, PRESS [F3] to access Basic Help.

♦ PRINT

♦ NEXT

♦ REZERO

♦ SAVE/RECALL

♦ SPEEDKEYS

♦ SUPER MENU ON/OFF

Start-Up Procedures 3 - 6

Page 27

Ultima System

Moving Through the System

Accessing the On

Screen Library

QUICK STEPS

From the Run Screen:

1. PRESS [HELP]

2. PRESS [▲] or [▼]

3. PRESS the [RIGHT

ARROW]

4. PRESS [▲] or [▼] - Repeat

Step 4 as needed

5. PRESS [ENTER]

6. Weigh as applicable

Moving Through the System is found by pressing [F4] while

in the HELP mode. When you select [F4], you get an

explanation of how to:

♦ Return to the Previous Screen

♦ Execute a Forced Operator Log-on

♦ Access the Supervisor Menu

To access the On Screen Library:

1. From the Run Screen, PRESS [HELP]. The On Screen

Library displays with Class Numbers shown in [ ]

brackets.

2. PRESS the [UP ARROW (▲)] or [DOWN ARROW (▼)]

key until the Class is highlighted.

3. PRESS the [RIGHT ARROW (

Subclasses or PLUs.

4. To move through the list, use the [UP ARROW (▲)] or

[DOWN ARROW (▼)] key until the SubClass or PLU is

highlighted.

5. PRESS [ENTER]. Product information for the PLU

displays.

6. Weigh the product as applicable.

)] key to view the

3 - 7 Start-Up Procedures

Page 28

Page 29

Chapter Four: Using the Ultima System

♦ Weighing, Printing and Applying (Auto Weigh)

♦ Auto Repeat

♦ Weighing, Printing and Applying (Semi Auto Weigh)

♦ Semi Auto Repeat

♦ Weighing and Printing (Manual Weigh)

♦ Manual Repeat

♦ Printing Subtotals and Totals

♦ Setting the Countdown

♦ Entering the Sell By or Best Before Dates

♦ Changing Product Information (Temporarily)

♦ Using Forced Price

♦ Using Forced Tare

♦ Using Platter Tare

Ultima System

4 - 1 Using the System

Page 30

Ultima System

Using the

Ultima System

Weighing, Printing and

Applying

(Auto Weigh)

The following sections explain how to:

♦ Weigh, print and apply (auto weigh)

♦ Weigh, print and apply duplicate labels (auto repeat)

♦ Weigh, print and apply (semi auto weigh)

♦ Weigh, print and apply duplicate labels (semi auto

repeat)

♦ Weigh and print (manual weigh)

♦ Weigh and print duplicate labels (manual repeat)

♦ Print subtotals and totals

♦ Set the countdown value

♦ Enter the sell by or best before dates

♦ Change product information (temporarily)

♦ Use forced price

♦ Use forced tare

♦ Use platter tare

Auto Weigh is used to weigh a package, print a label, and

apply the label to the package.

This mode is used most often for a fully automatic system.

When used with a fully automatic system, the package is

also wrapped.

QUICK STEPS

From the Start a Run Screen:

1. Highlight Auto Weigh and

PRESS [ENTER]

2. Enter the Operator ID, if

applicable

3. Enter the PLU

4. Place the package on the

weighing platform

To weigh, print and apply:

1. At the console, from the Start a Run Screen, highlight

Auto Weigh and PRESS [ENTER].

Using the System 4 - 2

Page 31

Ultima System

2. Enter your Operator ID (if required). The Run Screen

displays.

3. Enter the PLU number (PRESS the speed key, Type the

PLU number or select from the On Screen Library). The

PLU information displays. If Auto Lookup is not on, you

may have to PRESS [ENTER].

Auto Repeat

4. Place the package on the weighing platform. A label will

automatically print.

5. Place the next package on the weighing platform.

--OR--

Enter another PLU.

--OR--

PRESS [ESCAPE] to return to the Start a Run Screen.

Auto Repeat works the same as auto weigh, but it also

enables you to print duplicate labels automatically. It is used

to weigh a package, print duplicate labels, and apply the

labels to the package.

This mode is used most often for a fully automatic system.

When used with a fully automatic system, the package is

also wrapped.

4 - 3 Using the System

Page 32

Ultima System

Weighing, Printing and

Applying

(Semi Auto Weigh)

QUICK STEPS

From the Start a Run Screen:

1. Highlight Semi Auto

Weigh and PRESS

[ENTER]

2. Enter Operator ID, if

required

3. Enter the PLU

4. Place the package on the

weighing platform

Semi Auto Weigh is the mode most often used with semiautomatic systems (CLA) for pre-packaged products. It

weighs a package, prints a label, and applies the label to the

package.

To weigh, print and apply:

1. At the console, from the Start a Run Screen, highlight

Semi Auto Weigh and PRESS [ENTER].

2. Enter your Operator ID (if required). The Run Screen

displays.

3. Enter the PLU number (PRESS the speed key, type the

PLU number or select from the On Screen Library). The

PLU information displays. If Auto Lookup is not on, you

may have to PRESS [ENTER].

4. Place the package on the weighing platform. A label will

print automatically.

5. Place the next package on the weighing platform.

--OR--

Enter another PLU.

--OR-PRESS [ESCAPE] to return to the Start a Run Screen.

Using the System 4 - 4

Page 33

Ultima System

Semi Auto Repeat

Weighing and Printing

(Manual Weigh)

QUICK STEPS

From the Start a Run Screen:

1. Highlight Manual Weigh

and PRESS [ENTER]

2. Enter Operator ID, if

required

3. Enter the PLU

4. Place the package on the

weighing platform

5. PRESS [PRINT]

Semi Auto Repeat works the same as Semi Auto Weigh, but

it enables you to print duplicate labels automatically. It

weighs a package, prints duplicate labels, and applies the

labels to the package.

Manual Weigh is used for weighing a package and printing

a label. You would use this to create labels for large

prepackaged items.

To weigh and print:

1. At the console, from the Start a Run Screen, highlight

Manual Weigh and PRESS [ENTER].

2. Enter your Operator ID (if required). The Run Screen

displays.

3. Enter the PLU number (PRESS the speed key, Type the

PLU number or select from the On Screen Library). The

PLU information displays. If Auto Lookup is not on, you

may have to PRESS [ENTER].

4 - 5 Using the System

Page 34

Ultima System

4. Place the package on the weighing platform. The system

weighs the package.

5. PRESS [PRINT] to print the label.

6. Place the next package on the weighing platform.

--OR--

Enter another PLU.

--OR-PRESS [ESCAPE] to return to the Start a Run Screen.

Manual Repeat

Printing Subtotals and

Totals

QUICK STEPS

From the Start a Run Screen:

1. Select a Weigh Type

2. PRESS [ENTER]

3. Enter a PLU

4. Place the package on the

weighing platform.

5. Continue weighing

packages

6. PRESS [PREV] to print a

Subtotal label

7. Repeat steps 4 thru 6.

8. PRESS [NEXT] to print a

Totals label

9. PRESS [ESCAPE]

Manual Repeat works similar to manual weigh. It is used to

continually duplicate labels.

You can use Subtotal and Total to print one label for

multiple packages. For example, you can print a label that

subtotals all of your packages, then print a label that totals

all of your subtotals.

To print Subtotals and Totals:

1. From the Start a Run Screen, use the [UP ARROW (▲)]

and [DOWN ARROW (▼)] keys to select a Weigh Type.

A Weigh Type is selected when it is highlighted.

☛ Note

Subtotal and Total is not available when you select Manual

Repeat and Countdown Weigh Types.

Using the System 4 - 6

Page 35

Ultima System

2. PRESS [ENTER]. The Run Screen displays.

3. Enter the PLU number (PRESS the speed key, type the

PLU number or select from the On Screen Library). The

PLU information displays. If Auto Lookup is not on, you

may have to PRESS [ENTER].

4. Place the package on the weighing platform.

a. If you selected Auto Weigh or Semi Auto Weigh as

your weigh type, a label will automatically print.

b. If you selected Manual Weigh as your weigh type,

PRESS [PRINT] to print a label.

5. Continue weighing packages until you are ready to

subtotal the packages.

6. PRESS [PREV] to print the subtotal label.

7. Repeat steps 4 thru 6 to print subtotals for other groups of

packages.

8. PRESS [NEXT] to print a Totals label of all of the groups

weighed for that PLU number.

☛ Note

If labels are queued to be printed or labels are waiting to be

taken from one of the printers, a beep will alert the operator

that the [PREV] or [NEXT] key will not print a Subtotal or

Totals label.

9. Enter another PLU number.

--OR-PRESS [ESCAPE] to return to the Start a Run Screen.

☛ Note

A subtotal value will rezero once a subtotal label is printed.

A totals label will continue to calculate totals until you

escape from the Run Screen or type in a new PLU number.

4 - 7 Using the System

Page 36

Ultima System

Setting the Countdown

QUICK STEPS

From the Start a Run Screen:

1. Select Countdown

2. PRESS [ENTER]

3. Enter a PLU

4. Enter the kilograms

5. Enter the number of

cartons

6. Modify product fields, if

applicable

7. Weigh the product

8. PRESS [PRINT] or

[ESCAPE]

9. Continue weighing

10. PRESS [PRINT] or

[ESCAPE]

Setting the countdown allows you to specify the amount to

be labeled by weigh type and the number of cartons.

One of the following weigh types will be set by your

supervisor:

• By Weight

• By Value

• By Packages

Before you begin this procedure ask your supervisor to

verify that your Ultima is set up to countdown by weight.

To set the countdown by weight:

1. From the Start a Run Screen, select Countdown.

2. PRESS [ENTER]. The Run Screen displays, with the

Product Number field highlighted.

3. Enter a PLU. The appropriate field information displays.

Using the System 4 - 8

Page 37

☛ Note

can range from 0 to 99.99 pounds or 0 to 99.999 kilograms.

If you do not know the PLU number:

a. With your cursor at the Product Number field, PRESS

[HELP].

b. Select the product you want.

The PLU number and product description display in the

appropriate fields.

4. In the Countdown - Enter Weight field, enter the

minimum amount of weight from which you want to

countdown. This is the amount of weight per carton and

Ultima System

5. In the Countdown - Enter Cartons field, enter the number

of cartons. You can enter up to 9999 cartons per run.

6. Modify product fields, if applicable.

7. Weigh the product. When you reach or exceed the

amount of weight that you specified, the Carton

Complete message displays.

4 - 9 Using the System

Page 38

Ultima System

8. PRESS [PRINT] to print a carton label. The carton label

displays total net weight, the number of packages, and

the total price of the product contained in the carton.

--OR--

PRESS [ESCAPE] to skip the carton label.

9. Continue weighing the product until all cartons are

complete. The Run Complete message displays.

Entering the Sell By or

Best Before Dates

10. PRESS [PRINT] to print a run label. The run label

displays total net weight of all cartons, the total number

of packages and the total price of all cartons.

--OR--

PRESS [ESCAPE] to skip the run label.

11. PRESS [ENTER] to set up another countdown run.

--OR--

PRESS [ESCAPE] to return to the Start a Run Screen.

This enhancement enables you to modify the Sell By or Best

Before Dates directly from the appropriate field on the Run

Screen. These dates are also automatically calculated by

entering a number of days in the Shelf Life or Product Life

field.

Using the System 4 - 10

Page 39

Ultima System

QUICK STEPS

From the Start a Run Screen:

1. Select a Weigh Type

2. PRESS [ENTER]

3. Enter a PLU

4. Enter the date in the

appropriate field

To enter the Sell By Date:

1. From the Start a Run Screen, use the [UP ARROW (▲)]

and [DOWN ARROW (▼)] keys to select a Weigh Type.

A Weigh Type is selected when it is highlighted.

2. PRESS [ENTER]. The Run Screen displays.

3. Enter a PLU in the Product Number field. The

appropriate field information displays.

☛ Note

If you do not know the PLU number:

a. With your cursor at the Product Number field,

PRESS [HELP].

b. Select the product you want.

The PLU number and product description display in the

appropriate fields.

4 - 11 Using the System

Page 40

Ultima System

4. Use the [UP ARROW (▲)] or [DOWN ARROW (▼)] key

to select the Sell By or Best Before field.

5. Type the appropriate date and PRESS [ENTER]. The

date you enter displays and the cursor moves to the next

field.

☛ Note

Changing Product

Information

(Temporarily)

If you change the Sell By date, the Best Before date will

automatically update. However, if you change the Best

Before date, the Sell By date will not update.

Temporarily change the value of any of the fields listed next

to the “F” Keys, unless they are grayed. They are modifiable

depending on the type of PLU you have selected (i.e.

Random Weight, Fixed Weight, etc.).

♦ Unit Price/Lb. for Price

♦ Tare

♦ Shelf Life/Select Shelf Life

♦ Label & Graphic Type & Rotation

♦ By Count

♦ Total Price

♦ Net Weight (Oz.)

♦ Volume (Fluid Oz.)

Look At This

All changes to product information are recorded in the

Supervisor Mode and listed by Operator ID (if configured).

Using the System 4 - 12

Page 41

QUICK STEPS

From the Run Screen:

1. Move the cursor to the field

you want

2. TYPE the temporary values

Ultima System

To change product information:

1. From the Run Screen, move the cursor to the field you

want to change.

2. TYPE the temporary value(s), label type, or graphic ID.

(You may need to PRESS [ESC] to return to the PLU

screen.)

When the label is generated, the new information prints.

The changes revert to their original value when you enter a

new PLU or PRESS [ESC].

☛ Note

Fixed Weight products do not use the scale weight to

calculate Total Price or Net Weight.

☛ Note

If the UPC Numbering System for a Fixed Weight or Fluid

Ounce PLU equals 0, 6 or 7, you will not be able to edit any

of the fields that affect the price (i.e., Net Weight [Oz.],

Volume [Fluid Oz.], By Count or Total Price).

Using Forced Price

Random Weight PLUs 1. Enter your Operator ID (if required).

Your Supervisor may have set-up a PLU that requires you to

enter an item’s price. For example, you may sell three grades

of ground beef, all with a different price, but use the same

PLU Number. When you enter the PLU Number, the system

prompts you to enter the Unit Price or Total Price for the

grade the customer wants. The following explanation gives

you details for using Forced Price.

2. Enter the PLU Number (Type PLU number or select

from the On Screen Library). You are now on the Run

Screen. If Auto Lookup is not on, you will have to PRESS

[ENTER].

3. There is an audible beep and the cursor moves to the

Unit Price field. You cannot do anything else until you

enter a valid Unit Price.

4. TYPE the Unit Price and PRESS [ENTER].

5. To complete the transaction, follow the steps based on

your mode of operation.

4 - 13 Using the System

Page 42

Ultima System

Random Weight - By Count PLUs 1. Enter your Operator ID (if required).

2. Enter the PLU Number (Type PLU number or select

from the On Screen Library). You are now on the Run

Screen. If Auto Lookup is not on, you will have to PRESS

[ENTER].

3. There is an audible beep and the cursor moves to the

Total Price field. You cannot do anything else until you

enter a valid Total Price.

4. TYPE the Total Price and PRESS [ENTER].

5. To complete the transaction, follow the steps based on

your mode of operation.

Fixed Weight PLUs 1. Enter your Operator ID (if required).

2. Enter the PLU Number (Type PLU number or select

from the On Screen Library). You are now on the Run

Screen. If Auto Lookup is not on, you will have to PRESS

[ENTER].

3. There is an audible beep and the cursor moves to the

Total Price field. You cannot do anything else until you

enter a valid Total Price.

4. TYPE the Total Price and PRESS [ENTER].

5. To complete the transaction, follow the steps based on

your mode of operation.

Using Forced Tare

For PLUs that require a tare value, the PLU can be set-up to

require you to enter a tare value. This feature might be used

if different sized trays are used for the same product, but the

trays all weigh differently. By using the Forced Tare option,

only one PLU Number is required.

To enter the forced tare:

1. Enter your Operator ID (if required).

2. Enter the PLU Number. (Type a PLU number or select

from the On Screen Library). You are now on the Run

Screen. If Auto Lookup is not on, you will have to PRESS

[ENTER].

3. There is an audible beep and the cursor moves to the

Tare field. You cannot do anything until you enter a

valid Tare value.

4. TYPE the Tare value.

5. PRESS [ENTER] or [DOWN ARROW (▼)]. The cursor

then moves to the next active field, Product Number.

6. To complete the transaction, follow the steps based on

your mode of operation.

✎ Tip

A PLU can be set-up to require Forced Price and Forced

Tare. In the event this is the case, you will enter the Forced

Price first, followed by Forced Tare.

Using the System 4 - 14

Page 43

Ultima System

Using Platter Tare

During the initial scale set-up, the scale may be configured

for Platter Tare. This simply means that you can enter the

Tare value by placing the “container” on the platter (when

the cursor is on the Tare field) and pressing Enter or Down

Arrow to accept the weight value.

To enter the platter tare value:

1. Enter your Operator ID (if required).

2. Enter the PLU Number (Type PLU number or select

from the On Screen Library). You are now on the Run

Screen.

3. PRESS [ENTER] or [DOWN ARROW (▼)].

4. Move the cursor to the Tare field by pressing the Arrow

Keys.

5. When you are on the Tare field, the Softkey changes to

“Platter Tare” or “Keyboard Tare.” PRESS [F4] to select

Platter Tare.

6. Place the container on the platter.

7. PRESS [ENTER] or [DOWN ARROW (▼)] to accept the

Tare value. Notice that the field and Softkey now read

“Tare.”

8. To complete the transaction, follow the steps based on

your mode of operation.

4 - 15 Using the System

Page 44

Page 45

Ultima System

Chapter Five: Cleaning & Maintaining your System

♦ Hygiene Requirements for Cleaning & Sanitizing

♦ Cleaning the Printhead

5 - 1 Cleaning

Page 46

Ultima System

Cleaning and

Maintaining your

System

Hygiene Requirements

for Cleaning &

Sanitizing

Do Don’t

DO cover the complete system during

clean up and hose down of

surrounding areas.

DO use mild soap and water solution

to clean the exterior of the Ultima

(Palmolive Green or Ivory are

recommended).

This durable Ultima System has been designed and

manufactured to resist scratches, stains, alkaline, protein

and food acid when cared for properly. Improper care can

permanently damage the electronics and printer.

Proper cleaning prolongs the life and productivity of the

machine. This machine should be cleaned routinely during

the day and thoroughly cleaned at the end of the day. If the

system is not cleaned daily it will not run consistently and

will cause service problems. Improper cleaning and

sanitation will adversely effect performance of the

equipment.

Carefully clean the exterior of the Ultima with a clean

sponge or cloth and warm water solution.

Refer to the following Cleaning and Sanitizing guidelines.

DON’T dampen labels, electronic parts, or

connections.

DON’T use steam or a pressure (water) hose

to clean the system.

DO apply EPA-registered sanitizer

according to label directions to

disinfect surfaces.

DON’T allow water to enter the openings in

the housing.

DON’T use a hose or pour water in any area.

DON’T operate and/or store the system in

an environment with relative humidity levels

consistently in excess of 70%.

DON’T use:

• Chloride-Based cleaners

• Formula 409

• Glass Cleaners (i.e. Scotty’s Glass

Cleaner)

• Citrus-Based Cleaners (i.e. Citro-Sol or

Bio-T)

• Caustic Cleaners with high pH (i.e.

Butchers Block, concentrated Lysol or

Pinsol)

DON’T exceed EPA and registered

recommended concentrations for detergent

or sanitizer.

Cleaning 5 - 2

Page 47

Ultima System

Cleaning the Printhead

The printhead should be cleaned approximately once each

week, or whenever unclear labels are printed. It is a good

idea to clean the Printhead Roller whenever a new roll of

labels is installed. To obtain a Printhead Cleaning Kit,

contact your local Hobart office; request Part Number

00-184326.

Look At This

Do not use a metal tool on the printhead. This could scratch or

break the printhead. In addition, labels should not become

stuck on machine parts. If they do, remove the labels at once

following the instructions in the Printhead Cleaning Kit.

To clean the printhead:

1. Check printhead for labels or adhesive before inserting

every roll of labels. Clean the printhead as needed.

2. Turn power off to the printer.

3. Remove the label cassette.

4. Use the plastic “Lil’ ChiZler” to remove stuck on label

stock.

5. To remove burned-on adhesive, gently rub the printhead

surface with the eraser.

6. Soak the cotton swab tip with the Printhead Cleaning

Solution.

7. Scrub the printhead with the swab until all residue is

removed.

8. Moisten the swab as needed.

9. Allow the printhead to dry.

10. Return the Cleaning Kit to its holding box.

5 - 3 Cleaning

Page 48

Page 49

Chapter Six: Troubleshooting

¨ Possible System Problems

Ultima System

6 - 1 Troubleshooting

Page 50

Ultima System

y

Troubleshooting

In the event that your Ultima System does not operate as

expected, please read through the following troubleshooting

steps before calling for service.

Possible System

Problems

If you are experiencing problems with the label applier or

printer, review the following scenarios.

Problem Possible Cause Action/Solution

When I press

[POWER] the system

does not respond.

The Scale Warm-Up

message wonÕt go

away.

The Operator ID was

not accepted.

The system wonÕt

accept the date &

time.

When I press

[REZERO] the system

responds Outside Zero

Maintenance.

Over gross weight

displays on screen.

PLU not found You may have entered an invalid PLU

You may not have power running to the

system.

Weight may be on the platter. Make sure the platter/weigher is clear.

You may have entered the wrong ID. Verify that you are entering the proper

You may have entered information in

an incorrect format.

There is weight on the platter.

There is too much weight on the

platter/weigher.

number.

Verify that the system is plugged in and

the power switch, located on the back of

the printer, is turned on.

Power the printer down and up using

the switch on the back.

ID. If correct, have your Supervisor

check the ID number.

Verify that you are entering a valid date

& time.

1. At the console, PRESS [ESC] and

[POWER] to turn power OFF.

2. Make sure nothing is touching the

platter/weigher.

3. PRESS [POWER] to turn power ON.

Make sure the platter/weigher is clear

and PRESS [REZERO].

Verify PLU Number.

System prompts you

to take label and no

label is present.

Partial non-printed

label is exposed.

Out of Labels message

displays.

System prints blank

labels or partially

printed labels.

Troubleshooting 6 - 2

A portion of the label may be ÔhiddenÕ

in the label exit.

The labels may be improperly threaded.

No labels are loaded.

The labels may be improperly threaded

or the printhead or pressure roller may

be dirty.

Make sure that the label exit is clear.

Verif

that labels are properly threaded.

Load new labels.

Check to see that labels are threaded

properly. If the problem persists, clean

the Printhead with the Hobart

Printhead Cleaning kit.

Page 51

Chapter Seven: Index

Ultima System

7 - 1 Index

Page 52

Ultima System

— A —

About the Keyboard, 3-6

Accessing the On Screen Library, 3-7

Applying (Semi Auto Weigh), Weighing,

Printing and, 3-4, 4-4

Applying (Auto Weigh), Weighing, Printing

and, 3-4, 4-2

Auto Repeat, 3-4, 4-3

Auto Weigh, Weighing, Wrapping, Printing

and Applying, 3-4, 4-2

— B —

Basic Help, 3-6

Best Before Dates, Enter the Sell By or, 4-10

— C —

Changing Product Information (Temporarily),

4-12

CLEANING AND MAINTAINING YOUR

SYSTEM, 5-2

Cleaning the Printhead, 5-3

Cleaning & Sanitizing, Hygiene

Requirements for, 5-2

Communication Connections, 2-3

Connections, Communication, 2-3

Connections, Electrical, 2-2

Console, Using the, 2-3

Countdown, Setting the, 4-8

— D —

Date & Time, Setting the, 3-2

Display, User, 2-6

— E —

Electrical Connections, 2-2

Entering Operator IDs, 3-5

Entering the Sell By Date or Best Before

Dates, 4-10

Ñ F —

ÒFÓ Keys, Help on, 3-6

FCC Note, 1-3

Forced Price, Using, 4-13

Forced Tare, Using, 4-14

Function Keys, 1-2, 2-4

— H —

HELP Key Functions, 3-6

Help on "F" Keys, 3-6

Help, Basic, 3-6

Hygiene Requirements for Cleaning &

Sanitizing, 5-2

— I —

INTRODUCTION, 1-2

— K —

Keyboard, About the, 3-6

Keypad, The, 2-4

— L —

Label Cassette, Narrow, 2-7

Label Cassette, Removing and Replacing, 2-11

Label Cassette, Standard, 2-7

Labels, Loading, 2-7

Loading Labels, 2-7

Label Stock, Narrow, 2-7

Label Stock, Standard, 2-7

— M —

Main Power Switch, 2-2

MAINTAINING YOUR SYSTEM,

CLEANING AND, 5-2

Manual Overview, 1-3

Manual Repeat, 3-4, 4-6

Manual Weigh, Weighing and Printing,

3-4, 4-5

Moving Through the System, 3-7

Index 7 - 2

Page 53

Ultima System

— N —

Narrow Label Cassette, 2-7

Narrow Label Stock, 2-7

— O —

On Screen Library, Accessing the, 3-7

Operator IDs, Entering, 3-5

Operator Manual Overview, 1-3

Overview, Operator Manual 1-3

— P —

Platter Tare, Using, 4-15

Possible System Problems, 6-2

Power Cord, 2-2

Power Key, 2-4

Power Switch, Main, 2-2

Powering Up the System, 3-2

Printhead, Cleaning the, 5-3

Printing (Manual Weigh), Weighing and,

3-4, 4-5

Printing and Applying (Semi Auto Weigh),

Weighing, 3-4, 4-4

Printing and Applying (Auto Weigh),

Weighing, 3-4, 4-2

Printing Subtotals and Totals, 4-6

Problems, Possible System, 6-2

Product Information, Changing

(Temporarily), 4-12

Subtotals and Totals, Printing, 4-6

System, Powering Up, 3-2

SYSTEM, UNDERSTANDING THE, 2-2

— T —

Time, Setting the Date and, 3-2

Totals, Printing Subtotals and, 4-6

Totals Types, 3-5

Totals Types, Selecting Weigh and, 3-5

TROUBLESHOOTING, 6-2

Types, Totals, 3-5

Types, Weigh, 3-4

— U —

Understanding the Start a Run Screen, 3-3

UNDERSTANDING THE SYSTEM, 2-2

User Display, 2-6

Using Forced Price, 4-13

Using Forced Tare, 4-14

Using Platter Tare, 4-15

Using the Console, 2-3

USING THE ULTIMA SYSTEM, 4-2

— V —

Verify Correctness of Weight & Price, 1-3

Verifying Zero Weight, 3-4

— R —

Rezeroing the Scale, 3-4

— S —

Sanitizing, Hygiene Requirements for

Cleaning and, 5-2

Selecting Weigh and Totals Types, 3-5

Sell By or Best Before Dates, Entering, 4-10

Semi Auto Repeat, 3-4, 4-5

Semi Auto Weigh, Weighing, Printing and

Applying, 3-4, 4-4

Setting the Countdown, 4-8

Setting the Date & Time, 3-2

Speed Keys, 1-2

Standard Label Cassette, 2-7

Standard Label Stock, 2-7

Start a Run Screen, Understanding the, 3-3

START-UP PROCEDURES, 3-2

— W —

Weigh and Totals Types, Selecting, 3-5

Weigh Types, 3-4

Weighing and Printing (Manual Weigh),

3-4, 4-5

Weighing, Printing and Applying (Semi Auto

Weigh), 3-4, 4-4

Weighing, Printing and Applying (Auto

Weigh), 3-4, 4-2

— Z —

Zero Weight, Verifying, 3-4

7 - 3 Index

Page 54

Page 55

Page 56

F-34319 (10-99)

Loading...

Loading...