Page 1

TURBOWASH

TM

. . . Pot and Pan Sink

MODEL

TWII ML-110971

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 34504 Rev. B (June 2002)

Page 2

Installation, Operation, and Care of

TM

TurboWash

Pot and Pan Sink

SAVE THESE INSTRUCTIONS

GENERAL

The TurboWash pot and pan sink is the scullery manager's dream. Soiled pots, pans and utensils can

be cleaned in swirling hot water for as long as necessary until soil-adhesion is eliminated. Significantly

less manual effort is required on difficult to clean items. Once washed, the pots, pans and utensils can

be moved to the optional rinse and sanitizer sinks.

• The wash pump motor is rated 2 H.P. and has permanently sealed bearings.

• Sinks can be specified for left-to-right or right-to-left wash/rinse/sanitize flow.

• A scrapper sink is optional between soiled end and wash sink and may be equipped with or

without disposer.

• The AutoFill option provides an automatic timed initial fill for the wash sink.

• Wash Tank Pump Auto Shutoff and Wash Tank Heater are optional.

• The utensil basket accessory allows small items to be washed in the wash sink.

Nominal Dimensions

Front-to-back 34" overall. Sink depth 18"; to water level mark 14". Sink front-to-back 28". Counter

height 34". Height to counter rim 36"; to top of backsplash 45". Optional end styles (hemmed, rolled,

end splash, or dishwasher connection) add incrementally to the overall length. See table, next page.

© HOBART CORPORATION, 1997

– 2 –

Page 3

sehcnInishtgneLnoitceSelbaliavA

DNEDELIOS

EGDEEGDE

EGDEEGDE

EGDE

"0=demmeH"0"0"03"0"0"0"0=demmeH

1

1=delloR

/2""21resopsido/w"02"23"51"5.81"211=delloR

=hsalpSdnE

1

2

/2"

rehsawhsiD

noitcennoC

muminim"63

DNEDELIOS

DRAOBNIARDDRAOBNIARD

DRAOBNIARDDRAOBNIARD

DRAOBNIARD

)lanoitpO()lanoitpO(

)lanoitpO()lanoitpO(

)lanoitpO(

"02resopsido/w"63"63"81"02"5.812=hsalpSdnE

"42resopsidhtiw"63"24"02"42"42

"03"84"42"03"03

"63"45"03"63"63

"24"06"63"24

"84 "84

"45 "45

"06 "06

REPPARCS

KNISKNIS

KNISKNIS

KNIS

)lanoitpO()lanoitpO(

)lanoitpO()lanoitpO(

)lanoitpO(

KNISHSAW

)dradnatS()dradnatS(

)dradnatS()dradnatS(

)dradnatS(

KNISESNIR

)lanoitpO()lanoitpO(

)lanoitpO()lanoitpO(

)lanoitpO(

KNISREZITINAS

)lanoitpO()lanoitpO(

)lanoitpO()lanoitpO(

)lanoitpO(

DNENAELC

DRAOBNIARDDRAOBNIARD

DRAOBNIARDDRAOBNIARD

DRAOBNIARD

)lanoitpO()lanoitpO(

)lanoitpO()lanoitpO(

)lanoitpO(

DNENAELC

EGDEEGDE

EGDEEGDE

EGDE

1

/2"

1

/2"

rehsawhsiD

noitcennoC

muminim"02

INSTALLATION

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the TurboWash is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, verify that the electrical service agrees with the specifications on the data plate(s).

ASSEMBLY

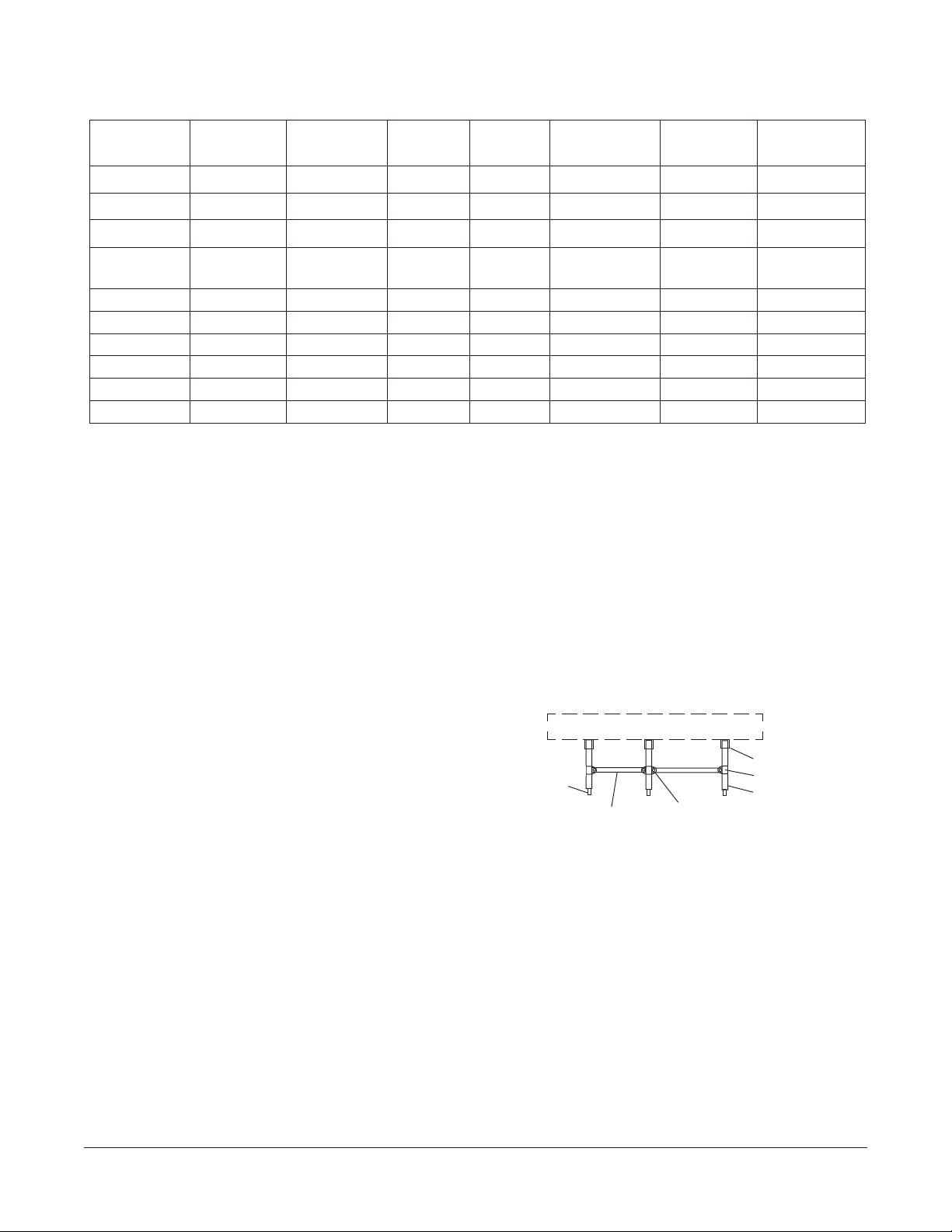

Assemble the H-frame leg sets into the front-rear

leg sockets and tighten the set screws. Fill set

screw heads with silicone sealant (NSF approved).

Allow space for the drain connection and assemble

the frame crossmembers between the rear legs

5

using clamps and

¦16"-18 Screws, Washers,

Lockwashers and Nuts, provided (Fig. 1).

Leveling Foot

TURBOWASH SINK

Frame Crossmember

Middle-Clamp - Bolts

Fig. 1

Leg Socket - Set Screw

End-Clamp - Bolt

Rear Leg

Location

Provide necessary space for proper operation of the TurboWash, including faucet head clearance and

turning diameter so each sink can be filled. Place the TurboWash so it does not interfere with the

operation of other equipment in the area. Place the TurboWash backsplash several inches from the

wall to allow room for leveling.

Leveling

Turn feet in or out to level the unit front-to-back and side-to-side. Slide the TurboWash flush against

the wall so the backsplash can be sealed with silicone sealant.

– 3 –

Page 4

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY,

AND PLUMBING CODES.

Drains

Drains underneath the TurboWash should be properly connected to a suitable drain (use 2" dia. pipe).

Recommended drain height is 10 inches above finished floor.

If a grease trap is required by code, it should have a minimum flow capacity of 42 gallons per minute.

Hot Water Connections

Hot water should be connected as required (temperature range 120 – 140°F). Total water hardness

of 4 – 6 grains per gallon is recommended.

Cold Water Connections

Cold water should be connected as required (temperature range 45 – 80°F). Total water hardness of

4 – 6 grains per gallon is recommended.

PLUMBING FITTINGS and Other Options

Temperature mix is provided by faucet(s), optional. Pre-rinse spray is optional. Manual, twist-handleoperated drains (optional) with- or without-overflow (optional) can be provided for installation on each

wash, rinse, and sanitizer sink. A free-flow drain (optional) is available for the scrapper sink when it

is not equipped with a disposer. A wash sink sump with strainer basket is optional — when so equipped,

the recommended drain height is 7 inches above finished floor. A wash sink separater is optional when

the wash sink is at least 42 inches long. Dishwasher connectability (optional) requires a drainboard

with minimum length of 36 inches at the soiled end or 20 inches at the clean end. Over-shelves

(optional) can be installed on the wall above the sink. Under-shelves (optional) can be provided for

installation on frame crossmembers underneath clean-end drainboards that are at least 30 inches long.

When supplied by others, all plumbing fittings and pipes must be copper, stainless steel or brass. When

auto-fill option is used with plumbing supplied by others, an ASSE-certified vacuum breaker must be

installed in accordance with local plumbing codes.

ELECTRICAL CONNECTION

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT/TAGOUT PROCEDURES.

WARNING: IF MORE THAN ONE ELECTRICAL SUPPLY CONNECTION IS PRESENT, ALL SUCH

CONNECTIONS MUST BE DISCONNECTED BEFORE SERVICING.

– 4 –

Page 5

ATADLACIRTCELE

ledoMesahP/ztreH/stloV

resopsidtuohtiwIIWT

,05-3DFledoMresopsiDhtiwIIWT

ro,051-3DF,521-3DF,57-3DF

tnioP-elgniSdna002-3DF

noitcennoClacirtcelE

,05-3DFledoMresopsiDhtiwIIWT

,051-3DF,521-3DF,57-3DF

dna003-3DFro002-3DF

noitcennoClacirtcelEtnioP-elgniS

noitcennoClacirtcelEetarapeS

YLNOresopsiD

,57-3DF,05-3DFsledoM

002-3DFro,051-3DF,521-3DF

1/06/042-802

3/06/042-802

3/06/084

1/06/042-802

3/06/042-802

3/06/084

1/06/021spmA52

1/06/042-802spmA51

yticapmAtiucriCmuminiM

eciveDevitcetorPmumixaMeciveDevitcetorPmumixaM

eciveDevitcetorPmumixaMeciveDevitcetorPmumixaM

SPMASPMA

SPMASPMA

SPMA

eciveDevitcetorPmumixaM

kniShsaWniretaeHcirtcelEtuohtiWspmA51

kniShsaWniretaeHcirtcelEhtiWspmA52

kniShsaWniretaeHcirtcelEtuohtiWspmA51

kniShsaWniretaeHcirtcelEhtiWspmA02

kniShsaWniretaeHcirtcelEtuohtiWspmA51

kniShsaWniretaeHcirtcelEhtiWspmA51

kniShsaWniretaeHcirtcelEtuohtiWspmA52

kniShsaWniretaeHcirtcelEhtiWspmA04

kniShsaWniretaeHcirtcelEtuohtiWspmA02

kniShsaWniretaeHcirtcelEhtiWspmA53

kniShsaWniretaeHcirtcelEtuohtiWspmA51

kniShsaWniretaeHcirtcelEhtiWspmA51

noitcennoClacirtcelEetarapeS

YLNOresopsiD

,57-3DF,05-3DFsledoM

,051-3DF,521-3DF

003-3DFro002-3DF

Compiled in accordance with the National Electrical Code, ANSI/NFPA 70, latest edition.

3/06/042-802spmA51

3/06/084spmA51

NOTE: Connections to the TWII control box are made through a 3¦4" conduit hole provided in the bottom.

Use copper wire only.

Replace only with same type and rating of fuse, 0.6 A, 250 Volt, Type 3AG Time Delay.

CHECK ROTATION (Three-Phase Motors Only)

Three-phase motors must rotate in the direction of the arrow on the pump or disposer housing. In order

to check rotation, observe the direction of the impeller shaft between the motor and pump housing.

Switch the pump on for a few seconds and then switch it off.

If the rotation is incorrect, DISCONNECT ELECTRICAL POWER SUPPLY and interchange any two

of the incoming power supply leads. Reconnect the electrical power supply and verify correct rotation.

Disposer motor protection, when the TWII is equipped with a disposer, is provided by the disposer

motor.

Finish Sealant

After installation, apply a bead of silicone sealant (NSF approved) around the backsplash and wall.

– 5 –

Page 6

OPERATION

CONTROLS

Manual Pump Control and No Wash Sink Heat.

PUMP Switch: [ Off - On - Start ].

PUMP

ON

Pump Control with Auto Shutoff and No Wash Sink Heat.

OFF

PUMP

ON

START

T

O START: Turn the switch to the Start position and

then release it to the On position.

PUMP ON Indicator Light is lit when the pump is On.

PUMP

ON

OFF

PUMP

ON

START

PUMP Switch: [ Off - On - Start ].

O START: Turn the switch to the Start position and

T

then release it to the On position. Pump automatically

shuts off after the preset time counts down.

PUMP ON Indicator Light is lit when the pump is On.

Manual Pump Control with Dual-Setting Wash Sink Heat Control.

PUMP Switch: [ Off - On - Start ].

T

O START: Turn the switch to the Start position and

then release it to the On position.

PUMP

ON

OFF

PUMP

ON

OFF OVERNIGHT

START

HEAT

NORMAL USE

HEAT

ON

SOAKING

PUMP ON Indicator Light is lit when the pump is On.

HEAT Switch: [ O

N

ORMAL USE: 110°F wash sink water temperature.

OVERNIGHT S OAKING: 140°F wash sink water temperature,

for overnite soaking only. See Washing for an Extended

Time, page 10.

HEAT ON Indicator Light is lit when the Heat Switch is on

Normal Use or Overnight Soaking (unless low water is

indicated by the float switch).

FF - NORMAL USE - OVERNIGHT SOAKING ].

Manual Pump Control with Timed Fill and No Wash Sink Heat.

PUMP Switch: [ Off - On - Start ].

PUMP

ON

PUMP

OFFON START

FILL

OFF ON

FILL

ON

TO START: Turn the switch to the Start position and

then release it to the On position.

PUMP ON Indicator Light is lit when the pump is On.

FILL [ OFF - ON ] Switch — Fills the wash sink for a preset

amount of time until the water level is sensed.

FILL ON Indicator Light is lit when the F

To conserve water, close Drain before turning FILL Switch

N.

O

– 6 –

ILL Switch is On.

Page 7

Manual Pump Control and Timed Fill with Dual Setting Wash Sink Heat Control.

PUMP Switch: [ Off - On - Start ].

T

O START: Turn the switch to the Start position and

then release it to the On position.

PUMP

ON

PUMP

ON

OFF

START

FILL / HEAT

NORMAL USE

OFF OVERNIGHT

SOAKING

HEAT

ON

PUMP ON Indicator Light is lit when the pump is On.

FILL / HEAT Switch: [ O

SOAKING ] — Fills the wash sink for a preset amount of time

until the water level is sensed.

ORMAL USE: 110°F wash sink water temperature.

N

VERNIGHT S OAKING: 140°F wash sink water temperature,

O

for overnite soaking only. See Washing for an Extended

Time, page 10.

HEAT ON Indicator Light is lit when the FILL / HEAT Switch

is on N

ORMAL USE or OVERNIGHT SOAKING (unless low water is

indicated by the float switch).

To conserve water, close Drain before turning FILL / HEAT

Switch to N

Pump Control with Auto Shutoff and Dual-Setting Wash Sink Heat Control.

ORMAL USE or OVERNIGHT SOAKING.

FF - NORMAL USE - OVERNIGHT

PUMP

ON

PUMP / TIMER

OFF

ON

HEAT

NORMAL USE

START

OFF OVERNIGHT

HEAT

ON

SOAKING

or

PUMP

ON

OFF

PUMP

ON

OFF OVERNIGHT

START

HEAT

NORMAL USE

SOAKING

HEAT

ON

Pump Control with Auto Shutoff and Timed Fill.

PUMP

ON

PUMP / TIMER

ON

OFF

START

FILL

OFF ON

FILL

ON

or

PUMP

ON

PUMP

OFFON START

FILL

OFF ON

FILL

ON

PUMP / TIMER or PUMP Switch: [ OFF - ON - START ].

TO START: Turn the switch to the Start position and then

release it to the On position. Pump automatically shuts off

after the preset time counts down.

PUMP ON Indicator Light is lit when the pump is On.

HEAT Switch: [ O

ORMAL USE: 110°F wash sink water temperature.

N

VERNIGHT S OAKING: 140°F wash sink water temperature,

O

FF - NORMAL USE - OVERNIGHT SOAKING ].

for overnite soaking only. See Washing for an Extended

Time, page 10.

HEAT ON Indicator Light is lit when the Heat Switch is on

Normal Use or Overnight Soaking (unless low water is

indicated by the float switch).

PUMP / TIMER or PUMP Switch: [ OFF - ON - START ].

T

O START: Turn the switch to the Start position and

then release it to the On position. Pump automatically

shuts off after the preset time counts down.

PUMP ON Indicator Light is lit when the pump is On.

FILL [ O

FF - ON ] Switch — Fills the wash sink for a

preset amount of time until the water level is sensed.

FILL ON Indicator Light is lit when the FILL Switch is

On. To conserve water, close Drain before turning

FILL Switch O

N .

– 7 –

Page 8

Pump Control with Auto Shutoff and Timed Fill with Dual Setting Wash Sink Heat Control.

PUMP / TIMER or PUMP Switch: [ OFF - ON - START ].

TO START: Turn the switch to the Start position and

SOAKING

HEAT

ON

then release it to the On position. Pump automatically

shuts off after the preset time counts down.

PUMP

ON

PUMP / TIMER

ON

OFF

START

FILL / HEAT

NORMAL USE

OFF OVERNIGHT

PUMP ON Indicator Light is lit when the pump is On.

PUMP

ON

PUMP

ON

OFF

START

Disposer Controls.

START

DISPOSER

or

FILL / HEAT

NORMAL USE

OFF OVERNIGHT

SOAKING

STOP

HEAT

ON

FILL / HEAT [ O

FF - NORMAL USE - OVERNIGHT SOAKING ]

Switch — Fills the wash sink for a preset amount of time

until the water level is sensed.

ORMAL USE: 110°F wash sink water temperature.

N

OVERNIGHT S OAKING: 140°F wash sink water temperature

— for overnite soaking only. See Washing for an

Extended Time, page 10.

HEAT ON Indicator Light is lit when the FILL / HEAT Switch

is on N

ORMAL USE or OVERNIGHT S OAKING (unless low water is

indicated by the float switch).

To conserve water, close Drain before turning FILL / HEAT

Switch to NORMAL USE or OVERNIGHT SOAKING.

START DISPOSER Push-Button Switch (green).

STOP Push-Button Switch (red).

T

O S TART: Push the START DISPOSER Switch. If either the

Disposer Cone Swirl option or Disposer Scrapper Sink

Swirl option is included, water will begin flowing into the

disposer (via the electrically controlled solenoid valve).

O STOP: Push the STOP Switch.

T

– 8 –

Page 9

Chemical Supplies

Ask your chemical supplies representative for a recommendation on the type and amount of lowsudsing detergents and chemical sanitizers to use with your TurboWash sink. Your chemical supplier

should provide instructions, time and temperature requirements, concentrations, and safety information

for the chemicals used. Test kits or disposable color swabs for verification of chemical concentrations

should also be available from your chemical supplier. Refer to the table below for Volume

Requirements for Wash and Sanitizer Sinks (by size).

htgneLkniShsaW

)edisotedis()edisotedis(

)edisotedis()edisotedis(

)edisotedis(

SEHCNISEHCNI

SEHCNISEHCNI

SEHCNI

"03.lag16

"23.lag46

"63.lag17

"24.lag18

"84.lag19

"45.lag201

"06.lag211

Wash Procedure

FILL: Wash Sink

FILL: Sanitizer Sink

STNEMERIUQEREMULOVKNISHSAW

emuloVkniShsaW

ninininini

snollaG.S.UsnollaG.S.U

snollaG.S.UsnollaG.S.U

snollaG.S.U

"5.81.lag13

"0.02.lag43

"0.42.lag14

"0.03.lag15

"0.63.lag16

htgneLkniSrezitinaS

)edisotedis()edisotedis(

)edisotedis()edisotedis(

)edisotedis(

SEHCNISEHCNI

SEHCNISEHCNI

SEHCNI

ninininini

STNEMERIUQEREMULOVKNISREZITINAS

emuloVkniSrezitinaS

snollaG.S.UsnollaG.S.U

snollaG.S.UsnollaG.S.U

snollaG.S.U

Fill wash sink with warm water (110°F) to Water Level mark on back

wall of sink. Do not overfill. After wash sink is filled with water, add

detergent to wash sink (detergent, quantity, and instructions should

be provided by your Chemical supplier).

Fill sanitizer sink with warm water to Water Level mark on back wall

of sink. After sanitizer sink is filled, add sanitizer to sanitizer sink

(sanitizer, quantity, minimum temperature, and instructions should

be provided by your Chemical supplier).

FILL: Rinse Sink

(optional)

• WASH

If immersion rinse is required by local code or health department, fill

rinse sink with warm water (120°F minimum per National Restaurant

Association) to the Water Level mark on back wall of sink. Some

localities may allow the rinse sink to be used for spray - rinsing at

some minimum temperature.

Start wash pump. Turn wash sink Heat Switch to Normal Use

[ 110°F ].

Pre-scrap all items — scrape loose food soil into trash receptacle

and pre-spray ware. Do not allow soiled ware to dry out.

Place large items in wash sink. Place small items in utensil basket.

Put utensil basket in wash sink. Do not nest or stack pans together

as this would inhibit wash action. Most items can be loaded or

unloaded while the pump is on. Sheet pans can be loaded or

unloaded easier with the pump turned off. Alternate sheet pans'

lengths and widths so they don't nest and inhibit washing action.

Wash items in wash sink for 3 – 10 minutes or as long as necessary

to obtain clean ware.

– 9 –

Page 10

• RINSE

Move items to rinse sink. Rinse items by immersing in rinse

sink or spraying with water.

• SANITIZE

CHANGE WATER

GENERAL

Washing for an Extended Time

TurboWash can clean extremely hard soils by soaking in the wash sink for an extended time or

overnight. The optional AutoShutoff timer will turn the pump off after the preset time lapses (4 hours

is preset at the factory). The optional wash tank heater will remain on Normal Use or Overnight Soaking

setting until shut off. NOTE: Overnight Soaking [140°F] Heater setting is recommended for overnite

use only. The next morning, drain the wash sink before reaching in. Spray off or cool hot items before

handling. Rinse, sanitize, stack, and allow clean ware to dry as normal.

Sanitize items by immersing in sanitizer sink for the required amount

of time which should be specified by your chemical supplier. Remove

items from sanitizer sink. Stack and allow clean ware to dry as per

local health codes and recommendations. If ware is not completely

clean, put it back in wash sink.

Change water at least every 4 hours or when it feels greasy or has

excessive floating debris. See Cleaning the TurboWash, page 11.

DO NOT put knives, sharp tools, towels, mops, scrub pads, plastic

bags, plastic wrap, or any small items in wash sink.

DO NOT run wash pump without 'pump-inlet' strainers in place.

DO pre-scrap all items before putting them in the wash sink.

DO skim any floating food particles from the wash sink to keep water

clean.

DOs and DON'Ts for Your New Hobart TurboWash

DO assure proper water hardness (4 – 6 grains per gallon is recommended).

DO pre-scrap pots and pans thoroughly — scrape loose food soil into trash receptacle and pre-spray

ware.

DO use only detergent and sanitizer recommended by your chemical professional.

DO at the end of the day, thoroughly clean the TurboWash. Rinse and allow to dry.

DO closely follow your chemical professional's prescribed deliming schedule.

DO use only products formulated to be safe on stainless steel.

DO NOT over soften water (recommended water hardness is 4 – 6 grains per gallon).

DO NOT allow food soil to accumulate on the sink bottom.

DO NOT exceed chemical manufacturer's recommended concentrations for detergent, sanitizer, or

lime scale remover.

DO NOT use steel wool to clean ware or TurboWash.

DO NOT allow objects such as knives and other sharp items in the wash sink.

DO NOT overload wash sink — keep all items below the water surface.

NOTE: Failure to follow use, care, and maintenance instructions may void your Hobart warranty.

– 10 –

Page 11

MAINTENANCE

CLEANING THE TURBOWASH

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT/TAGOUT PROCEDURES.

Maintain your TurboWash in a clean condition at all times. Clean before using, at least every four hours

during use or at a frequency necessary to maintain clean conditions, and at least once daily, if used.

Turn pump and heater Off.

Open drains and empty all sinks. Wipe out and remove any soil residues to a trash receptacle.

Release the latch and lift out the outer 'pump-inlet' strainer at the rear wall of the wash sink. Release

the latch and lift up the hinged 'inner pump-inlet' strainer at the rear of the wash sink. Lift up the hinged

heater cover on the side wall of the wash sink. Flush out any remaining food soil. Remove food soil

from sink bottom and dispose in trash receptacle. Clean sinks or components using a detergent

solution mixed according to the chemical manufacturer's instructions and a clean brush or cloth. Use

care when cleaning around heater compartment, and probe / float assembly — flush with a gentle

spray. Clean heater cover and both 'pump-inlet' strainers and replace in their original positions. When

necessary, wipe the wash, rinse, and sanitizer sinks with clean sanitizer diluted per the chemical

supplier's instructions and allow to air dry.

When needed, clean the exterior of the TurboWash as you would any appliance. If grease accumulates

around the pump motor fan cover, clean as necessary.

If lime or calcium scale accumulates in the sink area or as often as recommended by your chemical

supplier, delime the sink(s) using a deliming agent. Follow the chemical supplier's instructions for

proper concentration; and rinse sinks after deliming.

– 11 –

Page 12

S

a

TROUBLESHOOTING

motpmy

.ffotaehdnapmuP.deppirtrekaerbtiucriC nruT.lenaplacirtceletarekaerbtiucricteseR

thgilpmupdnapmuP

.nositaeh;ffoer

pmuP.ffosipmuP

.noerataehdnathgil

.deppirt

esuaCelbissoPnoitcAevitcerroCdetsegguS

taolfdesuacretawwoL

.ffonrutothctiws

.deggolchctiwstaolF .11egap,hsaWobruTehtgninaelCotrefeR

retfaderruccoffotuhSotuA

.despalemitteserpeht

rotcetorpdaolrevorotoM

.tratsernehtdnaffohctiwspmup

hsawotretawddA.desolcsiniarderusekaM

.tratsernehtdnaffohctiwspmupnruT.knis

hctiwspmupnruT.erudecorpgninaelckcehC

.tratsernehtdnaffo

rofsetunimwefatiaW.ffohctiwspmupnruT

sserpnehT.loocotrotcetorpdaolrevorotom

.tratserdnarotomnonottubteserlaunam

.ecivresrofllac,deggolcrodemmajsipmupfI

Auto Shutoff Timer Adjustment

The Auto Shutoff Timer is preset at the factory to turn the wash sink pump off 4 hours after being turned

on. Contact Hobart service to adjust the AutoShutoff timer setting — up to 500 minutes, if needed.

SERVICE

Rely on your plumbing contractor for repairs to standard fittings, faucets, and drains. Contact your local

Hobart service office for repairs or adjustments needed on the TurboWash equipment.

FORM 34504 Rev. B (June 2002) PRINTED IN U.S.A.

– 12 –

Loading...

Loading...