Page 1

•

MODEL PCN90 SERIES

ELECTRIC CONVECTION OVENS

CONVECTION

OVENS

peN90 ML-43719

\HOBART}

EXECUTIVE OFFiCES

TROY, OHIO 45374

FORM

16842

Rev.

A (4-90)

Page 2

- THIS PAGE INTENTIONALLY LEFT BLANK -

Page 3

Installation, Operation and Care of

PCN90 SERIES ELECTRIC CONVECTION OVENS

SAVE

THESE INSTRUCTIONS

GENERAL

The PCN90 Series electric convection ovens feature Perfect

equipped with a

The Model

The Model PCN902 consists

stack set for mounting one

The Model PCN902

Accessories available include additional racks and a removable stainless steel liner kit.

1/3

PCN901

h.p.

motor.

is a single

of

oven

is

a single PCN90

oven

which is furnished with a set of four

two single PCN90 ovens, a set of four

on

top of the other.

oven

furnished with a storage stand

Touch™

programmable controls. Each oven is

3

25

8"

on

adjustable stainless steel legs.

/4"

adjustable stainless steel legs, and a

four

6"

adjustable stainless steel legs.

INSTALLATION

UNPACKING

Immediately after unpacking, check the oven for possible shipping damage. If the oven is found to

save the packaging material and contact the carrier within

"

Prior to installation, test the electrical service to

be

sure that it agrees with the specifications

INSTALLING SINGLE OVENS

Installing Basic Oven (PCN90)

The basic oven must

other supports restricting air circulation

oven on the stand after uncrating.

Assembling the Legs

1.

Position the oven

2.

Attach the four leg assemblies to the bottom of the oven with the twenty-four bolts and lockwashers.

3.

Reposition the oven by setting it on its legs

be

installed

to

the Oven (PCN901)

on

its back, taking care not to scratch the sides.

on

legs or

be

mounted

on

the bottom will void the warranty. If using the modular stand, set the

in

the installed position.

15

days of delivery.

on

a modular stand. Installations

on

the

oven

on

concrete bases or

be

damaged,

data plate.

HOBART CORPORATION, 1989

©

-3-

Page 4

FRONT

OF

DEVICE

•

.0.

. .

:0:

~

REAR

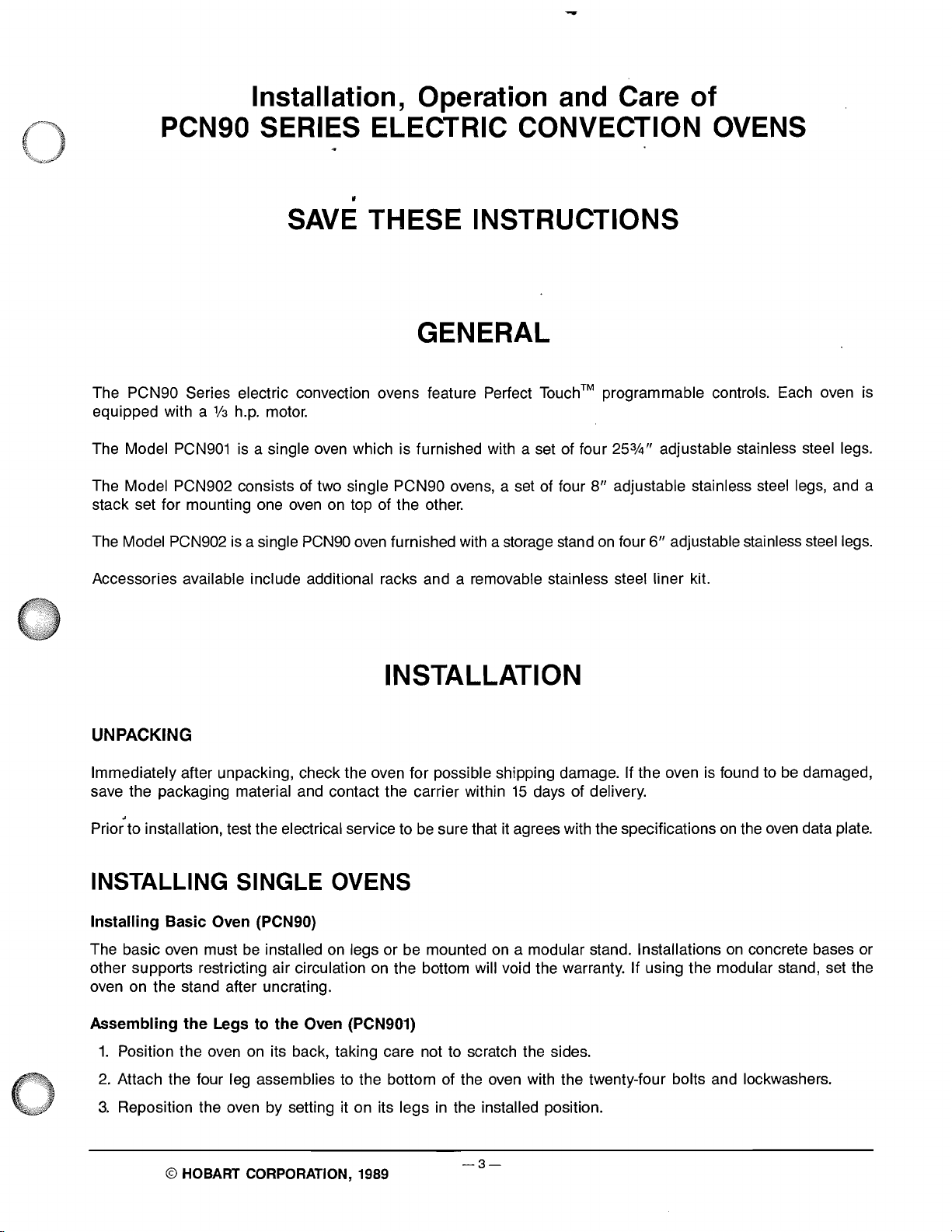

Fig.

1 - Installation of basic

for installing open stand, CX286).

BOTTOM

c:::==::J

OF

DEVICE

••

'\

:0:

LOCAnNGSTUDS

oven

on

cabinet - (procedures identical

Assembling Cabinet Base

1.

Screw two

2.

Mount the oven

Assembling

loceuing

I

the

Chimney and Flue Extension

or

Stand (PCN903)

studs (found

on

top of the stand or cabinet (Fig.

in

cabinet base or stand carton) into bottom of oven (Fig.

1).

1).

Remove the oven chimney and flue extension from the rear of the oven (motor compartment) and use the screws

provided to fasten the chimney to the top rear of the oven. NOTE: The flanges

cover.

under the top

Electrical

Connections

Also attach the flue extension.

the chimney are to

be

positioned

on

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE APPLICABLE

PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A

TO

INDICATE THAT

Assure that the electrical supply agrees with the specifications

Open the door of the wiring compartment cover by pushing the button

of the control panel). Remove the appropriate knock-out

YOU

ARE WORKING

ON

THE CIRCUIT.

on

the oven data plate.

on

on

the bottom of the oven and attach the power supply

THE DISCONNECT

the front of the oven (the lower portion

SWITCH

TAG

AT

conduit to the bottom of the oven.

Comply with the appropriate wiring diagram attached to the

oven

when making connections to the electrical supply

lines.

cover,

Replace the wiring compartment

and energize the power supply.

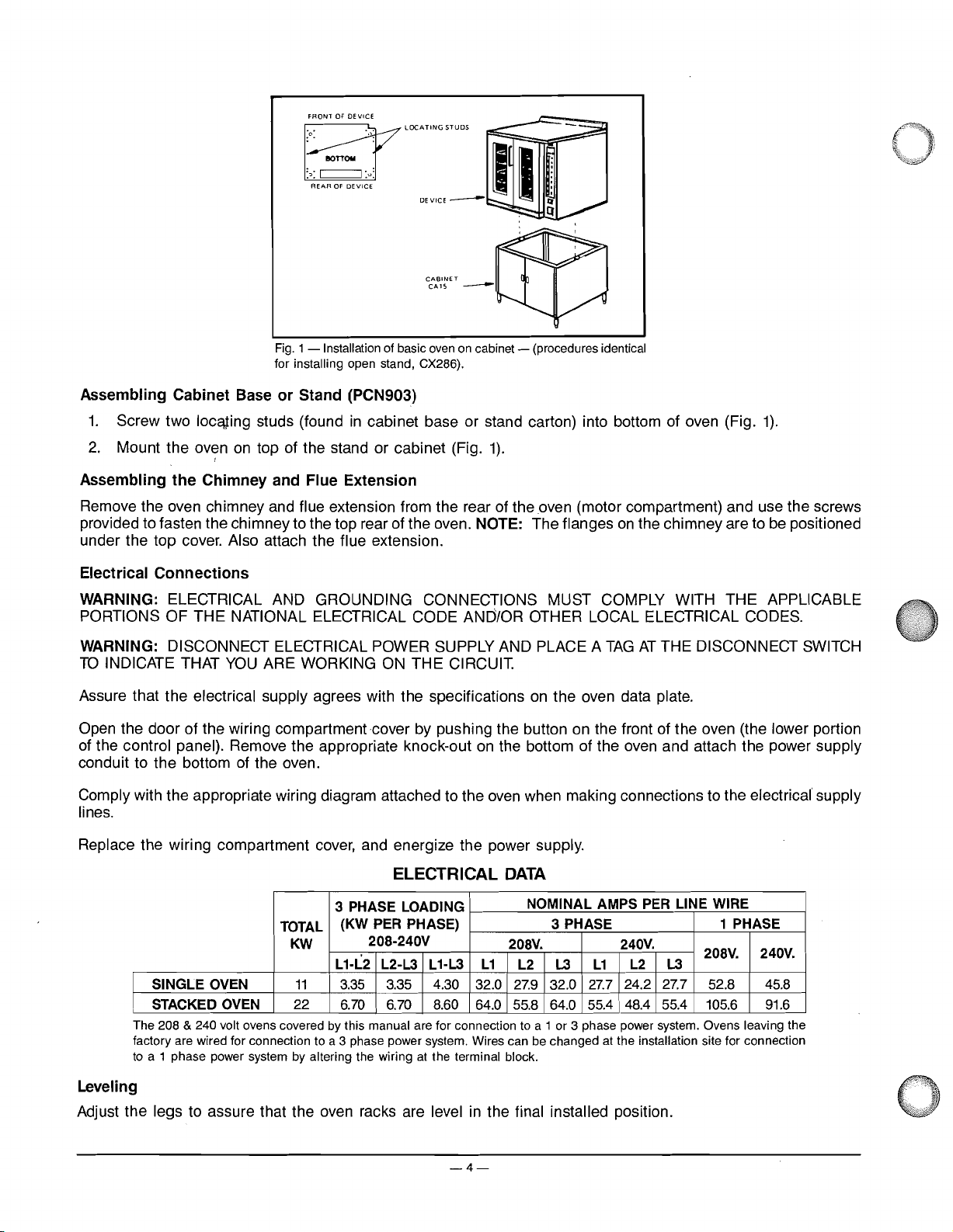

ELECTRICAL

3 PHASE LOADING

(KW

TOTAL

KW

SINGLE OVEN

I

I,

STACKED OVEN

The 208 & 240 volt ovens covered by this manual are for connection to a 1 or 3 phase power system. Ovens leaving the

factory are wired for connection to a 3 phase power system. Wires can be changed at the installation site for connection

to

a 1 phase power system by altering the wiring

11

22

PER PHASE) 3 PHASE 1 PHASE

208-240V

L1-L2 L2-L3 L1-L3

3.35

3.35

6.70

6.70 8.60 64.0 55.8 64.0 55.4

4.30

at

the terminal block.

DATA

NOMINAL AMPS PER LINE WIRE

208V. 240V.

L1

L2 L3

32.0

27.9

32.0

L2 L3

L1

24.2 27.7 52.8 45.8

27.7

48.4

55.4 105.6

Leveling

Adjust the legs to assure that the oven racks are level in the final installed position.

-4-

208V.

240V.

91.6

Page 5

INSTALLING DOUBLE OVENS

Assembling Stacked Ovens (PCN902)

1.

Position one oven

four leg assemblies with the twenty-four bolts and lockwashers provided.

2.

Place the lower oven (with legs)

the top cover plus the

3.

Install the two locating studs (included

upper oven.

4.

Remove oven chimneys stored at the rear of both ovens. Discard one chimney. Attach the remaining chimney

to

the top of the upper oven

under the top

5.

Move the oven with legs to the installed position and place the upper oven

the locating studs. Open the doors of the wiring compartment covers

both ovens. Also unfasten the control panel (of the lower

routing the power leads (furnished)

lock nut (also furnished).

6.

Attach the short flue extension over the exhaust vent

tube over the exhaust vent at the rear of the lower oven. These extensions should direct the exhaust fumes

upward through and above the top oven.

7.

Place the 1" conduit nipple through the 1%" hole

oven and clamp the two ovens together with the locknut from the underside.

(See

cover.

on

its back for access to the oven bottom, taking care not

on

Fig.

the floor and remove the two

Pia"

diameter knock-out

1).

(oven

without legs). NOTE: The flanges

at

the right front of the top cover.

in

the leg stack set) into the screw plates

t

oven

to

the top oven,

as

well

at

the rear of the upper oven. Slide the long flue extension

in

the bottom of the top oven and the top of the bottom

7/16"

only) and carefully pull forward. This will facilitate

as

attaching the one-inch conduit nipple and

to

scratch the sides. Attach the

diameter knock-outs

on

the under side of the

on

the chimney are

on

top of the lower oven using

by

pushing the button

on

each side of

to

be

on

positioned

the front of

Electrical

Connections

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE APPLICABLE

PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A

TO

INDICATE THAT

YOU

ARE WORKING

ON

THE CIRCUIT.

Assure that the electrical power supply agrees with the specifications

on

the wiring diagram

1.

Attach the power leads to the line side of the terminal block of the upper oven. Then carefully route these

leads (furnished

the oven.

as

part of the stack set) down through the conduit nipple and behind the control panel of

TAG

AT

THE DISCONf\IECT

on

the oven data plate and complies with

SWITCH

the lower oven.

2.

Attach these leads to the lower oven terminal block per the wiring diagram.

At

the same time, attach the

power supply conduit to the bottom of the lower oven. Also attach the power supply leads to the line side

,of the terminal block.

3.

Finally, inspect and check all wiring and terminal connections for tightness and proper routing away from

on

any moving parts (relay solenoid core), or pinch points (cover

oven frame). Then carefully replace the

lower oven control panel and wiring compartment covers for both ovens.

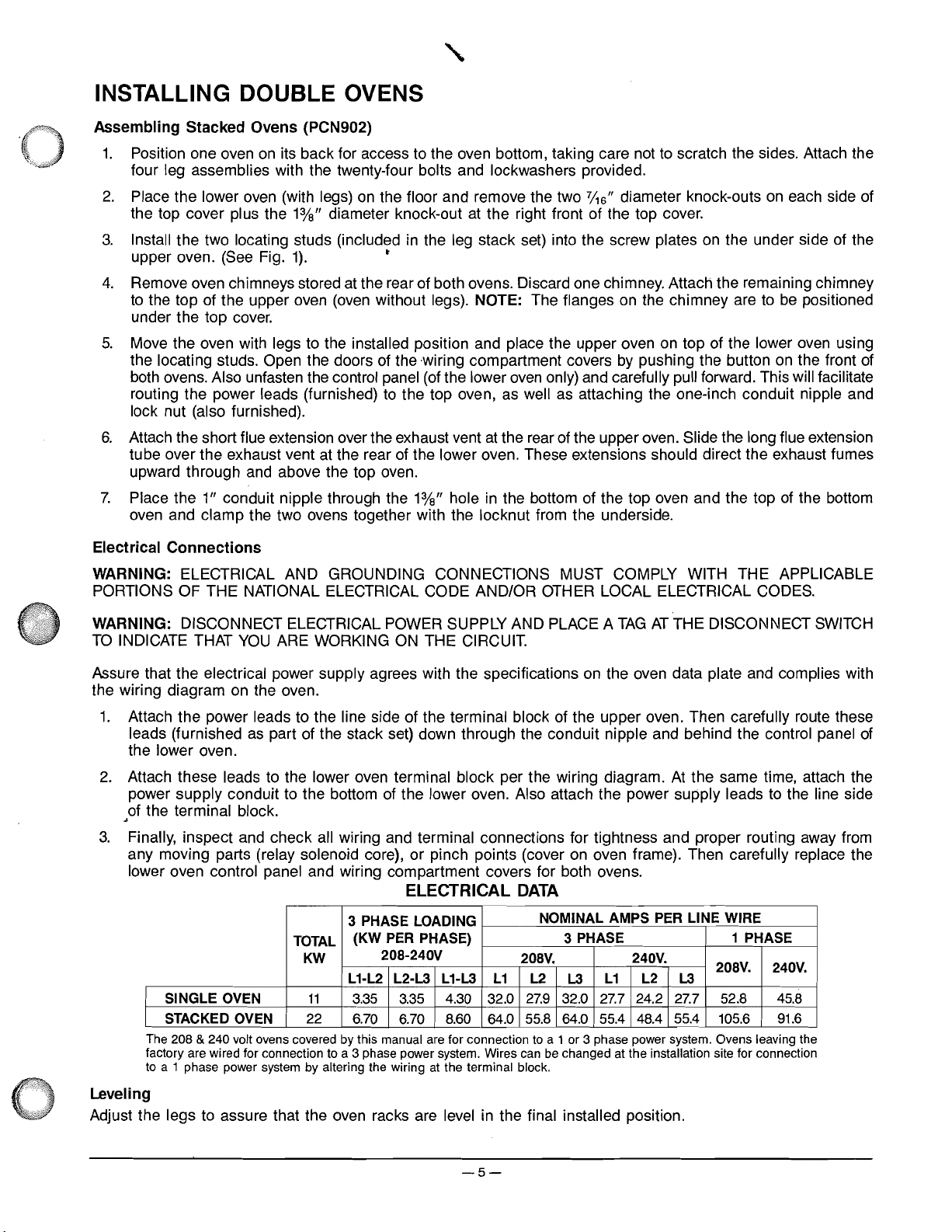

ELECTRICAL

3 PHASE LOADING

(KW

PER

TOTAL

KW 208V.

L1·L2 L1-L3

SINGLE OVEN

I

STACKED OVEN

I

The 208 & 240 volt ovens covered by this manual are for connection to a 1 or 3 phase power system. Ovens leaving the

factory are wired for connection to a 3 phase power system. Wires can

to a 1 phase power system by altering the wiring

11

22

3.35 3.35 4.30 32.0 32.0 27.7

6.70 6.70 8.60 64.0 55.8 64.0 55.4 48.4

PHASE) 3 PHASE

208-240V

L2·L3

at

the terminal block.

DATA

NOMINAL AMPS

L1

L2

27.9

be

PER

LINE WIRE

1 PHASE

240V.

L2

L1

L3

24.2 27.7 52.8 45.8

changed at the installation site for connection

208V.

L3

55.4 105.6 91.6

240V.

Leveling

Adjust the legs to assure that the oven racks are level in the final installed position.

-5-

Page 6

INSTALLING OPTIONAL LINER KITS

~

Fig. 2 - Contents of

stainless steel liner kit for standard

36"

deep convection ovens.

CX581

l _

The

CX581

Steps to Adding Panels

WARNING:

INDICATE

IMPORTANT: Remove all protective lining material from stainless steel panels prior to installation.

Remove all racks

rack back is raised

liner kit components are identified above. Please follow the sequence shown below to install.

DISCONNECT ELECTRICAL

THAT

YOU

ARE WORKING

Fig. 3 Fig. 4 Fig. 5

by

pushing down slightly

to

clear, pull straight out

POWER

ON

THE CIRCUIT.

on

front of rack top to disengage the positive rack rear lock. When

as

shown in Fig.

AND PLACE A

3.

TAG

AT

THE DISCONNECT

SWITCH

TO

Remove both left and right rack guides

as

center, and pUlling out

shown

Remove aluminized steel back blower baffle

left to right to clear side brackets as shown in Fig.

Fig. 6

Install top panel by inserting screws

shown

Install new back blower baffle

as

baffle supports. No screws

Install bottom panel

in

Fig.

6.

shown in Fig.

7.

Then press panel

are

by

lifting over rack guide brackets and pushing straight

by

required.

by

in

lifting them straight

Fig.

4.

by

lifting straight

Fig. 7

(3

screws

in

5.

Discard this blower baffle.

front, 2

up,

tilting the bottom of the guides toward the oven

up,

then pulling forward and out. Tilt slightly from

Fig. 8 Fig. 9

in

back) and screwing tightly to top of oven interior

as

tilting the panel slightly from left to right to clear the side rack guide brackets

up

against the oven's back interior. Lift and lower panel until it rests

in

as

shown in Fig.

8.

on

blower

Install left and right side panels placing the cut-out notches over light bank (right panel), thermostat guard (right

,and

panel)

Reassembling Rack Guides and Racks

rack guide support brackets (right

Reassemble the left and right rack guides

Insert racks

in

rack guides (reverse procedure

and

left panels), Fig.

by

inserting them in support brackets (reverse procedure

in

Fig. 3).

9.

in

Fig.

4).

-6-

Page 7

OPERATION

BEFORE FIRST USE

Before the oven

the new surfaces

Using a clean damp cloth, wipe the inside

Wipe the outer surfaces

Close the oven

300°F;

is

used for the first time, it must

in

the chamber.

to

remove any dirt of film that may have accumulated during shipment.

door,

turn the oven ON, and program one of the products for [TIME = 6:00:00; TEMP =

FAN = 2;

CC

= 0]. Start a cycle for this product button. Smoke with

be

"burned in" to release any odors that might result from heating

of

I

the oven, including the racks.

an

unpleasant odor will normally

be given off. When the display shows DONE, press the product button to cancel.

If your oven has the painted finish, apply a generous coat of wax or another hard glossy finish that will protect

the painted surfaces.

CONTROLS

Become familiar with the location and function

of

the controls illustrated in Fig.

ON - OFF Switch

LIGHT Switch

10

before programming the oven.

DISPLAY

HEAT (LED)

START

PRODUCT

Fig.

PROGRAMMABLE CONTROLS

The maximum programmable temperature is

will flash HIGH TEMP and a warning beeper will sound.

475

0

F.

If the temperature in the

10

CLEAR/ENTER

COOL/TEMP

PRODUCT (LED)

Product Strip

oven

should reach 5000 F.

the display

The maximum time that can

be

programmed is

19

hours, 59 minutes and 59 seconds.

-7-

Page 8

There are

four stages of cooking with TEMPerature,

on the first stage only but is

10

PRODUCT buttons (0-9) which may be programmed to automatically schedule one, two, three and/or

TIME,

FAN

in

effect for all stages.)

TEMP - Degrees Fahrenheit or Centigrade

TIME - HHMMSS

FAN

- 0 = Low Speed (during heat cycle), Otherwise

1 = Low Speed Continuous

HH

= Hours MM = Minutes SS = Seconds

and Cooking Curve setting for each stage. (CC is programmed

Off

2 = High Speed Continuous

CC

- 0 - 15 = See Cooking Curve

COOKING CURVE (CC): A relationship between temperature and time. If the oven temperature drops below the

set temperature for any reason, the control will compensate for that loss. The length of time between counts of

the timed countdown will increase to compensate for the temperature loss. The higher the CC number selected

"0"

the greater the increase. A cooking curve of

will not compensate for any change

in

temperature.

1 to 3

3 to 5

5

to 8

6 to 9

7 to 9

8

to

10

9 to

11

to

13

SETIINGS

SUGGESTED CC

Baked potatoes

Beef roast

Pies

Bread, cake

Buttermilk biscuits

Muffins

Cookies

Bacon

Generally the more delicate items will require the higher CC settings.

12

MANAGER SECURITY

The program for each PRODUCT may be operator or manager programmed. A manager programmed product

requires the

may not be changed or removed without first entering the

4 digit manager code

[0123J

to be entered before entering the program. Manager programmed products

4 digit manager code.

SERVICE

If a condition exists which requires a service call, the display will flash SRVICE each time the oven is turned

or just before

as long

servicer should be called.

'-

01\1

is displayed. Diagnosis and display of a problem will not interfere with the operation of the oven

as

the oven is operable. If the display reads OPEN or SHORT, the unit will not operate and an authorized

on

PROGRAMMING MODE

Please read entire instruction before beginning programming mode.

With ON/OFF switch ON

DISPLAY DO

1.

2.

ON Press CLEAR ENTER.

ENTER

...

Within 4 seconds you must press a PRODUCT (0-9). If you

wish to program a manager's PRODUCT, enter the Code

[0123J

Wait 5 seconds.

prior to a PRODUCT (0-9).

-8-

Page 9

Programming Mode (Cant.)

Ii

tl

,~

3.

4.

5.

6.

7.

DISPLAY

TIME-1

HHMMSS

TEMP-1

XXXF

FAN-?

FAN-X

CCO-15

CC-XX Press

TIME-2 If

DO

Enter the time for the

on

display.

2 and 4 zeros.

Press

Enter temperature for first stage.

Press

Enter fan setting for first stage.

o =

=

1

2

= High Speed.

Press

Enter the Cooking Curve

you

Repeat TIME, TEMP and

and/or 4

only at a

For

example:

START

START

Low

Low

START

START

wish to stop after this stage, press 0 and go

or wait 5 seconds.

or wait 5 seconds.

Speed (during heating cycle), Otherwise Off

Speed

or

or wait 5 seconds.

by

repeating steps

TI

ME prompt.

w~t

1st

stage. Time is entered right to left

To

enter 2 hours you must enter a

5 seconds.

(0-15).

FAN

settings for stages

3-5

as

required.

You

to

step

2,

3

may exit

8.

U

~

CC

The

8.

If

you

make a mistake and wish to step backward through a program you may do

you

When

program.

If you wish

9.

10.

If you wish to clear a PRODUCT program, simply press

To

clear a PRODUCT program that was entered with the manager code [0123],

[0123].

PRODUCT STRIP: After you program a

write directly

if products change.

000000

STORED

PROD-?

have corrected your error

If

you exit

to

I

on

by

review a program that has already been entered.

ON

TIIVIE-1

the strip with a permanent type felt tip marker or use labels which may

flashes

(Program was saved.)

you

pressing

"0"

you

PRODUCT,

To

step

must step forward by pressing

will delete the remainder of the program.

Press CLEAR/ENTER and PRODUCT

Wait 5 seconds.

Press

through the entire program. If

you

you

setting is entered

enter another program press a PRODUCT (0-9). Go to

3.

To

exit program mode press CLEAR.

START

will delete the remainder of the program.

"0"

may identify the PRODUCT

to step through the program.

at the

TIME-1

on

START.

prompt.

stage 1

so

You

you

you

must enter the manager code

on

only.

by

pressing CLEAR/ENTER.

must step through the entire

to

be

reviewed.

You

must step

press

"0"

to

exit

the PRODUCT

be

removed and replaced

STRIP.

review,

Simply

-9-

Page 10

NORMAL COOKING

With ON/OFF switch

DISPLAY

101.

102.

ON

PRE-HT

or

COO

Optional

Press COOL/TEMP (once)

Press COOLITEMP (twice) S YYYF

Press COOLITEMP

103.

READY

"Beeper Sounds"

ON

...

DO

Press the number of the pre-programmed PRODUCT

instruction

(0-9).

LNG Wait for temperature

to

103.

The LED of the PRODUCT selected will flash and

other products with a

= Actual temperature.

= Set temperature.

to

PRE·HT or COOLNG.

(3

times)

A XXXF

Returns

Load Product.

Other lighted PRODUCT(s) may

is

preheat

satisfied. If you wish to cook one of these

products, load and press that

to

stabilize at the TEMP 1 setting.

TEMP-1

within

10

degrees will be lit.

be

selected since the

PRODUCT.

Go

104.

105.

106.

DOOR

READY

Countdown begins.

I HHMMSS I

Close

Press

door.

START.

The total time for all stages programmed will be displayed and countdown begins. The normal interval between

is

counts

Compatible Products

Products are compatible if they have only one cooking stage which has the same temperature and same

as the one-stage product being cooked. During the cooking cycle, compatible product LED'S will

the cooking cycle the door may

that PRODUCT number pressed. The display will flash

flash

cooking time

one second, but the interval may change due to temperature variation and the selected cooking curve.

fan

be

lit. During

be

NOT

opened and one of these compatible products may be put

"OK"

if the product is compatible. If not, the display will

COM

PAT.

If the product is accepted, the shortest cooking time will be displayed. If the new product

is

less than the remaining time for the original product, the new time will

be

in

the oven and

displayed and counted

speed

down. When the time expires and the beeper sounds, open the door and remove the new product, close the door

and

press CLEAR. The remaining time for the original product will

be

displayed and counted down.

-10-

Page 11

Normal Cooking (Cant.)

Batch Processing

,

•

This feature allows

example: PRODUCT 1

1.

When preheat

you

to bake several batches of the same product and stagger the loading and unloading. For

is

programmed

is

satisfied and oven

10

minutes

is

ready,~d

at

375°F with a fan speed of 2

product

and

press

START.

and a CC

of

9.

Press PRODUCT

Prepare second batch, load second

batch and press PRODUCT 1 again. The display will continue to countdown the original time until expired. When

the original batch is removed, press CLEAR and the remaining time for batch 2 will countdown. The

will compensate for temperature loss during loading and unloading. The number of

by

the oven capacity.

or

If

you open the door, the timer freezes.

If

you wish to cancel a program

Optional

...

Timer continues

Press COOLITEMP (once)

Press COOLITEMP

Press COOLITEMP

107.

Countdown ends.

(twiCe)

(3

in

process, press CLEAR/ENTER two times.

to

countdown.

A XXXF

S YYYF

times) Returns

= Actual temperature.

= Set temperature.

to

countdown HHMMSS.

batch~s

s.

is

limited

CC

to

selection

twenty

DONE

"Beeper Sounds" Unload product.

108.

DOOR

Close

door.

';r

To

continue cooking mode, press CLEAR/ENTER, go to

102.

step

To

exit cooking mode, press CLEAR/ENTER two times.

LOADING

Press the PRODUCT for the program you want

as

load the oven

~

open, temperature drops will occur. The control uses cooking curves to adjust the cooking time, allowing for these

To

drops.

minimize heat loss during loading, the doors should be open for the least amount of time.

quickly

Close the door and press

MODEL

PCN901

PCN903

PCN902

NO.

STD.

RACKS

5

10

as

possible. Since the oven chamber

START.

RACK

STD. RACK

SPACING

IN.

2.87

2.87

DATA

(Pan

OPTIONAL

RACKS

to

select. When the display shows

Capacities Shown For

11

NO.

6 1.25

12

RACK

SPACING

IN. IN.

1.25

READY,

is

large and loading requires keeping the doors

Single

RACK

SIZE

27.5

x 20

27.5

x 20 6 2 1

Rack)

9"

00

PIE TINS

6 2

open the door and

#200

PANS

18"

x

PANS

1

26"

CONSERVING ENERGY

Turn

•

off unused equipment.

•

Do

not open door unnecessarily; use window for observation of food

-11-

in

oven.

Page 12

COOKING TEMPERATURES AND TIMES

Because of the moving air

in

the convection oven, the temperatures required

to

bake various products are lower

and the cooking times are shorter than in a conventional deck-type oven with still

are

subject

in

this manual are

to

many variations and tastes, the guidelines regarding temperature settings

SUGGESTED

ONLY.

You

should experiment with your food products

temperatures and times that give you the best results.

GUIDELINES FOR BAKING AND ROASTING

PRODUCT TEMPERATURE TIME

BREAD PRODUCTS

Bread

(24,

1-lb.

loaves)

Hamburger Rolls

Corn Bread

Yeast

Rolls 325F 25 min.

Baking Soda Biscuits

PASTRIES

Frozen Berry Pies (22

oz.)

340F

300F

335F

400F

350F

Frozen Fruit Pies (46 oz.) 350F 45-50 min.

Fresh Apple Pie (20 oz.)

(5

Sheet Cake

Ibs. per pan)

350-375F

315F

Sugar Cookies 300F

Cherry Crisp

300F

Chocolate Cake 335F 20 min. 5

Cinnamon Buns

Brownies

Danish

Angle Cakes

Cream Puffs

335F

350F

335F

250F

350F

Pumpkin Pie 300F

Fruit Cakes

275F

Apple Turnovers 350F

MEAT

Hamburger Patties

Steamship Round (80

(5

per lb.) (well done)

lb.

quartered)

400F

275F

Steamship Round (whole 60-80 Ibs.) 275F 8 hrs. (med.)

lb.

Ibs.)

avge.)

300F

275F

375F

300F

Rolled Beef Roast (20

Prime Ribs

Baked Stuffed Pork Chops

Veal

Roast

Boned

(15

Lamb Chops (small lean) 400F 6 min.

(10

Shell Steaks

Meat Loaf

FISH

Fish Stix

oz.) 450F

325F 40-45 min.

335F

Baked Stuffed Shrimp 400F

(1112

Baked Stuffed Lobster

Halibut Steaks (Frozen 5 oz.)

FOWL

Ibs.)

400F

350F

Chicken Breast - Thigh 350F

Chicken Back - Wing

(21/2

lb.

Chicken

Turkey Rolled

OTHER

quartered)

(18

lb. Rolls)

Macaroni and Cheese

350F

350F

310F

350F

Beef Pot Pies 400F 30-35 min. 5

Turkey

Pot

Stuffed Peppers

Pies 400F 30-35 min. 5

350F

Melted Cheese Sandwiches 400F

Pizza (7" Frozen)

Idaho Potatoes

'Where the number racks is

(120

count)

5,

insert the first rack

on

the bottom position and place the others

435F

440F 50 min. 5

30

min.

15

min. 5

25 min.

6 min.

34 min. 5 (30 pies)

25-30 min.

20-22 min. 5

15

min. 5

25 min. 5

20 min. 5

15

min. 5

12

min. 5

25-30 min. 3

20-25 min. 5

30-35 min.

70

min. 3

15

min.

10-12

min.

3

2

/4

hrs. (well done)

4 hrs. (med.)

3 hrs. (med.)

25-30 min.

3 hrs.

10

min.

7-8

min.

16-18

min.

6-7

min. 5

10

min. 3

30 min. 5

33-35 min.

30-33 min. 5

30 min.

3

3

/4

hrs.

30 min.

15-20

min. 3

10

min.

11

min. 6

on

every other rung.

air.

Since recipes and foods

and

cooking times contained

to

determine the cooking

NO.

RACKS

3 (every other rack starting

with bottom rack)

5

5

5

5 (20 pies)

5 (30 pies)

5

5

11

(264)

(2

pans ea. rack)

2

1

(2

roasts per pan)

3

(2

roasts per pan)

2

5

2

5 (24 per pan)

(16-18

5

5

per pan)

(2

pans per rack)

11

5

5 (26 per pan)

(6

pan - 2 rolls ea. rack)

3

5

(120)

5

-12-

Page 13

CLEANING YOUR CONVECTION OVEN

Always allow the

minimize the exposure of the operator to the hot

Leave the door

Press the COOUTEMP button. The

oven

to

cool prior to cleaning. If the oven is hot, make sure the doors are only slightly ajar

air.

To

speed up the cooling process:

ajar.

fan

will come

on

at high speed and will turn alternately

on

to

and off each

time the COOUTEMP button is pressed.

When the oven has cooled sufficiently, set the

CLEANING THE INTERIOR OF YOUR

Ovens With Standard Aluminized Steel Liners

Keep

the inside of the oven and racks wiped clean. If food particles or carbon accumulate

ON/OFF switch to OFF and clean the oven.

OVEN

so

doors cannot be

tightly closed, heat is wasted and the oven will not operate properly. Poorly closed doors permit a constant escape

of steam and vapor around the door. This causes condensation which deteriorates the finish around the oven front

and door lining.

When cleaning the interior of your oven, it is important to bear in mind that the aluminum coating, though tightly

is

adherent,

still a coating.

cold with mild detergent

be

all the cleaning that

To

preserve the coating and for ease of maintenance, clean often when the

(or

soap) and

is

necessary.

water.

This will prevent food and dirt from "baking on" and will frequently

oven

is

Where soil resists soap and water cleaning, use a wooden tool to loosen spillage from the cold oven. Follow with

a non-etching cleaner which is specifically recommended for aluminized steel. Use clear water to rinse; dry with

a soft clean cloth.

DO

NOT

USE STEEL WOOL, WIRE BRUSHES

OR

CAUSTIC SOLUTIONS SUCH

AS

LYE,

SODA ASH,

AMMONIA.

Ovens With Stainless Steel Liners

In

general, the principles detailed above for aluminized steel apply. Soap or detergent and water will usually handle

routine cleaning; dry with a soft clean cloth.

For

burned-on foods and grease which resist simple soap and water cleaning,

mixed into a paste may

used. Apply with stainless steel wool

or

be

This treatment is equally effective for "heat tint" (slightly darkened areas caused

in

to rub

the direction of the polish lines. Rinse with clear water and dry with a soft cloth.

an

abrasive cleanser (scouring powder)

sponge, always rubbing with the "grain".

by

oxidation). Again, remember

REMOVING PANELS

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A

TO

INDICATE

Remove tray racks

Remove right and left rack guides by lifting straight

Right and left panels may now be removed

not rest panels

Remove bottom panel

Remove blower baffle

on

the side. Blower wheel can now

THAT

YOU

by

on

bottom panel.

by

ARE

WORKING

ON

THE CIRCUIT.

pulling straight out.

up.

by

moving toward the center and pulling out.

by

pulling straight out.

lifting straight up and pulling out toward the front. Care should

be

cleaned

as

described in Cleaning

TAG

AT

THE DISCONNECT SWITCH

To

avoid scratching, do

be

exercised

The

Blower Wheel, immediately following.

to

clear brackets

OR

Top

panel and stainless steel interior panels

can

be

cleaned while

in

place.

If

removal of top panel is desired, unscrew

three screws from front top edge of top and two screws from rear flange of top. Slide out toward front.

by

Reassemble

reversing the above procedure.

-13-

Page 14

CLEANING THE BLOWER WHEEL

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A

TO

INDICATE

Remove all racks

Remove both right and left rack supports

Remove the blower baffle

THAT

by

YOU

ARE WORKING

pulling forward, lifting

by

lifting

up

and pulling out. Wash blower thoroughly with hot sudsy water using a sponge

ON

THE CIRCUIT.

up

and out.

by

lifting

up.

TAG

AT

THE DISCONNECT

SWITCH

or plastic web pad. Rinse with clean water and dry.

Replace the hardware

by

reversing the disassembly procedure.

CLEANING THE EXTERIOR OF YOUR OVEN

Wash

all exterior surfaces at least once daily using a cloth with warm water and a mild soap or detergent. Wjlere

surfaces have been waxed, use the cloth lightly - hard rubbing will remove polish. Follow with a clear rinse, then

dry.

This simple treatment will keep your equipment clean and sparkling, and eliminates the danger of grease

accumulation.

Permalucent Finish

If

grease has accumulated and attacked the PERMALUCENT finish, use

on

the container. NEVER use a scouring pad

on

the PERMALUCENT finish.

any

silicon-based polish following directions

If the surface is accidentally marred, it can

be

quickly and easily restored with a "PERMALUCENT Touch-Up Kit",

available through your Dealer. Full instructions are in each kit.

Cleaning Stainless Steel Surface

To

keep the stainless steel front spotless, clean regularly with a damp cloth and polish with a soft, dry cloth.

remove discolorations which may have formed when regular cleaning

soap and water.

CAUTION: Always

For

particularly stubborn discolorations, a self-soaping scouring pad may

rub

with the

"Grain"

in a horizontal direction.

was

neglected, use any detergent or plain

be

used.

Rinse, dry and polish with a soft cloth. Avoid using gritty soaps or harsh cleaners.

REPLACING LAMPS

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A

TO

INDICATE

Remove all racks

Remove both the right and left rack supports

THAT

by

YOU

ARE WORKING

pulling forward, lifting

ON

THE CIRCUIT.

up

and out.

by

lifting

up.

Remove ten screws from the light window bezel.

Pull out the bezel and window.

TAG

AT

THE DISCONNECT

To

SWITCH

Replace the bulb(s).

Replace the hardware

by

reversing the disassembly procedure.

-14-

Page 15

CABINET BASE

(TYP.

*"

~~iH

:SCT":'r'M

FOR

CN901,(N911,CN~21,CN93IlIJN971,

FOOT) 8

WA.CK.

TO

FLOtR:)

ON981&-PCNC)OI

-2-g

711'U

t'

16

1.----.

CAI5

CAI6

(CN90,CN92,DN97&PCN90)

(CN91

FRONT

37

CN93

~

- ,

&-

DN98)

r

4C'2

16

[,£;.!Q

&ON>O

CN"'~

1

2'OOT

1

~':

.J'--2~

, CN931,

,'PCN901

DN971,DN98\;

j! 3

- -

I

-Jr' .

J

, t

i'TVPrcAL

L

'16-

8"'AX

,11)1-1.

_,

I)PEN

32~

16

,~

ON."

CN'O.

("'~,

PCH,t'1

" 3

jL

I

4 ADJUETMENT

~

(HP'

FO,:T

'DOT)

EACH

ll,'

I'

32'B"

I

-t1

'

~

CN9ul,

-.!fl

FRO

C

N911,

Y.Jf.IJ:1.

CN921

'D'

t I

,254"

3

'~

\--

}~!I_n

-,~;

[,J

!

.r__

=

======u_2j8~

j

J

______

[]J

- - -

---

[]J

I'

I' . .U

54~

0n

l

0l l

'.

CONOUIT

CONN£C"OH

In

1I

OVEN - I \ OIA. HOLE

LO(ATJON

wrTH

(.''NCENIHI(

I~OIA,

Itl

i'NC<K(Jul

&.

BA~[

[01

....

OF

, ,

,

,

,

L

II

lLCCATtCl1 Itl

a

((JNDUIT CrrlllEc.rlON

OVEN

BASr

54-t

I

r- ' 38'

130~-~

CotlOulr

CONNECTiON

r,--<---g=

1----'

,

PCN90,

PCN901,

PCN902,

PCN9C3

• PCN904

r----··,

38

l

MAX,OOC'K

r-15~~

aPfN"

,

...

3'

44~.ft1,C.~9.s

" 'j)'N97

CN9C),CN92

& peN90 I

'"

-;;1

& ON98

Clj90,

CN9'?

CN92,

DN97, DNSI?\,

CN93,

CN921.

CN931,

CN922, CN923, CN924

DN9;",

CN932, CN933,

DNS73,

CN934

DN974

"

,.'

CN903,

CN913,

CNS04,

CN914,

CN911

r'(

./...-TEFlMINAL

BLOCK

CN91,

CN90l,

CN902,

DN98,

DN9~

I,DN9S"

,DN983,

DN984

<.;,,"

1

I

5

'2

-""'."..

TOP

/~A)(.

/

SWINe

"

DOOR

VIEW

'.

,

-..

"-

Q

i

111

Oll

CX286

CX337~~

OPEN STAND

CN'lQ

CN9?,DN~7tPCN9Q

NOMINAL DIMENSIONS IDENTICAL

BASE

SIDE

S,

AS

&-

BACK,

SHOWN

BELOW,

EXCEPT

TO

LESS

CABINET

DOORS,

I

I

.

j

/'/'

,,~....

/,l

l,~

I I

"'I',

I

n

-I.::r

2

2~

C"'"HEYAI-l

<8

-

II'~

•

F44"~CN93

5

U(

....

,"IG

4

I"

@

NOTE:

I

TOP

~,OIA

CO\l[~

)(NO(l<DUT

fOR

ill

/

36'

CN90,CN92

BmL<

nOlO'"

l.40TaR

~,4.'K)

(NOT

FDA

2-5PEEO

SE,PMl

.•

TE

2 ib

-...c=-rC'"

I

L_~'4'fTI4

i61

I

uJ

I'

I'

'.

• .

.

/'N

I \

alA

BASE

HOLE

FOR

WITH

CONOUIT

I~

(1IJ'.

CONN"tlON,

&.

2~(

11'1

(ON~~N1RIC

f2

a:

:::E

····

,

1

J

m,['

I-LI1

,

2

2"

8

I

ADJ.

(TYP~E"'CH

FOOT

FOOT)

a:

~

I

ce

~

I

"BLO'Wffi

2

SPEED

MOTOA.

J

1

1

20"

LO

...

~._-:

;J

"

r~FOR

SPEED

MOTOR.

l~

I

i

I

I FLUE

:

rr

EXTENSIONS

;-'\;:

..

'I-L

I 8

7

I

DN97

&,IDN98

& PCN90

KNGCI<QUT

it

D.

!Z

w

c

2':

::i

en

~

Loading...

Loading...