P660 MIXERS

ML-134198, 134199, 134200

P660 MIXER

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

F-34818 Rev. B (Apr. 2003)

Model P660 Mixer

© HOBART CORPORATION, 2002

– 2 –

TABLE OF CONTENTS

GENERAL............................................................................................................................................. 4

INSTALLATION.................................................................................................................................... 5

Unpacking....................................................................................................................................... 5

Location .......................................................................................................................................... 5

Electrical Connections ................................................................................................................... 6

Electrical Data ................................................................................................................................6

OPERATION ........................................................................................................................................ 7

Electromechanical Timer Controls (When Equipped).................................................................. 7

Programmable Timer Controller (When Equipped) ..................................................................... 8

Changing Speeds......................................................................................................................... 11

Bowl Lift ........................................................................................................................................ 11

Mixing............................................................................................................................................ 11

Wire Cage assembly (Before September, 2002 Production Fig. 5) ......................................... 12

Wire Cage assembly (After September, 2002 Production Fig. 6)............................................. 13

Attachments ................................................................................................................................. 15

Mixer Speeds (When Equipped) ................................................................................................. 15

CLEANING ......................................................................................................................................... 15

MAINTENANCE ................................................................................................................................. 16

Lubrication .................................................................................................................................... 16

Adjustments.................................................................................................................................. 18

TROUBLESHOOTING ....................................................................................................................... 19

Service .......................................................................................................................................... 19

– 3 –

2345678901234567890123456789012123456789

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

The P660 model mixer is a heavy-duty, 60-quart mixer which is designed primarily for preparing dough,

2345678901234567890123456789012123456789

2345678901234567890123456789012123456789

batter and pastry. It features a 2

2345678901234567890123456789012123456789

Installation, Operation and Care of

P660 MIXERS

SAVE THESE INSTRUCTIONS

GENERAL

1

/2 horsepower Hobart-built motor, a #12 Attachment Hub and an

electromechanical timer as standard equipment.

Also available are the following: 30-, 40- or 60-quart bowls, bowl adapters, special agitators and a

variety of other accessories and attachments. These are described in a separate

Handbook,

which is furnished with each mixer.

Use and Applications

Bowl Guard is standard equipment on all P660 models.

Programmable timer controller is optional on P660 models.

– 4 –

INSTALLATION

UNPACKING

Immediately after unpacking the mixer, check for possible shipping damage. If this machine is found

to be damaged after unpacking, save the packaging material and contact the carrier within 15 days of

delivery.

Prior to installation, test the electrical service to make sure that it agrees with the specifications on the

machine data plate.

LOCATION

Place the mixer in its operating location. There should be adequate space around the mixer for the user

to operate the controls and to install and remove bowls. The area above the mixer should allow the top

cover to be removed for routine maintenance and servicing.

Holes are provided in the base for permanent bolting to the floor; although this is not necessary in

normal installations. Four plastic plugs are supplied with the mixer to plug these holes if they are not

used.

Once placed in the operating location, level the mixer.

1. Remove the top cover screws and the top cover.

2. Place a level on the machined surface of the transmission case (Fig. 1).

3. Slide shims under the legs (base) of the mixer as required to level it front-to-back and side-toside.

NOTE: Do not replace the top cover until installation is complete.

Fig. 1

Check Lubrication Before Use

This mixer is shipped with oil in the transmission. Mixer production prior to September 2002 will have

oil in the planetary. Mixer production after September 2002 will have grease in the planetary. Check

oil levels before starting mixer. Refer to Lubrication, pages 16 to 17, for applicable lubrication

procedures.

– 5 –

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTION OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

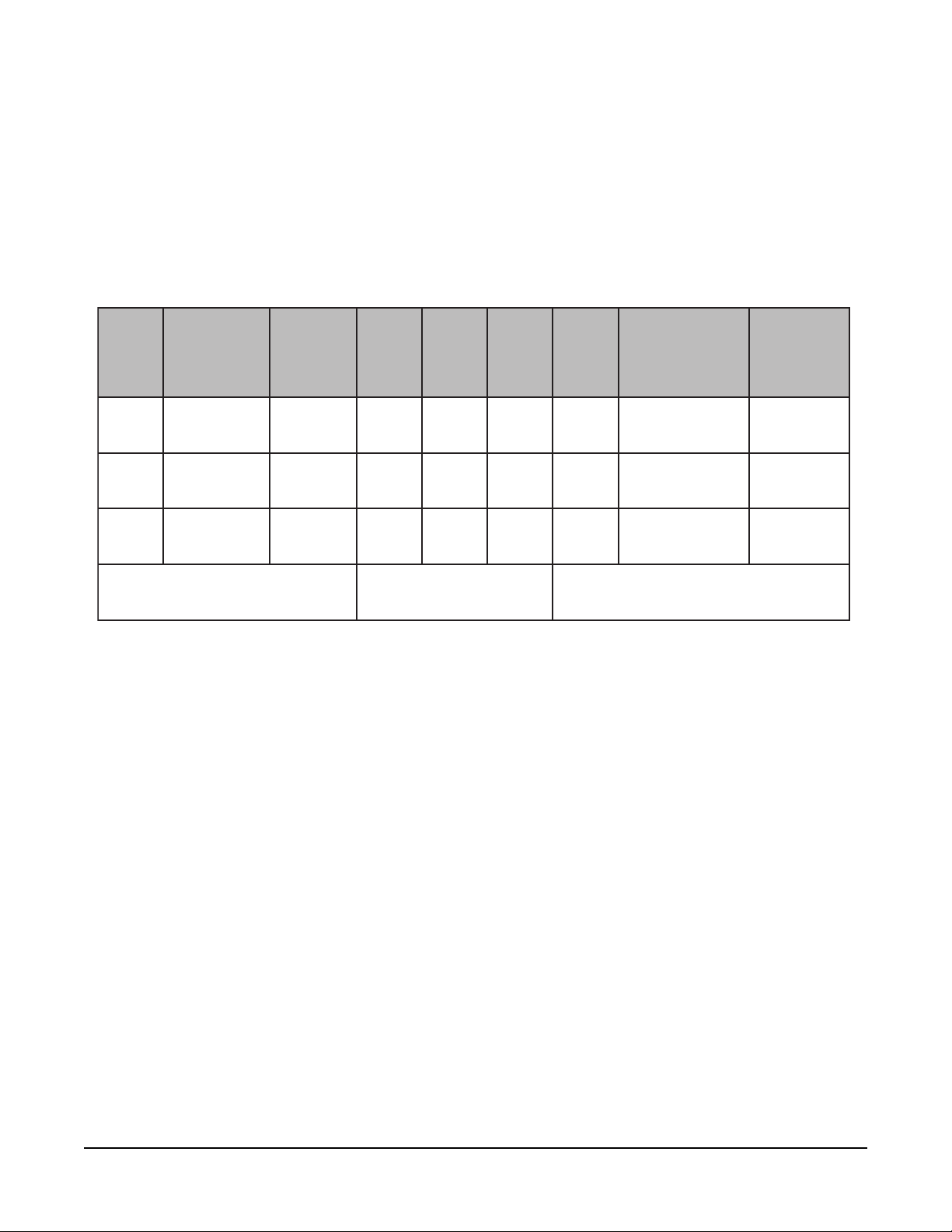

ELECTRICAL DATA

C°06

reppoC

erIW

eziS

tnemelElauD*

esuFyaleD-emiT

tiucriC

eziS

)spmA(

**rekaerBtiucriC

)spmA(

C°06

reppoC

eziSeriW

rekaerBtiucriCemiTesrevnI**

sledoM hP/zH/stloV

066P1/06/8020.02030301030321

066P1/06/0420.71525201030301

066P3/06/042/8026.8515141020221

A hole for

detaR

spmA

3

/4" trade size conduit is located at the top of the pedestal. Make electrical connections per

tiucriC

eziS

)spmA(

*esuF

eziS

)spmA(

the wiring diagram located on the inside of the Top Cover.

Check Rotation (Three-Phase Machines Only)

Three-phase machines must be connected so the planetary rotates in the direction of the arrow on the

Drip Cup. To check rotation:

1. Set the Gear Shift Lever on 1.

2. Apply power to the mixer, set the electromechanical timer on HOLD or, if equipped with a

programmable timer controller, set it on [ -- : -- ]. With the Bowl Support all the way up,

momentarily run the machine by pushing the START and then STOP buttons.

3. If rotation is incorrect, disconnect electrical power supply and interchange any two of the

incoming power supply leads.

– 6 –

Loading...

Loading...