Page 1

THE EDGE12 SLICER

MODEL

EDGE12-1 (120/60/1 voltage) ML-136246

EDGE12 SLICER

EDGE12-2 (220/50/1 voltage) ML-136247

701 S. RIDGE AV ENU E

TROY, OHIO 45374- 00 01

937 332-3000

www.hobartcorp.com

FORM 35283 Rev. A (March 2013)

Page 2

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Slicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Knife Sharpening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

– 2 –

Page 3

Installation, Operation and Care of

EDGE12 SLICER

SAVE THESE INSTRUCTIONS

GENERAL

The Edge12 slicer is equipped with a 1⁄2 HP motor. The slicer KNIFE is chrome-plated forged carbon

steel. The S

fi nish anodized cast aluminum for easy cleaning. The rear-mounted M

with extension behind the P

A cord and plug is furnished as standard equipment.

The Edge12 slicer must be thoroughly cleaned, rinsed and sanitized after installation and before

being used. Refer to Cleaning, page 5.

UNPACKING

Immediately after unpacking the slicer, check for

possible shipping damage. If the slicer is found to

be damaged, save the packaging material and contact

the carrier within 15 days of delivery.

LICER BASE, PRODUCT TRAY, KNIFE COVER, RING GUARD and GAUGE PLATE are made of smooth

EAT GRIP is hinged on a rod

RODUCT TRAY. The top-mounted knife SHARPENER is removable for cleaning.

INSTALLATION

Prior to installing the slicer, test the electrical

service to make sure that it agrees with the

specifi cations on the machine data plate. The data

plate is located on the right side of the slicer base.

The PRODUCT TRAY is secured to the slicer by turning

the K

NOB below the PRODUCT TRAY clockwise until

snug (Fig. 2).

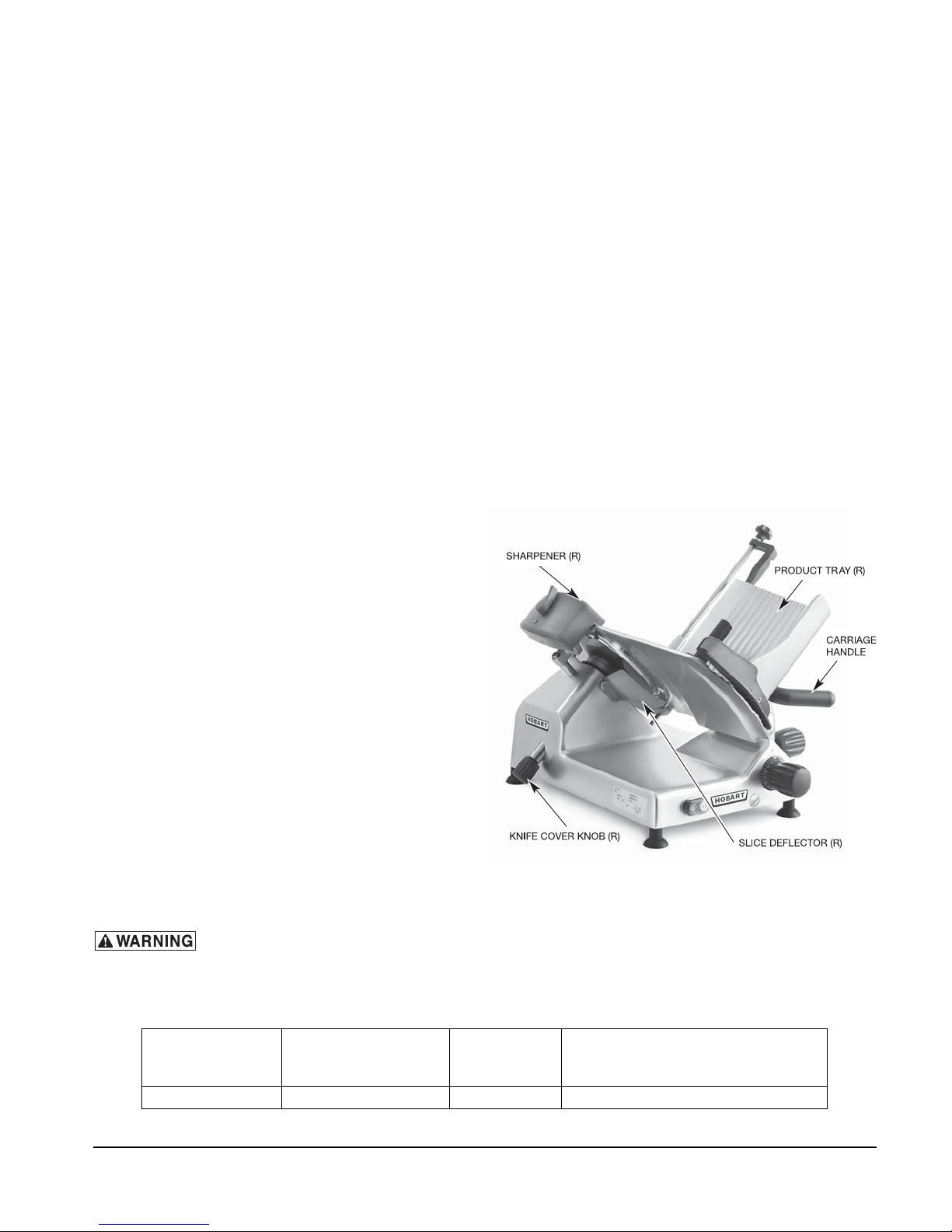

Mount the SHARPENER on top of the slicer (Fig. 1)

by lowering it onto its post. The S

HARPENER can be

removed for cleaning.

The SLICE DEFLECTOR (Fig. 1) should already be

mounted below the knife.

Fig. 1

(R) refers to removable part.

ELECTRICAL

This machine comes with a three-prong grounding plug. The outlet to which this

plug is connected must be properly grounded. If the receptacle is not the proper grounding type,

contact an electrician.

ELECTRICAL DATA

Model Volts / Hertz / Phase

EDGE12 120 / 60 / 1 4.0 15

Compiled in accordance with the National Electrical Code, NFPA 70, latest edition.

Machine

Amps

Minimum Circuit Ampacity

Maximum Protective Device

AMPS

©

HOBART CORPORATION, 2012

– 3 –

– 3 –

Page 4

OPERATION

SAFETY

SAFETY DEVICES INCORPORATED IN THIS SLICER MUST BE IN THEIR CORRECT OPERATING

POSITION ANY TIME THE SLICER IS IN USE.

NIFE COVER should already be secured in place with the KNIFE COVER KNOB on the left side tightened

The K

clockwise (Fig. 1). The R

The MEAT GRIP (Fig. 4) helps secure product in position and must be used when slicing short ends to

keep your hand(s) away from the knife.

When the slicer is not running, the INDEX KNOB

(Fig. 2) must be turned fully clockwise so the

G

AUGE PLATE covers the KNIFE edge.

Always UNPLUG the POWER CORD before cleaning

or moving the Slicer.

Rotating knife. Unplug machine

power cord before cleaning, servicing or

removing parts. Replace parts before use.

SLICING

ING GUARD is not removable.

With the G

T

RAY forward until it stops. With the MEAT GRIP

AUGE PLATE fully closed, pull the PRODUCT

out of the way, place the product to be sliced on

the P

RODUCT TRAY. Set the MEAT GRIP against the

product. Turn the slicer on by pressing the S

WITCH

Fig. 2

(R) refers to removable part.

ON (Fig. 2).

If the M

and rotating it 270° behind the P

T

RAY slot.

EAT GRIP is not needed, store it out of the way by lifting it to the top of the MEAT GRIP ROD

RODUCT TRAY. Allow it to rest on the small notch of the upper PRODUCT

Adjust the GAUGE PLATE to obtain the desired slice thickness by turning the INDEX KNOB (Fig. 2) to vary

the slice thickness from paper thin to

9

⁄16" thick. Use the CARRIAGE HANDLE (Fig. 2) to move the carriage

back and forth to slice.

CLEANING AND SANITIZING

Thoroughly clean, rinse and sanitize the slicer after each day’s use or after being idle for an extended

time.

The slicer knife is very sharp. Exercise extreme caution when working near the knife.

Unplug the machine power cord and turn index knob fully clockwise to close the

gauge plate before cleaning the slicer.

Note: Sanitizer concentration shall comply with Section 4-501.1 14, Manual and Mechanical Warewash-

ing Equipment, Chemical Sanitation – Temperature, pH, Concentration, and Hardness of the FDA Food

Code. If a chemical sanitizer other than chlorine, idine, or quaternary ammonium is used, it shall be

applied in accordance with t he EPA-registered label use instruc ti ons.

– 4 –

Page 5

Cleaning Surface and Parts:

Frequency: The slicer shall be cleaned and sanitized at intervals to comply with national, state

and/or local health codes.

Disassemble all removable slicer parts including P

D

EFLECTOR, KNIFE COVER, KNIFE COVER KNOB and SHARPENING STONE (See Fig. 1 and 2). Wash all sur-

RODUCT TRAY, MEAT GRIP, MEAT GRIP ROD, SLICE

faces of the machine with warm soapy water, a towel and mild detergent. Also, wash surfaces where

food or liquid can accumulate or where there is frequent hand contact including handles, knobs and

the control panel. Use generous amounts of soapy water on the sharpener hardware and knife hub.

Clean all removable parts with water, a towel and mild detergent (refer to Page 7). Rinse with water

and clean towel. Sanitize and let air dry.

• Excessive amounts of sanitizer and use of products not formulated for aluminum may void your

Hobart warranty.

• DO NOT wash any slicer components in a dishwasher.

• DO NOT hose down slicer or splash excessively with water.

• Use ONLY products for mulated to be safe on stainless steel or aluminum.

• DO NOT exceed chemical manufacturer’s recommended concentrations for detergent or sanitizer.

• DO NOT clean any parts of the slicer with a steel pad.

Cleaning Meat Grip and Product Tray:

Tur n I

position. Unscrew knob on P

extract M

P

NDEX KNOB fully clockwise until GAUGE PLATE is in closed position. Pull PRODUCT TRAY to home

RODUCT TRAY and lift to remove (Fig. 3 ). Unscrew MEAT GRI P KNOB in order to

EAT GRIP ROD from the PRODUCT TRAY (Fig. 4) . Set aside rod and MEAT GRIP. Wa sh surface area,

RODUCT TRAY, MEAT GRIP and MEAT GRIP ROD with water, a towel and mild detergent. Rinse, sanitize and

let air dry.

T o replace the P

Thread M

EAT GRIP ROD into PRODUCT TRAY extension and then inser t into MEAT GRIP. Tighten rod clock-

wise until snug.

RODUCT TRAY, lo wer the tra y onto the carriage and tighten the knob clockwise until snug.

Fig. 3 Fig. 4

– 5 –

Page 6

Cleaning Knife and Slice Defl ec tor:

With MEAT GRIP and PRODUCT TRAY removed, turn INDEX KNOB fully closed. Unscrew the KNIFE COVER KNOB

(Fig. 5) . Push the knob to remov e K

Remove t he S

the K

NIFE COVER KNOB, KNIFE COVER, SLICE DEFLECTOR and both sides of the KNIFE by wiping outward

LICE DEFLECTOR (Fig. 6) by unscrewing the stainless steel knob. Wash, rinse and sanitize

NIFE COVER. Remove both the KNIFE COVER and the KNIFE COVER KNOB.

from the center. Allow to air dry.

Fig. 5 Fig. 6

Cleaning Ring Guard:

Work a moistened paper towel between the RING GUARD and K NIFE. Insert the towel at the base of the

R

ING GUARD (Fig. 7). Manually rotate the KNIFE to wipe RING GUARD and the edge of GUARD PLATE.

To replace the K NIFE COVER, inser t the KNIFE COVER KNOB into its hole (lower left side) and position the

K

NIFE COVER over the center hole so the guide pin fi ts the hole in the rim and the hub fi ts the cen te r h ole .

Tighten the K

underneath the K

NIFE COVER KNOB (Fig. 5) so the threads at the end of the rod screw into the threaded hub

NIFE COVER.

Cleaning Sharpening Stone:

Each time the S

HARPENER is used, the sharpening stones should be examined for cleanliness. Scrub

stones with a stiff bristle brush. Rinse with clean water and sanitize.

Reassemble the S

HARPENER by lowering it onto the sharpener post (Fig. 8).

NOTE: Do not exceed chemical manufacturer’s recommended concentrations for detergent or

sanitizer. Do not exceed 200 parts per million concentration of available chlorine (1 tablespoon of

5.25% sodium hypochlorite bleach with 1 gallon of water). Concentrations greater than 200 ppm

accelerate corrosion of metals. Maximum exposure to sanitizing solution varies with temperature

and concentration. Rinse with clean water.

NOTE: Failure to follow use, care and maintenance instructions may void your Hobart warranty.

– 6 –

Page 7

Fig. 7 Fig. 8

GASKET INSPECTION

GASKET BETWEEN HANDLE/SPACER

AND SPACER/MEAT PUSHER

GASKET

BETWEEN THE

PRODUCT TABLE

AND THE

THUMB GUARD

PROTECTION ON

THE SWITCH

GASKET BETWEEN

THE PRODUCT TABLE

AND THE EXTENSION

GASKET BETWEEN

THE PRODUCT TABLE

AND THE SUPPORT

GASKET BETWEEN THE

HANDLE AND THE

PRODUCT TABLE SUPPORT

The recommended interval between inspections shall not exceed six months for components

that are detached for cleaning and sanitizing (all the gaskets in the images).

The inspections must be made by the manufacturer or its authorized service agent.

The slicer must be removed from service until repaired by the manufacturer or its

authorized service agent if any gasket or seal is found to be damag e d, o r mis sing.

Fig. 8

– 7 –

Page 8

KNIFE SHARPENING

MAINTENANCE

The K

applications where it is a practice to sharpen the K

NIFE will provide long service in normal food store or kitchen use. However, in high volume

NIFE frequently or even daily, the KNIFE will be

expended in a shorter time.

Sharpen only when necessary. Prolonged or sharpening too frequently results in unnecessary

knife wear.

Unplug machine power cord.

Tu rn the I NDEX KNOB fully clock wise to close the GAUGE PLATE. Remove the KNIFE COVER by uns c rew in g

the K

NOB and lifting it off the slic er.

Clean and sanitize the slicer as outlined in the cleaning section before sharpening the KNIFE. Food debris

must not be allowed to transfer from the K

NIFE to the SHARPENER. Plug in the machine power cord.

Turn the slic er ON. Pull the SHARPENER HANDLE (Fig. 10) forward for 5 seconds and release. Turn the

slicer off. Unplug machine power cord. Clean and sanitize the slicer as outlined in the c leaning section

after sharpening the K

NIFE. Replace the KNIFE COVER.

LUBRICATION

Maintain smooth slicing by applying a few drops of mineral oil on the C

the slicer base. Do not use vegetable oil.

Make sure that the circuit breaker has not tripped or the fuse blown.

SERVICE

Contact your local Hobart-authorized service offi ce for any repairs or adjustments needed on this

equipment.

FORM 35283 Rev. A (March 2013) PRINTED IN U.S.A.

Fig. 10

ARRIAGE SLIDE ROD underneath

TROUBLESHOOTING

– 8 –

Loading...

Loading...