Page 1

THE EDGE12 SLICER

MODEL

EDGE12-1 (120/60/1 voltage) ML-136246

EDG E12 SL ICE R

EDGE12-2 (220/50/1 voltage) ML-136247

701 S. RIDGE AVE NUE

TROY, OHIO 45374- 0001

937 332-3000

www.hobartcorp.com

FORM 35283 Rev. B (September 2015)

Page 2

TABLE OF CONTENTS

GENERAL .......................................... 3

INSTALLATION ...................................... 3

Unpacking ..................................... 3

Electrical ...................................... 4

OPERATION ........................................ 4

Safety ........................................ 4

Slicing ........................................ 5

Cleaning ...................................... 5

MAINTENANCE ..................................... 8

Knife Sharpening ............................... 8

Lubrication .................................... 8

TROUBLESHOOTING ................................. 8

Service ....................................... 8

© HOBART, 2012

– 2 –

Page 3

Installation, Operation and Care of

EDGE12 SLICER

SAVE THESE INSTRUCTIONS

GENERAL

The Edge12 slicer is equipped with a 1⁄2 hp motor. The slicer Knife is chrome-plated forged carbon

steel. The

nish anodized cast aluminum for easy cleaning. The rear-mounted

with extension behind the

A cord and plug is furnished as standard equipment.

The Edge12 slicer must be thoroughly cleaned, rinsed and sanitized after installation and before

being used. Refer to Cleaning, page 5.

UNPACKING

Immediately after unpacking the slicer, check for

possible shipping damage. If the slicer is found to

be damaged, save the packaging material and contact

the carrier within 5 days of delivery.

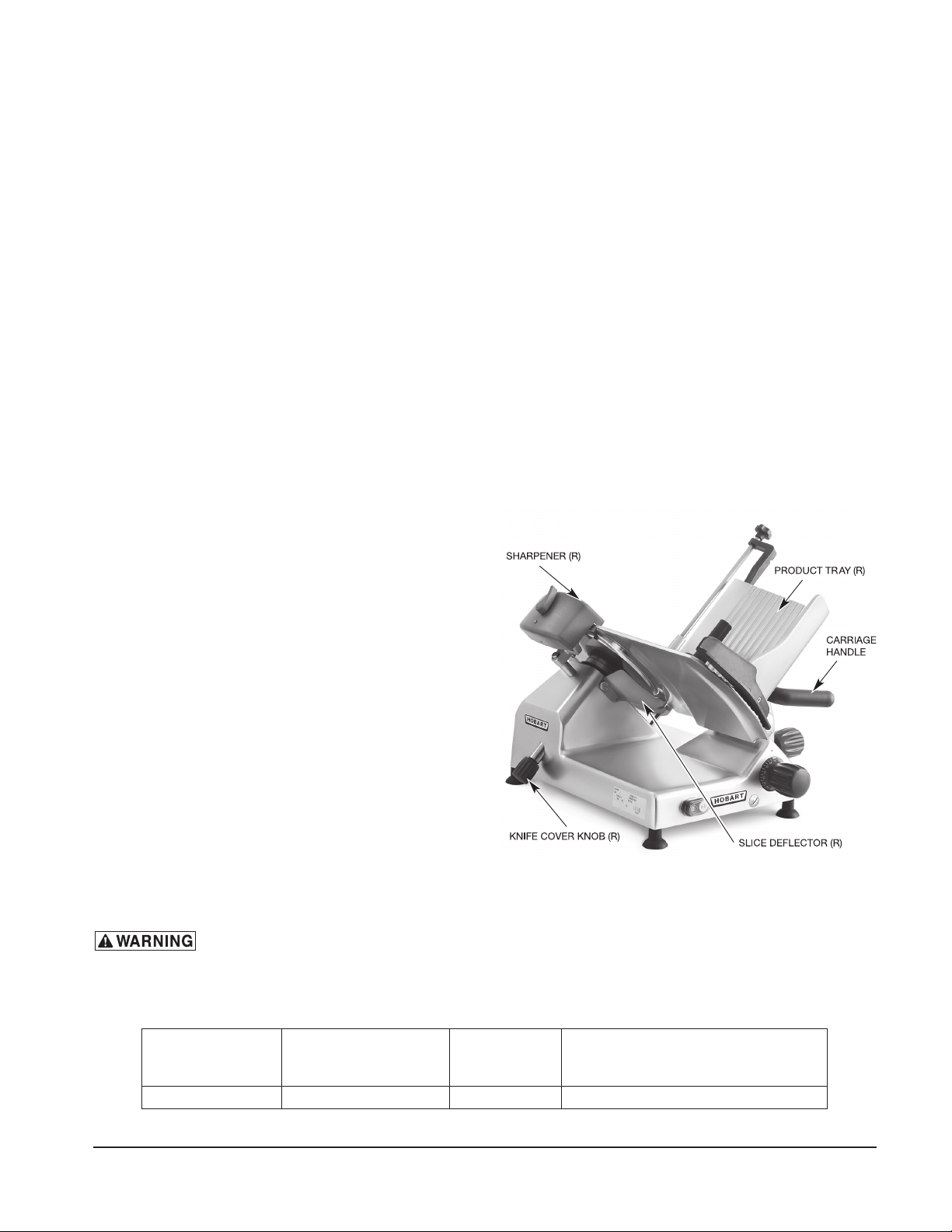

Slicer BaSe, product tray, Knife cover, ring guard and gauge plate are made of smooth

Meat grip is hinged on a rod

product tray. The top-mounted knife Sharpener is removable for cleaning.

INSTALLATION

Prior to installing the slicer, test the electrical

service to make sure that it agrees with the

specications on the machine data plate. The data

plate is located on the right side of the slicer base.

product tray is secured to the slicer by turning

The

KnoB below the product tray clockwise until

the

snug (Fig. 2).

Mount the Sharpener on top of the slicer (Fig. 1)

by lowering it onto its post. The

removed for cleaning.

The Slice deflector (Fig. 1) should already be

mounted below the knife.

ELECTRICAL

This machine comes with a three-prong grounding plug. The outlet to which this

plug is connected must be properly grounded. If the receptacle is not the proper grounding type,

contact an electrician.

Model Volts / Hertz / Phase

EDGE12 120 / 60 / 1 4.0 15

Compiled in accordance with the National Electrical Code, NFPA 70, latest edition.

Sharpener can be

ELECTRICAL DATA

Machine

Amps

Fig. 1

Minimum Circuit Ampacity

Maximum Protective Device

AMPS

(R) refers to removable part.

– 3 –

– 3 –

Page 4

OPERATION

SAFETY

SAFETY DEVICES INCORPORATED IN THIS SLICER MUST BE IN THEIR CORRECT OPERATING

POSITION ANY TIME THE SLICER IS IN USE.

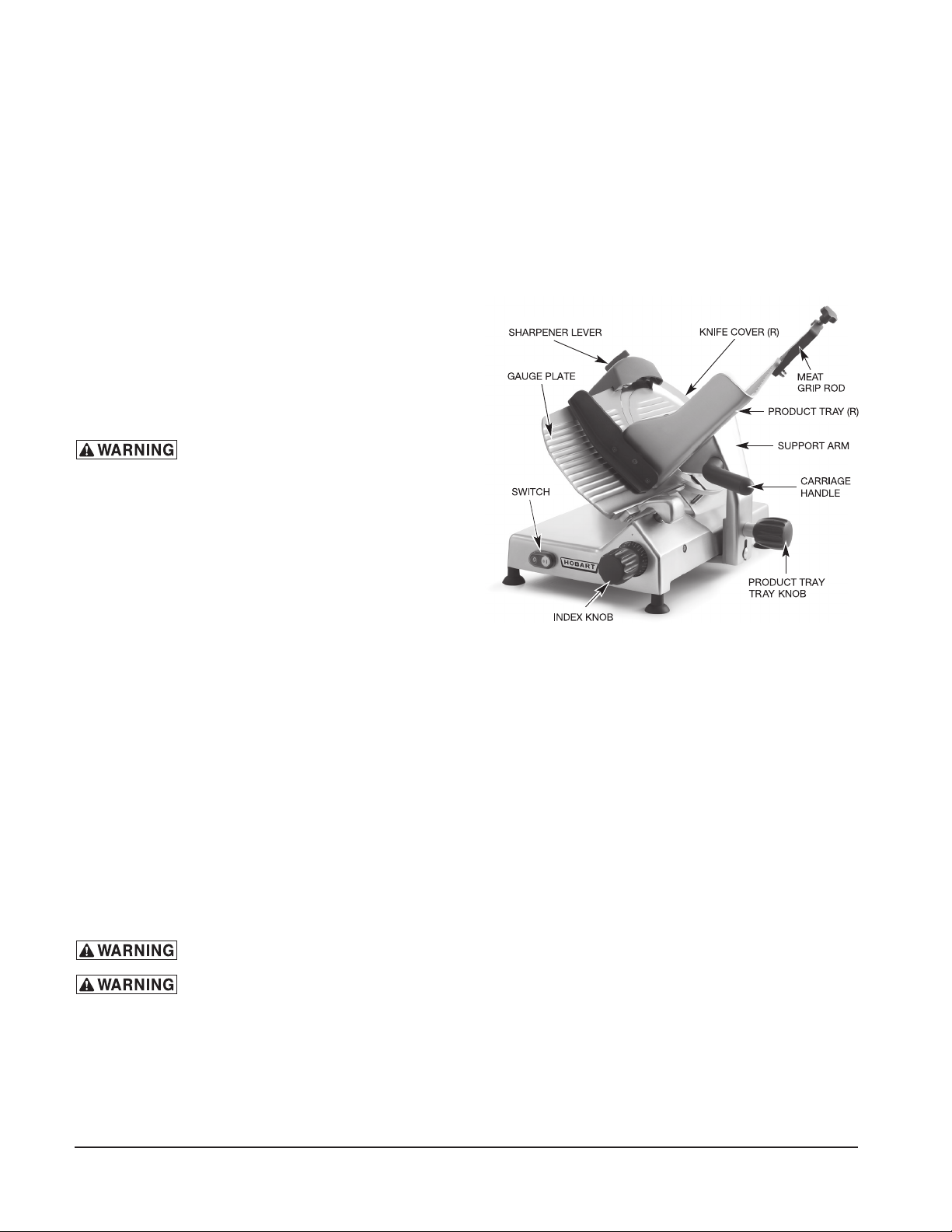

Knife cover should already be secured in place with the Knife cover KnoB on the left side tightened

The

clockwise (Fig. 1). The

The Meat grip (Fig. 4) helps secure product in position and must be used when slicing short ends to

keep your hand(s) away from the knife.

When the slicer is not running, the index KnoB

(Fig. 2) must be turned fully clockwise so the

gauge plate covers the Knife edge.

Always UNPLUG the power cord before cleaning

or moving the Slicer.

Rotating knife. Unplug machine

power cord before cleaning, servicing or

removing parts. Replace parts before use.

SLICING

ring guard is not removable.

With the

ray forward until it stops. With the Meat grip

t

gauge plate fully closed, pull the product

out of the way, place the product to be sliced on

product tray. Set the Meat grip against the

the

product. Turn the slicer on by pressing the

Switch

Fig. 2

(R) refers to removable part.

ON (Fig. 2).

If the

and rotating it 270° behind the

t

Meat grip is not needed, store it out of the way by lifting it to the top of the Meat grip rod

product tray. Allow it to rest on the small notch of the upper product

ray slot.

Adjust the gauge plate to obtain the desired slice thickness by turning the index KnoB (Fig. 2) to vary

9

the slice thickness from paper thin to

⁄16" thick. Use the carriage handle (Fig. 2) to move the carriage

back and forth to slice.

CLEANING AND SANITIZING

Thoroughly clean, rinse and sanitize the slicer after each day’s use or after being idle for an extended

time.

The slicer knife is very sharp. Exercise extreme caution when working near the knife.

Unplug the machine power cord and turn index knob fully clockwise to close the

gauge plate before cleaning the slicer.

Note: Sanitizer concentration shall comply with Section 4-501.114, Manual and Mechanical Warewash-

ing Equipment, Chemical Sanitation – Temperature, pH, Concentration, and Hardness of the FDA Food

Code. If a chemical sanitizer other than chlorine, idine, or quaternary ammonium is used, it shall be

applied in accordance with the EPA-registered label use instructions.

– 4 –

Page 5

Cleaning Surface and Parts:

Frequency: The slicer shall be cleaned and sanitized at intervals to comply with national, state

and/or local health codes.

Disassemble all removable slicer parts including

eflector, Knife cover, Knife cover KnoB and Sharpening Stone (See Fig. 1 and 2). Wash all sur-

d

product tray, Meat grip, Meat grip rod, Slice

faces of the machine with warm soapy water, a towel and mild detergent. Also, wash surfaces where

food or liquid can accumulate or where there is frequent hand contact including handles, knobs and

the control panel. Use generous amounts of soapy water on the sharpener hardware and knife hub.

Clean all removable parts with water, a towel and mild detergent (refer to Page 7). Rinse with water

and clean towel. Sanitize and let air dry.

• Excessive amounts of sanitizer and use of products not formulated for aluminum may void your

Hobart warranty.

• DO NOT wash any slicer components in a dishwasher.

• DO NOT hose down slicer or splash excessively with water.

• Use ONLY products formulated to be safe on stainless steel or aluminium.

• DO NOT exceed chemical manufacturer’s recommended concentrations for detergent or sanitizer.

• DO NOT clean any parts of the slicer with a steel pad.

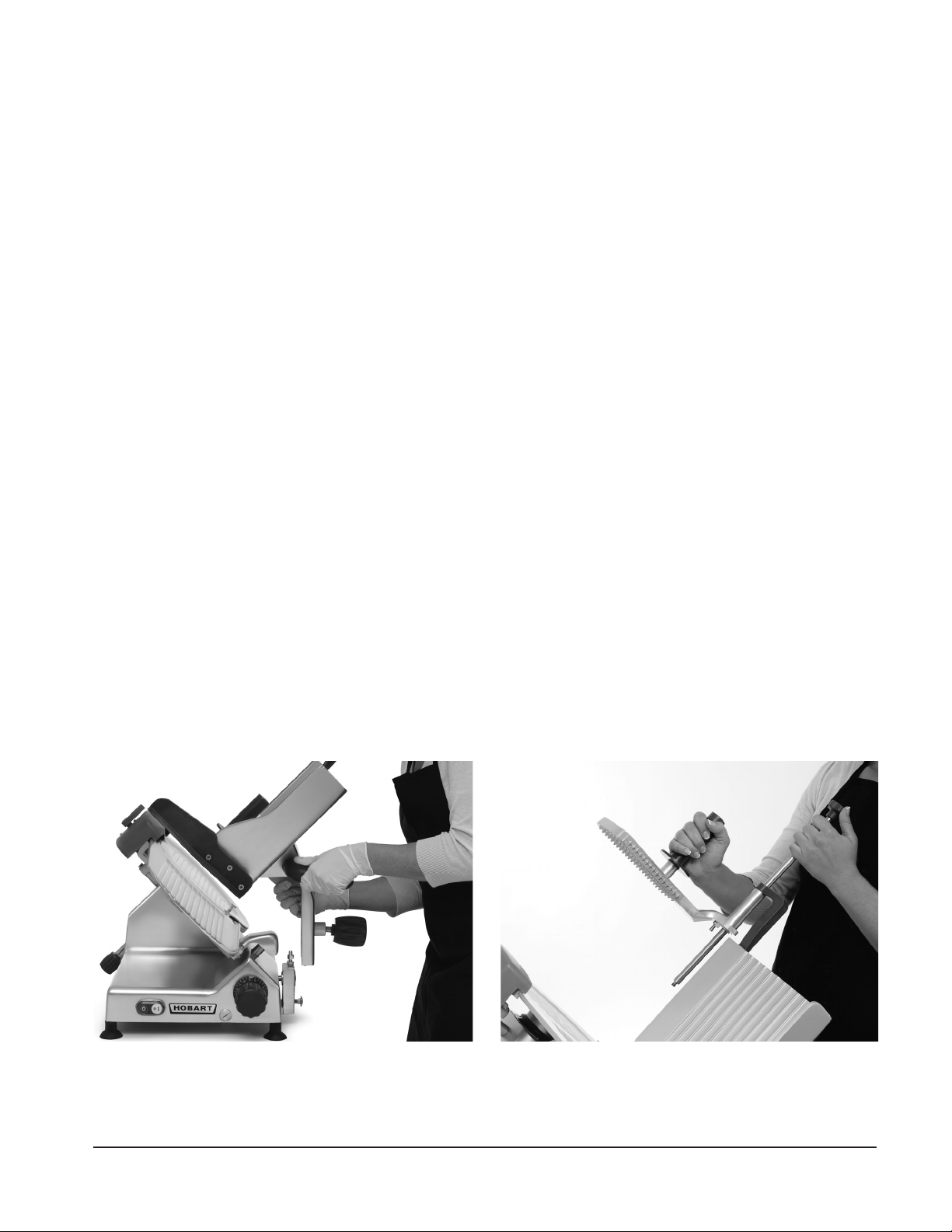

Cleaning Meat Grip and Product Tray:

index KnoB fully clockwise until gauge plate is in closed position. Pull product tray to home

Turn

position. Unscrew knob on

extract

Meat grip rod from the product tray (Fig. 4). Set aside rod and Meat grip. Wash surface area,

product tray and lift to remove (Fig. 3). Unscrew Meat grip KnoB in order to

product tray, Meat grip and Meat grip rod with water, a towel and mild detergent. Rinse, sanitize and

let air dry.

To replace the

Thread

Meat grip rod into product tray extension and then insert into Meat grip. Tighten rod clock-

wise until snug.

product tray, lower the tray onto the carriage and tighten the knob clockwise until snug.

Fig. 3 Fig. 4

– 5 –

Page 6

Cleaning Knife and Slice Deector:

With Meat grip and product tray removed, turn index KnoB fully closed. Unscrew the Knife cover KnoB

(Fig. 5). Push the knob to remove

Remove the

Knife cover KnoB, Knife cover, Slice deflector and both sides of the Knife by wiping outward

the

Slice deflector (Fig. 6) by unscrewing the stainless steel knob. Wash, rinse and sanitize

Knife cover. Remove both the Knife cover and the Knife cover KnoB.

from the center. Allow to air dry.

Fig. 5 Fig. 6

Cleaning Ring Guard:

Work a moistened paper towel between the

ring guard and Knife. Insert the towel at the base of the

ring guard (Fig. 7). Manually rotate the Knife to wipe ring guard and the edge of guard plate.

To replace the Knife cover, insert the Knife cover KnoB into its hole (lower left side) and position the

Knife cover over the center hole so the guide pin ts the hole in the rim and the hub ts the center hole.

Tighten the

underneath the

Knife cover KnoB (Fig. 5) so the threads at the end of the rod screw into the threaded hub

Knife cover.

Cleaning Sharpening Stone:

Each time the

Sharpener is used, the sharpening stones should be examined for cleanliness. Scrub

stones with a stiff bristle brush. Rinse with clean water and sanitize.

Reassemble the

Sharpener by lowering it onto the sharpener post (Fig. 8).

NOTE: Do not exceed chemical manufacturer’s recommended concentrations for detergent or

sanitizer. Do not exceed 200 parts per million concentration of available chlorine (1 tablespoon of

5.25% sodium hypochlorite bleach with 1 gallon of water). Concentrations greater than 200 ppm

accelerate corrosion of metals. Maximum exposure to sanitizing solution varies with temperature

and concentration. Rinse with clean water.

NOTE: Failure to follow use, care and maintenance instructions may void your Hobart warranty.

– 6 –

Page 7

Fig. 7 Fig. 8

PROTECTION ON

THE SWITCH

GASKET BETWEEN

THE PRODUCT TABLE

GASKET INSPECTION

GASKET BETWEEN HANDLE/SPACER

AND SPACER/MEAT PUSHER

GASKET

BETWEEN THE

PRODUCT TABLE

AND THE

THUMB GUARD

THE PRODUCT TABLE

AND THE EXTENSION

GASKET BETWEEN

AND THE SUPPORT

GASKET BETWEEN THE

HANDLE AND THE

PRODUCT TABLE SUPPORT

Fig. 8

The recommended interval between inspections shall not exceed six months for components

that are detached for cleaning and sanitizing (all the gaskets in the images).

The inspections must be made by the manufacturer or its authorized service agent.

The slicer must be removed from service until repaired by the manufacturer or its

authorized service agent if any gasket or seal is found to be damaged, or missing.

– 7 –

Page 8

MAINTENANCE

KNIFE SHARPENING

The Knife will provide long service in normal food store or kitchen use. However, in high volume

applications where it is a practice to sharpen the

expended in a shorter time.

Sharpen only when necessary. Prolonged or sharpening too frequently results in unnecessary

knife wear.

Unplug machine power cord.

Turn the index KnoB fully clockwise to close the gauge plate. Remove the Knife cover by unscrewing

KnoB and lifting it off the slicer.

the

Turn the slicer ON. Pull the Sharpener handle (Fig. 10) forward for 5 seconds and release. Turn the

slicer off. Unplug machine power cord. Clean and sanitize the slicer as outlined in the cleaning section

after sharpening the

Knife. Replace the Knife cover.

Knife frequently or even daily, the Knife will be

Fig. 10

LUBRICATION

Maintain smooth slicing by applying a few drops of mineral oil on the

the slicer base. Do not use vegetable oil.

carriage Slide rod underneath

TROUBLESHOOTING

Make sure that the circuit breaker has not tripped or the fuse blown.

SERVICE

Contact your local Hobart-authorized service ofce for any repairs or adjustments needed on this

equipment.

FORM 35283 Rev. B (September 2015) PRINTED IN U.S.A.

– 8 –

Page 9

O

D

E

D'

E

M

P

L

O

I

M

LA TRANCHEUSE EDGE12

TR ANC HEUSE EDG E12

MODÈLE

EDGE12-1 (TENSION 120/60/1) ML-136246

EDGE12-2 (TENSION 220/50/1) ML-136247

701 S. RIDGE AVE NUE

TROY, OHIO 45374- 0001

937 332-3000

www.hobartcorp.com

FORMULAIRE 35283 Rév. B (septembre 2015)

Page 10

TABLE DES MATIÈRES

GÉNÉRAL ............................................................................................................................................. 3

INSTALLATION ..................................................................................................................................... 3

Déballage ........................................................................................................................................ 3

Données électriques ........................................................................................................................ 3

UTILISATION ......................................................................................................................................... 4

Sécurité ........................................................................................................................................... 4

Tranchage ........................................................................................................................................ 4

Nettoyage ........................................................................................................................................ 4

ENTRETIEN .......................................................................................................................................... 8

Affûtage de la lame .......................................................................................................................... 8

Lubrication ..................................................................................................................................... 8

DÉPANNAGE ........................................................................................................................................ 8

Service de l'entretien ....................................................................................................................... 8

© HOBART, 2012

– 2 –

Page 11

Installation, utilisation et entretien

DE LA TRANCHEUSE EDGE12

CONSERVEZ CES INSTRUCTIONS

GÉNÉRAL

La trancheuse Edge12 est équipée d'un moteur de ½ HP (375 watts). La lame de la trancheuse est en

acier au carbone forgé et chromé. Le ni satiné du caisson, porte-produit, couvre-lame, de l'anneau de

protection et de la plaque d'épaisseur est fait d'aluminium moulé oxydé anodiquement et facile à nettoyer.

La poignée de saisie de la viande montée à l'arrière est articulée sur une tige avec une extension derrière

le porte-produit. L'Affûteuse xée sur le dessus de l'appareil peut être retirée pour nettoyage. Un cordon

et avec che est livré de série.

La trancheuse Edge12 doit être nettoyée, rincée et désinfectée soigneusement après son installation et

avant chaque utilisation. Voir la rubrique Nettoyage à partir de la page 4.

INSTALLATION

DÉBALLAGE

Dès après le déballage de la trancheuse, vériez si elle

peut avoir subi des dommages pendant le transport.

Si tel est le cas, conservez le matériel d'emballage et

contactez le transporteur dans les 5 jours suivant la

livraison.

Avant d'installer la trancheuse, vérier l'alimentation

électrique pour vous assurer qu'elle concorde avec les

données de la plaque signalétique. Celle-ci se trouve

du côté droit du caisson de l'appareil.

Le porte-produit est xé sur la trancheuse en tournant

le bouton du dessous dans le sens horaire jusqu'à ce

qu'il soit bien serré (Fig. 2).

Fixez l'affûteuse sur le dessus de l'appareil (Fig. 1) en

l'abaissant sur son support. Elle peut être retirée pour

nettoyage.

Le déecteur de tranches (Fig. 1) devrait être déjà xé

sous la lame.

DONNÉES ÉLECTRIQUES

Cet appareil est livré avec une che de mise à la terre à trois broches. La prise dans

laquelle elle est branchée doit être correctement mise à la terre. Si ce n'est pas le cas, contactez

un électricien.

DONNÉES ÉLECTRIQUES

Intensité minimale du circuit

Modèle Volts / Hertz / Phase Intensité (A)

EDGE12 120 / 60 / 1 4,0 15

Établies en conformité avec le Code national électrique, norme NFPA 70, édition la plus récente.

Dispositif de protection maximal

Le (A) fait référence aux pièces amovibles.

Fig. 1

A

– 3 –

Page 12

UTILISATION

SÉCURITÉ

LES DISPOSITIFS DE SÉCURITÉ INTÉGRÉS À CETTE TRANCHEUSE DOIVENT TOUJOURS ÊTRE

FIXÉS CORRECTEMENT À LEUR POSITION DE FONCTIONNEMENT LORSQUE LA TRANCHEUSE

EST EN MARCHE.

Couvre-lame devrait déjà être xé en place en serrant dans le sens horaire le Bouton du Couvre-lame

Le

situé du côté gauche (Fig. 1). L'anneau de protection n'est pas amovible.

Serre-viande (Fig. 4) aide à xer le produit en position

Le

et doit être utilisé quand on tranche des petits bouts de

façon à tenir votre (vos) main(s) éloignée(s) de la lame.

Lorsque la trancheuse n'est pas en marche, le B

d'épaiSSeur (Fig. 2) doit être complètement tourné vers

la droite de sorte que la

tranchant de la

lame.

plaque d'épaiSSeur couvre le

outon

Il faut TOUJOURS débrancher le Cordon d'alimentation

avant de nettoyer ou de déplacer la trancheuse.

Lame rotative. Débranchez le cordon d'alimentation de l'appareil avant le nettoyage,

l'entretien ou le retrait des pièces. Remettez les

pièces en place avant l'utilisation.

TRANCHAGE

plaque d'épaiSSeur entièrement fermée, tirez le porte-

La

roduit vers vous jusqu'à ce qu'il s'arrête. Après avoir

p

libéré le

Serre-viande, posez le produit à trancher sur le

Le (A) fait référence aux pièces amovibles

Fig. 2

porte-produit. Fixez le Serre-viande sur le produit. Allumez la trancheuse en appuyant sur le Commutateur

(Fig. 2).

Si vous n'avez pas besoin du

Serre-viande, rangez-le hors du chemin en l'élevant au-dessus de la

tige du Serre-viande et en le faisant pivoter de 270°derrière le porte-produit. Laissez-le reposer sur la

petite encoche d'arrêt supérieure du

Réglez la

plaque pour obtenir l'épaisseur de tranche désirée en tournant le Bouton d'épaiSSeur (Fig. 2)

pour couper des tranches nes comme du papier jusqu'à une épaisseur de

cher, servez-vous de la

poignée du Chariot pour lui imprimer un mouvement de va et vient.

porte-produit.

9

⁄16 po (14 mm). Pour tran-

NETTOYAGE ET DÉSINFECTION

Nettoyez à fond, rincez et désinfectez la trancheuse après chaque jour de service ou lorsqu'elle n'a pas

été utilisée depuis quelque temps.

La lame de la trancheuse est très tranchante. Soyez extrêmement prudent quand

vous travaillez près de la lame.

Avant de nettoyer la trancheuse, débranchez le cordon d'alimentation électrique

et tournez le bouton d'ajustement complètement vers la droite pour fermer la plaque d'épaisseur.

Remarque: la concentration du désinfectant doit être conforme à la section 4-501,114 du Code alimentaire

FDA traitant de l'assainissement chimique de l'équipement de lavage de vaisselle manuel et mécanique,

quant à la température, le pH, la concentration et la dureté. Si un assainisseur chimique autre que le

chlore, l'iode ou l'ammonium quaternaire est utilisé, il doit l'être en conformité avec les instructions de

l'étiquette enregistrée auprès de l'EPA (Agence de protection de l'environnement).

– 4 –

Page 13

Nettoyage des surfaces et des pièces :

Fréquence : la trancheuse sera nettoyée et désinfectée à des intervalles assez rapprochés pour être

conforme au code national, aux codes des états et/ou aux codes locaux.

Retirez toutes les pièces amovibles de la trancheuse y compris le P

éFleCteur de tranCheS, le Couvre-lame et son Bouton de Serrage, ainsi que la Pierre d'aFFûtage (Voir

D

orte-produit, le Serre-viande, le

Fig. 1 et 2). Lavez toutes les surfaces de l'appareil avec de l'eau chaude savonneuse, une serviette et

un détergent doux. Lavez également les surfaces où des aliments ou des liquides peuvent s'accumuler

ou les endroits fréquemment touchés par les mains, ce qui inclut les poignées, les boutons et les com-

mandes. Utilisez beaucoup d'eau savonneuse sur les éléments de montage de l'affûteuse et l'axe de

la lame. Nettoyez toutes les pièces amovibles avec de l'eau, une serviette et un détergent doux (référez-vous à la page 7). Rincez avec de l'eau et un chiffon propre. Désinfectez et laissez sécher à l'air.

• L'utilisation de trop de désinfectant et de produits non formulés pour l'aluminium peut entraîner

l'annulation de votre garantie Hobart.

• NE LAVEZ aucun des composants de la trancheuse au lave-vaisselle.

• NE LAVEZ pas la trancheuse au boyau ou ne l'aspergez pas d'eau de façon excessive.

• NE LAVEZ AUCUN des composants de la trancheuse au lave-vaisselle.

• N’UTILISEZ QUE des produits formulés pour nettoyer l’inox et l’aluminium en toute sécurité.

• NE DÉPASSEZ PAS la concentration des détergents et désinfectants recommandée par le fabricant

des ces produits chimiques.

• Aucune des pièces de la trancheuse NE DOIT être nettoyée à la laine d’acier.

Nettoyage du serre-viande et du porte produit :

Tournez le B

position fermée. Tirez le P

produit et soulevez-le pour le retirer (Fig. 3). Dévissez le Bouton du Serre-viande pour extraire la Tige

erre-viande du Porte-produit (Fig. 4). Mettez la tige et le Serre-viande de côté. Lavez la surface,

du S

orte-produit, le Serre-viande et la Tige du Serre-viande avec de l'eau, une serviette et un détergent

le P

outon de réglage complètement à droite jusqu'à ce que la Plaque d'épaiSSeur soit en

orte-produit vers vous en position maison. Dévissez le bouton du Porte-

doux. Rincez, désinfectez et laissez sécher à l'air libre.

Pour remettre le P

droite jusqu'à ce qu'il soit serré. Passez la T

produit et insérez-la dans le Serre-viande. Vissez la tige vers la droite jusqu'à ce qu'elle soit serrée.

orte-produit en place, abaissez-le sur le chariot et faites tourner le bouton vers la

ige du Serre-viande dans la barre d'extension du Porte-

Fig. 3

– 5 –

Fig. 4

Page 14

Nettoyage de la lame et du déecteur de tranches :

Après avoir retiré le Serre-viande et le Porte-produit, fermez complètement le Bouton d'épaiSSeur.

Dévissez le Bouton du Couvre-lame (Fig. 5). Poussez le bouton pour retirer le Couvre-lame. Retirez le

ouvre-lame et son Bouton. Retirez le DéFleCteur de tranCheS (Fig. 6) en dévissant le bouton en inox.

C

Lavez, rincez et désinfectez le C

deux côtés de la L

ame en essuyant du centre vers les bords. Laissez sécher à l'air.

ouvre-lame et son Bouton, le DéFleCteur de tranCheS, ainsi que les

Fig. 5 Fig. 6

Nettoyage de l'anneau de protection :

Passez une serviette en papier mouillée entre l’Anneau de proteCtion et la Lame. Insérez la serviette

à la base de l’A

proteCtion et le bord de la Plaque de proteCtion.

nneau de proteCtion (Fig. 7). Faites tourner la Lame à la main pour essuyer l’Anneau de

Pour remettre le Couvre-lame en place, insérez le Bouton du Couvre-lame dans son orice (côté inférieur gauche) et posez le C

s'engage dans le trou du rebord et que le moyeu s'ajuste dans l'orice central. Serrez le B

ouvre-lame (Fig. 5) pour que les lets au bout de la tige vissent dans le moyeu leté sous le Couvre-

C

lame.

ouvre-lame par-dessus le trou central de sorte que la cheville de guidage

outon du

Nettoyage de la pierre d'affûtage :

À chaque utilisation de l’affûteuse, il faut examiner les pierres pour voir si elles sont propres. Frottez les

pierres avec une brosse à poils rigides. Rincez-les à l’eau claire et désinfectez-les.

Remettez l'affûteuse en place en la faisant descendre sur son poteau de support (Fig. 8).

REMARQUE : ne dépassez pas la concentration des détergents et des assainisseurs recommandée

par le fabricant des produits chimiques. Ne dépassez pas la concentration de chlore actif de 200 ppm

[1 cuillerée à table (15 ml) d'hypochlorite de sodium dans 1 gallon US d'eau (3,78 l)]. Les concentrations

supérieures à 200 ppm accélèrent la corrosion des métaux. Le temps d'exposition maximal à des solu-

tions d'assainissement varie avec la température et la concentration. Rincez à l'eau propre.

REMARQUE : le défaut de vous conformer aux instructions d'utilisation, de soins et d'entretien peut

annuler votre garantie Hobart.

– 6 –

Page 15

Fig. 7 Fig. 8

INSPECTION DES JOINTS

Fig. 8

Les intervalles recommandés entre l'inspection des composants retirés pour nettoyage et désinfection

ne doivent pas dépasser 6 mois (tous les joints illustrés).

Les inspections doivent être effectuées par le fabricant ou le mandataire autorisé à faire l'entretien de

ses appareils.

Si tout joint ou scellement se trouve endommagé où perdu, la trancheuse doit

être retirée du service jusqu'à ce qu'elle ait été réparée par le fabricant ou le mandataire autorisé

à en faire l'entretien.

– 7 –

Page 16

ENTRETIEN

AFFÛTAGE DE LA LAME

Si elle est utilisée normalement dans un magasin d'alimentation ou une cuisine, la Lame durera long-

temps. Dans les applications à volume élevé cependant, où il est de coutume d'affûter la L

ou même quotidiennement, elle deviendra usée plus rapidement.

Il ne faut affûter que si cela s'avère nécessaire; des affûtages prolongés ou trop fréquents auront pour

résultat d'user la lame inutilement.

Débranchez le cordon électrique de l'appareil.

Tournez le Bouton de réglage complètement vers la droite pour fermer la Plaque d'épaiSSeur. Retirez le

ouvre-lame en dévissant son Bouton de Serrage et en le soulevant hors de la trancheuse. Lavez soi-

C

gneusement la zone autour de la L

Faites attention de ne pas laisser le gras de la viande passer de la

ame, les surfaces de la Lame découvertes et les rebords de celle-ci.

lame vers l'AFFûteuSe.

Branchez le cordon électrique de l'appareil. Allumez la trancheuse. Tirez la Poignée de l'aFFûteuSe (Fig.

10) vers l'avant pendant 5 secondes et relâchez-la. Éteignez l'appareil. Débranchez le cordon d'alimentation de l'appareil. Essuyez la trancheuse avec un chiffon humide propre pour retirer toutes les particules

de meulage. Remettez le C

ouvre-lame en place.

ame souvent

Fig. 10

LUBRIFICATION

Pour conserver un tranchage sans à-coups, appliquez quelques gouttes d'huile minérale sur le T

CouliSSement du chariot sous le caisson de la trancheuse. N'utilisez pas d'huile végétale.

ige de

DÉPANNAGE

Vériez si le disjoncteur ne s'est pas déclenché ou si un fusible n'est pas grillé.

SERVICE D'ENTRETIEN

Pour toute réparation ou réglage de cet appareil, contactez le bureau du Service de l'entretien Hobart

autorisé dans votre région.

FORMULAIRE 35283 Rév. B (septembre 2015) IMPRIMÉ AUX É.-U.

– 8 –

Loading...

Loading...