Page 1

INSTALLATION AND

OPERATION INSTRUCTIONS

(original instructions)

V1.6 2012.09.04

ECOMAX 502L(P)

GLASS- AND DISHWASHERS

Page 2

2

IMPORTANT NOTES

THE ORIGINAL INSTRUCTIONS.

ONLY TRAINED OR AUTHORIZED ADULT PERSONS OPERATE THE MACHINES.

USE IN ACCORDANCE WITH REGULATIONS

The machine is technical work equipment for express use in the work place.

The machine is exclusively to be used to wash ware such as plates, cups, glasses, cutlery, trays etc.

Do not use for electrically heated cooking and heat conservation appliances.

SAFETY:

Never hose down the machine.

The “Attention” symbol is shown beside instructions that are essential for the safe operation of the

machine.

Please read these passages thoroughly.

LIABILITY:

Installations and repairs which are carried out by non-authorized technicians or the use of other than

original spare parts, and any technical alterations to the machine, may affect the warranty set

out in the standard conditions of sale.

The machine can be used by one person only, does not allow two or more people operate at the same time.

MACHINE NOISE LEVEL:

The machine noise level is ≤ 70 dB (A).

USING ENVIRONMENT

Electric equipment shall be capable of operating correctly in the intended ambient air temperature. The minimum

requirement for all electrical equipment is correct operation between air temperature of +5℃ and +40℃.

The electrical equipment shall be capable of operating correctly when the relative humidity does not exceed 50% at a

maximum temperatrue of +40℃. Higher relative humidities are permitted at lower temperatures (for example 90% at

20℃).

Electrical equipment shall be capable of operating correctly at altitudes up to 1000m above mean sea level.

The equipment are not used in the potential explosive environment.

CONNECTING TENSIONS:

The machine described in this operation manual has following connecting tensions:

400 V/50 Hz/3 Ph/N/PE or 230 V/50 Hz/1 Ph/N/PE

GENERAL INFORMATION ON WASHING GLASSES AND CUTLERY:

The local supply water quality has a major impact on the wash and rinse result. A high content of minerals which are

dissolved in the water during the drying process may become visible in the form of spots and streaks.

Authorised service personnel can determine the content of minerals by measuring the electrical conductivity. Values of

less than 80 Microsiemens/cm indicate a low content of minerals. Higher contents need to be reduced below the critical

level by demineralising the water using specic demineralisation cartridges or a reverse osmosis system.

Please contact your authorised service partner for support.

We recommend the use of specic glass racks. These racks hold the glasses in slightly inclined positions – this will

Page 3

3

IMPORTANT NOTES

improve the rinse efciency.

To avoid unpleasant smelling glasses, specic chlorine-free detergent for glass washing should be used.

Before washing new glasses the rst time with a commercial glass washer, intensive basic cleaning is mandatory to

reduce the greasy lm which is on most glasses for protection during production. If not, water drainage is impaired and

streaks and spots may remain on glasses.

We recommend carrying out the basic cleaning manually in a sink (using gloves and a brush for cleaning) with a much

higher chemical concentration of detergent (minimum 10 g of detergent per liter).

As continued product improvement is a policy of HOBART, specications are subject to change without notice.

Company address: No.8 Yesheng Road, Xiqing Economic & Development Zone, Tianjin China.

Page 4

4 06.01.2012 BA-21907-001-GB

CONTENTS Page

1. BRIEF INTRODUCTION ................................................5

2. TRANSPORTATION, STORAGE AND INSTALLATIONS .....6

2.1. transportation and storage ...................................................................6

2.2. Location .............................................................................................6

2.3. Electrical connection............................................................................6

2.4. Water connection ................................................................................7

2.5. Drain connection .................................................................................7

3. CONTROLS ................................................................8

4. START-UP ..................................................................9

4.1. Detergent PUMP (OPTIONAL) ................................................................9

4.2. Rinse aid PUMP (OPTIONAL) .................................................................9

4.3. Priming the suction hoses ..................................................................10

4.4. Softener (optional) .............................................................................11

5. OPERATION .............................................................12

5.1. Preparation .......................................................................................12

5.2. Run ..................................................................................................13

6. SWITCH-OFF AND CLEANING THE MACHINE..............14

6.1. Switch-off..........................................................................................14

6.2. Cleaning (daily) ..................................................................................14

6.3. Cleaning (weekly) ...............................................................................14

7. SETTINGS ................................................................15

7.1. Adjustment of detergent dosage quantity .............................................15

7.2. Adjustment of rinse aid dosage quantity ..............................................15

7.3. Adjustment of water hardness ...........................................................16

8. FROST PREVENTION ................................................17

9. MAINTENANCE ........................................................18

10. TROUBLESHOOTING GUIDE ......................................19

10.1. Poor wash result ...............................................................................19

10.2. Other faults .......................................................................................20

10.3. Malfunctions ......................................................................................20

Page 5

1. BRIEF INTRODUCTION

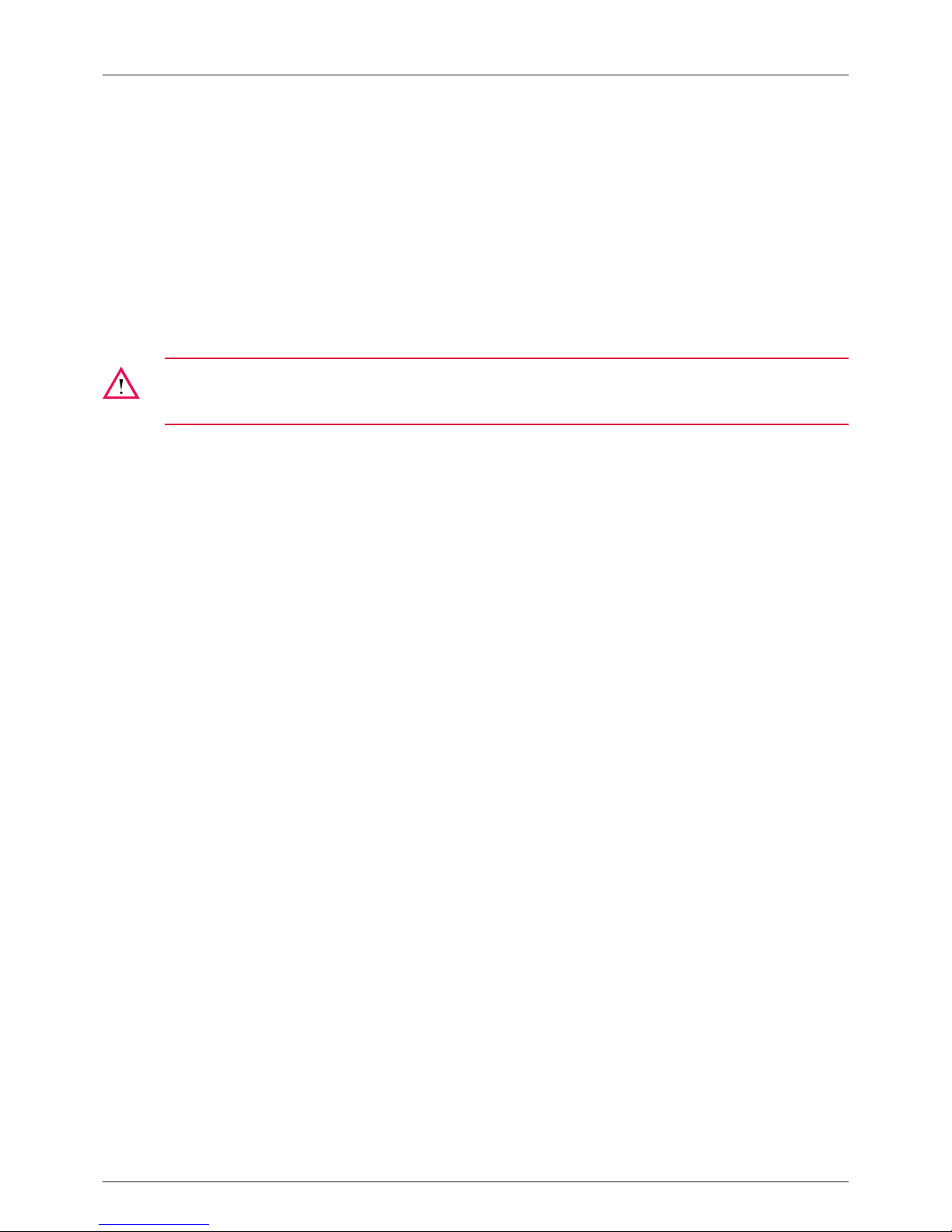

Introduction table:

1 Filling connection G3/4

2 Tank drain DN20

3 Power line

4 Detergent dosage

5 Rinse aid dosage

575

790

356

600

960

316

5

Page 6

6

2. TRANSPORTATION, STORAGE AND INSTALLATIONS

2.1. TRANSPORTATION AND STORAGE

Folklift must be used during transportation and storage instead of vertical

loading, pay attention to upturn and prevention of break, moisture and

load. (See the marks on the package).

2.2. LOCATION

– Rear wall clearance not required.

– Level machine by turning the feet.

– Distribute machine weight equally onto all feet

2.3. ELECTRICAL CONNECTION

Must be carried out by an authorized technician according to

the local and national codes.

– The electrical supply shall comply with the name-plate data.

– Line fuses and cable cross section shall comply with the

requirements.

NOTE: The machine with or without interlock function has different

working current. Please refer to the wiring diagram.

NOTE: A cut-off device shall be provided to connect the supply cord

(isolating switch or accessible plug device).According to EN

60 335 the appliance must be connected to an equipotential

conductor. The connecting screw ( ) is located beside the

cable inlet.

Page 7

7

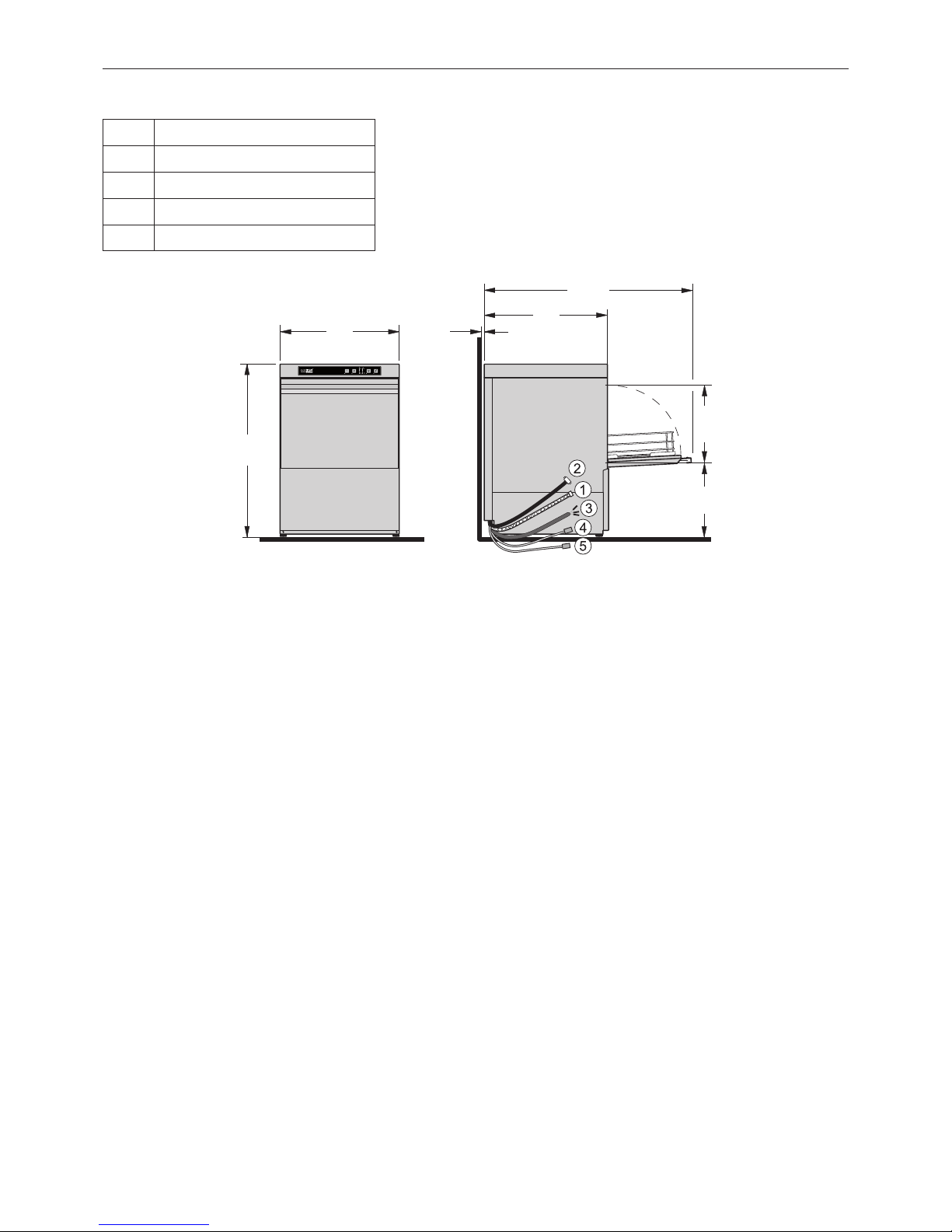

2.4. WATER CONNECTION

Must be carried out by an authorized technician according to

the national and local codes.

The machine must be operated with potable water. For water

with an extremely high mineral content an external demineralisation is strongly recommended

– Connect to warm water, if possible (max. 65°C).

– Water hardness:

• Machines without softener: max. 3.75° Clark = 0.5 mmol/l.

• Machines with softener: max. 37.5° Clark = 5.3 mmol/l.

– Line ow pressure

Line ow pressure 0,5 – 6 bar.

> 6 bar: pressure reducer valve necessary.

– Connect the union nut “A” (3/4”) of the water supply hose to the

site shut off valve.

– Do not kink or cut the supply hose. If an extended supply hose is

required, use one of the same specications as the original.

NOTE: The water hardness should be ≤0.5mmol/L. If not, water

softener is strongly recommended. Or else, may affect the

warranty set out in the standard conditions of sale.

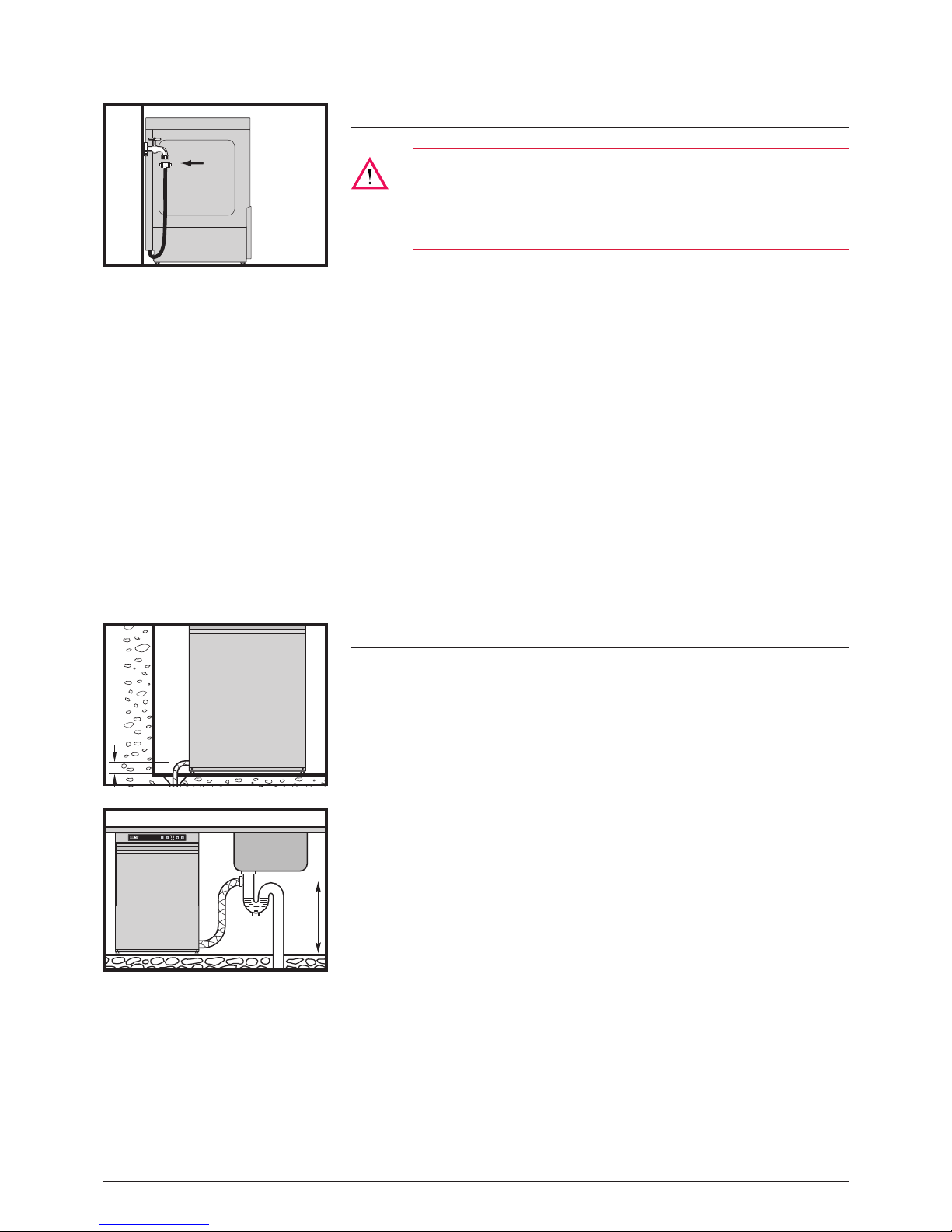

2.5. DRAIN CONNECTION

Machine without drain pump

– Ensure gravity drain.

– For these machine types, a oor drain is mandatory as the drain

hose exits the machine at approx. 60 mm above oor level. Otherwise, residual water may remain in the tank and hose.

– Do not kink drain hose.

Machine with drain pump

– Connection between machine and site drain must not exceed max.

height of 0,65 m.

– Do not place the drain hose loosely on the oor (the hose could be

rubbed through). Fix it at site!.

– Do not kink drain hose

A

max. 60 mm

max. 0.65 m

2. TRANSPORTATION, STORAGE AND INSTALLATIONS

Page 8

8

1

8

354

76

22

70

65

60

55

50

45

85

80

75

70

65

60

3. CONTROLS

➀

Machine ON/STOP button Pushing this button switches the machine on.

The LED lights up

− ashing = Machine is lling and heating.

− permanent = Maschine is ready to operate.

In case of operating error or faults, it is possible to switch-off the machine immediately without the drain cycle, by pushing this button.

After switch off, the machine is not voltage free!

➁

Program buttons By pushing these buttons, it is possible to select between short cycle (1) and

standard cycle (2).

The appropriate LED lights up.

➂

Drain/OFF button By pushing and holding (3 seconds) this button, the self-cleaning cycle starts.

At the end of the cycle, the machine switches off automatically. Machines with

optional drain pump will drain the tank automatically.

After switch off, the machine is not voltage free!

➃

Temperature indication Wash

➄

Temperature indication Rinse

➅

Salt required Indicating the need for regeneration salt to be added. (Only with built-in soft-

ener.)

➆

Regeneration indicator Softener regeneration active.The cycle running time can extend.

➇

Indicator for setting functions The individual LEDs are also used for various settings and special functions:

Hose priming – rinse aid

Hose priming – detergent

Adjustment of water hardness

Rinse aid dosage quantity

Detergent dosage quantity

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Left display: The LEDs 1 to 6 illuminate according to the selected

function.

Right display: Indicates the adjusted value

Page 9

9

4. START-UP

Attention:

The maximum suction head of the dosing pumps is 1.5 m. Do

not confuse the containers

Use only detergent and rinse aid for commercial applications.

Please pay attention to the manufacturer’s safety instructions.

NOTE: Before changing to a different product type (even from the

same supplier), the suction hoses must be rinsed thoroughly

with fresh water (procedure as described under section

4.3.). Otherwise, the mixing of different types of chemicals

will cause crystallization, which may result in a malfunction

of the dosing pump.

4.1. DETERGENT PUMP (OPTIONAL)

– Do not use any acidic detergent products with the optional built-in

detergent pump! (The ph-value has to be higher than 7.)

– Place the suction hose into the external detergent container.

Fill the suction hose according to chapter section 4.3.

4.2. RINSE AID PUMP (OPTIONAL)

– Place the suction hose (blue marking) into the external rinse aid

container. Fill the suction hose according to chapter section 4.3.

Page 10

10

4.3. PRIMING THE SUCTION HOSES

ATTENTION:

The machine has to be switched off.

– Open the door.

– Push Program buttons ➁ simultaneously.

• LEDs light up.

• In display ➇, the LEDs 1 and 11−20 illuminate (dependent on

basic setting).

– Push Program button “1” repeatedly, until the display LED 3 lights

up.

– Close the door.

– Push Program button “1” again.

• In display ➇ LED 4 lights up.

4.3.1. DETERGENT SUCTION HOSE

– Only with built in detergent pump.

– Push and hold programm ”2”.

• Hose will be lled.

• moving light display ➇ LEDs 15−18

– Releasing the button interrupts hose priming.

4.3.2. RINSE AID SUCTION HOSE

– Push Program button “1” again.

• In display ➇ LED 5 lights up.

– Push and hold Program button “2”.

• hose will be lled.

• moving light display ➇, LEDs 15−18

– Releasing the button interrupts hose priming.

– Termination of hose priming: Open door or do not press any button

for 30 seconds.

4. START-UP

Page 11

11

4.4. SOFTENER (OPTIONAL)

NOTE: For the rst run, the softener has to be lled with regenera-

tion salt and potable water.

Attention:

Filling the salt reservoir with cleaning agent will damage the

water softener.

– Open the door.

– Unscrew the softener lid and ll the softener with 1.5 kg of “Granu-

lar regeneration salt” (do not use salt tablets).

– Fill up the softener with potable water (only at the rst run). Clean

seal and rim of softener lid carefully, before closing the lid.

– Close lid and tighten.

– In order to prevent corrosion it is necessary to remove any salt

residues from tank bottom.

– Adjust the water hardness according to section 7.3.

When the Salt indicator ➅ ashes during operation, the softener

has to be relled with regeneration salt.

There will be a slight delay before salt light goes out after rell.

4. START-UP

Page 12

12

5.1. PREPARATION

– Check correct position of wash/rinse arms, strainer and overow

pipe.

– Open shut-off valve.

– Switch on main switch or put the plug in.

– Check level of detergent and rinse aid containers.

– Close door and push the ON button

➀

• tank will be lled.

• The button LED ashes during ll and heating cycle. This pro-

cess can take several minutes.

• When the LED changes to steady burning light, machine is ready

for operation.

– Place glasses and cups face downwards into the rack.

– Remove any food debris before loading plates into rack.

– Spray off greasy food leftovers.

If dishes are placed incorrectly, dishes may be not washed

cleanly.

Total weight of dishes and rack should be less than 25kg, and should

be placed steadily in the direction of operation to prevent human body

from injury caused by falling.

5. OPERATION

Page 13

13

5. OPERATION

5.2. RUN

– Put rack into the machine and close the door.

– Start the desired program by selecting the program button 1 or 2

Button "1" = Short cycle

Button "2" = Standard cycle

• The Program button LED ashes, wash cycle is running.

• As soon as the LED changes to steady light, the wash cycle is

nished.

– Open the door and take out rack.

– Allow dishes to dry for 1 minute approx.

– Caution lables

• Potential crushing hazard.

• Scalding and slipping hazzard. Heat insulating gloves and

clothes and non-slip shoes are required.

– The door is closed during wash/rinse operation; the door magnetic

switch is triggered in the case of door been opened, the spray risk

can be prevented from immediate stop of wash/rinse operation.

Page 14

14

6. SWITCH-OFF AND CLEANING THE MACHINE

6.1. SWITCH-OFF

– Versions with overow pipe: remove

– Close the door.

– Push and hold (min. 3 seconds) the Drain button

➂

• LED lights up.

The self-cleaning cycle will be started and the machine interior is

cleaned automatically.

NOTE: A nal inspection is recommended to remove any food

debris.

• Machines with optional drain pump will drain the tank automatically.

• At the end of program, the machine switches off automatically.

– Switch off main switch or unplug. Close the shut-off valve.

6.2. CLEANING (DAILY)

Attention:

To clean the machine do not use any chloric, acidic or abrasive

products and no metallic brushs.

– Open door, take out strainer and overow pipe.

Please ensure that food debris does not enter pump intake.

– Clean interior of the machine.

– Put strainer and overow pipe back into place.

6.3. CLEANING (WEEKLY)

– Loosen the retaining screws (A) by turning them counter-clockwise.

– Take out and clean wash and rinse arms.

– Put all components back into place.

Page 15

15

ATTENTION:

The machine has to be switched off.

– Open the door.

If the door will be closed or if no button is pressed for 30 seconds,the

indicator automatically switches off and the new settings will be saved.

Therefore the setting procedure can be interrupted at any time.

7.1. ADJUSTMENT OF DETERGENT DOSAGE

QUANTITY

Only with built in detergent pump.

– Push Program buttons ➁ simultaneously.

• LEDs light up.

• In the left display the bottom LED (1) is illuminated.

• The right display indicates the adjusted value of the detergent

dosage time: One LED corresponds to approx. 3.5 s ≈ 1 g/l

– Pre-adjusted value: “11−13” = 10.5 s ≈ 3 g/l.

– To adjust the detergent dosage time, push Program button “2”

repeatedly, until the desired value (0−35 s ≈ 0−10 g/l) is indicated.

Adjustment should be done in accordance with chemical suppliers

recommendations.

7.2. ADJUSTMENT OF RINSE AID DOSAGE QUANTITY

– Push Program button “1”.

• In display ➇ LEDs 1 and 2 illuminate.

• the right display indicates the adjusted value of the rinse aid

dosage time: One LED corresponds to approx. 2.5 s ≈ 0,1 g/l.

– Pre-adjusted value: “11−13” = 7.5 s ≈ 0,3 g/l.

– To adjust the rinse aid dosage time, push Program button “2”

repeatedly, until the desired value (0−25 s ≈ 0−1.0 g/l) is indicated

Adjustment should be done in accordance with chemical suppliers

recommendations.

7. SETTINGS

Page 16

16

7.3. ADJUSTMENT OF WATER HARDNESS

– With optional softener only.

– To adjust the softener to the local water hardness (obtain details

from local water authorit):

– Push Program button “1”.

LEDs 1 to 3 illuminate in the left display

– Push Program button “2” repeatedly, until the LEDs in display ➇

correspond to the required value.

LED "on" Range Water hardness*

11 H01 up to 7°eh

11 and 12 H02 8 to 14°eh

11 to 13 H03 15 to 21°eh

11 to 14 H04 22 to 30°eh

*(°eh = Clark)

7. SETTINGS

Page 17

17

This should be carried out by service personnel!

In case of frost or longer operation pauses (e.g. for seasonal operations)

the machine must be completely drained.

Reset for operation according to section section 3..

8. FROST PREVENTION

Page 18

18

In order to maintain the warranty, as well as a permanently safe, efcient,

and trouble-free operation of the machine, the required maintenance must

be carried out by authorized service technicians.

For this reason, we recommend the conclusion of an inspection and

maintenance contract which assures qualied support by specially

trained service technicians according to a time scheduled based on the

operating conditions.

For pumps, motors, power connector and other parts, you must

disconnect the power before repair.

9. MAINTENANCE

Page 19

19

10.1. POOR WASH RESULT

TYPE OF FAILURE POSSIBLE CAUSE

REMEDY

Washware are not clean. Wash arms stiff (you should be able to

turn them easily by hand).

Take out wash arms and clean them thoroughly.

Check water outlet from machine to wash arms is

clear.

Wash arm nozzles are clogged

(visual check).

Take out wash arm, remove cleaning cap and rinse

the wash arm thoroughly until soil is removed.

Replace correctly.

Rinse arm nozzles are clogged

(possibly by lime deposit)

Remove rinse arms and decalcify them in separate

container.

Detergent concentration is too low or too

high.

Check setting of detergent concentration. See also

operating instructions point 6.1.

Coarse strainer soiled. Take out strainer, empty and clean it.

Wrong program selected for heavily

soiled washware.

Select program with longer wash cycle.

Dishes or glasses do not dry

properly.

Rinse aid concentration too low. Increase concentration.

See also operating instructions point 6.2.

Items to be washed still greasy. Detergent concentration too low: increase

(see instructions).

Check if detergent is appropriate. If not choose a

stronger one.

Drain soiled water and rell machine. Check pre-scrapping procedure.

Rack is not suitable for type of washware.

Use appropriate racks to create a sloping position

which allows water to drain away from cavities.

Washware stays too long in the machine

at the end of program.

Take out washware as soon as cycle is completed to

enable the ware to dry.

Stripes and staines on

dishes or glasses.

Rinse aid concentration too high. Reduce quantity (see instructions).

Hard water or high mineral content. Check water quality.

Obtain details from local water authority.

Recommended values:

Ideal degree of hardness is 4° Clark.

Ideal conductivity value for glasses is max. 150 µS/

cm and for dishes max. 400 µS/cm.

Rack is not suitable for type of washware.

Use appropriate racks to create a sloping position

which allows water to drain away from cavities.

Insufcient rinse aid concentration

causes staines

Increase quantity (see instructions)

Machine with softener:

Wrong type of salt used. Use only granular regeneration salt.

10. TROUBLESHOOTING GUIDE

Page 20

20

10.2. OTHER FAULTS

TYPE OF FAILURES POSSIBLE CAUSE REMEDY

Glasses are totally or partially

cloudy

Surface of glasses is rough and porous,

this is called glass corrosion

This is not caused by a malfunction on the machine.

Replace with new glasses.

Glass breakages. Use of inappropriate dish or glass racks. Use appropriate racks.

10.3. MALFUNCTIONS

TYPE OF FAILURES POSSIBLE CAUSE REMEDY

Machine suddenly stops during wash program.

Machine is connected to an energy

management system which cuts out the

energy consumer at a given point, or machine is interlocked with another energy

consumer unit.

Connect machine separately (call electrician).

Blown site fuse. Check site fuses.

Temperature probe

rinse booster or tank defective.

Call the after sales service.

Pressure transmitter

rinse booster or tank defective.

Call the after sales service.

The four button LEDs ash. Control defective. Call the after sales service.

10. TROUBLESHOOTING GUIDE

Page 21

Page 22

22

HOBART China

No.8 Yesheng Road, Xiqing Ecomonic

& Development Zone, Tianjin China

Tel. 022-23974912/13/14/15

Fax 022-23974917

E-Mail: info@hobart.cn

Internet:

www.hobart.cn

As continued product improvement is a policy of HOBART,

specications are subject to change without notice.

Printed in China

Page 23

Dishwasher Maintenance

Clean machine(Customer)

Items Content

1 Tank flat strainer Visual inspection & cleaning

2 Wash tank housing Visual inspection (lime deposits etc.)

3 Wash & rinse arms Removing & cleaning of upper and lower wash arms. Tight en scr ews when installing.

4 Overflow & Tank strainer Check overflow tube in right place

5 Milled nut Check wash arm milled nut before operation, and tight it.

Machine inspection (Service)

Component Inspection Machine Type

1 General condition (first impression) - Visual control, condition

All

2 Machine tightness - Visual control, become less crowded All

3 Fill hose, fill valve & air gap system - condi t ion and function All

4 Water level wash tank, air chamber

- Condition & function due to visual control

- Check soil level inside air chamber

AMX/AM900

5 Pressure transmitter, pressure hose

- Check soil level inside air chamber

- Condition & function due to visual control

- Check sealing of pressure hose

All

6 Booster, rinse pump, rinse manifold

- Condition & function due to visual control

- Tightness

- Check Booster water level using routine S56 (Service manual)

AMX/AM900

7 Wash & rinse arms

- Check wash & rinse arm spinning

- Removing & cleaning of upper and lower rinse and wash arms

- Visual inspection of abrasion and lime deposits of wash & rinse arms , r eplace it when

necessary.

All

8

Wash arm bearing, sliding r i ng and

milled nut

- Visual inspection of abrasion and lime deposits of wash arm bearing sliding r ing and milled

nut, replace it when necessary.

Hxle-wash arm(00-883452-001), milled nut(7159006-6), gasket(00-775933-003).

All

- Visual inspection of abrasion, warping and deformation of wash arm washer, replace i t.

For AMX/AM900 H502L/E502L AM50E/AM60E

Machine maintenance after 0.5 year or 20 000 cycles. The mai nt enance m ust be car r i ed out by authori z ed

service technicians.

9

Wash

arm washer

p,pg ,p

Teflon washer(00-774072-001/002, 00-774072-007).

All

10 Safety equipment: hood end switch - Check function All

11 Bosster and tank heating elements - Condition, fuction and tightness All

12 Door & Hoodlift

- Operating noise (rolls)

- Adujstment of the hood in standby positi on

- Visual control, condition, tightness

- Function check

- Function, check door slide bearing, doorstop damper, r eplace it when necessary.

AMX/AM900

AM50E/60E

13 Door mechanism clamping force - Check clamping force AMX/AM900 AM60E

14 Bow - Function, check bow bearing AMX/AM900

15 Tighness of top cover / BAE

- Visual inspection: tightness top cov er and BAE

- Humidity in BAE, if necessary replace and change seal top cover

AMX/AM900

H(E)502L(P)

16

Machine control unit, contactor, fuses &

touch panel

- Check condition and function, if necessary test r un All

17

Control unit & circuit board: ______

number of cycles

- Visual inspection, check moisture penetrat ion All

18 Detergent & rinse aid dosing

- Check function

- Check dosing level

All

19 Detergent & Rinse aid hoses

- Check tightness, especially on interface hose / connection nipple

- Exchange all hoses every 2 years

All

20

Chemical sensor for rinse- and

deter

g

ent agent

- Check switching function All

21 Drain pump - Check residual water after drain, if necessary check drain pump (i mpeller) All

22 Drain hose - Visual inspection, exchange by porosity or damaging All

23 Wash & ri nse r esult - Performance control All

24 Softener (if exi st ing)

- Visual inspection, condition, corrosi on ect .

- Check hardness

All

25 Descale -Check the deposit of scale in wash tank and booster, descale it promptly. All

26

If necessary water analysis

_____°d (GH); ____°d (KH); ____µS

All

27 Test run All

28 Wash pump -Check the leakage of shaft seal. if necessary replace and change shaft seal.

V1.0 2013-1-9

Loading...

Loading...