Page 1

F37559 Rev. B (FEB, 2015)

MODEL DWT-CLe, DWT-FT & DWT-UW

DRAIN WATER TEMPERING

. . . FOR DISHWASHERS

MODEL

DWT-CLe ML-138241

DWT-FT ML-138242

DWT-UW ML-138315

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937-332-3000

www.hobartcorp.com

Page 2

Installation, Operation, Use and Care of

PART NO.

NAME OF PART

AMT.

814709

Base Plate Assy DWTCLe

1

814711

Drain Pipe Assy, DWT

1

814712

Cold Water Pipe Assy, DWT

1

542337

Hose Clamp

2

814679

Base Plate Bracket

1

SC-041-50

Cap Screw, ¼-20 x ½”

4

WL-03-036

Lock Washer

4

NS-15-01

Nut

4

PART NO.

NAME OF PART

AMT.

814710

Control Box Assy DWTFT

1

814768

Drain Pipe Assy, DWTFT

1

814769

Cold Water Pipe Assy, DWTFT

1

542337

Hose Clamp

2

SC-041-50

Cap Screw, ¼-20 x ½”

2

WL-03-036

Lock Washer

2

NS-15-01

Nut

2

PART NO.

NAME OF PART

AMT.

814770

Control Box Assy DWTUW

1

814711

Drain Pipe Assy, DWT

1

814712

Cold Water Pipe Assy, DWT

1

542337

Hose Clamp

2

SC-041-50

Cap Screw, ¼-20 x ½”

2

WL-03-036

Lock Washer

2

NS-15-01

Nut

2

Model DWT-CLe, DWT-FT & DWT-UW

Drain Water Tempering for Dishwashers

SAVE THESE INSTRUCTIONS

GENERAL

The Drain Water Tempering Kit reduces the temperature of drain water exiting a Hobart commercial dishwasher by adding

cold water to the drain water. The thermostat, provided, determines when additional cold water is needed and

automatically adds cold water to the drain.

INSTALLATION

Immediately after unpacking, check for possible shipping damage. If damage is found, save the packaging material and

contact the carrier within 15 days of delivery.

ML-138241-Z DWT-CLe – Drain Water Tempering Kit (complete)

ML-138242-Z DWT-FT – Drain Water Tempering Kit (complete)

ML-138315-Z DWT-UW – Drain Water Tempering Kit (complete)

Page 3

814709 – Base Plate Assy DWT-CLe

PART NO.

NAME OF PART

AMT.

294436-00003

Fuse Block

1

294681-025-4

Drain Thermostat 135F

1

814900

Grommet

3

814664

Control Harness

1

814665

Thermostat Harness

1

814666

Solenoid Valve Cable

1

814678

Base Plate

1

814691

Mylar Barrier

1

919742-00003

Terminal Block

1

FE-008-48

Fuse

1

SD-034-59

10-32 Type T Drive Screw

1

SD-008-17

6-20 Type B Drive Screw

7

Page 4

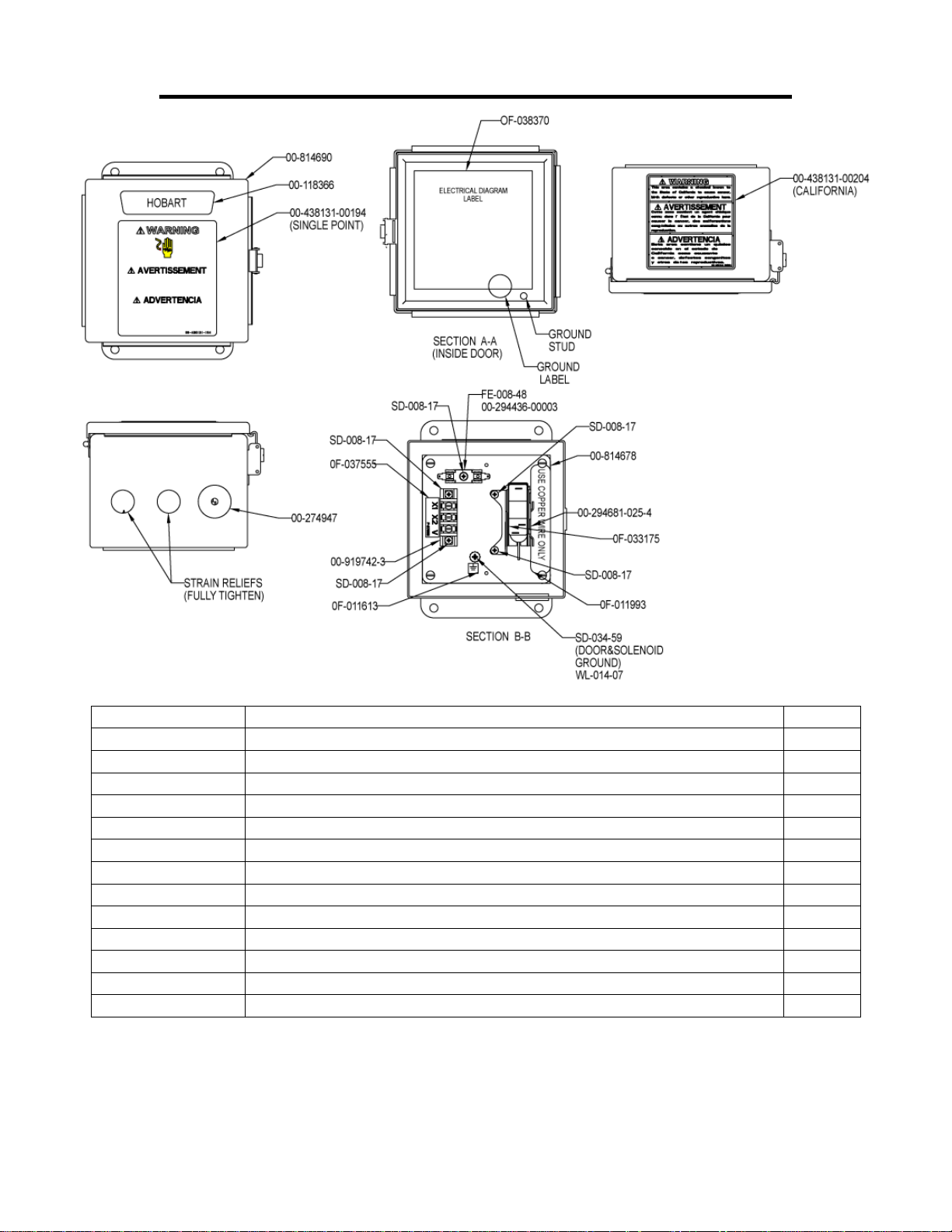

814710 – Control Box Assy DWT-FT

PART NO.

NAME OF PART

AMT.

274947

Grommet

1

294436-00003

Fuse Block

1

294681-025-4

Drain Thermostat 135F

1

814663-00003

Lead Wire – Ground

1

814665

Thermostat Harness

1

814666

Solenoid Valve Cable

1

814673

Control Cable

1

814678

Base Plate

1

814690

Control Box

1

919742-00002

Terminal Block

1

FE-008-48

Fuse

1

SD-034-59

10-32 Type T Drive Screw

1

SD-008-17

6-20 Type B Drive Screw

5

Page 5

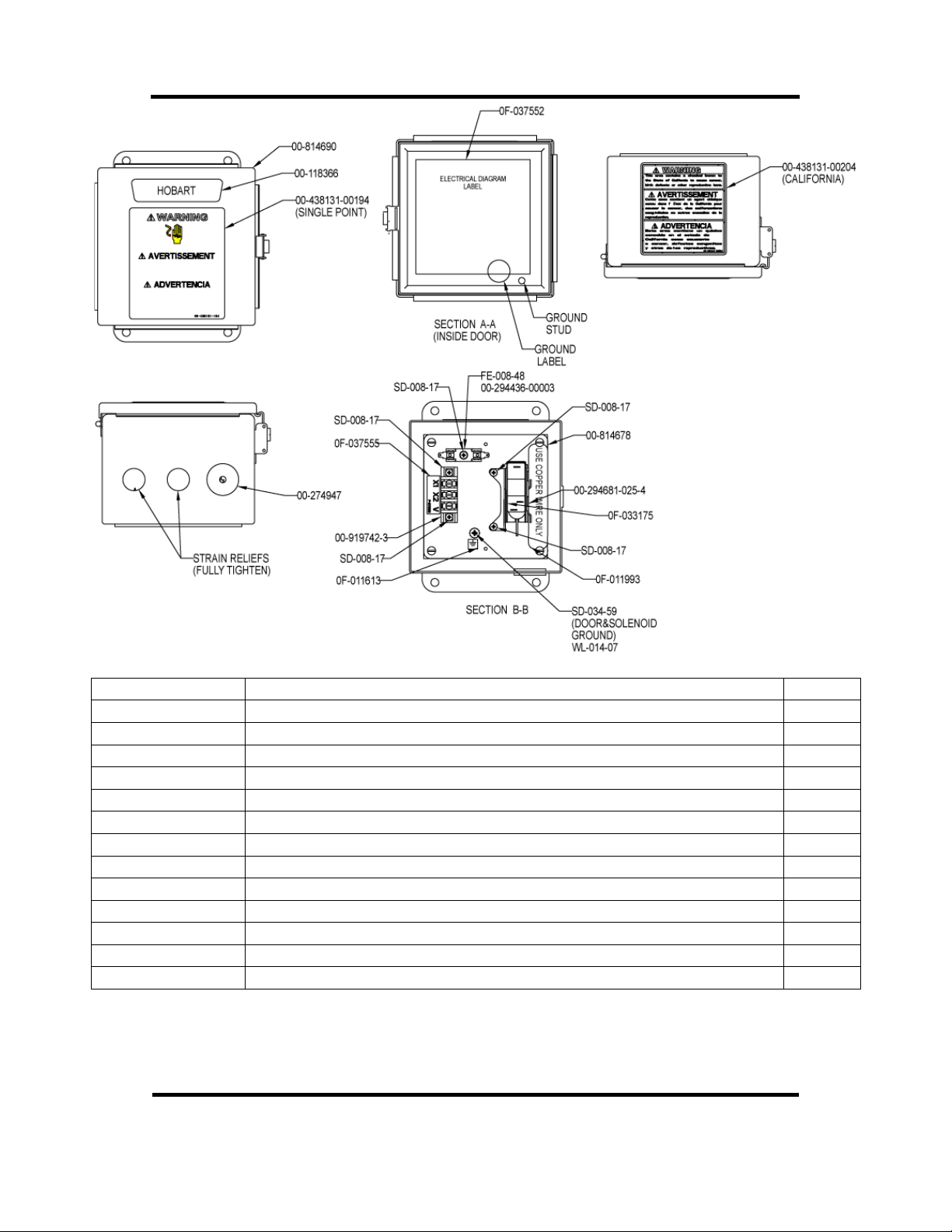

814770 – Control Box Assy DWT-UW

PART NO.

NAME OF PART

AMT.

274947

Grommet

1

294436-00003

Fuse Block

1

294681-025-4

Drain Thermostat 135F

1

814663-00003

Lead Wire – Ground

1

814665

Thermostat Harness

1

814666

Solenoid Valve Cable

1

814767

Control Cable

1

814678

Base Plate

1

814690

Control Box

1

919742-00002

Terminal Block

1

FE-008-48

Fuse

1

SD-034-59

10-32 Type T Drive Screw

1

SD-008-17

6-20 Type B Drive Screw

5

814712 – Cold Water Pipe Assy DWT

Page 6

PART NO.

NAME OF PART

AMT.

814712-00001

Cold Water Pipe Soldered Assy

1

223472

½” Backflow Preventer

1

270258

½” Line Strainer

1

435968-00001

½” Solenoid Valve

1

FP-040-42

½” x 1 1/8” Threaded Nipple

2

Page 7

814769 – Cold Water Pipe Assy DWT-FT

PART NO.

NAME OF PART

AMT.

814769-00001

Cold Water Pipe Soldered Assy

1

223472

½” Backflow Preventer

1

270258

½” Line Strainer

1

435968-00001

½” Solenoid Valve

1

FP-040-42

½” x 1 1/8” Threaded Nipple

2

Page 8

814711 – Drain Pipe Assy DWT

814768 – Drain Pipe Assy DWT-FT

Page 9

Plumbing connections must comply with applicable sanitary, safety, and

plumbing codes.

Electrical and grounding connections must comply with the applicable portions

of the National Electrical Code and/or other local electrical codes.

NOTE: The Drain Water Tempering Kit is wired for 120 VAC. It has been designed to obtain this

power from the main control box on the dishwasher. Please follow the instructions below.

1. Determine desired end of dishwasher for drain connection. If necessary remove plug and

relocate to other end of dishw asher drai n .

NOTE: UW50 must have drain connection at the end of the machine opposite the controls.

2. Remove any trim panels in the area to install the Drain Water Tempering Kit.

3. Undo the Union of the Drain Pipe Assy.

Page 10

4. Apply Thread Tape or Thread Sealant (not included) t o the mal e thr eads on the 2” male

adapter.

5. Thread the 2” male adapter (with female union) into the desired end of the drain. Tighten to

prevent leaks, but not to stress components.

6. Insert the ¾” street tee of the Cold Water Pipe Assy into the ¾” tee opening of the Drain Pipe

Assy.

7. Orient the Cold Water Pipe Assy to suit the machine. Solder the 3/4” copper joint of the two

tees, to connect the Drain Pipe Assy and the Cold Water Pipe As sy.

NOTE: Solenoid valve must be located within footprint of dishwasher.

8. Mount the Control Box Assy (on FT and UW50 machines) or the Base Plate Assy (on CLe

machines)

• CLe

o Remove the front trim panels

o Attach the Base Plate Assy part no. 814709 to the Base Plate Bracket part no.

814679 (using included nuts, washers, and bolts) – Re mov e edge protection

from plate where bracket is being attached.

NOTE: Mount Base Plate so that the capillary tube runs tow ards the floor .

Page 11

o Make sure Mylar Barrier is fully attached top and bottom

o Attach the Base Plate Bracket to front leg of the machine closest to installed

Drain Pipe Assy (using included nuts, washers, and bolts)

Page 12

• FT

o Remove the front trim panel

o Insuring the thermostat capillary and solenoid cable can easily reach t he dr ain

NOTE: New holes may need to be drilled for this.

• UW50

o Remove the rear and side lower trim panels

o Attach the Control Box to back leg of the machine (using included nuts,

without being stressed, mount the Control Box Assy on the machine frame close

to the drain location (using included nuts, washers, and bolts) .

washers, and bolts)

9. Remove the Wire Tie from the Therm ost at Capillary

10. Roughly locate the Drain Pipe Assy (soldered to the Cold Water Pipe Assy) under the

machine. DO NOT REASSEMBLE THE 2” UNION.

Page 13

11. Apply Thread Tape or Thread Sealant (not included) to the male threads on the Thermostat

Bulb Retainer.

12. Taking notice of the routing – carefully uncoil the thermostat capillary tube and insert the

thermostat bulb into the Cold Water Pipe Assy.

13. Thread the Thermostat Bulb Retainer into the Flush Bushing of the Cold Water Pipe Assy.

Tighten, but not to stress the components.

14. Reaching into the 2” pipe, route the Thermostat Bulb through the ¾” vertical pipe and down

into the 2” horizontal pipe. The Bul b o f the Th er mostat must lay flat on the bottom of the 2”

Drain Pipe and be pointed towards the machine.

Page 14

15. Once the bulb is properly oriented, tighten the Capillary Retainer.

16. Remove the cover of the Solenoid Valve.

17. Remove the appropriate knock-out of the Solenoid Valve.

18. Remove the Wire Tie from the Solenoid Valve Cable (connected to Base Plate Assy on CLe or

Control Box Assy on FT and UW50)

19. Taking notice of the wire routing – Attach the Strain Relief from the Solenoid Valve Cable to

the Solenoid Valve (where knock-out has bee n removed). Make sure the Strain Relief is fully

tightened to the cable and to the Solenoid.

Page 15

20. Attach the two quick connect terminals and the one ring terminal. Attach the Solenoid Valve

Cover.

21. Assemble the 2” Union to reconnect the two components of the Drain Pipe Assy.

o Take note that the THERMOSTAT BULB IS HORIZONTAL, POINTED TOWARDS THE

MACHINE DRAIN, AND TOUCHING THE BOTTOM OF THE 2” DRAIN PIPE.

22. Use the hose clamps to fasten the new installed piping to the frame of the dishwasher – this is

to remove the added weight from the drain body of the machine.

Page 16

23. ROUTE and SECURE the Capillary Tube of the Thermostat and the Solenoid Valve Cable to

the machine using Wire Ties (included). Any additional Capillary or Cable length should be

carefully coiled and wire tied at the Base Plate Assy (CLe) or Control Box Assy (FT and

UW50), where it will not be damaged. Do not place excess capillary tubing inside the control

box.

24. Connect the wiring to the main control box.

• CLe

o Remove the two Wire Way Covers at the back of the machine

o Remove the Main Control Box Cover on top of the machine

o Route the Harness with wires labeled DWT1 and DWT2 to the Wire Way,

through the Wire Way and into the Contr ol Bo x. Be sure to stay in the track with

the twisted pair wires.

o Connect the wire labeled DWT1 to the Terminal labeled DWT1

o Connect the wire labeled DWT2 to the Terminal labeled DWT2

Page 17

o Replace the Main Control Box Cover

o Replace the two Wire Way Covers

• FT

o Remove the Main Control Box Cover

o Route the FT Control Cable with wires labeled DWT1 and DWT2 to the Control

NOTE: If DWT1 and DWT2 do not exist in FT control box an external 120V power

source must be run to DWT control box.

o Attach to FT Control Cable with DWT1 and DWT2 and insert into the control box

o Connect the wire labeled DWT1 to the Terminal labeled DWT1

o Connect the wire labeled DWT2 to the Terminal labeled DWT2

o Replace the Main Control Box Cover

• UW50

o Remove the Main Control Box Cover

Box.

o Open the DWT-UW Control Box Cover

o Route the UW50 Control Cable with wires labeled 1FU-1SS and 2TB-2 to the

Wire Way, along the Wire Way, and into the Control Box

Page 18

o Remove the plug in the bottom of the Control Box to insert the Strain Relief and

Wires.

o Connect the wire labeled 1FU-1SS to the Terminal labeled 1FU-1SS

o Connect the wire labeled 2TB-2 to the Terminal labeled 2TB-2

o Tighten Strain Re lief.

o Replace the Main Control Box Cover

25. Make sure all Trim Panels have been replaced and properly secured

26. Note that the Backflow Preventer has a vent and may require piping

27. The incoming cold water line is to be connected to the strainer at the end of the Cold Water

Piping

28. For optimized performance insert a pressure regulator valve in the incoming cold water line.

Page 19

- THIS PAGE INTENTIONALLY LEFT BLANK –

Page 20

- THIS PAGE INTENTIONALLY LEFT BLANK -

Loading...

Loading...