Hitachi WJ200 User Manual

WJ200 Series Inverter

Quick Reference Guide

• |

Single-phase Input |

200V class |

• |

Three-phase Input |

200V class |

• |

Three-phase Input |

400V class |

Manual Number: NT3251AX |

Refer to the user manual for detail |

March 2012

Hitachi Industrial Equipment Systems Co., Ltd.

UL® Cautions, Warnings and Instructions

Warnings and Cautions for Troubleshooting and Maintenance

(Standard to comply with : UL508C,CSA C22.2 No.14-05) Warning Markings

GENERAL:

These devices are open type Power Conversion Equipment. They are intended to be used in an enclosure. Insulated gate bipolar transistor (IGBT) incorporating microprocessor technology. They are operated from a single or three-phase source of supply, and intended to control three-phase induction motors by means of a variable frequency output. The units are intended for general-purpose industrial applications.

MARKING REQUIREMENTS:

Ratings - Industrial control equipment shall be plainly marked with the Listee’s name, trademark, File number, or other descriptive marking by which the organization responsible for the product may be identified;

a)“Maximum surrounding air temperature rating of 50 ºC.”

b)“Solid State motor overload protection reacts with max. 150 % of FLA”.

c)“Install device in pollution degree 2 environment.”

d)“Suitable for use on a circuit capable of delivering not more than 100,000 rms Symmetrical Amperes, 240 or 480 Volts Maximum.”

e)“When Protected by CC, G, J or R Class Fuses.” or “When Protected By A Circuit Breaker Having An Interrupting Rating Not Less Than 100,000 rms Symmetrical Amperes, 240 or 480 Volts Maximum.”

f)“Integral solid state short circuit protection does not provide branch circuit protection. Branch circuit protection must be provided in accordance with the National Electrical Code and any additional local codes.”

1

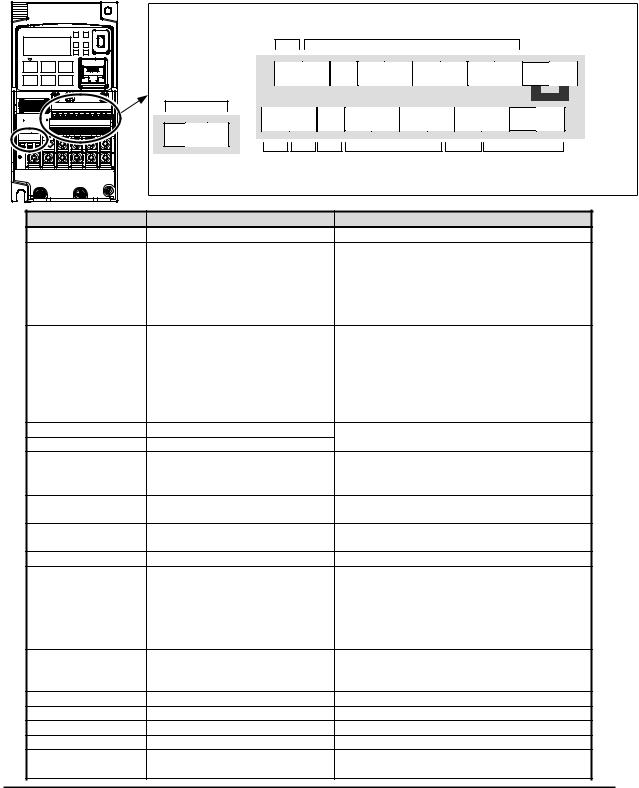

Terminal symbols and Screw size

|

Inverter Model |

|

|

Screw Size |

|

|

Required |

|

Wire range |

|

|

|

|

|

Torque (N-m) |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WJ200-001S |

|

M3.5 |

1.0 |

|

AWG16 (1.3mm2) |

|||

|

WJ200-002S |

|

|

||||||

|

WJ200-004S |

|

|

|

|

|

|

|

|

|

WJ200-007S |

|

M4 |

1.4 |

|

AWG12 (3.3mm2) |

|||

|

WJ200-015S |

|

M4 |

1.4 |

|

AWG10 (5.3mm2) |

|||

|

WJ200-022S |

|

|

|

|

|

|

|

|

|

WJ200-001L |

|

|

|

|

|

|

|

|

|

WJ200-002L |

|

M3.5 |

1.0 |

|

AWG16 (1.3mm2) |

|||

|

WJ200-004L |

|

|

|

|

|

|

|

|

|

WJ200-007L |

|

|

|

|

|

|

|

|

|

WJ200-015L |

|

M4 |

1.4 |

|

AWG14 (2.1mm2) |

|||

|

WJ200-022L |

|

M4 |

1.4 |

|

AWG12 (3.3mm2) |

|||

|

WJ200-037L |

|

M4 |

1.4 |

|

AWG10 (5.3mm2) |

|||

|

WJ200-055L |

|

M5 |

3.0 |

|

AWG6 (13mm2) |

|||

|

WJ200-075L |

|

|

|

|

|

|

|

|

|

WJ200-110L |

|

M6 |

|

3.9 to 5.1 |

AWG4 (21mm2) |

|||

|

WJ200-150L |

|

M8 |

|

5.9 to 8.8 |

AWG2 (34mm2) |

|||

|

WJ200-004H |

|

|

|

|

|

|

AWG16 (1.3mm2) |

|

|

WJ200-007H |

|

M4 |

1.4 |

|

||||

|

WJ200-015H |

|

|

|

|

|

|

|

|

|

WJ200-022H |

|

M4 |

1.4 |

|

AWG14 (2.1mm2) |

|||

|

WJ200-030H |

|

|

|

|

|

|

|

|

|

WJ200-040H |

|

M4 |

1.4 |

|

AWG12 (3.3mm2) |

|||

|

WJ200-055H |

|

M5 |

3.0 |

|

AWG10 (5.3mm2) |

|||

|

WJ200-075H |

|

|

|

|

|

|

|

|

|

WJ200-110H |

|

M6 |

|

3.9 to 5.1 |

AWG6 (13mm2) |

|||

|

WJ200-150H |

|

|

|

|

|

|

|

|

2

Fuse Sizes

Distribution fuse size marking is included in the manual to indicate that the unit shall be connected with a Listed Cartridge Nonrenewable fuse, rated 600 Vac with the current ratings as shown in the table below or Type E Combination Motor Controller marking is included in the manual to indicate that the unit shall be connected with,LS Industrial System Co.,Ltd,Type E Combination Motor Controller MMS Series with the ratings as shown in the table below:

|

Inverter Model |

|

|

Type |

|

|

Fuse Rating |

|

|

Type E CMC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WJ200-001S |

|

|

|

|

|

|

|

|

|

|

|

WJ200-002S |

|

|

|

|

|

10A, AIC 200kA |

|

|

|

|

|

WJ200-004S |

|

|

|

|

|

|

|

|

MMS-32H,240V,40A |

|

|

WJ200-007S |

|

|

|

|

|

20A, AIC 200kA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

WJ200-015S |

|

|

|

|

|

30A, AIC 200kA |

|

|

|

|

|

WJ200-022S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WJ200-001L |

|

|

|

|

|

|

|

|

|

|

|

WJ200-002L |

|

|

|

|

|

10A, AIC 200kA |

|

|

|

|

|

WJ200-004L |

|

|

|

|

|

|

|

|

|

|

|

WJ200-007L |

|

|

|

|

|

15A, AIC 200kA |

|

|

MMS-32H,240V,40A |

|

|

WJ200-015L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WJ200-022L |

|

|

|

|

|

20A, AIC 200kA |

|

|

|

|

|

WJ200-037L |

|

|

Class J |

|

|

30A, AIC 200kA |

|

|

|

|

|

WJ200-055L |

|

|

|

|

60A, AIC 200kA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

WJ200-075L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MMS-100H,240V,80A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WJ200-110L |

|

|

|

|

|

80A, AIC 200kA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

WJ200-150L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WJ200-004H |

|

|

|

|

|

|

|

|

|

|

|

WJ200-007H |

|

|

|

|

|

10A, AIC 200kA |

|

|

|

|

|

WJ200-015H |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WJ200-022H |

|

|

|

|

|

|

|

|

MMS-32H,480V,40A |

|

|

WJ200-030H |

|

|

|

|

|

15A, AIC 200kA |

|

|

|

|

|

|

|

|

|

|

|

|

or |

|

||

|

WJ200-040H |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

MMS-63H,480V,52A |

|

|

|

WJ200-055H |

|

|

|

|

|

30A, AIC 200kA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

WJ200-075H |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WJ200-110H |

|

|

|

|

|

50A, AIC 200kA |

|

|

|

|

|

WJ200-150H |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3

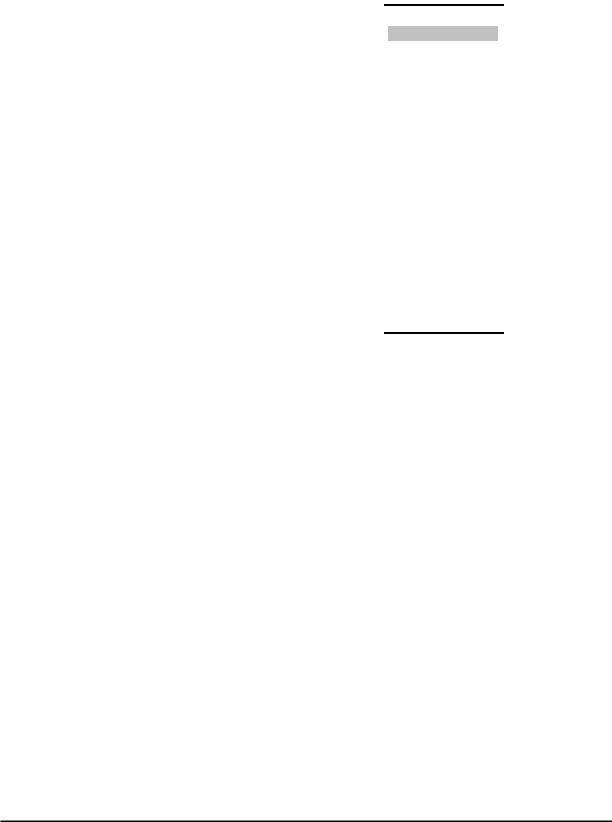

Inverter Specification Label

The Hitachi WJ200 inverters have product labels located on the right side of the housing, as pictured below. Be sure to verify that the specifications on the labels match your power source, and application safety requirements.

Model name |

-001SF |

Ver:2.0 |

|

Input ratings |

|||

200-240 |

2.0/1.3 |

||

Output ratings |

200-240 |

1.2/1.0 |

|

MFG number |

05A_T12345_A_-001 |

1005 |

|

|

Inverter Specification Label

The model number for a specific inverter contains useful information about its operating characteristics. Refer to the model number legend below:

|

WJ200 |

|

|

|

001 |

|

S |

|

F |

|

Configuration type |

|

||||

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Series name |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

F=with keypad |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input voltage: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S=Single-phase 200V class |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L=Three-phase 200V class |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H=Three-phase 400V class |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Applicable motor capacity in kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

001=0.1kW |

037=3.7kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

002=0.2kW |

040=4.0kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

004=0.4kW |

055=5.5kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

007=0.75kW |

075=7.5kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

015=1.5kW |

110=11kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

022=2.2kW |

150=15kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

030=3.0kW |

|

4

WJ200 Inverter Specifications

Model-specific tables for 200V and 400V class inverters

The following tables are specific to WJ200 inverters for the 200V and 400V class model groups. Note that “General Specifications” on page in this chapter apply to both voltage class groups. Footnotes for all specification tables follow the table below.

|

Item |

|

|

|

|

Single-phase 200V class Specifications |

|

||||

WJ200 inverters, 200V models |

|

001SF |

|

002SF |

004SF |

007SF |

015SF |

022SF |

|||

Applicable motor size |

|

kW |

VT |

0.2 |

|

0.4 |

0.55 |

1.1 |

2.2 |

3.0 |

|

|

|

|

|

CT |

0.1 |

|

0.2 |

0.4 |

0.75 |

1.5 |

2.2 |

|

|

|

HP |

VT |

1/4 |

|

1/2 |

3/4 |

1.5 |

3 |

4 |

|

|

|

|

CT |

1/8 |

|

1/4 |

1/2 |

1 |

2 |

3 |

Rated capacity (kVA) |

|

200V |

VT |

0.4 |

|

0.6 |

1.2 |

2.0 |

3.3 |

4.1 |

|

|

|

|

|

CT |

0.2 |

|

0.5 |

1.0 |

1.7 |

2.7 |

3.8 |

|

|

|

240V |

VT |

0.4 |

|

0.7 |

1.4 |

2.4 |

3.9 |

4.9 |

|

|

|

|

CT |

0.3 |

|

0.6 |

1.2 |

2.0 |

3.3 |

4.5 |

Rated input voltage |

|

|

|

Single-phase: 200V-15% to 240V +10%, 50/60Hz ±5% |

|||||||

Rated output voltage |

|

|

Three-phase: 200 to 240V (proportional to input voltage) |

||||||||

Rated output current (A) |

|

VT |

1.2 |

|

1.9 |

3.5 |

6.0 |

9.6 |

12.0 |

||

|

|

|

|

CT |

1.0 |

|

1.6 |

3.0 |

5.0 |

8.0 |

11.0 |

Starting torque |

|

|

|

|

|

200% |

at 0.5Hz |

|

|

||

Braking |

Without resistor |

|

|

|

100%: ≤50Hz |

|

70%: ≤ 50Hz |

20%: ≤ 50Hz |

|||

|

|

|

|

|

|

|

50%: ≤60Hz |

|

50%: ≤ 60Hz |

20%: ≤ 60Hz |

|

|

With resistor |

|

|

|

|

150% |

|

|

100% |

||

DC braking |

|

|

|

|

|

Variable operating frequency, time, and braking |

force |

||||

Weight |

|

|

|

kg |

1.0 |

|

1.0 |

1.1 |

1.6 |

1.8 |

1.8 |

|

|

|

|

lb |

2.2 |

|

2.2 |

2.4 |

3.5 |

4.0 |

4.0 |

5

WJ200 Inverter Specifications, continued…

|

Item |

|

|

|

|

Three-phase 200V class Specifications |

|

||||||

WJ200 inverters, 200V models |

|

|

001LF |

002LF |

|

004LF |

|

007LF |

015LF |

|

022LF |

||

Applicable motor size |

kW |

|

VT |

0.2 |

0.4 |

|

0.75 |

|

1.1 |

2.2 |

|

3.0 |

|

|

|

|

|

CT |

0.1 |

0.2 |

|

0.4 |

|

0.75 |

1.5 |

|

2.2 |

|

|

HP |

|

VT |

1/4 |

1/2 |

|

1 |

|

1.5 |

3 |

|

4 |

|

|

|

|

CT |

1/8 |

1/4 |

|

1/2 |

|

1 |

2 |

|

3 |

Rated capacity (kVA) |

200V |

|

VT |

0.4 |

0.6 |

|

1.2 |

|

2.0 |

3.3 |

|

4.1 |

|

|

|

|

|

CT |

0.2 |

0.5 |

|

1.0 |

|

1.7 |

2.7 |

|

3.8 |

|

|

240V |

|

VT |

0.4 |

0.7 |

|

1.4 |

|

2.4 |

3.9 |

|

4.9 |

|

|

|

|

CT |

0.3 |

0.6 |

|

1.2 |

|

2.0 |

3.3 |

|

4.5 |

Rated input voltage |

|

|

|

Three-phase: 200V-15% to 240V +10%, 50/60Hz ±5% |

|

||||||||

Rated output voltage |

|

|

|

Three-phase: 200 to 240V (proportional to input voltage) |

|||||||||

Rated output current (A) |

|

|

VT |

1.2 |

1.9 |

|

3.5 |

|

6.0 |

9.6 |

|

12.0 |

|

|

|

|

|

CT |

1.0 |

1.6 |

|

3.0 |

|

5.0 |

8.0 |

|

11.0 |

Starting torque |

|

|

|

|

|

|

|

200% at 0.5Hz |

|

|

|

||

Braking |

Without resistor |

|

|

|

100%: ≤50Hz |

|

|

70%: ≤ 50Hz |

20%: ≤ 50Hz |

||||

|

|

|

|

|

|

50%: ≤60Hz |

|

|

50%: ≤ 60Hz |

20%: ≤ 60Hz |

|||

|

With resistor |

|

|

|

|

150% |

|

|

|

|

100% |

||

DC braking |

|

|

|

|

Variable operating frequency, time, and braking |

force |

|||||||

Weight |

|

|

|

kg |

1.0 |

1.0 |

|

1.1 |

|

1.2 |

1.6 |

|

1.8 |

|

|

|

|

lb |

2.2 |

2.2 |

|

2.4 |

|

2.6 |

3.5 |

|

4.0 |

|

|

|

|

|

|

|

|

||||||

|

Item |

|

|

|

|

Three-phase 200V class Specifications |

|

||||||

WJ200 inverters, 200V models |

|

|

037LF |

055LF |

|

075LF |

|

110LF |

150LF |

|

|

||

Applicable motor size |

kW |

|

VT |

5.5 |

7.5 |

|

11 |

|

15 |

18.5 |

|

|

|

|

|

|

|

CT |

3.7 |

5.5 |

|

7.5 |

|

11 |

15 |

|

|

|

|

HP |

|

VT |

7.5 |

10 |

|

15 |

|

20 |

25 |

|

|

|

|

|

|

CT |

5 |

7.5 |

|

10 |

|

15 |

20 |

|

|

Rated capacity (kVA) |

200V |

|

VT |

6.7 |

10.3 |

|

13.8 |

|

19.3 |

20.7 |

|

|

|

|

|

|

|

CT |

6.0 |

8.6 |

|

11.4 |

|

16.2 |

20.7 |

|

|

|

|

240V |

|

VT |

8.1 |

12.4 |

|

16.6 |

|

23.2 |

24.9 |

|

|

|

|

|

|

CT |

7.2 |

10.3 |

|

13.7 |

|

19.5 |

24.9 |

|

|

Rated input voltage |

|

|

|

Three-phase: 200V-15% to 240V +10%, 50/60Hz ±5% |

|

||||||||

Rated output voltage |

|

|

|

Three-phase: 200 to 240V (proportional to input voltage) |

|||||||||

Rated output current (A) |

|

|

VT |

19.6 |

30.0 |

|

40.0 |

|

56.0 |

69.0 |

|

|

|

|

|

|

|

CT |

17.5 |

25.0 |

|

33.0 |

|

47.0 |

60.0 |

|

|

Starting torque |

|

|

|

|

|

|

|

200% at 0.5Hz |

|

|

|

||

Braking |

Without resistor |

|

|

|

|

20%: ≤50Hz |

|

|

|

||||

|

|

|

|

|

|

|

20%: ≤60Hz |

|

|

|

|||

|

With resistor |

|

|

100% |

|

|

|

80% |

|

|

|

||

DC braking |

|

|

|

|

Variable operating frequency, time, and braking |

force |

|||||||

Weight |

|

|

|

Kg |

2.0 |

3.3 |

|

3.4 |

|

5.1 |

7.4 |

|

|

|

|

|

|

lb |

4.4 |

7.3 |

|

7.5 |

|

11.2 |

16.3 |

|

|

6

WJ200 Inverter Specifications, continued…

|

Item |

|

|

|

|

|

Three-phase 400V class Specifications |

|

|||||

WJ200 inverters, 400V models |

|

|

004HF |

|

007HF |

|

015HF |

022HF |

030HF |

|

040HF |

||

Applicable motor size |

kW |

|

VT |

0.75 |

|

1.5 |

|

2.2 |

3.0 |

4.0 |

|

5.5 |

|

|

|

|

|

CT |

0.4 |

|

0.75 |

|

1.5 |

2.2 |

3.0 |

|

4.0 |

|

|

HP |

|

VT |

1 |

|

2 |

|

3 |

4 |

5 |

|

7.5 |

|

|

|

|

CT |

1/2 |

|

1 |

|

2 |

3 |

4 |

|

5 |

Rated capacity (kVA) |

380V |

|

VT |

1.3 |

|

2.6 |

|

3.5 |

4.5 |

5.7 |

|

7.3 |

|

|

|

|

|

CT |

1.1 |

|

2.2 |

|

3.1 |

3.6 |

4.7 |

|

6.0 |

|

|

480V |

|

VT |

1.7 |

|

3.4 |

|

4.4 |

5.7 |

7.3 |

|

9.2 |

|

|

|

|

CT |

1.4 |

|

2.8 |

|

3.9 |

4.5 |

5.9 |

|

7.6 |

Rated input voltage |

|

|

|

Three-phase: 400V-15% to 480V +10%, 50/60Hz ±5% |

|

||||||||

Rated output voltage |

|

|

|

Three-phase: 400 to 480V (proportional to input voltage) |

|||||||||

Rated output current (A) |

|

|

VT |

2.1 |

|

4.1 |

|

5.4 |

6.9 |

8.8 |

|

11.1 |

|

|

|

|

|

CT |

1.8 |

|

3.4 |

|

4.8 |

5.5 |

7.2 |

|

9.2 |

Starting torque |

|

|

|

|

|

|

|

|

200% at 0.5Hz |

|

|

|

|

Braking |

Without resistor |

|

|

|

100%: ≤50Hz |

|

70%: ≤ 50Hz |

20%: ≤ 50Hz |

|||||

|

|

|

|

|

|

50%: ≤60Hz |

|

50%: ≤ 60Hz |

20%: ≤ 60Hz |

||||

|

With resistor |

|

|

|

|

|

|

150% |

|

|

|

|

|

DC braking |

|

|

|

|

Variable operating frequency, time, and braking |

force |

|||||||

Weight |

|

|

|

kg |

1.5 |

|

1.6 |

|

1.8 |

1.9 |

1.9 |

|

2.1 |

|

|

|

|

lb |

3.3 |

|

3.5 |

|

4.0 |

4.2 |

4.2 |

|

4.6 |

|

|

|

|

|

|

|

|

|

|||||

|

Item |

|

|

|

|

|

Three-phase 400V class Specifications |

|

|||||

WJ200 inverters, 400V models |

|

|

055HF |

|

075HF |

|

110HF |

150HF |

|

|

|

||

Applicable motor size |

kW |

|

VT |

7.5 |

|

11 |

|

15 |

18.5 |

|

|

|

|

|

|

|

|

CT |

5.5 |

|

7.5 |

|

11 |

15 |

|

|

|

|

|

HP |

|

VT |

10 |

|

15 |

|

20 |

25 |

|

|

|

|

|

|

|

CT |

7.5 |

|

10 |

|

15 |

20 |

|

|

|

Rated capacity (kVA) |

380V |

|

VT |

11.5 |

|

15.1 |

|

20.4 |

25.0 |

|

|

|

|

|

|

|

|

CT |

9.7 |

|

11.8 |

|

15.7 |

20.4 |

|

|

|

|

|

480V |

|

VT |

14.5 |

|

19.1 |

|

25.7 |

31.5 |

|

|

|

|

|

|

|

CT |

12.3 |

|

14.9 |

|

19.9 |

25.7 |

|

|

|

Rated input voltage |

|

|

|

Three-phase: 400V-15% to 480V +10%, 50/60Hz ±5% |

|

||||||||

Rated output voltage |

|

|

|

Three -phase: 400 to 480V (proportional to input voltage) |

|||||||||

Rated output current (A) |

|

|

VT |

17.5 |

|

23.0 |

|

31.0 |

38.0 |

|

|

|

|

|

|

|

|

CT |

14.8 |

|

18.0 |

|

24.0 |

31.0 |

|

|

|

Starting torque |

|

|

|

|

|

|

|

|

200% at 0.5Hz |

|

|

|

|

Braking |

Without resistor |

|

|

|

|

20%: ≤50Hz |

|

|

|

|

|||

|

|

|

|

|

|

|

20%: ≤60Hz |

|

|

|

|

||

|

With resistor |

|

|

|

150% |

|

|

|

|

||||

DC braking |

|

|

|

|

Variable operating frequency, time, and braking force |

||||||||

Weight |

|

|

|

kg |

3.5 |

|

3.5 |

|

4.7 |

5.2 |

|

|

|

|

|

|

|

lb |

7.7 |

|

7.7 |

|

10.4 |

11.5 |

|

|

|

7

The following table shows which models need derating.

1-ph 200V class |

Need |

3-ph 200V class |

Need |

3-ph 400V class |

Need |

|

derating |

|

derating |

WJ200-004H |

derating |

WJ200-001S |

|

WJ200-001L |

|

|

|

WJ200-002S |

|

WJ200-002L |

|

WJ200-007H |

|

WJ200-004S |

|

WJ200-004L |

|

WJ200-015H |

|

WJ200-007S |

|

WJ200-007L |

|

WJ200-022H |

|

WJ200-015S |

|

WJ200-015L |

|

WJ200-030H |

|

WJ200-022S |

|

WJ200-022L |

|

WJ200-040H |

|

|

|

WJ200-037L |

|

WJ200-055H |

|

|

|

WJ200-055L |

|

WJ200-075H |

|

|

|

WJ200-075L |

|

WJ200-110H |

|

|

|

WJ200-110L |

|

WJ200-150H |

|

|

|

WJ200-150L |

|

|

|

need derating |

|

|

|

|

|

need no derating

Use the following derating curves to help determine the optimal carrier frequency setting for your inverter and find the output current derating. Be sure to use the proper curve for your particular WJ200 inverter model number.

8

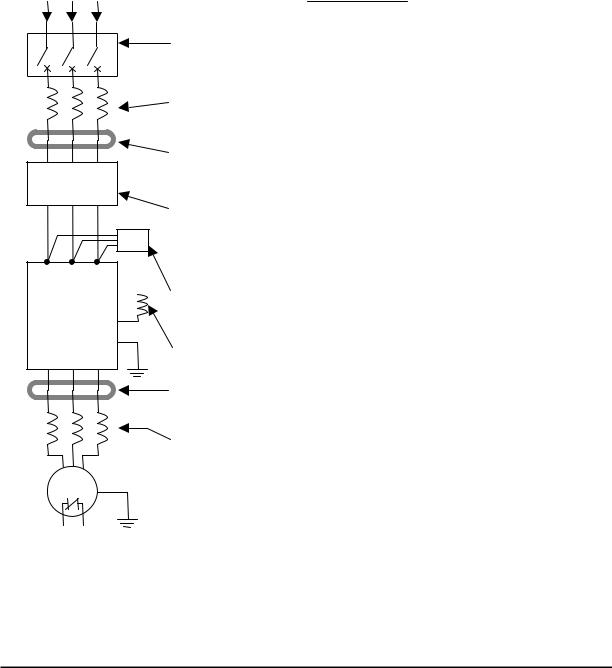

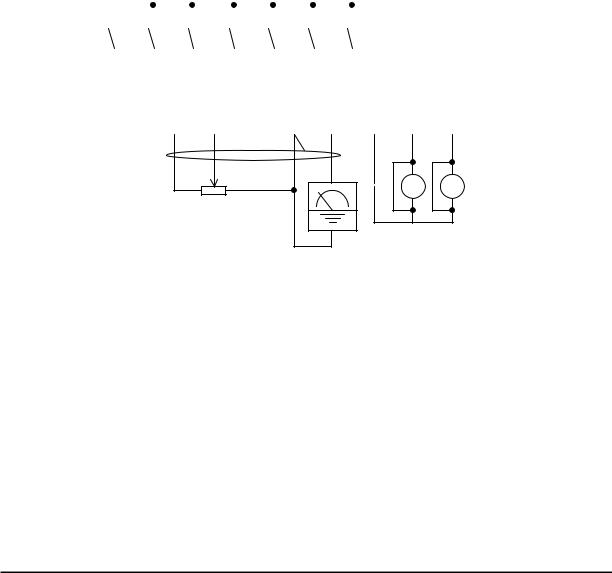

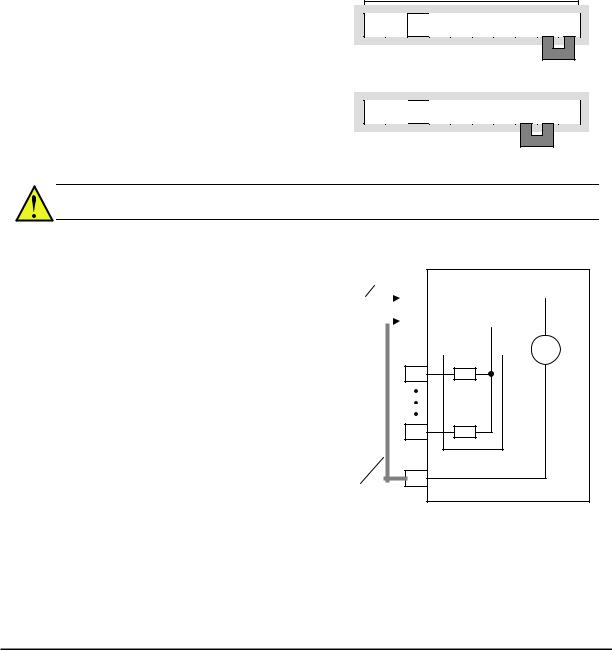

Basic System Description

A motor control system will obviously include a motor and inverter, as well as a circuit breaker or fuses for safety. If you are connecting a motor to the inverter on a test bench just to get started, that’s all you may need for now. But a system can also have a variety of additional components. Some can be for noise suppression, while others may enhance the inverter’s braking performance. The figure and table below show a system with all the optional components you might need in your finished application.

Breaker,

MCCB or

GFI

L1 L2 L3

+1

Inverter +

GND T1 T2 T3

From power supply

Name |

Function |

Breaker / |

A molded-case circuit breaker (MCCB), ground fault |

disconnect |

interrupter (GFI), or a fused disconnect device. NOTE: The |

|

installer must refer to the NEC and local codes to ensure |

|

safety and compliance. |

Input-side |

This is useful in suppressing harmonics induced on the |

AC Reactor |

power supply lines and for improving the power factor. |

|

WARNING: Some applications must use an input-side AC |

|

Reactor to prevent inverter damage. See Warning on next |

|

page. |

Radio noise filter |

Electrical noise interference may occur on nearby |

|

equipment such as a radio receiver. This magnetic choke |

|

filter helps reduce radiated noise (can also be used on |

|

output). |

EMC filter (for |

Reduces the conducted noise on the power supply wiring |

CE applications, |

between the inverter and the power distribution system. |

see Appendix D) |

Connect to the inverter primary (input) side. |

Radio noise filter |

This capacitive filter reduces radiated noise from the main |

(use in non-CE |

power wires in the inverter input side. |

applications) |

|

DC link choke |

Suppress harmonics generated by the inverter. However, it |

|

will not protect the input diode bridge rectifier. |

Radio noise filter |

Electrical noise interference may occur on nearby |

|

equipment such as a radio receiver. This magnetic choke |

|

filter helps reduce radiated noise (can also be used on |

|

input). |

Output-side |

This reactor reduces the vibration in the motor caused by |

AC Reactor |

the inverter’s switching waveforms, by smoothing the |

|

waveform to approximate commercial power quality. It is |

|

also useful to reduce harmonics when wiring from the |

|

inverter to the motor is more than 10m in length. |

LCR filter |

Sine wave shaping filter for output side. |

M

Thermal switch

9

Determining Wire and Fuse Sizes

The maximum motor currents in your application determines the recommended wore size. The following table gives the wire size in AWG. The “Power Lines” column applies to the inverter input power, output wires to the motor, the earth ground connection, and any other components shown in the “Basic System Description” on page 9. The “Signal Lines” column applies to any wire connecting to the two green connectors just inside the front cover panel.

|

Motor Output |

|

|

|

|

|

Wiring |

|

|

|

Applicable |

||||||||||

|

|

|

|

|

|

|

|

|

equipment |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

kW |

|

|

HP |

|

|

Inverter Model |

|

|

|

|

|

|

|

Fuse (UL-rated, |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power Lines |

|

|

Signal Lines |

|

class J, 600V , |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

VT |

|

|

CT |

|

|

VT |

|

|

CT |

|

|

|

|

|

|

|

|

Maximum |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

allowable current) |

0.2 |

0.1 |

¼ |

1/8 |

WJ200-001SF |

AWG16 / 1.3mm2 |

|

0.4 |

0.2 |

½ |

¼ |

WJ200-002SF |

||

(75°C only) |

||||||

0.55 |

0.4 |

¾ |

½ |

WJ200-004SF |

||

|

||||||

1.1 |

0.75 |

1.5 |

1 |

WJ200-007SF |

AWG12 / 3.3mm2 |

|

(75°C only) |

||||||

|

|

|

|

|

||

2.2 |

1.5 |

3 |

2 |

WJ200-015SF |

AWG10 / 5.3mm2 |

|

3.0 |

2.2 |

4 |

3 |

WJ200-022SF |

||

|

||||||

0.2 |

0.1 |

¼ |

1/8 |

WJ200-001LF |

|

|

0.4 |

0.2 |

½ |

¼ |

WJ200-002LF |

AWG16 / 1.3mm2 |

|

0.75 |

0.4 |

1 |

½ |

WJ200-004LF |

||

|

||||||

1.1 |

0.75 |

1.5 |

1 |

WJ200-007LF |

|

|

2.2 |

1.5 |

3 |

2 |

WJ200-015LF |

AWG14 / 2.1mm2 |

|

(75°C only) |

||||||

|

|

|

|

|

||

3.0 |

2.2 |

4 |

3 |

WJ200-022LF |

AWG12 / 3.3mm2 |

|

(75°C only) |

||||||

|

|

|

|

|

||

5.5 |

3.7 |

7.5 |

5 |

WJ200-037LF |

AWG10 / 5.3mm2 |

|

(75°C only) |

||||||

|

|

|

|

|

||

7.5 |

5.5 |

10 |

7.5 |

WJ200-055LF |

AWG6 / 13mm2 |

|

11 |

7.5 |

15 |

10 |

WJ200-075LF |

(75°C only) |

|

15 |

11 |

20 |

15 |

WJ200-110LF |

AWG4 / 21mm2 |

|

(75°C only) |

||||||

|

|

|

|

|

||

18.5 |

15 |

25 |

20 |

WJ200-150LF |

AWG2 / 34mm2 |

|

(75°C only) |

||||||

|

|

|

|

|

||

0.75 |

0.4 |

1 |

½ |

WJ200-004HF |

AWG16 / 1.3mm2 |

|

1.5 |

0.75 |

2 |

1 |

WJ200-007HF |

||

2.2 |

1.5 |

3 |

2 |

WJ200-015HF |

|

|

3.0 |

2.2 |

4 |

3 |

WJ200-022HF |

AWG14 / 2.1mm2 |

|

4.0 |

3.0 |

5 |

4 |

WJ200-030HF |

||

|

||||||

5.5 |

4.0 |

7.5 |

5 |

WJ200-040HF |

AWG12 / 3.3mm2 |

|

(75°C only) |

||||||

|

|

|

|

|

||

7.5 |

5.5 |

10 |

7.5 |

WJ200-055HF |

AWG10/ 5.3mm2 |

|

11 |

7.5 |

15 |

10 |

WJ200-075HF |

(75°C only) |

|

15 |

11 |

20 |

15 |

WJ200-110HF |

AWG6 / 13mm2 |

|

(75°C only) |

||||||

|

|

|

|

|

||

18.5 |

15 |

25 |

20 |

WJ200-150HF |

AWG6 / 13mm2 |

|

(75°C only) |

||||||

|

|

|

|

|

18 to 28 AWG / 0.14 to 0.75 mm2 shielded wire (see Note 4)

10A

20A

30A

10A

15A

20A

30A

60A

80A

80A

10A

15A

30A

50A

50A

Note 1: Field wiring must be made by a UL-Listed and CSA-certified closed-loop terminal connector sized for the wire gauge involved. Connector must be fixed by using the crimping tool specified by the connector manufacturer.

Note 2: Be sure to consider the capacity of the circuit breaker to be used.

Note 3: Be sure to use a larger wire gauge if power line length exceeds 66ft. (20m). Note 4: Use 18 AWG / 0.75mm2 wire for the alarm signal wire ([AL0], [AL1], [AL2]

terminals).

10

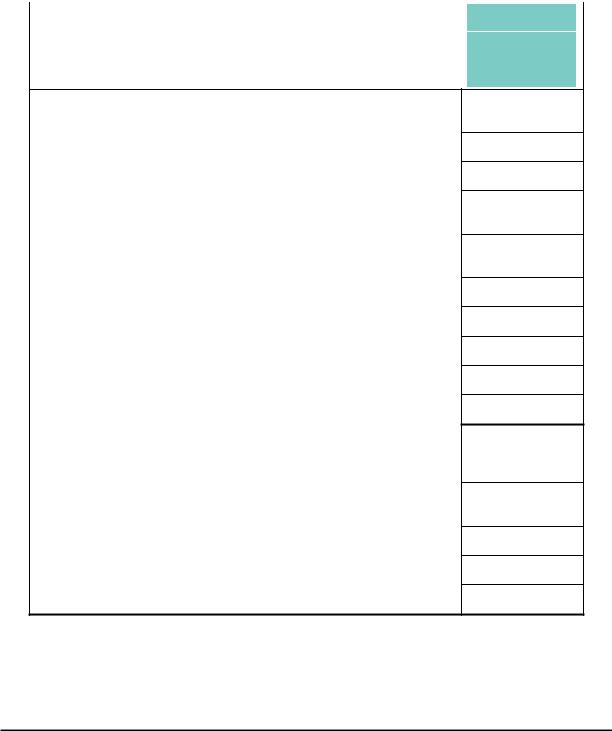

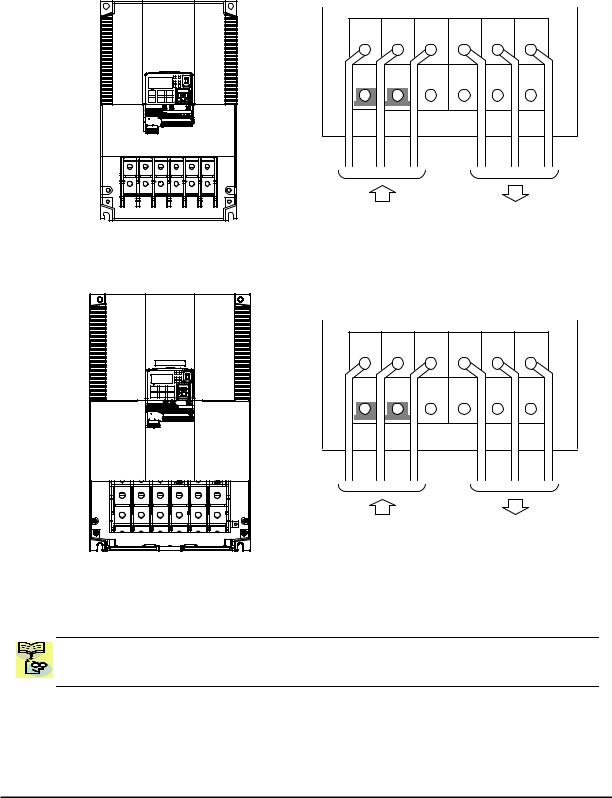

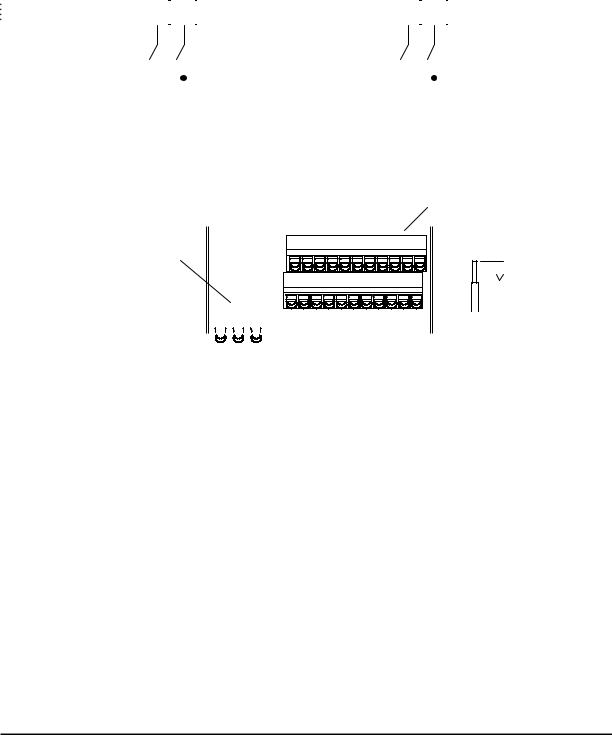

Wire the Inverter Input to a Supply

In this step, you will connect wiring to the input of the inverter. First, you must determine whether the inverter model you have required three-phase power only, or single-phase power only. All models have the same power connection terminals [R/L1], [S/L2], and

[T/L3]. So you must refer to the specifications label (on the side of the inverter) for the acceptable power source types! For inverters that can accept single-phase power and are connected that way, terminal [S/L2] will remain unconnected.

Note the use of ring lug connectors for a secure connection.

Single-phase 200V 0.1 to 0.4kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||

Three-phase 200V |

|

0.1 to 0.75kW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

Single-phase |

|

|

|

|

|

|

|

|

|

|

|

Three-phase |

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

RB |

+1 |

|

+ |

|

|

- |

|

|

|

|

RB |

PD/+1 |

|

P/+ |

N/- |

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

L1 |

|

|

N |

U/T1 |

V/T2 |

W/T3 |

|

|

R/L1 |

S/L2 |

T/L3 |

U/T1 |

V/T2 |

W/T3 |

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power input Output to Motor |

Power input Output to Motor |

Chassis Ground (M4) |

|

Single-phase 200V |

0.75 to 2.2kW |

Three-phase 200V |

1.5, 2.2kW |

Three-phase 400V |

0.4 to 3.0kW |

Single-phase |

Three-phase |

RB +1 + -

RB PD/+1 P/+ N/-

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L1 |

|

|

N U/T1 V/T2 W/T3 |

|

R/L1 |

S/L2 |

T/L3 U/T1 V/T2 W/T3 |

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power input Output to Motor |

Power input Output to Motor |

Chassis Ground (M4) |

|

11

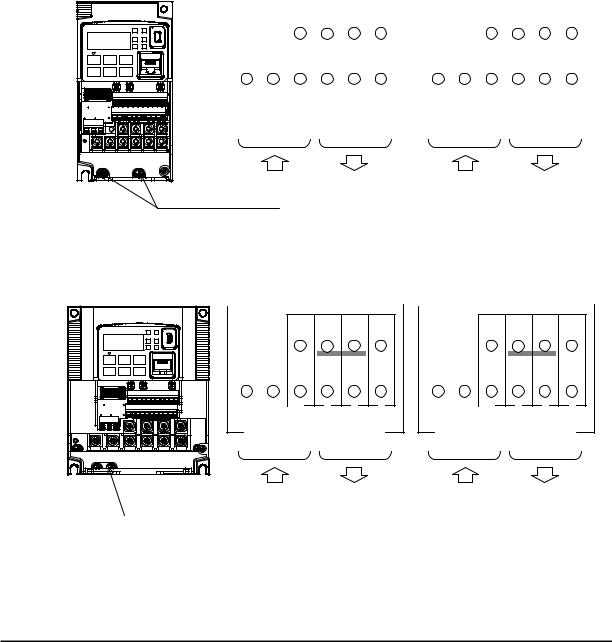

Three-phase 200V 3.7kW

Three-phase 400V 4.0kW

RB PD/+1 P/+ |

N/- |

R/L1 |

S/L2 |

T/L3 |

U/T1 |

V/T2 |

W/T3 |

Chassis Ground (M4) |

Output to Motor |

Power input |

Three-phase 200V |

5.5, 7.5kW |

Three-phase 400V |

5.5, 7.5kW |

R/L1 |

S/L2 |

T/L3 |

U/T1 |

V/T2 |

W/T3 |

PD/+1 |

P/+ |

N/- |

RB |

G |

G |

|

|

|

Power input |

Output to Motor |

|

12

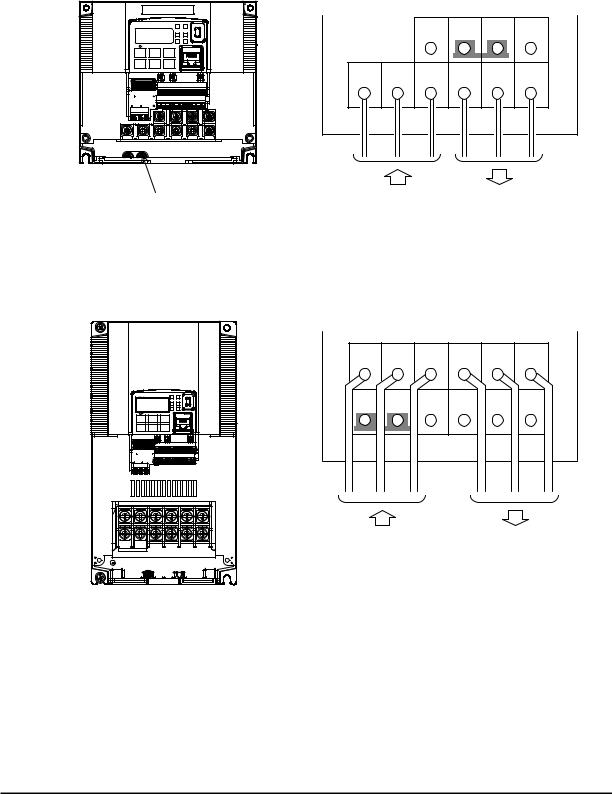

Three-phase 200V 11kW

Three-phase 400V 11, 15kW

R/L1 |

S/L2 |

T/L3 |

U/T1 |

V/T2 |

W/T3 |

PD/+1 |

P/+ |

N/- |

RB |

G |

G |

|

|

|

Power input |

Output to Motor |

|

Three-phase 200V 15kW

R/L1 |

S/L2 |

T/L3 |

U/T1 |

V/T2 |

W/T3 |

PD/+1 |

P/+ |

N/- |

RB |

G |

G |

|

|

|

Power input |

Output to Motor |

|

NOTE: An inverter powered by a portable power generator may receive a distorted power waveform, overheating the generator. In general, the generator capacity should be five times that of the inverter (kVA).

13

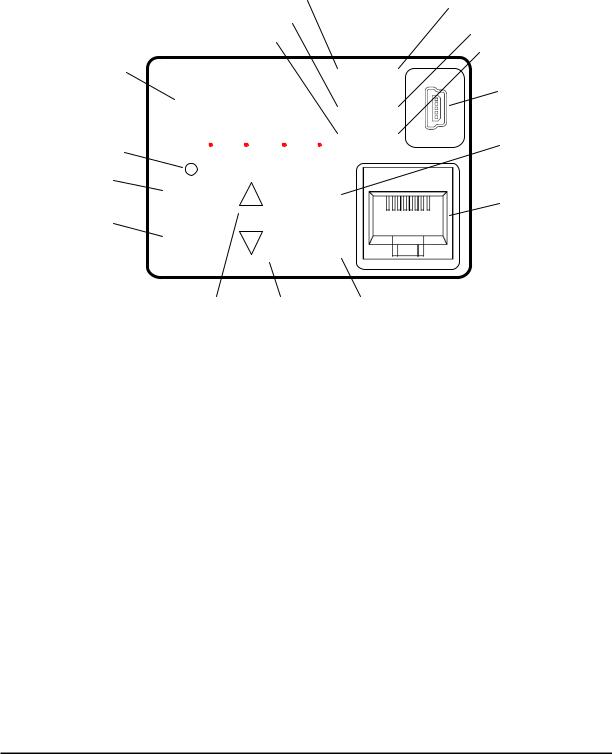

Using the Front Panel Keypad

Please take a moment to familiarize yourself with the keypad layout shown in the figure below. The display is used in programming the inverter’s parameters, as well as monitoring specific parameter values during operation.

|

|

|

|

|

(4) RUN LED |

|

|

(1) POWER LED |

||||

|

|

|

(5) Monitor LED [Hz] |

|

|

|

|

|

(2) ALARM LED |

|||

|

(6) Monitor LED [A] |

|

|

|

|

|

(3) Program LED |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

(8) 7-seg LED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RUN |

|

PWR |

(15) USB connector |

|

|

|

|

|

|

|

|

|

||||

(7) Run command LED |

|

|

8888 |

|

|

|

|

|||||

|

|

|

A |

|

PRG |

|

||||||

|

|

|

|

|

|

|

|

|

Hz |

|

ALM |

|

(9) RUN key |

|

|

|

|

|

|

|

|

|

|

|

(10) STOP/RESET key |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RUN |

|

1 |

|

STOP |

|

|

|

(16) RJ45 connector |

|

|

|

|

|

|

RESET |

|

|

|

||||

(11) ESC key |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ESC |

|

2 |

|

SET |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(12) Up key (13) Down key (14) SET key

Key and Indicator Legend

|

Items |

|

|

Contents |

|

(1) |

POWER LED |

|

|

Turns ON (Green) while the inverter is powered up. |

|

(2) ALARM LED |

|

|

Turns ON (Red) when the inverter trips. |

|

|

(3) |

Program LED |

|

|

Turns ON (Green) when the display shows changeable parameter. |

|

|

|

Blinks when there is a mismatch in setting. |

|

||

|

|

|

|

|

|

(4) |

RUN LED |

|

|

Turns ON (Green) when the inverter is driving the motor. |

|

(5) |

Monitor LED [Hz] |

|

Turns ON (Green) when the displayed data is frequency related. |

|

|

(6) |

Monitor LED [A] |

|

|

Turns ON (Green) when the displayed data is current related. |

|

(7) |

Run command LED |

|

Turns ON (Green) when a Run command is set to the operator. (Run key is effective.) |

|

|

(8) |

7-seg LED |

|

|

Shows each parameter, monitors etc. |

|

(9) |

RUN key |

|

Makes inverter run. |

|

|

(10) STOP/RESET key |

|

|

Makes inverter decelerates to a stop. |

|

|

|

|

Reset the inverter when it is in trip situation |

|

||

|

|

|

|

|

|

|

|

|

|

Go to the top of next function group, when a function mode is shown |

|

(11) ESC key |

|

|

Cancel the setting and return to the function code, when a data is shown |

|

|

|

|

Moves the cursor to a digit left, when it is in digit-to-digit setting mode |

|

||

|

|

|

|

|

|

|

|

|

|

Pressing for 1 second leads to display data of d001, regardless of current display. |

|

(12) Up key |

|

|

Increase or decrease the data. |

|

|

(13) Down key |

|

|

Pressing the both keys at the same time gives you the digit-to-digit edit. |

|

|

|

|

|

|

Go to the data display mode when a function code is shown |

|

(14) SET key |

|

|

Stores the data and go back to show the function code, when data is shown. |

|

|

|

|

|

|

Moves the cursor to a digit right, when it is in digit-to-digit display mode |

|

(15) USB connector |

|

|

Connect USB connector (mini-B) for using PC communication |

|

|

(16) RJ45 connector |

|

|

Connect RJ45 jack for remote operator |

|

|

14

Keys, Modes, and Parameters

The purpose of the keypad is to provide a way to change modes and parameters. The term function applies to both monitoring modes and parameters. These are all accessible through function codes that are primary 4-character codes. The various functions are separated into related groups identifiable by the left-most character, as the table shows.

RUN

PWR

PWR

8888

Hz

Hz

ALM A PGM

ALM A PGM

RUN |

1 |

STOP |

|

RESET |

|||

|

|

ESC

2

2

SET

SET

|

Function |

|

|

Type (Category) of Function |

|

|

Mode to Access |

|

|

PRG LED |

|

|

Group |

|

|

|

|

|

|

Indicator |

|

||

|

|

|

|

|

|

|

|

|

|

||

|

“d” |

|

Monitoring functions |

|

|

Monitor |

|

|

|

|

|

|

“F” |

|

Main profile parameters |

|

|

Program |

|

|

|

|

|

|

“A” |

|

Standard functions |

|

|

Program |

|

|

|

|

|

|

“b” |

|

Fine tuning functions |

|

|

Program |

|

|

|

|

|

|

“C” |

|

Intelligent terminal functions |

|

|

Program |

|

|

|

|

|

|

“H” |

|

Motor constant related functions |

|

|

Program |

|

|

|

|

|

|

“P” |

|

Pulse train input, torque, EzSQ, and |

|

|

Program |

|

|

|

|

|

|

|

|

|

communication related functions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

“U” |

|

User selected parameters |

|

|

Program |

|

|

|

|

|

|

“E” |

|

Error codes |

|

|

− |

|

|

− |

|

|

You can see from the following page how to monitor and/or program the parameters.

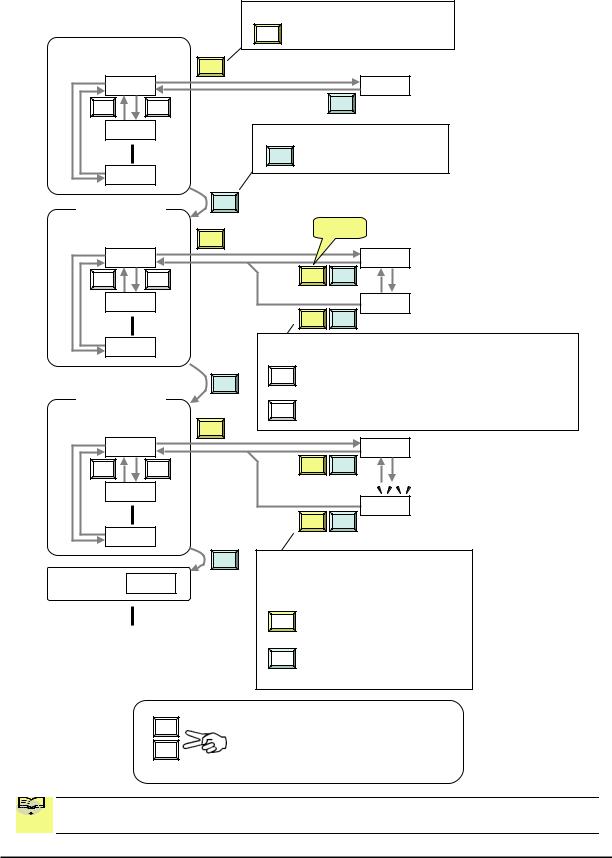

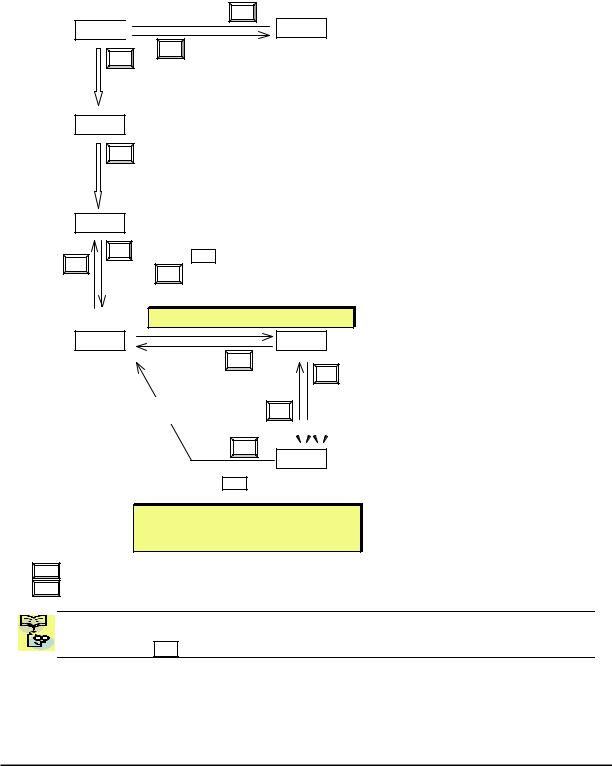

Keypad Navigation Map

The WJ200 Series inverter drives have many programmable functions and parameters. Chapter 3 will cover these in detail, but you need to access just a few items to perform the powerup test. The menu structure makes use of function codes and parameter codes to allow programming and monitoring with only a 4-digit display and keys and LEDs. So, it is important to become familiar with the basic navigation map of parameters and functions in the diagram below. You may later use this map as a reference.

15

|

Func. code display |

||

|

|

|

|

|

|

SET |

: Moves to data display |

Group "d" |

|||

|

|

|

|

Func. code display |

SET |

|

|

|

|

|

|

|

|

|

|

d001 |

|

|

|

|

0.00 |

V |

U |

|

|

|

ESC |

|

|

|

|

||

d002 |

|

|

Func. code display |

||

|

|

|

|||

|

|

|

ESC : Jumps to the next group |

||

d104 |

|

|

|

|

|

Group "F" |

|

ESC |

|

|

|

|

|

|

|

|

|

Func. code display |

SET |

|

|

Save |

|

|

|

|

|

|

|

F001 |

|

|

|

|

50.00 |

V |

U |

|

|

SET |

ESC |

|

|

|

|

||

F002 |

|

|

|

|

50.01 |

|

|

|

|

|

|

|

|

|

|

SET |

ESC |

F004 |

|

|

Data display |

(F001 to F003) |

|

|

|

|

Data does not blink because of real time synchronizing |

||

|

|

ESC |

SET : Saves the data in EEPROM |

||

|

|

|

and returns to func. code display. |

||

Group "A" |

|

|

|

||

|

|

ESC |

: Returns to func. code display without saving data. |

||

Func. code display |

|

||||

SET |

|

|

|

||

|

|

|

|

|

|

A001 |

|

|

|

|

00 |

V |

U |

|

|

SET |

ESC |

|

|

|

|

||

A002 |

|

|

|

|

|

|

|

|

|

|

01 |

|

|

|

|

SET |

ESC |

A165 |

|

|

|

|

|

Group "b" b001

U

U

V

V

ESC Data display

When data is changed, the display starts blinking, which means that new data has not been activated yet.

SET |

: Saves the data in EEPROM and |

|

returns to func. code display. |

|

: Cancels the data change and |

ESC |

|

|

returns to func. code display. |

Press the both up and down key at the same time in func. code or data display, then single-digit edit mode will be enabled.

Refer to 2-34 for further information.

NOTE: Pressing the [ESC] key will make the display go to the top of next function group,

NOTE: Pressing the [ESC] key will make the display go to the top of next function group,  regardless the display contents. (e.g. A021 [ESC] b001)

regardless the display contents. (e.g. A021 [ESC] b001)

16

[Setting example]

After power ON, changing from 0.00 display to change the A002 (Run command source) data.

Press [ESC] key to show

the function code

ESC

d001

SET

ESC

Data of d001 will be shown on the display after the first power ON

0.00

Press [ESC] key to move on to the function group F001

F001

ESC

Press [ESC] key Once to move on to the function group A001.

A001

U V

Press Up key to change increase

function code (A001 |

A002) |

Press SET key to display the data of A002

SET

Display is solid lighting.

A002

ESC

Press up key to increase the data (02 01)

SET

02

U

V

01

Press SET key to set and save the data

When data is changed, the display starts blinking, which means that new data has not been activated yet.

SET :Fix and stores the data and moves back to the function code

ESC :Cancels the change and moves back to the function code

Function code dxxx are for monitor and not possible to change.

Function codes Fxxx other than F004 are reflected on the performance just after changing the data

(before pressing SET key), and there will be no blinking.

17

|

|

|

|

|

|

|

When a function code is shown… |

|

|

When a data is shown… |

|

|

|

|

|

|

|

|

|

|

|

Cancels the change and moves back to the |

|

|

ESC |

key |

|

|

Move on to the next function group |

|

|

|

|||

|

|

|

|

|

function code |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fix and stores the data and moves back to |

|

|

SET |

key |

|

|

Move on to the data display |

|

|

|

|||

|

|

|

|

|

the function code |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

key |

|

|

Increase function code |

|

Increase data value |

|

|

|

U |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

key |

|

|

Decrease function code |

|

Decrease data value |

|

|

|

V |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

Note

Keep pressing for more than 1 second leads to d001 display, regardless the display situation. But note that the display will circulates while keep pressing the [ESC] key because of the original function of the key.

(e.g. F001 A001 b001 C001 … displays 50.00 after 1 second)

18

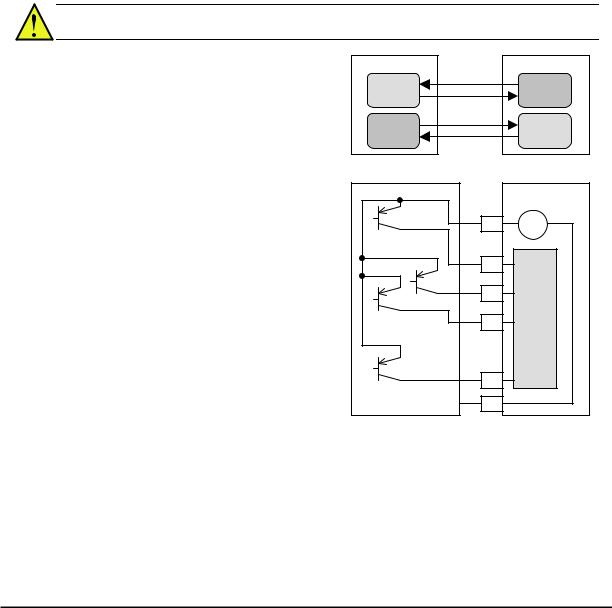

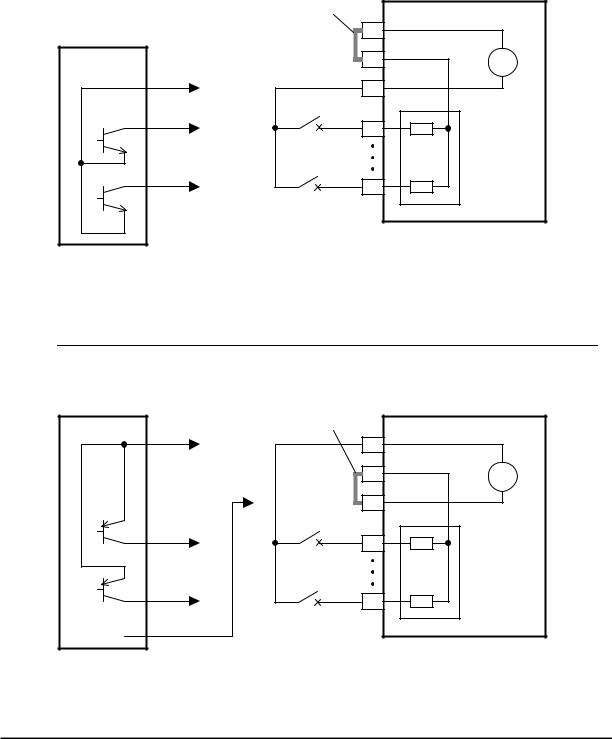

Connecting to PLCs and Other Devices

Hitachi inverters (drives) are useful in many types of applications. During installation, the inverter keypad (or other programming device) will facilitate the initial configuration. After installation, the inverter will generally receive its control commands through the control logic connector or serial interface from another controlling device. In a simple application such as single-conveyor speed control, a Run/Stop switch and potentiometer will give the operator all the required control. In a sophisticated application, you may have a programmable logic controller (PLC) as the system controller, with several connections to the inverter.

It is not possible to cover all the possible types of application in this manual. It will be necessary for you to know the electrical characteristics of the devices you want to connect to the inverter. Then, this section and the following sections on I/O terminal functions can help you quickly and safely connect those devices to the inverter.

CAUTION: It is possible to damage the inverter or other devices if your application exceeds the maximum current or voltage characteristics of a connection point.

The connections between the inverter and other devices rely on the electrical input/output characteristics at both ends of each connection, shown in the diagram to the right. The inverter’s configurable inputs accept either a sourcing or sinking output from an external device (such as PLC). This chapter shows the inverter’s internal electrical component(s) at each I/O terminal. In some cases, you will need to insert a power source in the interface wiring.

In order to avoid equipment damage and get your application running smoothly, we recommend drawing a schematic of each connection between the inverter and the other device. Include the internal components of each device in the schematic, so that it makes a complete circuit loop.

After making the schematic, then:

1.Verify that the current and voltage for each connection is within the operating limits of each device.

Other device |

signal |

WJ200 inverter |

|

Input |

Output |

||

return |

|||

circuit |

circuit |

||

|

|||

Output |

signal |

Input |

|

return |

|||

circuit |

circuit |

||

|

|||

Other device |

|

WJ200 inverter |

|

|

P24 |

+ - 24V |

|

|

1 |

|

|

|

2 |

Input |

|

|

|

||

… |

3 |

circuits |

|

|

|||

|

|

||

|

… |

|

|

|

7 |

|

|

GND |

L |

|

2.Make sure that the logic sense (active high or active low) of any ON/OFF connection is correct.

3.Check the zero and span (curve end points) for analog connections, and be sure the scale factor from input to output is correct.

4.Understand what will happen at the system level if any particular device suddenly loses power, or powers up after other devices.

19

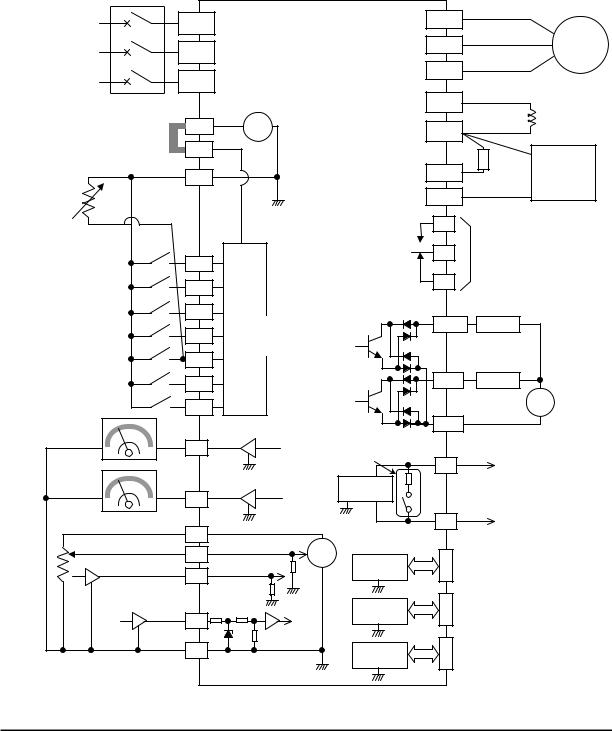

Example Wiring Diagram

The schematic diagram below provides a general example of logic connector wiring, in addition to basic power and motor wiring converted in Chapter 2. The goal of this chapter is to help you determine the proper connections for the various terminals shown below for your application needs.

Breaker, MCCB |

|

|

|

|

|

|

|

|

|

or GFI |

|

|

|

|

|

|

|

|

|

|

|

R |

WJ200 |

|

(T1) |

|

|

|

|

Power source, |

|

|

|

|

U |

|

|

|

|

|

(L1) |

|

|

|

|

|

|

|

|

3-phase or |

|

S |

|

|

|

V(T2) |

|

|

Motor |

1-phase, per |

|

|

|

|

|

|

|||

inverter model |

|

(L2) |

|

|

|

W(T3) |

|

|

|

|

|

T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N(L3) |

|

|

|

PD/+1 |

|

|

|

|

|

|

24V |

|

|

|

|

DC reactor |

|

|

|

P24 |

+ - |

|

|

P/+ |

|

|

(optional) |

Jumper wire |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|||

(Sink logic) |

PLC |

|

|

|

|

|

|

Braking |

|

|

|

|

|

|

|

|

Brake |

||

|

|

|

|

|

|

|

|

unit (optional) |

|

|

|

L |

|

|

|

RB |

|

resistor |

|

|

|

|

|

|

|

(optional) |

|

||

Thermistor |

Forward |

|

L |

|

|

N/- |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

GND for logic inputs |

|

AL1 |

|

Relay contacts, |

||

|

|

|

|

|

|

|

|

||

Intelligent inputs, |

|

|

|

|

|

AL0 |

|

type 1 Form C |

|

7 terminals |

|

1 |

|

|

|

|

|

|

|

NOTE: For the wiring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AL2 |

|

|

|

|

of intelligent I/O and |

|

2 |

|

|

|

|

|

|

|

analog inputs, be sure |

|

Input |

|

|

|

Open collector output |

|||

|

|

|

|

|

|||||

to use twisted pair / |

|

3/GS1 |

circuits |

|

Output circuit |

|

|

Freq. arrival signal |

|

shielded cable. Attach |

|

[5] configurable as |

|

11/EDM |

|||||

the shielded wire for |

|

4/GS2 |

|

Load |

|

||||

each signal to its |

|

discrete input or |

|

|

|

|

|

|

|

respective common |

|

5/PTC |

thermistor input |

|

|

|

|

|

|

terminal at the inverter |

|

|

|

|

|

|

|

|

|

end only. |

|

|

|

|

|

12 |

|

Load |

|

Input impedance of |

|

6 |

|

|

|

|

|

||

each intelligent input is |

|

|

|

|

|

|

|

|

+ |

4.7kΩ |

|

7/EB |

|

|

|

|

|

|

|

Meter |

|

|

|

|

CM2 |

|

- |

||

|

|

|

|

|

|

|

|||

|

|

EO |

|

Termination resistor (200Ω) |

GND for logic outputs |

||||

|

|

|

|

|

|

|

|||

|

|

|

|

(Change by slide switch) |

SP |

|

|

|

|

Meter |

|

|

L |

|

|

Serial communication port |

|||

|

|

|

|

RS485 |

|

||||

|

|

|

|

|

|

||||

|

|

AM |

|

transceiver |

|

(RS485/Modbus) |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

L |

SN |

|

NOTE: Common for |

|

Analog reference |

|

10Vdc |

|

|

|||||

H |

|

|

|

|

|

RS485 is “L”. |

|||

0~10VDC |

|

|

|

|

|

|

|

||

O |

|

+ |

RS485 |

|

RJ45 port |

|

|||

|

|

Apprx.10kΩ |

- |

|

|

||||

4~20mA |

|

|

(Optional operator port) |

||||||

OI |

|

transceiver |

|

||||||

Apprx.100Ω |

|

|

|

|

|

||||

Pulse train input |

|

|

L |

|

USB (mini-B) port |

||||

|

L |

|

|

||||||

|

|

USB |

|

||||||

24Vdc 32kHz max. |

|

|

|

|

(PC communication port) |

||||

|

|

EA |

|

|

transceiver |

|

USB power: Self power |

||

|

|

|

|

|

|

||||

|

|

|

|

|

L |

|

|

|

|

|

|

L |

|

|

Option port |

|

Option port connector |

||

GND for analog signals |

|

|

|

controller |

|

|

|

|

|

|

|

L |

|

|

|

|

|

||

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20

Control Logic Signal Specifications

The control logic connectors are located just behind the front housing cover. The relay contacts are just to the left of the logic connectors. Connector labeling is shown below.

RS485 |

Logic inputs |

comm. |

|

Relay |

SN 7 |

|

6 |

5 4 |

3 |

2 |

1 |

L |

PLC P24 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

contacts |

|

|

|

|

|

|

|

Jumper wire |

||

|

SP |

EO |

EA |

H |

O |

OI |

L |

AM CM2 |

12 11 |

||

|

AL2 AL1 AL0 |

|

|

|

|

|

|

|

|

|

|

|

RS485 |

|

Pulse |

Pulse |

Analog |

Analog |

Logic |

||||

|

comm. |

|

Train |

Train |

input |

output |

output |

||||

|

|

|

output |

input |

|

|

|

|

|

|

|

Terminal Name |

Description |

|

|

|

|

|

|

Ratings |

|

|

|

P24 |

+24V for logic inputs |

|

|

|

24VDC, 100mA. (do not short to terminal L) |

||||||

PLC |

Intelligent input common |

|

|

To change to sink type, remove the jumper |

|||||||

|

|

|

|

|

wire between [PLC] and [L], and connect it |

||||||

|

|

|

|

|

between [P24] and [PLC]. In this case, |

||||||

|

|

|

|

|

connecting [L] to [1]~[7] makes each input |

||||||

|

|

|

|

|

ON. Please remove the jumper wire when |

||||||

|

|

|

|

|

using external power supply. |

|

|

||||

1 |

Discrete logic inputs |

|

|

|

27VDC max. (use PLC or an external supply |

||||||

2 |

(Terminal [3],[4],[5] and [7] |

|

referenced to terminal L) |

|

|

||||||

3/GS1 |

have dual function. See |

|

|

|

|

|

|

|