Page 1

MENU

FOREWORD

This workshop manual has been prepared to provide information regarding repair procedures on Hino Trucks.

Applicable for HINO 155, 155h, 195, 195h series, equipped with J05E engine

When making any repairs on your vehicle, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owner

All information and specifications in this manual are based upon the latest product information available at the time of printing.

Hino Motors Sales U.S.A., Inc. reserves the right to make changes at any time without prior notice.

Please note that the publications below have also been prepared as relevant workshop manuals for the components and systems in these vehicles.

Chassis Workshop Manual

J05E Engine Workshop Manual S5-LJ05E04A

Trouble shooting Workshop Manual

's Manual.

Manual Name Pub. No.

S1-LXJE03A

S1-LXJE03A EWD

S7-LXJE03C 1/7

S7-LXJE03C 2/7

S7-LXJE03C 3/7

S7-LXJE03C 5/7

S7-LXJE03C 6/7

S7-LXJE03C 7/7

Page 2

CHAPTER REFERENCES REGARDING THIS WORKSHOP MANUAL

Use this chart to the appropriate chapter numbers for servicing your particular vehicle.

MANUAL No. S7-LXJE03C 4/7 (U.S.A.), S7-LXJE04C 4/7 (CANADA)

CHAPTER

HYBRID 3-001

MODELS HINO 155, 155h, 195, 195h

Production Code XFC710, XFC720, XFC740, XJC700, XJC710, XJC720, XJC740

Page 3

INDEX: TROUBLE SHOOTING GROUP 1/2

GENERAL INTRODUCTION

ENGINE

HYBRID

WORKSHOP

MANUAL

TRANSMISSION

CLUTCH

PROPELLER SHAFT

AXLE

DIFFERENTIAL

BRAKE

STEERING

SUSPENSION

All rights reserved. This manual may not be

reproduced or copied in whole in part, without the written consent of Hino Motors, Ltd.

FRAME AND FRAME ACCESSORY

CAB MOUNTING AND CAB SUSPENSION

BODY CONSTRUCTION

BODY INSIDE ACCESSORY

BODY OUTSIDE ACCESSORY

AIR BAG AND SEAT BELT

HEATER AND AIR CONDITIONER

Page 4

INDEX: TROUBLE SHOOTING GROUP 2/2

ELECTRICAL

CONTROL SYSTEM

Page 5

HYBRID 3–1

3

HYBRID

3-001

TROUBLE SHOOTING.................................... 3-4

HYBRID CONTROL SYSTEM......................................3-4

TROUBLE SHOOTING STEPS

FOR HYBRID SYSTEM ..........................................3-4

SAFETY MEASURES

FOR HIGH-VOLTAGE WORK ...............................3-12

LIST OF CONNECTOR SYMBOLS......................3-15

HV SYSTEM WIRING DIAGRAM ......................... 3-19

HEARING SHEET.................................................3-21

HYBRID ECU .............................................................3-22

DIAGNOSIS CODE TABLE...................................3-22

FREEZE FRAME DATA LIST ................................3-30

LIST OF DATA MONITOR ITEMS .........................3-33

COMMON INSPECTION CHART.........................3-36

DTC: P0500 (TC51) ..............................................3-41

DTC: P0501 (TC5B)..............................................3-51

DTC: P0562 (TC71) ..............................................3-57

DTC: P060B (TCB2) .............................................3-66

DTC: P0617 (TC59) ..............................................3-69

DTC: P062F (TCB3)..............................................3-78

DTC: P0810 (TC9C)..............................................3-81

DTC: P0810 (TC9D)..............................................3-85

DTC: P0A01 (TC7B) .............................................3-89

DTC: P0A02 (TC78)..............................................3-98

DTC: P0A03 (TC79)............................................3-106

DTC: P0A06 (TC7F)............................................3-113

DTC: P0A07 (TC7E) ...........................................3-125

DTC: P0A0F (TC31)............................................3-129

DTC: P0A1D (TC12) ...........................................3-133

DTC: P0A1D (TC17) ...........................................3-136

DTC: P0A78 (TC21)............................................3-139

DTC: P0A78 (TC22)............................................3-142

DTC: P0A7E (TC48) ...........................................3-145

DTC: P0A82 (TC67)............................................3-151

DTC: P0A84 (TC66)............................................3-164

DTC: P0A85 (TC65)............................................3-177

DTC: P0A90 (TC2A) ...........................................3-183

DTC: P0A92 (TC29)............................................3-195

DTC: P0A93 (TC7A) ...........................................3-210

DTC: P0AFD (TC6B)...........................................3-217

DTC: P0BCA (TC68)...........................................3-221

DTC: P0C73 (TC80)............................................3-227

DTC: P3000 (TC42) ............................................3-234

DTC: P3001 (TC41) ............................................3-243

DTC: P3001 (TC43) ............................................3-246

DTC: P3001 (TC44) ............................................3-249

DTC: P3001 (TC45) ............................................3-252

DTC: P3001 (TC46) ............................................3-255

DTC: P3001 (TC47) ............................................3-259

DTC: P3001 (TC4A)............................................3-263

DTC: P3001 (TC4B)............................................3-267

DTC: P3001 (TC4C)............................................3-270

DTC: P3009 (TC49) ............................................3-273

DTC: P3128 (TC7D)............................................3-289

DTC: P3129 (TC7C)............................................3-301

DTC: P314C (TC82)............................................3-306

DTC: P314D (TC81)............................................3-311

DTC: P324B (TC62)............................................3-323

DTC: P324C (TC61)............................................3-328

DTC: P33B1 (TC64)............................................3-334

DTC: P33B2 (TC63)............................................3-339

DTC: U0073 (TC11) ............................................3-345

DTC: U0074 (TC16) ............................................3-350

DTC: U0100 (TC13) ............................................3-354

DTC: U0101 (TC18) ............................................3-358

DTC: U0110 (TC14) ............................................3-365

DTC: U0111 (TC15) ............................................3-373

DTC: U0121 (TC24) ............................................3-381

DTC: U0155 (TC25) ............................................3-388

DTC: U110A (TC26)............................................3-395

DTC: U1136 (TC27) ............................................3-402

INVERTER................................................................3-409

DIAGNOSIS CODE TABLE .................................3-409

FREEZE FRAME DATA LIST ..............................3-415

DATA MONITOR ITEM LIST................................3-417

CONNECTION DIAGRAM ..................................3-420

INSULATION RESISTANCE MEASUREMENT

PROCEDURE FOR HYBRID MOTOR

[ROTATION MACHINE] .......................................3-421

DTC: P0562 (TC96) ............................................3-423

DTC: P0562 (TCA0)............................................3-433

DTC: P0604 (TC18) ............................................3-443

DTC: P0604 (TCD2)............................................3-445

DTC: P0605 (TC17) ............................................3-447

DTC: P0605 (TCD1)............................................3-449

DTC: P060B (TC1A) ...........................................3-451

DTC: P060C (TC1C) ...........................................3-454

DTC: P062F (TC41) ............................................3-456

DTC: P0A0D (TC20) ...........................................3-458

DTC: P0A1B (TC16) ...........................................3-465

Page 6

HYBRID3–2

DTC: P0A1B (TC92)............................................3-472

DTC: P0A1B (TC97)............................................3-474

DTC: P0A1B (TC3F) ...........................................3-476

DTC: P0A1B (TCA1) ...........................................3-478

DTC: P0A1B (TCA2) ...........................................3-480

DTC: P0A1B (TCA3) ...........................................3-482

DTC: P0A1B (TCA4) ...........................................3-484

DTC: P0A1B (TCA5) ...........................................3-486

DTC: P0A1B (TCA6) ...........................................3-488

DTC: P0A1B (TCA7) ...........................................3-490

DTC: P0A1B (TCA8) ...........................................3-492

DTC: P0A1B (TCA9) ...........................................3-494

DTC: P0A1B (TCAA)...........................................3-496

DTC: P0A1B (TCBB)...........................................3-503

DTC: P0A1B (TCBC)...........................................3-505

DTC: P0A1B (TCBD)...........................................3-507

DTC: P0A1B (TCBE)...........................................3-509

DTC: P0A1B (TCBF) ...........................................3-511

DTC: P0A1B (TCD3) ...........................................3-513

DTC: P0A1B (TCD4) ...........................................3-515

DTC: P0A1B (TCD5) ...........................................3-517

DTC: P0A1D (TC21) ...........................................3-519

DTC: P0A2B (TCE9) ...........................................3-523

DTC: P0A2B (TCED)...........................................3-534

DTC: P0A2C (TCDA)...........................................3-545

DTC: P0A2D (TCDB) ..........................................3-555

DTC: P0A2F (TC33)............................................3-566

DTC: P0A3C (TC34) ...........................................3-573

DTC: P0A3F (TCB7) ...........................................3-593

DTC: P0A41 (TCC0) ...........................................3-602

DTC: P0A42 (TCC1) ...........................................3-614

DTC: P0A51 (TCD6) ...........................................3-626

DTC: P0A51 (TCD7) ...........................................3-629

DTC: P0A78 (TC13) ............................................3-632

DTC: P0A78 (TC14) ............................................3-645

DTC: P0A78 (TC15) ............................................3-664

DTC: P0AA1 (TCD8) ...........................................3-671

DTC: P0AA4 (TCD9) ...........................................3-678

DTC: P0ADB (TC1F)...........................................3-687

DTC: P0ADC (TC93)...........................................3-694

DTC: P0ADF (TC1E)...........................................3-702

DTC: P0AE0 (TC95)............................................3-709

DTC: P0AE6 (TC1D) ...........................................3-717

DTC: P0AE7 (TC94)............................................3-724

DTC: P0AEE (TC22) ...........................................3-732

DTC: P0AEE (TC23) ...........................................3-735

DTC: P0AEF (TC24) ...........................................3-738

DTC: P0AF0 (TC25)............................................3-742

DTC: P0BEA (TCB3)...........................................3-746

DTC: P0BEA (TCB4)...........................................3-749

DTC: P0BEB (TC9A)...........................................3-752

DTC: P0BEC (TC9B)...........................................3-755

DTC: P0BEE (TCB5)...........................................3-758

DTC: P0BEE (TCB6)...........................................3-761

DTC: P0BEF (TC9C)...........................................3-764

DTC: P0BF0 (TC9D) ...........................................3-767

DTC: P3126 (TC12) ............................................3-770

DTC: U0073 (TC91) ............................................3-783

DTC: U0074 (TC3E)............................................3-788

DTC: U0293 (TC31) ............................................3-792

BATTERY ECU .........................................................3-801

DIAGNOSIS CODE TABLE .................................3-801

LIST OF FREEZE FRAME DATA.........................3-804

LIST OF DATA MONITOR ITEMS .......................3-806

CONNECTION DIAGRAM...................................3-809

DTC: P0562.........................................................3-810

DTC: P0604.........................................................3-816

DTC: P0605.........................................................3-819

DTC: P060B ........................................................3-822

DTC: P062F ........................................................3-825

DTC: P0A1F ........................................................3-828

DTC: P0A7D........................................................3-831

DTC: P0A7F ........................................................3-835

DTC: P0A80 ........................................................3-840

DTC: P0A95 ........................................................3-845

DTC: P0A9D........................................................3-850

DTC: P0A9E........................................................3-854

DTC: P0AAE .......................................................3-858

DTC: P0AAF........................................................3-862

DTC: P0ABF........................................................3-866

DTC: P0AC0........................................................3-873

DTC: P0AC1........................................................3-880

DTC: P0AC2........................................................3-887

DTC: P0AC7........................................................3-894

DTC: P0AC8........................................................3-898

DTC: P0ACC .......................................................3-902

DTC: P0ACD .......................................................3-906

DTC: P0AEA .......................................................3-910

DTC: P0AEB .......................................................3-914

DTC: P0AFC .......................................................3-918

DTC: P0B25 ........................................................3-921

DTC: P0B3D........................................................3-925

DTC: P0B42 ........................................................3-930

DTC: P0B47 ........................................................3-935

DTC: P0B4C........................................................3-940

DTC: P0B51 ........................................................3-945

DTC: P0B56 ........................................................3-950

DTC: P0B5B........................................................3-955

DTC: P0B60 ........................................................3-960

DTC: P0B65 ........................................................3-965

DTC: P0B6A........................................................3-970

DTC: P0B6F ........................................................3-975

DTC: P0B74 ........................................................3-980

DTC: P0B79 ........................................................3-985

DTC: P0B7E........................................................3-990

DTC: P0B83 ........................................................3-995

DTC: P0B88 ......................................................3-1000

DTC: P0B8D......................................................3-1005

Page 7

DTC: P0B92 ......................................................3-1010

DTC: P0B97 ......................................................3-1015

DTC: P0B9C .....................................................3-1020

DTC: P0BA1......................................................3-1025

DTC: P0C30......................................................3-1030

DTC: P3004 ......................................................3-1036

DTC: P3011 ......................................................3-1039

DTC: P3012 ......................................................3-1044

DTC: P3013 ......................................................3-1049

DTC: P3014 ......................................................3-1054

DTC: P3015 ......................................................3-1059

DTC: P3016 ......................................................3-1064

DTC: P3017 ......................................................3-1069

DTC: P3018 ......................................................3-1074

DTC: P3019 ......................................................3-1079

DTC: P301B ......................................................3-1084

DTC: P3020 ......................................................3-1087

DTC: P3021 ......................................................3-1092

DTC: P3022 ......................................................3-1097

DTC: P3023 ......................................................3-1102

DTC: P3024 ......................................................3-1107

DTC: P3025 ......................................................3-1112

DTC: P3026 ......................................................3-1117

DTC: P3027 ......................................................3-1122

DTC: P3028 ......................................................3-1127

DTC: P3029 ......................................................3-1132

DTC: P302F ......................................................3-1137

DTC: P3065 ......................................................3-1142

DTC: P308A ......................................................3-1147

DTC: U0074 ......................................................3-1152

DTC: U0293 ......................................................3-1156

HYBRID 3–3

Page 8

HYBRID/TROUBLE SHOOTING3–4

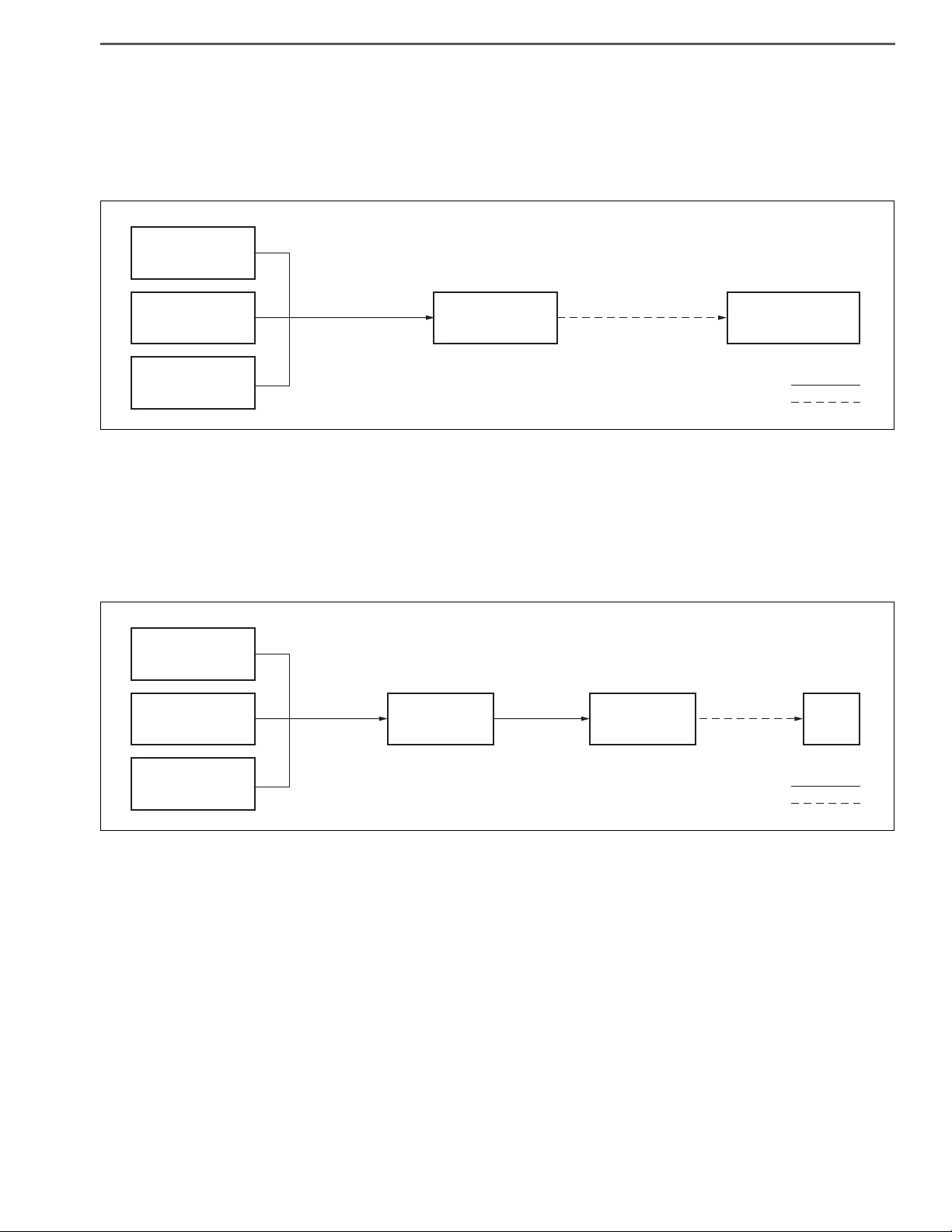

HV BATTERY ECU

HV SYSTEM ALARM

HV WARNING LIGHT

ENGINE ECU

VEHICLE CONTROL ECU

CLUTCH ECU

MIL

HV ECU OR COMMUNICATION

FUNCTION PERFORM

ALARMING ONLY WHEN THE

FUNCTION FAILS.

INVERTER

MALFUNCTION INFORMATION

MIL ON REQUEST

MALFUNCTION INFORMATION

MIL ON REQUEST

MALFUNCTION

INFORMATION

MIL ON

REQUEST

MIL ON REQUEST

HV ECU

READ CODE AND

DIAGNOSE

READ CODE AND DIAGNOSE

READ CODE AND

DIAGNOSE

SERVICE TOOL

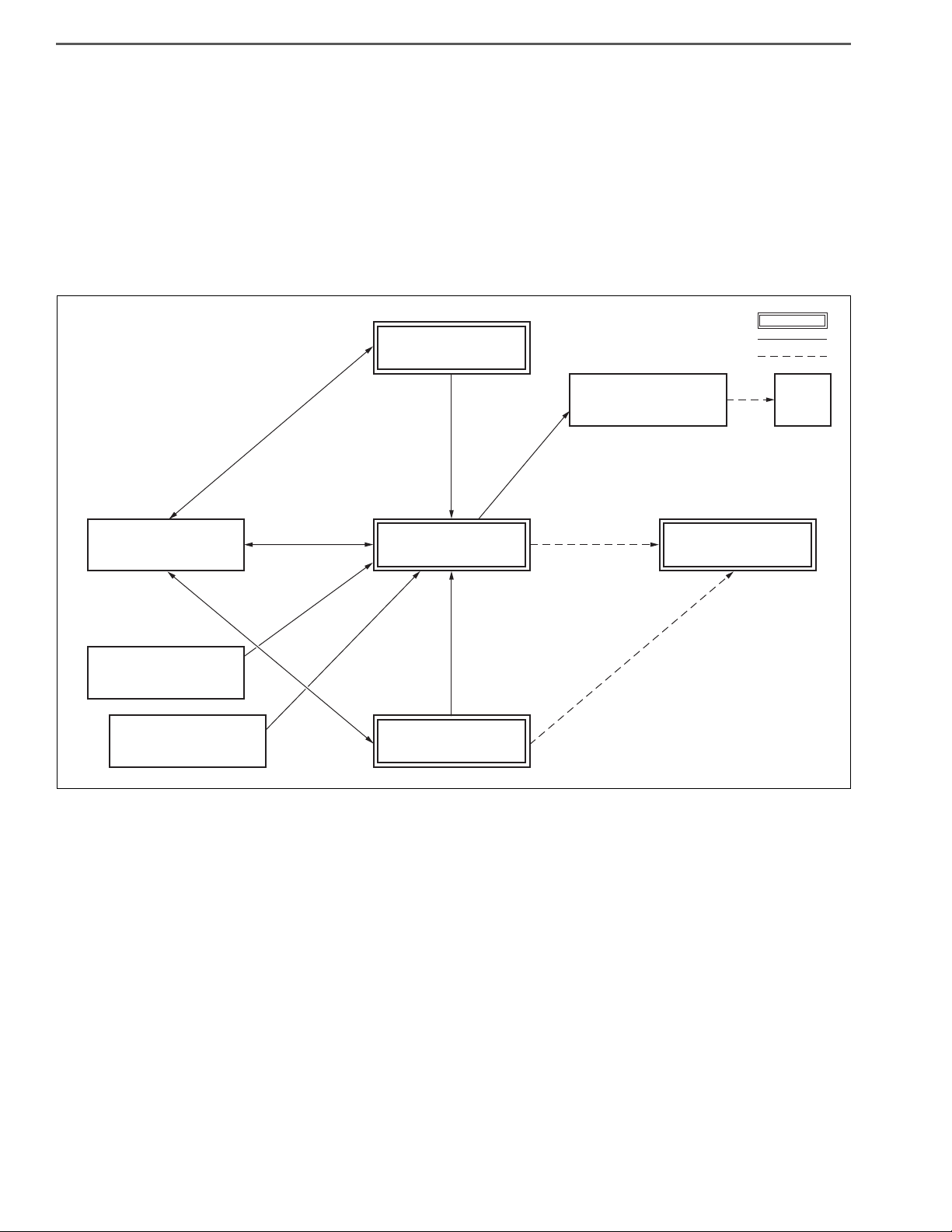

HYBRID CONTROL SYSTEM:

CAN:

SIGNAL LINE:

SHTS03ZZZ0300001

TROUBLE SHOOTING

HYBRID CONTROL SYSTEM

TROUBLE SHOOTING STEPS FOR HYBRID SYSTEM

CONFIGURATION DIAGRAM OF HYBRID TROUBLE SHOOTING SYSTEM

EN01H03ZZZ030602002001

Page 9

HYBRID/TROUBLE SHOOTING 3–5

LIGHT ON OR LIGHT OFF

HV WARNING LIGHT

HV ECU

MALFUNCTION

INFORMATION

HV BATTERY ECU

INVERTER

CLUTCH ECU

CAN:

SIGNAL LINE:

SHTS03ZZZ0300002

LIGHT ON OR

LIGHT OFF

MIL

HV ECU

MIL ON

REQUEST

ENGINE ECU

MIL ON

REQUEST

HV BATTERY ECU

INVERTER

VEHICLE CONTROL

ECU

CAN:

SIGNAL LINE:

SHTS03ZZZ0300003

1. HV WARNING LIGHT LIGHTING PROCESS

(1) The HV ECU controls the HV warning light.

(2) The HV warning light turns on in case of malfunction of the HV ECU, the HV battery ECU, the inverter, or the

clutch ECU.

(3) The HV ECU receives information regarding malfunction of the HV battery ECU, the inverter, and the clutch ECU

via CAN.

2. ABOUT MIL

(1) The engine ECU controls whether to turn on or turn off MIL.

(2) When a malfunction relevant to emission occurs in the HV system or vehicle control ECU, the MIL light ON

request is sent from the HV ECU to the engine ECU using CAN.

(3) HV battery ECU, inverter and vehicle control ECU send the MIL light ON request to the engine ECU using CAN

via HV ECU.

Page 10

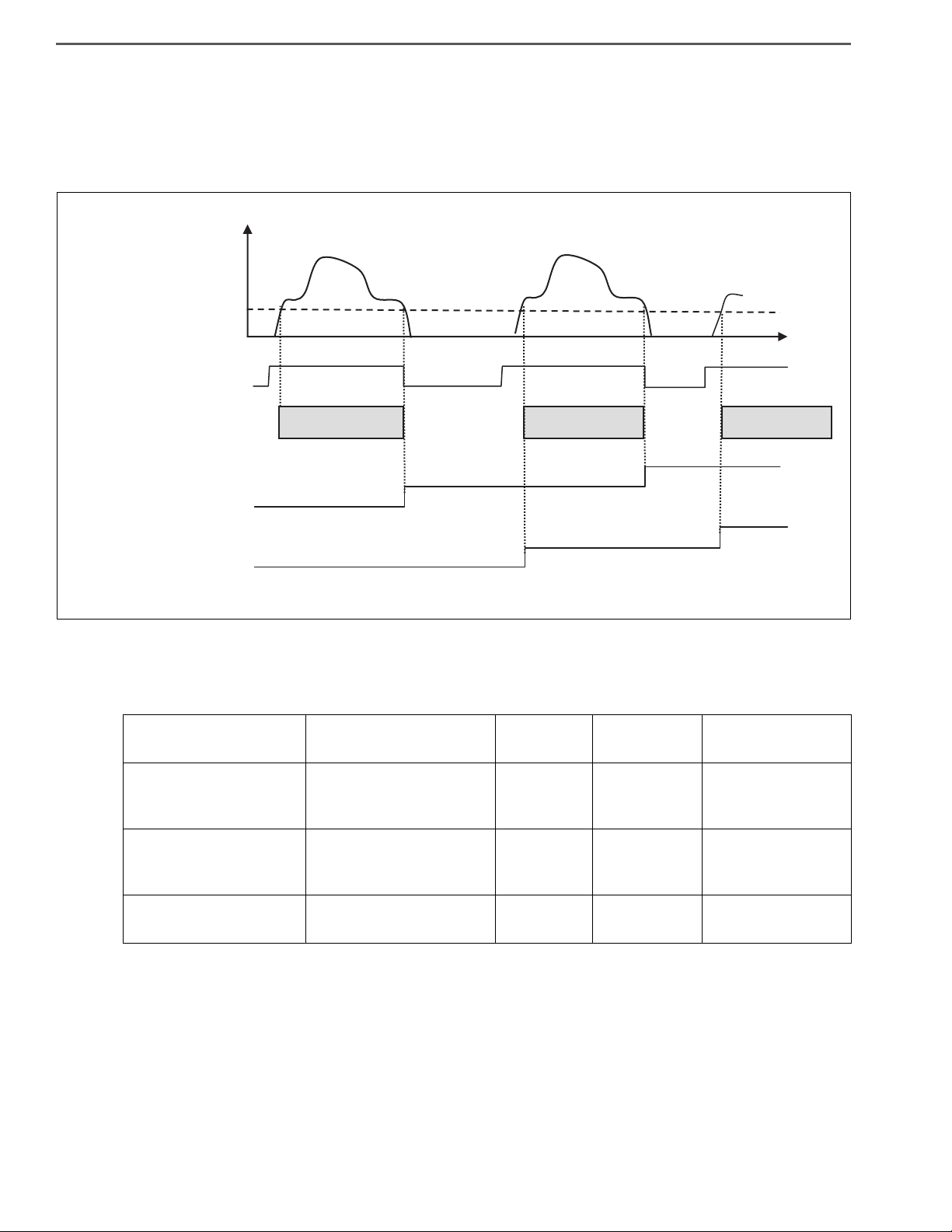

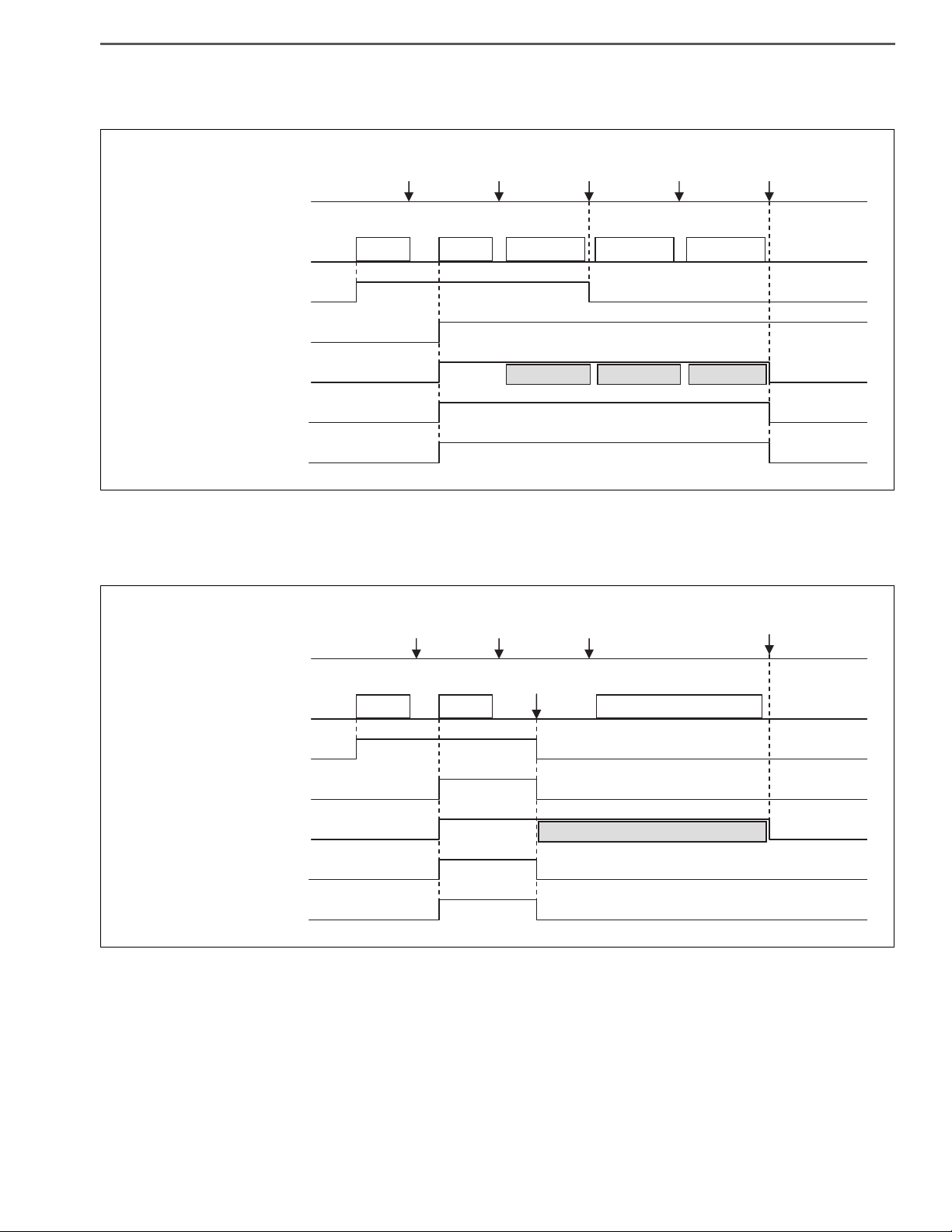

3. DEFINITION OF MALFUNCTION

DCY#3

CONFIRMATION TIME

t

COMPLETION

OF DCY#2

COMPLETION

OF DCY#2

COMPLETION

OF DCY#1

COMPLETION OF

DCY#1

DCY#1

CONFIRMATION TIME

DCY#2

CONFIRMATION TIME

ON

LOCK

[r/min]

IDLING SPEED-150 [r/min]

COMPLETION OF

HV BATTERY ECU DCY

COMPLETION OF

INVERTER DCY

STARTER KEY

DCY

COMPLETION OF

HV ECU DCY

ENGINE

SPEED

0

0

0

SHTS03ZZZ0300004

(1) Driving cycle

The driving cycle (hereinafter referred to as "DCY") is confirmed when the engine revolution becomes equal to or

more than the value calculated using the following formula [idling speed minus 150 r/min] after the starter key is

turned to the "ON" position. DCY is completed when the starter key is turned to the "LOCK" position.

HYBRID/TROUBLE SHOOTING3–6

* Completion of DCY is the timing to delete the Permanent diagnosis code and Pending diagnosis code.

(2) Definition of diagnosis code

The following table shows malfunctions that are displayed on the service tool.

Pending diagnosis code

Confirmed diagnosis

Permanent diagnosis

*1 This light lights for malfunctions relevant to emission.

*2 If a malfunction is recovered, control is switched from failsafe control to normal control; however the

Confirmed diagnosis code is not deleted.

Code name

code

code

Definition of diagnosis

code

HV warning

light

MIL Effect on vehicle

Diagnosis code that is

being detected (malfunc-

Light OFF Light OFF Normal control

tion is not confirmed).

Diagnosis code in which

the malfunction is con-

Light ON Light ON *1 Failsafe control *2

firmed

Stored diagnosis code Light OFF Light OFF Normal control

Page 11

HYBRID/TROUBLE SHOOTING 3–7

COMPLETION OF

DCY#1

COMPLETION OF

DCY#2

DETECTION OF

MALFUNCTION

CONFIRMATION

DETECTION OF

MALFUNCTION

CONFIRMATION

LIGHT ON

LIGHT ON

DCY

VEHICLE CONDITION

PENDING MALFUNCTION

CONFIRMED MALFUNCTION

HV WARNING LIGHT

MIL

SHTS03ZZZ0300005

CONFIRMATION

LIGHT ON

LIGHT ON

COMPLETION OF

DCY#1

COMPLETION OF

DCY#2

DETECTION OF

MALFUNCTION

DCY

VEHICLE CONDITION

PENDING MALFUNCTION *1

CONFIRMED MALFUNCTION

HV WARNING LIGHT

MIL

SHTS03ZZZ0300006

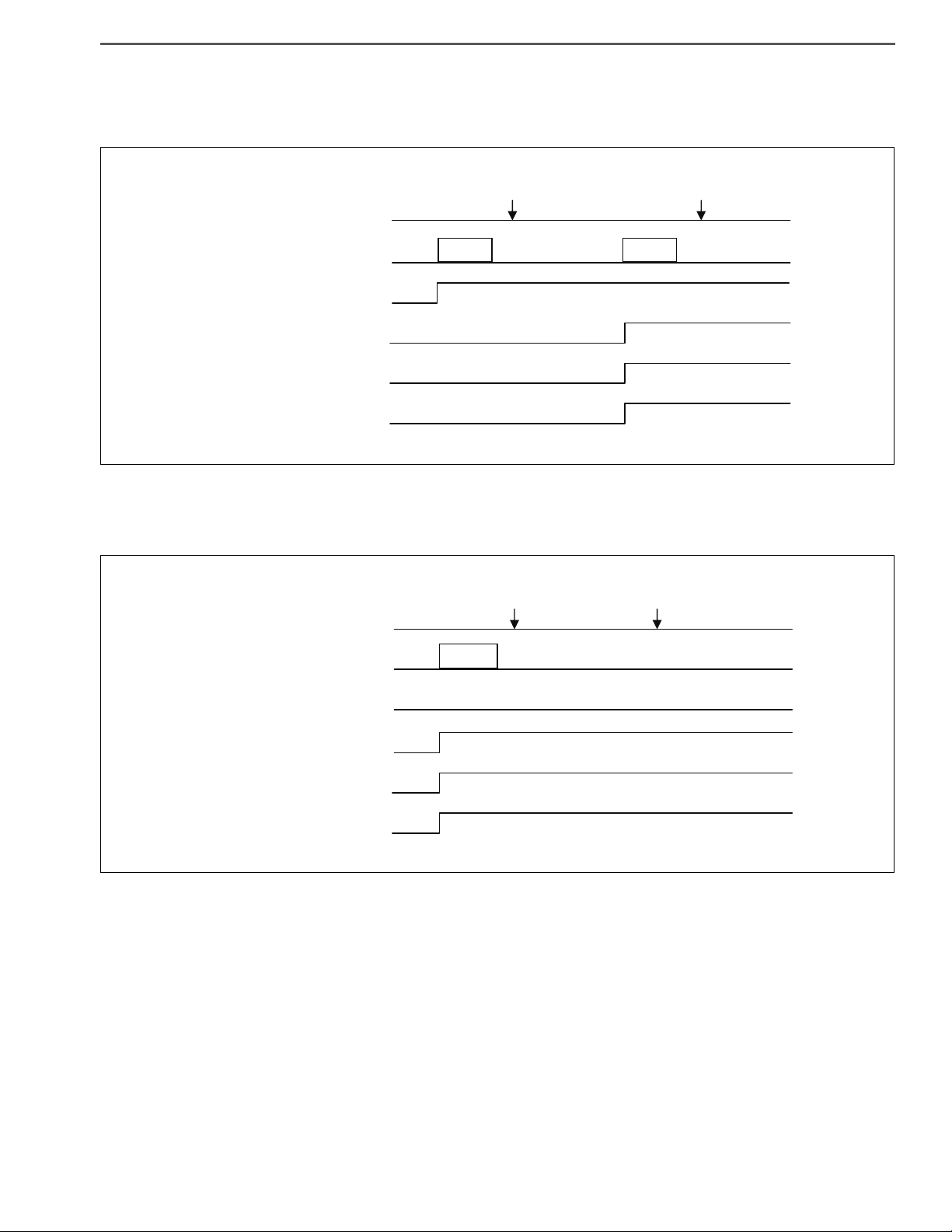

(3) Pending diagnosis code

Represents the diagnosis code in which the malfunction is confirmed by detecting the malfunction in 2DCY or

more. The following table shows examples in which the malfunction is confirmed in 2DCY.

(4) Confirmed diagnosis code

Represents the diagnosis code in which the malfunction is confirmed by detecting the malfunction in 1DCY.

*1 For the malfunction in which the Confirmed malfunction is confirmed in DCY, the Pending malfunction

is not confirmed.

Page 12

HYBRID/TROUBLE SHOOTING3–8

CONFIRMATION

CONFIRMATION

LIGHT ON

LIGHT ON

COMPLETION OF

DCY#1

COMPLETION OF

DCY#2

DETECTION OF

MALFUNCTION

DCY

VEHICLE CONDITION

CONFIRMED MALFUNCTION

PERMANENT MALFUNCTION

HV WARNING LIGHT

MIL

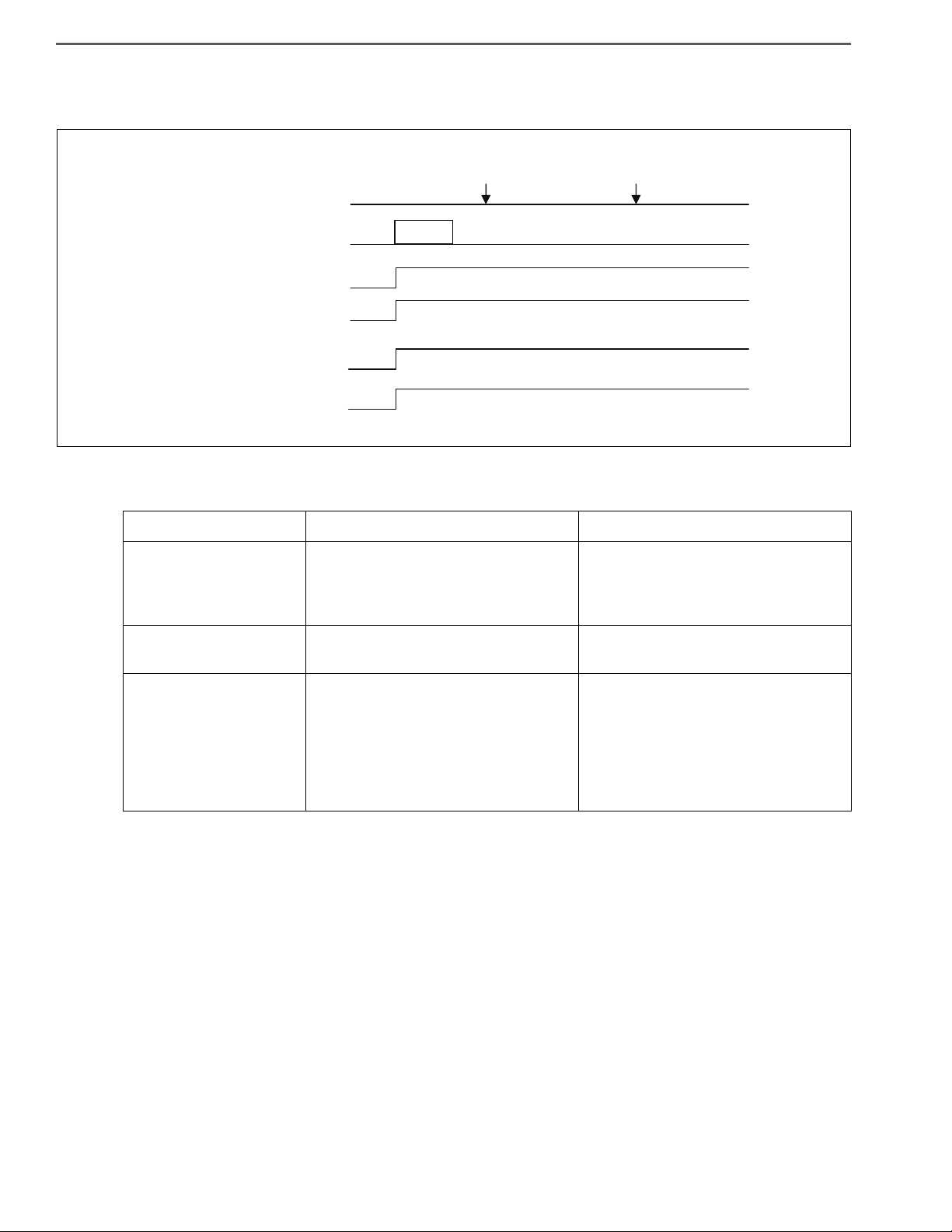

SHTS03ZZZ0300007

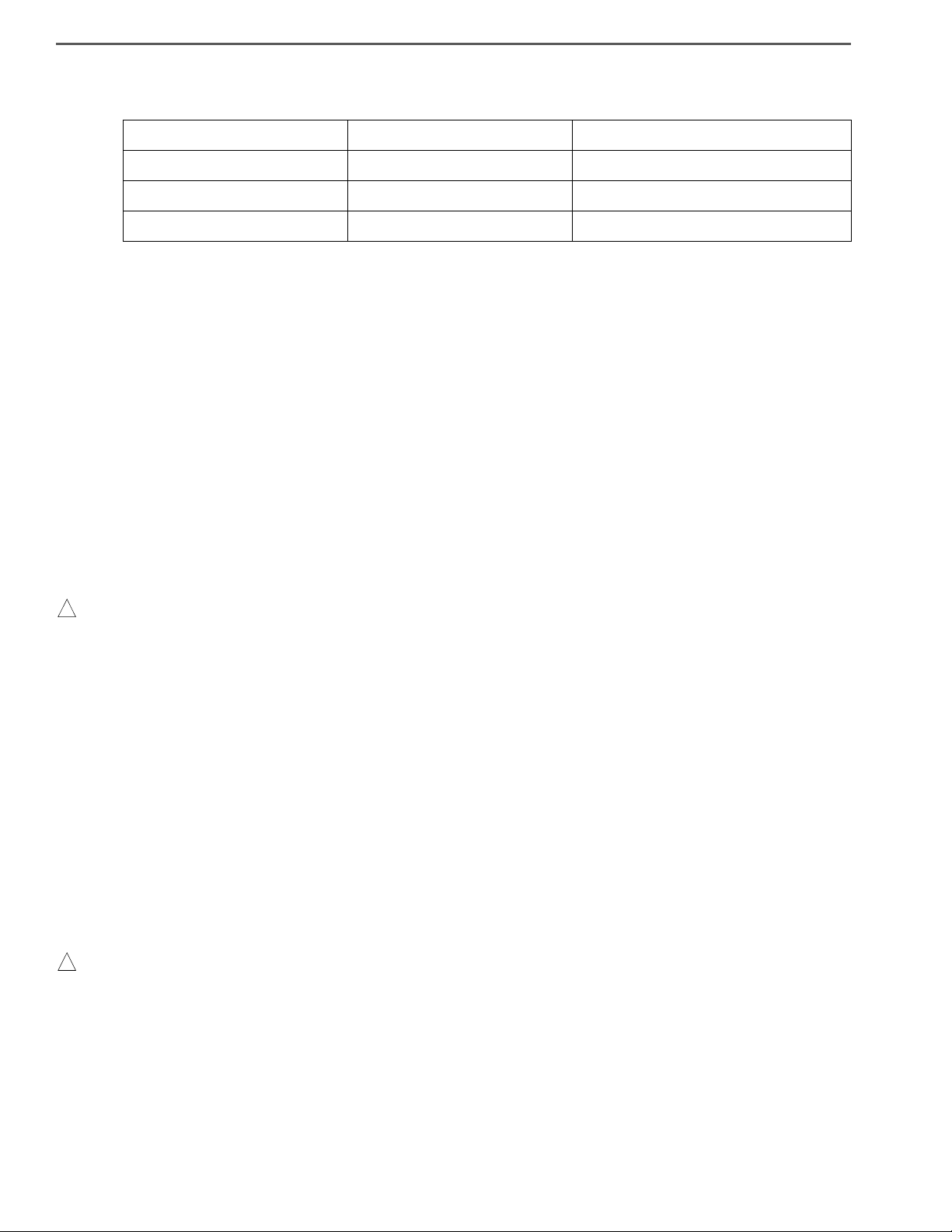

(5) Permanent diagnosis code

Permanent malfunction is confirmed by confirming the Confirmed malfunction.

(6) Deletion of diagnosis code

Code name Deletion from vehicle condition Deletion using the service tool

This code is deleted when condition

Pending diagnosis code

to be judged normal is satisfied and

malfunction detection condition is

Instant deletion

not satisfied in 1DCY

Confirmed diagnosis

code

None Instant deletion

This code is deleted after performing

the predetermined operation when

Permanent diagnosis

code

This code is deleted when condition

to be judged normal is satisfied in

3DCY. *1

condition to be judged normal is satisfied and malfunction detection con-

dition is not satisfied in 1DCY after

deleting the diagnosis code using

the service tool. *1

*1 Refer to the following figure and 4. Procedure for deleting the Permanent malfunction for details.

Page 13

HYBRID/TROUBLE SHOOTING 3–9

CONFIRMATION

DELETION

DELETION

LIGHT OFF

LIGHT OFF

LIGHT ON

LIGHT ON

CONFIRMATION

CONFIRMATION

COMPLETION OF

DCY#1

COMPLETION OF

DCY#2

COMPLETION OF

DCY#3

COMPLETION OF

DCY#4

COMPLETION OF

DCY#5

DETECTION OF

MALFUNCTION

DETECTION OF

MALFUNCTION

DCY

VEHICLE CONDITION

PENDING MALFUNCTION

CONFIRMED MALFUNCTION

PERMANENT MALFUNCTION

HV WARNING LIGHT

MIL

NORMAL JUDGMENT #1 NORMAL JUDGMENT #2 NORMAL JUDGMENT #3

NORMAL JUDGMENT

DCY#1

NORMAL JUDGMENT

DCY#2

NORMAL JUDGMENT

DCY#3

SHTS03ZZZ0300008

CONFIRMATION

DELETION

DELETION

DELETION

DELETION OF THE MALFUNCTION

CODE USING THE SERVICE TOOL

LIGHT OFF

LIGHT OFF

LIGHT ON

LIGHT ON

CONFIRMATION

CONFIRMATION

COMPLETION OF

DCY#1

COMPLETION OF

DCY#2

COMPLETION OF

DCY#3

COMPLETION OF

DCY#4

DETECTION OF

MALFUNCTION

DETECTION OF

MALFUNCTION

DCY

VEHICLE CONDITION

PENDING MALFUNCTION

CONFIRMED MALFUNCTION

PERMANENT MALFUNCTION

HV WARNING LIGHT

MIL

NORMAL JUDGMENT #1

*1

SHTS03ZZZ0300009

•

The following figure shows deletion of the Pending diagnosis code and deletion of the Permanent diagnosis

code in 3DCY.

• The following figure shows clearing of Pending malfunction code, Confirmed malfunction code, and Perma-

nent malfunction code by using the service tool.

*1 Refer to 4. Procedure for deleting the Permanent malfunction (1).

Page 14

HYBRID/TROUBLE SHOOTING3–10

! CAUTION

! CAUTION

4. PROCEDURE FOR DELETING THE PERMANENT MALFUNCTION

There are two procedures for deleting the Permanent diagnosis code.

Confirmed diagnosis code Permanent diagnosis code Deletion procedure

None Present Deletion using the procedure (1)

Present Present Deletion using the procedure (1) or (2)

Present None —

(1) Procedure for deleting the Permanent diagnosis code after deleting the diagnosis code using the service tool

a. Turn the starter key "ON".

b. Delete the diagnosis codes using the service tool.

- Delete diagnosis codes from the following systems.

• ECU of the HV system in which the Permanent diagnosis code is occurring.

(Deletion of engine ECU must be performed after performing deletion in the order of HV battery ECU

Inverter HV ECU.)

• Engine ECU

c. Set the starter key to the "LOCK" position and wait for 30 seconds or more.

d. Turn the starter key "ON".

e. Start the engine.

f. Idle the engine for 6 minutes or more.

g. Keep the engine revolution at 1,150 r/min or more for 6 minutes or longer.

h. Set the starter key to the "LOCK" position and wait for 30 seconds or more.

i. Turn the starter key "ON".

j. Start the engine.

k. Wait for 30 seconds or more.

l. Set the starter key to the "LOCK" position.

• Trouble shooting the malfunction is conducted before following the above procedure, therefore the malfunction

does not occur or the malfunction does not occur while following the above procedure.

• The HV warning light must turn off when the diagnosis code is deleted at (b).

When the HV warning light turns off, it is possible to check that there is no malfunction in the HV system.

• Condition to be judged normal for the malfunction occurred in the above steps (d) to (g) must be satisfied.

Condition to be judged normal varies depending on malfunction.

(2) Procedure for deleting the Permanent diagnosis code in 3DCY

a. Turn the starter key "ON".

b. Start the engine.

c. Idle the engine for 2 minutes or more.

d. Set the starter key to the "LOCK" position.

e. Wait for 30 seconds or more.

f. Repeat the steps from (a) to (e) for 3 times in total (3DCY).

g. Turn the starter key "ON".

h. Start the engine.

i. Wait for 30 seconds or more.

j. Set the starter key to the "LOCK" position.

• The above procedure is satisfied when making normal driving operation; therefore the Permanent diagnosis

code may be deleted when making similar driving operation if the malfunction is recovered.

• Trouble shooting the malfunction is conducted before following the above procedure, therefore the malfunction

does not occur or the malfunction does not occur while following the above procedure.

• Condition to be judged normal for the malfunction occurred in the above steps (a) to (d) must be satisfied. Con-

dition to be judged normal varies depending on malfunction.

Page 15

HYBRID/TROUBLE SHOOTING 3–11

! CAUTION

5. TROUBLE SHOOTING PROCEDURE

(1) Trouble shooting procedure (when using genuine Hino service tool)

a. Check the DTC of the HV ECU using the service tool (trouble shooting tool).

b. Record the DTC and TC No. (detailed DTC) of freeze frame data.

c. Perform trouble shooting for the relevant DTC. For an inverter/HV battery line malfunction, read the DTC of

each ECU for trouble shooting according to the HV ECU diagnostic chart.

d. After trouble shooting, delete the DTC of each ECU using the service tool and conduct a trial running to check

that the malfunction does not recur.

• When inspecting the high voltage line, wear insulating gloves because of a risk of electrical shock. Before per-

forming inspection, be sure to remove the service plug after the starter key is turned to the "LOCK" position.

When inspecting the HV battery, wear safety glasses.

Do not touch the terminals of the high voltage line for 7 minutes after removing the service plug.

• One diagnosis code (DTC) may contain more than 1 malfunction. Read TC No. (detailed DTC) of freeze frame

data with the trouble shooting tool and perform trouble shooting according to the relevant trouble shooting

chart.

• When inspecting the harness, first check the connector for fitting looseness, and the fitting surface for entry of

foreign matters.

• There may be irregular contact or temporary noise due to partial fitting of the connector if parts are returned to

normal without repairing or replacing parts using the diagnostic chart.

• The service tool or trouble shooting tool described in the trouble shooting chart indicates the genuine Hino ser-

vice tool.

• If the starter key is turned "ON" in the state that connectors, etc. are disconnected while performing the trouble

shooting chart, the malfunction may be recorded due to disconnection of a connector. In such case, be sure to

delete the diagnosis code using the trouble shooting tool.

HINT

If there is no malfunction and the engine does not stop with the idling stop function, the following cases are conceivable.

• A vehicle is not running at vehicle speed of 5 km/h or more from the last idling stop.

• The change lever is located at a position other than "D" and "4".

• When the turn signal light and the hazard light are ON. (Even if the turn signal light switch signal and the hazard

light switch signal transmitted to the HV ECU are Low, the engine does not stop automatically by use of the

idling stop function.)

• When a vehicle stopped on a sloped road.

• While PTO is operating.

• While DPR is operating.

• Capacity of the HV battery is low.

• Engine coolant temperature is low.

• The engine is still running. (The engine is running at approximately 1 km/h or more.)

• When the status of the idling stop cancel switch is "ON".

• Brake vacuum pressure is low. (Even if the low brake vacuum pressure switch signal transmitted to the HV ECU

becomes Low, the engine does not stop automatically by use of the idling stop function.)

Page 16

HYBRID/TROUBLE SHOOTING3–12

!WARNING

!CAUTION

1

2

3

SHTS03ZZZ0300010

SAFETY MEASURES FOR HIGH-VOLTAGE

WORK

EN01H03ZZZ030602002002

1. CAUTIONS ON INSPECTION OF HYBRID CONTROL SYSTEM

(1) To inspect the high-voltage system or disconnect the low-

voltage connector in the PCU box, be sure to take actions to

prevent electric shocks, i.e. wearing insulated gloves and disconnection of service plug. Removed service plug should be

put in a pocket so as to prevent other engineers from using it

by mistake during work.

Note that the SMR is turned "ON" and high-voltage circuit is activated when the starter key is turned to "ON."

Since any failure may occur when the starter key is turned to "ON"

with the service plug removed, never turn the starter key to "ON"

unless otherwise instructed in this document.

(2) All wire harness connectors for the high-voltage circuit are

orange colored. Further, "HIGH VOLTAGE" caution label is

attached to high-voltage components such as the hybrid battery. Do not touch these wiring and components unnecessarily.

(3) Turn the starter key "LOCK" and remove the service plug.

Then wait for at least 7 minutes before starting the work.

NOTICE

In the 7 minutes the high-voltage capacitor in the inverter discharges.

Page 17

HYBRID/TROUBLE SHOOTING 3–13

! CAUTION

INCORRECT

SHTS03ZZZ0300011

(4) Check the insulated gloves for damage such as cracks and

break before use. Also, do not use wet insulated gloves.

(5) Do not carry on any metal product such as a pen and scale

which may fall to cause short circuit while working.

(6) Be sure to wear insulated gloves when it is necessary to

touch any high-voltage terminal without insulating coating.

(7) After disconnecting high-voltage connectors and terminals,

insulate them with insulator tape without delay.

(8) After working on high-voltage components, check for any

component or tool left, tightening condition of high-voltage

terminals and connector conditions again before connecting

the service plug.

(9) Do not reserve the hybrid battery.

(10) Do not disassemble the hybrid battery.

High voltage is applied to the hybrid battery even when the service plug is disconnected. Further, high-alkaline electrolyte is

used.

(11) Make sure to use the insulated tools.

Recommended tools: FACON's Facom-quality insulated tools

(12) Turn the starter key to "LOCK" for resistance inspection.

(13) Turn the starter key to "LOCK" before removing/installing

connectors.

(14) Alert other workers with indication such as "High-voltage

work. Don't touch" on the vehicle during works on high-volt-

age components.

(The next page is an example of the indication. You may copy

and use it.)

Page 18

HYBRID/TROUBLE SHOOTING3–14

SHTS03ZZZ0300012

Page 19

HYBRID/TROUBLE SHOOTING 3–15

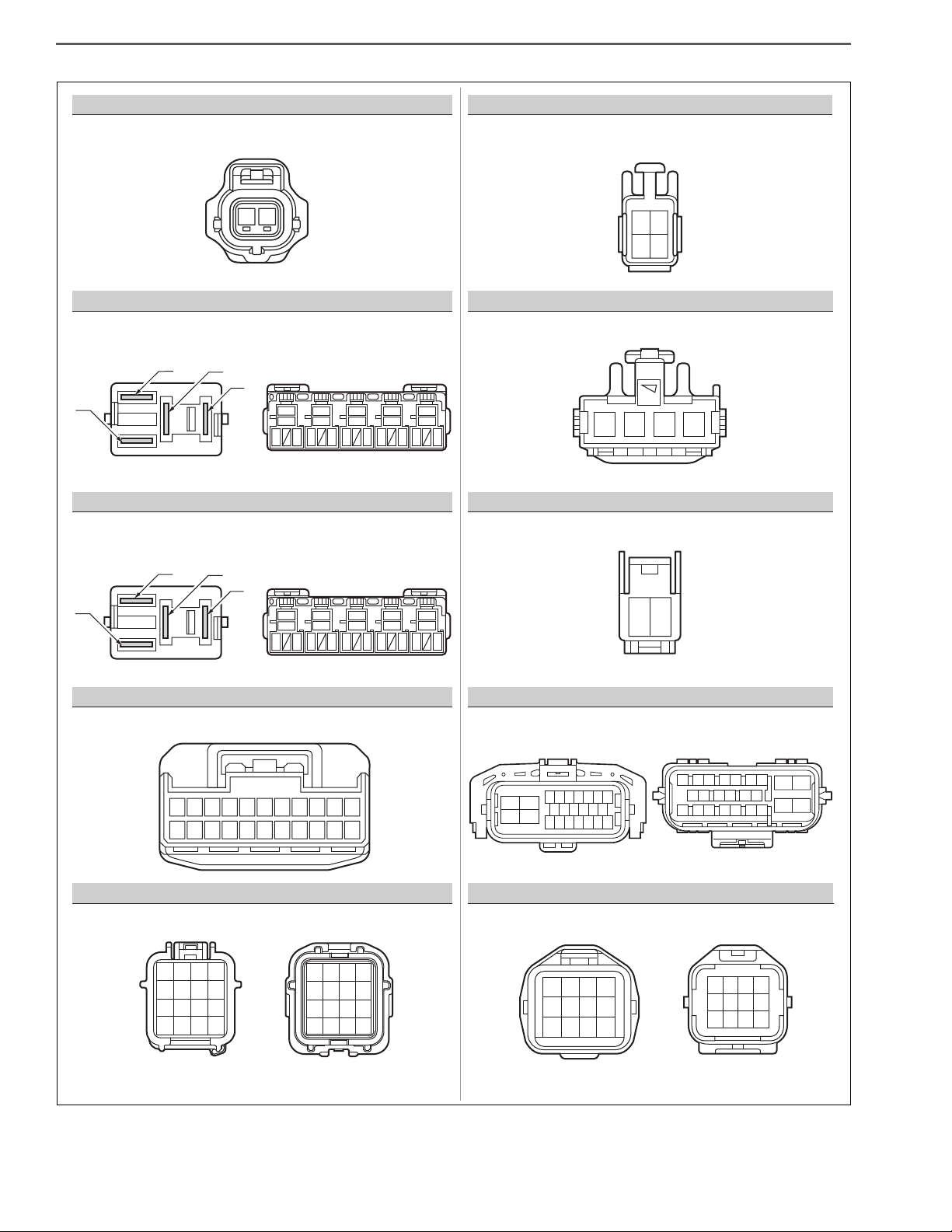

WHITE

WHITE

ORANGE

BLACK

BLACK

BLACK

DARK GRAY

WHITE

WHITE

WHITE

132

23

456789

11112

2316221521

142013

2417251826

19

10

1

9 10111213141516

2345678

1

12 13 14 15 16 17 18 19 20 21 22

10 1123456789

1

5

23

6748

11 12 13 14 15 16 17 18 19

23456789

20

2423 25 26 27 28 29

21 22

30

110

1234

1

2

3

4

56789

10 11

30 31

12

13

14

15

1617 1819 20

2122 2324 25 26272829

3233 3435 36 373839 40

78910

11 123413 14 15 16

17 18 19 20 21 22 23 24

12 56

1819

20 21 22 23 24 25 26

7 8 9 1011121314151617

123456

BATTERY ECU (CAN)A

B

F

G

J/C DIAG CAN

INVERTER COOLING WATER PUMP

BATTERY ECU (TEMPERATURE MONITORING)

C

H

HV ECU1

BATTERY ECU (VOLTAGE MONITORING)

D

I

HV ECU2

INVERTER

E

J

HV ECU3

INVERTER COOLING RADIATOR FAN

SHTS03ZZZ0300013

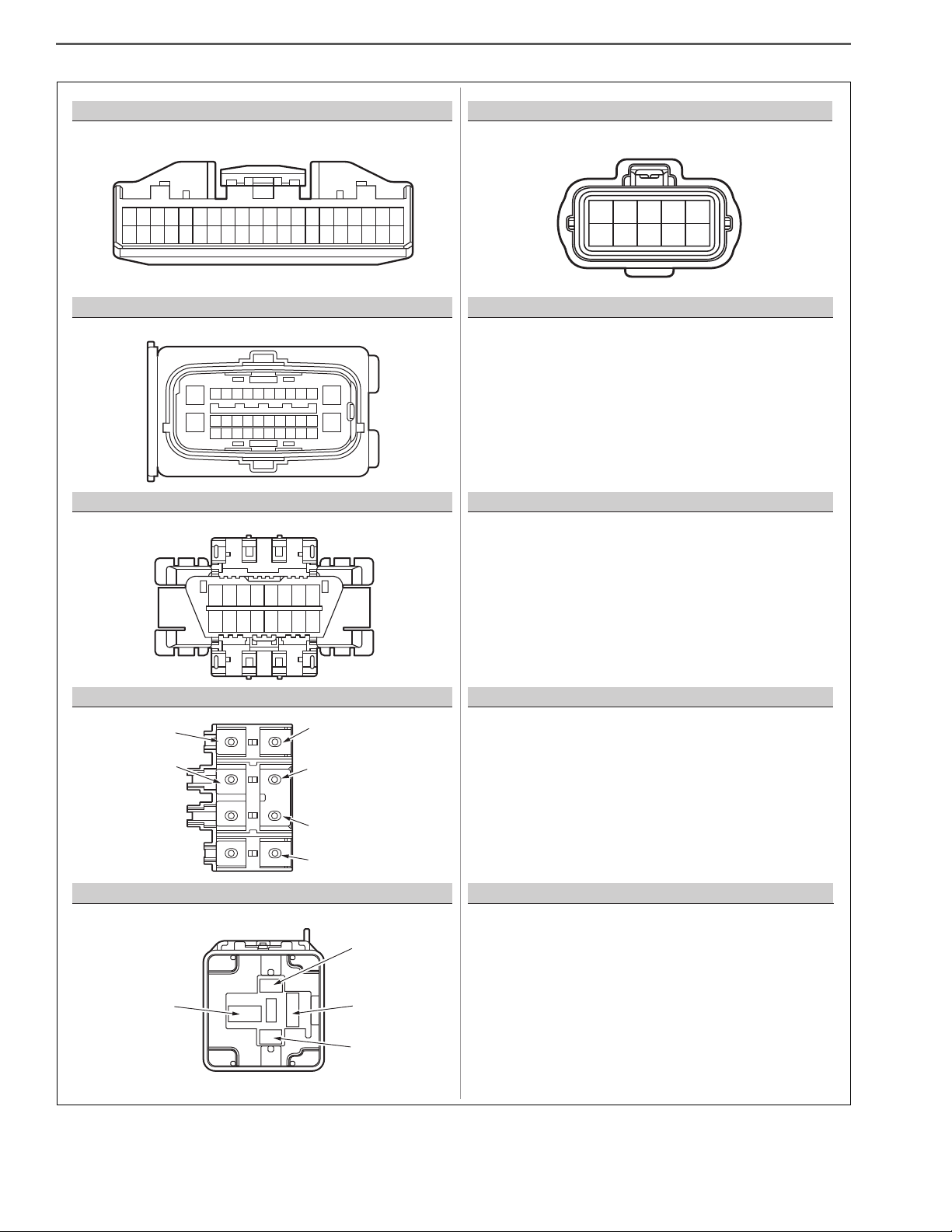

LIST OF CONNECTOR SYMBOLS

EN01H03ZZZ030602002003

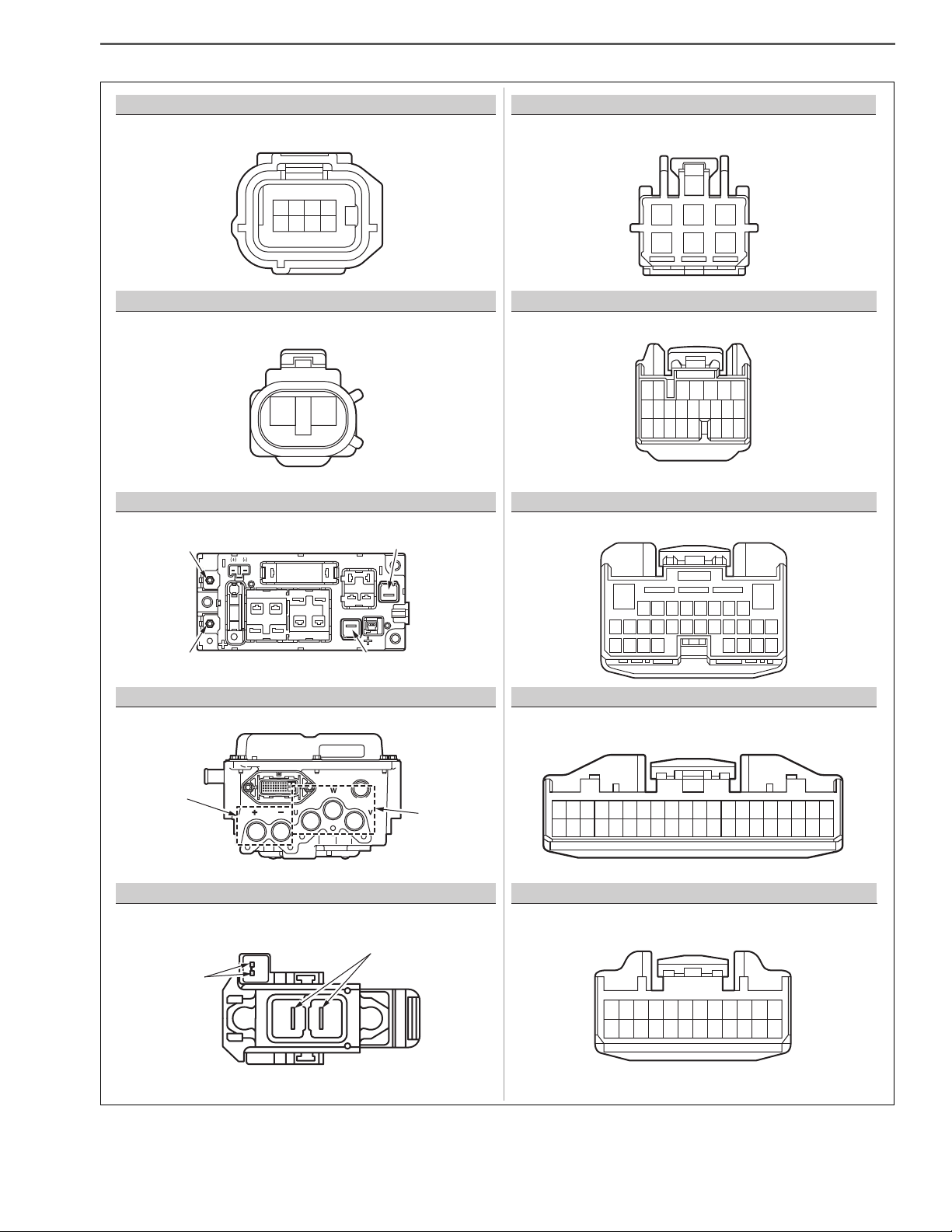

Page 20

HYBRID/TROUBLE SHOOTING3–16

123456

16 17

78910

12 13 14 15 18 19 20 211122

12 11 10

1

65

78

9

234

10 11 12

234

56

78

9

1

21

17 16

34567

8

101112131415

181920212223

9

24

3456789

1011 1213 1415

1819 202122 2324

2

17

1

16

21

1234

12

34

GRAY BLACK

WHITE

(RELAY BLOCK SIDE)

BLACK

BLACK BLACK

BLACK

WHITE

WHITE

BLACK BLACK

1234

5678

9 101112

13 14 15 16

4321

8765

12 11 10 9

16 15 14 13

(RELAY BLOCK SIDE)

(COMPONENT SIDE)

(COMPONENT SIDE)

3

5

L

N

2

1

3

5

2

1

12

INVERTER START RELAY

L

N

HV BATTERY START RELAY

O J/C CTRL CAN

P PCU HARNESS 16-PIN

R

HV BATTERY COOLING FAN

S

SMR DRIVE

SERVICE PLUG SWITCH

T

X PCU HARNESS 24-PIN

K

COOLANT TEMPERATURE SENSOR

PCU HARNESS 12-PINY

SHTS03ZZZ0300014

Page 21

HYBRID/TROUBLE SHOOTING 3–17

BLACK WHITE

BLACK WHITE

WHITE

WHITE

WHITE

12

2

13

1

2

12 3 4 5 6

816

17

7

9101112131415

21

201918 22 23 24

123

456

1526374

8

123456789101112

242322212019181716151413

E’: BATT IN(-)C’: BATT OUT(-)

F’: BATT IN(+)D’: BATT OUT(+)

I’

J’

H’

G’

10

12 13 14 15 16 17 1819 20

23456789

21

241123 2526 27 28 292230

1

1212223234245256267278289

29 301031113212331334143515361637173818391940

20

METER 1

d-1

A’

RESOLVER

B’

ROTATION MACHINE TEMPERATURE SENSOR

C’ D’ E’ F’

G’ H’

HIGH VOLTAGE J/B (IN BATTERY PACK)

INVERTER HIGH VOLTAGE

I’ J’ SERVICE PLUG

a

STARTER SWITCH

b

AT ECU

c

VEHICLE CONTROL ECU

d-2 METER 2

SHTS03ZZZ0300015

Page 22

HYBRID/TROUBLE SHOOTING3–18

BLACK

BLACK BLACK

BLACK

1212223234245256267278289

29 301031113212331334143515361637173818391940

20

5

1

3

2

4

6789

1314

24151617 1819 20 2122 23

252627 28 2930 3132 3334

161514131211109

87654321

h: BATT(-)

m: BATT(+)

p: INV(+)

3

1

2

5

q: INV(-)

k: DDC(-)

I: DDC(+)

1011

12

e

f

ABS ECU

CLUTCH ECU

k, l, m, n, p, q

HIGH VOLTAGE J/B (IN ECU-BOX)

r

IG1-1 RELAY

t

NEUTRAL SWITCH

h

DLC3

1

10

5432

8967

SHTS03ZZZ0300016

Page 23

HYBRID/TROUBLE SHOOTING 3–19

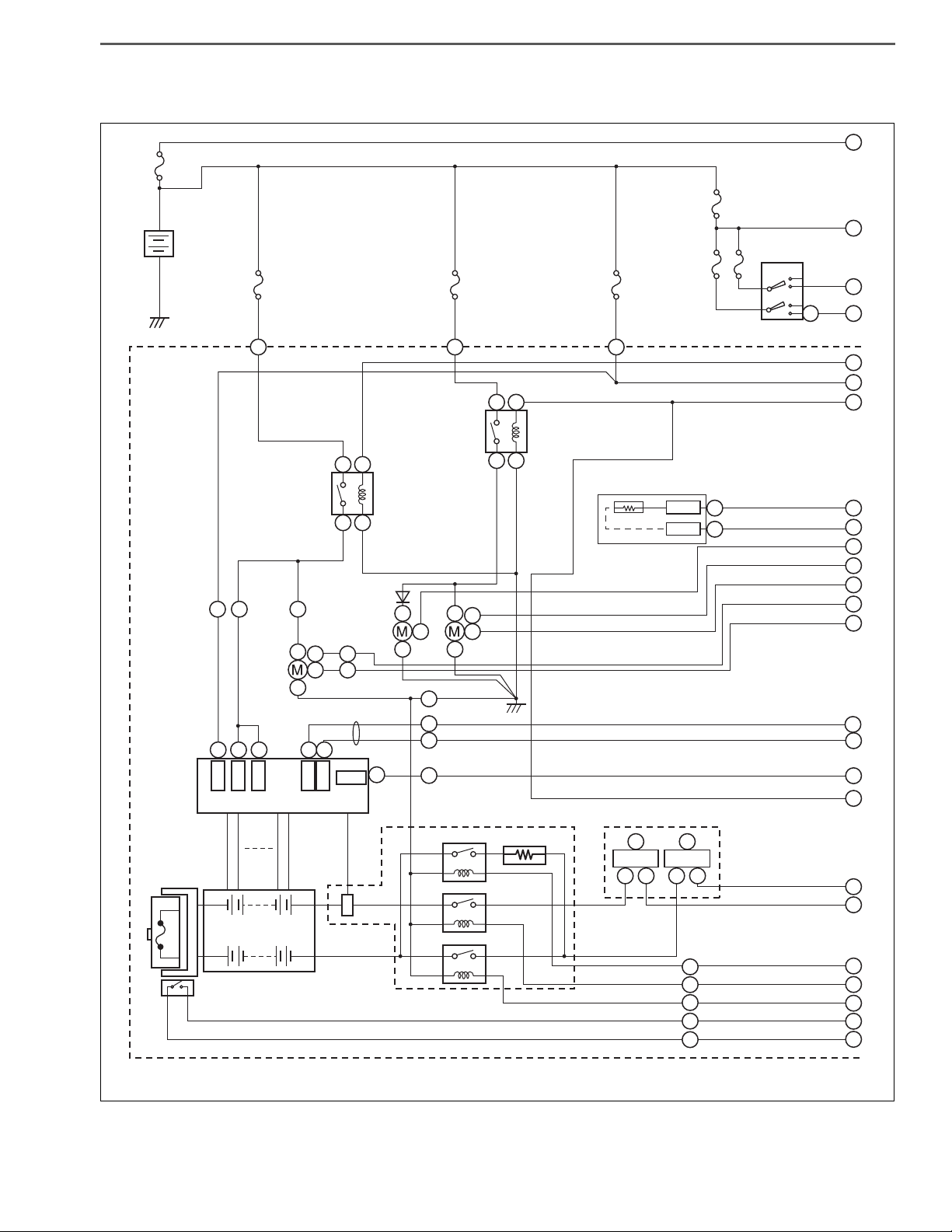

F_HV_10A

INVERTER

START RELAY

W/TEMP_SSR

MF_PWR_1_50A

F_AM2_10A

F_AM1_10A

CANL

SMR1

HIGH VOLTAGE J/B

(IN BATTERY PACK)

HIGH VOLTAGE J/B

(IN ECU BOX)

HOUSING GND

SMR2

SMR3

IG2

IGCT

AM

CANH

BATTERY ECU

SERVICE PLUG

288V

HV BATTERY

CURRENT

SENSOR

GND

L1L

L

x

PCI_B_2 20A

PCI_B_20A

x

L

3

np

J/B (+)

l

25

WATER PUMP

RADIATOR FAN

HV BATTERY

START RELAY

F

F

E

F

F

E

E

4

1

3

3

2

R

RP

P

R

3

A1A2A

13

A18A

19

A

12

9

P13P

14

4

1

2

111

RP

212

P

15

P

6

P

7

P

2

3

4

5

1

P

16

N1N

x

NN

3

123

25

1

2

3

4

5

6

7

8

9

12

11

10

14

13

15

16

18

19

20

21

22

23

24

25

mq

J/B (-)

k

P

P

P

P

HV BATTERY

COOLING FAN

KEY CYLINDER

ON

ST

THW

E2

K

K

a

6

2

1

17

SMR: System Main Relay

SHTS03ZZZ0300017

HV SYSTEM WIRING DIAGRAM

EN01H03ZZZ030602002004

Page 24

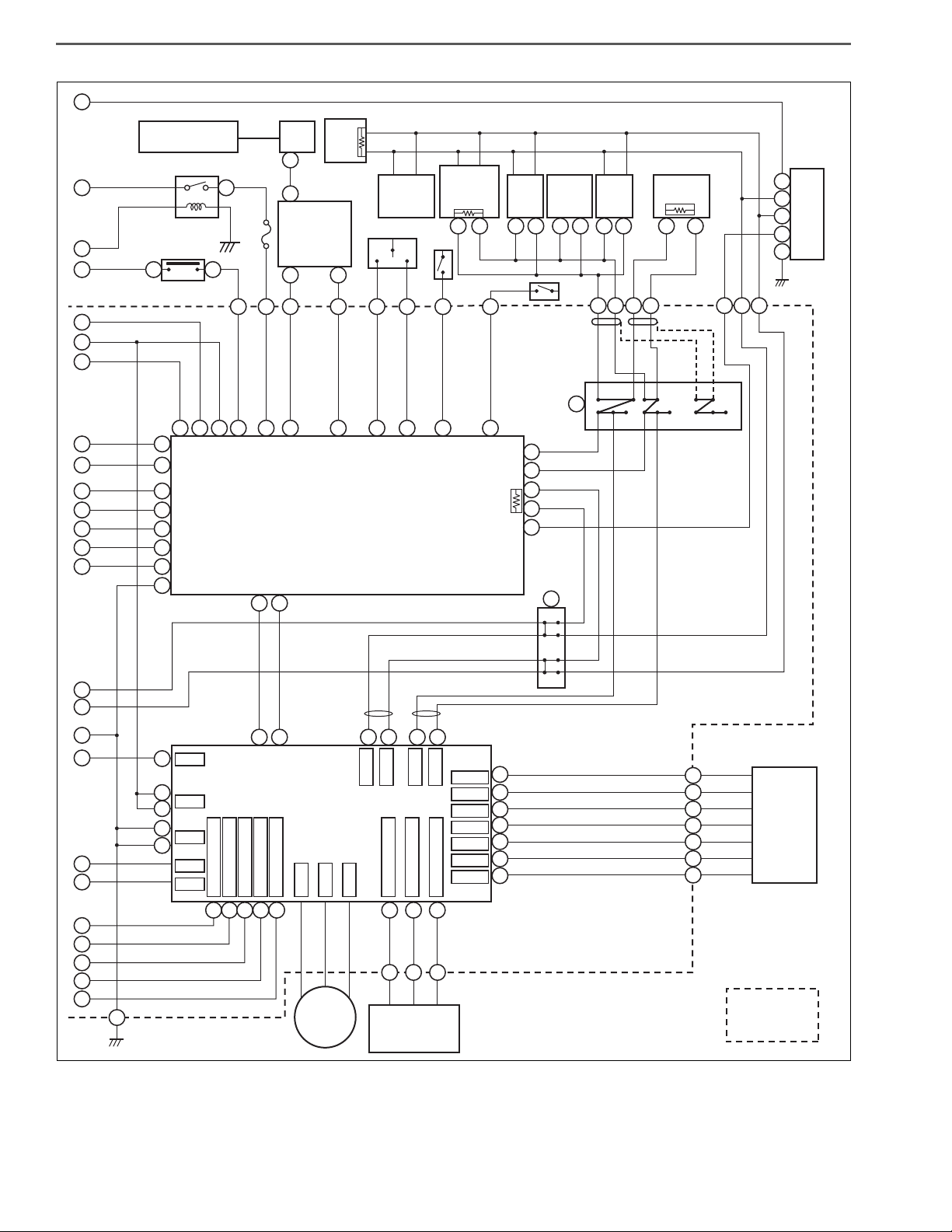

HYBRID/TROUBLE SHOOTING3–20

DCU

F_ECU_IG_NO.1_10A

VEHICLE SPEED

PULSE

HV WARNING

LIGHT

IG1-1

76

61

15 2520 19

X

J

o

J

X

VEHICLE

CONTROL

ECU

VCM WARN SW

or

A/C WARN SW

HYD WARN SW

HAZ SW

TURN SW

WHEEL SPEED

SENSOR

ABS

ECU

METER

CANL1

CANH1

32

D

9

3

D

I

8

7

D

I

21 22

D

CANL2

CN4-26 SLD4

CN4-35 THA1

CN4-34 P5A1

R1

CANH2

33

DD

23

D

30

D

31

D

10

D

11

D

25

D

38D39D40D16D5

D

34D35D26

D

24

D

12

D

14

D

13

D

15

D

27

D

3Y8

Y

4

Y

ROTATION

MACHINE

THERMISTER

ROTATION

MACHINE

16

X

W1

V1

U1

CN4-40 CON3

CN4-39 CON2

CN3-38 CON1

CN4-16 ILK1

CN4-5 ILKO

INVERTER

PCU

INTERNAL

CIRCUIT

HV ECU

CAN J/C

(CONTROL)

CAN J/C (DIAG)

cc

ABS

ECU

20

H

29

Y

1

R2

Y

2

S1

Y

5

S2

Y

6

RESOLVER

S3

Y

10

S4

F+

F-

GND

+B

ON

Y

11

SLD3

Y

9

19

J

21

J

22

J

G

h

h

h

h

h

DLC3

15

56

34

78

12

ff

X

xxx

X

CLUTCH

ECU

13

23

I

1

127

8

12 13

16

1411109543

24 21 22

20 8 9

14

16

6

14

13

4

ee

21 20

AT

ECU

ENGINE

ECU

bb

METER

d2 d2

I2J1H

XX

4J3

X

J

24

X

d1

1

2

3

4

5

6

7

8

9

14

15

16

18

17

19

20

21

22

23

24

25

d1

tt

r

22

NSSW

22

f

23

18

19

5

7

12

d1

H

11

X

4

H

20

X

19

H

19

X

10

H

9

X

11

RL

H

18

5

H

30

12

I

17

I

18

11

10

H

26

13

H

24

H

25

J

5

15

SHTS03ZZZ0300018

NOTICE

For connector symbols, refer to "List of connector symbols."

Reference: HYBRID, TROUBLE SHOOTING, HYBRID CONTROL SYSTEM, LIST OF CONNECTOR SYMBOLS (Page

3-15)

Page 25

HYBRID/TROUBLE SHOOTING 3–21

Gradual braking

Sudden braking

Operation by left foot

Engine

HV

Details of the

vehicle

Result of interviewConfirmation result of vehicle

Vehicle type

Date of occurrence

Warehousing date

Travel distance Km

Registration date

Sex

Male

Urban area

Mountain

( )

Suburb

Others

Female

Age group

Age

Occupation

Previous vehicle

Frequency of use

Others

Others

Main place

for use

Characteristic of the customer

(Scheduled) delivery date of the vehicle

Frame No.

Unit No. or the like

Option

Details of interview (Please describe the situation prior to the occurrence and before and

after the occurrence in a time-series manner as much as possible.)

Cold area Others ()

Frequency / date /

week month

Running condition Road surface state

When starting

During acceleration

During steady running

During deceleration

During braking

During stoppage

During parking

During turning

During ABS operation

Others

( )

Vehicle speed [km/h]

Shift position (display) Lighting of warning light

Brake operation

Frequency of occurrence

A/C status

1234

5

at operation

6R

Engine status

Flat (horizonal) road

Upward ° Downward

Inclination ° .%

Distance km

Dry paved road

Wet paved road

Rough paved road

Unpaved road

Snow road, compressed

snow road, frozen road

Uneven road, curbstone

Others

( )

At start

Immediately after the

start

After minutes after

the start

After minutes after

the start of running

At the stoppage of the

system

During engine stoppage

During engine start

During engine rotation

Yes No

Charge

Engine

Others

(ޓޓޓޓ)

Yes No

Engine

Brake

ABS

Brake

HV

Others

( )

Always

Sometimes

Only one time

Vehicle state

Confirmation result of warning lamp Confirmation result of diagnosis code

Charge

Weather:

Air temperature: °C

Amount of remaining fuel

(fuel gauge)

Remaining amount

A/C

OFF

FULL

Unknown

SHTS03ZZZ0300019

HEARING SHEET

1. HEARING OF REQUESTS FROM CUSTOMER

(1) As the steps of trouble shooting are advanced, hear requests from customer without fault by referring this hear-

ing sheet.

EN01H03ZZZ030602002005

Page 26

HYBRID/TROUBLE SHOOTING3–22

HYBRID ECU

DIAGNOSIS CODE TABLE

Symbol Lighting pattern

☆ Light is turned on when any fault occurs, and off when the fault is resolved

DTC

No.

P0500

P0501

P0562

Diagnosis code

name

Abnormality in

vehicle speed

sensor

Abnormality in

characteristics

of vehicle

speed sensor

Abnormality in

power supply

voltage

TC

Description of

No.

51

5B

71

malfunction

No vehicle

speed signal

input

Abnormality in

characteristics

of the vehicle

speed sensor

Control power

supply voltage

reduction

Vehicle behavior for occur-

rence of malfunction

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

Idling stop is not working. 1 ☆☆

HV system stop

Since the hybrid system

stops, the following symptom occur.

- The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

- Idling stop is not working.

- Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

EN01H03ZZZ030602003001

Number

of mal-

function

confir-

mation

DCY

1 ☆☆

1 ☆

HV

Warning

Light

MIL

P060B

P0617

P062F

P0810

Abnormality in

A/D converter

Malfunction of

starter switch

Abnormality in

EEPROM

Abnormality in

clutch system

(idling stop

inhibited)

Abnormality in

B2

the A/D converter

Sticking the

59

starter signal

circuit to High

EEPROM

B3

abnormality

Abnormality in

the clutch ECU

9C

(idling stop is

prohibited.)

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

Idling stop is not working. 1 ☆☆

Recording a diagnosis code

may not be available.

Idling stop may not work. 1 ☆

1 ☆☆

1 ☆☆

Page 27

DTC

No.

Diagnosis code

name

TC

Description of

No.

HYBRID/TROUBLE SHOOTING 3–23

Number

malfunction

Vehicle behavior for occur-

rence of malfunction

of mal-

function

confirmation

DCY

HV

Warning

Light

MIL

P0810

P0A01

P0A02

P0A03

Abnormality in

clutch system

(idling stop

available)

Abnormality in

characteristics

of inverter coolant temperature sensor

Coolant temperature sensor Low

abnormality

Coolant temperature sensor High

abnormality

Abnormality in

the clutch ECU

9D

(idling stop is

available.)

Abnormality in

characteristics

7B

of the inverter

coolant temperature sensor

GND short circuit of the

inverter cool-

78

ant temperature sensor

circuit

Inverter coolant temperature sensor

circuit discon-

79

nected or

power supply

(positive side)

shorted

Idling stop may not work. 1 ☆

Behavior of vehicle does not

vary.

Behavior of vehicle does not

vary.

Behavior of vehicle does not

vary.

2 ☆☆

1 ☆☆

1 ☆☆

P0A06

P0A07

P0A0F

P0A1D

HV water pump

drive signal

Low abnormality

HV water pump

drive signal

High abnormality

Engine system

abnormality

Abnormality in

HV ECU function

Disconnection

or GND short

circuit of the HV

7F

water pump

drive signal circuit

HV water pump

drive signal cir-

7E

cuit power supply (positive

side) shorted

31 Engine misfire

Sticking of the

12

control CAN

register

Behavior of vehicle does not

vary.

Behavior of vehicle does not

vary.

The engine does not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

CHG, AST, ECO and SOC

lights may turn off.

1 ☆☆

1 ☆☆

1

1 ☆☆

Page 28

DTC

No.

P0A1D

P0A78

Diagnosis code

name

Abnormality in

HV ECU function

Abnormality in

the inverter

TC

Description of

No.

17

21

malfunction

Sticking of the

DIAG CAN register

Serious abnormality in the

inverter

HYBRID/TROUBLE SHOOTING3–24

Number

Vehicle behavior for occur-

rence of malfunction

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

CHG, AST, ECO and SOC

lights may turn off.

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop may not work.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

of mal-

function

confir-

mation

DCY

1 ☆☆

1 ☆

HV

Warning

Light

MIL

P0A78

P0A7E

P0A82

P0A84

Abnormality in

the inverter

Abnormality in

high temperature of HV battery

Abnormality in

function of HV

battery cooling

fan

Abnormality in

HV battery

cooling fan

drive signal

Low

Slight abnor-

22

mality in the

inverter

Abnormally

high tempera-

48

ture of the HV

battery

Abnormality in

the HV battery

67

cooling FAN

function

Disconnection

or GND short

circuit of the HV

66

battery cooling

FAN drive signal circuit

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop may not work.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

Behavior of vehicle does not

vary.

Behavior of vehicle does not

vary.

1 ☆

1 ☆☆

2 ☆☆

1 ☆☆

P0A85

Abnormality in

HV battery

cooling fan

drive signal

High

HV battery

cooling fan

drive signal cir-

65

cuit power supply (positive

side) shorted

Behavior of vehicle does not

vary.

1

☆☆

Page 29

DTC

No.

P0A90

Diagnosis code

name

Abnormality in

motor function

TC

Description of

No.

2A

malfunction

Abnormality in

the motor function

HYBRID/TROUBLE SHOOTING 3–25

Number

Vehicle behavior for occur-

rence of malfunction

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

of mal-

function

confirmation

DCY

1 ☆☆

HV

Warning

Light

MIL

P0A92

P0A93

P0AFD

P0BCA

P0C73

P3000

Abnormality in

charging performance

Abnormality in

inverter cooling system

Abnormality in

low temperature of HV battery

Abnormality in

HV battery

cooling fan

revolving number signal High

Abnormality in

HV water pump

function

Abnormality in

status of HV

battery ECU IG

signal

Abnormality in

29

HV battery

charging power

Abnormally

high tempera-

7A

ture of the

inverter coolant

Abnormally low

6B

temperature of

the HV battery

HV battery

cooling fan

speed signal

68

circuit power

supply (positive

side) shorted

Abnormality in

80

the HV water

pump function

Abnormality in

the HV battery

42

ECU IG signal

status

Behavior of vehicle does not

vary.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

Idling stop is not working. 2 ☆☆

Behavior of vehicle does not

vary.

Behavior of vehicle does not

vary.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

2 ☆☆

1 ☆☆

1 ☆☆

2 ☆☆

1 ☆

P3001

Abnormality in

HV battery line

Abnormality in

the HV battery

41

ECU memory

system

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

1 ☆

Page 30

DTC

No.

P3001

P3001

Diagnosis code

name

Abnormality in

HV battery line

Abnormality in

HV battery line

TC

Description of

No.

43

44

malfunction

Abnormality in

the HV battery

system

Abnormality in

the HV battery

system

HYBRID/TROUBLE SHOOTING3–26

Number

Vehicle behavior for occur-

rence of malfunction

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

of mal-

function

confir-

mation

DCY

1 ☆

1 ☆

HV

Warning

Light

MIL

P3001

P3001

P3001

Abnormality in

HV battery line

Abnormality in

HV battery line

Abnormality in

HV battery line

Disconnection

of the HV bat-

45

tery high voltage fuse

Request for

stopping dis-

46

charge of the

HV battery

Auxiliary

charge request

47

for the HV battery

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

- The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

- Idling stop is not working.

- Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

1 ☆

1 ☆

1 ☆

Page 31

DTC

No.

P3001

P3001

Diagnosis code

name

Abnormality in

HV battery line

Abnormality in

HV battery line

TC

Description of

No.

4A

4B

malfunction

Abnormal

external overload in the HV

battery

Abnormality in

the HV battery

voltage detection circuit

HYBRID/TROUBLE SHOOTING 3–27

Number

Vehicle behavior for occur-

rence of malfunction

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

of mal-

function

confirmation

DCY

1 ☆

1 ☆

HV

Warning

Light

MIL

P3001

P3009

P3128

P3129

P314C

Abnormality in

HV battery line

Abnormality in

leakage

Abnormality in

HV radiator fan

revolution number Low

Abnormality in

HV radiator fan

revolution number High

Abnormality in

HV water pump

revolution number signal Low

Stoppage of the

regeneration

function

4C

according to

request for

stopping

charge

Electrical leak-

49

age

HV radiator fan

7D

revolution signal Low failure

HV radiator fan

7C

revolution signal High failure

GND short circuit of the HV

82

water pump

revolution signal circuit

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

Behavior of vehicle does not

vary.

Behavior of vehicle does not

vary.

Behavior of vehicle does not

vary.

Behavior of vehicle does not

vary.

1 ☆

1

2 ☆☆

2 ☆☆

1 ☆☆

Page 32

DTC

No.

Diagnosis code

name

TC

Description of

No.

HYBRID/TROUBLE SHOOTING3–28

malfunction

Vehicle behavior for occur-

rence of malfunction

Number

of mal-

function

confir-

mation

DCY

HV

Warning

Light

MIL

P314D

P324B

P324C

Abnormality in

HV water pump

revolution number signal High

Abnormality in

inverter start

relay Low

Abnormality in

inverter start

relay High

Disconnection

of the HV water

81

pump revolution signal circuit

GND short circuit of the

62

inverter start

relay excitation

circuit

Inverter actuate relay excitation circuit

61

disconnected

or power supply (positive

side) shorted

Behavior of vehicle does not

vary.

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

The engine may not start

running. However, the

engine starts up by the

starter for starter-equipped

vehicles.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

1 ☆☆

1 ☆☆

1 ☆☆

P33B1

P33B2

U0073

U0074

Abnormality in

HV battery ECU

start relay Low

Abnormality in

HV battery ECU

start relay High

Abnormality in

CAN communication with HV

ECU (control

CAN)

Abnormality in

CAN communication with HV

ECU (DIAG

CAN)

GND short circuit of the HV

64

battery ECU

start relay excitation circuit

The HV battery

ECU start relay

excitation circuit discon-

63

nected or

power supply

(positive side)

shorted

Control CAN

communica-

11

tion disabled

due to bus off

DIAG CAN communication dis-

16

abled due to

bus off

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

CHG, AST, ECO, SOC light

turns off.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

1 ☆☆

1 ☆☆

1 ☆☆

1 ☆☆

Page 33

DTC

No.

U0100

U0101

U0110

Diagnosis code

name

Engine ECU

CAN communication blackout

TCM ECU CAN

communication blackout

Inverter CAN

communication blackout

TC

Description of

No.

13

18

14

malfunction

Engine ECU

CAN communication blackout

AT ECU CAN

communication blackout

Inverter CAN

communication blackout

HYBRID/TROUBLE SHOOTING 3–29

Number

Vehicle behavior for occur-

rence of malfunction

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

of mal-

function

confirmation

DCY

1 ☆☆

1 ☆

1 ☆☆

HV

Warning

Light

MIL

U0111

U0121

U0155

U110A

U1136

HV battery ECU

CAN communication blackout

ABS ECU CAN

communication blackout

Meter ECU CAN

communication blackout

Vehicle control

ECU CAN communication

blackout

Clutch ECU

CAN communication blackout

HV battery ECU

15

CAN communication blackout

ABS ECU CAN

24

communication blackout

Meter ECU CAN

25

communication blackout

Vehicle control

ECU CAN com-

26

munication

blackout

Clutch ECU

27

CAN communication blackout

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

Idling stop is not working. 1 ☆

Idling stop is not working. 1 ☆

Idling stop is not working. 1 ☆

Idling stop is not working.

Lowering the speed during

deceleration may decrease

to deactivate the regeneration function.

1 ☆☆

1 ☆

Page 34

HYBRID/TROUBLE SHOOTING3–30

FREEZE FRAME DATA LIST

EN01H03ZZZ030602003002

Item Description Display range Unit

TC No. Detailed code of DTC No. 00 - $FF —

Stop light switch (CAN reception)

DPR regenerating signal

(CAN reception)

Idling stop authorized state

(CAN reception)

Idling stop request signal

Driver request torque rate

Engine torque rate

Standard engine torque Engine torque to be a standard 0 - 1,000 Nm

Accelerator pedal opening

(CAN reception)

Represents brake pedal communication input

status. Pedal ON = 1 / Pedal OFF = 0

Received from the engine during DPR regenerating. ON = 1 / OFF = 0

Received from the engine when enabling idling

stop (ON = 1 / OFF = 0).

Sent to the engine for auto stop of idling stop.

ON = 1 / OFF = 0

Ratio of torque based on accelerator pedal opening to standard engine torque

Ratio of torque based on fuel injection quantity to

standard engine torque

Represents the accelerator pedal opening. 0 - 100 %

0 - 1 —

0 - 1 —

0 - 1 —

0 - 1 —

-128 - 127 %

-128 - 127 %

Engine revolution

(CAN reception)

Engine control request mode

Required engine torque limiting

value

Specified value of motor torque

Effective motor torque value Torque calculated from actual current id, iq -32,768 - 32,767 Nm

Actual motor torque value Represents the motor output torque. -32,768 - 32,767 Nm

Vehicle speed Represents a vehicle speed. 0 - 200 km/h

Motor revolution Represents the motor revolution. -32,768 - 32,767 r/min

HV battery voltage Represents the HV battery DC voltage. 0 - 600 V

HV battery current Represents HV battery DC current. -500 - 500 A

Power supply voltage Represents the HV ECU power supply voltage. 0 - 40 V

Represents the engine revolution. 0 - 4,000 r/min

Represents the operation request to the engine.

0 = No request, 1 = Rotational request, 2 = Rotational restriction, 3 = Torque limiting, Torque

instruction = 4

Ratio of limiting request torque to the engine to

standard engine torque

Represents a torque command value to the

inverter.

0 - 4 —

-128 - 127 %

-32,768 - 32,767 Nm

HV battery capacity (SOC) Represents the HV battery capacity (SOC). 0 - 100 %

Maximum temperature of HV battery

Minimum temperature of HV battery

HV battery discharge limit value Represents the HV battery discharge limit value. 0 - 200 kW

Represents the maximum temperature of the HV

battery.

Represents the minimum temperature the HV battery.

-128 - 127 C

-128 - 127 C

Page 35

HYBRID/TROUBLE SHOOTING 3–31

Item Description Display range Unit

HV battery charge limit value Represents the HV battery charge limit value. 0 - 200 kW

Represents the judged value of gear position.

Gear position (CAN reception)

Neutral= 0 / 1st gear = 1 / 2nd gear = 2 /

3rd gear = 3 / 4th gear = 4 / 5th gear = 5 /

6th gear = 6 / R = 10

0 - 10 —

HV warning light

Inverter start relay

HV battery ECU start relay

Engine intake air temperature Represents the engine intake air temperature. -40 - 210 C

Starter signal

Idling stop cancel switch

(CAN reception)

ABS activation signal

(CAN reception)

Exhaust brake switch

(CAN reception)

HV control mode information

Represents the HV warning light output status.

ON = 1 / OFF = 0

Represents the inverter start relay output status.

ON = 1 / OFF = 0

Represents the HV battery ECU start relay output

status. ON = 1 / OFF = 0

Represents the starter signal input status.

ON = 1 / OFF = 0

Represents the idling stop cancel switch signal

input status. Idling stop cancel status ON = ON.

ON = 1 / OFF = 0

Represents the ABS activation signal input status. ON = 1 / OFF = 0

Represents the retarder lever signal input status.

ON = 1 / OFF = 0

Represents the operating condition of the HV

system.

0 = OFF

1 = Engine startup

2 = At acceleration by motor

3 = Deceleration by motor + retarder

4 = Deceleration by motor or foot brake

5 = Battery charging

6 = Engine stop

7 = Forced battery charging

8 = At manufacturing inspection

9 = At EV

10 = At gear shifting

0 - 1 —

0 - 1 —

0 - 1 —

0 - 1 —

0 - 1 —

0 - 1 —

0 - 1 —

0 - 15 —

Engine loss torque rate Represents the engine loss torque rate. -128 - 127 %

Required engine revolution value Required revolution to engine 0 - 4,000 r/min

Instruction of motor revolution Instructed revolution to motor -32,768 - 32,767 r/min

Motor temperature Motor temperature 0 - 200 C

Inverter internal temperature Inverter internal temperature 0 - 200 C

Starter key Starter key status ON = 1 / OFF = 0 0 - 1 —

System main relay 3 (SMR3) state

Clutch operation permission signal

HV battery leakage crest value HV battery leakage crest value 0 - 4.995 V

Represents the system main relay 3 (SMR3) output state. ON = 1 / OFF = 0

Represents the clutch operation permission state

sent from the clutch ECU. Prohibit = 0 / Enable = 1

0 - 1 —

0 - 1 —

Page 36

HYBRID/TROUBLE SHOOTING3–32

Item Description Display range Unit

Select lever position

(CAN reception)

Clutch state (CAN reception)

Shift transmission condition

(CAN reception)

Vehicle driving mode

System required torque System required torque -32,768 - 32,767 Nm

Turn signal light actuation signal

Clutch oil temperature Clutch oil temperature -40 - 215 C

HV system coolant temperature HV system coolant temperature -128 - 127 C

HV battery cooling FAN drive

request Duty

HV battery cooling FAN drive

request revolution

Select lever position

AT-P = 0 / AT-RL = 1 / AT-N = 2 / AT-D = 3 /

AT-4 range = 4 / AT-3 range = 5 / AT-Others = 6

Clutch state Engaged = 0 / partial clutch = 1 /

disengaged = 2 / unknown = 3

Shift transmission condition OFF = 0 / UP = 1 /

DOWN = 2 / Changing gear = 3

HINT

The indication of "UP" means "Charging gear".

Vehicle driving mode Normal = 0, ECO = 1, PWR =

2

Turn signal light actuation signal OFF = 0, Right

turn = 1, Left turn = 2, Hazard = 3

HV battery cooling FAN drive request Duty 0 - 100 %

HV battery cooling FAN drive request revolution 0 - 10,000 r/min

0 - 255 —

0 - 3 —

0 - 3 —

0 - 2 —

0 - 3 —

HV battery cooling FAN revolution

HV battery cooling FAN revolution

HV battery cooling FAN revolution voltage

HV radiator fan revolution HV radiator fan revolution 0 - 10,000 r/min

HV water pump drive request

Duty

HV water pump drive request revolution

HV water pump revolution

HV system coolant temperature

sensor voltage

HINT

Even if the HV battery cooling FAN drive request

revolution is 0 r/min, 0-100 r/min appears.

HV battery cooling FAN revolution voltage 0 - 5 V

HV water pump drive request Duty 0 - 100 %

HV water pump drive request revolution 0 - 10,000 r/min

HV water pump revolution

HINT

Even if the HV water pump drive request revolution is 0 r/min, approximately 0-480 r/min appears.

HV system coolant temperature sensor voltage 0 - 5 V

0 - 10,000 r/min

0 - 10,000 r/min

Page 37

HYBRID/TROUBLE SHOOTING 3–33

LIST OF DATA MONITOR ITEMS

EN01H03ZZZ030602003003

Item Description

Number of diagnosis codes Number of recorded diagnosis codes 0 - 255 Codes

Stop light switch (CAN reception)

DPR regenerating signal

(CAN reception)

Idling stop authorized state

(CAN reception)

Idling stop request signal

Accelerator pedal opening

(CAN reception)

Engine revolution (CAN reception) Represents the engine revolution. 0 - 4,000 r/min

Vehicle speed Represents a vehicle speed. 0 - 200 km/h

Motor revolution Represents the motor revolution.

Represents the brake pedal communication

input status. Pedal ON = 1 / Pedal OFF = 0

Received from the engine during DPR regenerating. ON = 1 / OFF = 0

Received from the engine when enabling idling

stop (ON = 1 / OFF = 0).

Sent to the engine for auto stop of idling stop.

ON = 1 / OFF = 0

Represents the accelerator pedal opening. 0 - 100 %

Display

range

0 - 1 —

0 - 1 —

0 - 1 —

0 - 1 —

-32,768 32,767

Unit

r/min

HV battery voltage Represents the HV battery DC voltage. 0 - 600 V

HV battery current Represents the HV battery DC current. -500 - 500 A

Power supply voltage Represents the HV ECU power supply voltage. 0 - 40 V

HV battery capacity (SOC) Represents the HV battery capacity (SOC). 0 - 100 %

Maximum temperature of the HV

battery

Minimum temperature of the HV

battery

HV battery discharge limit value